Emerson ZX0200-TFD, ZX0500-TFD, ZX0300-TFD, ZX0400-TFD, ZX0600-TFD User Manual

...

User Manual

Copeland Scroll

TM

ZX condensing unit for refrigeration applications

About Emerson Climate Technologies

Emerson Climate Technologies, a business segment of Emerson, is the world’s leading provider of heating, air conditioning and

refrigeration solutions for residential, industrial and commercial applications. The group combines best-in-class technology

with proven engineering, design, distribution, educational and monitoring services to provide customized, integrated climate-

control solutions for customers worldwide. Emerson Climate Technologies’ innovative solutions, which include industry-leading

brands such as Copeland Scroll and White-Rodgers, improve human comfort, safeguard food and protect the environment. For

mor

e information, visit EmersonClimateAsia.com.

Emerson Climate Technologies is pleased

to offer the ZX platform refrigeration

condensing units (CDU) specifi cally

designed for medium temperature (ZX-MT

& ZXB-MT), digital modulated variable

capacity medium temperature (ZXD) and

low temperature (ZXL-LT) refrigeration.

ZX series CDU has been highly successful in

the Asian market and enjoys proven success

with its energy savings and customer-

friendly electronic features.

Emerson Climate Technologies, With Our Partners,

Will Provide Global Solutions To Improve Human Comfort,

Safeguard Food And Protect The Environment.

Our Vision

Table of Contents

Disclaimer 04

Features and Benefits 04

Nomenclature 05

Bill of Material 05

Physical Layout of the Unit 06

Product Specification

Quali ed Refrigerants And Oils 07

E2 Control Board - Rotary Switch And Dip Switch Setting (ZX-MT, ZXB-MT & ZXL-LT) 08

Defrost Module Function Set 09

Digital Scroll Controller (ZXD) 09

ZX CDU Intelligent Store Solution Module 10

Installation

Condensing Unit Handling 14

Electrical Connection 14

Refrigeration Piping Installation 15

Expansion Valve Selection for Low Ambient Application 16

Location and Fixing 16

Start Up and Operation 17

Diagnostic Initialization Message (ZX-MT, ZXB-MT & ZXL-LT) 17

Diagnostic Messaging - LED Definition (ZX-MT, ZXB-MT & ZXL-LT) 18

Alarm Messaging - Digital Scroll Controller (ZXD) 18

Wiring Diagram 19

Contact Lists 28

4

ZX Platform CDU

Disclaimer

Thank you for purchasing the ZX platform condensing unit from Emerson Climate Technologies. ZX platform CDUs are the

best in class within the capacity and operating range available in the market. ZX CDU is designed to operate reliably and

to deliver high operating efciencies in medium and low temperature refrigeration applications. It also provides constant

monitoring of the compressor operating conditions and displays the running or fault conditions of the CDU. ZX platform CDUs

have to be installed by following the industry trade practices for its safe and reliable operation. It is assumed that the CDU

is selected, installed and serviced only by professionals. The user manual does not cover good industry practices which are

essential on a refrigeration equipment installation. No responsibility can be accepted for damage caused by inexperienced or

inadequately trained site technicians or improper installation design.

If in doubt, please consult your local sales ofce, quoting unit model and serial number as shown on each unit nameplate. In

case of any ambiguity, the wiring diagram supplied with each unit takes precedence over the diagram in this manual.

Introduction to ZX Platform CDU

ZX medium temperature, ZXB medium temperature, ZXD digital medium temperature and ZXL low temperature series have

been highly successful in the Asian market and enjoys proven success with its energy savings and customer-friendly electronic

features. ZX, ZXB, ZXD and ZXL CDUs have been applied by several well known end-users and chain retailers throughout Asia.

The ZX platform is also gaining wider acceptance in the global market and specic variants have been developed and exported

to the USA and to the European and Middle East markets.

Receiving your unit

All units are shipped with a holding charge of dry nitrogen inside at a low but positive pressure. Suitable labeling is prominently

displayed on both the unit and the packaging. Service connectors are provided on the CDU service valve for the convenient

checking of the integrity of the holding charge.

