Emerson ZBH38KJE, ZBH30KJE, ZRH49KJE, ZBH45KJE, ZBHV45KJE Application Manuallines

...

Application Guidelines

Copeland Scroll™ Horizontal Compressors

for Air-Conditioning Applications

ZRH49K* to ZRH72K*, ZBH30K* to ZBH45K*

ZRHV45K* & ZRHV72K*

C6.2.7/1007-0619/E

About these guidelines ............................................................................................... 1

1 Safety instructions ........................................................................................... 1

1.1 Icon explanation ............................................................................................................... 1

1.2 Safety statements ............................................................................................................ 1

1.3 General instructions ......................................................................................................... 2

2 Product description ......................................................................................... 3

2.1 General information about Copeland Scroll™ compressors ........................................... 3

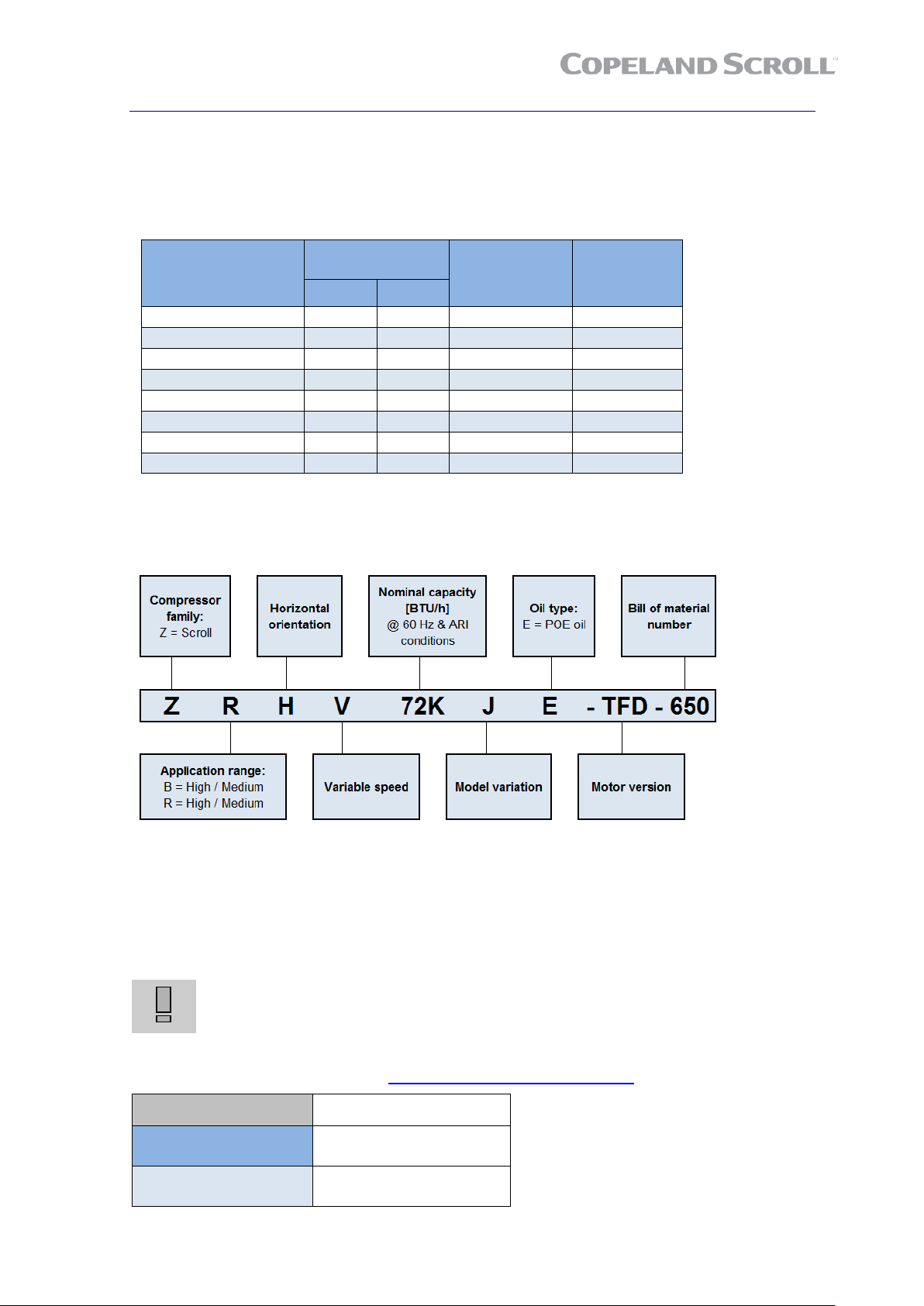

2.2 Nomenclature ................................................................................................................... 3

2.3 Application range ............................................................................................................. 3

2.3.1 Qualified refrigerants and oils .............................................................................. 3

2.3.2 Application limits ................................................................................................... 4

