Page 1

INSTRUCTION MANUAL

INSTRUCTION MANUAL

®

ProSet 3400 Series

ProSet

Pneumatic Blind Rivet Tool

Pneumatic Blind Rivet Tool

3400 Series

Page 2

Contents

Introduction.......................................................................................................... .....................................2

Safety Instructions....................................................................................................................................3

Specifications ...........................................................................................................................................4

Packaged Accessories..........................................................................................................................4

Tool Requirements................................................... .................... .......... .................... ...........................4

ProSet® 3400 Tool Dimensions.............................................................................................................5

Common Nosepieces .......................... .................... .......... .................... .......... .................... .................6

Basic Tool Operation ................................................................................................................................6

Front End Service.................................................................................................................................7

Mandrel Collection System (MCS) – ProSet® 3400 MCS .....................................................................8

Cleaning the Collector Silencer.............................................................................................................8

T ool A ssembly T orque Requirements....................................................................................................9

ProSet® 3400/3400MCS Diagram ..........................................................................................................10

Parts List ................................................................................................................................................12

Hydraulic Oil Charging Procedure ..........................................................................................................14

Maintenance...........................................................................................................................................15

Safety Data.............................................................................................................................................16

Troubleshooting......................................................................................... .............................................17

EC Declaration of Conformity .................................................................................................................18

Notes........................................................................... ...........................................................................19

Introduction

®

POP

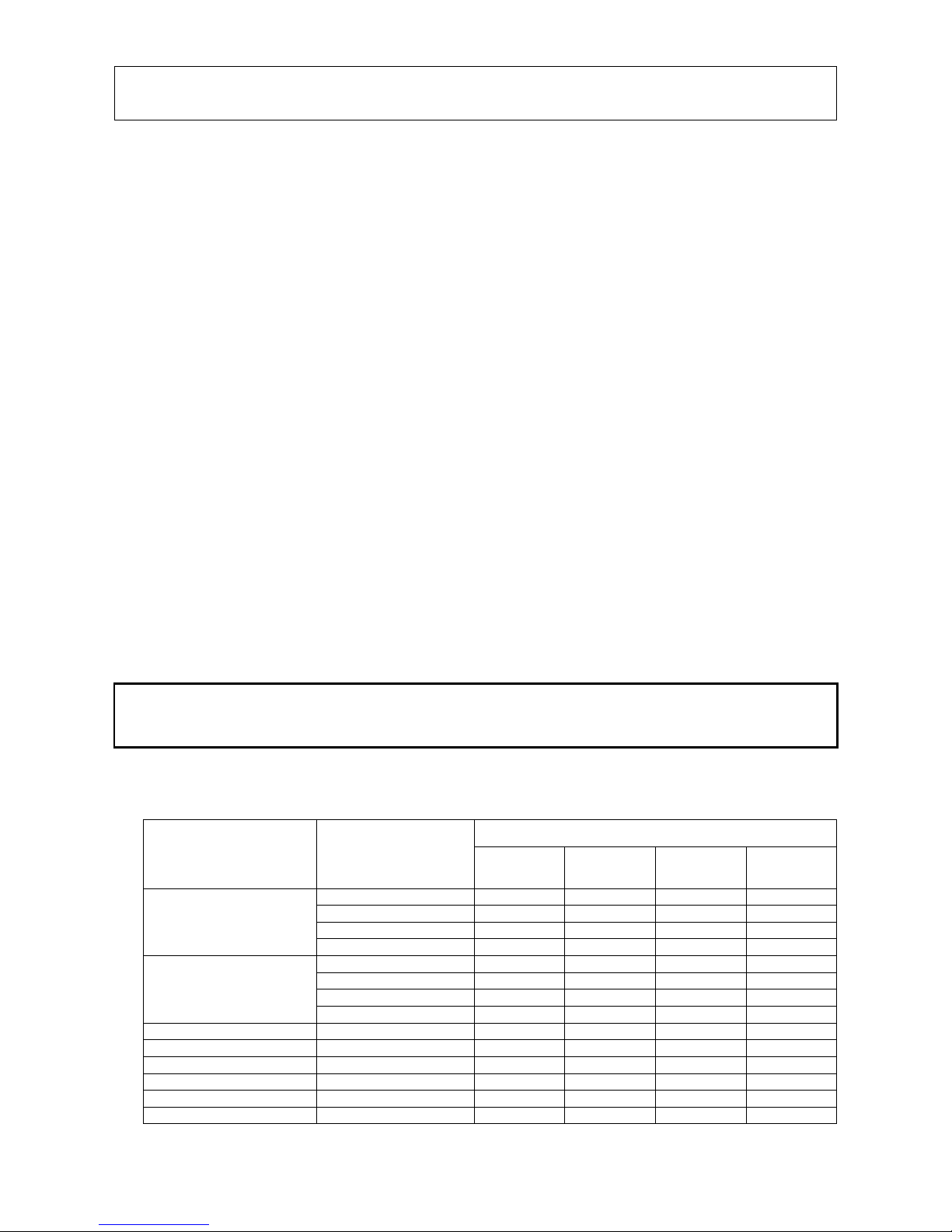

ProSet® 3400 tools are light weight, Air/Hydraulic rivet setting tools recommended for use with genuine

®

Brand Rivets per the following chart:

POP

Rivet Type

(Body – Mandrel)

Al – Al 9 9 9 9

Open End & MultiGrip™

Closed End

LSR Rivets Al – Al 9 9 9

T - Rivet Al – St 9 9 9

Self Plugger St – St 9 9 9

HR™ Rivets St – St 9 9 9

HS Rivets Al – Al; St – St, NA NA NA 9

Ultra-Grip® Al – Al; St – St; SS – SS NA NA 9

Al: Aluminum, St: Steel, SS: Stainless Steel, Cu: Cooper, M o: Monel . (*) Use PRG540-46 Jaws and FAN276-064 Jaw Pusher set up.

(**) Use PRG540-46 Jaws and DPN276-006 Jaw Pusher set up. (†) Use PRG540-44 Jaws and DPN276-006 Jaw Pusher set up.