Caution! It is very important to check that this holding pressure exists at the time you receive each unit from us or our

authorized representatives. Please inform us or our authorized representative if the holding charge is non-existent. Failure to

do so could void the claim for other related system faults at a later period.

Transit damage is essentially an insurance claim and is not covered under manufacturing defect. It is also advisable to inspect

the rest of the unit for obvious physical damage and inform us or our authorized representative in case any is discovered.

ZX Platform Condensing Unit was designed based on three factors

demanded by industry users:

Intelligent Store Solutions - A most innovative approach to enterprise facility management, Emerson’s Intelligent

Store™ architecture integrates hardware and services, to provide retailers a single view into their entire network of facilities and

understanding what facilities actually cost to operate and maintain.

The Intelligent Store architecture transforms data from store equipment and controls into actionable insights. Designed to

deliver value in both new and existing stores, Emerson aims to help the retailers:

• Make better decisions on recourses investment for greatest impact

• Gain accurate feedback and customized service to your specic needs

• Reduce operational costs and boost the protability at most convenience

Energy Efficiency - Utilizing Copeland Scroll

TM

compressor technology, variable speed fan motor, large capacity condenser

coil and advanced control algorithms, energy consumption is signicantly reduced. End-users can save more than 20% on

annual energy costs rather than using hermetic reciprocating units.

Reliability - Combining the proven reliability of Copeland Scroll

TM

compressors with advanced electronics controller and

diagnostics, equipment reliability is greatly enhanced. Fault code alerts and fault code retrieval capabilities provide information

to help improve speed and accuracy of system diagnostics. Integrated electronics provide protection against over-current,

over-heating, incorrect phase rotation, compressor cycling, high pressure resets, low pressure cut-outs. It can also send out a

warning message to an operator when there is a liquid oodback, which can prevent critical damage on the unit.

