Emerson EMC DX-202, DX-205, DX-318, DX-430, DX-450 User Manual

...

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

EMERSON EMC

POSITIONING DRIVES & MOTORS

- - -

Including IOM-1, PCM-1, PCM-5

T-16, Thumbwheels, and Parallel Programming

Other Manuals available, but bound separately:

T-21 Data Entry Panel

Information furnished by EMERSON EMC is believed to be

accurate and reliable. However, no responsibility is assumed

by MERSON EMC for its use. EMERSON EMC reserves the

right to change the design or operation of the equipment

described herein and any associated motion products without

notice. EMERSON EMC also assumes no responsibility for

any errors that may appear in this document. Information in

this document is subject to change without notice.

P/N 400221-00 REV: A7

DATE: 6/24/92

- 1 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TABLE OF CONTENTS

INTRODUCTION....................................................................................................................................................... 6

OVERVIEW ............................................................................................................................................................. 6

S

YSTEM OVERVIEW ................................................................................................................................................... 7

I

NTRODUCTION TO THE BASIC POSITIONING DRIVE AMPLIFIER ................................................................................... 8

P

ERIPHERALS ............................................................................................................................................................. 9

O

PERATOR INTERFACE............................................................................................................................................. 10

T-21 D

ATA ENTRY TERMINAL ................................................................................................................................. 10

T-16 N

UMERIC DISPLAY.......................................................................................................................................... 10

TW-XXX T

POSITIONING DRIVE SPECIFICATIONS......................................................................................................... 12

DX-SERIES MOTORS AND AMPLIFIERS TYPICAL SPEED TORQUE CURVES ........................................ 15

INSTALLATION...................................................................................................................................................... 17

ASSEMBLY AND INSTALLATION CONSIDERATIONS ................................................................................ 17

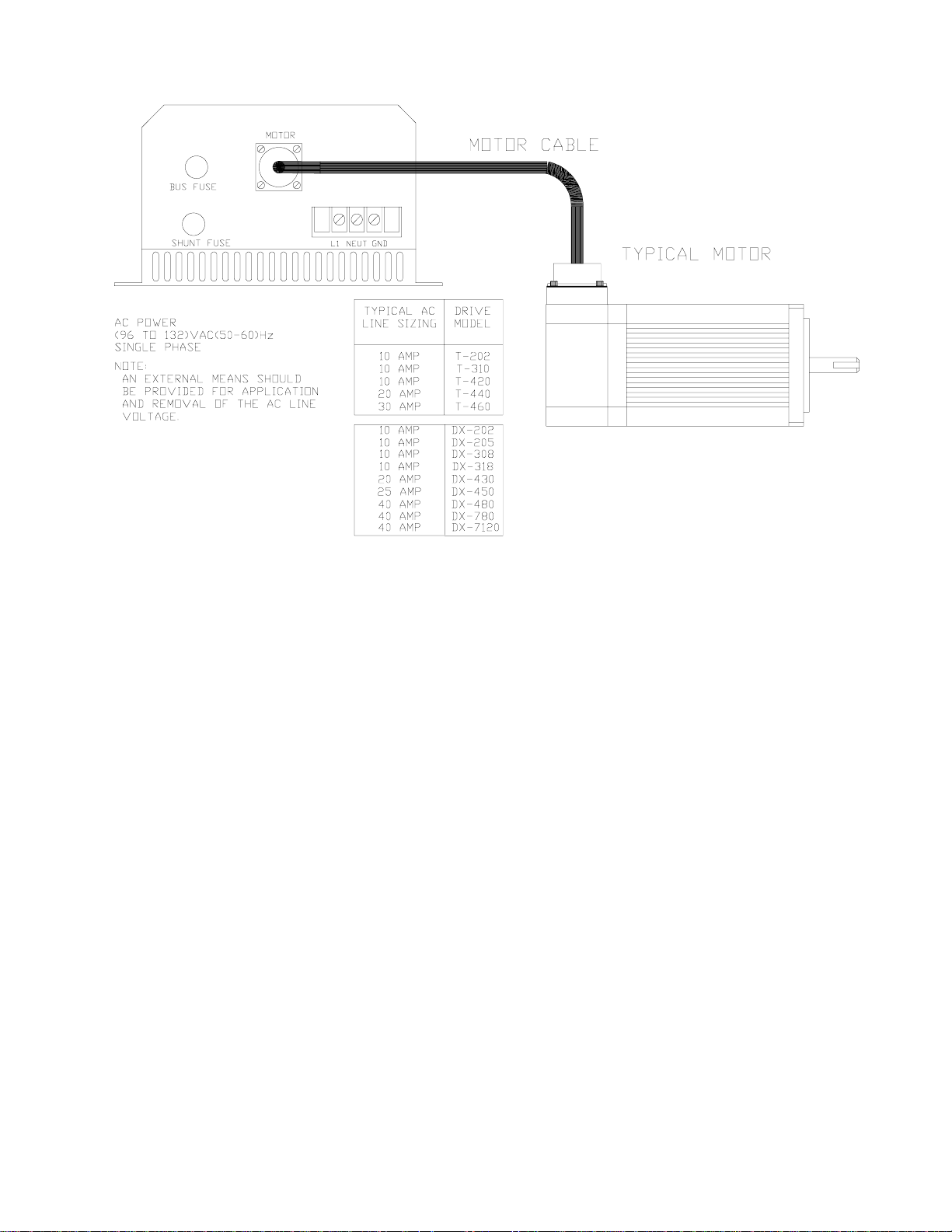

TYPICAL 120 VAC LINE SIZING (SINGLE PHASE MODELS)....................................................................... 18

