EMH metering

GmbH & Co. KG

Neu-Galliner Weg 1 • 19258 Gallin

GERMANY

Tel. +49 38851 326-0

Fax +49 38851 326-1129

E-Mail info@emh-metering.com

Web www.emh-metering.com

Tel. +49 38851 326-1930 (Technical Support)

E-Mail support@emh-metering.com

Instructions for use

XC-RACK

Digital 4-Quadrant-/Combi meter

EN

Edition: 27.06.2018 Technical specications are subject to change!

Scope of delivery .................................................................................... 2

Important notes....................................................................................... 2

Target group........................................................................................ 2

Intended Use ...................................................................................... 2

Maintenance and warranty instructions .............................................. 2

Care and disposal instructions............................................................ 3

Basic safety notes............................................................................... 3

Technical data......................................................................................... 4

Housing, display and operating elements............................................... 5

Nameplate .......................................................................................... 6

Display ................................................................................................ 7

Installation and commissioning............................................................... 9

Mounting an connection ................................................................... 10

Installation check register C.86.0 (optional) ..................................... 14

Error register F.F ............................................................................... 15

Abbreviations ........................................................................................ 16

EU Declaration of Conformity ............................................................... 17

XC-RACK-BIA-E-1.70

2

Scope of delivery

Please check the content of the package, before starting with the installation and commissioning.

• 1 XC-RACK device

• 1 Instructions for use

If the content is incomplete or damaged, please contact your source of

supply. Store, use and transport the meter such, that it is protected from

moisture, dirt and damage.

Important notes

This instruction is part of the documentation. All versions of this device

are described in this instruction. Therefore characteristic features may

be described, which are not valid for your device.

Further informations about this device refer to the product manual. Pay attention to all component accompanying documents

when operating this device.

Target group

This instruction is inteded for technicians who are responsible for

installation, connection and maintenance of the device. The device has

to be installed and put into operation only by qualied electricians in accordance with generally accepted rules of technology and if necessary

the regulations, which are relevant for the installation of telecommunications equipment and end devices.

Intended Use

The meter has to be used for measuring electrical energy only and has

to operate within the specied values (refer to nameplate).

Maintenance and warranty instructions

The devices are maintenance-free. In case of damage (e. g. due to

transportation, storage) no repairs may be carried out idependently.

Opening of the meter invalidates any warranty claim. The same applies

for any defect caused by external inuences (e. g. lightning, water, re,

3

extreme temperatures and weather conditions) and any inappropriate or

improper use or handling.

Only authorised personnel are allowed to break the sealing!

Care and disposal instructions

DANGER!

Contact of parts under voltage is extremely dangerous!

When cleaning the housing of the meter, the conductor to which the

meter is connected must be de-energized.

Clean the housing with a dry cloth. Do not use chemical cleaning

agents!

