Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Programming Manual

Control and Power Unit

TMP

Emhart Teknologies

TUCKER GmbH, Max-Eyth-Straße 1, 35394 Gießen

Tel.: 0641/405-0; Fax.: 0641/405-383; Mail: Info@tucker.de

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Table of Contents

1. Menu Access and Selection 1

1.1 Sub-Menu “Keyboard Functions“ 2

1.2 Sub-Menu “Weld Parameter Monitor“ 3

1.3 Sub-Menu “Programming“ 5

1.3.1 Functions Menü “Programming Weld Parameters“ 5

1.3.2 Functions Menü “Programming Output/Feeder“ 8

1.4 Sub-Menu “Statistics“ 9

1.4.1 “Fault Memory“ 9

1.4.2 “WOP-Memory“ 11

1.4.3 “Weld Output Statistics“ 13

1.4.4 “Weld Program Statistics“ 14

1.4.5 “Maintenance“ 15

1.5 Sub-Menu “Clear Fault Condition“ 17

1.6 Sub-Menu “Status Weld Sequence“ 20

1.7 Sub-Menu “Status Customer Interface“ 22

1.8 Sub-Menu “Status Feeder/Stud Divider“ 24

1.9 Sub-Menu “Status TMP ....“ 25

1.10 Sub-Menu “Functions“ 27

1.10.1 Functions Menu “Display System Configuration“ 27

1.10.2 Functions Menu “Test Mode Cycle Functions“ 28

1.10.3 Functions Menu “Test Mode Outputs Interface“ 30

1.10.4 Functions Menu “Test Mode Weld Process“ 31

1.10.5 Functions Menu “TEST Mode Power Supply“ 32

1.11 Sub-Menu “Warnings“ 34

1.12 Sub-Menu “Extended Functions“ 35

1.12.1 Functions Menu “System Parameters“ 36

1.12.2 Functions Menu “Mechanical Parameter“ 37

1.12.3 Functions Menu “Weld Program“ 40

1.12.4 Functions Menu “Copy Programs“ 42

1.12.5 Functions Menu “Clear Funktions“ 44

1.12.6 Functions Menu “ZCPU System Test“ 45

1.12.7 Functions Menu “De/Activate Program“ 46

1.12.8 Functions Menu “Stud Length Detection“ 47

1.12.9 Functions Menu “Set Date and Time“ 49

Appendix A Main Menu TMP Systemsoftware 50

Appendix B DIP-Switch information 61

Appendix C Fault Messages 62

Appendix D Error Memory Messages 79

Appendix E Messages regarding pilot arc voltage 80

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

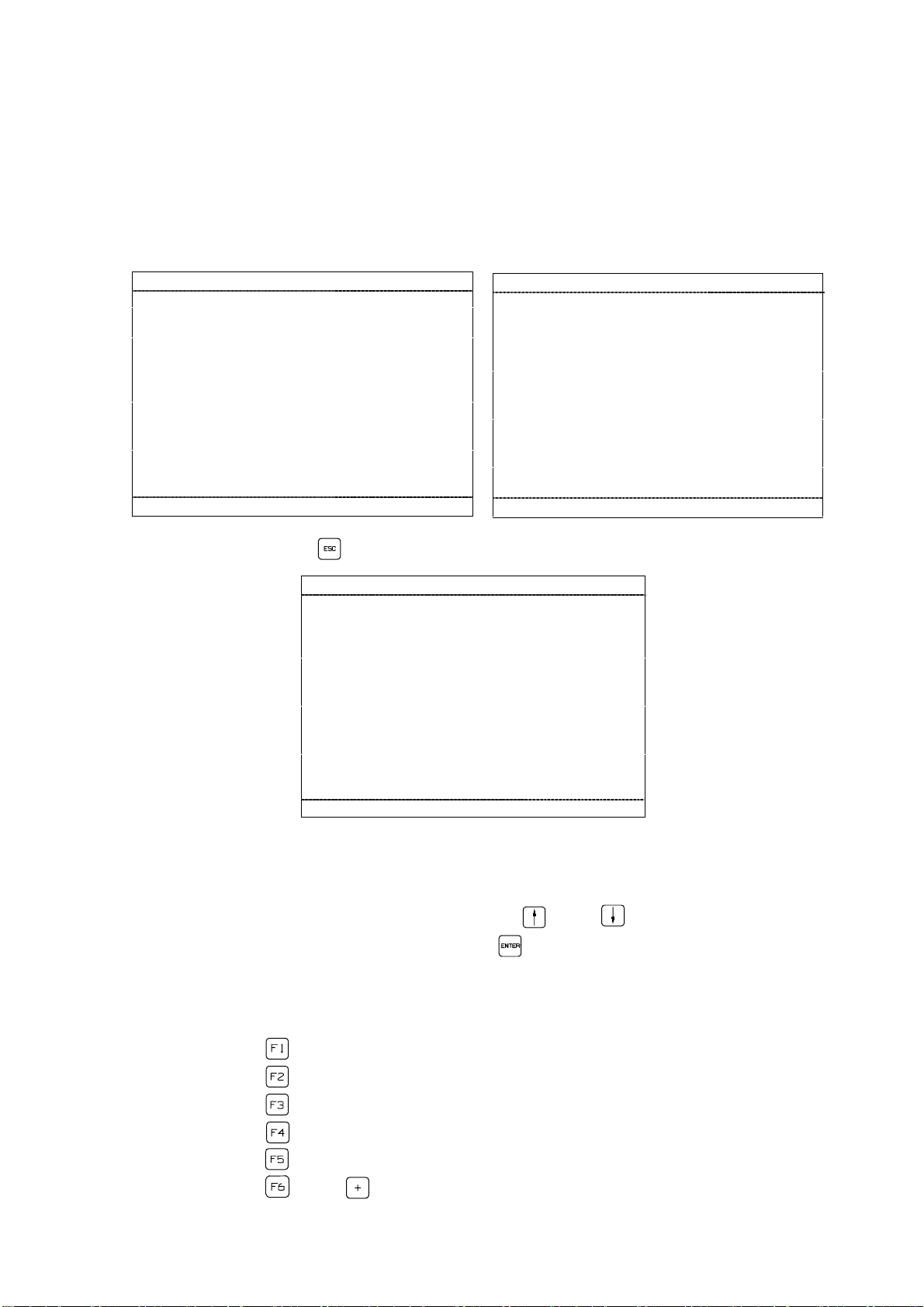

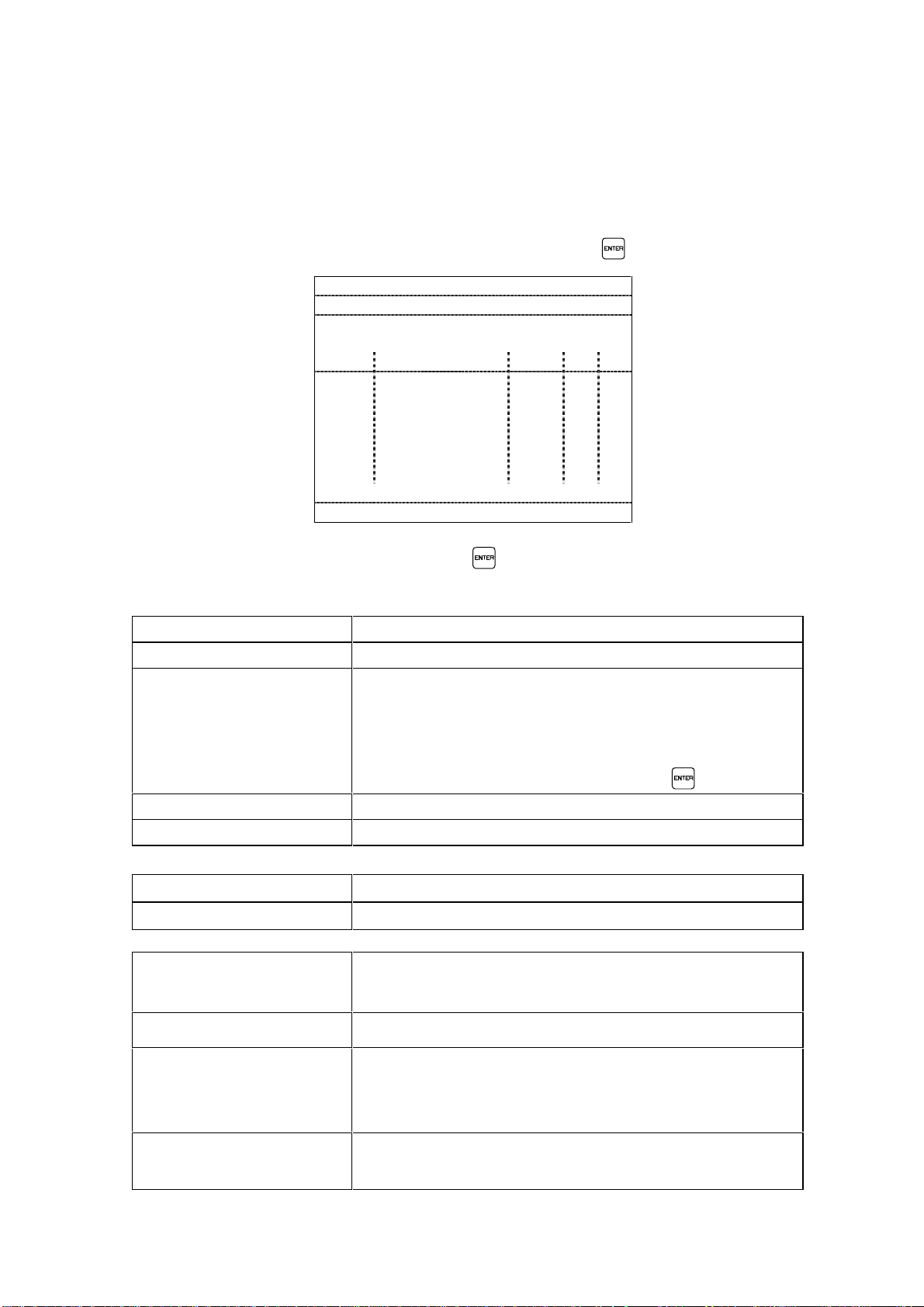

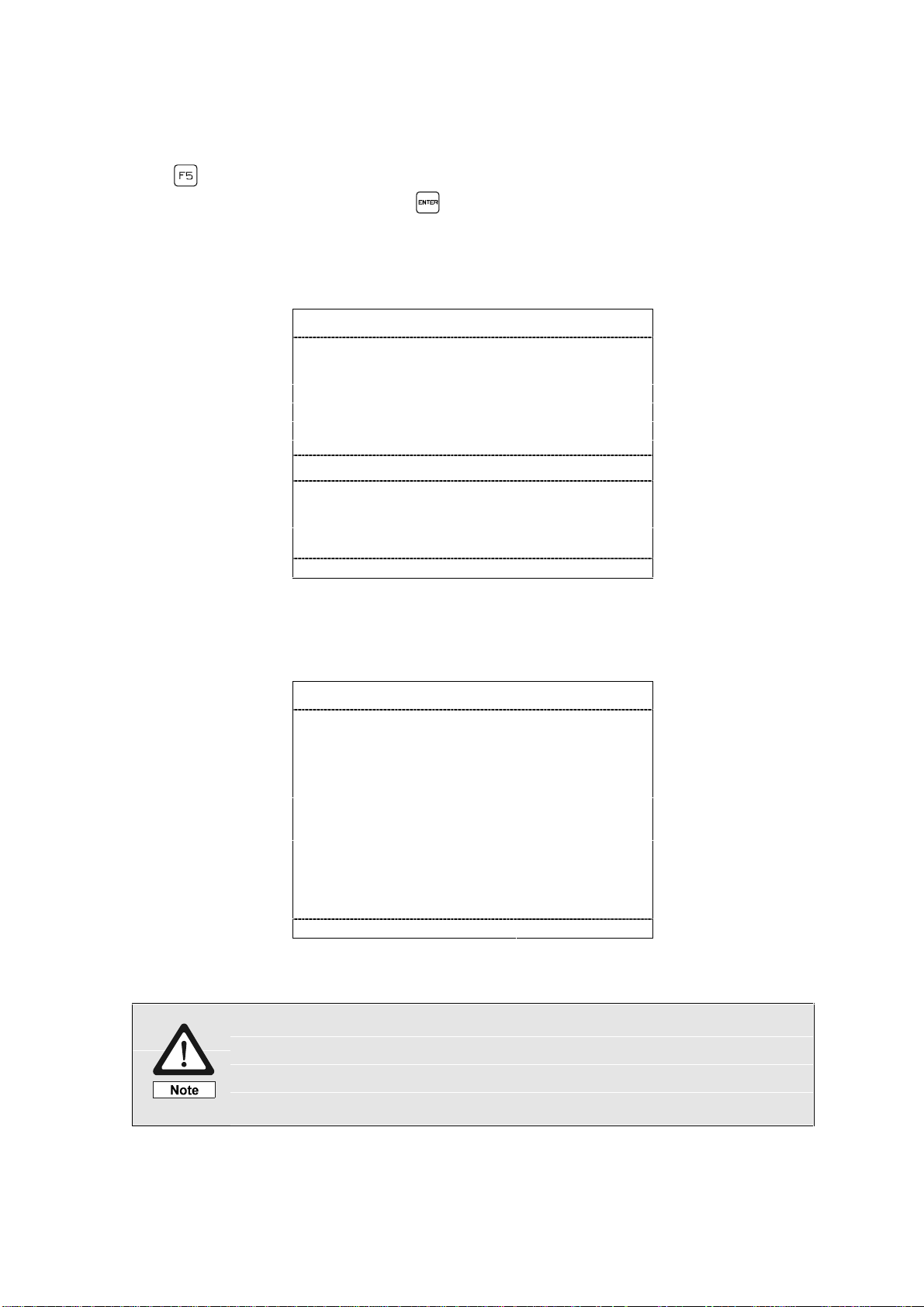

1. Menu Access and Selection

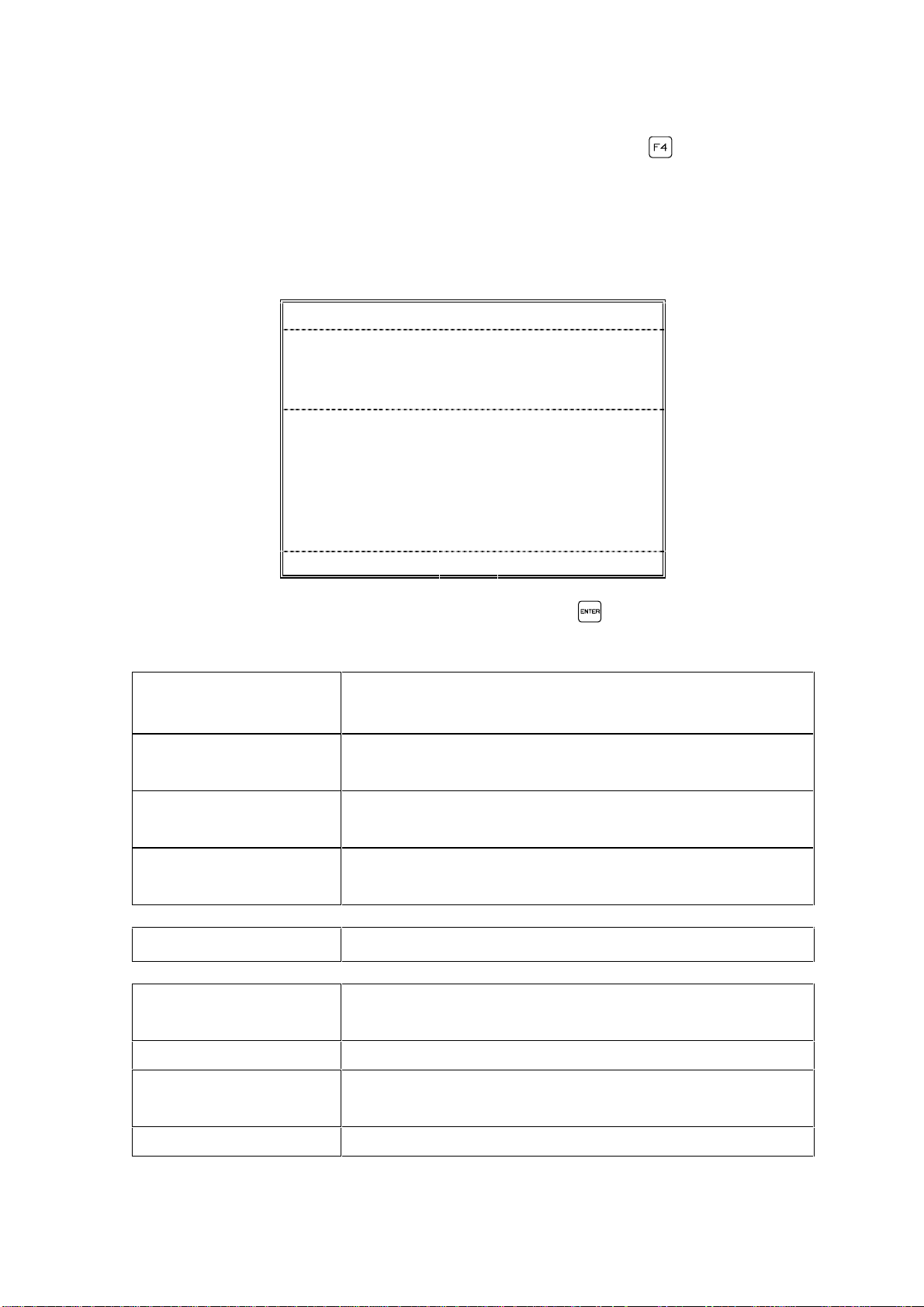

When switching the TMP weld unit on the screen display will be activated. The

TMP will identify itself by presenting unit and peripherals types as well as the

corresponding software versions.