2.3.3 Comparison between ZRH* and ZBH* compressors ........................................... 4

2.4 Special requirements for transport applications............................................................... 4

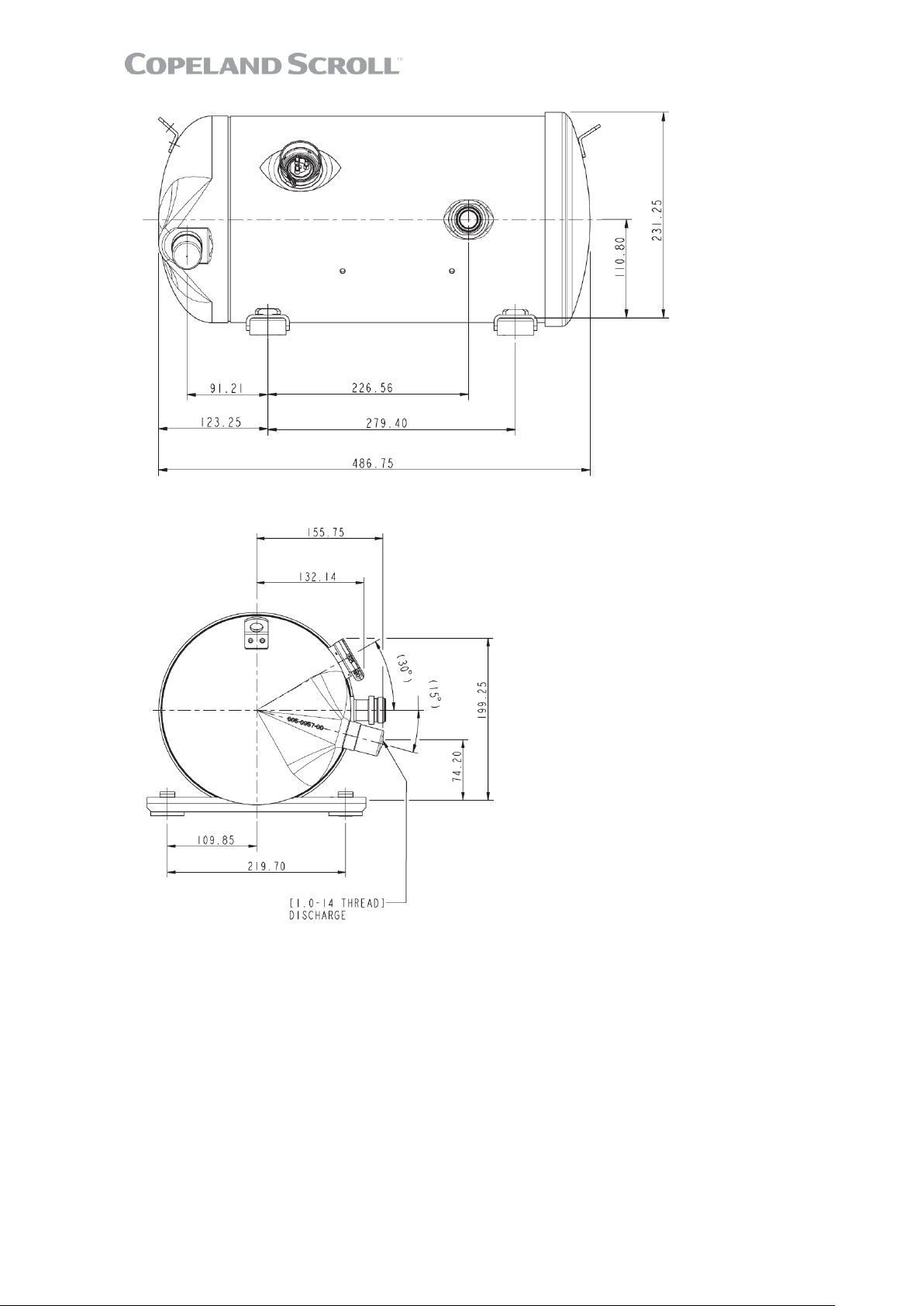

2.5 Dimensions ...................................................................................................................... 5

3 Installation ........................................................................................................ 7

3.1 Compressor handling ....................................................................................................... 7

3.1.1 Transport and storage .......................................................................................... 7

3.1.2 Positioning and securing ...................................................................................... 7

3.1.3 Installation location ............................................................................................... 7

3.1.4 Mounting parts ...................................................................................................... 8

3.2 Brazing procedure ............................................................................................................ 8

3.3 Shut-off valves and adaptors ........................................................................................... 9

3.4 Accumulators ................................................................................................................. 10

3.5 Screens .......................................................................................................................... 10

3.6 Mufflers .......................................................................................................................... 10

4 Electrical connection ..................................................................................... 11

4.1 General recommendations............................................................................................. 11

4.2 Electrical installation ...................................................................................................... 11

4.2.1 Molded plug connection ..................................................................................... 11

4.2.2 Assembly of the molded plug cable ................................................................... 11

4.2.3 Removing the molded plug cable ....................................................................... 12

4.2.4 Wiring diagram ................................................................................................... 12

4.2.5 Motor winding ..................................................................................................... 12

4.2.6 Protection devices .............................................................................................. 13

4.2.7 Crankcase heater ............................................................................................... 13

4.3 Inverter operation ........................................................................................................... 13

4.4 Pressure safety controls ................................................................................................ 15

4.4.1 High-pressure protection .................................................................................... 15

4.4.2 Low-pressure protection ..................................................................................... 15