5

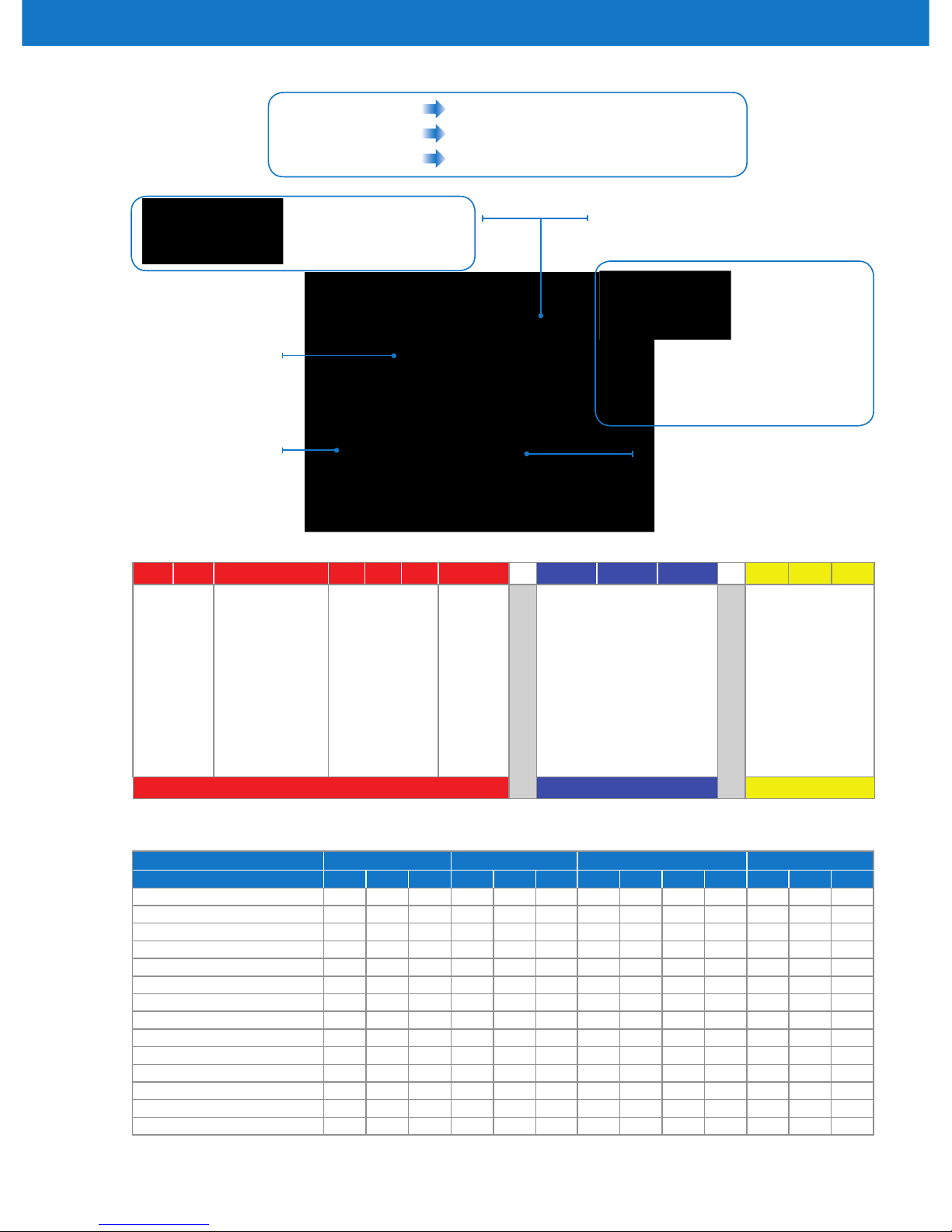

Copeland Scroll Compressor Technology –

High Ef ciency, Ultra Quiet, High Reliability

Intelligent Store Better Decision Making

• Compressor Reverse Rotation

• Compressor Over Current

• Compressor Internal Motor

Protector Trip

• Discharge Gas Over Heat

• High Pressure Cut Out

• Low Pressure Cut Out (only on

MT series)

• Refrigerant Flood Back

• Compressor Minimum Off Time

• Internal Thermal Sensor Failure

• Intelligent Store Solution:

Communication and Retail Store

Monitoring

Intelligent Store

Solution Module

Built-in ZX Platform

Controller

Highest Ef ciency Lower Energy Bills

Reliability

Lower Maintenance Cost

ZXD Family

ZX, ZXB and ZXL Family

Figure 1. ZX Platform CDU Features

Nomenclature

Variable Speed Fan

Motor and High

Ef ciency Fan Blade

Oversized Condenser

Coil for Maximum Heat

Transfer

Bill of Material

CDU Family ZX ZXB ZXL ZXD

BOM 401 451 481 401 451 461 451 461 471 481 450 451 461

Liquid Line Filter Dryer/Sight Glass

Oil Separator

Accumulator

Adjustable LP Switch

Fixed LP Switch

E2 Controller

Digital Scroll Controller

Fan Speed Controller

Intelligent Store Solution Module

Circuit Breaker

Sound Jacket

Low Ambient Kit

Defrost Module ACC ACC ACC ACC

ACC

ACC

Filter Drier ACC

- Capacity modulation to control precise

room temperature and humidity

- With real time monitoring of compressor

operating conditions

Z X L 0 2 0 E - T F D - 4 5 1

Unit Family

Blank = Medium Temp

B = Medium Temp (R134a)