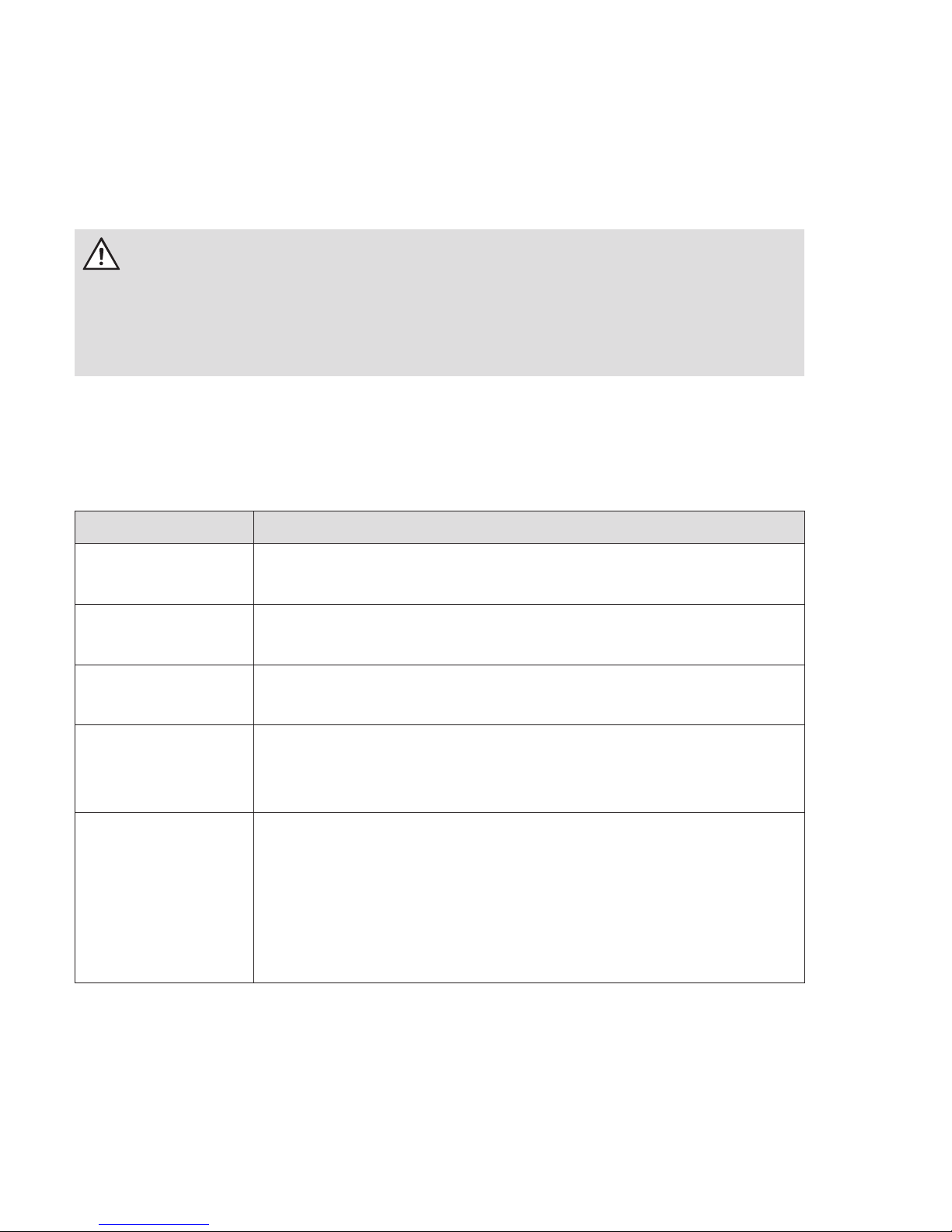

The following table lists the components and how to handle them at the

end of their life cycle:

Components Waste collection and disposal

PCB‘s Electronic waste: dispose in accordance with local

regulations.

LEDs,

LC display

Special waste: dispose in accordance with local

regulations.

Metal parts Scrap, recyclable: separate according to type and

recycle.

Plastic parts Separate according to type and recycle (re-granula-

te). Send for waste incineration if necessary (energy

generation by thermal process).

Batteries When disposing you have to take safety measures

to prevent short circuit. Dispose the batteries inside

the original package or insulate the terminals. Do

not throw the batteries into the domestic waste, but

dispose them correctly in accordance with the local

waste and environmental regulations.

Basic safety notes

The following safety notes have to be observed in principle:

• Observe the local standards, guide lines, regulations and instruc-

tions for safety at work and electrical installations.

4

• Choose the conductor cross section corresponding to the maximum

current loading.

• Provide exible wires with ferrules.

Technical data

Voltage, current,

frequency

see nameplate

Inputs

S0-input

low voltage

or system voltage

maximum number: 1, max. 27 V DC, 27 mA

(not potential-free)

maximum number: 8, 18...40 V DC

maximum number 8, 58...240 V AC

Outputs

Opto-MOSFET

maximum number: 8, max. 250 V AC/DC,

100 mA (make contact)

Temperature range specied operating range: -25 °C...+55 °C

limit range for operation, storage and

transport: -40 °C...+70 °C

Relative humidity max. 95 %, non-condensing, accor-

ding to IEC 62052-11, EN 50470-1 and

IEC 60068-2-30

Class of protection I

Degree or protection

housing

terminals

housing material

IP 50

IP 20

aluminium alloy, polycarbonate, without

halogen

Environmental condi-

tions

mechanical: M1 according to Measuring Ins-

truments Conditions Directive (2014/32/EU)

electromagnetic: E2 according to Measuring

Instruments Conditions Directive (2014/32/

EU)