Software version 1 Software version 2

T U C K E R #########

System software V ##.##

Keypad/Display V ##.##

Central CPU V ##.##

SMPS V ##.##

Interface ########### V ##.##

Output 1 #### / #### V ##.##

Output 2 #### / #### V ##.##

Output 3 #### / #### V ##.##

Output 4 #### / #### V ##.##

Output 5 #### / #### V ##.##

<F1..F5> <ESC>

System software V ##.##

Keypad/Display V ##.##

Central CPU V ##.##

SMPS V ##.##

Interface ########### V ##.##

Output 1 #### / #### V##.## LM V ##.##

Output 2 #### / #### V##.## LM V ##.##

Output 3 #### / #### V##.## LM V ##.##

Output 4 #### / #### V##.## LM V ##.##

Output 5 #### / #### V##.## LM V ##.##

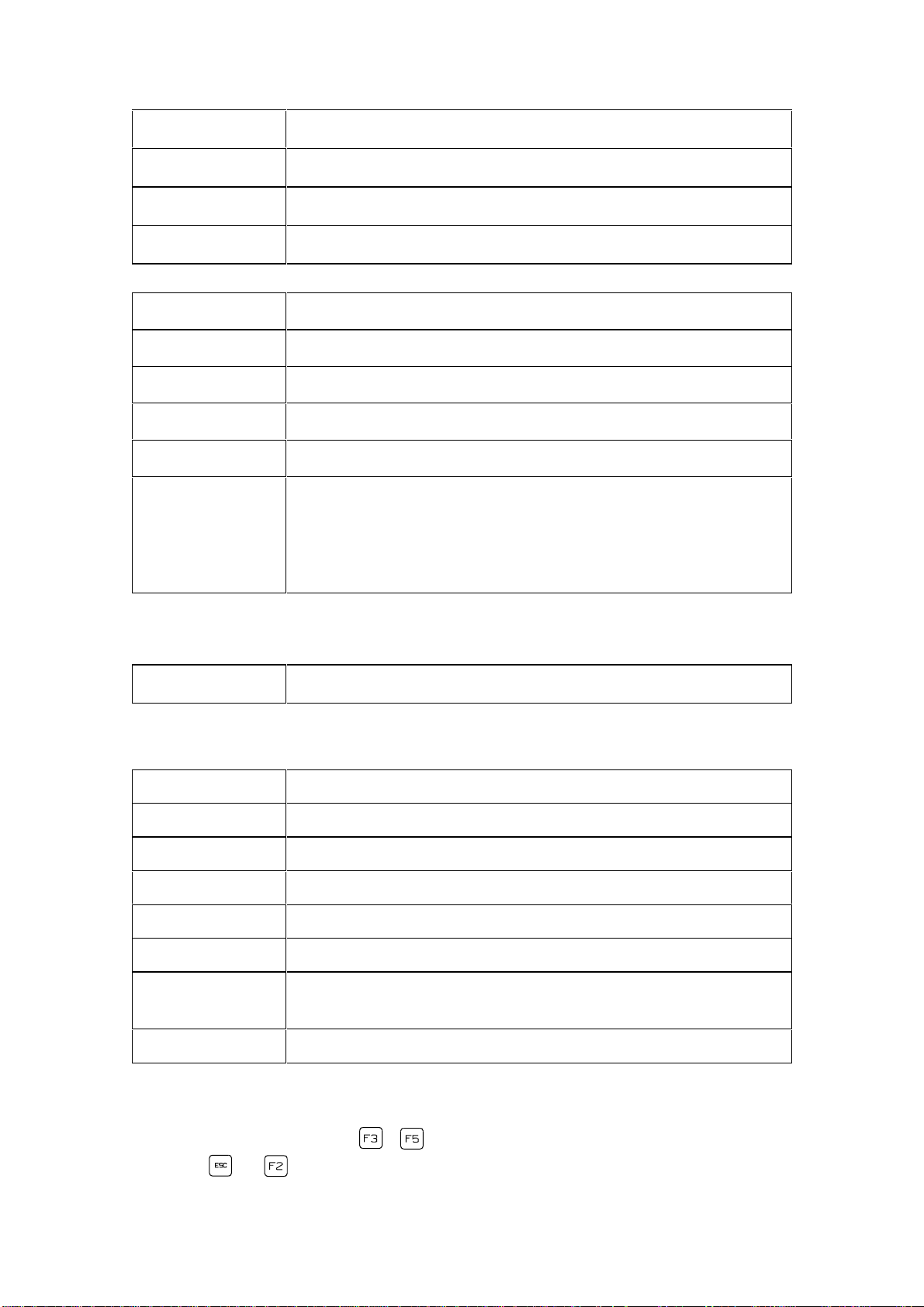

Now please press the key to open the main menu.

OPERATION

Weld parameter monitor

Programming

Statistics

Fault reset

Status weld sequence

Status customer interface

Status Feeder/Stud-Divider

Status TMP

Functions

Warnings

T U C K E R #########

<F1..F5> <ESC>

<↓↑> <ENTER> <F1..F5>

As soon as the main menu appears on the screen the sub-menues listed can be

selected.

1. Position the cursor with the direction keys and on the corresponding

submenu and confirm your selection with .

2. Sub-menus with alterable contents may also be selected by pressing one of the

function keys listed below directly.

• Function key : open main menu "Function Keys"

• Function key : open main menu "OPERATION"

• Function key : open main menu "Programming"

• Function key : open main menu "Monitor Parameters"

• Function key : open main menu "Reset Fault"

• Function key and open changing over languages.

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

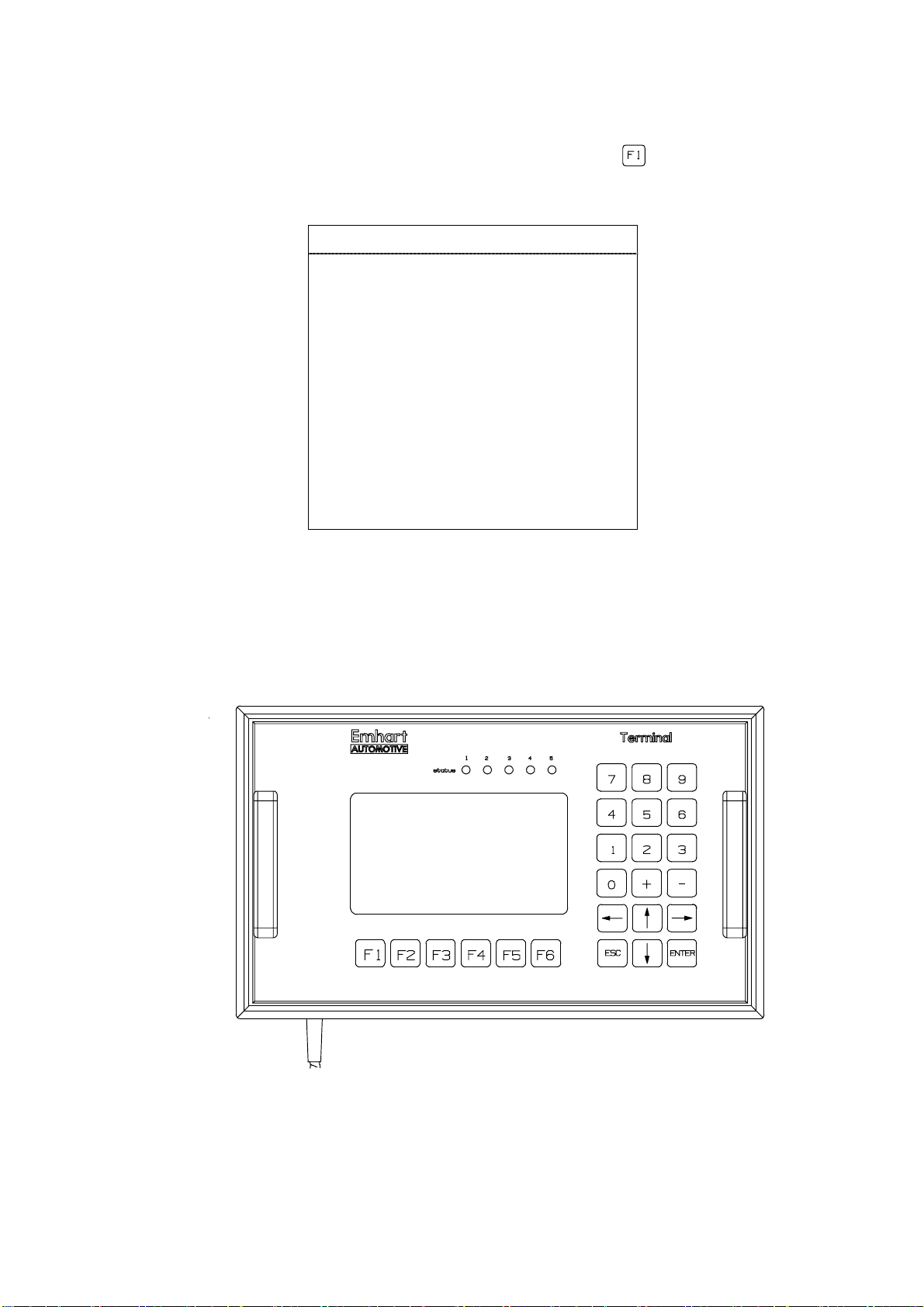

1.1 Sub-Me nu “Keyboard Functions“

The sub-menu “Keyboard Functions“ is selected via the key. This menu informs

the user about the configuration of the operation control keys.

Key Functions

F1 - Display key functions

F2 - Main menu

F3 - Programming

F4 - weld parameter monitoring

F5 - fault reset

F6 - Release Manual Functions

ESC - ESCAPE, abort

ENT - ENTER, confirmation

0..9 - input SKK/PK, program no.

+ - - change, set/reset values

<↓↑> - select menu, value

Exit the menu by pressing any key.

