EMI CAHG09, CAHH12, CAHH24, CAHH09, CAHG12 Installation, Operation And Maintenance Manual

...

P/N 240008108, Rev. B [082509]

CACG/CAHG &

CACH/CAHH

High-Efciency Cassette Ductless Split System Air Handlers

Straight cool / Heat pump nominal capacities

CAHG09

CAHH09

CAHG12

CAHH12

CAHG24

CAHH24

Units

9,000 12,000 18,000 24,000 Btuh

2.6 3.5 5.3 7. 0 kW

Straight cooling only — circuit load — two circuits

CACG-36 & CACH-36

Units

30,000 36,000 Btuh

8.8 10.5 kW

Installation, Operation and

Maintenance Manual

ECR International LLC

2201 Dwyer Ave.

Utica, NY 13504

www.enviromaster.com

An ISO 9001-2000 Certified Company

CAHH12

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 2 P/N 240008108, Rev. B [082509]

Contents

To the Installer

Retain this manual and warranty for

future reference. Before leaving the premises, review this manual to be sure the unit

has been installed correctly and run the

unit for one complete cycle to make sure

it functions properly.

To obtain technical service or warranty

assistance during or aer the installation

of this unit, contact your local representative. For a local representative listing, visit

our web site:

www.enviromaster.com

For further assistance call:

1-800-228-9364

When calling for assistance, please have

the following information ready:

Model Number _____________

Serial Number _____________

Date of installation ___________

WARNING

Shipping damage MUST

be reported to the carrier

IMMEDIATELY.

Examine the exterior. Remove

cover and examine compressor

and piping for signs of damage.

NOTICE

e EMI Ductless Series of high eciency evaporators are backed by EMI

and ECR International and are tested,

rated, and certied in accordance with

AHRI Standard 210/240-2008 and

UL-1995.

Due to ongoing product development,

product designs and specications may

change without notice.

Please contact the factory for more

information.

Contents . . . . . . . . . . . . . . . . . . . . . . . . . 2

Read Before Proceeding

. . . . . . . . . . . . . . . 3

Verify Unit Before Installing (continued)

. . . . . 6

Piston/Orifice Replacement (when required)

. . 7

Mounting the Unit

. . . . . . . . . . . . . . . . . . . 8

Condensate Piping

. . . . . . . . . . . . . . . . . . .13

Duct Connections

. . . . . . . . . . . . . . . . . . .14

Refrigerant Piping

. . . . . . . . . . . . . . . . . . .15

Refrigerant Processing

. . . . . . . . . . . . . . . .18

Final Assembly

. . . . . . . . . . . . . . . . . . . . .19

Final Assembly (continued)

. . . . . . . . . . . . .20

Remote Thermostat Selection (optional for CACH/

CAHH)

. . . . . . . . . . . . . . . . . . . . . . . . . . .21

Electrical Wiring

. . . . . . . . . . . . . . . . . . . . .22

Initial Start-Up — CACG/CAHG Units ONLY

. . .24

Initial Start-Up — CACH/CAHH Units ONLY

. . .28

CACH/CAHH Microprocessor Controller Overview

31

Setting the CACH/CAHH Controller . . . . . . . .35

CACH/CAHH Microprocessor Controller

Operation

. . . . . . . . . . . . . . . . . . . . . . . .38

CACH/CAHH Remote Thermostat Operation

. .45

CACH/CAHH Controller Features

. . . . . . . . . .47

CACH/CAHH Controller Fault Conditions

. . . . .48

Maintenance

. . . . . . . . . . . . . . . . . . . . . . .49

Troubleshooting — General

. . . . . . . . . . . . .50

Troubleshooting — CACG/CAHG Units

. . . . . .52

Troubleshooting — CACH/CAHH Units

. . . . . .55

Frequently Asked Questions

. . . . . . . . . . . . .56

Dimensions

. . . . . . . . . . . . . . . . . . . . . . .58

Dimensions (continued)

. . . . . . . . . . . . . . .59

Specifications

. . . . . . . . . . . . . . . . . . . . . .60

System Options

. . . . . . . . . . . . . . . . . . . . .61

Test Unit Performance Data Sheet

. . . . . . . . .63

EMI’s Product Line

. . . . . . . . . . . . . . . . . . .64

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 3

Read Before Proceeding

Recognize this symbol as an indication of

important safety information.

WARNING

Completely read all instructions

prior to assembling, installing, operating, or repairing this product.

Inspect all parts for damage prior to

installation and start-up. e EMI Ductless high eciency evaporator must be

installed ONLY by qualied installation

personnel.

DANGER

Tampering with this unit is danger-

ous

. Tampering voids all warranties.

DO NOT aempt to modify or change

this unit in any way.

DANGER

e EMI ductless unit must:

Be connected to a properly grounded •

electrical supply with the proper

voltage as stated on the rating plate.

Have proper overcurrent protection •

(time-delay fuse/HACR Breaker) as

listed on the rating plate.

Ensure there are no power feeds to the

unit such as fire alarm circuits, BMS

circuits, etc.

Failure to follow these instructions can

result in a re, explosion, or electrical

shock causing property damage, personal

injury, or death.

Safety Instructions

is manual is intended as an aid to qualied service personnel for proper installation, operation, and maintenance of the

EMI Ductless high eciency evaporator.

Read these instructions thoroughly and

carefully before aempting installation or

operation.

Failure to follow these instructions may

result in improper installation, operation,

service, or maintenance, possibly resulting

in re, electrical shock, property damage,

personal injury, or death.

Read all instructions before using this

unit. Install or locate this unit only in accordance with these instructions. Use this

unit only for its intended use as described

in this manual.

Check the rating plate on the unit before

installation to make certain the voltage

shown is the same as the electric supply to

the unit. e rating plate is located on the

top panel only.

This unit must be connected only to a

properly grounded electrical supply. Do

not fail to properly ground this unit.

Turn o the electrical supply before servicing the unit.

Do not use the unit if it has damaged wiring, is not working properly, or has been

damaged or dropped.

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 4 P/N 240008108, Rev. B [082509]

Product description

e EMI Ductless Cassee Air handlers •

are available in three cabinet sizes with

four output capacities from 9,000–24,000

Btuh, and two cooling only capacities

from 30,000–36,000 Btuh.

Key features include a condensate pump •

with safety switch and a 36” (0.9 m) li

(measured from the base or boom of

the unit), fresh air inlet and branch duct

knockouts, and motorized air vanes models 24 and 36 only).

Electric heat is a factory-installed option •

ONLY (there are no eld installed electric

heat kits available). (See NOTICE on

next page.)

The cassette air handler accepts a 24 •

volt thermostat control (thermostat not

included).

Designed for low noise levels, easy instal-•

lation and maintenance and a slim line

fascia, all ensure minimum intrusion into

the conditioned environment.

Due to ongoing product development, all •

designs and specications are subject to

change without notice.

These cassette air handlers produce •

system SEER’s meeting or exceeding 13

when matched with EMI outdoor units:

Single-zone condensing units –

S1CG/S1HG 09–24 and S1CG 30–

36.

Dual-zone condensing units –

S2CG/S2HG side discharge.

Multi-zone, top discharge condens- –

ing units T2CG/T2HG, T3CG/

T3HG, or T4CG/T4HG.

Refer to specications contained in –

this document.

All EMI air handlers are backed by En-•

viromaster International LLC and are

tested, rated, and certied in accordance

with ARI standards 210/240-2008 and

UL 1995.

Verify Unit Before Installing

Standard features

CACG/CAHG units

“G” units require a remote thermostat •

for operation. They do not include an

onboard controller.

External thermostat required.•

CACH/CAHH units

“H” units include an on-board micropro-•

cessor controller with infrared remote.

e remote is required to adjust seings •

and congure the controller.

Also included is a bank of DIP switches for •

seing operating behavior. ese can be

used to select operation by the on-board

controller or by a remote thermostat.

When operated by remote thermostat, the •

controller oers limited options.

Materials of Construction

Galvanized steel cabinet with re-resistant •

thermal and acoustic foam insulation.

Light grey high-impact ABS fascia.•

Expanded polystyrene drain pan with a •

tough, re-retardant thermoplastic liner.