intended location: indoor according to EN

50470-1

Weight approx. 2,3 kg

5

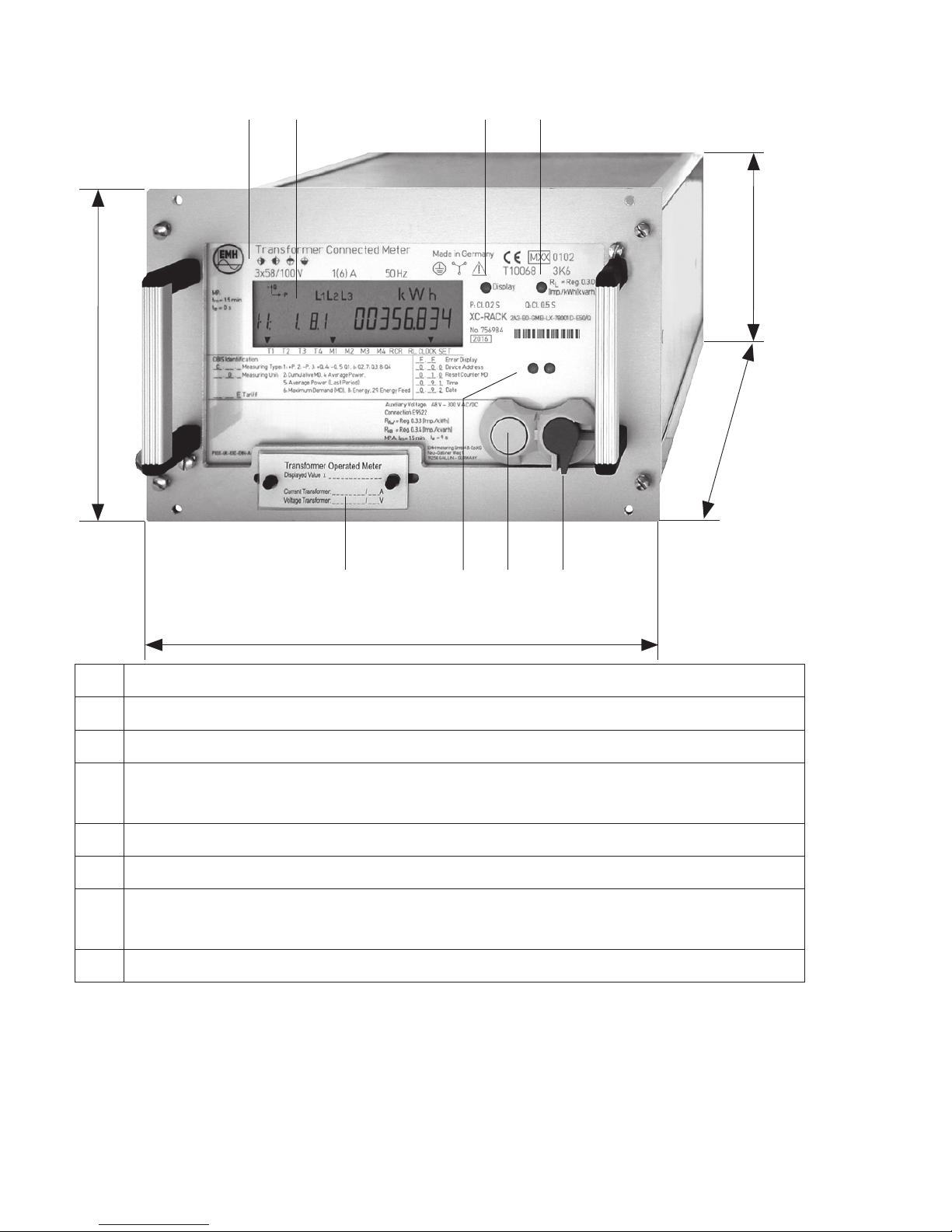

Housing, display and operating elements

1 Nameplate

2 LC display

3 Call-up sensor (optical)

4 Test-LED (continuously lit-up = no energy consumption or incor-

rect ow direction)