4.4.3 Internal pressure relief valve .............................................................................. 15

C6.2.7/1007-0619/E

4.5 Discharge gas temperature protection ........................................................................... 15

4.6 Motor protection ............................................................................................................. 16

4.7 High-potential testing ..................................................................................................... 16

5 Start-up & operation ....................................................................................... 17

5.1 Strength pressure test .................................................................................................... 17

5.2 Tightness/pressure test .................................................................................................. 17

5.3 System evacuation ......................................................................................................... 17

5.4 Preliminary checks – Pre-starting .................................................................................. 17

5.5 First start ........................................................................................................................ 18

5.6 Charging procedure ....................................................................................................... 18

5.7 Initial start-up ................................................................................................................. 18

5.8 Rotation direction ........................................................................................................... 18

5.9 Starting sound ................................................................................................................ 19

5.10 Deep vacuum operation ................................................................................................. 19

5.11 Refrigerant migration ..................................................................................................... 19

5.12 Pumpdown cycle ............................................................................................................ 19

5.13 Shell temperature ........................................................................................................... 20

5.14 Minimum run time .......................................................................................................... 20

5.15 Shut-off sound ................................................................................................................ 20

5.16 Oil level .......................................................................................................................... 20

6 Maintenance & repair ..................................................................................... 21

6.1 Exchanging the refrigerant ............................................................................................. 21

6.2 Replacing a compressor ................................................................................................ 21

6.2.1 Compressor replacement ................................................................................... 21

6.2.2 Start-up of a new or replacement compressor ................................................... 21

6.3 Lubrication and oil removal ............................................................................................ 22