Al – St / SS 9 9 9 9

St – St 9 9 9 9

SS – SS; Mo – St /SS 9 9 9 9

Al – Al 9 9 9 9

Al – St / SS; Cu – St 9 9 9 9

St – St 9 9 9 9

SS – SS 9 9 9 9

1/8”(*)

[3.2 mm]

Material

Rivet Diameter

5/32” (*)

[4.0 mm]

3/16” (**)

[4.8 mm]

(†)

NA

(†)

9

(†)

9

(†)

8

(†)

9

1/4” (†)

[6.4 mm]

Page 2 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 3

A

TO INSURE PROPER FUNCTIONING AND SAFE OPERATION R EAD THIS MANUAL

CAREFULLY BEFORE SETTING UP OR OPERATING THE POP® ProSet® 3400 SERIES TOOLS

1. DO NOT use this tool in a manner other than that recommended by Emhart Teknologies.

2. Always wear eye protection when using or when near a tool that is in use.

3. This tool is NOT designed for use in explosive atmospheres.

4. Inspect tool for damage before connecting to air supply including all air connections.

5. Trained personnel must perform tool repair and/or maintenance at the prescribed intervals.

6. Disconnect the air supply when adjusting, servicing or removing any part of the tool.

7. Keep fingers off the trigger when connecting the air supply or if the air supply fails.

8. Keep fingers away from the front of the tool when connecting the air supply or setting rivets.

9. DO NOT point the tool at anyone.

Safety Instructions

A

10. DO NOT operate tool with the Nose Housing removed.

11. DO NOT operate tool without the Deflector or Collector.

12. DO NOT modify the tool in any way. Modification will make void any applicable warranties

and could result in damage to the tool or physical injury to the user.

13. DO NOT look into the tool from the front or the back during use or when connected to air

supply.

14. The operating pressure must not exceed 100 psi (6.9 bar).

15. DO NOT direct tool exhaust towards anyone.

16. Wash hands if exposed to hydraulic fluid or lubricant.

17. Keep hair, fingers and loose clothing away from moving parts of the tool.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 3

Page 4

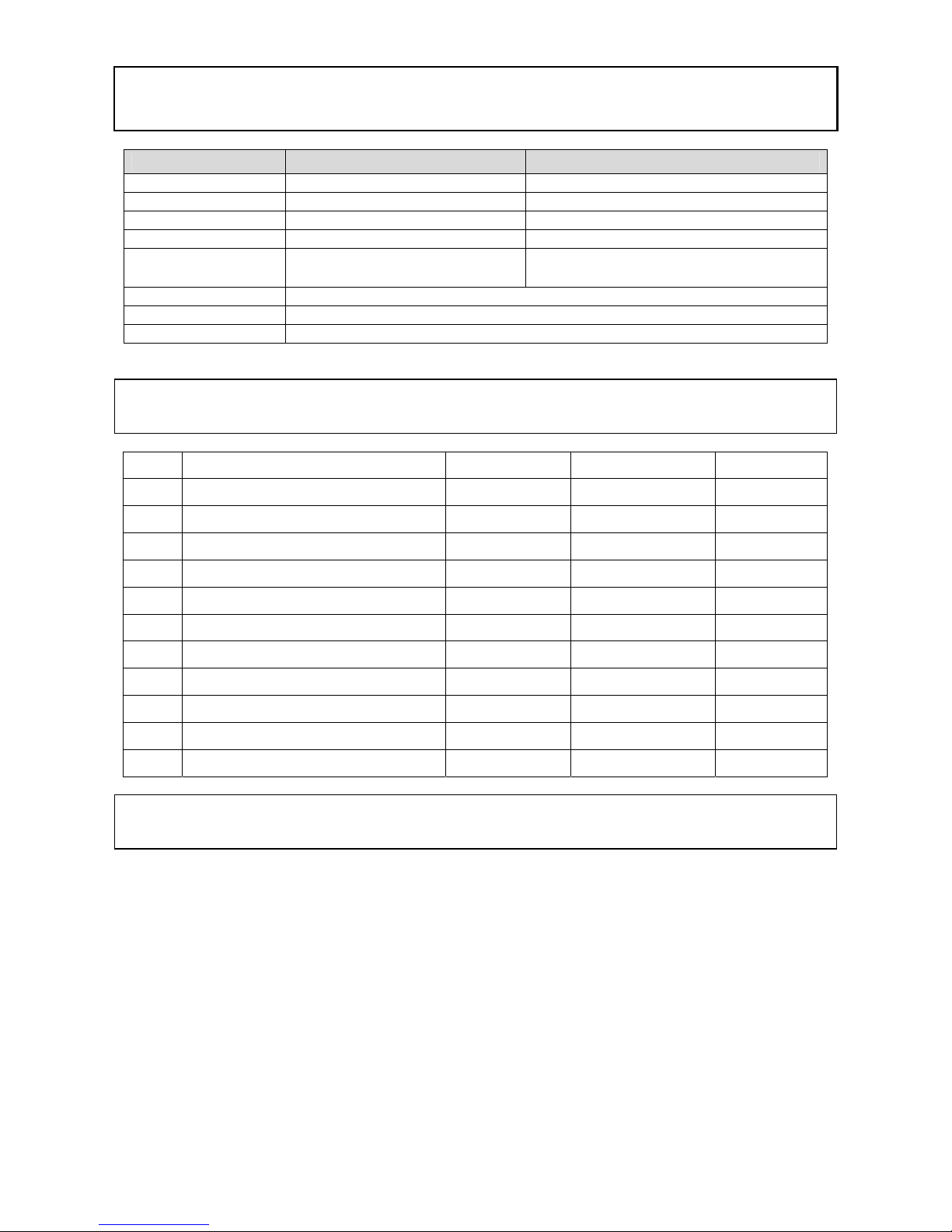

Specifications

ProSet® 3400 ProSet® 3400MCS

Weight

Length

Height

Stroke

Air Consumption

Pulling Force

Noise Level

Vibration Level 0.61 m/s2, Time to 2.5 m/s2 > 24hrs (EAV)

Qty Item ProSet® 3400 ProSet® 3400MCS Part No.

ProSet

®

3400 Rivet Tool

1

1 Operating Instructions

4.19 lbs. (1.90 kg) 4.41 lbs. (2.00 kg)

12.17” (309 mm) 13.15” (344 mm)

12.44” (316 mm) 10.20” (316 mm)

1.02” (26 mm) 1.02” (26 mm)

0.172 cu. ft. per rivet

(4.86

l per rivet)

4160 lbs. @ 90 psi (18500 N @ 0.62 MPa)

L

= 78.5 dB(A), LWA = 84.0 dB(A), L

Aeq,T

2.83 scfm (m ax .)

(80 l /min (max.))