5 Reset button (sealable)

6 Call-up button

7 Optical data interface (D0) with magnetic xing for the optical

communication head

8 Sealable transformer plate

21 3 4

8 67 5

203 mm

132,5 mm

112 mm

264 mm

6

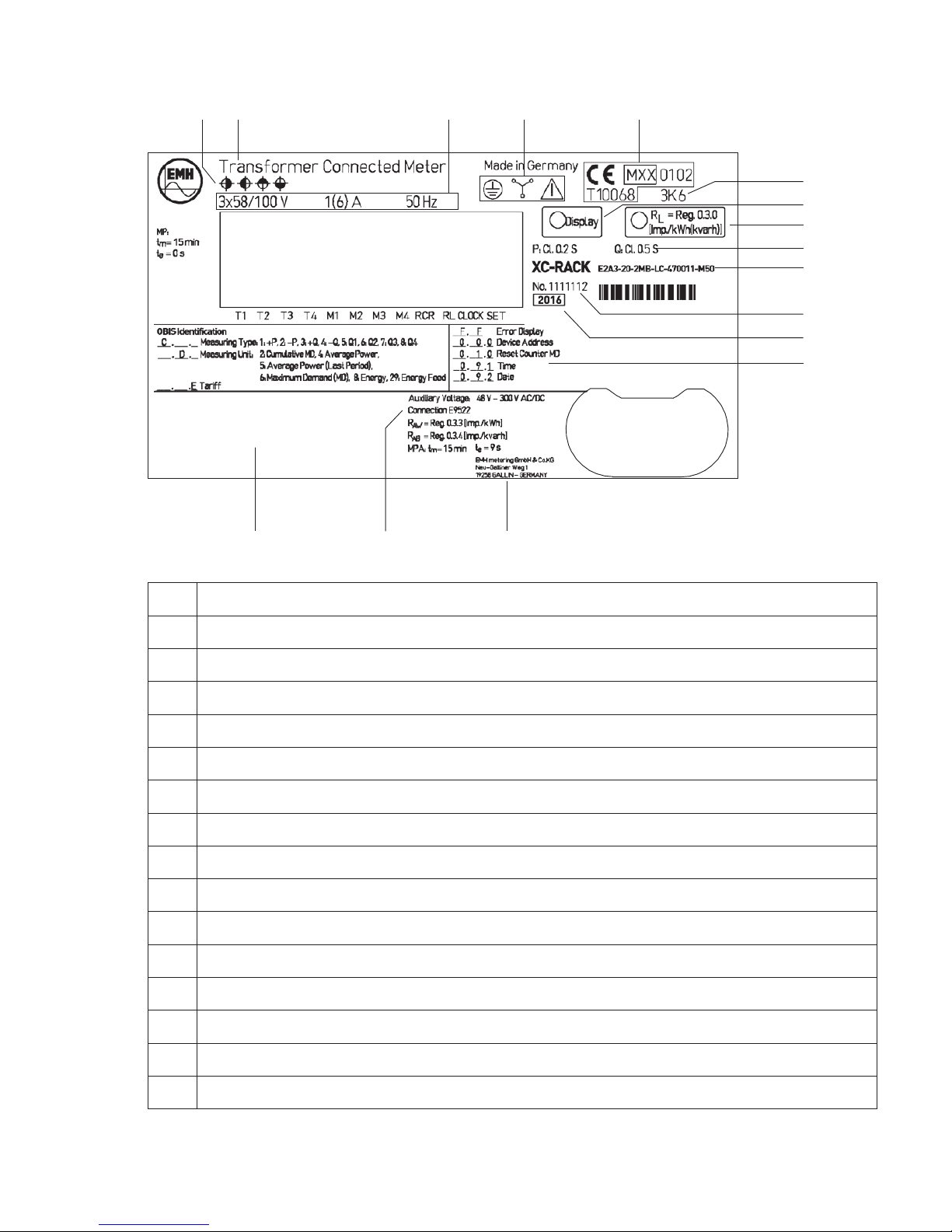

Nameplate

1 Registered quadrants

2 Type designation

3 Voltage, current, frequency

4 Safety and instruction notes

5 Conformity and approval mark

6 Temperature class according to IEC 60721-3-3

7 Call-up sensor (optical)

8 Test-LED

9 Accuracy class

10 Type key

11 Serial number

12 Model year

13 OBIS-index of the most important registers

14 Manufacturer address

15 Contact sequence number

16 Space for ownership inscription

6

7

11

12

13

8

9

10

2 3 4 51

1516 14

7

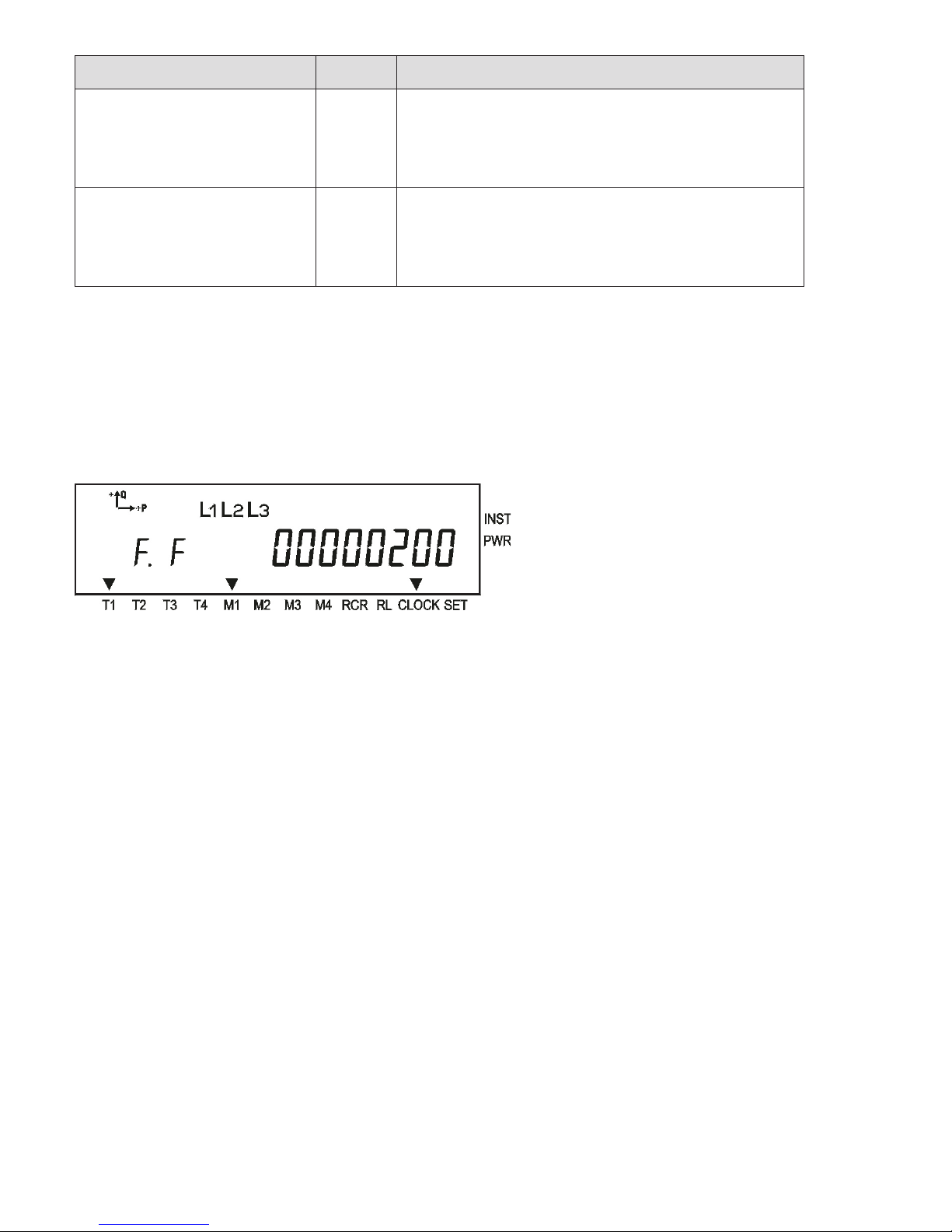

Display

1. The operation display shows the current direction of energy as

measured by the meter (export/import of active energy, export/im-

port of inductive/capactive reactive energy). If current is owing it is

possible to see in which quadrant is being measured by means of

the energy direction arrow:

1. quadrant +P/+Q 3. quadrant –P/–Q

2. quadrant –P/+Q 4. quadrant +P/–Q

2. The battery status display shows the charging status of the buffer

battery of the real time clock. The following display are possible:

= Full voltage, real-time clock is buffered when there is no

voltage

= discharged, no buffering of the real time clock is possible

The battery status display appears only with devices with a

battery-bufered Real Time Clock.

3. The communication display is continually lit-up when there

is communication with the meter via data interfaces (optical or

electrical) or the display ashes when the parameterisation status

is active. At a XC-Rack with LMN-interface the Display lights up in

irregular intervals, because it communicated intern, to provide the

collection of the data by SMGW.

INST

PWR