D = Digital Medium Temp

L = Low Temp

1.5 to 7.6 HP

E = Ester Oil

O = Mineral Oil

PFJ = 220V/240V- 1ph- 50 Hz

TFD = 380V/420V- 3ph- 50 Hz

TF5 = 200V/230V- 3ph- 60 Hz

200V/220V - 3ph - 50 Hz

TF7=380 - 3ph - 60 Hz

Bill of Material

Base Model Electrical Code Bill of Material

Note: ACC- Accessory

Proprietary Electronic Algorithms Present Advantage On Diagnose,

Communication, and Protection Purposes. They Are Also Fundamental

to Control Fan Speed, Optimizing Energy Performance for Local Seasonal

Ambient Temperatures

6

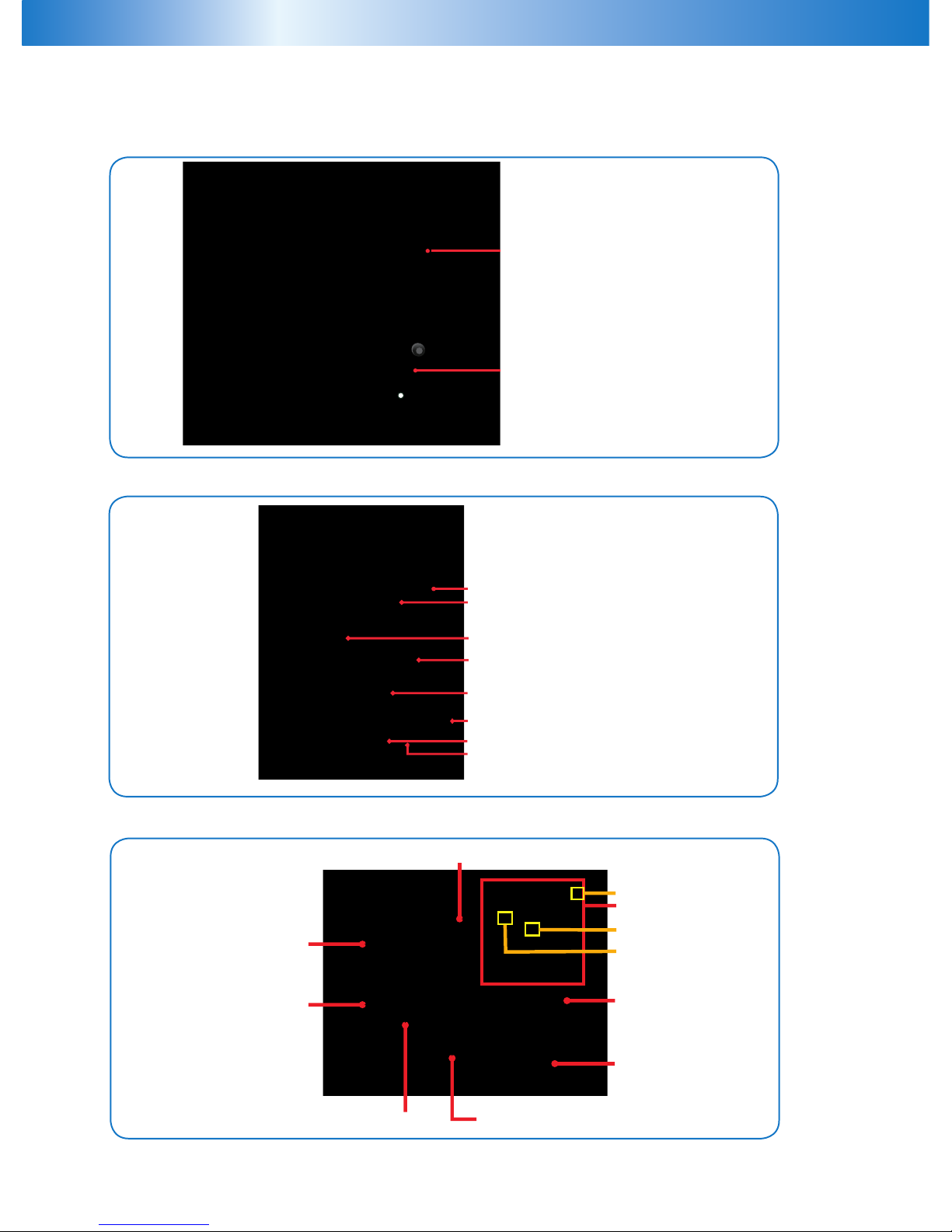

Physical Layout of the Unit

The following figures give an introduction to the physical layout of the ZX Platform CDU

ZX-MT, ZXB-MT & ZXL-LT E2 Controller

Scroll Compressor

See Fig. 5 for LED and keypad

ZXD Digital Scroll Controller

Figure 4. Shows the layout of the E2 controller, electrical components, dip switches and rotary switch in the E2 control board.

Figure 2. Identies the Electronic controller assembly on a ZX platform CDU.

Figure 3. Identies other major components layout on a ZX platform CDU.