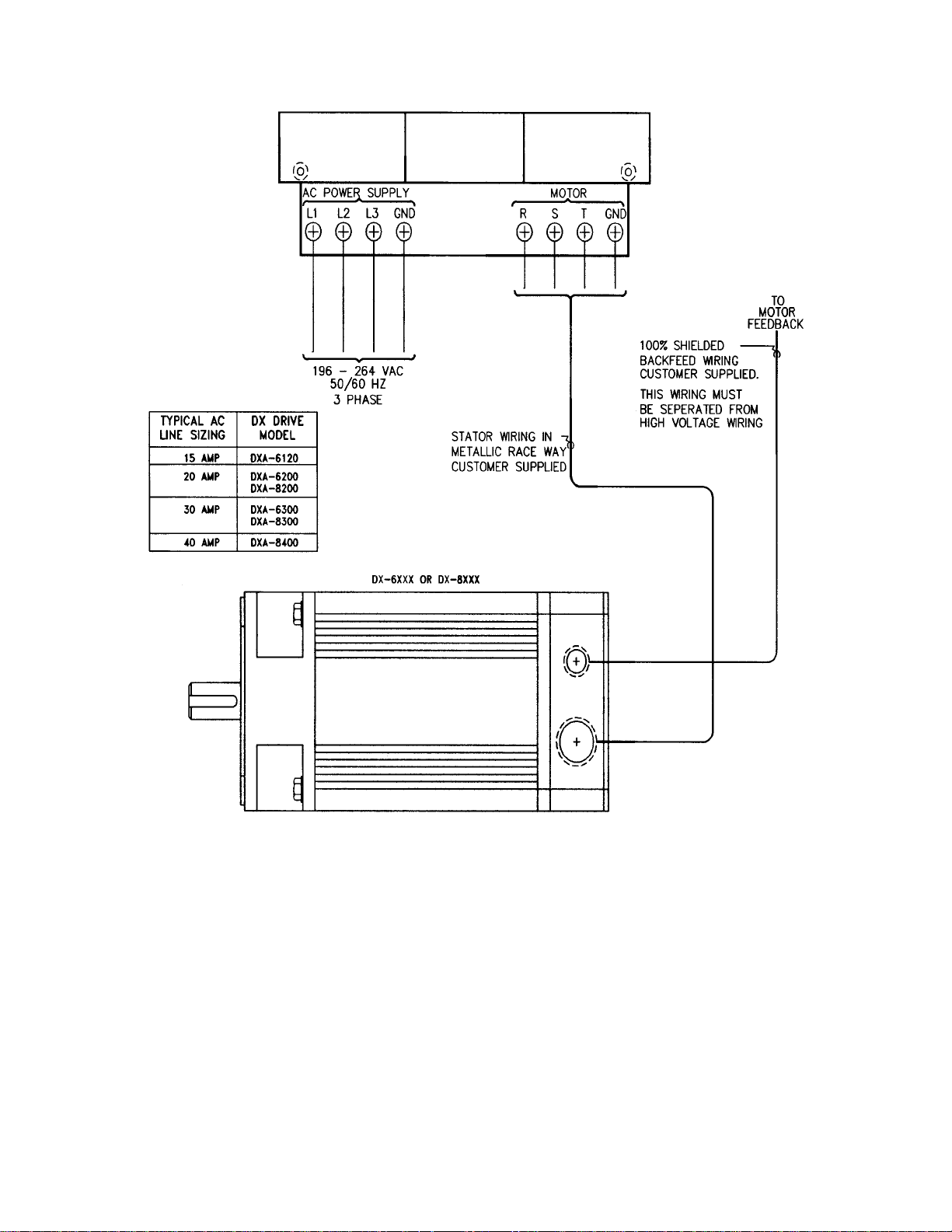

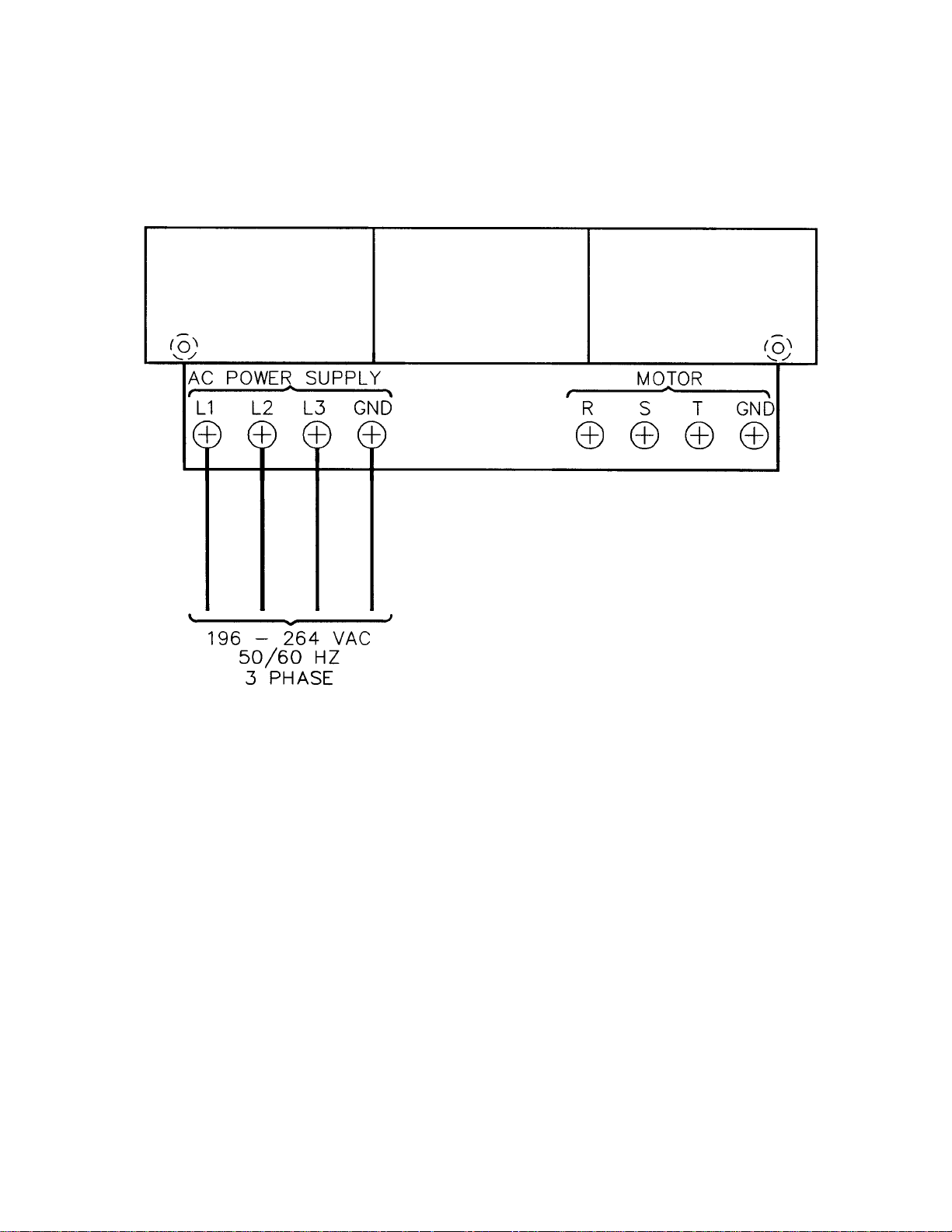

TYPICAL 230 VAC 3 PHASE MODELS.............................................................................................................. 19

AMPLIFIER MOUNTING INFORMATION ........................................................................................................ 27

AMPLIFER I/O LOCATIONS............................................................................................................................... 32

MOTOR MECHANICAL INFORMATION.......................................................................................................... 36

MOTOR WIRING .................................................................................................................................................. 43

MAIN/AUXILIARY AX

CABLE WIRING DIAGRAMS.............................................................................................................................. 48

HUMBWHEEL INTERFACE...................................................................................................................... 10

Wiring Considerations .......................................................................................................................................................20

Safety Considerations ........................................................................................................................................................21

Brake Option......................................................................................................................................................................21

Power Line......................................................................................................................................................................... 21

Grounding Considerations .................................................................................................................................................23

Electrical Noise..................................................................................................................................................................25

Magnetic Coil Noise ..........................................................................................................................................................25

Mechanical Consideration..................................................................................................................................................26

Load Coupling ...................................................................................................................................................................26

Selecting An Enclosure......................................................................................................................................................27

Amplifier Losses................................................................................................................................................................ 27

System Troubleshooting ....................................................................................................................................................27

POWER ......................................................................................................................... 46

TDS/TDL CABLE.............................................................................................................................................................48

TDT Cable .........................................................................................................................................................................48

Optional Bulkhead Connectors ..........................................................................................................................................49

OPERATING MODES............................................................................................................................................. 50

MODE SELECTION .............................................................................................................................................. 51

POSITIONING DRIVE CONFIGURATION AND PROGRAMMING ............................................................. 57

How To Start......................................................................................................................................................................58

PCX Program Revision...................................................................................................................................................... 58

Moving Through The Menus .............................................................................................................................................58

Changing Values In The Data Enter Screens .....................................................................................................................58

USING PCX DISK FILES...................................................................................................................................... 59

1. Data File........................................................................................................................................................................59

2. List File.........................................................................................................................................................................59

On-line Operations.............................................................................................................................................................60

ESTABLISHING COMMUNICATIONS .............................................................................................................. 62

DISK FILE OPERATIONS .................................................................................................................................... 63

DRIVE SETUP ....................................................................................................................................................... 64

LIMITS ................................................................................................................................................................... 68

INDEXING OPERATION MODE......................................................................................................................... 70

JOG ......................................................................................................................................................................... 75

HOME..................................................................................................................................................................... 76

OVERVIEW OF BASIC OPERATION MODES.................................................................................................. 84

Serial Mode........................................................................................................................................................................84

- 2 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Output Functions................................................................................................................................................................87

Input Functions ..................................................................................................................................................................88

DIAGNOSTICS......................................................................................................................................................... 98

F -POSITION ERROR FAULT............................................................................................................................ 100

FAULT INDICATOR CODES............................................................................................................................. 101

STABILIZATION OF HIGH INERTIA LOADS ................................................................................................ 106

INSTALLATION OF THE IOM-1 ....................................................................................................................... 107

INPUT/OUTPUT INTERFACE ........................................................................................................................... 108

Output Functions..............................................................................................................................................................110

Input Functions ................................................................................................................................................................111

EXAMPLES OF I/O CONNECTIONS TO THE IOM-1 ..................................................................................... 112

Detailed Description of Additional I/O Functions With the Addition of the IOM-1........................................................113

Input Functions ................................................................................................................................................................113

Output Function ...............................................................................................................................................................113

PARALLEL INTERFACE .................................................................................................................................... 114

CUSTOMER SUPPLIED THUMBWHEEL INTERFACE ................................................................................. 115

Thumbwheel Wiring........................................................................................................................................................116

PARALLEL PROGRAMMING INTERFACE ................................................................................................... 123

THUMBWHEEL AND PARALLEL PROGRAMMING SETUP AND OPERATION................................... 129

THUMBWHEEL AND PARALLEL PROGRAMMING INTERFACE ............................................................. 129

DATA FIELD NUMBER ................................................................................................................................................129

DATA FIELD PURPOSE................................................................................................................................................130

INDEX NUMBER ................................................................................................................................................ 131

T-16 SETUP AND OPERATION ........................................................................................................................ 136

INSTALLATION AND CONNECTIONS OF THE PCM-1 ............................................................................... 138

INPUT/OUTPUT INTERFACE (PCM-1)............................................................................................................ 139

OVERVIEW ......................................................................................................................................................... 139

O

UTPUT FUNCTIONS .............................................................................................................................................. 141

WHAT ARE PROGRAMS?................................................................................................................................. 147

DESCRIPTION OF PROGRAMMING FUNCTIONS ........................................................................................ 149

WAIT FOR INPUT..........................................................................................................................................................149

DWELL TIME.................................................................................................................................................................149

UPDATE OUTPUTS.......................................................................................................................................................149

EXECUTE INDEX..........................................................................................................................................................149

EXECUTE PROGRAM...................................................................................................................................................149

EXECUTE COMPOUND INDEX ..................................................................................................................................149

END .................................................................................................................................................................................149

HOW TO CREATE A PROGRAM...................................................................................................................... 151

PROGRAMMING CAPABILITIES .................................................................................................................... 154

SUSPEND/RESUME FUNCTIONS...................................................................................................................... 155

E

XTENDED SUSPEND/RESUME PROGRAMMING...................................................................................................... 156

INSTALLATION AND CONNECTIONS OF PCM-5........................................................................................ 158

SYNCHRONIZATION CABLE........................................................................................................................... 159

SCS-2 SYNC

ENCODER..................................................................................................................................... 161

BASIC OPERATION ........................................................................................................................................... 162

Some Application Examples............................................................................................................................................162

BI-POLAR SYNCHRONIZATION ..................................................................................................................... 168

ADDITIONAL PCM-5 PROGRAMMING .......................................................................................................... 177

PARAMETERS .................................................................................................................................................... 177

LEAD AXIS.......................................................................................................................................................... 177

SYNC RATIO....................................................................................................................................................... 177

SYNC VELOCITY SCALE FACTOR AND SYNC VELOCITY DECIMAL POINT ....................................... 178

BI-POLAR SYNC ENABLED............................................................................................................................. 179

INDEX, HOME .................................................................................................................................................... 179

PROGRAMS......................................................................................................................................................... 180

- 3 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SERIAL INTERFACE ........................................................................................................................................... 182

EXAMPLE OF A SERIAL MULTI-DROP CONNECTION............................................................................... 183

SERIAL SIGNAL FLOW DIAGRAMS............................................................................................................... 183

SETTING UP THE SERIAL INTERFACE SWITCHES AND PROTOCOL ..................................................... 184

LOCATIONS OF SWITCHES ............................................................................................................................. 184

SERIAL CABLES ................................................................................................................................................ 186

Wiring Diagrams From Computer to Drive .....................................................................................................................186

Wiring Diagram for DD-XXX Multi-Drop Cable............................................................................................................187

SERIAL INTERFACE CONTROL...................................................................................................................... 188

ASCII COMMANDS............................................................................................................................................ 189

SUMMARY OF SERIAL COMMANDS.............................................................................................................. 210

INDEX...................................................................................................................................................................... 216

- 4 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CUSTOMER SERVICE

Emerson EMC offers a wide range of services to support our customers’ needs. Listed below are

some examples of these services.

SERVICE SUPPORT (612) 474-8833

Emerson Electronic Motion Control’s products are backed by a team of professionals who will

service your installation wherever it may be. Our Customer Service Center in Minneapolis,

Minnesota, is ready to help you solve these occasional problems over the telephone. It’s there, at

the Center, that we are available 24 hours a day for emergency service to help speed any problem

solving. Also, all hardware replacement parts, should they ever be needed, are available through

our customer service organization. Need on-site help? Emerson provides on-site service, in

most cases, the next day. Just call Emerson’s Customer Service Center when on-site service or

maintenance is required.

TRAINING SERVICES (612) 474-1116

Emerson EMC maintains a highly trained staff of instructors to familiarize customers with

Emerson Electronic Motion Controls and their applications. A number of courses are offered,

many of which can be taught in your plant upon request.