Display- and Control Panel

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

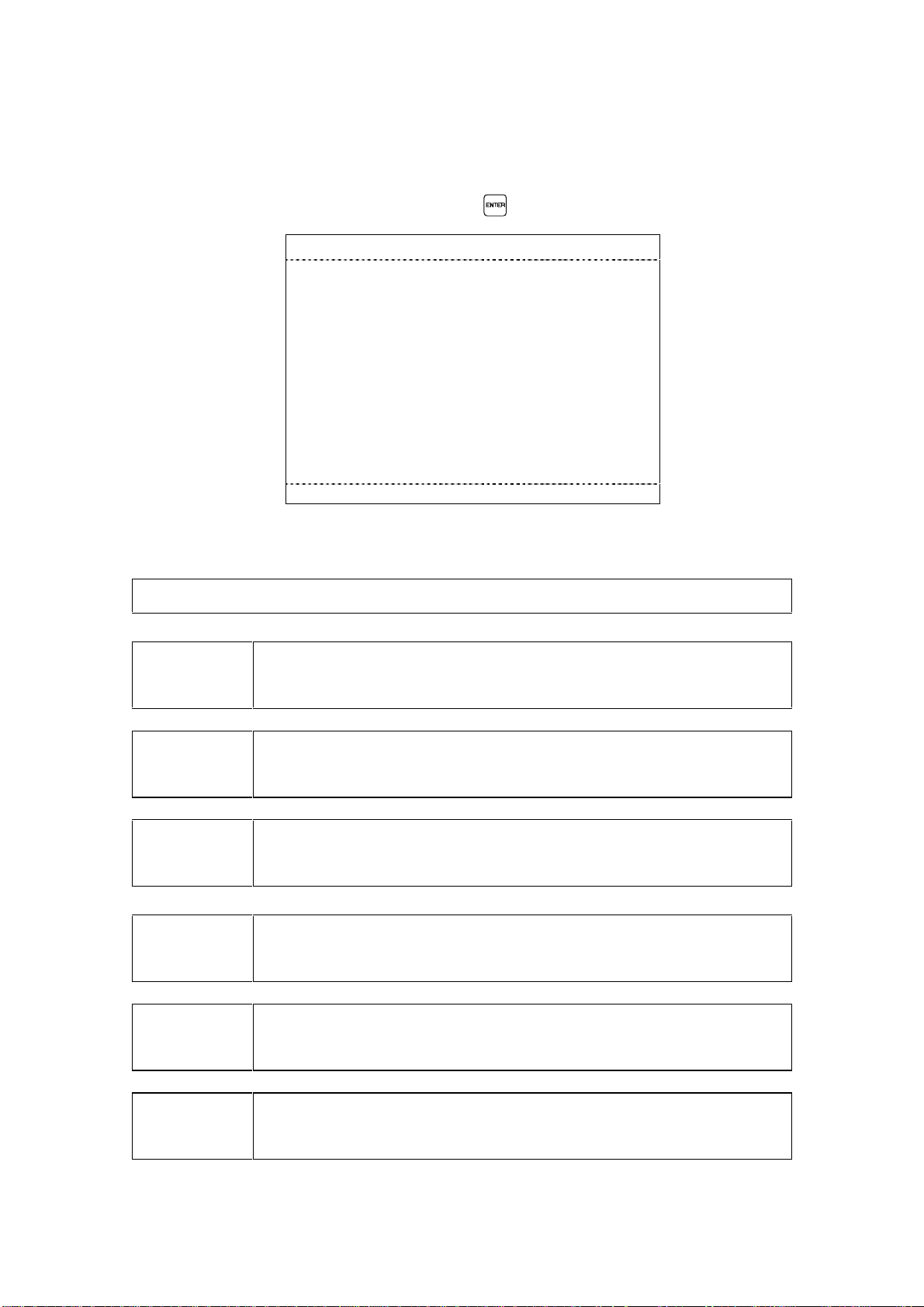

1.2 Sub-Menu “Weld Parameter Monitor“

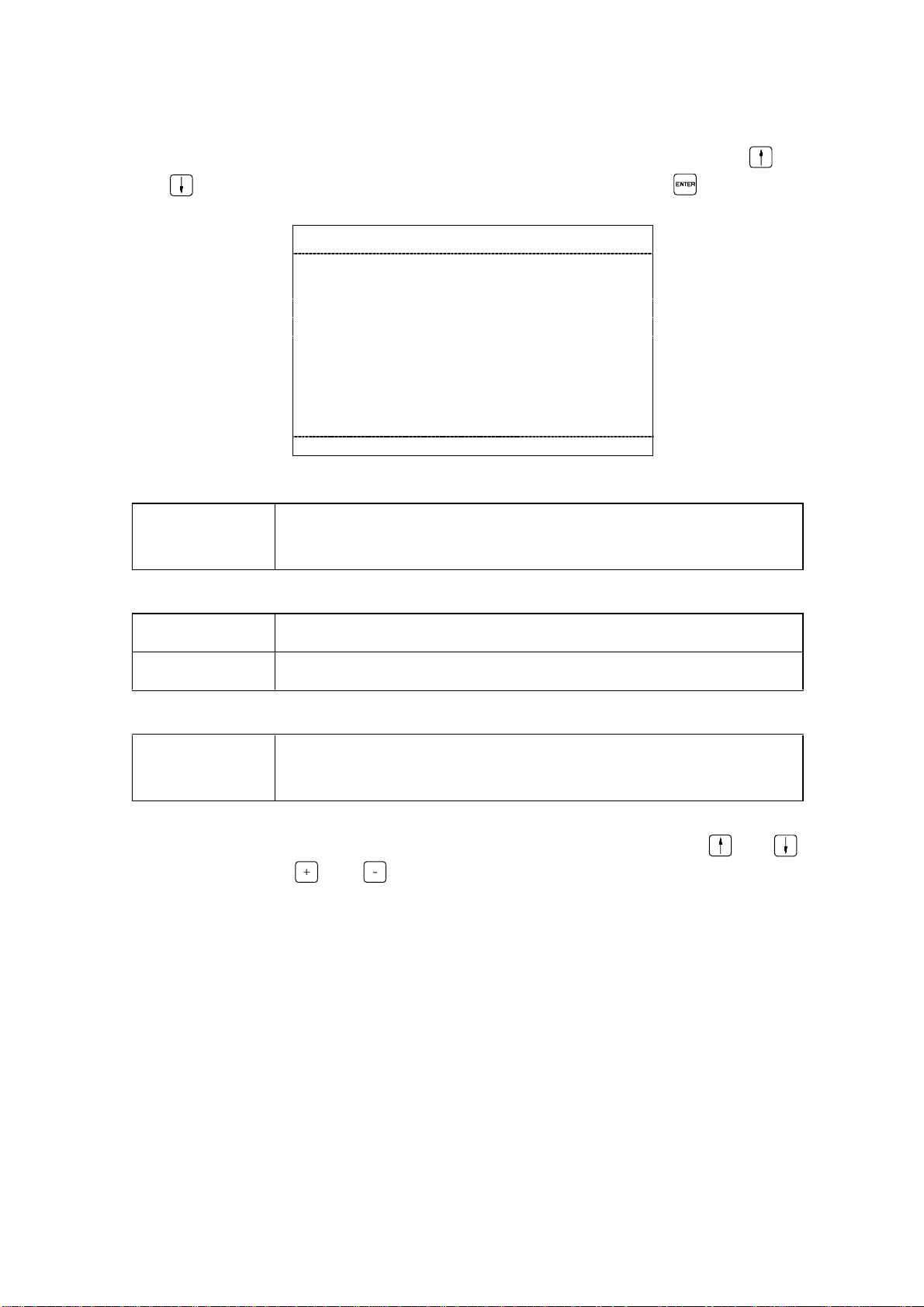

Having selected the sub-menu "Weld Parameter Monitor" using or through the

direction keys the cursor will move to the first menu line requesting selection of th e

TMP output (1-5) to be monitored as well as the program no. (1-27) of the weld

program to be monitored.

Remark: Output "0" described below has a special function.

Weld parameter monitor

SKK/PK outlet : # Program.No.:. . . . ###

Weld part ident : ################

Autoplunge : #### Optimization. . . . .####

Ref +tol -tol Act

Vp ## ## ## ## V #

Vw ## ## ## ## V #

Iw #### ### ### #### A #

tw ### ## ## ###,# ms #

td ##,# ##,# ms #

#Lift #,## ,## ,## #,## mm #

Fault : ################### #################

< 0..5> <ENTER> <F1..F5> <ESC>

Select output and program number and confirm with . The individual menu lines

of the display signify the following:

SKK/PK Output 0 The parameters of the weld tool that welded last will be

displayed in the table.

SKK/PK Output 1-5 The parameters of the last weld of the selected weld

tool will be listed.

Progr.-Nr. 0 The parameters of the last weld program will be

displayed in the table.

Progr. Nr. 01 - 127 The parameters of the selected weld program will be

displayed in the table.

Weld part ident Display of the program ident for the weld part.

Autoplunge: Yes

The deenergization time of the solenoid will be auto-

(tw = we ld time)

matically adjusted to the reference stud drop time.

Autoplunge No Automatic autoplunge is not activated.

Optimization: Yes

(Up to max. 800A/60ms)

Automatic adjustment of the weld curr ent Iw / wel d time

tw when welding through impurities on work surfaces.

Optimization: No No optimization of weld current (Iw) and weld time (tw).

3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Ref Preset value set according to weld program.

+ tol Positive tolerance. "0" selections will not be monitored.

- tol Negative tolerance. "0" selections will not be monitored.

Act Actually measured weld parameters of last weld.

Vp [V]

Arc voltage in pilot current phase. *

Vw [V] Arc voltage in weld current phase.

Iw [A] Weld current.

tw [ms] Weld time.

td [ms] Stud drop time.

Lift [mm] Lift distance.

An exclamation mark before the text Lift signifies that the

stud length measurement function for SD2 has been

deactivated in terms of position.

* Some voltage values are of particular importance (see Annex E).

Fault The fault will be displayed that has occu red during welding.

Possible fault indications are:

None Weld cycle without fault.

SMPS Defect within SMPS, welding was stopped.

Lift Cycle On Fault when enabling the solenoid.

No arc Voltage Defective lift; short circuit in weld circuit.

Short circuit weld The last weld performed was a short circuit operation.

Lift Cycle Off Fault when disabling the solenoid.

Drop Time

Monitoring time in weld sequence was exceeded.

Timeout

No Weld Current The last weld performed was an open circuit operation.

Faults will be recorded under a fault nu mber in the fault mem or y.

Selecting the function keys .. will open the corresponding sub-menu. By

pressing or you will access the main menu.

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

1.3 Sub-Menu "Programming"

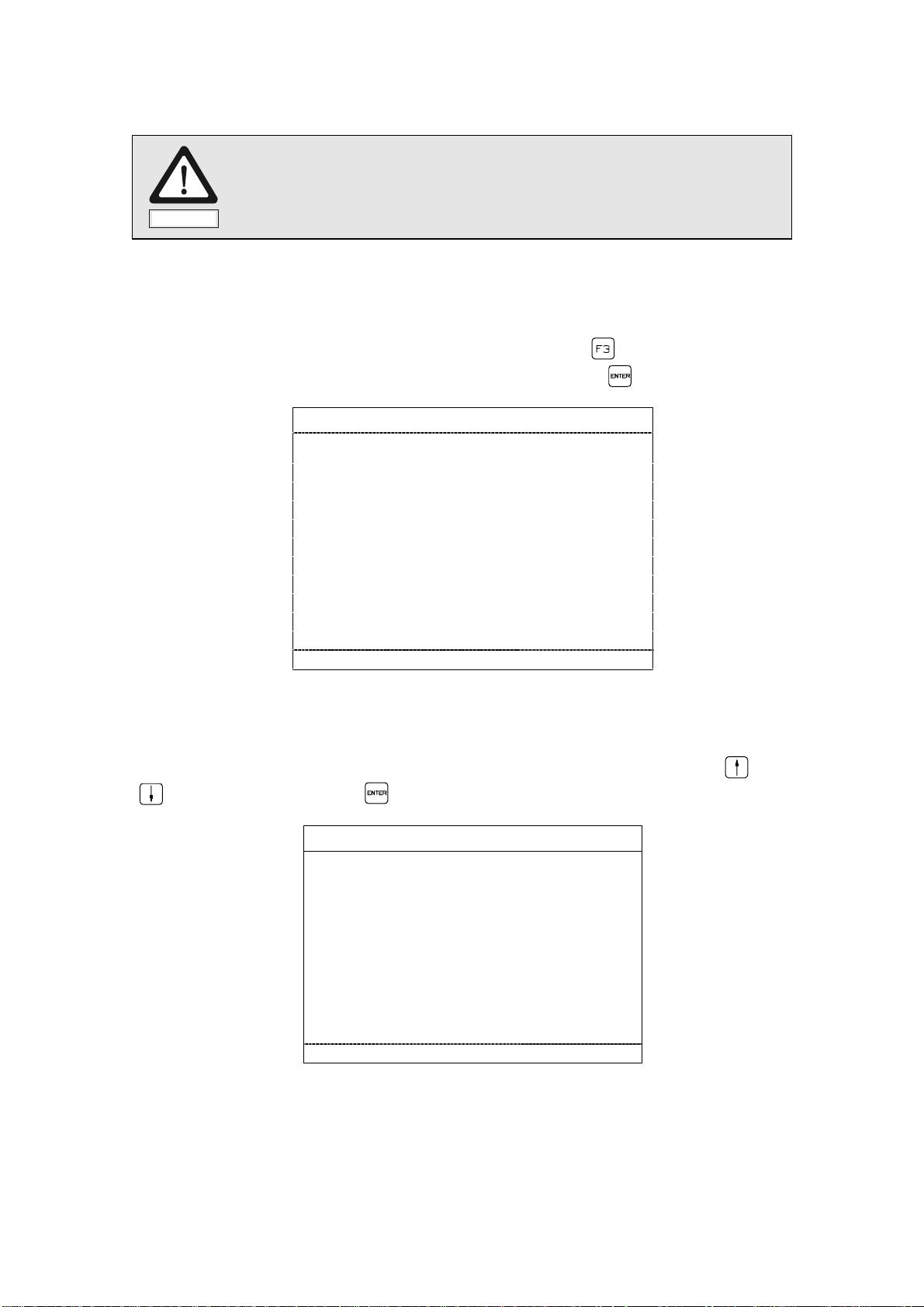

Please note that opening of the sub-menu "Programming" is

Note

The sub-menu "Programming" is to be selected for programming of the weld

parameters as well as the weld outputs and the specific feed times.

Direct access will be accomplished via the function key or by positioning the

cursor on the second line of the main menu and pressing .

Programming

Weld parameters

Output/feeder

exclusively reserved for authorized and qualified personnel.

<↓↑> <ENTER> <F1..F5> <ESC>

1.3.1 Function Menu "Programming Weld Parameters"

The function menu "Programming Weld Parameters" is selected via the and

keys and confirmed via .

Programming weld parameters

Output No . . . . . . . . . . . : #

Weld programm no . . . . : ###

Weld programm activ. . . ####

Weld diameter. . . . . . . . . #####

Workpiece gauge . . . . . . #####

Workpiece coating . . . . . ########

Energy adjustment . . . . . ### %

<1..9> <↓↑> <+,-> <ENTER> <F1..F5> <ESC>

The significance of the indivi dual menu l ines i s descri bed on the foll ow i ng pag es.

5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Output No.: The output number defines the weld tool which will be

addressed based on the TMP connector configuration.

When indicating the output the follow i ng operati on modes ar e to be differentiated:

Standard

operation

In standard operation (feeder - SKK/PK) the output no. must

be entered corresponding to the TMP connector configuration.

For example: "TMP-pin 1 - feeder 1 - SKK/PK no. 1".

SD2 operation

When using a 2-way stud divider "SD2" only output no. 1 is to

be addressed.

SD5 operation

When using a 5-way stud divider the output no. is to be

entered corresponding to the "SD5" configuration. For

example: "SD5 connector configuration 3 - SKK no. 3".

SD5 opera tion When using a 5-way stud divider the output no. is to be

entered corresponding to the "SD5" configuration. For

example: "SD5 connector configuration 3 - SKK no. 3".

Weld Program

No.

For each weld task a specific weld program should be

available which is to be addressed via the corresponding

program no. (1 - 127).

Enter a number between 1 and 5 for the weld output as well as between 1 and 127

for a weld program via the numerical keypad and confirm with or press

to exit the input mode.

Yes External program selection enabled.

No External program selection disabled.

Remark: if no external program selection is requested only

weld program 1 may be activated for the corresponding

output.

Weld diameter Selection of weld flange diameter.

Flange diameter Selection of flange diameter in a range from 2 mm - 8 mm

(step size: 1 mm).

SWB10 When welding T-studs with a l ength of 3,8 m m and a flang e

diameter of 3 mm the TUCKER-name SWB10 is to be entered.

Workpiece

Gauge

Selection of sheet thickness of work surface: 0,8 mm, 1,2 mm,

2 mm or >2 mm.

6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

Coating Selection of work surface coating.

none Untreated work surface.

galvanized Galvanized work surface.

Energy adjustment Weld ener gy adjustment in a range from -50% - +50%

(step size: 5%).

Programming is to be executed by the and keys. The selections of the

individual parameters can be either confirmed with or rejected with .

By pressing the or the key the cursor will move to the field "output no." and

enables further programming. By pressing you will return to the sub-menu

"programming".

7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

1.3.2 Function Menu "Programming Output / Feeder"

The function menu "Programming Output / Feeder" will be selected via the

and keys in the sub-menu "Programming" and confirmed with .

Programming output/feed time

Weld output No . : #

Output active....... ####

Feed time............. #### ms

<1..9> <↓↑> <+,-> <ENTER> <F1..F5> <ESC>

Weld output no. The weld output no. will define the weld tool which will be

addressed based on the TMP connector configuration.

Yes The output of the TMP weld unit is activated.

No The output of the TMP weld unit is not activated.

Feed time The time between feeding signal and arrival of the stud in the

stud receiver is to be selected in a range from 50 ms - 1600 ms.

Remark: Programming is to be performed via the numerical keys, the and

keys as well as the and keys.