T1 T2 T3 T4 M1 M2 M3 M4 RCR RL CLOCK SET

1 2 4 5 63

8 79

8

4. The phase display signalises connection of the individual phase

voltages. With an incorrect rotating eld all three symbols ash.

5. The unit is displayed corresponding to the measured energy type or

the displayed measured value.

6. In the additional cursor eld operation conditions of the meter are

represented. The black arrows show if an installation error has been

registered or if the power threshold has been exceeded.

INST The cursor is active if an entry has been registered in the

installation check register.

PWR The cursor is active, if a power threshold set in the meter

is exceeded.

7. In the standard cursor eld operation conditions of the meter are

represented. The black arrows show which tariff and maximum

demand is active and via which hardware (clock or ripple control

receiver) the meter is controlled.

T1 - T4 Tariff information for energy. All tariff registers which can

be activated are displayed on the nameplate.

M1 - M4 Tariff information for maximum demand. All tariff registers

which can be activated are displayed on the nameplate

RCR The cursor ashes, when the internal ripple control recei-

ver is activated and ready to receive. The relevant cursor

is continually active when the internal RCR receives a

telegram.

RL The cursor ashes for the duration of the activation of a

reset inhibition.

CLOCK The cursor is active, if the internal clock controls the tariff

device.

SET The cursor is active, when the meter is in the set mode.

8. In the value area the measured values are represented.

9. In this OBIS code area the measured values are dened by means

of the OBIS code. The display is capable of displaying the long

OBIS code.

9

DANGER!

Contact of parts under voltage is extremely dangerous!

When installing or changing the meter, the conductor to which the

meter is connected must be de-energized.