APPLICATION ENGINEERING (612) 474-1117

An experienced staff of factory Application Engineers provides complete customer support for

tough or complex applications. Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

- 5 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION

OVERVIEW

The EMERSON EMC Positioning Drives are the first servo products specifically designed to

offer high performance position control without the maze of boards, wires, connectors, pot

adjustments and transformers normally associated with servo systems. The DX-Series drives

support brushless motors and range in size from 2 in-lbs. To 400 in-lbs., continuous. Special

care in motor selection has resulted in drives that have excellent torque to inertia ratios.

The drives consist of ruggedly constructed enclosures which contains all the required

components for position and velocity control. The drives also provide connections for

interfacing with external machine inputs and outputs, and logic control, along with a serial

interface port that is used to program the drive.

Calibration

Calibration of the Positioning Drive is virtually eliminated because all user potentiometer

adjustments have been eliminated. The potentiometer adjustments have been replaced by

firmware. The software pre-sets the compensation values and continuously adjusts these values

during motion. This allows the system to operate over a large inertial range without any manual

adjustments or tuning required.

Installation

Installation and wiring is fast and easy because the Positioning Drive operates in most

environments directly from an AC line source without requiring a separate isolation transformer.

The unit is designed to be back mounted within a standard Nema enclosure typically found in a

production facility. The size has also been minimized to allow users to reduce the space

requirements for incorporating a servo control into their production machinery.

Motor

Each Positioning Drive includes a high performance servo motor whose characteristics have

been matched to the drive amplifier. Thus, the chance for a mismatch between the motor and the

Positioning Drive is eliminated.

Programming and Troubleshooting

EMERSON EMC provides an easy to use software programming package with every drive that

operates on an IBM PC/XT/AT or compatible computer with 512K bytes of RAM and a serial

interface port. This software makes the Positioning Drive simple to program even for first time

servo users. It is almost essential that the user of the positioning servo drive have access to a

personal computer (PC). The PC can be used to change data, up and down load data and most

importantly, help solve problems during operation and startup.

- 6 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

System Overview

Following are the specific model numbers used in configuring the Positioning Drives.

Table I Positioning Drive Components

DX-202 (2 in-lbs.) DXA-202 Amplifier

DXM-202 Motor

TDT-XX Cable

DX-205 (5 in-lbs.) DXA-205 Amplifier

DXM-202 Motor

TDT-XX Cable

DX-308 (8 in-lbs.) DXA-308 Amplifier

DXM Motor

TDL-XX Cable

DX-318 (18 in-lbs.) DXA-318 Amplifier

DXM Motor

TDL-XX Cable

DX-430 (30 in-lbs.) DXA-430 Amplifer

DXM or DXE-430 Motor*

TDL-XX Cable

DX-450 (50 in-lbs.) DXA-450 Amplififer

DXM or DXE-430 Motor*

TDL-XX Cable

DX-480 (80 in-lbs.) DXA-480 Amplifier

DXM or DXE-480 Motor*

TDL-XX Cable

DX-780 (80 in-lbs.) DXA-780 Amplifier

DXM-780 Motor

TDL-XX Cable

DX-7120 (120 in-lbs.) DXA-7120 Amplifier

DXM-7120 Motor

TDL-XX Cable

DX-6120 (120 in-lbs.) DXA-6120 Amplifier

DXM-6120 Motor

RC-XX Cable

DX-6200 (300 in-lbs.) DXA-6200 Amplifier

DXM-6200 Motor

RC-XX Cable

DX-6300 (300 in-lbs.) DXA-6300 Amplifier

DXM-6300 Motor

RC-XX Cable

DX-8200 (200 in-lbs.) DXA-8200 Amplifier

DXM-8200 Motor

DX-8300 (300 in-lbs.)

DX-8400 (400 in-lbs.) DXA-8400 Amplifier

NOTE: The DX-8XXX series motor and Amplifiers are interconnected Via screw terminals so as to

allow for customer provided wiring Not to exceed 100ft.

NOTE: XX = CABLE LENGTH (FT)15

25 25

50 50

*NOTE: DX-430, DX-450 and DX-480 Drives can be provided with Motors that have either typical

English or metric flange and Shaft dimensions. The metric motor is designated with a DXM

prefix and the English version is designated with a DXE prefix.

DXA-8300 Amplifier

DXM-8300 Motor

DXM-8400 Motor

- 7 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Introduction to the basic positioning drive amplifier

The Positioning Drive amplifier is different from common analog amplifiers in that it includes a

position feedback loop and the electronics to control motion functions. To accomplish this, the

motor uses resolver feedback. The resolver converter electronics in the amplifier develops

velocity and position feedback signals required for high performance and precise velocity and

position control.

In addition the amplifier offers three standard modes of control providing a host of alternatives

for implementing real time motion control.

In the ANALOG TORQUE or VELOCITY mode, the amplifier responds to a conventional +/10 volt signal. Most variable speed drives and servo amplifiers on the market today receive

commands via analog input.

The true power and versatility of the Positioning Drive is best utilized in the additional

positioning control modes. In most applications the user will use one of the following modes of

operation.

In the PULSE mode, the drive responds to a serial pulse train representing externally generated

incremental position change commands. These commands are normally in the form of CW or

CCW directional pulses. This mode is commonly used to control DC stepper motors or numeric

controlled (CNC) machinery.

The INDEXING mode allows up to thirty-two different indexes or positions to be preprogrammed and stored in a non-volatile memory. These indexes plus other commands such as

STOP and JOG are selected easily by the drive’s parallel input/output (I/O) lines from devices

such as PLCs or operator push buttons. Parallel I/O commands can be used for stand alone

operation or, simultaneously in conjunction with any other two control modes.

Another powerful feature of the INDEXING mode allows ASCII commands through the

standard RS423 serial interface. This interface port allows the user to down load new

dimensional data e.g., position, distance, velocity, etc., and command an internally generated

index using those parameters. These ASCII serial commands are well suited to operation from

the RS232C serial interface on an IBM Personal Computer (PC) or Programmable Logic

Controller (PLC) with ASCII or Basic Module.

For additional stand alone motion control capability, the drive is designed to accept a series of

application oriented modules called “PCM” modules. The PCMs can be attached to any drive by

simply plugging them onto the front. The PCM is designed to share the power supply inside of

the drive and includes 12 additional optically isolated inputs/outputs (making a total of 24).

When attached, the PCM module extends the operation of the Positioning Drive system.

The IOM-1, PCM-1, PCM-2 and PCM-5 modules are designed to be plug-on additions to

EMERSON EMC’s line of Positioning Drives. Each module is intended to enhance a specific

performance characteristic of the positioning drives.

- 8 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Peripherals

IOM-1 Input/Output Expander Module

The IOM Module mounts to the front of the basic drive to double the I/O capability for those

applications where the number of inputs and outputs provided with the basic unit are not

adequate for interfacing motion to the machine logic controllers. Each of these lines are

optically isolated and can be connected in either a current sinking or current sourcing

arrangement. In addition, the IOM-1 includes the parallel interface port required for connecting

1 or 2 thumbwheels and 1 remote display or parallel communications with a PLC.

PCM-1

The PCM-1 module converts the basic Positioning Drive from a “smart” servo drive system with

indexing capabilities into a motion control system capable of executing numbered sequences of

indexes called motion programs. Each motion program combines basic indexes to achieve

complex motion profiles beyond what is possible with the basic drive. In addition, the PCM

module greatly increases the non-volatile memory storage capability of the standard digital drive.

This allows the user greater flexibility in both the size and the number of programs (and indexes)

available. Another advantage of PCM-1 is that it increases the number of input lines from 8 to

16 and the number of output lines is increased from 4 to 8. All inputs and outputs are assignable

from a standard list of I/O functions. Lastly, the PCM-1 allows the user to create compound

indexes and includes the parallel interface port required for connecting 1 or 2 thumbwheels and 1

remote display or parallel communications with a PLC.

PCM-5

The PCM-5 has most of the capability of the PCM-1. The PCM-5 is able to do electronic

synchronized line shafting and ratio control. This is accomplished by using an external encoder

or drive representing a lead axis connected to the PCM-5. The drive with the PCM-5 can then be

synchronized to the lead device. This mode of operation also allows for pulse counting of the

lead device and indexing at velocities proportional to its speed. With this capability, flying

shear/cutoff applications can easily be configured.

- 9 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operator Interface

Emerson EMC can provide three different peripheral devices to enhance the operator friendliness

of your drive. The T-21 Data Entry Terminal is ideally suited for providing machine operators

with the ability to enter and/or alter and display machine motion parameters controlled by

Emerson Digital Positioning Servo Drive. The T-16 displays position and velocity parameters

using large sized LEDs that are visible from several feet away. Emerson EMC offers a simple

thumbwheel interface called a TW-XXX that is offered in many different configurations. The

TW-XXX is used to change data of a specific motion parameter or parameters. The thumbwheel

option is ideal for applications needing minimum operator interface.

T-21 Data Entry Terminal

The T-21 communicates with any Emerson Positioning Drive using serial ASCII codes and

allows the machine designer to access, display, or alter certain motion parameters such as index

length. For frequently accessed motion parameters, the operator cam simply depress one of three

user programmable function switches located on the front panel. By depressing the correct

function key, the proper user created message is displayed. The message can be created to

include information as to what setup parameter is being changed, on which axis, etc. If more

than 3 operator altered setup parameters are required, a fourth F(x) key allows the user to store

up to 95 additional operator alterable setup functions.

T-16 Numeric Display

The T-16 is used to display position or velocity of the drive. The T-16 has 7 large LEDs that are

visible from several feet away. This allows the operator to view data shown on the display from

different positions on a machine. The T-16 requires the use of the ION-1 or a PCM-1 module.

The T-16 plugs into the parallel port on the module.

TW-XXX Thumbwheel Interface

The thumbwheel interface provides the user with a non-serial interface method for making

changes to specific motion functions. The user can set up the thumbwheel to change velocities,

distances/positions, dwell times, index counts, and acceleration and deceleration times. All the

thumbwheels are mounted in a small, self contained enclosure. Cables can be ordered in specific

lengths from 3 feet to 50 feet. The TW-XXX requires the user to have an IOM-1 or a PCM-1

module. The TW-XXX plugs into the parallel port on the module.