8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

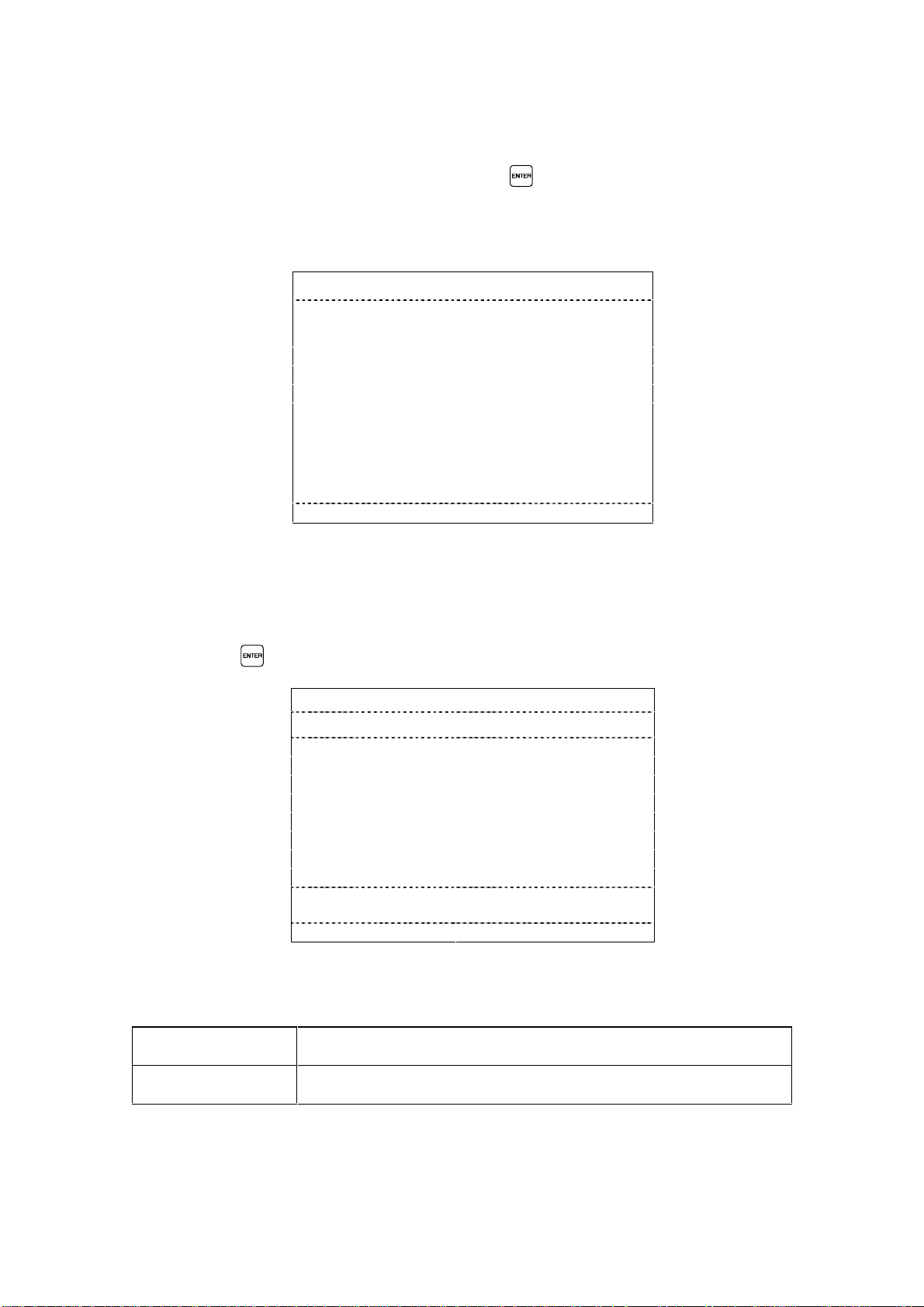

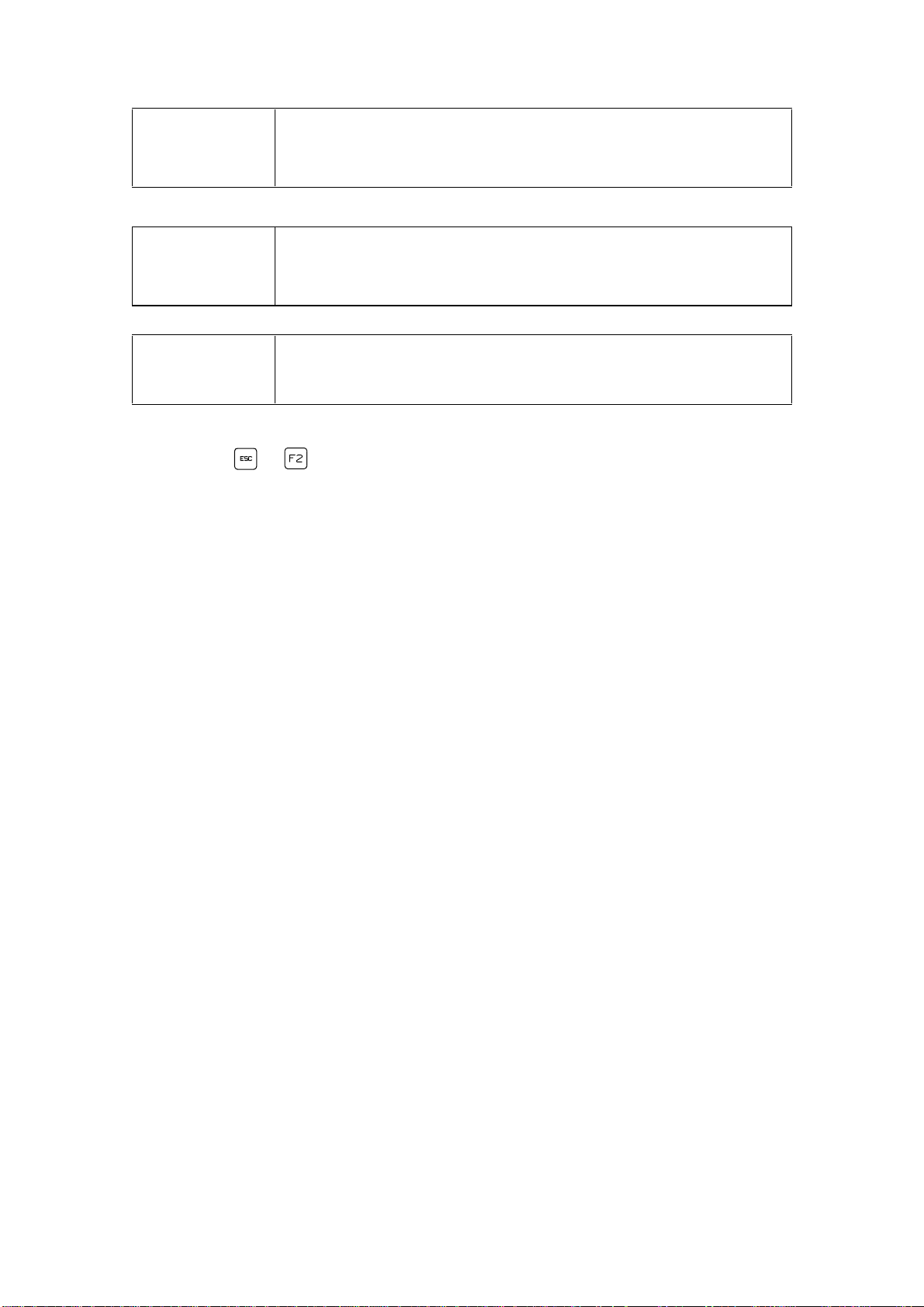

1.4 Sub-Menu "Statistics"

The sub-menu "Statistics" will be selected by positioning of the cursor on the third

line of the main menu and by presing the key. The sub-menu "Statistics"

contains sub menus in which information on faults, welds and maintenance are

recorded.

Statistics

Fault memory

WOPs memory

Weld output statistics

Weld program statistics

Maintenance

<↓↑> <ENTER> <F1..F5> <ESC>

1.4.1 Sub-Menu "Faul t Memory"

By positioning the cursor on the first line of the sub-menu "Statistics" and then

pressing the key you can access the "Fault Memory" screen.

Fault memory Fault no. ###

O Prg Fault type No. Date Time

# ### ########### ### ##.##.## ##:##:##

# ### ########### ### ##.##.## ##:##:##

# ### ########### ### ##.##.## ##:##:##

# ### ########### ### ##.##.## ##:##:##

# ### ########### ### ##.##.## ##:##:##

# ### ########### ### ##.##.## ##:##:##

Fault description:

<↓↑> <F1..F5> <ESC>

The individual menu lines will be described on the following page:

Fault Memory All faults of the equipment will be recorded.

Fault No. Number of fault on which the cursor is positioned.

9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

A

Display of output 1 - 5.

Prg

If faults occur during the weld sequence the weld program

will be displayed.

Fault Type

Information at which component the faul t occurr ed

(unit / SKK/PK / feeder / stud divider).

No.

Date

Time

No. of fault message.

Date of fault.

Time of fault.

Fault Description Short fault description (according to current cursor position).

With the keys and you can alternately display the fault memory.

By pressing you will return to the sub-menu "Statistics". By pressing you

will return to the main menu.

Trouble Shooting Information:

• Faults can be reset based on the information "Fault Messages".

• Faults which can not be reset on location through the listed remedial measures

require the replacement of the weld unit.

• Faults occurred at a peripheral unit are to be remedied based on the information

given in the corresponding operating manual.

• Faults will be reset in the menu "Clear Fault Cond ition".

10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

1.4.2 "WOP- Memory"

The "WOP-Memory" contains messages and information about welds out of

tolerance (Weld Outside Parameter = WOP)

The "WOP-Memory" screen can be accessed by positioning of the cursor on the

second line of the sub-menu "Statistics" and by pressing .

WOP-mem Outlet:# Prog:### Page:###

Weld part ident : ################

Date........ ##.##.## Time .......... .##:##:##

Autoplunge. ..#### Optimization.... ...####

Ref +tol -tol Act

Vp ## ## ## ## V #

Vw ## ## ## ## V #

Iw #### ### ### #### A #

tw ### ## ## ###,# ms #

td ##,# ##,# ms #

#Lift #,## ,## ,## #,## mm #

Fault : #################################

<0..5> <↓↑> <ENTER> <F1..F5> <ESC>

Select output number and confirm with . The individual menu lines of the

display signify the following:

WOP-Memory Record for all welds out of tolerance.

Weld part ident Display of the program ident for the weld part

O Those outputs for which WOP‘s are to be displayed

can be entered with the numerical keys 1 - 5.

With the key 0 all WOP‘s will be displayed in

sequence of their occurrence.

The selection must be confirmed with .

Prog. Display of current weld program.

Page Display of current page.

Date Date when WOP occurred.

Time Time when WOP occurred.

Autoplunge: Yes

(tw = we ld time)

The de-energization time of the solenoid will be auto-

matically adjusted to the reference stud drop time.

Autoplunge: No

Optimization: Yes

(up to max. 800A/60ms)

Automatic autoplunge was not activated.

An automatic adjustment of the weld curr ent Is / wel d

time ts when welding through impur iti es on w ork

surface was performed.

Optimization: No No optimization of weld current lw and weld time tw

performed.

11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Ref

Preset value set according to weld program.

+ tol

- tol

Act

Positive tolerance. "0" selections will not be measured.

Negative tolerance. "0" selections will not be measured.

Actually measured weld parameters of the last weld

performed.

Vp [V]

Vw [V]

lw [A]

tw [ms]

td [ms]

Lift [mm]

Arc voltage in pilot current phase.

Arc voltage in weld current phase.

Weld current.

Weld time.

Stud drop time.

Lift distance.

Fault The fault will be displayed that has occured during welding.

• Possible fault messages are:

None Weld sequence without fault.

SMPS Defect within SMPS, welding was stopped.

Lift Cycle On Fault when enabling the solenoid.

No arc voltage Defective lift; short circuit in weld circuit.

Short circuit weld The last weld performed was an short circuit operation.

Lift Cycle Off Fault when disabling the solenoid.

Drop Time

Monitoring time in weld sequence was exceeded.

Timeout

No weld currentt The last weld performed was an open circuit operation.

The WOPs can be alternately displayed with the keys and .

By pressing you will return to the sub-menu "Statistics". By pressing you

will return to the main menu.

12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

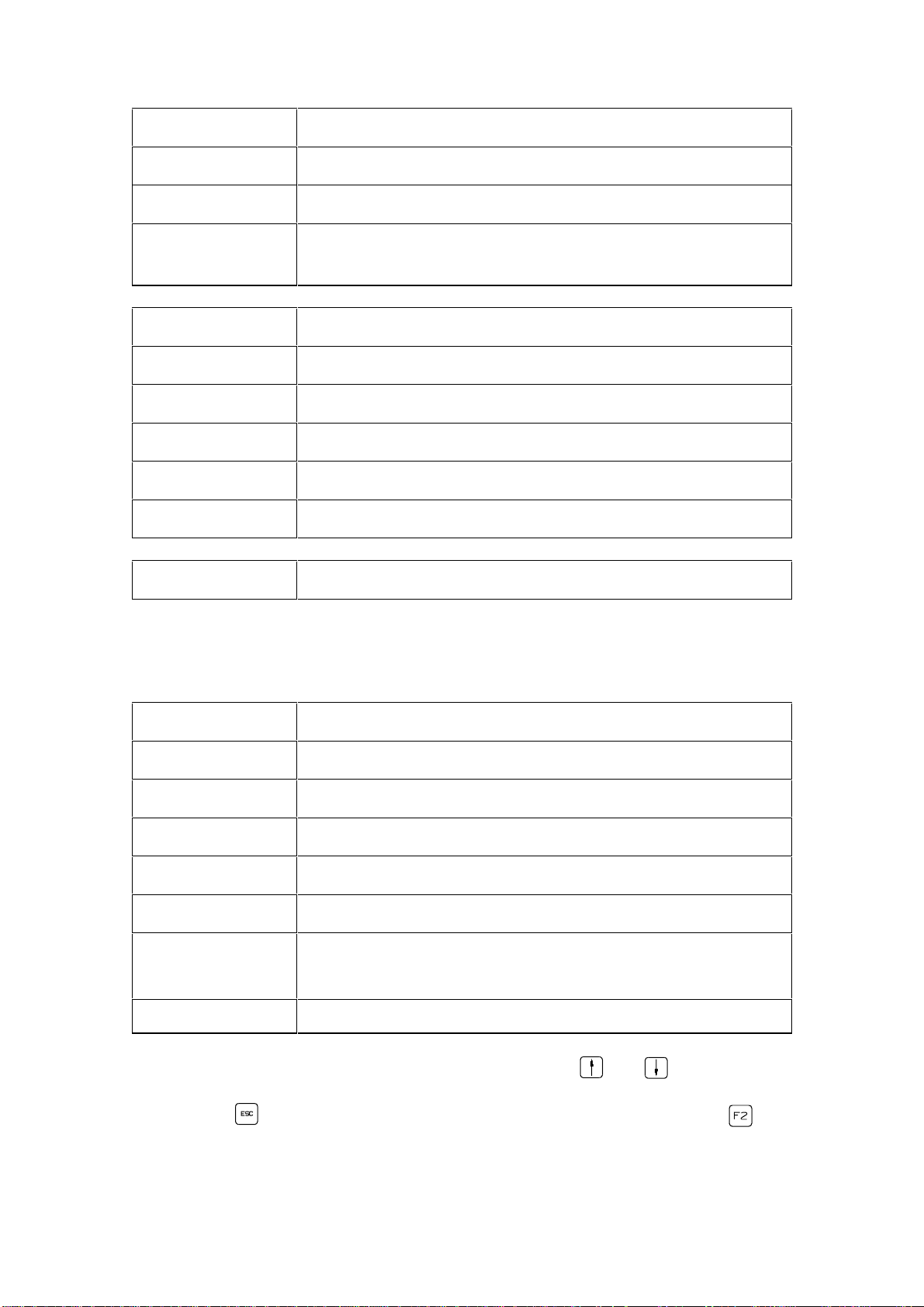

1.4.3 "Weld Output Statistics"

By positioning the cursor on the third line of the sub-menu "Statistics" and then

pressing the key you can access the memory menu "Weld Output Statistics"

screen.