Oil Separator

(Optional In MT CDU)

Liquid Receiver

Liquid Sight Glass/

Moisture Indicator

Liquid Filter Drier

Suction And Liquid

Service Valve

Receiver Out Service Valve

Compressor Oil Sight Glass

Accumulator

2-Bit Dip Switch

3-Bit Dip Switch

Rotary Switch

E2 Control Board

Power Isolation Switch

E2 Power Board

Compressor Cont

actor

Defrost Module

Intelligent Store

Solution Module

Fuse Holder Electrical Cable connectors

7

Program Mode: browses parameter codes or

increase value

Hot Key Insert : Hot key programming

procedure

INFO Menu: Press and release it to access

INFO Menu

Program Mode: below parameter codes or

decrease value

Maintenance /Clock

Suction pressure

Suction temperature display

Discharge pressure

Condenser temperature display

Enter Alarm

Manual Restart

Setup Menu

ZX ZXB ZXD ZXL

Model

BOM

Model

BOM

Model

BOM

Model

BOM

401 451 ALL ALL ALL

ZXB015E 0.74

ZX0200/E

1.18

1.68 ZXB020E 0.74

ZXL0200/E 1.06

ZX0250/E

1.33

1.83 ZXB025E 0.74

ZXL0250/E 1.06

ZX0300/E

1.33

1.83 ZXB030E 1.36

ZXL0300/E 1.06

ZXB035E 1.36

ZXL0350/E 1.74

ZX0400/E

1.83

2.33 ZXB040E 1.36 ZXD0400/E 1.74

ZXL0400/E 1.74

ZX0500/E

1.83

2.33 ZXB050E 1.89 ZXD0500/E 2.27

ZXL0500/E 1.74

ZXB055E 1.89

ZX0600/E

1.66

2.16 ZXD0600/E 2.27

ZXL0600/E 2.27

ZX0750/E

1.66

2.16 ZXD0750/E 2.27

ZXL0750/E 2.27

ZX0760/E

1.66

2.16

Figure 5. Shows LED and keypad of ZXD digital scroll controller.

Product Specication

For application envelope, envelope varies according to applications and refrigerants. Please refer to ZX platform product

catalogue, product manual, or Copeland

TM

Brand Products Selection Software.