= 103.6 dB(C)

Peak

Packaged Accessories

9

9 9

9

-

P449

1 Maintenance Manual

1 Nosepiece for 4 size open end rivets

1 Nosepiece for 5 size open end rivets

1 Nosepiece for 6 size open end rivets

1 Nosepiece for 8 size open end rivets Installed Installed PRN811

1 Jaw Pusher (Assy) for 4&5 size rivets

1 Air Line Assembly

1 4 mm Hex. Socke t Screw Key

1 Warranty Card

9 9

9 9

9 9

9 9

9 9

9 9

9 9

9 9

P551

PRN414

PRN514

PRN614

FAN276-064

FAN276-154

DPN239-139

FG2184

Tool Requirements

Air supply *

Recommended Operating Pressure 72.5-90 PSI (0.50-0.62 MPa) dry, filtered

Maximum Operating Pressure 100 PSI (0.69 MPa) dry, filtered

Hydraulic Oil **

Jaw Lubricant **

Seal Lubric ant **

POP

POP

POP

®

®

®

6 scfm (150

p/n: PRG540-130 [1 qt. (.945 ml)]

p/n: PRG510-130 [6 oz. (177 ml)]

p/n: PSA075508P [1 ¾ oz. (54 g)]

l /min) Minimum

(*) Note: For best results and long service life, use dry, filtered air supply.

(**) Note: See lubricant safety information.

Page 4 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 5

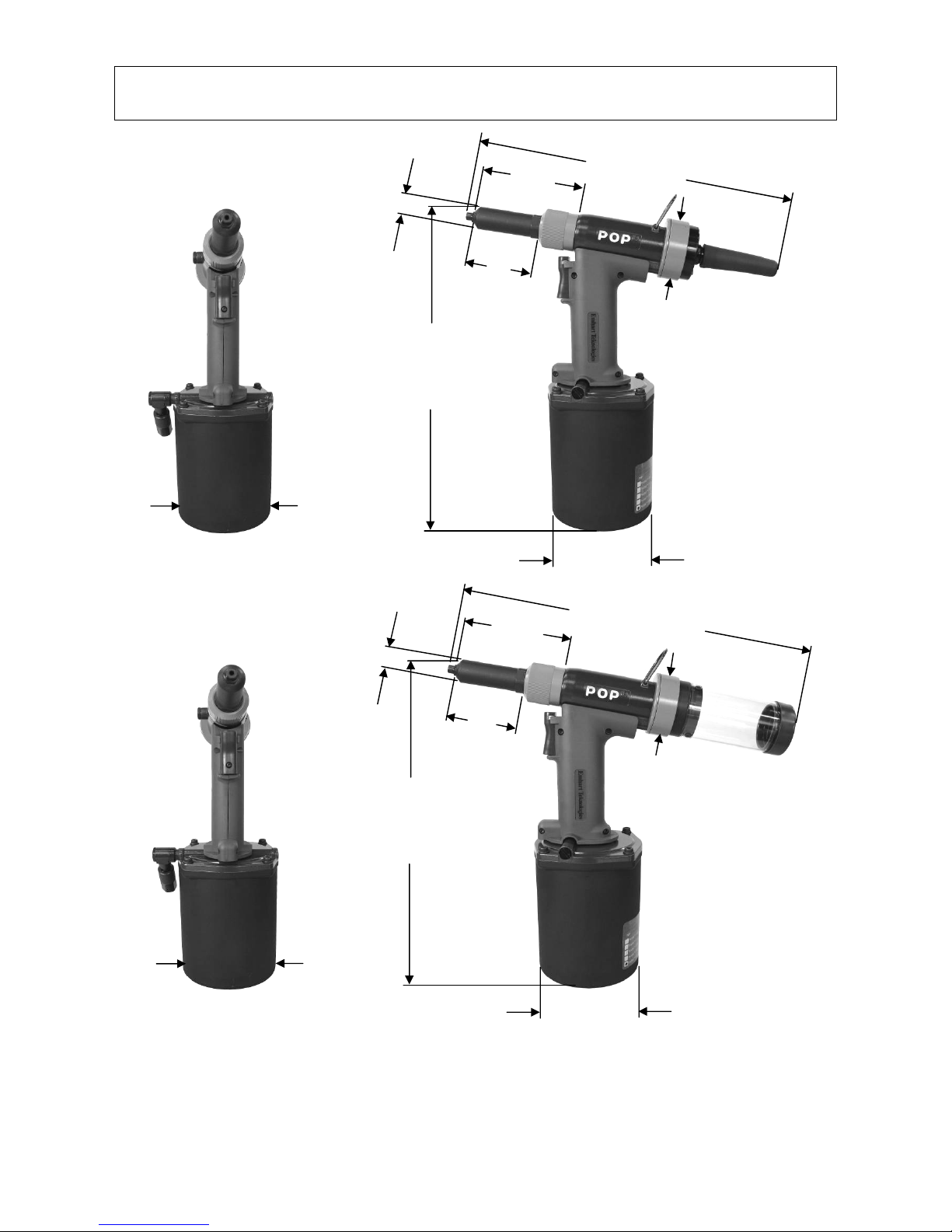

ProSet® 3400 Tool Dimensions

.882” (22.4 mm)

4.06”

(103 mm)

2.66” (67.5 mm)

12.44” (316 mm)

4.21” (107 mm)

.882” (22.4 mm)

4.06”

(103 mm)

2.66” (67.5 mm)

12.44” (316 mm)

4.21” (107 mm)

•

12.17” (309 mm)

4.21” (107 mm)

13.15” (334 mm)

4.21” (107 mm)

2.32” (59 mm)

ProSet® 3400

2.32” (59 mm)

ProSet® 3400 MCS

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 5

Page 6

Common Nosepieces

Rivet

Diameter

1/8”

(3.2 mm)

5/32”

(4.0 mm)

3/16”

(4.8 mm)

1/4”

(6.4 mm)

Open End

PRN414* PRN424 PRN434 PRN414* PRN4HR - -

PRN514* PRN524 PRN534 PRN514* PRN5HR - -

PRN614* PRN624 PRN634 PRN614* PRN6HR - N-406

PRN811* PRN822 - PRN811* - PRN8PS

Closed End HR Rivets

Steel

Mandrel

Aluminum

Mandrel

Aluminum

Body

Steel

Body

HS Rivets

Ultra-Grip

PRN8PS or

N-407

®

Jaw Pusher

FAN276-064*

DPN276-006*

* Included with the tool

For T-Rivets use PRN625 n osepi ec e when usin g 3/16 ” (4. 8mm) dia meter rive ts and P RN82 5 for ¼” (6.4 mm)

diameter rivets. For Monobolt

®

rivets use N-410 nosepiece for 3/16” (4.8mm) and N-414 for ¼” (6.4mm)

diameter rivets.