Air Systems

Fans are backward-curved impeller •

centrifugal design; dynamically and statically balanced; and mounted on integral

mounting rails.

Single-fan models 9, 12 & 24 are –

designed with re-retardant plastic

or aluminum impellers.

Twin-fan model 36 is designed with –

re-retardant plastic impellers.

Motors are multispeed, enclosed type –

with thermal protection and sealed

lifetime bearings.

Permanent, washable lter (user acces-•

sible).

Branch duct knockouts on three sides •

for remote discharge locations (using no

more than two non-adjacent sides).

Fresh air intake capability on three sides of •

cabinet (only two on models 9–12).

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 5

Verify Unit Before Installing (continued)

Four plastic air vanes, motor driven with •

auto sweep or xed position stop seing

on models 24 and 36. Models 9–12 are

equipped with manually-adjusted air

vanes.

Coil

Coil is seamless, copper tubing, arranged •

in staggered conguration, with enhanced

aluminum ns, tested to 600 psig.

e tubes are mechanically expanded for •

secure bonding to n shoulder.

Refrigeration Circuit

Units are equipped with a serviceable •

fixed orifice expansion device and use

R410A refrigerant only.

Controls and Components

(factory installed or supplied)

Connections for 24V remote thermo-•

stat.

Custom control board featuring program-•

mability, configuration, and multiple

modes of operation. (CACH/CAHH

only)

Controls also feature anti-short-cycle •

timer, post purge fan relay, and an onboard 30-amp electric heat relay.

Condensate pump with 36” (0.9 m) li •

(measured from base of unit).

24V Transformer.•

System options

24V remote thermostat.•

Electric Heat (@ 230V) •

1.5 kW models 9–12 –

3 kW model 24 –

5 kW model 36. –

Heat pump applications

NOTICE

Electric heat option EMI heat pumps

are intended to operate with an indoor

air handler, with electric heat. If an indoor air handler without electric heat is

matched with a heat pump condenser,

the system will deliver cold air during

defrost.

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 6 P/N 240008108, Rev. B [082509]

Remote thermostat applications

CACG/CAHG units require a remote •

thermostat for operation. CACH/

CAHH units can be operated by a remote

thermostat by conguring the unit’s DIP

switches.

A thermostat can be obtained through •

EMI or your local distributor.

NOTICE

Make sure the thermostat is suitable for

unit operation (i.e., cooling only, cooling/electric heat, heat pump.) See thermostat requirements in this manual.

Mechanical characteristics

Filters

Metal framed lters are ed. ese are •

reusable and may be vacuum cleaned.

Condensate pump

A condensate pump is designed to carry •

water out of the unit. e pump is xed

to a mounting bracket which can be

withdrawn from the side of the chassis

and incorporates an inspection hole to

allow a visual check of the pump during

operation. A oat switch stops the cooling action (shuts off the compressor)

should the pump become blocked or fail.

(Important: Total li for this pump is 36”

(0.9 m) or less.)

Air vanes

Air outlet vanes are manually adjustable •

on the models 9 and 12 or driven by an

electric motor on the models 24 and 36.

Where ed, the motorized air vanes can •

be set to auto sweep or can be stopped in

a xed position.

Heating

e cassee may be ed with electric •

heaters which are equipped with overtemperature limit switches. Consult

factory for available models with electric

heat.

Fresh air connection

Fresh air may be introduced to the unit •

by the addition of ducts connected to the

fresh air knockouts on the cassee case.

Recommended maximum length is 10’ •

(3m) of 4” (0.1m) diameter duct. e

fresh air volume is approximately 7–10%

of the unit’s published maximum air ow

(if more than 10% make up air is needed,

a fresh air booster fan is required).

Refer to Performance Data section of this •

manual for further information.

e cassee is best installed in new con-•

struction or existing construction with a

suspended or false ceiling with enough

clearance to accommodate concealing

the piping and electrical connections to

the unit.

Verify Unit Before Installing (continued)

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 7

Piston/Orifice Replacement (when required)

NOTICE — model 24 with T2, T3 or T4 condenser

Piston/orifice replacement e factory-installed piston/orice must be replaced

when a model 24 air handler is matched with a T2CG/T2HG4400, T2CG/T2HG2400

or T2C/T3CG/T3H2240 condenser that has a 24,000 Btuh compressor (designated

by a “4” in the capacity decoding eld). e piston will need replacement only on the

24,000 Btuh zone.

All other applications use the factory-installed orice.

Follow these instructions to replace the orice BEFORE mounting the unit.

Replacing the piston/orifice

Disassemble the orice joint, remove the 1.

factory-installed orice, and replace with

the orice listed in Figure 1 (supplied in

the Kit Bag).

Piston/orifice replacementFigure 1

Model Condenser Factory-installed orifice size

(Inches)

Replacement orifice size

(Inches)

CAHG/

CAHH

24

T2C/T2H4400

T2C/T2H2400

T3C/T3H2240

0.054 0.047

CACG/

CACH

36

S1CG3000

.070 .063

Make sure the o-ring is in good condition 2.

and properly installed.

18 Piston Change

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 8 P/N 240008108, Rev. B [082509]

Mounting the Unit

Before installing, consider:

Determine the best location for mounting •

the unit for room air circulation.

Locate outdoor and indoor units as close •

together as possible.

Determine how power wire (high and •

low-voltage) condensate drainage, and

refrigerant piping may be run to and from

the unit.

Ensure that interconnect tubing is within •

the limits given in Table 1.

Tubing specificationsTable 1

S1CG

or

S2CG

Model

Max.

Length

Equivalent

feet

Max.

Lift

Max.

Trap

Height

Liquid

Line

Suction

Line

“H” “P” O.D. O.D.

09

50’

(15 m)

20’

(6 m)

15’

(5 m)

1/4" 1/2"

12 1/4" 1/2"

18

100’

(30 m)

35’

(11 m)

20’

(6 m)

3/8" 5/8"

24 3/8" 3/4"

30 3/8" 3/4"

36 3/8" 3/4"

NOTICE

Piping may be roughed in before wallboard or panels are placed in new construction. PVC pipe (3” or 4” I.D.) may

be used as a pipe chase.

Unpacking

e Cassee fascia and main chassis are packaged together for increased protection.

Remove the banding straps and li the 1.

cardboard lid.

Fascia is packed in bubble wrap and on 2.

top of the chassis (fascia is not aached

to the chassis for shipping).

Cardboard template is between the chas-3.

sis and the fascia.

NOTICE

Do not throw template away with packaging

Li the fascia and template from the box

4.

and set aside.

Remove the cassette chassis from the

5.

box utilizing the four corner brackets

for liing.

WARNING

Do not use the drain or refrigerant connections for liing.

In order to protect the fascia from dirt and 6.

damage, it should be returned to the box

until it is ready to be installed.

NOTICE

Do not throw away the two polystyrene

blanking-o pieces with packaging

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 9

Mounting the Unit (continued)

Blanking off

e fascia discharge slot(s) will need blanking o when ducts are used to channel the

conditioned air to other areas.

Position the two polystyrene blanking o •

strips (provided) in the fascia discharge

slots to direct the air to the ducts.

Up to two non-adjacent sides may be •

blanked o.

If the fascia discharge slot needs

blanking off —

Remove the inlet grilles and lters (see 1.

Figure 2, Page 9) and (Figure 3, Page 9).

Once the grilles and lters are removed, 2.

turn the fascia over so the polystyrene

insulation is exposed (Figure 4, Page 9).

Push one of the polystyrene blanking-o 3.

pieces into the recess in the polystyrene

fascia insulation.

Models 9–12 — one grille & one Figure 2

filter

Model 24 — two hinged grilles Figure 3

and two filters (Model 36, not

shown has three grilles and

three filters)

hinge

Applying blanking-off piecesFigure 4

blanking-off

Pieces

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 10 P/N 240008108, Rev. B [082509]

Mounting the Unit (continued)

Positioning

e cassee installation position should be

selected with the following in mind:

Pipe work, electrical connections, control 1.

box and condensate pump access panels

should be readily accessible. Refer to the

cassee dimensions in the back of this

manual.

e unit should be positioned at least 5 2.