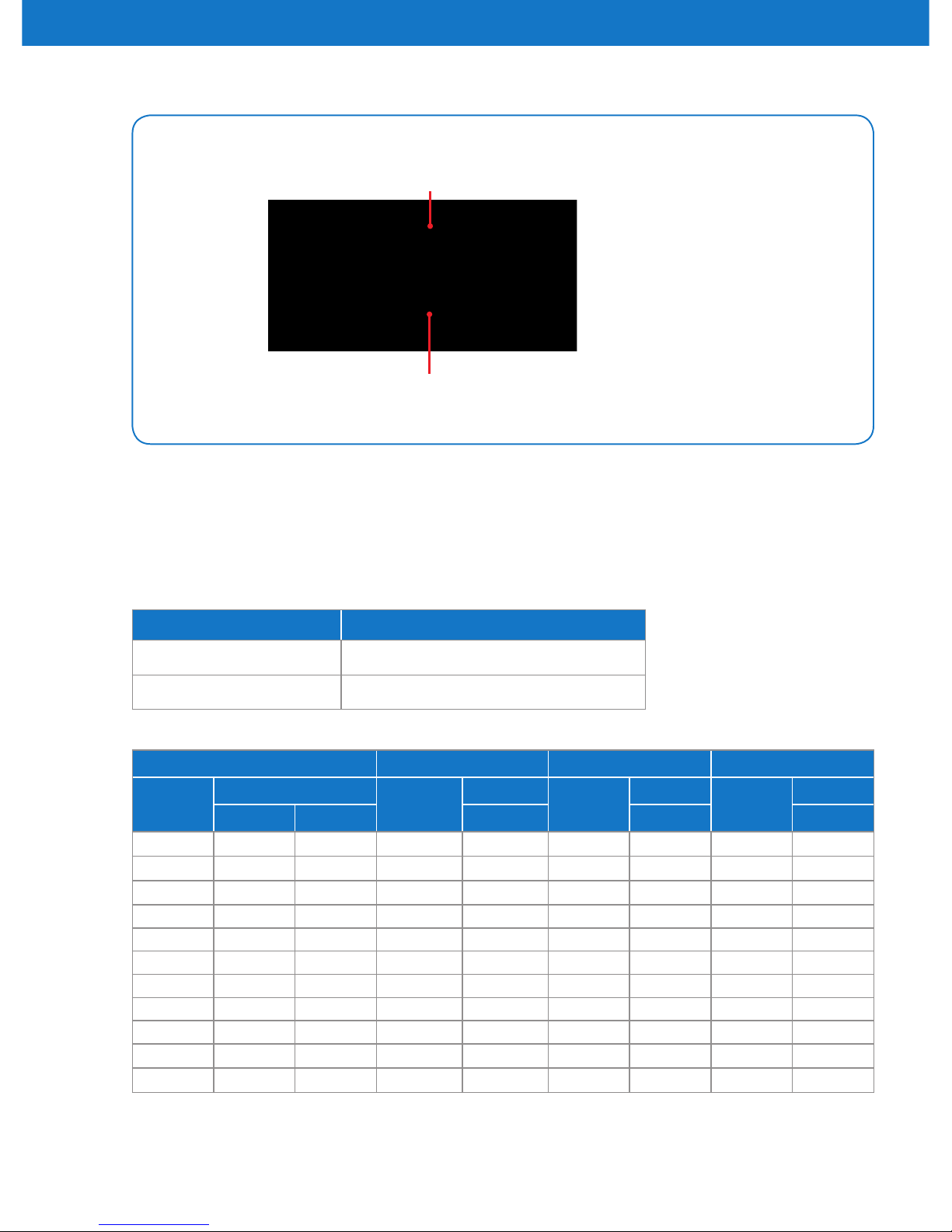

Qualified Refrigerants and Oils

Oils are pre-charged in both compressor and oil separator. Total oil volume (liter) for each unit is shown in the table below:

REFRIGERANT OIL

R404A/R507/R134a

Emkarate RL 32 3MAF

Mobil EAL Artic 22 CC

R22 Suniso 3GS

8

E2 Control Board Dip Switch Setting (ZX-MT, ZXB-MT & ZXL-LT)