• Remove the relevant back-up fuses, for two-sided supply on the

mains side as well as on the generation side.

• Store the back-up fuses in such a way that other people cannot

ret them unnoticed.

• If you use selective circuit breakers for disconnection from the

mains, secure them against being switched on again unnoticed.

• Only use the dedicated screw terminals for installation and connection of the meter.

Installation and commissioning

DANGER!

Risk of danger to life due to electric arc and electric shock!

The in- and outputs including the external power supply inputs are not

secured internally.

• Secure the inputs/external power supply inputs with back-up fuses

of ≤ 0,5 A according to valid technical directives.

• Secure the outputs in compliance with the current value speci-

ed on the nameplate of the meter according to valid technical

directives.

NOTICE!

Damage of the terminals due to excessive torque!

The appropriate torque depends on the type of the connection line and

on the maximum current.

• Tighten the terminals with the required torque according to

IEC 60999-1.

10

DANGER!

Contact of parts under voltage is life endangering!

S0-inputs are not potential-free. The S0-inputs are, depending on the

voltage version, internally electrical connected to the measurement

connections or to the auxiliary voltage and therefore potential carrying.

• Observe the device-specic wiring diagram inside the terminal

cover.

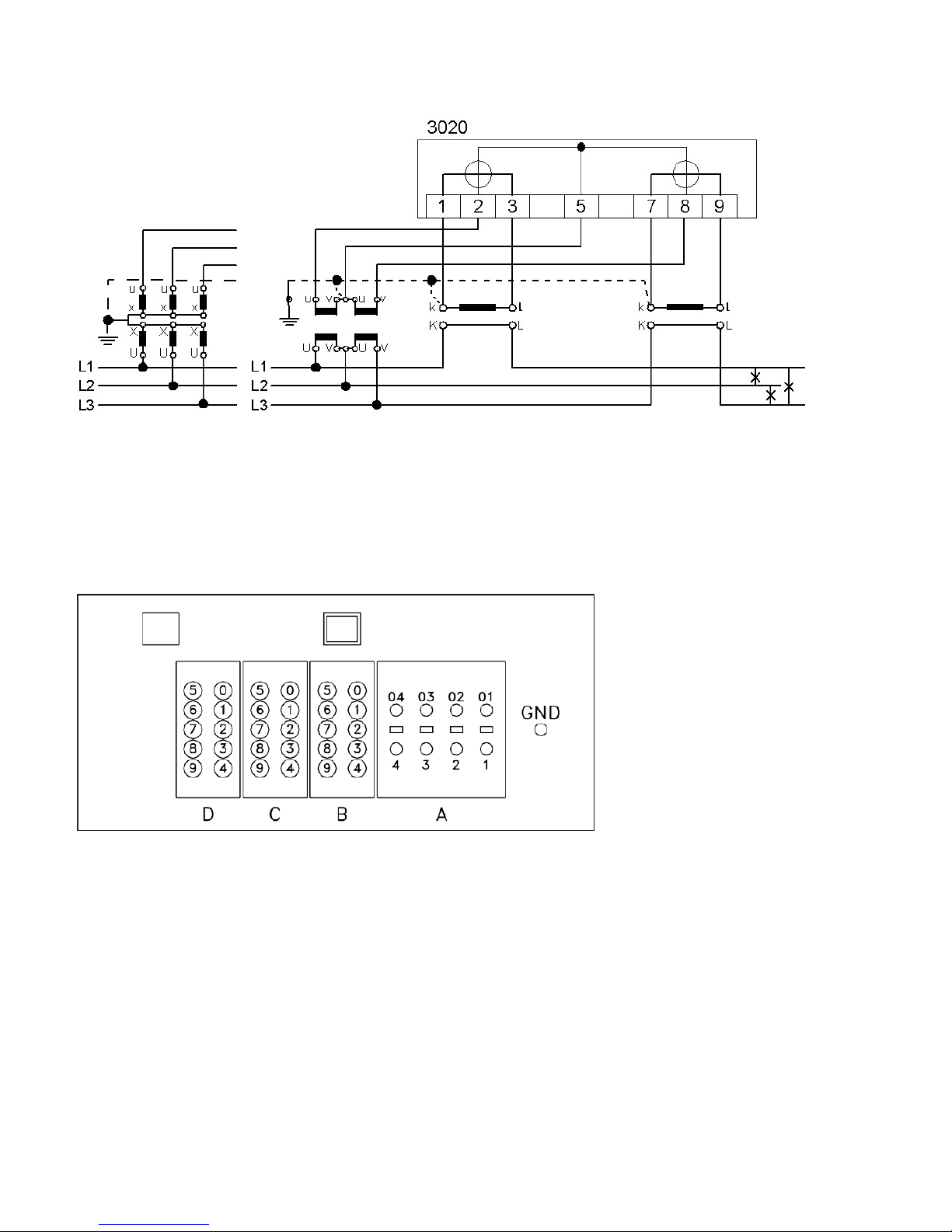

Mounting an connection

The meters are suitable for mounting in a 19″ racks.