6.4 Oil additives ................................................................................................................... 22

6.5 Unbrazing system components ..................................................................................... 22

7 Dismantling & disposal .................................................................................. 23

DISCLAIMER .............................................................................................................. 23

C6.2.7/1007-0619/E 1

About these guidelines

The purpose of these guidelines is to provide guidance in the application of Copeland Scroll™

horizontal compressors in users’ systems. They are intended to answer the questions raised while

designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the compressors. Emerson cannot guarantee the performance and reliability of

the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications. For transport or rail applications, other

considerations such as high vibration and shocks, power supply characteristics, high ambient

temperatures, frequent cycling etc. may apply. It is the responsibility of the system designer/planner

to define the individual requirements to qualify the compressor and the complete system for their

specific needs. Please contact the Application Engineering department at Emerson or your local

Emerson representative for additional support.

1 Safety instructions

Copeland Scroll compressors are manufactured according to the latest European safety standards.

Particular emphasis has been placed on the user’s safety.

These compressors are intended for installation in systems according to the EC Machinery Directive

MD 2006/42/EC. They may be put to service only if they have been installed in these systems

according to instructions and conform to the corresponding provisions of legislation. For relevant

standards please refer to the Manufacturers Declaration, available at www.climate.emerson.com/en-

gb.

These instructions should be retained throughout the lifetime of the compressor.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

WARNING

This icon indicates instructions to

avoid personal injury and material

damage.

CAUTION

This icon indicates instructions to avoid

property damage and possible

personal injury.

High voltage

This icon indicates operations with a

danger of electric shock.

IMPORTANT

This icon indicates instructions to avoid

malfunction of the compressor.

Danger of burning or frostbite

This icon indicates operations with a

danger of burning or frostbite.

NOTE

This word indicates a recommendation

for easier operation.

Explosion hazard

This icon indicates operations with a

danger of explosion.

1.2 Safety statements

▪ Refrigerant compressors must be employed only for their intended use.

▪ Only qualified and authorized HVAC or refrigeration personnel are permitted to install,

commission and maintain this equipment.

▪ Electrical connections must be made by qualified electrical personnel.

▪ All valid standards for connecting electrical and refrigeration equipment must be

observed.

▪ The national legislation and regulations regarding personnel protection must be observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

2 C6.2.7/1007-0619/E

1.3 General instructions

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only approved refrigerants and

refrigeration oils must be used.

WARNING

High shell temperature! Burning! Do not touch the compressor until it has

cooled down. Ensure that other materials in the area of the compressor do not

come into contact with it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

CAUTION

Contact with POE! Material damage! POE lubricant must be handled

carefully and the proper protective equipment (gloves, eye protection, etc.)

must be used at all times. POE must not come into contact with any surface

or material that it might damage, including without limitation, certain polymers,

eg, PVC/CPVC and polycarbonate.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid

collisions and tilting.

C6.2.7/1007-0619/E 3

2 Product description

2.1 General information about Copeland Scroll™ compressors

These application guidelines deal with Copeland Scroll horizontal compressors for airconditioning and other applications with HFC refrigerants. This compressor range consists

of models ZRH49KJE to ZRH72KJE and ZBH30KJE to ZBH45KJE fixed speed, and models

ZRHV45KJE and ZBHV72KJE variable speed.

Compressor

Cooling capacity

[kW]

Displacement

[m³/h]

Motor

R407C

R134a

ZBH30KJE

10.0

7.0

11.7

TFD/TF5

ZBH38KJE

12.6

8.6

14.4

TFD/TF5

ZBH45KJE

14.8

10.2

17.1

TFD/TF5

ZBHV45KJE

14.8

10.2

17.1

TFD/TF5

ZRH49KJE

10.2

7.1

11.8

TFD/TF5

ZRH61KJE

13.0

8.9

14.5

TFD/TF5

ZRH72KJE

15.0

10.5

17.1

TFD/TF5

ZRHV72KJE

15.0

10.5

17.1

TFD/TF5

Table 1: Cooling capacity at 5°C/50°C/10K/0K

2.2 Nomenclature

The model designation contains the following technical information about the compressor:

ARI conditions:

Evaporating temperature ........ 7.2°C Liquid sub-cooling ........... 8.3K

Condensing temperature ........ 54.4°C Ambient temperature ....... 35°C

Suction gas superheat ............ 11K

2.3 Application range

2.3.1 Qualified refrigerants and oils

IMPORTANT

It is essential that the glide of refrigerant blends (primarily R407C) be carefully

considered when adjusting pressure and superheat controls.