. (1.5m) from a wall or similar obstruction.

Position the unit as close to the center 3.

of the room as possible to ensure air is

distributed evenly.

Position the unit so that the discharge 4.

air does not blow directly on the remote

thermostat, if used.

e unit should not be positioned directly 5.

above any obstructions.

e condensate drain should have suf-6.

cient fall 1” per 10’ (8 mm/m) in

any horizontal run between cassee and

drain.

Maximum condensate pump li is 36” 7.

(0.9m).

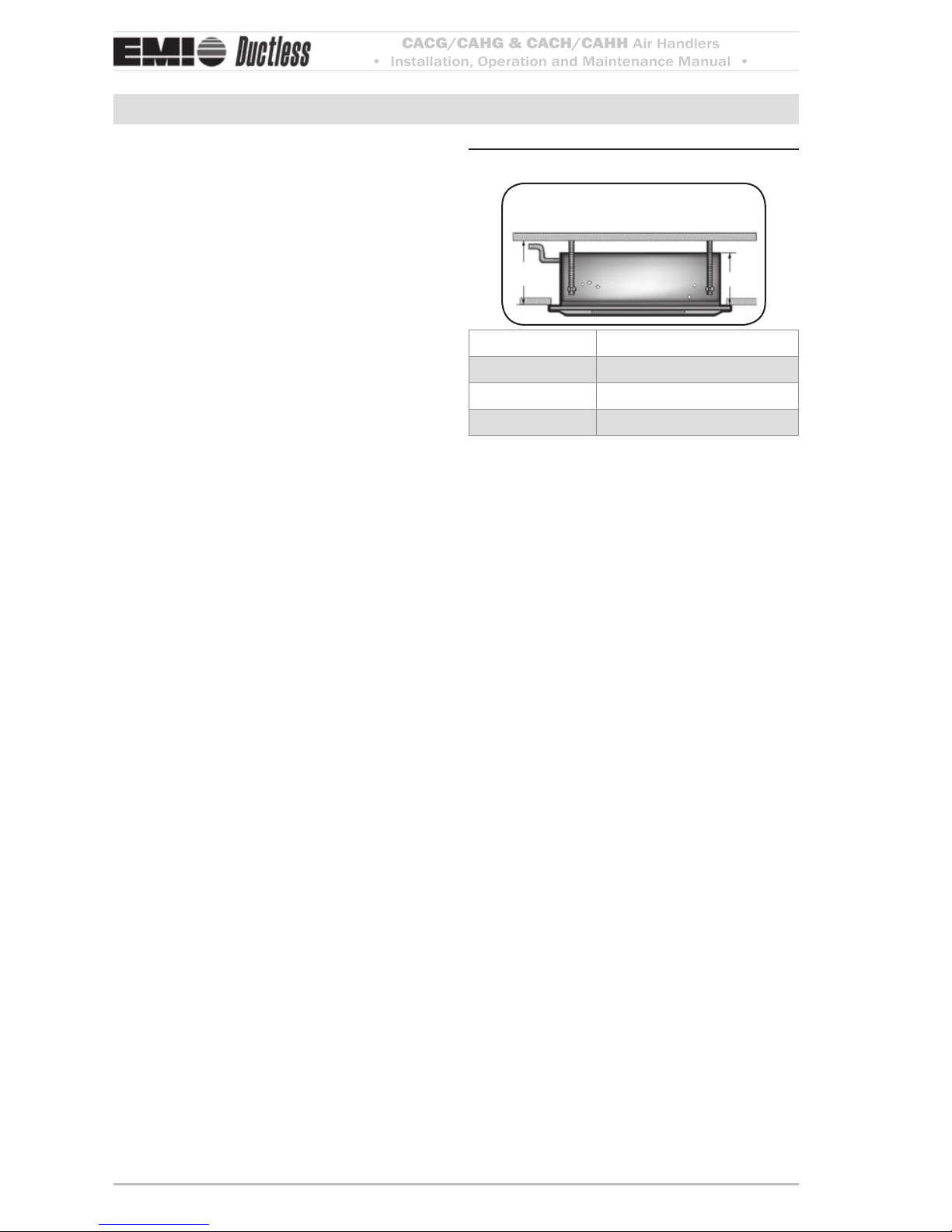

ere should be a minimum 1” (25.4mm) 8.

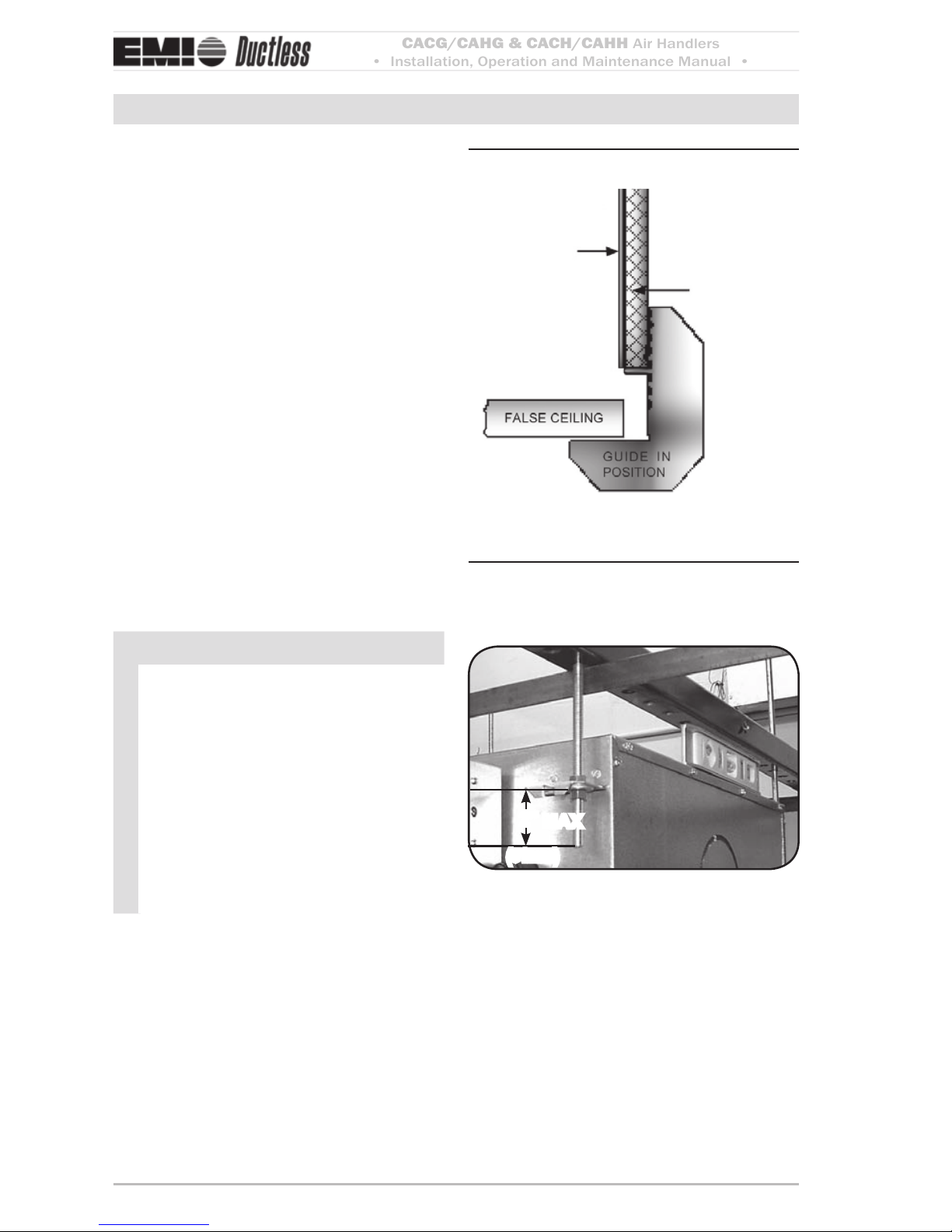

clearance above the depth of the cassee

and the false ceiling for proper installation. See (Figure 5, Page 10). (See the

cassee dimensions in the back of this

manual for cabinet sizing).