DANGER!

Low voltage inputs are separated from hazardous live voltages only

by basic insulation. Therefore the low voltage inputs should not be

accessible under normal operational conditions.

The valid wiring diagram can be found on the top of the meter and also

in the delivery documents. Please refer also to the chapter “installation

check register C.86.0“ on page 14.

Transfomer operated meter for connection to current and voltage

transformers in four-wire systems.

A A A A A AB B B B

01 1 1 02 2 2 03 33 0

L1

L2

L3

u u u

x x x

X XX

UUU

k k k

K K KL L L

4020

11

Transformer connected meter for connection at current and

voltage transformers in three-wire systems (Aron circuit).

The terminals of the meter are at the back. Following variants for connecting the meter are available:

a) Meter with Essailec-plug-in system

Communication interface

Optical bre interface

LLS

12

The conguration of the contacts is variable and can be set by the

customer. For example:

Contact Meaning Contact Meaning

D0 RS485 B+ C0 A+ GND

D5 RS485 A- C1 A+ Pulses

D1 RS485 GND C3 R+ Pulses

D2 S0- C4 R+ GND

D7 S0+ C5 A- Pulses

D4 MPA+ C6 A- GND

D9 MPA- C8 R- Pulses

C9 R- GND

Contact Meaning Contact Meaning

B0 N = Neutral A1 - A01 Current phase 1

B1 Voltage phase 1 A2 - A02 Current phase 2

B2 Voltage phase 2 A3 - A03 Current phase 3

B3 Voltage phase 3

B5 Auxiliary voltage

B6 Auxiliary voltage

b) Meter with Sub-D plug

Communication interface

Optical bre interface

LLS

The conguration of the Essailec contacts is variable and can be set as

shown above. Pin assignment of the Sub-D plug is x:

Contact Meaning

5 GND

3 RS485 B+

8 RS485 A-

13

c) Meter with Phoenix screw-type terminals

Ethernet interface

Optical bre interface LLS

The conguration of the contacts is variable and can be set by the

customer. For example:

Contact Meaning Contact Meaning

1

Current phase 1 In

3

Current phase 1 Out

4

Current phase 2 In

6

Current phase 2 Out

7

Current phase 3 In

9

Current phase 3 Out

2

Voltage phase 1

20

S0+

5

Voltage phase 2

21

S0-

8

Voltage phase 3

27

RS485 A-

11

N = Neutral

28

RS485 B+

40

GND pulses

29

RS485 GND

41

A+ Pulses

37

MPA+

42

A- Pulses

35

MPA-

43

R+ Pulses

90

GND pulse inputs

44

R- Pulses

91

Pulse input 1

92

Pulse input 2

93

Pulse input 3

94

Pulse input 4

14

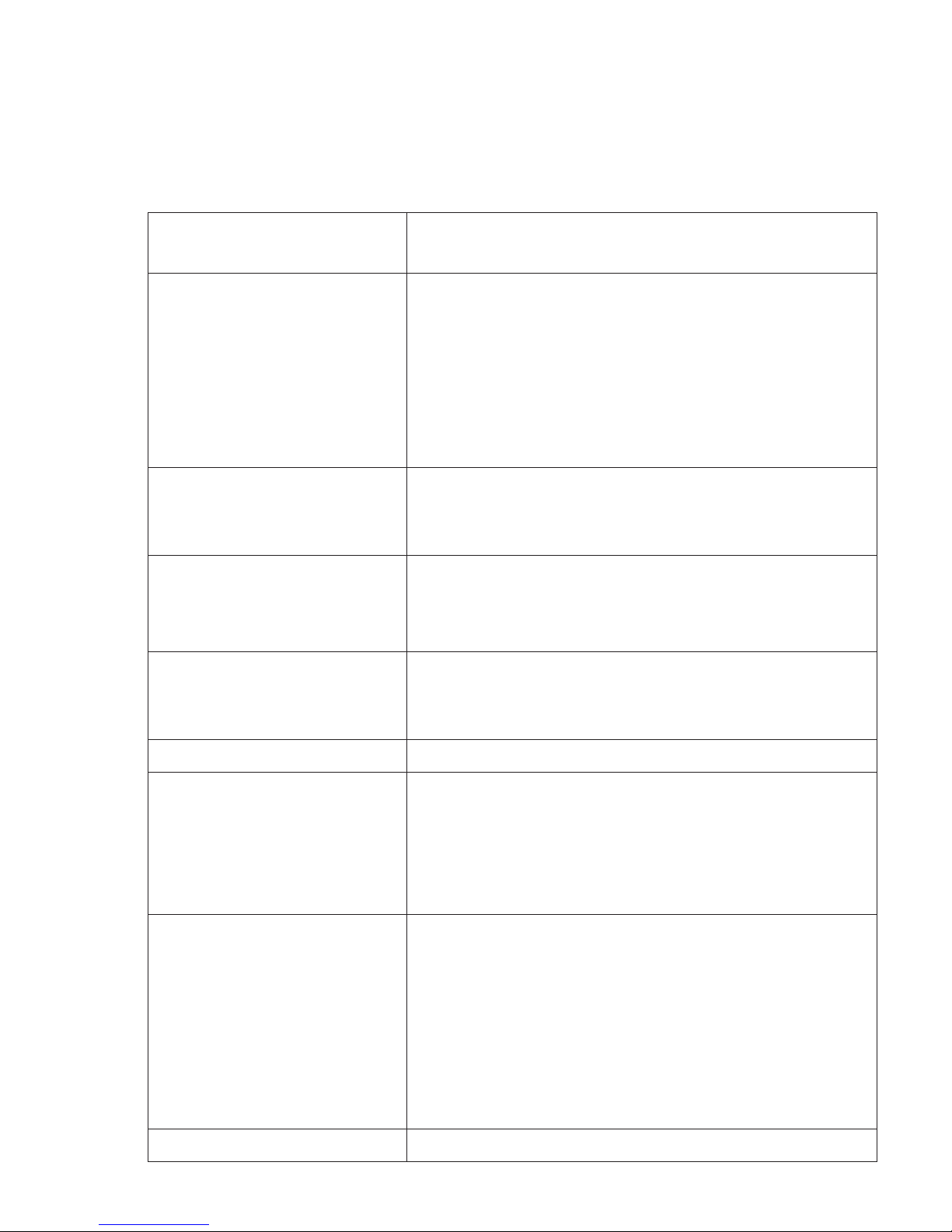

Installation check register C.86.0 (optional)

The installation check register C.86.0 registrates installation errors.

Normally, it is shown in the scrolling list or can be called up via the callup list.

Not used

Wrong phase sequence

Phase failure

Negative energy direction

Current interruption

Max. current exceeded

Undervoltage

Overvoltage

Event Value Meaning

Wrong phase sequence

1

Loss of neutral

2

Wrong phase sequence

4

Assymetric current, e. g. 30 %

8

Assymetric voltage, e. g. 18 %

Phase failure

1

Phase failure L1

2

Phase failure L2

4

Phase failure L3

8

Failure of auxiliary supply voltage

Negative energy

direction

1

Negative energy direction L1 (P)

2

Negative energy direction L2 (P)

4

Negative energy direction L3 (P)

Current interruption

1

Current interruption L1

2

Current interruption L2

4

Current interruption L3

Maximum current

exceeded

(I > Imax)

1

Maximum current exceeded L1

2

Maximum current exceeded L2

4

Maximum current exceeded L3

15

Event Value Meaning

Undervoltage

(U < 80 %)

1

Undervoltage L1

2

Undervoltage L2

4

Undervoltage L3

Overvoltage

(U > 115 %)

1

Overvoltage L1

2

Overvoltage L2

4

Overvoltage L3

Error register F.F

The meter has 32 error ags which are represented by a 8 digit Hex-

code. With the help of this register, functional errors in the meter are

registered. Output of the error register takes place via the display and

one of the readout lists.

Clearing the error register

To clear the error register use the W5-write command F.F(). To be able

to execute this command the meter must be in the parameterisation

status. After carrying out the command the parameterisation status is

switched off.

Further informations about the error register F.F refer to the product

manual.

16

Abbreviations

DIN Deutsches Institut für Normung e.V.

(German Institute for standards)

EN European standards

GND Ground

IEC International Electrotechnical Commission

IP Ingress Protection

L1, L2, L3 External conductor

LC Liquid Crystal

LED Light Emitting Diode

OBIS Object-Identication-System

P Active power

+P Positive active power (customer imports from utility)

-P Negative active power (customer exports to utility)

PCB Printed Circuit Board

Q Reactive power

+Q Positive reactive power

-Q Negative reactive power

RCR Ripple control receiver

S0 Interface according to IEC 62053-31

17

The current EU Declaration of Conformity can be found in the

download area of www.emh-metering.com.

EU Declaration of Conformity

18

19

20

Loading...

Loading...