Weld outlet statistics

WOP

Number of

O

WIP &WO P

1 ####### ####### # # ###### #####

2 ####### ####### # # ###### #####

3 ####### ####### # # ###### #####

4 ####### ####### # # ###### #####

5 ####### ####### # # ###### #####

Number of

WOP

repeat

lim act

Number

of faults

<F1..F5> <ESC>

auto

rep.feed

The individual menu lines signify the following:

Output Display of the output the statistics are related to.

Number of WIP & WOP Total number of welds.

Number of WOPs Total number of welds out of tolerance.

WOP repeat limit Display of programmed acceptable sequential welds

that may be out of tolerance.

Actual WOP repeat Actual number of sequential welds out of tolerance.

Number of faults Total number of faults occurred.

Auto refeed No. of studs automatically supplied due to missing

SOW-signal during internal slide rail control.

The information for the individual weld programs can be alternately displayed with

the keys and .

By pressing you will return to the sub-menu "Statistics".

By pressing you will return to the main menu.

13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

1.4.4 "Weld Program Statistics"

By positioning the cursor on the fourth line of the sub-menu "Statistics" and then

pressing the key you can access the memory menu "Weld Program Statistics"

screen.

Weld program statistics Outlet:#

number

of

Prog

<↓↑> <F1..F5> <ESC>

WIP&WOP

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

####### ####### # # #####

number

of

WOP

WOP

repeat

lim act

auto.

rep.

feed

Select output number and confirm with . The individual menu lines of the

display signify the following:

Weld Program Statistics Statistics of welds within and out of tolerance for the

individual outputs.

Output Selection of the ouput for which statistical information

is to be displayed.

Prog Display of the program the statistics are related to.

Number of WIP & WOP T otal number of welds.

Number of WOPs Total number of welds out of tolerance.

WOP repeat limit Display of programmed acceptable sequential welds

that may be out of tolerance.

Actual WOP repeat Actual number of sequential welds out of tolerance.

Auto refeed No. of studs automatically supplied due to missing

SOW-signal during internal slide rail control.

The information for the individual weld programs WOP‘s can be alternately

displayed with the keys and .

By pressing you can select another output, by pressing again you will

return to the sub-menu "Statistics".

By pressing you will return to the main menu.

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

1.4.5 "Maintenance"

The "Maintenance" screen contains information about the condition of the

connected weld tools due to wear.

By positioning the cursor on the fifth line of the sub-menu "Statistics" and then

pressing the key you can access the "Maintenance" screen.

Maintenance

Collet maint. – No. welds

12345

Act. ###### ###### ###### ###### #####

Warn. ###### ###### ###### ###### #####

Fault ###### ###### ###### ###### #####

Monitor - drop time (ms)

Act. ###,# ###,# ###,# ###,# ###,#

Warn. +# -# +# -# +# -# +# -# +# -#

Fault +# -# +# -# +# -# +# -# +# -#

<F1..F5> <ESC>

The individual menu lines signify the following:

Maintenance The wear of the collet as well as the drop time of the connected

weld tools will be displayed.

Collet Maint.No. of Welds

Weld statistics will begin with assembly of new col l et.

Remark: After replacing the collet the maintenance met er must

be reset.

Act. Actual number of welds performed with a collet.

Warn. Programmed number of welds with which, when exceeded, the

corresponding maintenance warning will become active.

Fault Programmed number of welds with which, when exceeded, the

weld output will be set into fault condition.

Monitor Drop

Time (ms)

Monitoring of the mechanical parameter "stud drop time".

Remark: The difference refers to the established drop time of

the past 8 welds in relation to the programmed (!) drop time.

Act.

Deviation of actual measured stud drop time from the programmed one will be displayed.

Warn.

Programmed deviation with which, when exceeded, the corresponding maintenance warnin g will become active.

Fault

Programmed deviation with which, when exceeded, the corresponding weld output will be set to fault condition.

15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Maintenance Information:

• The maintenance warning will be transmitted to the customer interface and will

appear as " ! " in the corresponding field of the sub-menu " Status TMP . . . . ".

• Irrespective of the TMP unit maintenance warnings the prescribed maintenance

intervals of the unit components must be maintained.

• Information on the specific maintenance works can be read from the

corresponding operating manuals.

• Having repaired the unit components the maintenance statistics in the menu "

Clear Functions" must be reset to " 0 ".

16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

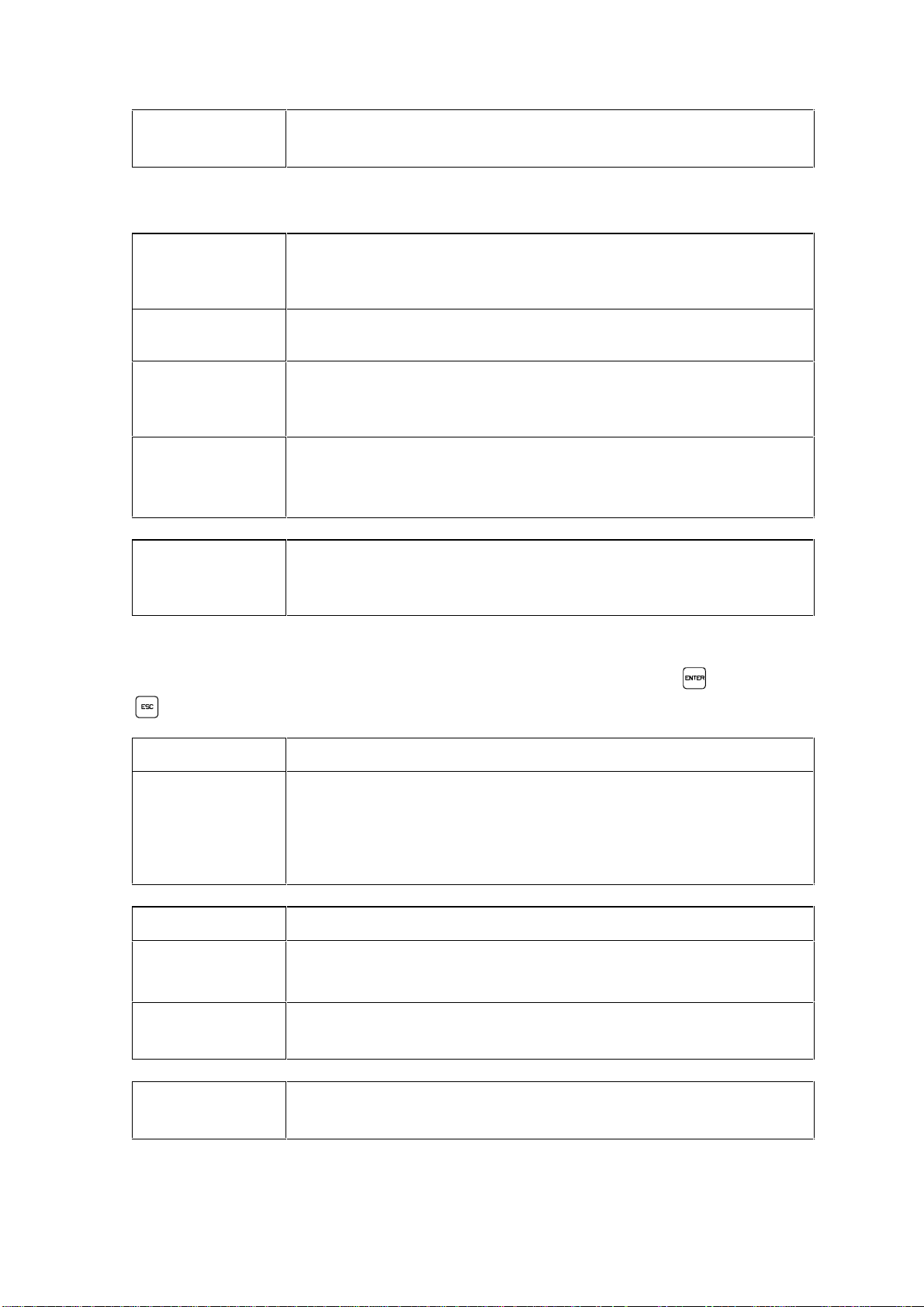

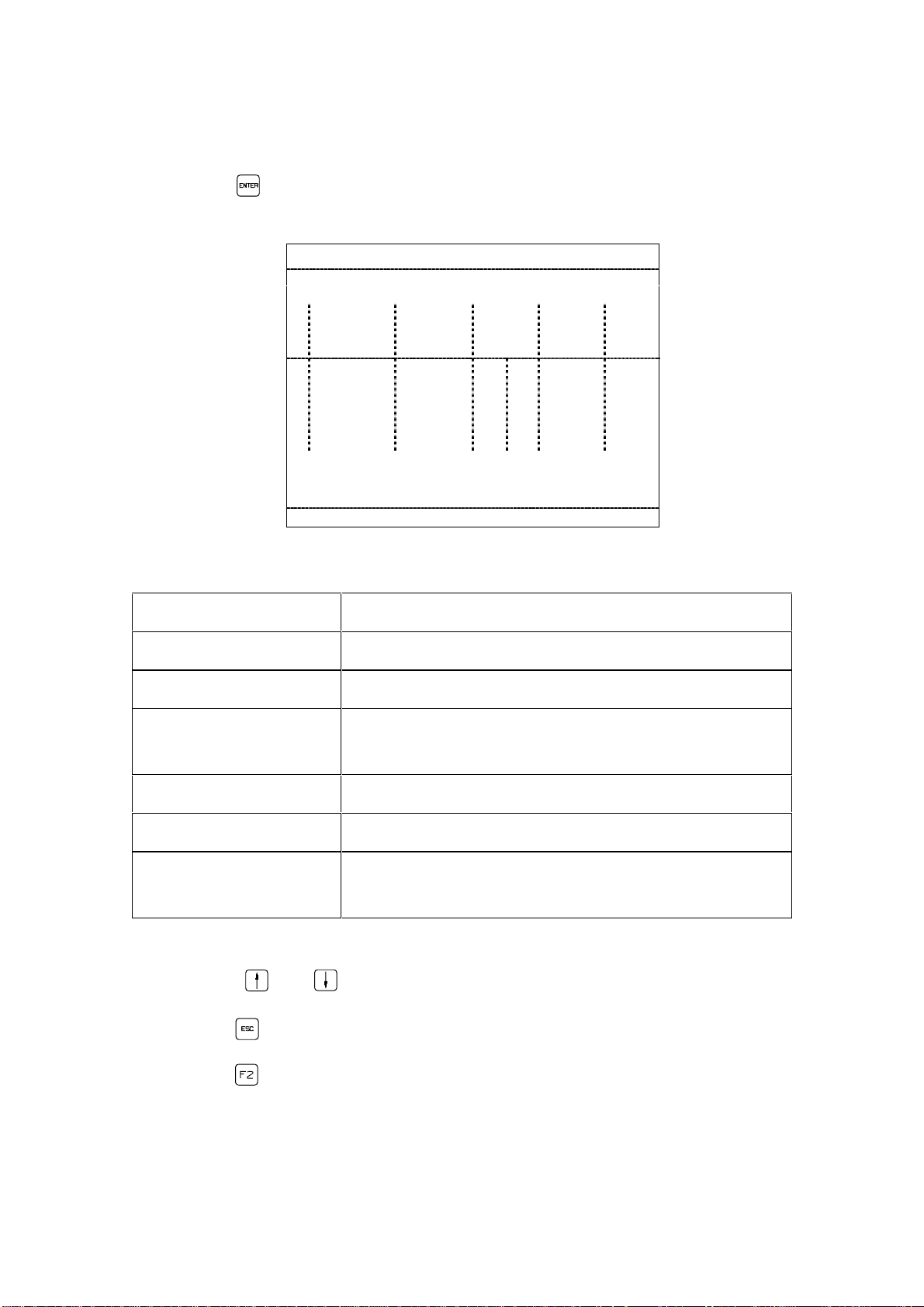

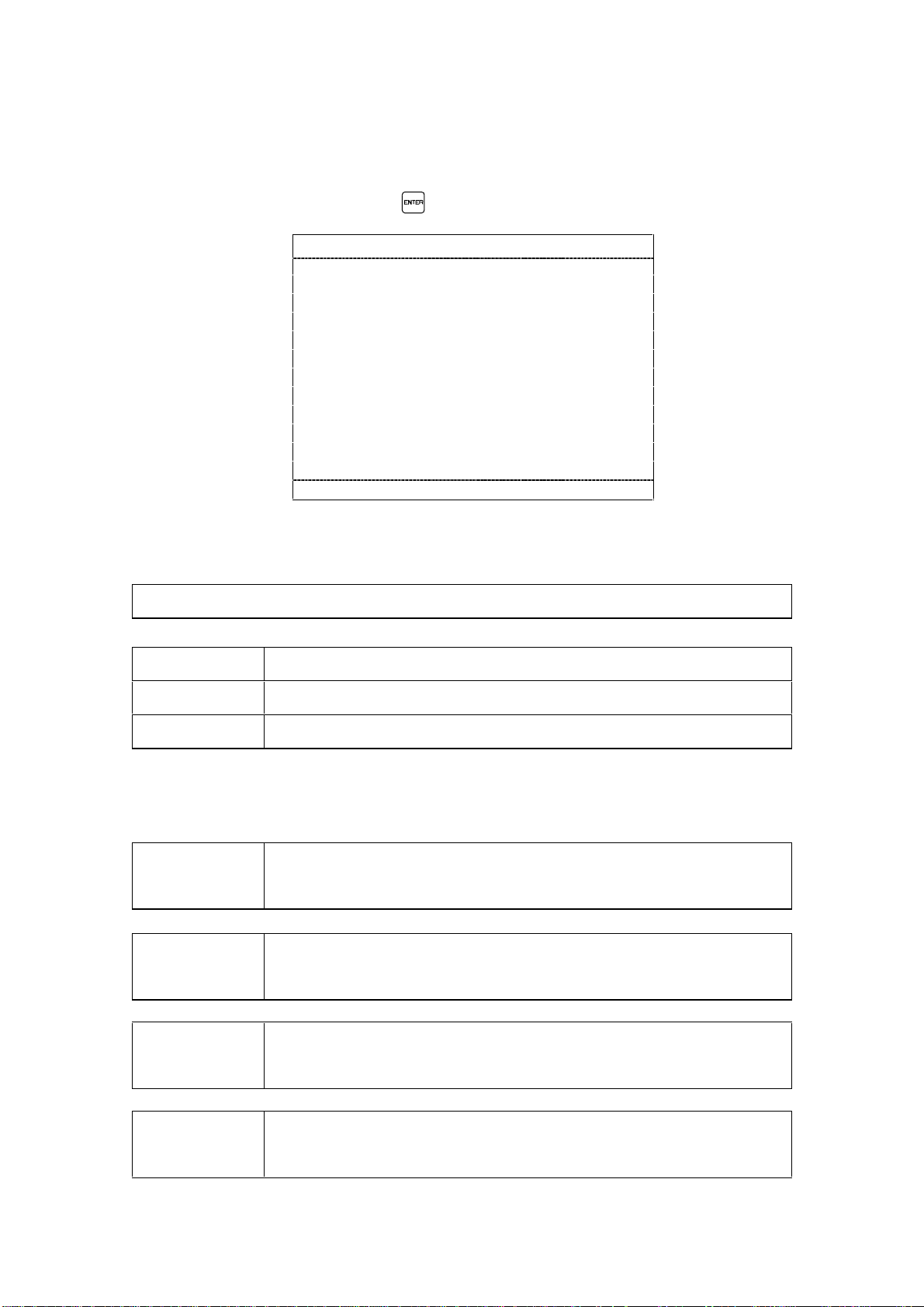

1.5 Sub-M e nu "Clear Fault Condition"

The sub-menu "Clear Fault Condition" can be selected directly with the function

key or by positioning the cursor on the fourth line of the main menu

"OPERATION" and then pressing .