Spacing requirementsFigure 5

Dimension A + 1” = minimum space

above the false ceiling for installation

A

A +1”

Model Dimension A

9 & 12 11.84” (0.3 m) min.

24 12.55” (0.32 m) min.

36 14.51” (0.37 m) min.

Remote thermostat

A remote thermostat can be obtained through

EMI or your local distributor. e remote

thermostat is required for CACG/CAHG

units, optional for CACH/CAHH units.

In addition to positioning the cassee correctly, it is very important to locate the wall

mounted thermostat in the optimum position

to ensure good temperature control. The

installation should be selected with the following points in mind:

Position the thermostat approximately 5

1.

. (1.5m) above oor level.

Avoid external walls and dras from win-

2.

dows and doors.

Avoid positioning near shelves and cur-

3.

tains as these restrict air movement.

Avoid heat sources (direct sunlight, heat-

4.

ers, dimmer switches, etc.)

Seal wiring holes in the wall behind the

5.

thermostat to avoid dras.

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 11

Mounting the Unit (continued)

Mounting method

In existing construction, remove enough •

ceiling panels to provide clearance space

for mounting unit to ceiling joists.

Before beginning the installation, inspect •

the unit location, test the strength of the

ceiling joists to insure they will support

the weight of the unit.

Determine mounting method: •

On wooden beams use threaded rods, –

washers, and nuts to suspend support

brackets.

With metal structures, secure thread- –

ed rods on an existing angle or install

a new support angle.

On newly built concrete slabs secure –

threaded rods with inserts and embedded bolts.

For previously built concrete slabs –

install hanging bolts with an expansion anchor.

Follow local building codes for required •

safety cables, braces, etc.

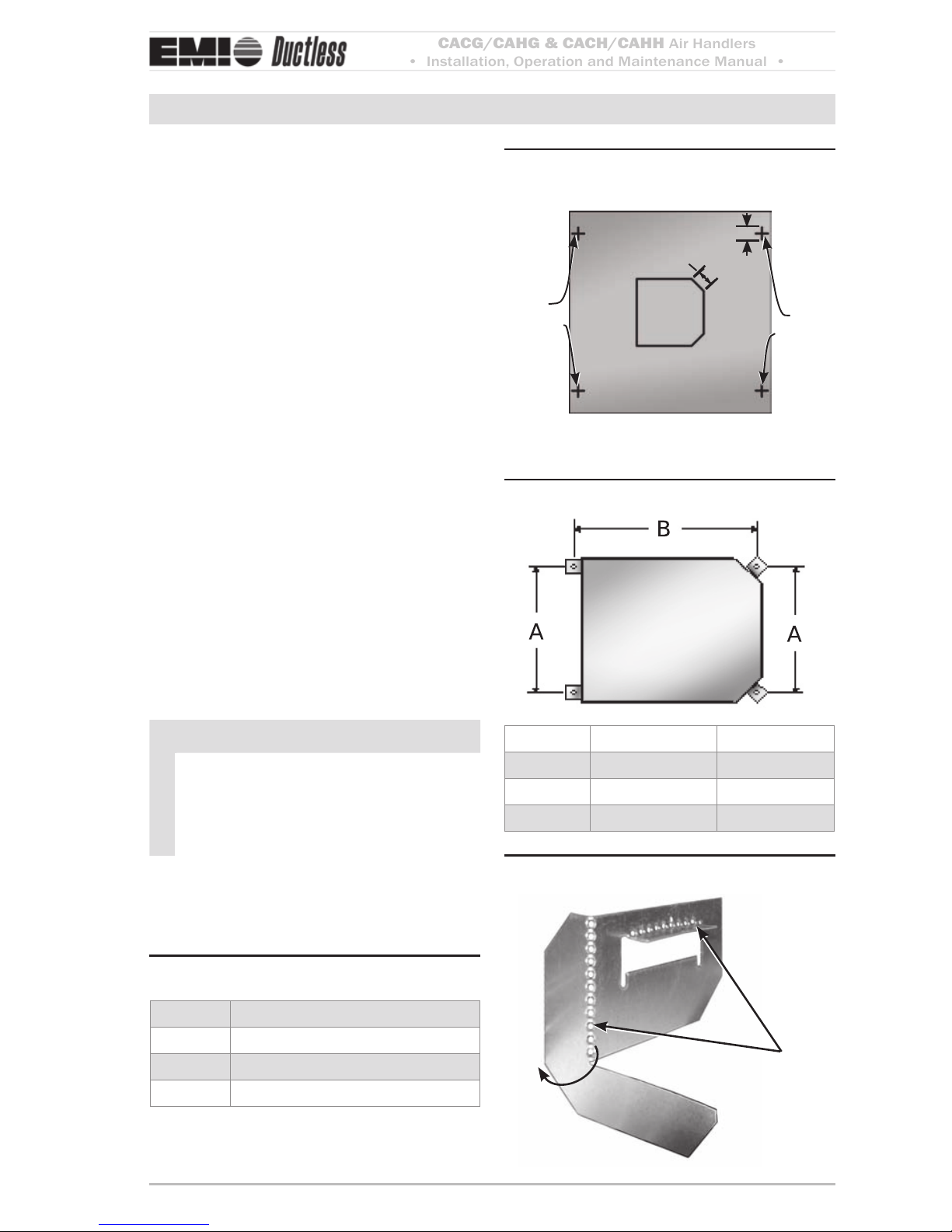

Ceiling opening

NOTICE

Make sure the ceiling grid is supported

separately from the Cassee. e ceiling

must not be supported by any part of the

Cassee unit, fascia or any associated

wiring or pipe work.

Cut an opening in the false ceiling with the

size shown in (Table 2, Page 11).

Ceiling opening sizesTable 2

Model Dimensions

9 & 12 23¼” x 23¼” (591 x 591 mm)

24 33/” x 33/” (860 x 860 mm)

36 46” x 33/” (1168 x 860 mm)

Ceiling cutout/rod placement Figure 6

template (shipped with unit)

(51mm x 45°)

2.000 x 45° TYP

rod

Positions

1.500 TYP

rod

Positions

(38mm TYP)

Ceiling rod positionsTable 3

A

A

B

Model Dimension A Dimension B

9 & 12 19.50” (495mm) 22.87” (581mm)

24 29.19” (740mm) 30.80” (782mm)

36 29.19” (740mm) 43.06” (1094mm)

Mounting bracketsFigure 7

Fold

bracket along

perforations

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 12 P/N 240008108, Rev. B [082509]

Mounting the Unit (continued)

Mounting

Use the template (see 1. Figure 6, Page 11)

to cut the ceiling opening and determining the rod positions.

Install hanger bolts using 3/8” (10mm) 2.

all-thread rod at the centers shown in

(Table 3, Page 11).

Prepare the installation guides by fold-3.

ing the metal bracket by hand along the

perforations (Figure 7, Page 11).