- 10 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FAMILY OF POSITIONING DRIVE PRODUCTS

Figure 1 Peripherals

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 11 -

POSITIONING DRIVE SPECIFICATIONS

Specifications +/- 10%

Table II Positioning Drive Specifications

DRIVE PERFORMANCE

Drive Model#Motor

Model #

DX-202 DXM-202 2/4 .0000855 3000 7 AMP 2A(S.B.) 1.8 23 1.1/2.2

DX-205 DXM-205 5/10 .000253 3000 7 AMP 2A(S.B.) 1.8 23 3.0/6.0

DX-308 DXM-308 8/16 .0005 3000 7 AMP 2A(S.B.) 2.9 34 2.8/5.6

DX-318 DXM-318 18/36 .001 3000 10 AMP 5A(S.B.) 3.38 40 5.4/10.8

DX-430 DXM-430 30/60 .0026 3000 15 AMP 5A(S.B.) 3.38 40 8.9/17.8

DX-450 DXM-450 50/85 .0052 3000 25 AMP 5A(S.B.) 3.38 40 14.8/24.0

DX-480 DXM-480 80/160 .00772 3000 30 AMP 8A(S.B.) 3.36 42 24/48

DX-780 DXM-780 80/160 .013 3000 30 AMP 8A(S.B.) 3.38 40 24/48

DX-7120 DXM-7120 120/240 .021 2000 30 AMP 8A(S.B.) 5.57 66 24/48

DX-6120 DXM-6120 120/240 .0096 3000 15 AMP 7A 8 100 15/30

DX-6200 DXM-6200 200/400 .0192 3000 20 AMP 7A 8 100 25/50

DX-6300 DXM-6300 300/600 .0268 3000 30 AMP 10A 8 100 38/76

DX-8200 DXM-8200 200/300 .04 3000 20 AMP 7A 7.4 96 27/41

DX-8300 DXM-8300 300/450 .08 3000 30 AMP 10A 7.4 96 40/60

DX-8400 DXM-8400 400/600 .12 3000 40 AMP 10A 7.4 96 54/81

INPUT VOLTAGE: DX-202, DX-205, DX-308, DX-430, DX-450, DX-480, DX-780, DX-

INPUT VOLTAGE: DX-6120, DX-6200, DX-6300, DX-8200, DX-8300, DX-8400 = 196-

SWITCHING FREQUENCY: DX-202, DX-205, DX-308, DX-430 = 20 Khz

DEAD BAND: Zero

VELOCITY SIGNAL INPUT: ±10 vdc typical (10 bit resolution speed selection ±10 volt)

TORQUE SIGNAL INPUT: ± vdc typical (10 bit resolution speed selection ±10 volt)

PULSE MODE INPUT: TTL compatible, 500 nsec minimum pulse width, 210 Khz max

ANGULAR ACCURACY: Cable Length 15FT

USER UNITS/REV: Programmable Range (200-25000)

AMPLIFIER THERMAL SHUT DOWN AS DETECTED IN POWER STAGE:

All Drives: 80º - 90º C

MOTOR THERMAL SHUT DOWN AS DETECTED IN MOTOR (CASE TEMP):

All Motors: 100º - 115º C

Torque

Cont/Peak

IN/LBS

Rotor Interia

IN/LBS/SEC

Max. RPM Bus Fuse Shunt Fuse KT

IN-LBS/AMPKEVolts/KRPM

7120 = 96-132 VAC, 50/60 Hz, single phase

264 VAC 3 PHASE 50/60 Hz

DX-450, DX-480, DX-780, DX-7120 = 15 Khz

DX-6120, DX-6200 = 15 Khz

DX-6300 = 12 Khz

DX-8200, DX-8300, DX-8400 = 10 Khz

frequency

50FT 100FT

Minutes ±20 ±30 ±40

Amplifier

Current

Ratings

- 12 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPTIONAL FAIL-SAFE BRAKE: (Activated by the Positioning Drive)

Table III Fail Safe Brake

Model Holding Torque

IN-LBS

DX-308 12

DX-318 25

DX-430 45

DX-450 75

DX-480 120

DX-780 120

DX-7120 180

DX-6120 400

DX-6200 400

DX-6300 400

*DX-8200 300

*DX-8300 450

*DX-8400 600

*Special (consult factory)

COMMAND PULSE: 5-15 vdc

MODE INPUTS: 25-70 milliamps

ANALOG INPUTS: -10 vdc to +10 vdc operating range

-12 vdc to +12 vdc absolute maximum

Different input greater than 9K ohms

SERIAL INTERFACE: RS423 signal compatible

Xmit, Rec, and GND

INPUTS AND OUTPUTS: Outputs: sink or source (2 terminals);

200 Ma max (external current limit required) each

Inputs: 10 to 30 vdc (internal current limit provided)

10, 12, 15 and 24 vdc typical

Table IV User Memory Capacity

User Memory Capacity

Drive

Drive

w/IOM-1

Jog 2 2 2 2

Home 1 1 1 1

Indexes 32 32 256 256

Programs 0 0 64 64

Drive

w/PCM-1

Drive

w/PCM-5

- 13 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table V Number of User Programs

Number of Required

User Programs

1 1000

2 500

3 333

4 250

5 200

--

--

-62 16

63 15

Average Number of Available

Steps Per Program

Table VI Motor Load Specifications

Motor Radial and Axial Load Specifications

Motor Max Radial Load Max Axial Load

DXM-202 10 lbs 8 lbs

DXM-205 10 lbs 8 lbs

DXM-308 20 lbs 15 lbs

DXM-318 20 lbs 15 lbs

DX* -430 50 lbs 20 lbs

DX* -450 50 lbs 20 lbs

DX* -480 75 lbs 40 lbs

DXM-780 150 lbs 50 lbs

DXM-7120 150 lbs 50 lbs

DXM-6120 150 lbs 50 lbs

DXM-6200 150 lbs 50 lbs

DXM-6300 150 lbs 50 lbs

DXM-8200 150 lbs 50 lbs

DXM-8300 150 lbs 50 lbs

DXM-8400 150 lbs 50 lbs

- 14 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

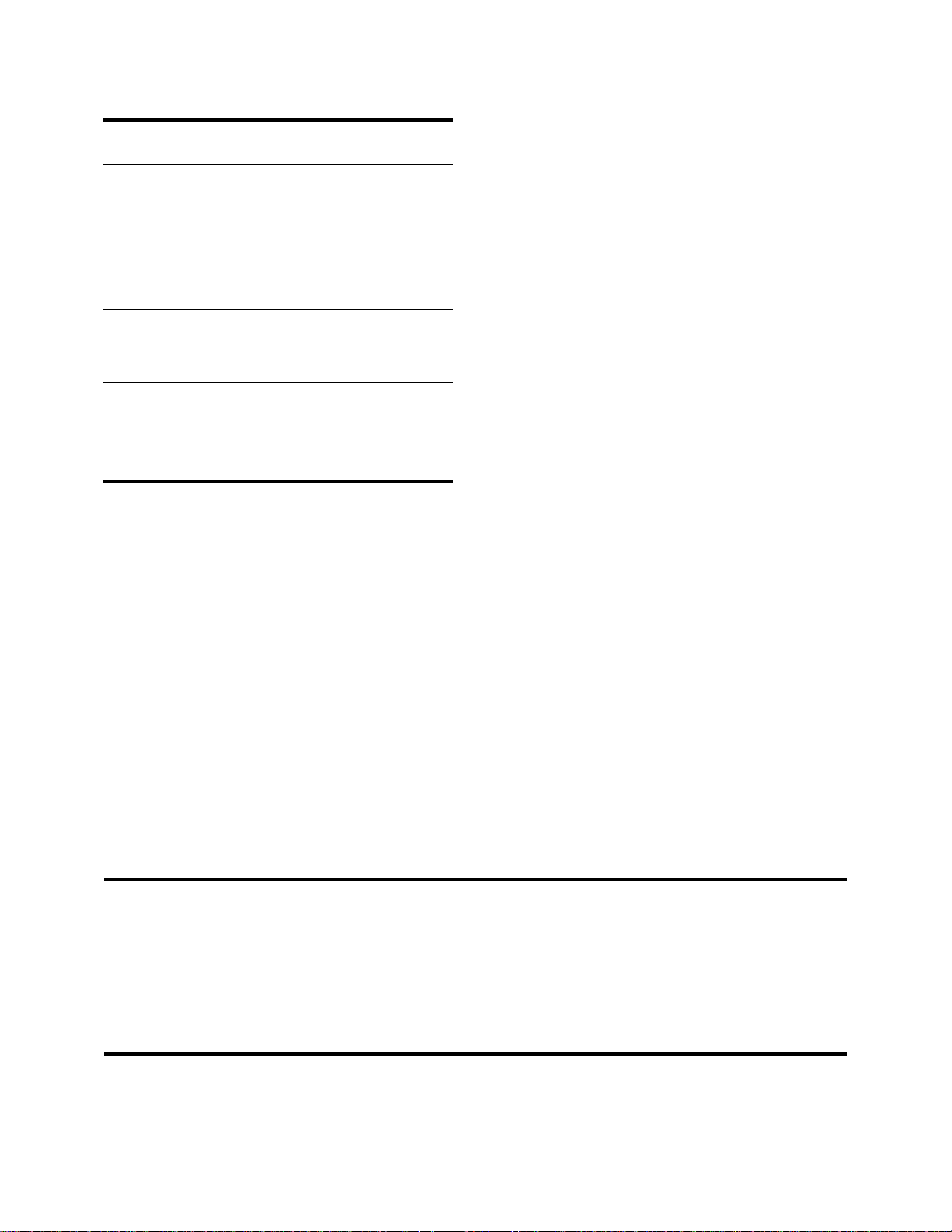

DX-SERIES MOTORS AND AMPLIFIERS TYPICAL SPEED

TORQUE CURVES

DX-202, DX-308, DX-318, DX-430, DX-480, DX-780

Figure 2 Typical Speed Torque Curve

DX-7120

Figure 3 Typical Speed Torque Curve

DX-205

Figure 4 Typical Speed Torque Curve

∗ Continuous torque rating of the motors is measured using a 10” X 10” X 0.25” mounting plate that

acts as a heatsink.

∗ All specifications are ± 10%.