In case of no fault condition the following will be displayed on the monitor when the

sub-menu "Clear Fault Condition" is selected:

OPERATION

Weld parameter monitoring

Programming

Statistics

Fault reset

No fault exist

Status TMP

Functions

Warnings

<↓↑> <ENTER> <F1..F5>

In case of a TMP system fault all fault sources will be displayed

Fault condition

To continue operation clear

the fault condition.

<F1..F5> <ESC>

If system faults requires the opening of the weld unit it is exclusively

reserved for authorized and qualified personnel. All fault messages

will be cleared when the TMP unit is switched on again, following

the remedy of the fault condition.

17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

In case there are simultaneous faults at other TMP outputs apart from the unit

faults (flashing of one, of several or of all "operation/error"-LED‘s) these can be

represented as follows after the system fault has been remedied.

Fault output #

<RESTART> <SET WC> <STUD>

<←↓↑→> <ENTER> <F1..F5> <ESC>

Select output and program number and confirm with . The individual menu lines

of the display signify the following:

Fault Output # The fault is only related to the TMP output displayed. All faults

of this output will be listed.

The fault occurred will cause a defective weld cycle.

In case there are simultaneous faults at other TMP outputs these can be

represented alternately with the direction keys and .

The sub-menu "Clear Fault Conditio n" offers the user several possibilities how to

deal with fault messages

The below mentioned operations can be selected with the two cursor keys ,

and activated by pressing the key.

RESTART By selecting RESTART the fault will be reset and the weld will

be performed if there is a start weld signal, if possible.

SET WC With the command SET WC the fault will be reset, if possible

and the signal "Welding complete" will be issued.

STUD With the command STUD a stud feeding cycle will be initiated,

if possible.The screen display remains the same; the fault

message will not be reset.

Remark: In case the fault message will not reset after having performed the

corresponding operation the f ollowing message will be displayed:

"Function cannot be performed"

18

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

Please note the remedial measures in the corresponding operating manuals for

the reseting of faults at unit peripherals.

Having reset the fault the menu selected before the fault occurred will be redisplayed automatically.

Irrespective of the removal of faults you can exit the sub-menu "Fault Reset" by

pressing and return to the main menu.

Remark: If the fault can not be cleared by either RESET, RESTART or SET WC

reseting of faults is limited to the remedial measures listed in section "Fault

Messages".

Operational defects of the weld equipment which can not be

cleared through the listed remedial measures are to be fixed by

qualified service personnel.

19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

1.6 Sub-Menu "Status Weld Sequence"

The sub-menu "Status Weld Sequence" is to be selected for obtaining an overview on the weld circuit-related signals. Position the cursor on the corresponding

menu line of the main menu and press the key.

Status weld sequence

12345

Weld cycle # # # # #

Feed cycle # # # # #

SOW # # # # #

Angularity switch PK # # # # #

Start weld # # # # #

Start feed # # # # #

SKK R-position # # # # #

I. Tolerance # # # # #

Program number ### ### ### ### ###

<F1..F5> <ESC>

The individual menu lines of the dispay signify the following:

The status information is related to output 1 ... 5 of the TMP-weld unit.

Weld cycle *: Weld cycle operation.

-: No weld cycle operation.

Feed cycle *: Stud feeding operation.

-: No stud feeding operation.

SOW *: SOW (stud on workpiece) signal is active.

-: No SOW signal.

Angularity

switch PK

*: Angultary signal is active.

-: No angultary signal.

Start weld *: Start weld signal is active.

-: No start weld signal.

Start feed *: Start feed signal is active.

-: No start feed signal.

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

SKK R-position *: SKK retracted signal is active.

-: No SKK retracted signal

I/O Tolerance *: Parameters are within the operating tolerance range.

-: Parameters are out of operating tolerance range

Program

number

1-127 : Display of program no under which the last weld was

performed.

By pressing or you will return to the main menu.

21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

1.7 Sub-menu "Status Customer Interface"

The sub-menu "Status Customer Interface" is to be selected for obtaining an

overview on interface signals given. Position the cursor on the sixth menu line of

the main menu and press the key.

Status customer interface

#####

Operation mode #### #### #### #### ####

Start weld #####

Start feed #####

Without weld #####

Reset fault #####

Restart #####

Set WC #####

Start SKK F-pos. #####

Start SKK R-pos. #####

Program number ### ### ### ### ###

<F1..F5> <ESC>

The individual menu lines of the display signify the following:

Status information is related to output 1 ... 5 of the TMP - weld unit.

AUT Selected operation mode: "automatic".

MAN Selected operation mode: " man ual " .

STOP Selected operation mode: "operati on stop ".

The following menu lines represent through “ * “ whether a signal has been given

or through“ - “ that a signal has not been given.

Start Weld *: The signal "start weld " is set via the interface.

-: The "start weld" signal has not been set

Start Feed *: The signal "start feed" is given via the interface.

-: The signal "start feed" has not been set

Without weld *: The signal "without weld" has been set.

-: The signal "without weld" has not been set

Reset fault *: The signal “reset fault“ is set.

-: The signal “reset fault“ has not been set.

22

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Restart *: The signal "restart" has been set.

-: The signal "restart" has not been set

Set WC *: The signal “Weld complete“ is set.

-: The signal “Weld complete“ has not been set.

Start SKK F-pos. *: The signal for advancing the weld head slide rail is set.

-: The signal "start SKK extend" has not been set

Start SKK R-pos. *: The signal for retracting the weld head slide rail is set.

-: The signal “start SKK retract“ has not been set.

Program number

1...127: Number of the weld program selected via the

customer interface.

Remark: If a signal is set the corresponding command is given via the customer

interface.

By pressing or you will return to the main menu.

23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

1.8 Sub-menu "Status Feeder / Stud Divider"

The sub-menu "Status Feeder / Stud divider" is to be selected for obtaining an

overview on the feeder and stud divider signals. Position the cursor on the seventh

menu line of the main menu and press the key.

Status feeder / stud divider

#####

Operation mode ### ### ### ### ###

Feed cycle #####

Piston retracted #####

Pos. Stud divider #####

SKK R-position #####

Angularity switch PK #####

Start weld #####

Start feed #####

Stud level low #####

<F1..F5> <ESC>

The individual menu lines of the display signify the following:

Status information is related to output 1 ... 5 of the TMP - weld unit.

Operation Mode

Feeder is in operation mode "Automatic","Manual" or "Test".

Feed cycle *: Display that a feeding cycle is performed.

-: No feeding cycle performed.

Piston retracted *: SKK/PK piston is retr acted.

-: Piston is not retracted.

Position Stud Div. *: Display of current stud divider position.

-: No stud divider position recognized.

SKK retracted *: SKK is retracte d.

-: No input signal “SKK retracted“.

Angularity switch

PK

*: Angultary signal is active.

-: No angultary signal.

Start weld *: Start weld signal is active.

-: No start weld signal.

Start feed *: Start feed signal is active.

-: No start feed signal.

Stud level low *: Stud level low signal is active.

-: No stud level low signal.

By pressing or you will return to the main menu.

24

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

1.9 Sub-menu "Status TMP . . . . "

This sub-menu contains specific messages and information on the peripheral

units. Position the cursor on the eighth menu line of the main menu and press the

key.

Status TMP

Date. . . . . . . . . . . ##.##.## Time . . . . . . . ##.##.##

Software. . . . . . . V##.## Address. . . . . . . . . ###

Interface. ########### SMPS ready. . . . . ####

Operation stop. . . . #### Emergency . . . . . . ####

#####

Connection ##### ##### ##### ##### #####

SF-Typ #### #### #### #### ####

SKK/PK ### ### ### ### ###

SF..A/D # # # #

Lift sensor #### #### #### #### ####

Maintenance # # # #

<F1..F5> <ESC>

By pressing or you will return to the main menu.

The individual menu lines of the display signify the following:

Date Shows the date in the sequence of "day.month.year".

Time Shows the time in the sequence of "hour:minutes:seconds".

Software

The version no. (V ##.##) informs about the present software

version of the TMP weld unit.

Address When connecting several TMP weld units to a central personal

computer each TMP must be attributed a custom er - speci fic addr ess

Interface The following customer interface are possible: parallel, Interbus-S,

Profibus DP or no interface.

SMPS ready The weld energy source SMPS is ready / not ready

Stop

Display of existing / not existing stop operation

Operation

Emergency Display of existing / not existing emergency stop

Connection norm: standard feeder configurated

SD2-M master feeder SD2 configurated

SD2-S: slave feeder SD2 configurated

SD5-Z: SD5 feeder configurated

SD5-W: SD5 divider configurated

PKE: manual gun extension configurated

25

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

SF-Typ Represents the connected feeder type, i.e. SF 12, SF 50, SF 52,

SF 53, SF 54, SF 56. If no feeder is connected,“ - “ is displayed.

SKK/PK If a weld head is connected, SKK is displayed, otherwise PK or

“ - “ is displayed.

SF..A/D If the feeder is equipped for slide rail control, “ D “ is displayed,

otherwise “ A “ or “ - “ is displayed.

Lift sensor If the weld head is equipped for lift measuring, “ yes “ is displayed,

otherwise “ no “ or “ - “ is displayed.

Maintenance If the weld tool exceeded the programmed limit value, “ ! “ is

displayed, otherwise “ - “ is displayed.

26

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

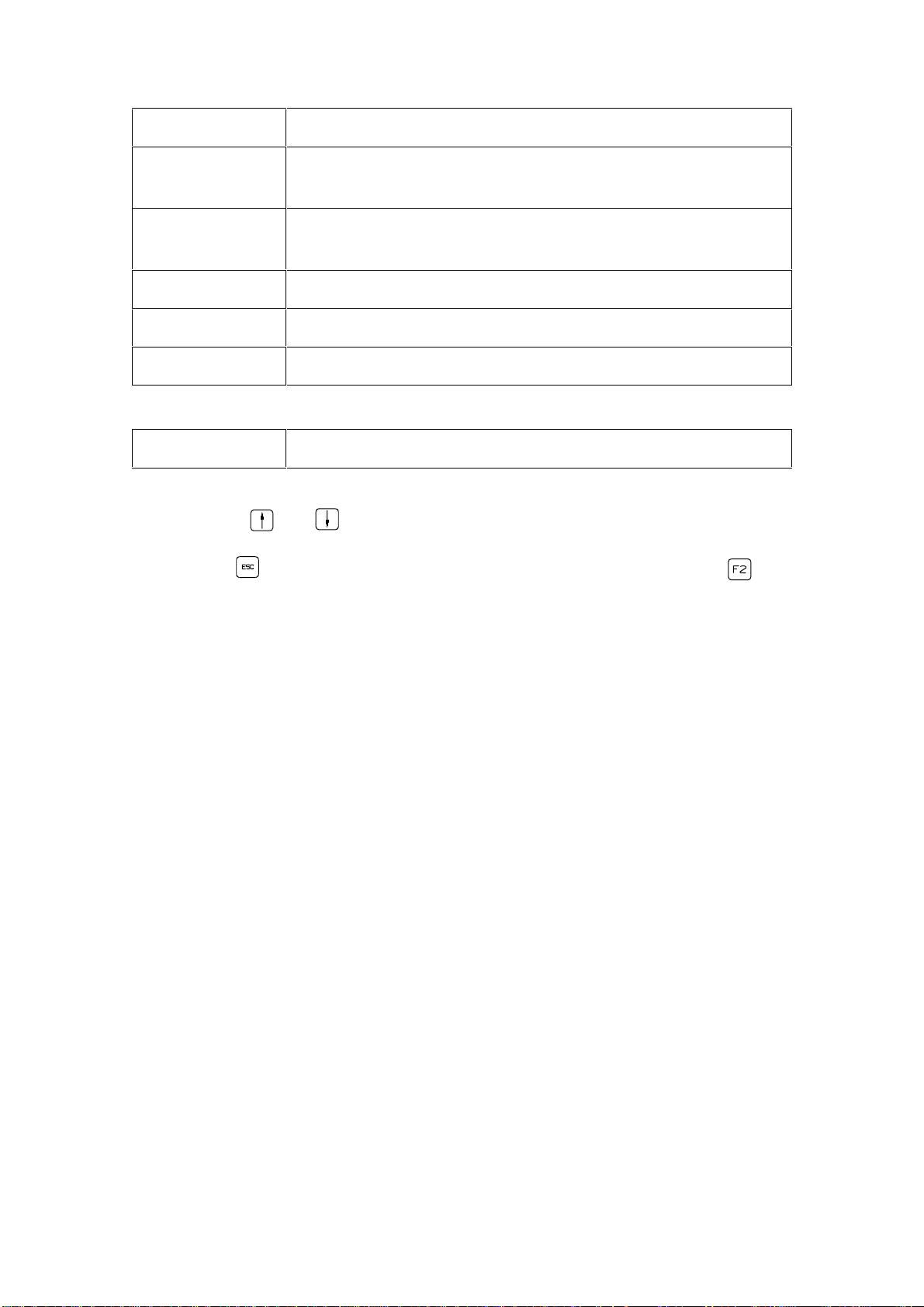

1.10 Sub-menu "Functions"

This sub-menu contains a command mode for the manual control of the TMP as

well as the possibility to display the software levels.

The sub-menu "Functions" will be opened by positioning the cursor on the last

menu line of the main menu and by pressing the key.

The individual functions are to be selected via the keys , and .

.Functions

display system configuration

test mode cycle functions

test mode outputs interface

test mode weld process

test mode power supply

<↓↑> <ENTER> <F1..F5> <ESC>

By pressing or you will return to the main menu.

1.10.1 Function Menu "Displa y System Configuration"

This sub-menu will be selected b y positioning the cursor on the first menu line of

the sub- menu "Functions" and by pressing the key.

E M H A R T T M P ####

System software V ##.##

Keypad/Display V ##.##

Central CPU V ##.##

SMPS V ##.##

Interface ########### V ##.##

Outlet 1 #### / #### V ##.##

Outlet 2 #### / #### V ##.##

Outlet 3 #### / #### V ##.##

Outlet 4 #### / #### V ##.##

Outlet 5 #### / #### V ##.##

<F1..F5> <ESC>

The TMP will identify itself by displaying unit and peripherals as well as the

corresponding software versions.

By pressing you will return to the sub-menu "Functions".

27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

1.10.2 Function Menu "Test Mode Cycle Functions"

In test mode important control commands can be given directly at the control

panel. These control commands supersede external customer control and will be

executed immediately.

This sub-menu will be selected by positioning the cursor on the second menu line

of the sub- menu "Functions" and by pressing the key

Test mode cycle functions

12345

Cyclus ##### ##### ##### ##### #####

SKK F-pos. ##### ##### ##### ##### #####

SKK R-pos. ##### ##### ##### ##### #####

Start feed ##### ##### ##### ##### #####

Lift ##### ##### ##### ##### #####

Set WC ##### ##### ##### ##### #####

Color mark ##### ##### ##### ##### #####

Reference outlet : #

SKK ext. . . #### ms Drop time. . . ##, # ms

SKK ret. . . #### ms Lift. . . . . . . . #, ## ms

<←↓↑→> <ENTER>=Start <F1..F5> <ESC>

To execute a certain function the corresponding menu line as well as the TMP

output number is to be selected with the cursor keys. The start command will be

given by operating the key.