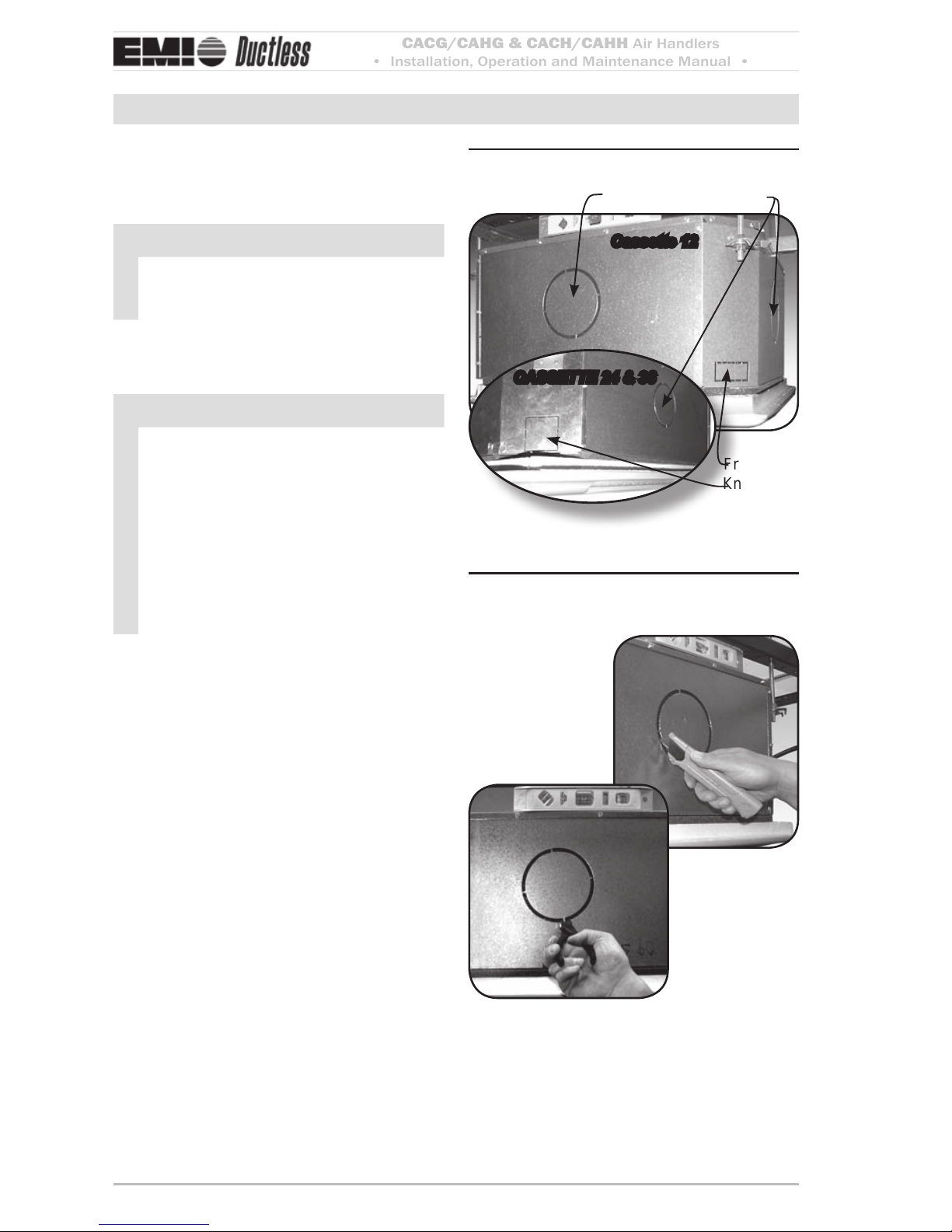

Li the cassee onto the hanging rods. 4.

Level at the correct distance from the ceil-5.

ing with the aid of the installation guides

as shown in (Figure 8, Page 12).

Secure the unit in position with locknuts 6.

and washers on either side of the cassee

bracket.

Ensure threaded rod does not protrude 7.

more than 2” (51mm) below the mounting bracket see (Figure 9, Page 12).

NOTICE

If the ceiling is not level or even, it is

important that the cassee is installed

level to ensure correct pump operation

and to maintain fan clearances.

Place a carpenter’s level on the unit.

A maximum slope of 1/8” (3mm) over

the length of the chassis toward the condensate drain is allowed.

Any slight discrepancy between the cassee and ceiling will be taken up by the

fascia foam seal.

Positioning installation guidesFigure 8

Inner CAse

InsulAtIon

CAssette

CAse

Threaded rods must not pro-Figure 9

trude more than 2 inches below

the mounting brackets

mAx

2”

(51mm)

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 13

Condensate Piping

e unit can now be piped up in accordance

with good refrigeration and/or plumbing

practices.

The Cassette is supplied with a 1/2” I.D.

exible PVC hose for connection to copper

or plastic drain piping.

When installing the cassette, consider the

following:

Maximum pump li is 36” (0.9m).1.

The highest point in the condensate 2.

piping should be as close to the unit as

possible. is prevents a large volume of

water draining back into the unit when it

is switched o.

NOTICE

ere is a check valve at the pump discharge to prevent water from draining

back into the unit. is piping technique

will minimize any issues should the

check valve become stuck open from

airborne debris.

Condensate pipe-work should slope 3.

downwards in the direction of water ow

with a minimum gradient of 1” per 10’

(8mm/1m). There must be no uphill

gradients other than in the rst 36” (0.9m)

of pipe-work from the cassee.

When multiple cassees are connected to 4.

a common condensate drain, ensure the

drain is large enough to handle the total

volume of condensate.

NOTICE

A drain line vent may be required to prevent siphoning of water from the drain

pan and associated noise.

The highest point of the con-Figure 10

densate piping should be as

close to unit as possible

Correct

Incorrect

Condensate drainFigure 11

Condensate Drain Connection

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 14 P/N 240008108, Rev. B [082509]

Duct Connections

Branch duct and fresh air duct collars can be

aached to the cassee chassis by following

the steps below.

NOTICE

Recommendation no more than

10 feet (3m) of branch duct or fresh air

duct should be installed.

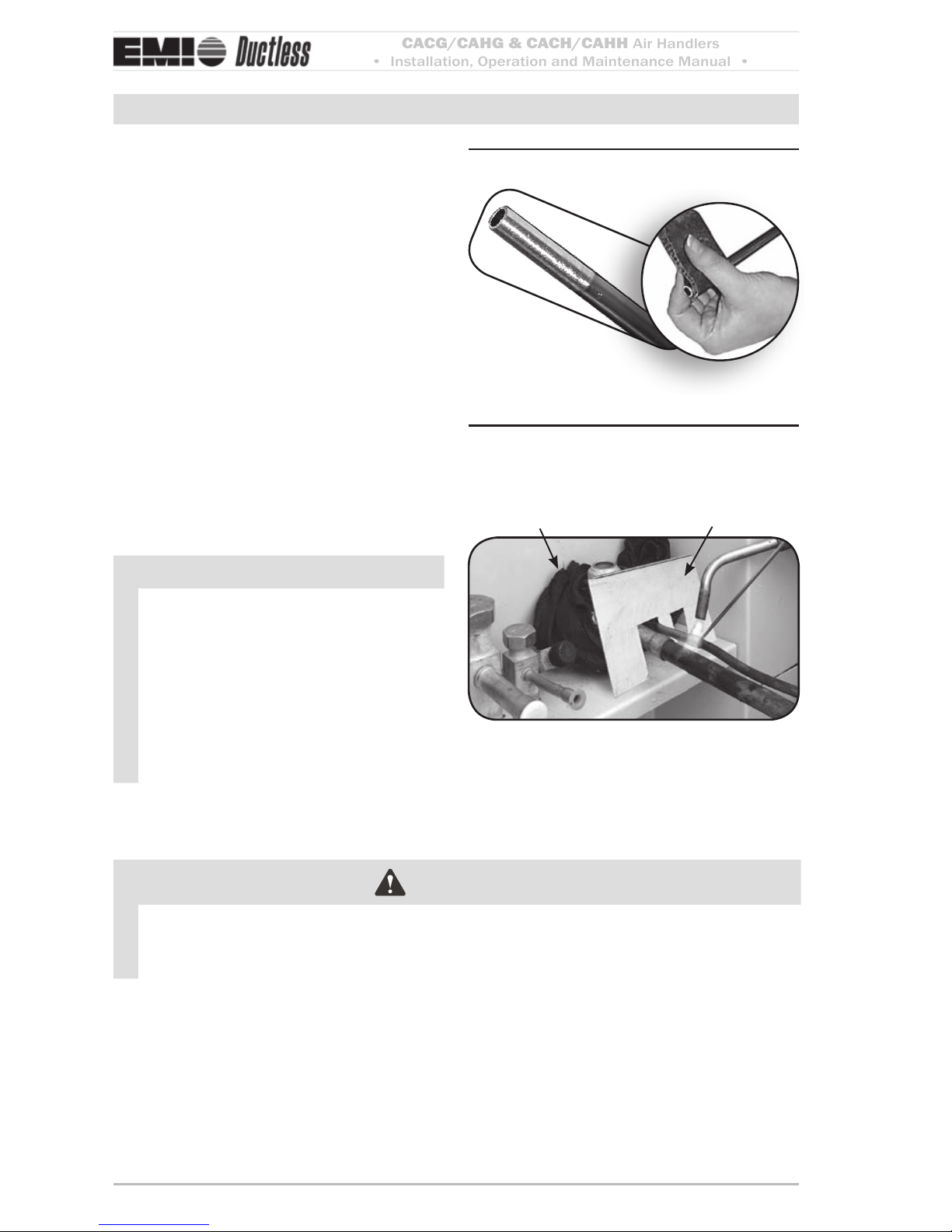

Locate the knock-out holes (1. Figure 12,

Page 14).