- 15 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

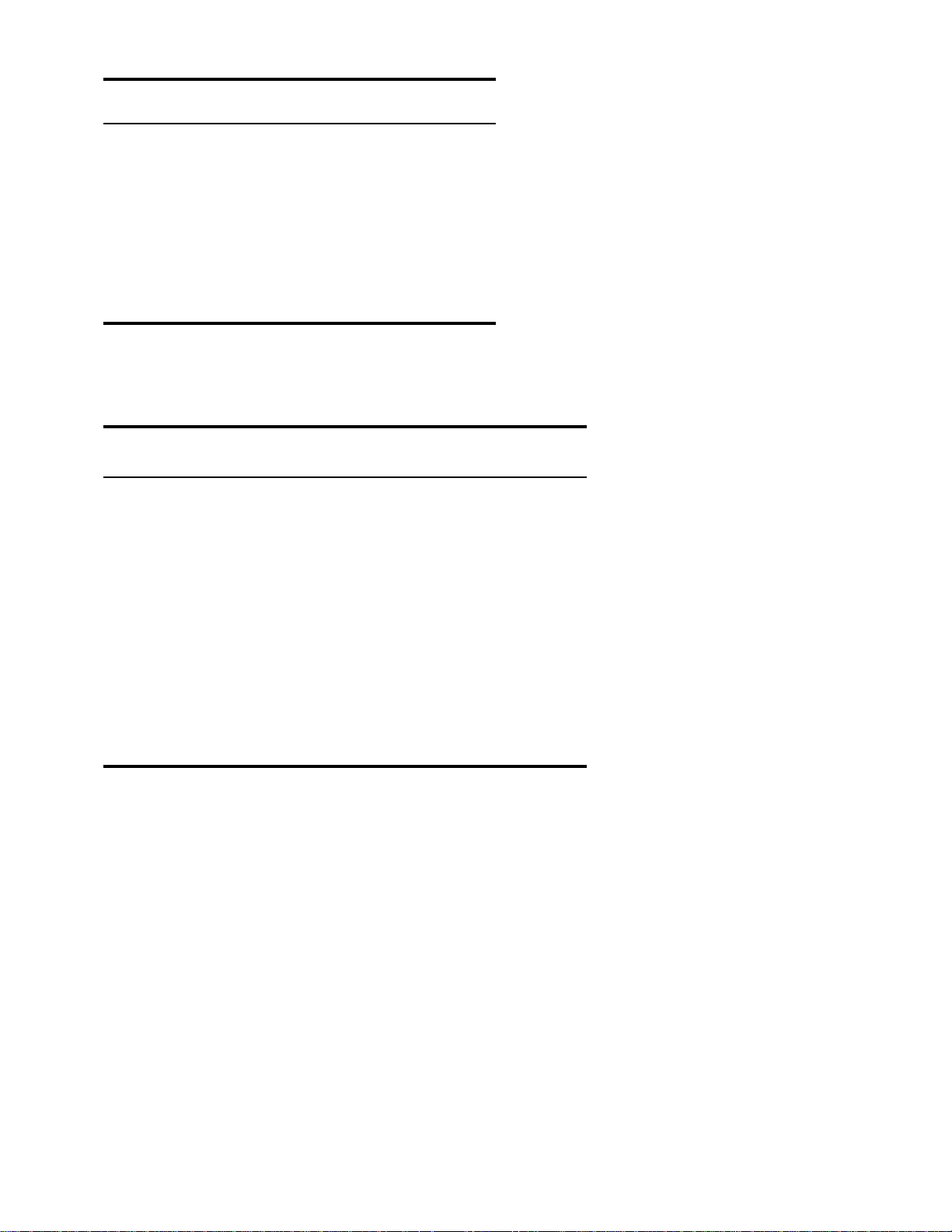

DX-450

Figure 5 Typical Speed Torque Curve

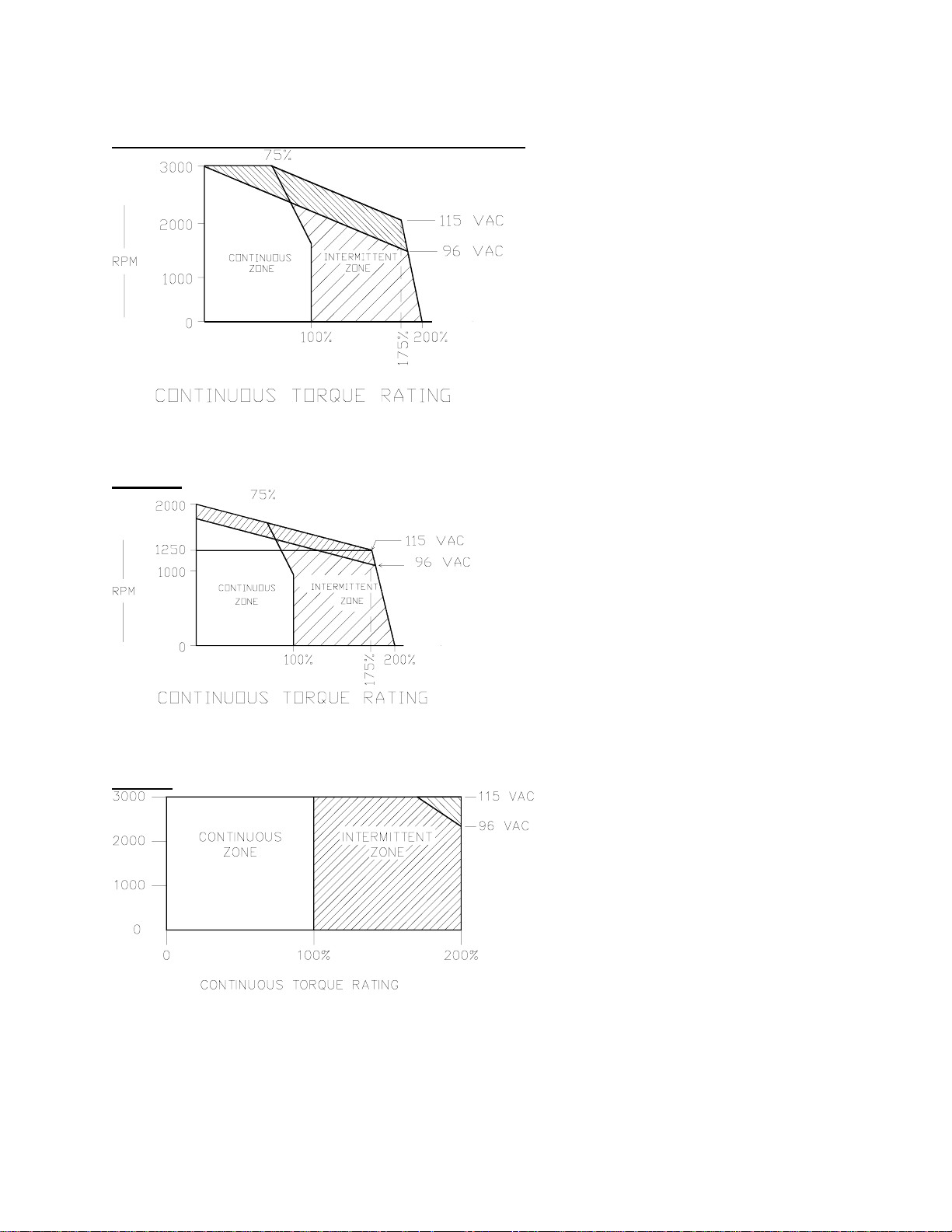

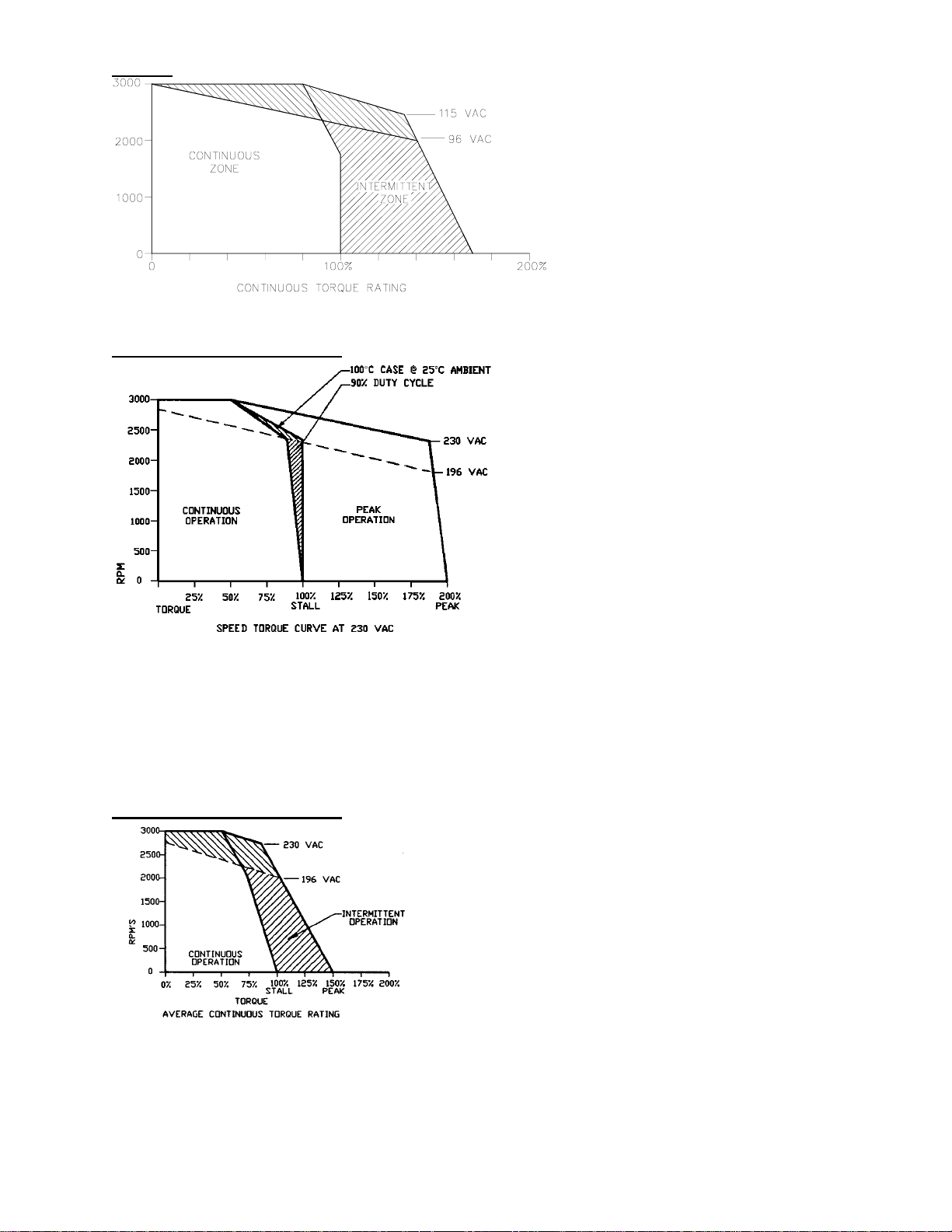

DX-6120, DX-6200, DX-6300

Figure 6 Typical Speed Torque Curve

1) Peak operation is available for ≥1.0 seconds from 0 torque.