Basic Tool Operation

Before operating the tool check the following:

Ins pect t ool for damage or leaking oil – do not use tool if it is damaged or leaking oil.

Chec k t hat correct nosepiece is fitted and tightened to 60 - 65 in-lbs [6.8 – 7.3 N-m] torque.

Chec k that the Nose Housing Nut (8) is tight – hand tighten only.

Connec t tool to air supply – see air supply requirements (page 4).

Fit Mandrel Collector (113) – (MCS tool only).

Open air s up ply valve by sliding red OS Slider (130) on side of tool (see note below).

Insert rivet into nosepiece.

Position rivet in work piece.

Pull trigger to set rivet.

Release trigger – if equipped, MCS suction will draw spent mandrel into the collector.

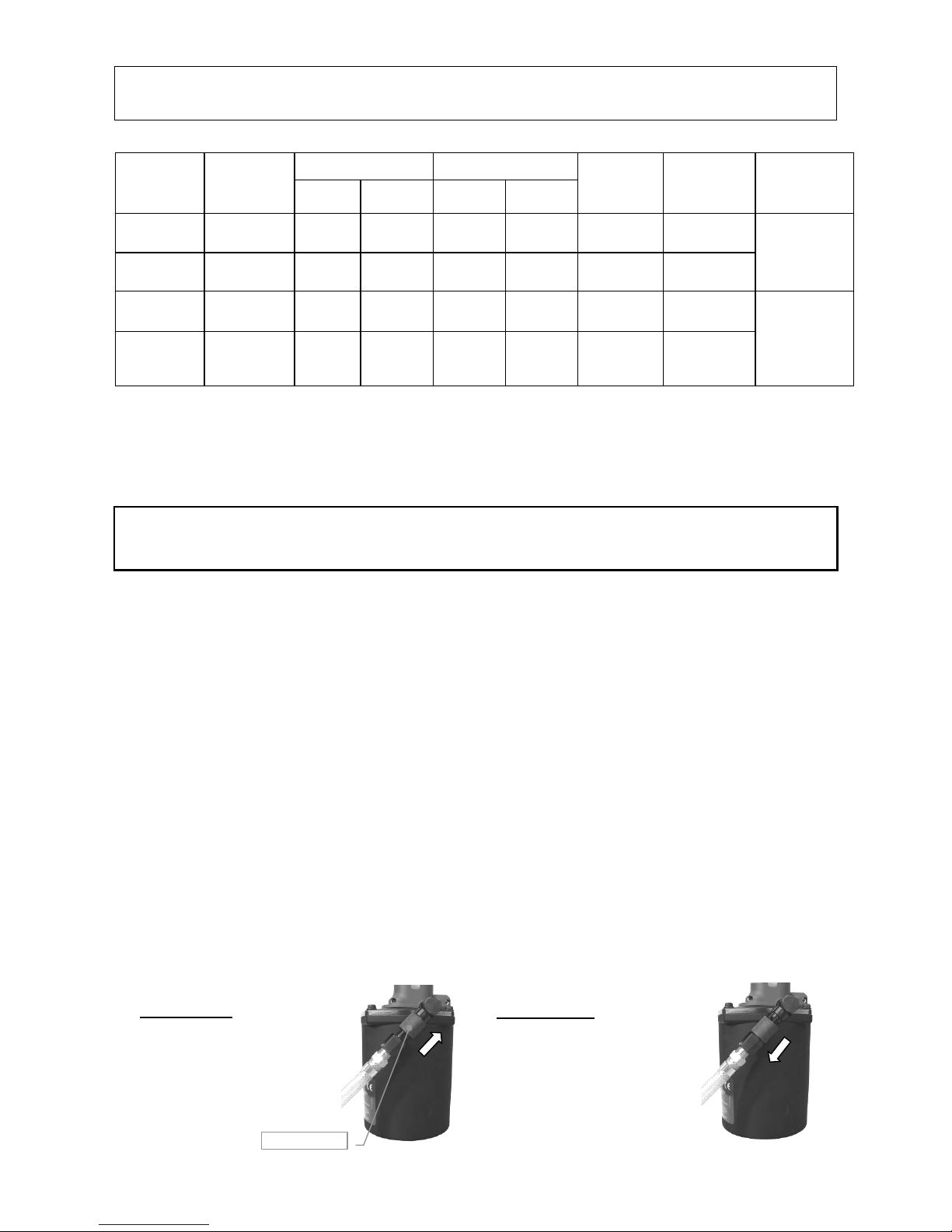

! Note: The ProSet

save air when the tool is not in use.

®

3400 has an OS (Open-Shut) Valve for switching the air supply ON and OFF to

Air Supp ly ON: Open OS Valve

by sliding OS Slider in the

direction shown (up).

Air Supp ly OF F

by sliding OS Slider in the

direction shown (down).

: Close OS Valve

OS Slider

Page 6 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 7

Front End Service

For optimum tool performance, Front-End maintenance should be performed regularly as per the “Preventative

Maintenance Schedule”.

Nose Housing Nut

Nose Housing

Wrench Flat

Jaw Guide Lock motion

O-Ring

Pulling Head Locking Teeth.

Jaw Guide teeth

1

Jaw Guide

Pulling Head

Jaw Guide Lock

Housing Adapter

! Note: UNPLUG AIR SUPPLY while servicing front-end to avoid INJURY.

1. REMOVE NOSE HOUSING:

Unscrew the Nose Housing Nu t by hand and

slide Nose Housing off the tool.

2. REMOVE JAW GUIDE TO ACCESS JAWS

AND INTERNAL PARTS:

Pull back the Jaw Guide Lock to disengage the

Jaw Guide Lock teeth and unscrew and remove

the Jaw Guide.

Remove Jaws, Jaw Pusher, and Jaw Pusher

Spring fo r servicing.

3. CLEAN PARTS:

Clean Jaws, Jaw Guide, Jaw Pusher, Spring

and thread area of the Pu lling Head.

Apply Seal Lubricant to outside surface of Jaws

and inside surface of the Jaw Guide.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 7

4. REASSEMBLY OF INTERNAL PARTS AND JAW

GUIDE:

Place the Jaws into the Jaw Guide and slide the Jaw

Pusher Spring and Jaw Pusher into the Pulling Head.

Apply a small amount of Seal Lubricant to the Pulling

Head threads and Jaw Guide Lock teeth. Screw the Jaw

Guide onto the Pulling Head until it stops. Check to

make sure the teeth are engaged.