Oil recharge values can be taken from Copeland Scroll compressors brochures or Copeland™ brand

products Select software available at www.climate.emerson.com/en-gb.

Qualified refrigerants

R407C & R134a

Copeland brand

products standard oil

Emkarate RL 32 3MAF

Servicing oils

Emkarate RL 32 3MAF

Mobil EAL Arctic 22 CC

Table 2: Qualified refrigerants and oils

4 C6.2.7/1007-0619/E

2.3.2 Application limits

CAUTION

Inadequate lubrication! Compressor breakdown! The superheat at the

compressor suction inlet must always be sufficient to ensure that no refrigerant

droplets enter the compressor. For a typical evaporator-expansion valve

configuration a minimum stable superheat of at least 5K is required.

NOTE: The application envelopes for all horizontal compressor models covered in these

guidelines are available in Copeland brand products Select software at

www.climate.emerson.com/en-gb.

2.3.3 Comparison between ZRH* and ZBH* compressors

ZRH* and ZBH* horizontal compressor models are basically available in two BOM variations:

▪ BOM 650 Compressor with brazing stub tubes, electrical box ready for molded plug IP65

▪ BOM 651 Compressor with Rotalock connections, electrical box ready for molded plug IP65

Table 2 below describes the differences and similarities between ZRH* and ZBH* models:

Compressor

version

BOM 650

BOM 651

ZRH*

Brazing stub tubes

Electrical connection ready for

molded plug IP65

Without oil sight glass

Without oil service Schraeder valve

Rotalock connections

Electrical connection ready for molded

plug IP65

Without oil sight glass

Without oil service Schraeder valve

ZRHV*

Brazing stub tubes

Electrical connection ready for

molded plug IP65

Without oil sight glass

Without oil service Schraeder valve

Variable speed

Rotalock connections

Electrical connection ready for molded

plug IP65

Without oil sight glass

Without oil service Schraeder valve

Variable speed

ZBH*

Brazing stub tubes

Electrical connection ready for

molded plug IP65

Oil sight glass

Oil service Schraeder valve

Rotalock connections

Electrical connection ready for molded

plug IP65

Oil sight glass

Oil service Schraeder valve

ZBHV*

Brazing stub tubes

Electrical connection ready for

molded plug IP65

Oil sight glass

Oil service Schraeder valve

Variable speed

Rotalock connections

Electrical connection ready for molded

plug IP65

Oil sight glass

Oil service Schraeder valve

Variable speed

Table 3: Differences and similarities between ZRH* and ZBH* horizontal scroll compressors

2.4 Special requirements for transport applications

Transport air-conditioning or refrigeration applications can be particularly sensitive and require

experience and thorough case-by-case analysis. Compared to static applications, additional

demands in terms of applicability to specific norm and standard requirements can arise. The system

designer must pay particular attention to higher demands with regard to shock stress, high vibration

levels, power supply and other installation characteristics.

The qualification for the parts and individual requirements, like system components, piping, piping

layout, fixation, as well as a study about shock, vibration and load requirements must be carried out

by the unit designer for the whole system. Emerson can provide support and assistance with

individual projects.

C6.2.7/1007-0619/E 5

2.5 Dimensions

Figure 1: Dimensions of models ZBH30KJE to ZBH45KJE and ZBHV45KJE

6 C6.2.7/1007-0619/E

Figure 2: Dimensions of models ZRH42KJE to ZRH72KJE and ZRHV72KJE

Loading...

Loading...