NOTICE

e number of knockouts varies with

unit size.

Branch duct knock-outs are 5¼”

(133mm) round.

Fresh air knockouts are:

1¼” x 2½” (32 x 64mm) rectangular •

on models 9 & 12.

3” (76mm) square on models 24 •

and 36.

Cut the black insulation around the 2.

knock-out (Figure 13, Page 14).

Snip the tabs holding the knock-out in 3.

place (Figure 13, Page 14).

Remove the metal knock-out and the 4.

black insulation behind it.

Aach the duct collars (eld supplied) to 5.

the chassis using self-drilling screws.

Repeat steps above for remaining duct 6.

work.

KnockoutsFigure 12

fresh air

knockout

branch Duct knockout

Cassette 12

CAssette 24 & 36

Cut insulation and snip out Figure 13

knockouts

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 15

Refrigerant Piping

CAUTION

Avoid piping on wet and rainy days.•

Use only clean, refrigeration-grade •

copper tubing.

Use tubing benders to guard against •

kinking.

Be certain no burrs remain on the •

ings.

Cap ends of lines until ready for con-•

nections. Be certain that plastic end

caps remain in place when inserting

through wall openings.

Insulate the suction and condensate •

lines all the way to the cassee.

Isolate tubing from transmiing vibra-•

tion to the building or unit and avoid

contact with sharp edges.

Wrap refrigeration valves with a wet •

rag “heat sink” to protect valves while

brazing. (See Figure 16, Page 16.)

DO NOT use a suction line size larger •

than the condenser service valve connection. is can harm the compressor. Install a reducer, when used, only

on the inside connection.

NOTICE

e cassee is equipped with a Flo Rater

piston expansion device. Connections

are sweat type.

Piping connections at unitFigure 14

suction line liquid line

(When a reducing bushing is required, install

only at the indoor suction-line connection.)

Line sizing

Size lines per (1. Table 11, Page 60).

e suction line size must match the con-2.

denser service valve connection.

When matching the model 24 with an a.

18,000-Btuh condenser, you must use

a 5/8-inch suction line, with a reducer

installed as shown in (Figure 14,

Page 15).

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 16 P/N 240008108, Rev. B [082509]

Refrigerant Piping (continued)

Clean ends of tubingFigure 15

Place wet rag “heat shield over Figure 16

valves plus a sheet metal shield

to protect paint

Wet rag heat sink

shield

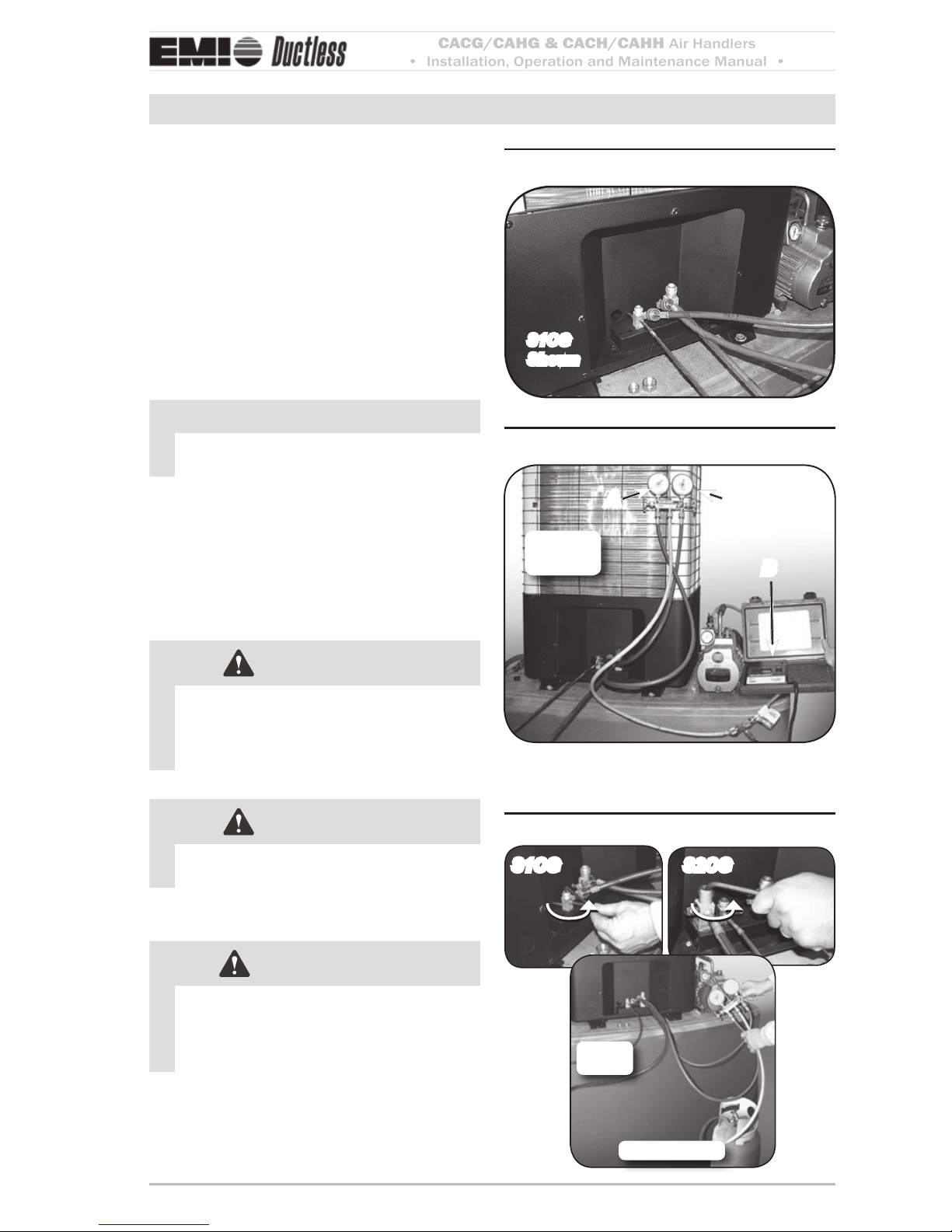

Refrigerant piping

Clean the ends of tubing and insert into 1.

ings (Figure 15).

Before brazing (2. Figure 16):

Protect valves by wrapping with a wet a.

rag “heat sink” before brazing.

Use a shield to protect the paint as b.

shown. (e shield can be made from

scrap metal.)

Braze tubing into ings, using a continu-3.

ous nitrogen purge.

e suction line must be insulated the 4.

entire length with closed cell, foam tube

insulation.

Do not insulate the liquid line.5.

Connect the outdoor unit according to 6.

the instructions supplied with unit.

NOTICE

Maximum equivalent pipe run should 1.

comply with (Table 1, Page 8).

Horizontal pipe runs should be 2.

slightly inclined, so as to encourage

oil to flow in the direction of the

compressor, for beer oil return.

Good refrigeration practices must be 3.

employed to ensure the correct pressure drop and good oil return.

CAUTION

Pressure test all eld installed piping with nitrogen. Using a suitable vacuum pump,

evacuate the tubing and indoor unit to 500 microns or less, with service valves remaining

front seated (closed).

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 17

Refrigerant Piping (continued)

Refrigerant processing

Aach manifold set (1. Figure 17).

Evacuate line to 500 microns or less to 2.

ensure all moisture has been removed and

there are no leaks.

Once certain of a good evacuation and 3.

leak free joints, back-seat the valves

(counter-clockwise) to open and allow

factory charge to ll lines and indoor unit

(Figure 18, Page 17).

NOTICE

Refer to refrigerant charge table for specied charge.