Apply Jaw Lubricant to the Jaw area by submerging the

assembled Jaw Guide into Ja w lube abo ut 1 in. (25mm).

Clean off excess Jaw Lube from the outside of the Jaw

Guide.

(! Make sure the air supply is disconnected !)

5. REINSTALL NOSE HOUSING ASSEMBLY:

Refit the Nose Housing and hand-tighten the Nose

Housing Nut securely against the O-Ring. If the nut is

not tightened sufficiently against the O-Ring there may

be a loss of suction on the MCS tool version.

Page 8

Mandrel Collection System (MCS) – ProSet® 3400 MCS

For safety purposes, removing the Collector from the tool automatically turns the MCS suction OFF. Refitting

the Collector turns the MCS suction ON.

MCS suction ON

MCS suction OFF

Cleaning the Collector Silencer

For optimum performance, the Collector Silencer should be cleaned at regular intervals as per the

“Preventative Maintenance Schedule”.

! Note: UNPLUG AIR SUPPLY while servicing Collector to avoid INJURY.

1. CLEAN THE COLLECTOR :

• Remove and empty the Collect or (113) by turning counterclockwise.

• Remove the Collector End Nut (122) (17mm wrench) and remove the Collector End Cap (120).

• Re move the Collector Silencer (119).

• Clean and remove debris from all c omponents.

Collector Body (118)

Collector End (121 )

Collector Silencer (119)

Collector End Nut (122)

Collector End Cap (120)

Page 8 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 9

2. RE-ASSEMBLE THE COLLECTOR :

• Secure Collector End (121) to Collector Body (118). Use a screwdriver or similar tool to hold the

Collector End in place during re-assembly (see picture below).

• Place the Collector Silencer (119) onto the Collector End (121).

• Place Collector End Cap (120) on C ollector End (121).

• Install and tighten Collector End Nut (122) on Collector End (121).

Screwdriver

Tool Assembly Torque Requirements

Item Part No. Description Torqu e Value

1

137

136

135

61 DPN276-031 Sleeve Lower 55 - 63 ft-lbs (75 - 85 N-m)

81 DPN276-043 Sleeve Lock Nut 44 - 52 ft-lbs (60 - 70 N-m)

111 DPN907-003 Socket Head Cap Screw 46 - 51 in-lbs (5.2 – 5.8 N-m)

See exploded ProSet

PRN81 1

PRN614

PRN514

PRN414

®

3400/3400MCS Diagram

Nosepiece 8 size

Nosepiece 6 size

Nosepiece 5 size

Nosepiece 4 size

60 – 65 in-lbs (6.8 – 7.3 N-m)

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 9

Page 10

ProSet® 3400/3400MCS Diagram

ProSet® 3400/3400MCS Diagram

Page 10

Page 10 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 11

(*) These items require Loctite

(†) These items have a specific tightening torque as indicated in the “Tool Assembly Torque Requirements” table.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 11

®

242 adhesive.

Page 12

Parts List

Item Part No. Description 3400

1 PRN811 Nosepiece 1 1

2 PRG540-44 Jaws 1 1

3 DPN276-001 Jaw Guide 1 1

4 DPN276-002 Pulling Head 1 1

5 DPN276-003 Jaw Guide Lock 1 1

6 DPN276-004 Nose Housing 1 1

7 DPN900-059 O-Ring 1 1

8 DPN276-005 Nose Housing Nut 1 1

9 DPN276-006 Jaw Pusher 1 1

10 DPN900-060 O-Ring 1 1

11 DPN901-019 Jaw Pusher Spring 1 1

12 DPN901-020 Spring 1 1

13 DPN276-007 Pulling Head Joint 1 1

14 DPN276-008 Hydraulic Piston 1 1

15 DPN276-009 Spacer Pipe 1 1

16 DPN276-010 Housing Adapter 1 1

17 DPN900-061 O-Ring 1 1

18 DPN276-011 Rod Seal Case 1 1

19 DPN908-015 Scraper 1 1

20 DPN900-062 O-Ring 1 1

21 DPN908-021 B.U-Ring 2 2

22 DPN908-022 Penta Seal 2 2

23 DPN900-063 O-Ring 1 1

24 DPN908-023 B.U-Ring 1 1

25 DPN900-064 O-Ring 1 1

26 DPN276-012 Handle Upper 1 1

27 DPN901-021 Return Spring 1 1

28 DPN900-065 O-Ring 2 2

29 DPN276-013 MCS Valve Case 1 1

30 DPN276-014 MCS Valve Rod 1 1

31 DPN900-066 O-Ring 2 2

32 DPN901-022 Spring 1 1

33 DPN276-015 End Cap Adapter 1 1

34 DPN276-016 MCS Cap Front 1 1

35 DPN276-017 Slider 1 1

36 DPN900-067 O-Ring 1 1

37 DPN276-019 MCS Cap Tail 1 1

38 DPN900-068 O-Ring 2 2

39 DPN276-018 Slider Pusher 1 1

40 DPN900-069 O-Ring 1 1

41 DPN276-020 End Cap 1 1

42 DPN276-061 Collar 2 2

43 DPN276-021 Collar Screw 2 2

44 DPN276-023 Ejector Guide 1 1

45 DPN900-013 O-Ring 1 1

46 DPN907-002

47 DPN276-024 End Cap Plate - 1

48 FAN276-022 Ejector (Assembly) 1 1

DPN900-045

52

DPN239-047

53

DPN900-007

54

DPN900-070

55

DPN900-036

56

DPN276-028

57

DPN276-029

58

DPN902-002

59

60 DPN276-030 Upper Plate 1 1

DPN276-031

61

DPN276-085

62

FAN276-033

63

FAN276-036

66

DPN900-071

69

FAN275-022

70

71 DPN275-025 EXT Valve Head 2 2

DPN901-008

72

DPN275-024

73

DPN275-023

74

DPN900-030

75

Socket Head Cap Screw

O-Ring 2 2

Fill Screw 1 1

O-Ring 1 1

O-Ring 1 1

O-Ring 1 1

Sleeve Upper 1 1

Restrictor 1 1

Retaining Ring 1 1

Sleeve Lower 1 1

Pan Head Screw 1 1

Handle Lower Assembly

Air Piston Assembly 1 1

O-Ring 1 1

EXT Valve (Assembly)