2) Speed torque curves are based on 144” sq. by ½” thick aluminum face plate.

3) Derate available torque by 1% per °C for operation above 30°C, to an ambient temperature of

45°C, for motor and amplifier.

DX-8200, DX-8300, DX-8400

Figure 7 Typical Speed Torque Curve

∗ Continuous torque rating of the motors is measured using a 10” X 10” X 0.25” mounting plate that

acts as a heatsink.

∗ All specifications are ± 10%.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 16 -

INSTALLATION

OVERVIEW

The Positioning Drives were designed with simple installation in mind. The Drive normally

back-mounts into a standard NEMA enclosure. Because of its small footprint and no need for

external transformers, boards and power supplies, the Positioning Drive saves significant panel

space and cost over alternative servo positioning systems. Wiring and connecting the drive is

equally simple. AC line power is connected via provided screw terminals. All 120 VAC models

use single phase 50/60 Hz power. All 230 VAC models use 3 phase 50/60 Hz power.

Inputs and outputs for control and status are wired to a 12 position, detachable terminal strip (this

also makes servicing easy). The RS423 serial interface used for setup, status and control can be

connected with a 9 pin D-type connector. The motor connections for the 120 VAC single phase

models are accomplished with factory supplied cable and mating connectors. The higher power

230 VAC 3 phase models are connected via screw terminals at the amplifier and motor. This

allows the user to supply his own wire.

The larger drive motors also have NPT pipe thread holes for metallic raceways. It is a

requirement that the stator wiring R, S, T be run in metallic raceways and 1-1/4” pipe conduit

holes are provided. The feedback wiring must be done by using shielded cabling with 100%

shielding via a foil shield and a braided shield.

ASSEMBLY AND INSTALLATION CONSIDERATIONS

The following procedures outline the methods necessary to assure reliable and trouble free

installation of the EMERSON EMC Positioning Drive.

- 17 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TYPICAL 120 VAC LINE SIZING (SINGLE PHASE MODELS)

Figure 8 Typical 120 VAC Line Sizing

The approximate AC line source VA rating can be determined by multiplying the AC line sizing

by 120 VAC.

Example: DX-780

Line sizing = 40 amp

(40 amps) ∗ (120 VAC) = 4800 VA

- 18 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TYPICAL 230 VAC 3 PHASE MODELS

Figure 9 Typical 230 VAC 3 Phase Connections

The approximate AC line source VA rating can be determined by W = E•I 1.732

Example: DX-8200 = 20 Amps

Watts = 230 VAC • 20 Amps • 1.732 = 7,967

- 19 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The following table should be used as a guideline for minimum sizing the AC wiring.

Table VII Typical Line Ampacities & Wire Gauges

Drive Typical Line

Ampacities

DX-202 10 A 16 AWG

DX-205 10 A 16 AWG

DX-308 10 A 16 AWG

DX-318 10 A 16 AWG

DX-430 20 A 12 AWG

DX-450 25 A 12 AWG*

DX-480 40 A 10 AWG*

DX-780 40 A 10 AWG*

DX-7120 40 A 10 AWG*

DX-6120 15 A 12 AWG*

DX-6200 20 A 12 AWG*

DX-6300 30 A 10 AWG*

DX-8200 20 A 12 AWG*

DX-8300 30 A 10 AWG*

DX-8400 40 A 8 AWG*

Recommended

Minimum Wire Gauge

* AC power lines that are farther than 50 ft. from the power source, many require a larger gauge that

what is recommended above.

Wiring Considerations

If you are not sure of your grounding or signal wiring techniques, you should observe the

recommended practices according to the IEEE Ground Book, ANSI Standard C1141 and the

National Electric Code.

Wiring of any industrial equipment should be done with some consideration for future

troubleshooting and repair. All wiring should be either color coded or tagged with industrial

wire tabs.

All I/O wiring must be done with industrial grade insulated wire to withstand the environment of

the application. 18 to 24 gauge wire must be used for I/O wiring. The use of larger gauge wire

will cause the I/O terminals to prematurely fatigue. Each input and output to the control unit is

designed to have high noise immunity. This does not mean that high voltage, noise emitting

wiring on the rest of the application can be run adjacent to the control inputs. Precautions should

be taken to eliminate any possible noise from reaching the drive.

- 20 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety Considerations

The user is responsible for emergency interlock switches. Any master interlock should be wired

to shut down AC power to all parts of the system. Your system should be designed such that

power is disconnected from the output loads any time the equipment is not running, or when the

emergency stop is activated.

Brake Option

An additional safety and operational feature can be added by ordering the optional fail-safe

brake. The brake allows the motor shaft to be held whenever power is removed from the brake

coil (such as in a power failure). The user can control the on/off operation of the brake through

either serial commands or an assigned input line. The power supply needed to operate the brake

is provided internally in the drive.

Power Line

The lower power 120 VAC (DX-202 thru DX-7120) drives are designed to operate on a 50/60

Hz, single phase AC power line. The AC voltage of this power line must be within the specified

range of 96-132 VAC and be free of voltage transients which exceed this range. If it is found

that the AC power does not meet these specifications, further AC line conditioning may be

required. Also, if there is sensitive electronic equipment (digital computer, test equipment, etc.)

operating on the same AC power line as the Drive, additional EMI/RFI filtering may be required

to reduce the effects of conducted AC line noise. Operation at 96 VAC will reduce the drive’s

performance at high (max) speed.

The AC input lines are connected to the drive by means of the 3-position terminal strip located

on the bottom plate of the drive. The AC line wires should be connected as shown below.

Insufficient or incorrectly applied AC line power is a major cause of drive problems. Wiring

sizing and transformer selection (if necessary) should be done carefully.

CAUTION: To insure proper operation after a power down the user should wait a minimum of

10 seconds before reapplication of power.

Figure 10 Typical 120 VAC Drives

• L2 is the AC neutral wire and must be grounded (see “Grounding Considerations”.)

- 21 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The high power 230 VAC (DX-6120, DX-6200, DX-6300, DX-8200, DX-8300, DX-8400) are

designed to operate on 3 phase AC power. The AC voltage for these drives must be between 196

to 264 VAC.

The AC input lines are connected to the drive by means of the 4 terminals located on the bottom

plate of the drive. The AC line wires should be connected as shown below. Insufficient AC line

power from wire size and control transformers is a major cause of drive problems.

Figure 11 Typical 230 VAC Drives

The GND terminal is bonded to the chassis and must be connected to earth ground.

- 22 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

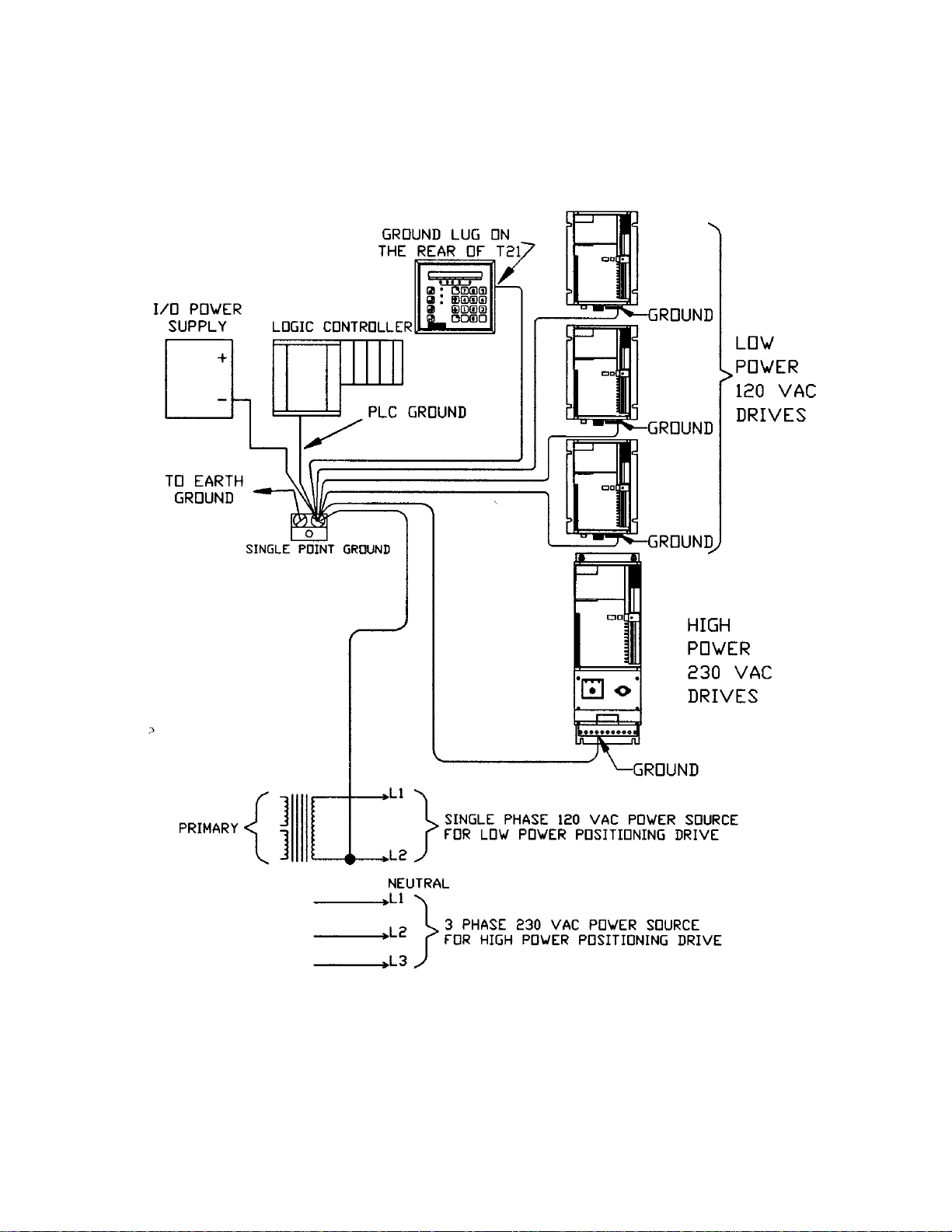

Grounding Considerations

The GND terminal of the drive is internally bonded to the frame. The enclosure ground and the

drive ground should be a common single point that ultimately is a continuous electrical path to

earth ground. The following example illustrates the ideal grounding arrangement of the AC

power.

Figure 12 Grounding Illustration

NOTE: These ground wires should not be shared with other equipment. Also note that the

neutral (L2) for the 120 VAC source for the low power positioning drive is grounded.