Use only R410A refrigerant. Add and

4.

remove only liquid, never vapor.

Charge to proper weight, charge based on 5.

feet of interconnect (Figure 19, Page 17).

See tables on page 18.

CAUTION

Refer to the charts in the condenser

manual to “fine tune” the refrigerant

charge.

CAUTION

Charging should be done with a dial-acharge or weighed in with a scale.

WARNING

It is illegal to discharge refrigerant into

the atmosphere. Use proper reclaiming

methods & equipment when installing

or servicing this unit.

Manifold set connections at unitFigure 17

s1CG

shown

Manifold set up for evacuationFigure 18

A C

B

s1CG

shown

ManifoldA Vacuum pumpB

Micron gageC

Charging the unitFigure 19

s2CGs1CG

Refrigerant

s1CG

shown

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 18 P/N 240008108, Rev. B [082509]

S1CG/S1HG and top discharge R410A refrigerant charge table

Table 4

(CAC_ refers to CACG/CACH; CAH_ refers to CAHG/CAHH)

Condenser

Evaporator

pairing

Line charge

per foot

Factory

charge

Top discharge, Multi-zone

S1CG9

S1HG9

CAH_9

.25 oz/ft

(23 g/m)

39.50

51.25

Circuit capacity

Line charge

per foot

Factory

charge

S1CG2

S1HG2

CAH_12

.25 oz/ft

(23 g/m)

33.75

45.75

S1CG8

S1HG8

CAH_24

.64 oz/ft

(59 g/m)

62.25

63.00

09 (9,000 Btuh)

.25 oz/ft

(23 g/m)

41

S1CG4

S1HG4

CAH_24

.64 oz/ft

(59 g/m)

63.00

74.00

12 (12,000 Btuh)

.25 oz/ft

(23 g/m)

35

S1CG3 CAC_36

.64 oz/ft

(59 g/m)

97.50 18 (18,000 Btuh)

.25 oz/ft

(23 g/m)

65

S1CG6 CAC_36

.64 oz/ft

(59 g/m)

110.00 24 (24,000 Btuh)

.25 oz/ft

(23 g/m)

63

S2CG/S2HG R410A refrigerant charge table

Table 5

Condenser

Evaporator

pairing

Line charge

per foot

Factory

charge

Condenser

Evaporator

pairing

Line charge

per foot

Factory

charge

S2CG99

S2HG99

(2)

CAH_09

.25 oz/ft

(23 g/m)

40/40

51/51

S2CG92

S2HG92

(1) CAH_09 +

(1)CAH_12

.25 oz/ft

(23 g/m)

40/34

51/46

S2CG22

S2HG22

(2)

CAH_12

.25 oz/ft

(23 g/m)

34/34

46/46

Refrigerant Processing

NOTICE – to find charge adjustment

To nd the charge adjustment and system charge for any evaporator and tubing 1.

length:

Line Adjustment = (Line Charge/FT) x Line Length

System Total = Factory Charge + Line Adjustment

Round to the nearest ounce and allow for gauges and hoses.2.

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008108, Rev. B [082509] 19

Final Assembly

Assembly instructions

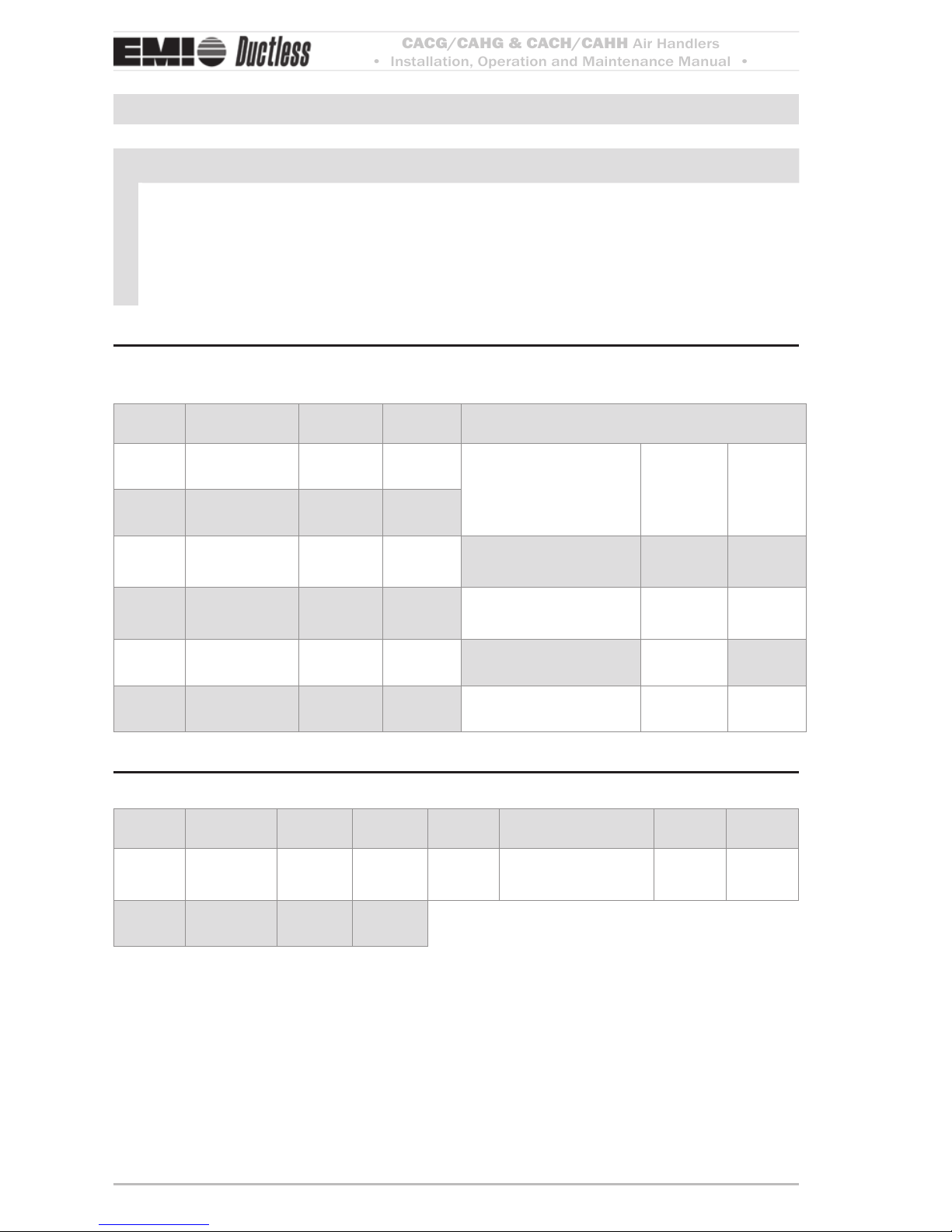

To install the four fascia mounting bolts:1.

Remove the bolts and washers from a.

the supplied kit bag.

Put washers onto the bolts. b.

Screw the mounting bolt with washer c.

into the chassis leaving approximately

1” (25mm) to hang the fascia.

Ensure the white panel fasteners holding 2.

the fascia polystyrene are pushed rmly in

(fasteners may have loosened in transit).