EXT Valve Spring 2 2

EXT Valve Case 2 2

EXT Valve Rod 2 2

O-Ring 2 2

3400

MCS

6 6

1 1

2 2

Item Part No. Description 3400

DPN900-072

76

DPN276-039

77

FAN276-040

78

DPN276-043

81

DPN276-044

82

DPN276-045

83

DPN900-073

84

DPN900-012

85

DPN900-074

86

DPN900-035

87

DPN276-046

88

DPN239-069

89

DPN900-075

90

DPN900-076

91

DPN276-047

92

DPN276-048

93

DPN276-049

94

DPN239-120

95

FAN239-074

96

DPN900-014

99

DPN902-001

100

DPN239-078

101

DPN906-001

102

DPN239-150

103

DPN900-015

104

DPN239-083

105

DPN276-050

106

DPN907-001

107

108 DPN239-086 Hexagon Nut 4 4

DPN276-051

109

DPN276-052

110

DPN907-009

111

DPN276-063

112

FAN276-055

113

DPN276-056

114

DPN900-077

115

DPN276-057

116

DPN903-001

117

DPN276-058

118

DPN276-059

119

DPN276-060

120

DPN276-062

121

DPN239-152

122

DPN900-079

123

DPN276-080

124

DPN900-022

125

PRG510-56

126

DPN276-053

127

DPN276-076

128

DPN276-054

129

DPN276-078

130

DPN900-078

131

DPN276-077

132

DPN900-080

133

PRG540-46

134

PRN414

135

PRN514

136

PRN614

137

FAN276-064

138

DPN239-139

141

FAN276-154

142

DPN276-155

143

DPN276-156

144

DPN276-157

145

DPN276-158

146

O-Ring 1 1

Tube Seal Case 1 1

Tube Assembly 1 1

Sleeve Lock Nut 1 1

Bottom Plate 1 1

J Valve Cap 1 1

O-Ring 1 1

O-Ring 1 1

O-Ring 3 3

O-Ring 1 1

J Valve Rod 1 1

EXT Silencer 1 1

O-Ring 1 1

O-Ring 1 1

J Valve Fitting 1 1

H.L Fitting 1 1

Air Tube 2 2

Fitting 2 2

S Valve Case Assembly

O-Ring 2 2

Retaining Ring 1 1

S Valve Rod 1 1

Button Head Cap Screw

Trigger 1 1

O-Ring 2 2

Connect Tube 1 1

Handle R,L 1 1

Socket Head Cap Screw

Plug 1 1

Chamber 1 1

Socket Head Cap Screw

Hook 1 1

Collector (Assembly) - 1

Collector Lock Col lar - 1

O-Ring - 2

Collector Lock - 1

Flat Head Cap Screw

Collector Body - 1

Collector Silencer - 1

Collector End Cap - 1

Collector End - 1

Collector End Nut - 1

O-Ring 1 Deflector Adapter 1 O-Ring 1 Deflector 1 R Joint Spacer 1 1

R Joint 1 1

R Joint Adapter 1 1

OS Slider 1 1

O-Ring 2 2

OS Joint 1 1

O-Ring 1 1

Accessories

Jaws 1 1

Nosepiece 4 size 1 1

Nosepiece 5 size 1 1

Nosepiece 6 size 1 1

Jaw Pusher (Assembly)

HS Screw Key 4mm 1 1

Air Line Assembly 1 1

Air Line Fitting 1 1

Hose Female Fitting 1 1

Air Tube 1 1

Ear Clamp 2 2

3400

MCS

1 1

1 1

4 4

4 4

- 3

1 1

Page 12 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 13

Optional Parts and Kits are also available separately.

Part No. Description

FAN276-075 ProSet® 3400 Font End Extension Kit –

7.9” length

Contains:

2 PRG540-44 Jaws 1

3 DPN276-001 Jaw Guide 1

5 DPN276-003 Jaw Guide Lock 1

7 DPN900-059 O-Ring 1

8 DPN276-005 Nose Housing Nut 1

9 DPN276-006 Jaw Pusher 1

10 DPN900-060 O-Ring 1

11 DPN901-019 Jaw Pusher Spring 1

12 DPN901-020 Spring 1

DPN276-067 Nose Housing 1

DPN276-068 Pulling Head Extension 1

DPN276-069 Pulling Head Joint 1

FAN276-072 Jaw Pusher (Assembly) 1

FAN276-152 ProSet® 3400/3400MCS Seal Kit

Contains:

7 DPN900-059 O-Ring 1

17 DPN900-061 O-Ring 1

19 DPN908-015 Scraper 1

20 DPN900-062 O-Ring 1

21 DPN908-021 B.U-Ring 2

22 DPN908-022 Penta Seal 2

23 DPN900-063 O-Ring 1

24 DPN908-023 B.U-Ring 1

25 DPN900-064 O-Ring 1

45 DPN900-013 O-Ring 1

54 DPN900-007 O-Ring 1

69 DPN900-071 O-Ring 1

76 DPN900-072 O-Ring 1

86 DPN900-074 O-Ring 2

131 DPN900-078 O-Ring 2

Part No. Description

FAN276-165 ProSet® 3400 MCS Retrofit Kit

Contains:

47 DPN276-024 End Cap Plate 1

113 FAN276-055 Collector Assembly 1

FA203-408 Remote MCS (MCS5000) Adaptor Kit

for 4, 5 & 6 Size Rivets

Contains:

MCS5000-78 Adapter Cap 1

MCS5000-81 Strain Relief 1

PRT5250-24 Tapered Bushing 4 size rivets 1

PRT5250-26 Tapered Bushing 5 & 6 size rivets 1

PRT5250-98 Fitting for 5 & 6 size rivets 1

PRT5250-99 Fitting for 4 size rivets 1

FA203-414 Remote MCS (MCS5000) Adaptor Kit

for 8 Size Rivet

MCS5000-23 3/8” Hose Fitting 2

MCS5000-24 3/8” Hose – 15ft 1

MCS5000-78 Adapter Cap 1

PRH840-3400 PRH840 Corner Head Adaptor

DPN276-081 Corner Head Adapter 1

DPN276-082 Draw Bolt 1

DPN905-008 Socket Set Scr ew 3

PRH840-19 Draw Bolt Pin 1

PRH850-3400 PRH850 Corner Head Adaptor

DPN276-083 Corner Head Adapter 1

DPN276-084 Draw Bolt 1

DPN905-008 Socket Set Scr ew 3

PRH850-19 Draw Bolt Pin 1

RP4-501 RP4/RP5 Receptacle for ProSet® 3400

RP6-501 RP6 Receptacle for ProSet® 3400

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 13

Page 14

(

)

Hydraulic Oil Charging Procedure

! I MPORTANT. TOOL MUST BE DISCONNECTED FROM THE AIR SUPPLY. USE ONLY APPROVED

HYDRAULIC OIL SPECIFIED IN THIS MANUAL.