- 23 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

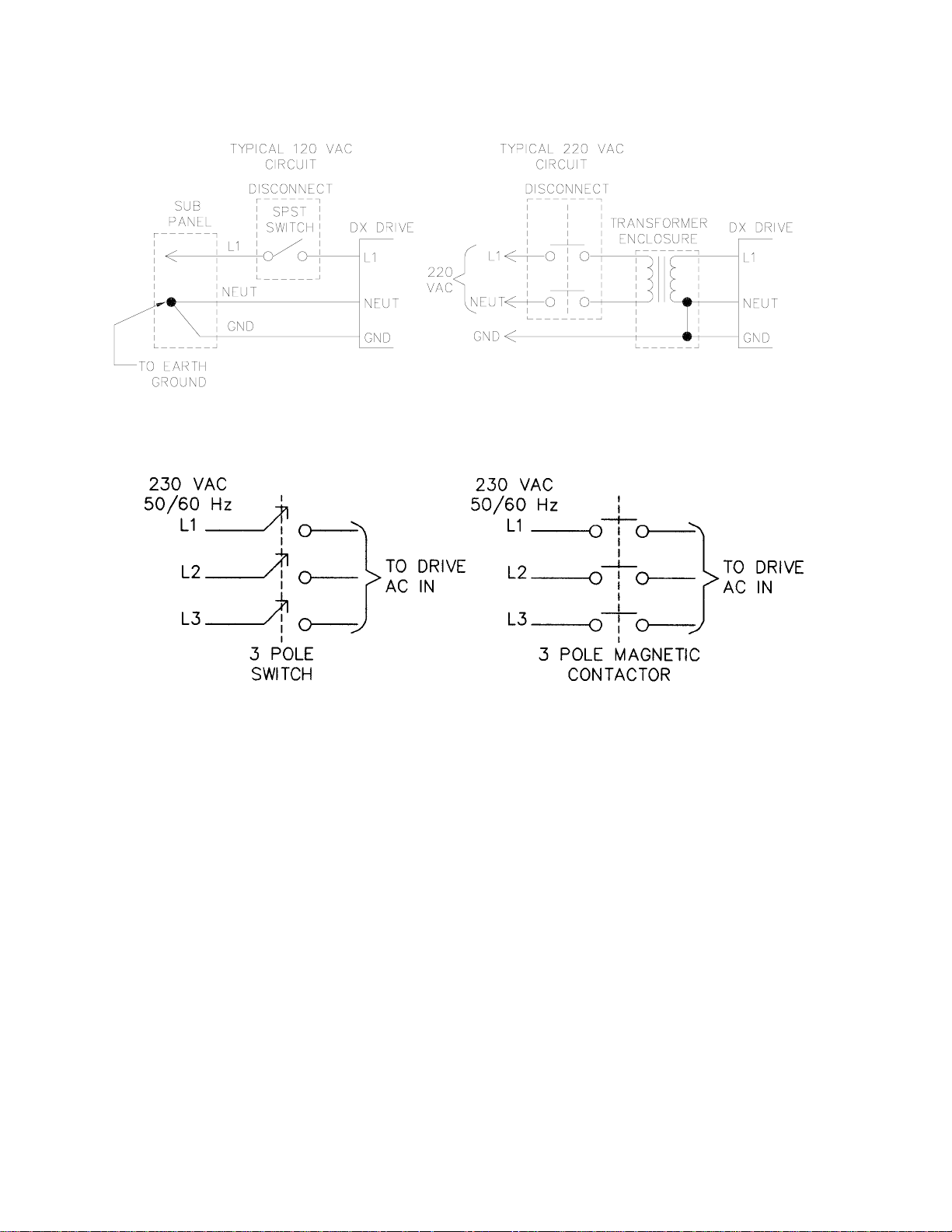

The following two circuits are given as EMC recommended external disconnecting examples for

the 120 VAC low power drives.

Figure 13 External Disconnect Examples (120 VAC Low Power)

The following examples are for the 230 VAC models. (DX-6XXX’s & DX-8XXX’s)

Figure 14 External Disconnect Examples (230 VAC High Power)

- 24 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Electrical Noise

Effects of electrical noise on the electronic equipment are greatly reduce when the techniques

outlined below are closely followed.

1. Do not run low power control signals and high power wiring in the same raceway.

NOTE: If mixing wire cannot be avoided, then the low voltage control input and output

wiring must be shielded. The shield for these wires should only be connected to ground only

at the source end of the signals.

2. Never connect both ends of a shielded cable to ground. This may cause a ground loop

condition which could be very difficult to locate.

3. It is suggested that all the wires in the system be kept as short as possible.

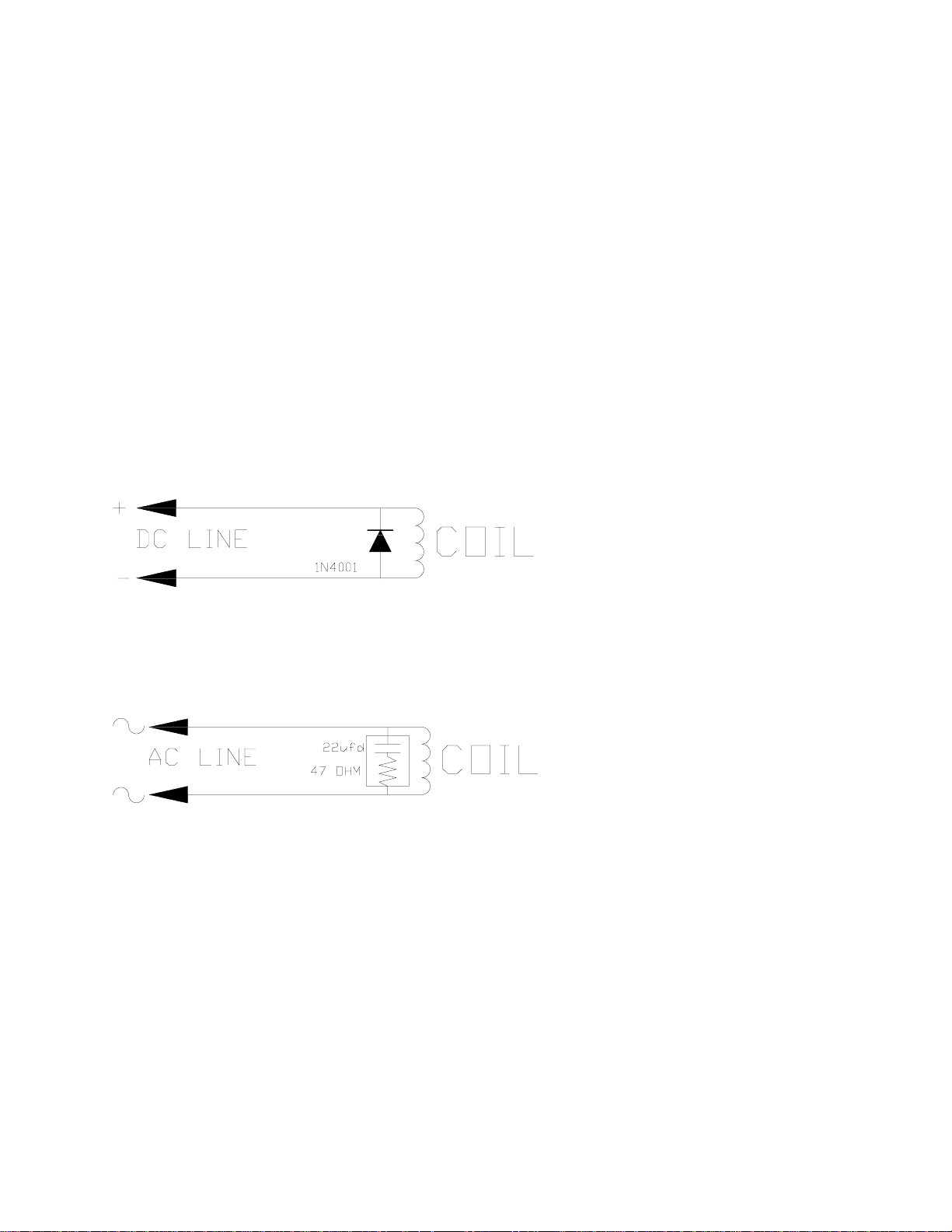

Magnetic Coil Noise

In the case of DC relays, a diode is installed across the coil in a direction that will cause the

voltage transient to be dissipated through the diode.

Figure 15 Magnetic Coil Noise (DC Line)

In the case of AC coils a capacitor and resistor are installed across the coil to supress the

unwanted transient.

Figure 16 Magnetic Coil Noise (AC Line)

The specific values of resistance and capacitance may vary depending on the inductance of the

coil. Consult the relay manufacturer for the proper values to use. These suppressor networks

greatly extend the life of the contacts controlling the coil because the transient energy, which can

easily reach 1000 volts, shunts through the suppressor’s rather than arcing across the controlling

contacts as they open.

- 25 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Mechanical Consideration

To provide good mechanical alignment the mounting surface of the motor face plate is held

perpendicular to the motor shaft to within 0.005 inches of the motor shaft. Projecting above the

plane of the mounting surface is a close tolerance circular pilot boss, which, when matched with

a pilot hole in the mounting structure, facilitates interchanging the motor, and minimizes the

need for mechanical adjustments. The mounting surface is fitted with four holes, equally spaced

on a bolt circle pattern.

The mounting panel must be stiff enough so it does not deflect significantly when radial loads

are applied to the motor shaft. The mounting panel should also have good thermal conductivity,

especially if peak performance is demanded of the motor.

Mechanical shock to the motor case or shaft (e.g., from striking or dropping) must be avoided to

prevent damage to the motor. Possible results from striking or dropping include: Misalignment

of the resolver; damage to armature bearings; cracking of the motor case; unbonding or

demagnetization of the permanent magnets. Any of these would render the motor unserviceable.

Load Coupling

A flexible coupling must be used on the motor shaft to minimize mechanical stress due to radial

loads, axial loads and/or misalignment. Radial and axial loading cannot exceed specified values.