Remark: Test mode will be automatically cancelled if no key is operated within 60s.

- As a precaution additionally the “ “ - key must be pressed.

Attention: With certain software levels (f.i. System V1.30, OPEL carline) these

test functions may still be performed despite the system bein g in stop

operation mode.

The individual menu lines of the display signify the following:

Cycle The command for executing a weld sequence test without

performing an actual weld can be given.

SKK ext. The command for advancing the weld head can be given.

SKK ret. The command for retracting the weld head can be given.

Start feed The command for “stud feeding“ can be given.

Lift The command for executing a lift can be given.

28

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Set WC A WC-signal is generated for the selected output

Color mark A color mark is generated for the selected output

The readings of the selected TMP output will be displayed in menu lines 10

and 11. If the connected SKK is equipped with a lift measuring system

(option) the measured lift will be displayed in menu line 11.

By pressing you will exit the "test mode cycle functions". By pressing you

will return to the main menu.

29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

1.10.3 Function Menu "Test Mode Outputs Interface"

2 3 4 5

# # # #

# # # #

# # # #

# # # #

# # # #

# # # #

# # # #

# # # #

In the function menu "Test Mode Outputs Interface" the customer interface

signals may be set and tested.

This sub-menu will be selected by position ing the cursor on the third menu line

of the sub- menu "Functions" and by pressing the key.

Test mode outputs interface

1

Operation mode #### #### #### #### ####

Ready #

SOW #

SKK R-position #

I.Tolerance #

Fault #

WC #

Maintenance #

Emergency stop #

Fault code ### ### ### ### ###

<←↓↑→> <ENTER>=Start <F1..F5> <ESC>

The cursor can be moved within the table with the direction keys. Signals will be

set or cancelled by pressing or .

The individual menu lines of the dispay signify the following:

Operation

mode

The following operation modes can be simulated: AUTO, TEST,

PROG, ERR, STOP, NO

Outputs The following outputs can be connected: ready, SOW, SKK back,

i. tolerance, fault, WC, maintenance, emergency stop.

Fault code An fault code no. from 1 - 255 can be set.

The test mode can only be performed if the signal for stop

operation has been set by customer control.

By pressing you will exit the "Test Mode Outputs Interface" mode. By pressing you will return immediately to the main menu.

30

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

1.10.4 Function Menu "Test Mode Weld Process"

During test mode all signals at the customer interface will be processed as in

standard operation. Control commands will be executed without the weld cur-rent

being enabled.

This function will be selected by position ing the cursor on the fourth menu line of

the sub- menu "Functions" and by pressing the key.

Test mode weld process

1234 5

Weld cycle # # # # #

Feed cycle # # # # #

SOW # # # # #

Angularity switch PK # # # # #

Start weld # # # # #

Start feed # # # # #

SKK R-position # # # # #

I.Tolerance # # # # #

Program number ### ### ### ### ###

Warning ! The TMP-unit will work in test mode

However the unit will not weld !

<F1..F5> <ESC>

Regarding the function, this menu isidentical with the menu “Status Weld

Process“. It displays various process data.

The test mode can only be performed if the signal for “Without

welding“ has been set by customer control.

By pressing or you will return to the main menu.

31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

1.10.5 Functions Menu “Test Mode Power Supply“

In the Function Menu "Test Mode Power Supply" the function of the SMPS can be

tested in a short circuit

• Select the requested function menu with the direction keys and .

• Confirm your entry with .

Test mode power supply

Output No. . . . . . . . . . . : #

Quantity of testcycles. : ###

Start . . . . . . . . . . . . . . . : #####

Actual weld current . . . . : #### A

Actual cycle count. . . . . : ###

The short circuit test can be stopped

with the <ESC> key

<←↓↑→> <+, -> <ENTER> <F1..F5> <ESC>

• Select the output that is to be tested.

• Position the cursor on the menu line "Start".

• Confirm your entry with .

• Press to start the test cycle.

Remark: Test mode will be automatically cancelled if no key is operated within 60 s.

• Press and simultaneously to start the function.

Remark: With some software versions it is possible to execute these test functions

even with an active Operation stop.

The individual menu lines of the display signify the following:

Output nr. Select the output for which the test mode is to be executed

Number of cycles

Number of test cycles that are to be simulated.

(ref)

Start Press the keys and simultaneously to start the

function

32

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Weld current act The measured weld current

Number of cycles

Number of test cycles executed

(act.)

• By pressing you will return to the function menu.

• By pressing you will return to the main menu.

33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

1.11 Function Menu "Warnings"

The sub-menu “Warnings“ can be accessed by positioning the cursor on the tenth

line of the main menu “OPERATION“ and by pressing the key

If there is no warning message available when selecting the sub-menu “Warnings “

the following screen message will be displayed:

OPERATION

Weld parameter monitor

Programming

Statistics

Fault reset

No warning message available

Status TMP

Functions

Warnings

<↓↑> <ENTER> <F1..F5>

Warnings will be marked by “ slow “ flashing of the corresponding output LED. If

there are warnings available they will be displayed in the sub-menu “Warnings“.

Warnings

<F1..F5> <ESC>

The following warnings can be displayed:

Maintenance

The number of welds exceeds the set limit value

clamping tongs

Maintenance weld

head

The gun drop time established via 10 welds exceeds

the programmed limit values (the differences to the

programmed drop time are evaluated).

Level to low The proximity switch for monitoring the filling level in the

stud feeder is not covered.

C-CPU: empty

battery RAM-module

The battery in the RAM-module on the central CPU is

run down. Before replacing the RAM-module a backup

via PC should be performed.

C-CPU: empty

battery clock

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The battery for securing the real-time clock is run down

and must be replaced.

34

Page 38

1.12 Sub-Menu "Extended Functions"

Access to the sub-menu "Extended Functions" is secured by a

code and is exclusively reserved for the service personnel.

Extended functions

System parameters

Mechanical parameters

Weld parameters

Copy programs

Clear functions

ZCPU system test

De / activate programs

Stud length detection

Set date and time

<↓↑> <ENTER> <F1..F5> <ESC>

This menu gives access to all data which are related to the weld process.

The menu “Extended Functions“ can be accessed via the sub-menu “Program-

ming“ by pressing first the < + > key and then the < 0 > key.

There is also the possibility to access the individual sub-menues directly through

the following codes.

<+> <1> : System parameters

<+> <2> : Mechanical parameters

<+> <3> : Weld parameters

<-> <99> : Clear functions

35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

1.12.1 Function Menu "System Parameters"

This function menu will be selected by positioning the cursor on the first menu line

of the "Extended Functions" menu and by pressing the key.

TMP version1 TMP version 2

System parameters

Address Interface . . . . . ###

Network . . . . . .###

Language . . . . . . ###########

Parameter printout: . . . . . #######

###########

#############

##########

<↓↑> <+, -> <ENTER> <F1..F5> <ESC>

System parameters

Address Interface . . . . . . ###

Network . . . . . . .###

Language . . . . . . . . . . . . . .###########

<↓↑> <+, -> <ENTER> <F1..F5> <ESC>

Address Interface The unit address Interface serves to identify the TMP

when connecting it to the Pro-Bus customer interface.

Address Network The unit address Network serves to identify the TMP

when connecting several weld units to a central PC.

Select a number between 1 and 255 to identify the unit.

Language

There are two country-specific languages available to the

user for the communication between the TMP weld unit

and the operating personnel.

Parameter printout

The printer output can be activated and adapted here

- Printing of WOP or WIP and WOP

- Individual or all weld outputs

- Bautrate

36

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

1.12.2 Function Menu "Mechanical Par ameters"

This function menu will be selected by positioning the cursor on the second menu

line of the "Extended Functions" menu and by pressing the key.

Mechanical parameters outlet : #

Outlet active . . . .####

Slide rail . . . . ######

Start feed . . . . ##################

Feedtime . . . . . . ####

Loadtime . . . . . ####

Repeat feed . . . .#### Feed adj . . . . . . ####

Permitted WOP . # Color mark . . . . . ####

Protect. gas . . . .#### Air blow . . . . . . . ####

Pre-gas (ms) . . . #### Angularity . . . . . . ####

Post-gas (ms) . . #### Stud monitor. . . . ####

Maint. at . . . . ###### tp-Maint . . . . . . + # - #

Fault at . . . . ###### tp-Fault . . . . . . + # - #

<1..5> <←↓↑→> <+,-> <ENT> <F1..F5> <ESC>

When the menu "mechanical parameters" has been opened the cursor will move

into the heading requesting the input of the selected SKK/PK outlet no. (1 - 5).

SKK/PK: No. in

standard

operation

SKK/PK: No in

operation with SD2

In standard operation (feeder - SKK/PK) the SKK/PK no. is to be

entered according to the TMP configuration. For example: "TMP

output 1 - feeder 1 - SKK/PK No. 1".

For programming the weld head parameters as well as for

programming the parameters of t he "master" f eeder select o nly the

SKK/PK output no. 1.

Information: In order to program the feeding time of the second

stud feeder select SKK/PK output no. 2 while the menu line

"SKK/PK active" displays "yes".

SKK/PK: No. in

operation with

SD5

When operating with a 5-way stud divider the SKK no. must be

entered as it is at the "SD5-stud divider".

For example: "SD5-output 3 - SKK No. 3".

Enter the respective SKK/PK output no. with the numerical keys and confirm with

The cursor is now positioned in the first menu line requesting input. With the

direction keys you can access the various menu lines directly.

The individual menu lines of the display signify the following:

SKK/PK active

Slide rail

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Yes : The output of the TMP-weld unit is activated.

No : The output of the TMP-weld unit is not activated.

Internal: The SKK slide rail will be controlled by the TMP-weld unit.

External: The SKK slide rail will be under customer-specified control.

37

Page 41

Start feed

Extern after SOW: The customer may execute a start signal for

"stud feeding" after the collet has diseng ag ed from the w elded

stud.

Intern after SOW: The TMP weld unit will execute the "stud feeding"

cycle after the collet has disengaged from the welded stud.

Extern after WC: The customer may execute a start signal for

"stud feeding" after the end of each welding process.

Internal after WC: The TMP weld unit will execute the "stud feeding"

cycle after the end of each welding process.

Feedtime

Loadtime

Repeat

feed

Feed

adjustment

The time between executing the stud feeding signal and arrival of

the stud in the receiver can be adjusted in a range from of 50 ms 1600 ms.

T-Studs SWB 10 with SF 54: The time between piston retract

signal and the end of feedtime can be adjusted in a range from

50 ms - 1600 ms.

Other Studs with SF ..: The time between piston retract signal and

enabling of the blow air can be adjusted in a range from

50 ms - 1600 ms.

Yes: If the SOW signal is not recognized when the weld tool

moves forward the feeding process will be repeated.

No:

No auto-refeed requested.

Yes: The feeding cycle is terminated upon arrival of the stud in

the weld tool disregarding the feeding time.

(Condition: SKK/PK is equipped with a sensor for weld stud

detection).

No automatic feed adjustment.

No:

Permitted

WOP

Sequential welds out of tolerance can be limited by the customer

by selecting a number between 1 - 9. When this number has been

reached the welding operation will be interrupted.

Color mark Yes: When connecting color marking units SMB 128 (option) welds

out of tolerance will be marked by color.

No: Welds out of toleran c e will not be marked by color.

Protec. gas

Yes: Shielded arc welding operation with gas ( opti on) is activated

No: Shielded arc welding operation with gas is not activated.

38

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

Air blow Yes: If the weld tool is optionally equipped with an air nozzle

for clearing the work surface, it will be activated

No: Air nozzle for clearing the work surface will not be activated.

Pre-gas The time of protect. gas flow before weld begin can be adjusted

in a range from 0 ms - 1000 ms.

Post-gas

The time of protect. gas flow after the weld has been performed

can be adjusted in a range from 0 ms - 1000 ms.

Angularity

switch

Yes : n.c.

No : n.c.

Stud monitor Yes: Stud length detection will be activated.

Special case SD2: Additionally testing of the feeder

allocated by the programm is activated.

No: Stud length detection will not be activated.

Maint. at 0...950.000 : Number of welds with a collet after which the

maintenance warning will be activated (step size: 5000).

" 0 " selections will not be monitored.

tp-Maint. 0 - ±8 : Tolerance value for testing the drop time. If it is exceeded

the maintenance warning will be a c tivated.

" 0 " selections will not be monitored.

Fault at 0...950.000 :. Number of welds with a collet after which the output

will be set into fault condition (step size: 5000).

“ 0 “ selections will not be monitored.

tp-Fault 0 - ± 8 : Tolerance value for testing the drop time. If it is exceeded

the output will be set into fault condition.

“ 0 “.selections will not be monitored.

Remark: Programming is to be effected via the and keys

Programmed parameters will be confirmed with or rejected with . You may

exit the input mode by pressing the key.

39

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

1.12.3 Function Menu "Weld Program"

This function menu will be selected by positioning the cursor on the third menu line

of the "Extended Functions" menu and by pressing the key.

This menu consists of two monitor pages. You can alternately display them by

pressing the keys and in the corresponding menu line.

Outlet: # Weld program: ###

Program active . . . . . . ####

Pilot current . . . . . . . .. ## A

Pilot current time. . . . . ## ms

Weld current . . . . . . . #### + ### - ### A

Weld current time . . . . ### + ## - ## ms

Varc pilot current. . . . . ## + ## - ## V

Varc weld current . . . . ## + ## - ## V

Optimization. . . . . . . . ####

Weld type . . . . . . . . . . ###########

Program continues <##>

<1..5> <←↓↑→> <+,-> <ENT> <F1..F5> <ESC>

When the menu "Weld Program" has been opened the cursor will move into the

heading requesting the input of the selected outlet no. (1 - 5).

Enter the outlet no. as well as the number of the weld program with the numerical

keys and confirm each with .

Now the cursor is positioned in the first menu line. You can access the various

menu lines with the direction keys and directly.

Program active Yes : External program selection enabled

No : External Program selection disabled.

Remark: if no external program selection is requested only weld

program 1 may be activated for the corresponding output.

Pilot current Selection of pilot current in a range from 20A - 30A.

Pilot current time

Weld current Selection of weld current in a range from 100A - 1000A.*

+ tolerance

- tolerance

Selection of pilot current time 30 ms - 60 ms.

Positive tolerance from 0 - 100A (Selection of “0“ will cancel monitoring)

Negative tolerance from 0 - 100A (Selection of “0“ will cancel monitoring)

* depending on the unit type!

Weld current time Selection of weld time in a range from 6 ms - 1000 ms.

+ tolerance

Positive tolerance from 0 - 8 ms (Selection of “0“ will cancel

monitoring)

- tolerance

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Negative tolerance from 0 - 8 ms (Selection of “0“ will cancel monitoring)

40

Page 44

Varc pilot current Input of arc voltage value (pilot current phase) for parameter monitoring

(range: 16V - 36V).

+ tolerance Positive tolerance from 0V-10V (Selection of “0“ will cancel monitoring)

- tolerance Negative tolerance from 0V-10V (Selection of “0“ will cancel monitoring)

Varc weld current Input of arc voltage value (in main current phase) in a range from

16V - 36V.

+ tolerance Positive tolerance from 0V–10V (Selection of “0“ will cancel monitoring)

- tolerance Negative tolerance from 0V–10V (Selection of “0“ will cancel monitoring)

Optimization No : Optimization of weld parameters not requested.

Current : Automatic adjustment of the weld current when welding

through impurities on work surfaces.