1. Disconnect from air supply.

2. Remove Nose Housing (6) and Collector (113).

3. Remove four Socket Head Cap Screws (111) using 4mm Hex-Key wrench

(141-accessory). (Fig. 1)

4. Turn tool upside down and remove Chamber (110).

Then pull out Air Piston Assembly (66) and Tube Assembly (78). (Fig. 2)

5. Drain the oil from the tool into a waste oil container.

6. Clean the dirt off the Air Piston Assembly (66) and inner Chamber (110)

with a clean rag.

Apply a thin layer of Seal Lub ricant to inner Chamber.

7. Loosen Jaw Guid e (3) approximately 3 full turns or a 0.12" (3mm) gap

and loosen Fill Screw (53) approximately 3 - 3½ full turns or a

0.14"(3.6mm) gap (Fig. 3).

8. Secure the tool upside down again an d pour hydrau lic oil into Sleeve Lower (61) t o the le vel of

the Backup Ring (white part) (21). (Fig. 4)

9. Push Air Piston Assembly (66) into Sleeve Lo wer (61) to half- way point so th at dirt y h ydraulic

oil and air bubbles wil l come out from the loosened Fill Screw (53).

Hold Air Piston Assembly until no more oil or bubbles come out. (Fig. 5)

10. Loosely tighten Fill Screw (53) and pull out Air Piston Assembly (66).

11. Pour more h ydraulic oil into Sleeve Lower (61) to the level of

the Backup Ring and push Air Piston Assembly (66) into

Sleeve Lower (61). Push Air Piston inwards then outwards 5-6

times in a slow, constant motion.

Then pull it out and check for bubbles rising to the oil

surface.

If there are still bubbles, repeat the procedure until there

are no more bubbles (Fig. 6).

It may be necessary to repeat this procedure 2-3 times to bleed all bubbles

from the oil.

If after 3 attempts, there are still bubbles in the oil, go back to step No.5 and start again by draining the hydraulic oil.

Backup Ring (21)

Sleeve Lower (61)

Fig. 4

e

Air Piston Assembly (66)

Fig. 5

Fill Screw (53)

Socket Head Cap

Screw

Air Piston Assembly (66)

0.14"(3.6mm)

Fill Screw (53)

Air Piston Assembly (66)

111

Chamber (110)

Tube Assembly (78)

Fig. 3

Jaw Guide (3)

Tube Assembly (78)

Sleeve Lower (61)

Fig. 1

Fig. 2

0.12"(3mm)

Fig. 6

Page 14 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 15

12. When there are no more bubbles in the oil, top off the hydraulic oil in the Sleeve Lower (61) to the le ve l of the Bac kup

Ring (21).

13. Make sure the Jaw Guide (3) is loose (see step No.7) . Push the Air Pist on Assembl y (66) and Tube Assembly (78)

into the Sleeve Lower (61 ) t o the h a lf -way point. While holding the Air Piston at the half-way point, replace the Nose

Housing and hand tighten.

14. With a clean rag, wipe off any oil on t he Air Piston Assembly (66), H andle Lower Asse mbly (63), and S leeve Lowe r

(61). Put Chamber (110) over Air Piston Assembly (66) then turn the tool upright and tighten the four Socket Head

Cap Screws (111) to a Torque of 65 - 75 in-lbs (7.5 – 8.5 N-m).

15. Remove the Nose Housing (6), and tighten the Jaw Guide (3) by hand until it stops.

16. Loosen the Fill Screw (53) approximately 3 - 3½ full turns or a 0.14"(3.6mm) gap to allow excess hydraulic oil and

bubbles to escape. When no more oil comes out, tighten the Fill Screw (Fig. 7).

17. Wipe off any dirt and oil on the tool.

18. Replace the Nose Housing (6) and Collector (113).

Fig. 7

Fill Screw (53)

Note: During assembly and disassembly, do not allow any metal swarf or dirt into the Hydraulic

Oil and inner Chamber.

Maintenance

Preventative Maintenance Schedule

Item Action Frequency

Clean and lubricate Front

End of tool

Inspect jaws

Collector

Note: Only use Emhart specified greases and lubricants

See “Front End Service”

Look for broken jaws and

damage or wear on jaw teeth.

Empty Collector

Clean Collector Silencer

1 x per day or

5,000 rivet settings.

During “Front End Service” or when jaws

slip on mandrel.

When the quantity of stored spent

Mandrels starts to interfere with

mandrels entering the Collector.

(Storage quantity depends on rivet –

approx. 50-60 1/4” (6.4mm) rivets).

Once a week or when MCS suction will

not pull spent mandrels into the

Collector.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 15

Page 16

Safety Data

SEAL LUBE

LUBRIPLATE

Manufactured by:

Fiske Brothers Refining Co.

Phone: (419) 691-2491

Emergency: (800) 255-3924

ALVANIA® EP Grease 1

Prod Code: 71124

Manufactured by:

Shell Oil Products

Phone: (877) 276-7285

MSDS#: 57072E-5

First Aid:

SKIN:

Remove any contaminated clothing and

wash wit h soap and warm water. If

injected by high pressure under skin,

regardless of the appearance of its size,

contact a physician IMMEDIATELY.

Delay may cause loss of affected part

of body.

INGESTION:

Call a physician immediately. Do not

induce vomiting.

EYES:

Flush with clear water for 15 minutes or

until irritation subsides. If irritation

persists, consult a physic ia n.

Fire:

FLASH POINT: COC- 400°F

Cool exposed containers with water.

Use foam, dry chemical, carbon dioxide

or water spray.

Environment:

WASTE DISPOSAL:

Assure conformity with applicable

disposal regulations. Dispose of

absorbed material at an approved

waste disposal facility or site.

SPILLAGE:

Scrape up grease, wash remainder with

suitable petroleum solvent or add

absorbent.

Handling/ Storage:

Keep containers closed when not in

use. Do not handle or store near heat,

sparks, flame or strong oxidants.

Lubriplate® is a registered trademark of Fiske

Brothers Refining Company.

(P/N: PSA075508P)

®

130-AA

JAW LUBE (P/N: PRG510-130)

SUNPAR 107

Manufactured By:

Sunoco, Inc.