ZX Model

ZXB Model

ZXL Model

Related Software

Version

300-0043-02 V2.2

With Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZX0200-TFD 1 OFF ON/ON

ZX0300-TFD 2 OFF ON/ON

ZX0400-TFD 3 OFF ON/ON

ZX0500-TFD 4 OFF ON/ON

ZX0600-TFD 5 OFF ON/ON

ZX0750-TFD 6 OFF ON/ON

ZX0760-TFD 6 OFF ON/ON

ZX0200-PFJ 7 OFF ON/ON

ZX0250-PFJ 8 OFF ON/ON

ZX0300-PFJ 9 OFF ON/ON

ZX0400-PFJ A OFF OFF/OFF

ZX0200-TF5 1 ON ON/ON

ZX0300-TF5 2 ON ON/ON

ZX0400-TF5 3 ON ON/ON

ZX0500-TF5 4 ON OFF/OFF

ZX0600-TF5 5 ON OFF/OFF

ZX0750-TF5 6 ON OFF/OFF

ZX0200-TF7 7 ON ON/ON

ZX0300-TF7 8 ON ON/ON

ZX0400-TF7 9 ON ON/ON

ZX0500-TF7/

ZX0600-TF7

A ON ON/ON

ZX0750-TF7 B ON ON/ON

Related Software

Version

300-0043-03 V2.1

W/O Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZX0200-TFD 1 OFF ON/ON

ZX0300-TFD 2 OFF ON/ON

ZX0400-TFD 3 OFF ON/ON

ZX0500-TFD 4 OFF ON/ON

ZX0600-TFD 5 OFF ON/ON

ZX0750-TFD 6 OFF ON/ON

ZX0200-PFJ 7 OFF ON/ON

ZX0250-PFJ 8 OFF O

N/ON

ZX0300-PFJ 9 OFF ON/ON

ZX0400-PFJ A OFF OFF/OFF

Related Software

Version

300-0043-00 V2.2

With Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZXB015E-TFD 1 OFF ON/ON

ZXB020E-TFD 2 OFF ON/ON

ZXB025E-TFD 3 OFF ON/ON

ZXB030E-TFD 4 OFF ON/ON

Related Software

Version

300-0043-00 V2.2

With Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZXL0200-TFD 1 OFF ON/ON

ZXL0250-TFD 2 OFF ON/ON

ZXL0300-TFD 3 OFF ON/ON

ZXL0350-TFD 4 OFF ON/ON

ZXL0400-TFD 5 OFF ON/ON

ZXL0500-TFD 6 OFF ON/ON

ZXL0600-TFD 7 OFF ON/ON

ZXL0750-TFD 8 OFF ON/ON

ZXL0200-TF5 /

ZXL0250-TF5

1 ON ON/ON

ZXL0300-TF5 2 ON ON/ON

ZXL0350-TF5 3 ON OFF/OFF

ZXL0400-TF5 4 ON OFF/OFF

ZXL0500-TF5 5 ON OFF/OFF

ZXL0600-TF5 6 ON OFF/OFF

ZXL0750-TF5 7 ON OFF/OFF

ZXL0200-TF7 /

ZXL0250-TF7

8 ON ON/ON

ZXL0300-TF7 9 ON ON/ON

ZXL0350-TF7 A ON ON/ON

ZXL0400-TF7 B ON ON/ON

ZXL0500-TF7 C ON ON/ON

ZXL0600-TF7 /

ZXL0750-TF7

D ON ON/ON

Related Software

Version

300-0043-01 V2.0

W/O Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZXL0200-TFD 1 OFF ON/ON

ZXL0250-TFD 2 OFF ON/ON

ZXL0300-TFD 3 OFF ON/ON

ZXL0350-TFD 4 OFF ON/ON

ZXL0400-TFD 5 OFF ON/ON

ZXL0500-TFD 6 OFF ON/ON

ZXL0600-TFD 7 OFF ON/ON

ZXL0750-TFD 8

OFF ON/ON

Related Software

Version

300-0043-00 V2.2

With Fan Speed Control

Model

Rotary

Switch

S2 Bit 3

S3 Bit1/

Bit2

ZXB035E-TFD 5 OFF ON/ON

ZXB040E-TFD 6 OFF ON/ON

ZXB050E-TFD 7 OFF ON/ON

ZXB055E-TFD 8 OFF ON/ON

9

Digital Scroll Controller (ZXD)