Time : Aut omatic adjustment of the weld time ts when welding

through impurities on work surfaces.

Weld type DC : Welding with constant current

Pulse : Welding with pulse wave form current

Remark: Programming is to be performed with the keys and .

Program

continues

The second menu page can be displayed by pressing the

direction key .

Having pressed the key the cursor will have moved to the second menu page.

Outlet : # Weld program: ###

Program continues . . . < ↑ >

Start delay . . . . . . . . . ### ms

Lift distance . . . . . . . . # ,## +, ## -, ## mm

Drop time . . . . . . . . . . ## ms

Autoplunge . . . . . . . . . ####

Air blow . . . . . . . . . . . ####

Detect stud . . . . . . . . . ####

Corresponding stud . . #########

Weld part ident. . . . . . ################

<1..5> <←↓↑→> <+,-> <ENT> F1..F5> <ESC>

Program continues The first menu page can be displayed by pressing the direction key

Start Delay If the weld location is not sufficiently stable the time between SOW and

lift can be adjusted in a range between 0 ms - 500 ms.

41

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

Lift distance

+ tolerance

- tolerance

Drop time Input of the time between de-energizing of the solenoid and the plunging

Autoplunge Yes : Autoplunge is activated to keep weld time constant.

Input of lift value in a range from 0,6mm-3,0mm for parameter monitoring

(step size: 0,1 mm).

Note: Input only necessary when the connected weld tool is equipped with an

integrated lift measurement system to detect distance.

Positive tolerance from 0-0,6mm (Selection of “0“ will cancel monitoring)

Negative tolerance from 0-0,6mm (Selection of “0“ will cancel monitoring)

of the stud into the melted work surface.

Note: Input serves to adapt weld time to stud plunge time and also

serves as reference value for maintenance monitoring

No : No autoplunge requested.

Air blow Yes: If the weld tool is optionally equipped with an air nozzle

for clearing the work surface, it will be activated

No:

Air nozzle for clearing the work surface will not be activated.

Detect stud

Yes : Stud detection via the length measurement function of the lift

measuring system is activated.

No : No autoplunge requested

Attention: Stud detection function is only performed if the stud detection

function in the mechanical parameters has been activated as well.

Remark: If "Detect Stud" is activated it will be verified before each weld whether the

stud length of the supplied stud is according to the programmed reference value. In

case of an deviation the corresponding fault message will be initiated.

Corresponding

stud

Feeder 1 - 5 : The weld program will be attributed a feeder.

Note: It will be verfied before the weld whether the last stud feed was

performed by the correct feeder.

None : Corresponding stud verification feature not requested

Remark: Verification of corresponding stud is only possi ble dur i ng operati on wi th a 2way stud divider SD 2.

Weld part

identification

Input of an alpanumeric text for identification of the weld part

Remark: Programming is to be effected via the , , and keys.

Programmed parameters will be confirm ed with or rejected with . You may

exit the input mode by pressing the key.

42

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

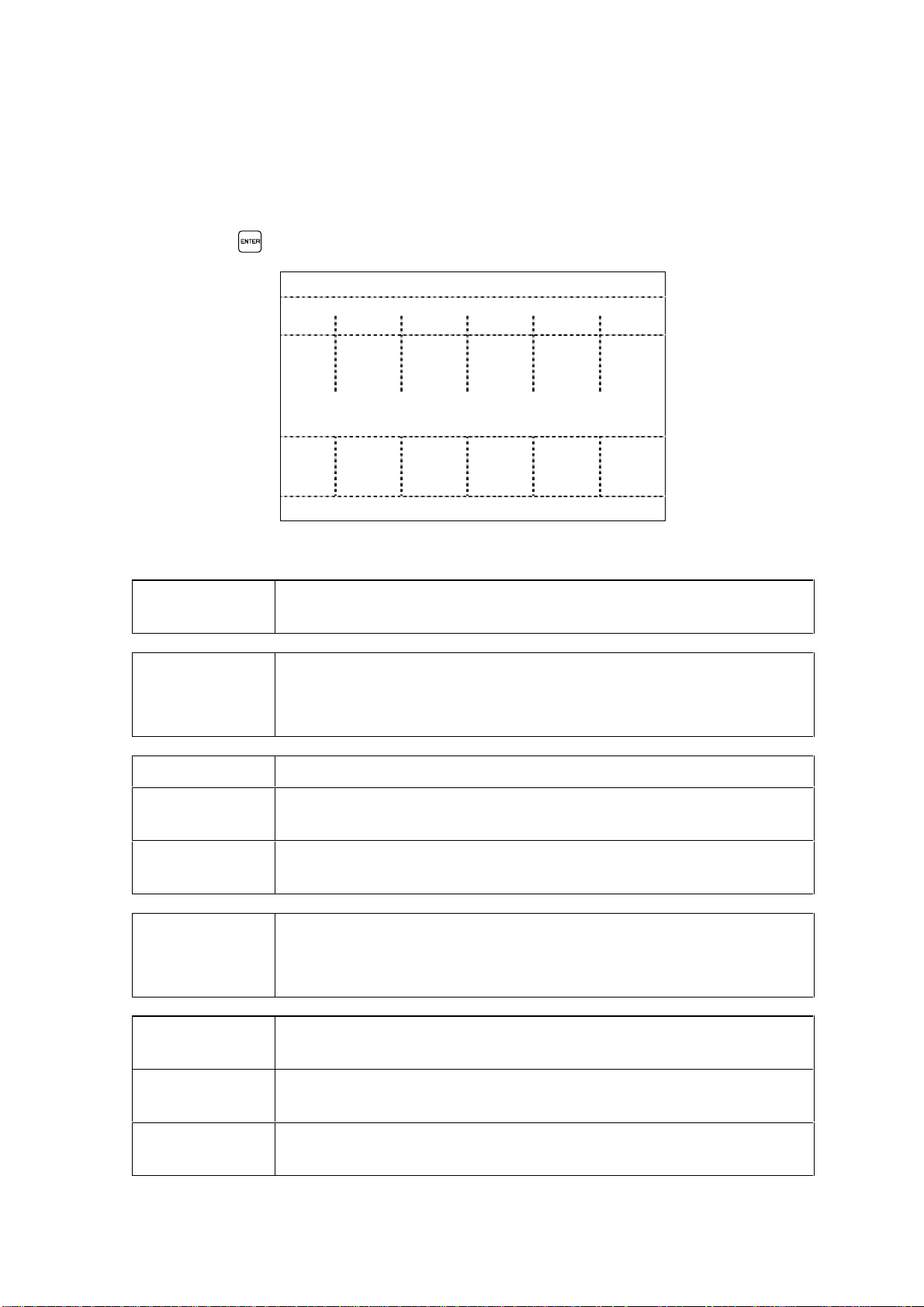

1.12.4 Function Menu "Copy Programs"

The function menu "Copy Programs" serves to transfer weld programs.

This function menu will be selected by positioning the cursor on the fourth menu

line of the "Extended Functions" menu and by pressing the key.

Copy programs

Single program

Program area

Programs per output

Copy Outlet # ####### ###

To Outlet # ####### ###

#### ####### ###

<1..9> <↓↑> <ENTER> <F1..F5> <ESC>

The user has the following possibilities to copy weld programs:

Single Program In selecting "Single Program" one copy of the weld program will

be made

Program Area In selecting "Program Area" several copies of the weld program

will be made

Programs per

Output

In selecting "Programs per Output" allweld programs of an

output will be copied

Select the requested copy function with the direction keys and and confirm

with .

Select a number between 1 and 5 for the weld output as well as a number

between 1 and 127 for the weld program and confirm your input with .

By pressing the cursor will move to the function selection and by pressing

again you will exit the menu.

Information on copying programs:

Weld programs will need to be copied when in a robot unit studs are to be welded

at different weld locations with identical programs. The stud detection is not

copied.

If a weld program is copied to an address under which a program is

already stored the existing program will be overwritten by the new

program.

43

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

1.12.5 Function Menu "Clear Functions"

The function menu "Clear Functions" serves to Clear and thus to reset counters

and memories of the statistics menu.

This function menu will be selected by positioning the cursor on the fifth me nu line

of the "Extended Functions" menu and by pressing the key.

Clear functions

1 2 3 4 5

Maintenance ####################

Statistic ####################

Fault memory ########################

WOP memory ########################

<←↓↑→> <ENTER>=Clear <F1..F5> <ESC>

The individual menu lines signify the following:

Maintenance

By clearing "Maintenance" the statistics in "Maintenance"

menu information will be reset to "0" . Any existing

maintenance warning will be automatically reset

Statistic

By clearing the "Statistics" the information in the two statistics

menus "Weld Output" and "Weld Program Statistics" will be

reset to "0"

Fault Memory

By clearing the "Fault Memory" all information will be deleted

in the "Fault Memory"

WOP Memory

By clearing the "WOP Memory" all information will be deleted

in the "WOP Memory"

For selecting statistics or a memory position the cursor with the direction keys

And and confirm with the key. The message "Activate Clear Function"

will appear on the display.

By pressing the key the selected memory will be cleared, by pressing the

selection will be cancelled. By pressing again you will exit the menu "Clear

Functions".

44

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

1.12.6 Function Menu "ZCPU S ystem Test"

This function menu will be selected by positioning the cursor on the sixth menu

line of the "Extended Functions" menu and by pressing the key.

ZCPU System test

RAM-Module:

- existent . . . . . . . . . . . . . . . . . . . . . . #

RAM-Module Battery:

- within operating tolerance. . . . . . . . #

- voltage level (Volts) . . . . . . . . . . .#, #

ZCPU Battery:

- within operating tolerance. . . . . . . . #

- voltage level (Volts) . . . . . . . . . . .#, #

<F1..F5> <ESC>

The individual menu lines will be described on the following pages:

RAM-Module : The system test checks whether the RAM-module is responsive.

Existent * :

A RAM-Module is existent.

No RAM-Module.

- :

RAM-Module battery : The system checks the battery in the RAM-Module

Tolerance * : The battery voltage is within the operating tolerance.

The battery voltage is out of the operating tolerance

- :

Voltage level The system test will indicate the measured battery voltage

ZCPU-Module battery : The system checks the battery on the ZCPU (real-time

clock)

Tolerance * : The battery voltage is within the operating tolerance.

- : The battery voltage is out of the operating tolerance

Voltage level The system test will indicate the measured battery voltage

By pressing the key you will exit the function menu "ZCPU System Test“.

45

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

1.12.7 Function Menu "De/Activate Program"

The function menu “De/Activate Program“ displays a clearly arranged overview on

the active/inactive weld programs in terms of output. Individual programs may be

de/activated.

The function menu is selected by positioning the cursor on the seventh line of the

“Extended Functions“ menu and then pressing the key.

Overview active programs O: #

12345678910

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39 40

41 42 43 44 45 46 47 48 49 50

51 52 53 54 55 56 57 58 59 60

61 62 63 64 65 66 67 68 69 70

71 72 73 74 75 76 77 78 79 80

81 82 83 84 85 86 87 88 89 90

91 92 93 94 95 96 97 98 99 100

101 102 103 104 105 106 107 108 109 110

111 112 113 114 115 116 117 118 119 120

121 122 123 124 125 126 127

<1..5> <←↓↑→> < + >=active < - >=inactive <ESC>

An overview on all programs nos. is displayed. Program numbers displayed in

italic are activated.

In order to alter a de/activation the cursor must be positioned on the requested

program number via the arrow keys , , or and then the keys or

must be pressed.

The status of the program will be altered correspondingly and the cursor moves

automatically to the next position.

Exit the menu with .

46

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

1.12.8 Function Menu "Stud Length Detection"

From the function menu“Stud Length Detection“ a reference value for the stud

length can be stored in memory if a lift measuring system is available. This value is

then considered for checking the supplied stud, if the stud detection function (see

“Mechanical Parameters“ as well as “Weld Parameters“) has been activated.

This function menu will be selected by po sitioning the cursor on the fifth menu line

of the sub-menu "Functions" and by pressing the key.

Stud length detection

Feeder number : #

Stud load . . . . . : #########

Process . . . . . . : #########

Value (ref) . . . . : ### mm

Checkup . . . . . : ########

Difference . . . . : ####

The length of the stud

selected will be stored in mem.

<1..5> <↓↑> <ENTER> <F1..F5> <ESC>

Select a number between 1 and 5 for the feeder and confirm your input with .

The individual menu lines signify the following:

Feeder number

Stud load

Process

Input of feeder no. 1 to 5

Note: In a SD2-application both feeders/studs must be measured for

the master output.

....?.... : Press and simultaneously, to load a stud on

the selected feeder.

started: The stud feed cycle has begun.

Note: If you are not sure whether the right stud has been supplied, you

should always perform this function before a reference measurement.

....?.... : Press and simultaneously to start the

reference measurement process (stud length)..

During internal slide rail control the head will be

advanced automatically to the front position.

started: The reference measurement process has begun.

Note: If you are not sure whether the right stud has been supplied, you

should always perform this function before a reference measurement

47

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 51

Value (ref.) The stud length is displayed.

Test The stud length will be tested.

Difference The difference of the displayed stud length to the measured

value will be displayed.

• Press to get to the menu line "Feeder number".

• Press again, to return to the Sub-Menu "Extended Functions".

48

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

1.12.9 Function Menu "Set Date and Time"

The date and time can be changed in the function menu “Set Date and Time“.

This function menu will be selected by positioning the cursor on the nin th line of

the “Extended Functions“ menu and by pressing the key.

Set date and time

Date : ##.##.##

Time : ##:##:##

<0..9> <←↓↑→> <ENTER> <F1..F5> <ESC>

In order to change the date or the time, move to the number to be changed with

the arrow keys , , or . The selected number is represented in italic.

Then enter a new number via the numerical keys. Confirm this number with the

key thereby exiting the menu. Only meaningful numbers will be accepted.

By pressing changes will be rejected and the menu is also exited.

The individual menu lines signify the following:

Date The current date will be displayed.

Time The current time will be displayed.

Note: If the date changes after the TMP has been switched off or nonsense

numbers are displayed, probably the battery jumper for the real-time clock has not

been set.

49

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 53

Appendix A:TMP Software Main-Menu OPERATION

OPERATION

------------------------------------- Weld parameter monitor

Programming

Statistics

Fault reset

Status weld sequence

Status customer interface

Status Feeder/Stud-Divider

Status TMP

Functions

Warnings

-------------------------------------<↓↑> <ENTER> <F1..F5>

Weld parameter monitor

--------------------------------------- SKK/PK outlet: # Program.No ...:###

Weld part ident : ################

Autoplunge...#### Optimization..####

| Ref +tol -tol | Act | |

----+----------------+-------+---+- Vp | ## ## ## | ## | V | #

Vw | ## ## ## | ## | V | #

Iw | #### ### ### | #### | A | #

tw | ### ## ## | ###,# | ms| #

td | ##,# | ##,# | ms| #

#Lift| #,## ,## ,## | #,## | mm| #

Fault :################################

---------------------------------------<0..5> <ENTER> <F1..F5> <ESC>

Programming

--------------------------------------- Weld parameters

Outlet/feeder

Programming weld parameters

----------------------------------------

Outlet No. ........: #

Weld position No......:###

Weld position aktive... ####

Weld diameter.......... #####

Workpiece gauge........ #####

Workpiece coating......########

Energy adjustment...... ### %

---------------------------------------<↓↑> <ENTER> <F1..F5> <ESC>

---------------------------------------<1..9> <↓↑> <+,-> <ENTER> <F1..F5> <ESC>

Programming outlet/feed time

----------------------------------------

Weld outlet no....:#

Outlet active......####