Emergency Phone: (800) 424-9300

First Aid:

SKIN:

Wash with soap and water until no

odor remains. If redness or

swelling develops, obtain medical

assistance. Wash cloths before

reuse.

INGESTION:

Do not induce vomiting! Do not

give liquids! Obtain emergency

medical attention. Small amounts

that accidentally enter mouth

should be rinsed out unti l taste of it

is gone.

EYES:

Flush with water.

Fire:

FLASH POINT: Greater than 200°F

Can be made to burn. Use wat er

spray, regular foam, dry chemical or

carbon dioxide.

Environment:

WASTE DISPOSAL:

Do not flush to drain or storm sewer.

Contract authorized disposal

service.

SPILLAGE:

Contain Spill. Absorb onto inert

material. Shovel, sweep or

vacuum spill.

Handling/ Storage:

NFPA Class IIIB Storage. Avoid

prolonged breathing of mist or

vapor. Avoid prolonged or

repeated contact with skin. Avoid

contact with eyes. Wash thoroughly

after handling.

Please refer to the actual MSDS for complete safety and handling

information. These can be obtained from the point of purchase.

HYDRAULIC OIL (P/N: PRG540-130)

MOBIL DTE 26

Manufactured By:

ExxonMobil Corporation

Emergency Phone: (609) 737-4411

MSDS Fax on Demand:

(613) 228-1467 MSDS # 602649-00

Shell TELLUS 68

Manufactured By:

SOPUS Products

Health Information: (877) 504-9351

MSDS Assistance:

(877) 276-7285 MSDS # 402288L-0

Distributed By:

Emhart Teknologies

Phone: (203) 924-9341

First Aid:

SKIN:

Remove contaminated clothing and

shoes and wipe excess from skin.

Flush skin with water, then wash with

soap and water. If irritation occurs,

get medical attention.

INGESTION:

Do not induce vomiting. In general, no

treatment is necessary unless large

quantities of product are ingested.

However, get medical attention.

EYES:

Flush with water. If irritation occurs, get

medical attention.

Fire:

FLASH POINT: 390°F/198.9°C

Material will float and can be re-ignited

on the surface of water. Use water fog,

‘alcohol foam’, dry chemical or carbon

dioxide (CO2) to extinguish flames. Do

not use a direct stream of water.

Environment:

SPILLAGE:

Soak up residue with an absorbent such

as clay, sand or other suitable material.

Place in a non-leaking container and

seal tightly for proper disposal.

Handling:

Wash with soap and water before

eating, drinking, smoking, applying

cosmetics or using toilet. Properly

dispose of leather articles such as

shoes or belts that cannot be

decontaminated. Use in a well

ventilated area.

Storage:

Store in a cool, d ry pla ce w ith adeq ua t e

ventilation. Keep away from open

flames and high temperatu res.

Page 16 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Page 17

Symptom Probable Cause Remedy

TOOL FAILS TO OPERATE

TOOL NOT RETURNING

Troubleshooting

Tool not connected to air supply.

OS Valve is in “OFF” position.

Insufficient air pr essure.

Air pressure is too high.

Tool is low on hydraulic fluid.

Possible jam due to debris in Nose Housing. Perform “Front End Service” and check for de bris

Connect to recommended air supply source.

Slide OS Valve to ON position.

Adjust air supply pressure.

Adjust air supply pressure.

Service tool by qua lified service personnel.

or damage.

TOOL LOSING STROKE

JAWS SLIPPING ON MANDRELS

JAWS FAIL TO OPEN

MANDREL STICKING IN JAWS

RIVET FAILS TO INSERT INTO

NOSEPIECE

RIVET MANDREL DOES NOT

BREAK

MCS NOT WORKING

LOW VACUUM

Tool low on hydraulic fluid. Service tool by qualified service personnel.

Jaws dirty or need lubrication.

Jaws worn.

Dirty Nose Housing, Jaws or Jaw Guide.

Nose Housing or Nos epiece loose.

Excess hydraulic oil in tool.

Jaws dirty or need lubrication.

Incorrect nosepiece.

Shear ring stuck in hole of nosepiece.

Rivet not fully set.

Mandrel break load requirement too high.

Insufficient air pr essure.

Tool not connected to air supply.

Collector not tight or missing.

Mandrel path blocked.

Dirty Collector Silencer.

Collector is full of mandrels.

Insufficient air pr essure.

Clean and lube jaws.

Replace jaws.

Perform “Front End Service” and clean inside of

Nose Housing.

Tighten Nose Housing or Nosepiece.

Service tool by qua lified service personnel.

Perform “Front End Service” to clean and

lubricate Jaws.

Install correct nosepiece.

Remove shear ring, check for the correct

Nosepiece and review application parameters to

ensure proper riveting.

Repeat stroke required, or change rivet.

Upgrade tool.

Adjust air supply pressure to recommended

level.

Connect to recommended air supply source.

Check Collector.

Clear mandrel path.

Clean or change Collector Silencer.

Discard the mandrels.

Adjust air supply pressure.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 17

Page 18

EC Declaration of Conformity

We, Emhart Teknologies

Tucker Fasteners Limited

Birmingham B42 1BP

United Kingdom.

Declare that:

ProSet® 3400

ProSet® 3400 MCS

Conforms to the following standards:

EN ISO 12100 part 1 and part 2 ISO prEN 15744

ISO 3744 EN 28662 - 1

ISO prEN 792 part 1 EN 12096

EN ISO 4871

Following the provisions of the Machine Directive 98/37/EEC which replaces Directive 89/392/EEC and its

amending Directives 91/368/EEC, 93/44/EEC and 93/68/EEC.

Signed: ____________________________________

Birmingham

st

. July 2008

1

Page 18 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

94'

4

-

,

Eymard Chitty, Vice President, R&D

Page 19

Notes

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 19

Page 20

Blind Rivets

Emhart Teknologies

USA Office

50 Shelton Technology Center

Shelton, CT 06484

Tel: 877-EMHART-1

FAX: 800-225-5614

Canada Office

9870 Boulevard du Golf

Anjou, Quebec Canada

Tel: 514-351-0330

FAX: 514-351-0458

Mexico Office

Av. Antonio Dovali Jaime No 70

Torre B Piso 9

La Fe, Santa Fe

Mexico, D.F. 01210

Tel: 52-55-5326-7100

FAX: 52-55-5236-7141

www.emhartamericas.com

© Emhart Teknologies P551.r3 (01/12)

EMHART

-raccricer_ocims

A StanleyBlack&Decker, Inc. Company

Loading...

Loading...