Table VIII Load Coupling

Motor Max Radial Load Max Axial Load

DXM-202 10 lbs** 8 lbs

DXM-205 10 lbs** 8 lbs

DXM-308 20 lbs** 15 lbs

DXM-318 20 lbs** 15 lbs

DX* -430 50 lbs** 20 lbs

DX* -450 50 lbs** 20 lbs

DX* -480 75 lbs** 40 lbs

DXM-780 150 lbs** 50 lbs

DXM-7120 150 lbs** 50 lbs

DXM-6120 150 lbs** 50 lbs

DXM-6200 150 lbs** 50 lbs

DXM-6300 150 lbs** 50 lbs

DXM-8200 150 lbs** 50 lbs

DXM-8300 150 lbs** 50 lbs

DXM-8400 150 lbs** 50 lbs

* M-(XXX) = Metric E –(XXX) = English

** Maximum radial load is rated at 1 inch from the motor face

Gear Reduce Oil

It is strongly suggested that a synthetic oil is used in the gear reducer or rotary tables. This will

reduce the amount of current it takes to drive the motor.

- 26 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Selecting An Enclosure

The EMERSON EMC Positioning Drive is designed for the industrial environment. However,

no sophisticated electronic system can tolerate certain atmospheric contaminants such as

moisture, oils, conductive dust and metallic particles. Therefore, if the drive is going to be

subjected to this type of environment, we strongly urge you to mount your drive in a NEMA type

12 enclosure. Proper ventilation and filtering should also be provided. Amplifier losses should

be considered for enclosure sizing and ventilation.

Amplifier Losses

The exact power losses in any application depend on the application. The following table losses

would represent typical examples. The bridge power losses and shunt power losses can be

derated based on any duty cycle for power demand.

The logic supply power consumption varies based on PCM modules. For all 120 VAC models,

the logic power consumption is about 60 watts for the 230 VAC models. The consumption is

about 100 watts.

The next consideration would be bridge power losses which vary by amplifier size. The table

represents losses based on maximum continuous output current to the motor.

In applications where constant acceleration and deceleration occur, additional losses occur in the

shunt regulator where energy stored in the rotating inertia is commutated to the drives BUS

capacitors. This energy causes the BUS voltage to increase and once sensed, the excess voltage

is shorted through a load resistor. These losses could easily equal the bridge power losses.

Table IX Amplifier Losses (By Model)

Model Logic Supply Bridge Losses Shunt Losses Total

DXA-202 60W 10W 10W 80W

DXA-206 60W 25W 25W 110W

DXA-308 60W 45W 45W 150W

DXA-318 60W 100W 100W 260W

DXA-430 60W 130W 130W 320W

DXA-450 60W 200W 200W 460W

DXA-480 60W 340W 340W 740W

DXA-780 60W 340W 340W 740W

DXA-7120 60W 340W 340W 740W

DXA-6120 100W 400W 400W 900W

DXA-6200 100W 700W 700W 1500W

DXA-6300 100W 1000W 1000W 2100W

DXA-8200 100W 700W 700W 1500W

DXA-8300 100W 1000W 1000W 2100W

DXA-8400 100W 1500W 1500W 3100W

System Troubleshooting

If you encounter a system problem, double check the installation instructions. These instructions

eliminate most of the problems encountered. If you have a problem, call EMERSON EMC at

(612) 474-8833 and ask for Customer Service Department.

AMPLIFIER MOUNTING INFORMATION

- 27 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

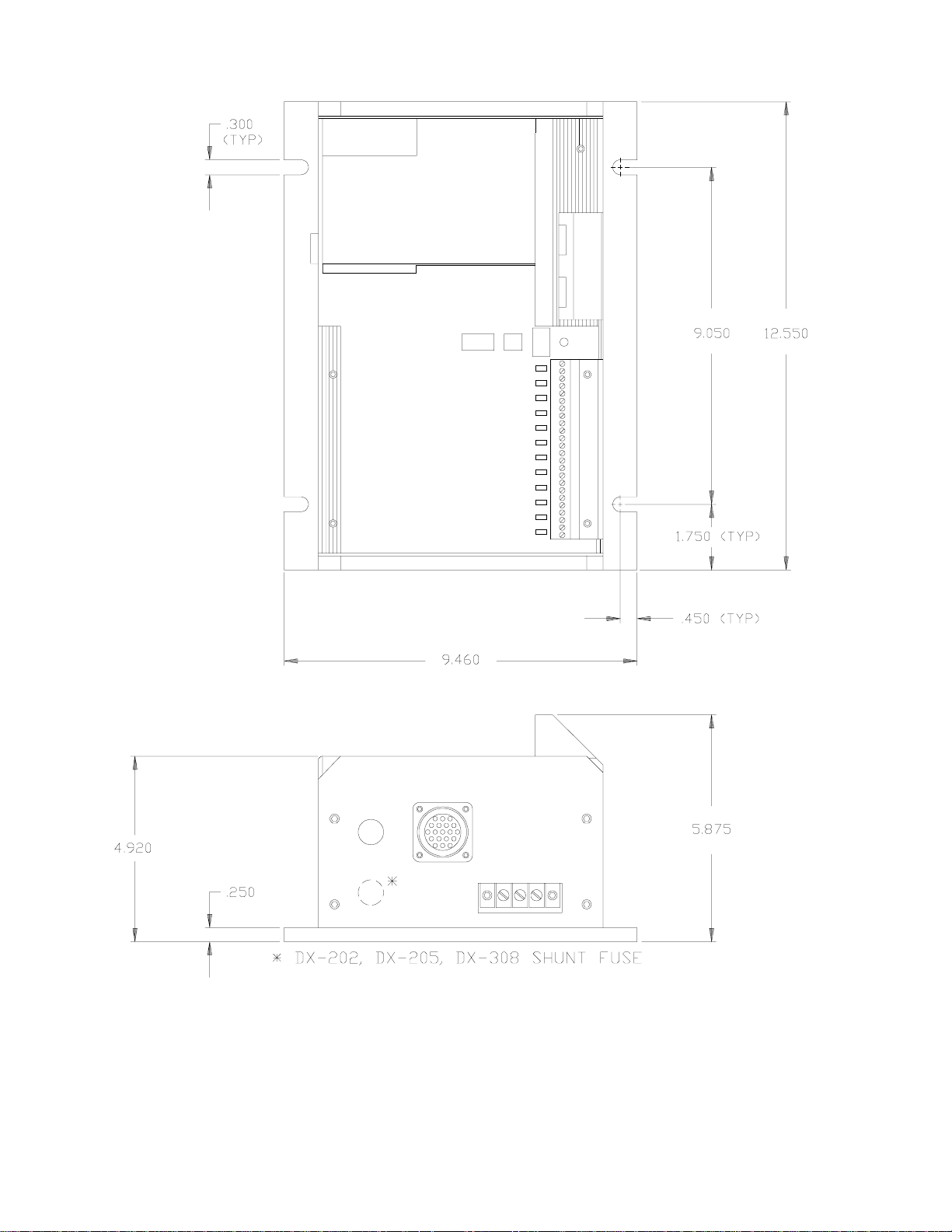

DX-202, DX-205, DX-308

Figure 17 Amplifier Mounting Information (DX-202, DX-205, DX-308)

- 28 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

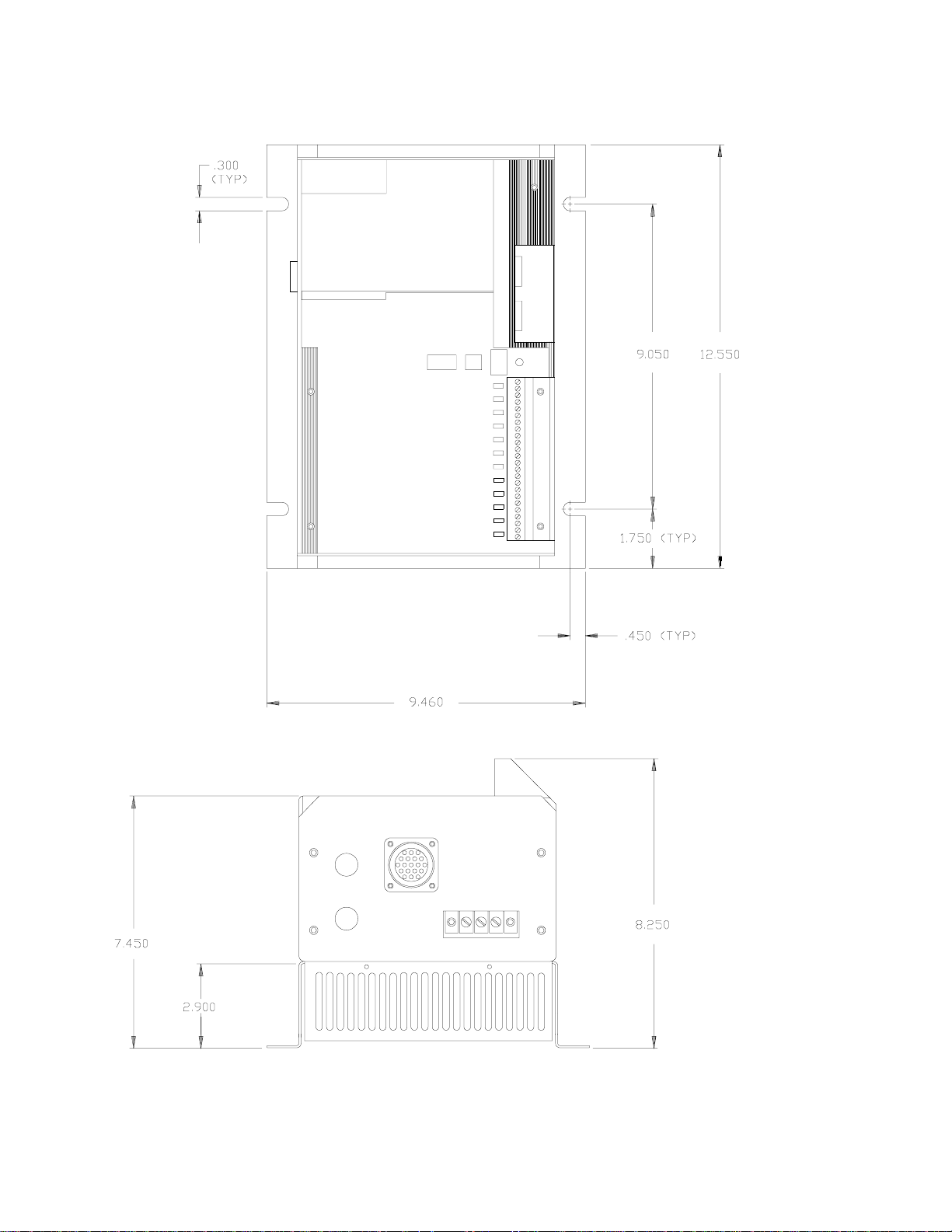

DX-318, DX-430, DX-450

Figure 18 Amplifier Mounting Information (DX-318, DX-430, DX-450)

- 29 -

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...