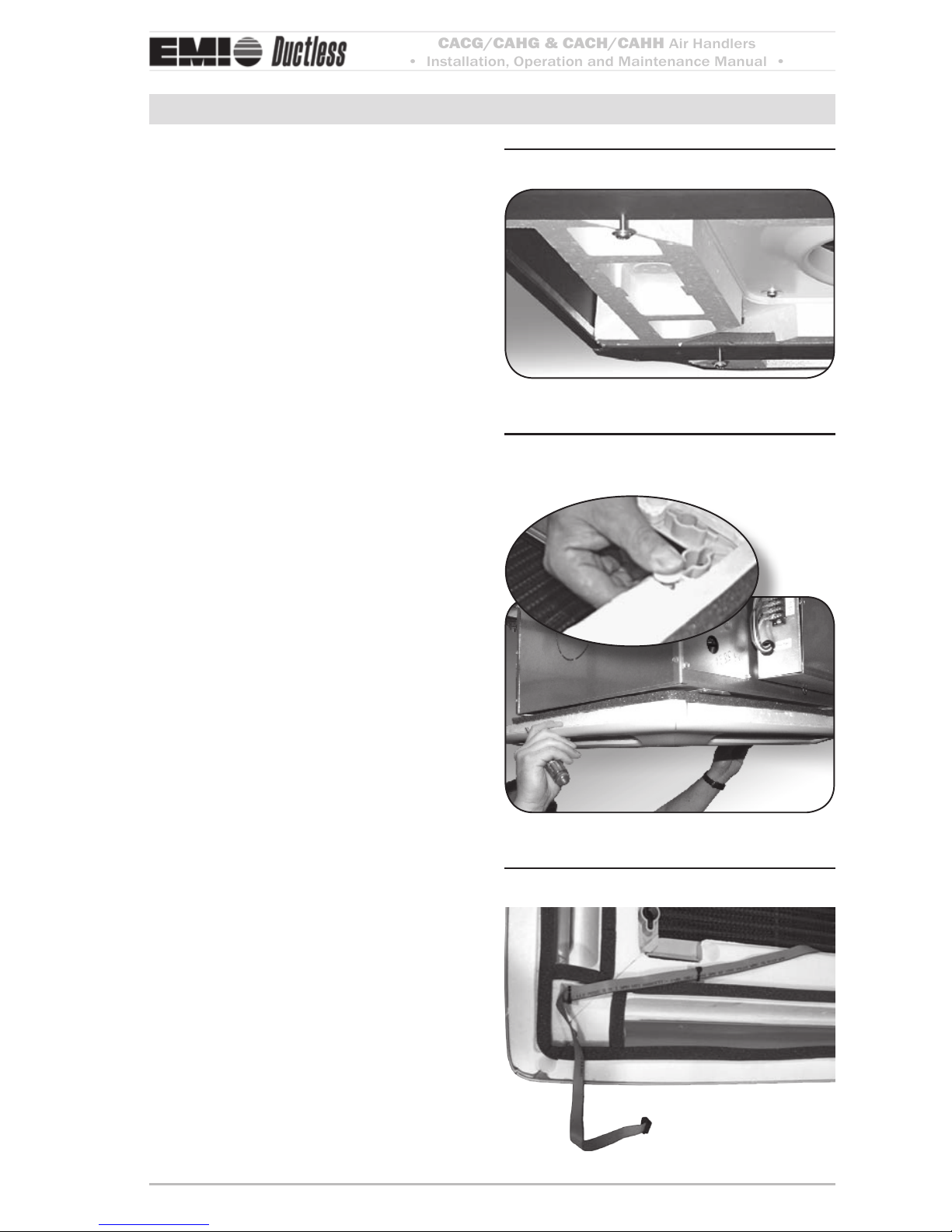

Li the fascia onto the chassis mounting 3.

bolts. Align the key hole brackets with

the mounting bolts and slide the fascia

forward to lock into position.

On Cassee 24 and 36 units connect the 4.

vane motor plug by plugging it into the

socket connection on the chassis.

Ensure that the polarized connector a.

(2 position) is in the proper orientation and connected.

Route the wires in a way that ensures b.

they won’t become trapped, cut, broken or chaed.

ONLY Cassette “H” models (CACH/5.

CAHH) contain a second cable connection to the control box for the Infrared

Unit Mount Control.

Ensure that the polarized (10 position) 6.

connector is in the proper orientation and

connected.

Route the wires in a way that ensures that 7.

they won’t become trapped, cut, broken,

or chaed (Figure 22, Page 19).

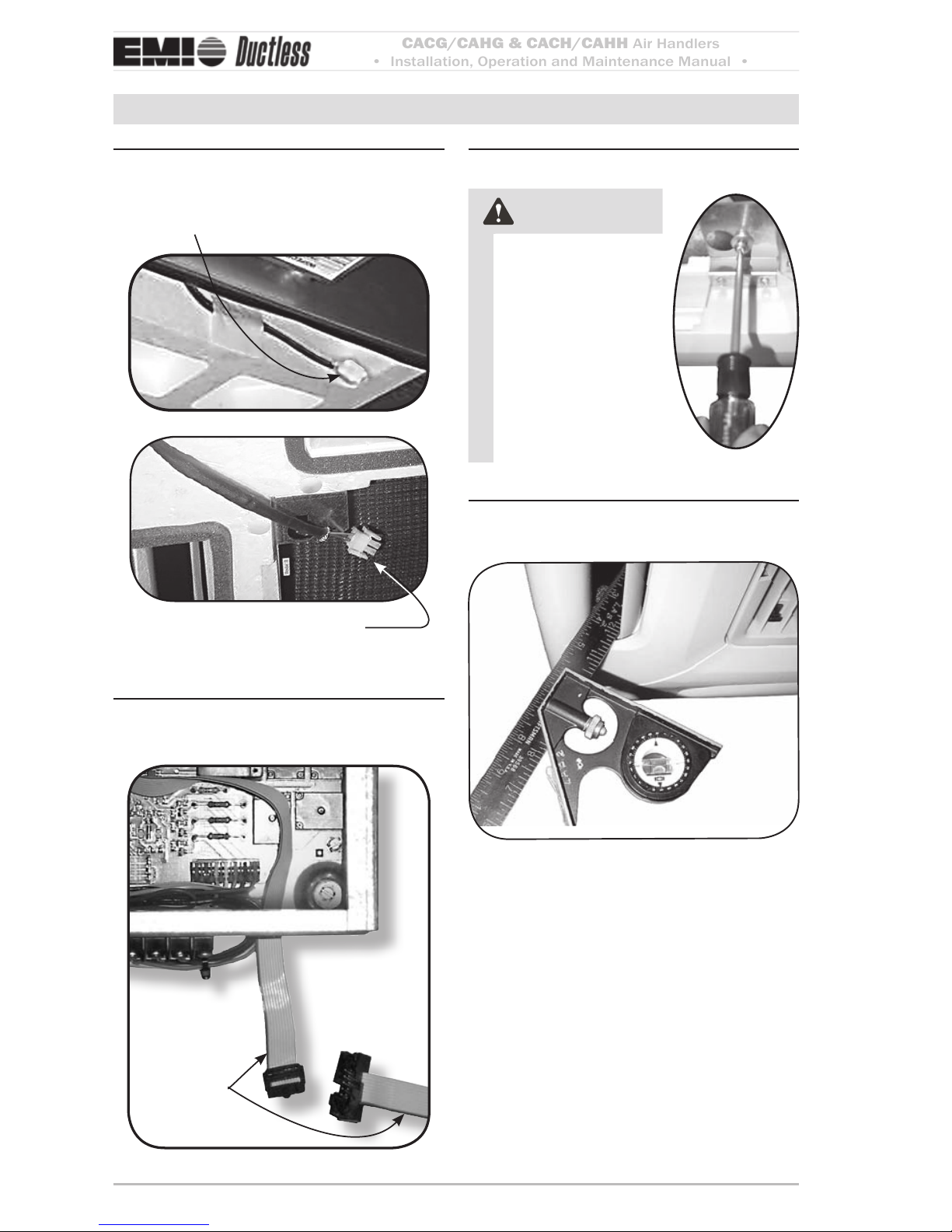

e fascia can now be tightened up to the 8.

Cassee chassis. make sure a good seal is

obtained between fascia and chassis, this

is necessary to prevent recirculation.

With lter(s) in place, the inlet grille(s) 9.

can now be installed onto the fascia.

Mounting boltsFigure 20

White panel fasteners must be Figure 21

pushed in

Wire routingFigure 22

CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 20 P/N 240008108, Rev. B [082509]

Final Assembly (continued)

Connect vane motor plug into Figure 23

socket on chassis

female vane motor plug on

chassis

Male vane motor plug on fascia

Connect infrared unit cable (“H” Figure 24

units only)

red stripe is

Conductor #1

Polarized

10 Position

Connector

Secure fascia to chassisFigure 25

CAUTION

DO NOT over-tight-

en the bolts is

could cause damage

to the fascia and drain

pan.

Adjust louver position to 30°

Figure 26

from plumb

Loading...

Loading...