Note: The settings given in the table are pre-set at the factory for new units

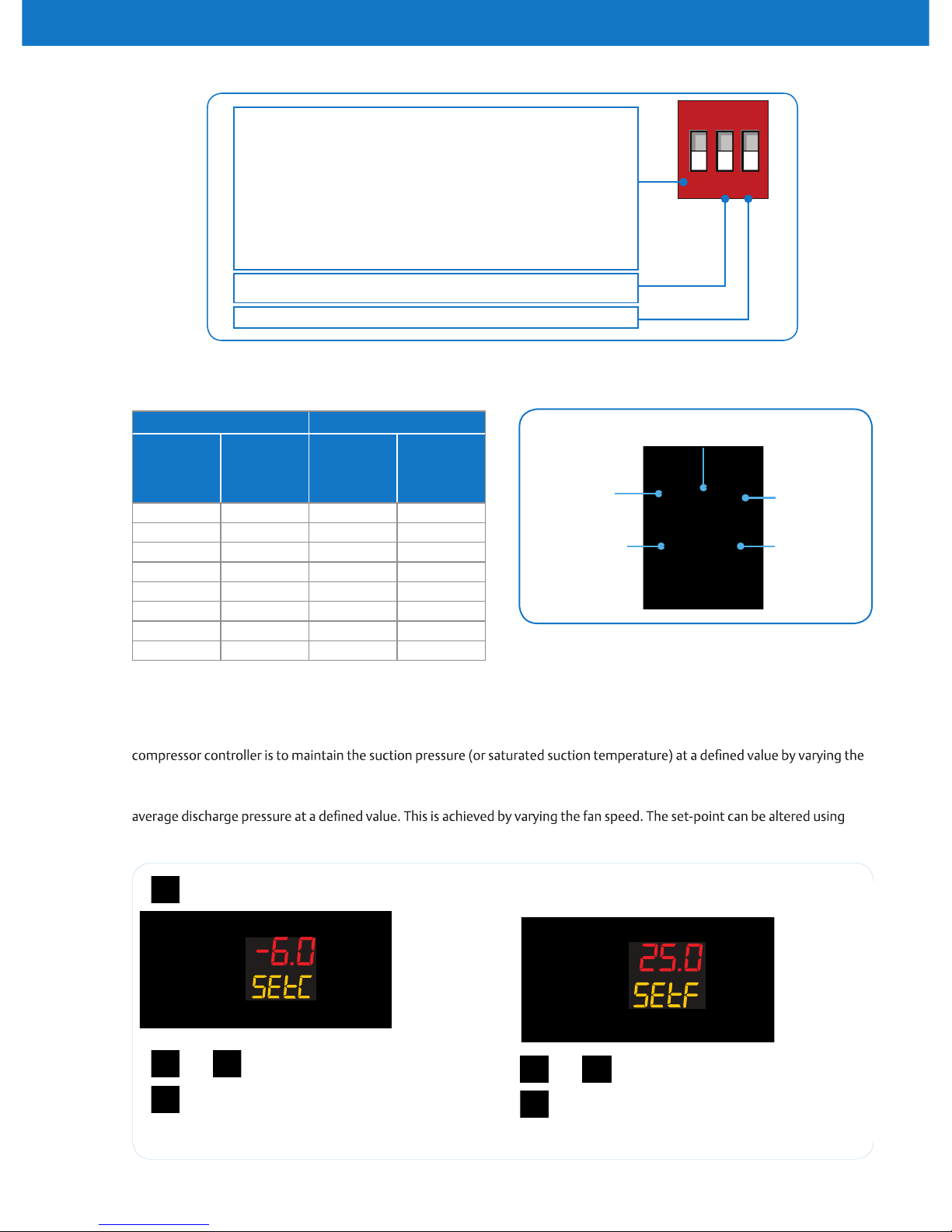

Then SEtF (fan speed control set point) will be displayed

automatically.

SEtC value

Flashing

Or to change set value within 30 seconds

press to memorize new value and Exit, or wait for

30 seconds without pressing any key to memorize value

and exit.

Press for more than 2 seconds

or to change set value within 30 seconds

press to memorize new set value.

SEtC value

Flashing

Time of Defrost Time of Defrost Interval

Rotary

Switch1

Time

(min)

Rotary

Switch2

Time

(hours)

0 0 0 0

1 5 1 1

2 10 2 2

3 15 3 3

4 20 4 4

5 25 5 5

6 30 6 6

7 35 7 7

Defrost Module Function Set

Defrost Duration (in Minutes)

Defrost Interval

(in Hours)

E2 Connector

Manual Defrost

Button

Remote Connector

For Manual Defrost

Figure 6. Defrost Module

The controller has been pre-programmed with a number of parameter values that are set for typical application. Individual

installation requirements, however, may make it necessary to alter parameter settings. The control target of the digital scroll

available compressor capacity. The set-point can be altered using the SEtC parameter. Factory setting SEtC is -6

o

C.

The control target of the fan speed controller is to maintain the average condenser mid-coil temperature and hence the

the SEtF parameter. Factory setting SEtF is 25

o

C. Initial setting of set point for saturated suction temperature.Pre-set value is

located in the SEtC position as shown in the diagram below:

ON

1 2 3

Use setting in the table

For ZX-MT Unit:

OFF: Evaporator ON/OFF logic is same as compressor and this is the factory

default setting

ON: Evaporator fan will be ON for all time irrespective of whether the

compressor is turned ON or OFF

Not applicable for ZX/ZXL/ZXB units

For ZXL-LT & ZXB-MT Units:

OFF: SH target value set at 5K and this is the factory default setting

for R404A, R134A and R22

ON: SH target value set at 10K, for R407F

Loading...

Loading...