Digital

Application Guidelines

Digital Scroll™ Compressors for Refrigeration

ZBD21K* to ZBD114K*

ZFD13KVE to ZFD25KVE

ZFD41K5E

About these guidelines .............................................................................................. 1

1 Safety instructions .......................................................................................... 1

1.1 Icon explanation ................................................................................................. 1

1.2 Safety statements............................................................................................... 1

1.3 General instructions ............................................................................................ 2

2 Product description ........................................................................................ 3

2.1 Common information about Copeland Scroll Digital™ compressors............................ 3

2.2 Nomenclature .................................................................................................... 4

2.3 Dimensions ....................................................................................................... 4

2.4 Application range ............................................................................................... 5

2.4.1 Qualified refrigerants and oils ..................................................................... 5

2.4.2 Application limits and operating envelopes ................................................... 6

3 Installation....................................................................................................... 7

3.1 Compressor handling .......................................................................................... 7

3.1.1 Transport and storage ............................................................................... 7

3.1.2 Positioning and securing............................................................................ 7

3.1.3 Installation location ................................................................................... 7

3.1.4 Mounting parts ......................................................................................... 7

3.2 Solenoid valves for models ZBD21K* to ZBD57K* and ZFD13KVE to ZFD25KVE ........ 8

3.2.1 Securing the filter screen in position ............................................................ 8

3.2.2 Solenoid valve installation – General recommendations ................................. 9

3.2.3 Solenoid valve installation – Tubing recommendations ................................... 9

3.3 Copeland Scroll Digital compressors ZFD13KVE to ZFD25KVE with vapour injection /

wet vapour injection ................................................................................................... 9

3.3.1 Vapour injection (EVI = Economized Vapour Injection) ..................................10

3.3.2 Wet vapour injection (vapour injection + liquid injection) ................................10

3.4 Discharge check valve .......................................................................................11

3.5 Brazing procedure .............................................................................................11

3.6 Shut-off valves and adaptors ...............................................................................12

3.7 Oil separator.....................................................................................................13

3.8 Accumulators....................................................................................................13

3.9 Screens ...........................................................................................................13

3.10 Mufflers............................................................................................................14

3.11 Suction line noise and vibration ...........................................................................14

4 Electrical connection .................................................................................... 15

4.1 General recommendations ..................................................................................15

4.2 Electrical installation ..........................................................................................15

4.2.1 Terminal box...........................................................................................17

4.2.2 Motor winding .........................................................................................17

4.2.3 Motor protection ......................................................................................18

C6.2.24/1014-0215/E

4.2.4 Protection devices ...................................................................................18

4.2.5 Crankcase heaters ..................................................................................18

4.3 Pressure safety controls .....................................................................................18

4.3.1 IPR valve (Internal Pressure Relief valve) ...................................................18

4.3.2 High-pressure control ...............................................................................18

4.3.3 Low-pressure control ...............................................................................19

4.4 Discharge temperature protection ........................................................................19

4.5 High potential testing .........................................................................................20

5 Starting up & operation................................................................................. 21

5.1 Strength pressure test ........................................................................................21

5.2 Tightness/pressure test ......................................................................................21

5.3 Preliminary checks – Pre-starting .........................................................................21

5.4 Charging procedure ...........................................................................................21

5.5 Initial start-up ....................................................................................................22

5.6 Rotation direction ..............................................................................................22

5.7 Pressure fluctuations .........................................................................................22

5.8 Starting sound ..................................................................................................22

5.9 Deep vacuum operation .....................................................................................23

5.10 Shell temperature ..............................................................................................23

5.11 Minimum run time ..............................................................................................23

5.12 Sound characteristics.........................................................................................23

5.13 Shut-off sound ..................................................................................................23

5.14 Frequency ........................................................................................................23

5.15 Oil level............................................................................................................24

5.16 Digital system control .........................................................................................24

5.17 Power factor .....................................................................................................24

6 Maintenance & repair .................................................................................... 25

6.1 Exchanging the refrigerant ..................................................................................25

6.2 Rotalock valves .................................................................................................25

6.3 Replacing a compressor .....................................................................................25

6.3.1 Compressor replacement..........................................................................25

6.3.2 Start-up of a new or replacement compressor ..............................................25

6.4 Lubrication and oil removal .................................................................................26

6.5 Oil additives......................................................................................................26

6.6 Unbrazing system components............................................................................27

7 Dismantling & disposal ................................................................................. 27

DISCLAIMER............................................................................................................. 27

C6.2.24/0215-0515/E

WARNING

This icon indicates instructions to

avoid personal injury and material

damage.

CAUTION

This icon indicates instructions to

avoid property damage and possible

personal injury.

High voltage

This icon indicates operations with a

danger of electric shock.

IMPORTANT

This icon indicates instructions to

avoid malfunction of the compressor.

Danger of burning or frostbite

This icon indicates operations with a

danger of burning or frostbite.

NOTE

This word indicates a

recommendation for easier operation.

Explosion hazard

This icon indicates operations with a

danger of explosion.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

About these guidelines

The purpose of these application guidelines is to provide guidance in the application of Copeland

Scroll™ compressors in users’ systems. They are intended to answer the questions raised while

designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the compressors. Emerson Climate Technologies will not guarantee the

performance and reliability of the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications only. For mobile applications, contact

Application Engineering as other considerations may apply.

1 Safety instructions

Copeland Scroll compressors are manufactured according to the latest European and US Safety

Standards. Particular emphasis has been placed on the user’s safety.

These compressors are intended for installation in systems according to the Machinery Directive

MD 2006/42/EC and to the Pressure Equipment Directive PED 97/23/EC. They may be put to

service only if they have been installed in these systems according to instructions and conform

to the corresponding provisions of legislation. For relevant standards please refer to

Manufacturers Declaration, available at

www.emersonclimate.eu.

These instructions should be retained throughout the lifetime of the compressor.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

1.2 Safety statements

Refrigerant compressors must be employed only for their intended use.

Only qualified and authorized HVAC or refrigeration personnel are permitted to install,

commission and maintain this equipment.

Electrical connections must be made by qualified e lectrical personnel.

All valid standards for connecting electrical and refrige ration equipment must be

observed.

The national legislation a nd regula tions regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

C6.2.24/0215-0515/E 1

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only approved refrigerants and

refrigeration oils must be used.

WARNING

High shell temperature! Burning! Do not touch the compressor until it has

cooled down. Ensure that other materials in the area of the compressor do

not get in touch with it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

CAUTION

Contact with POE! Material damage! POE lubricant must be handled

carefully and the proper protective equipment (gloves, eye protection, etc.)

must be used at all times. POE must not come into contact with any surface

or material that it might damage, including without limitation, certain

polymers, eg, PVC/CPVC and polycarbonate.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid

collisions and tilting.

1.3 General instructions

2 C6.2.24/1014-0215/E

Compressor

Cooling Capacity kW

Motor

R404A

R407A

R407F

R448A

R449A

R134a

R450A

R513A*

ZBD21KCE

5.09

4.88

4.67

3.14

2.67

3.00

PFJ/TFD

ZBD29KCE

6.83

6.35

6.77

3.97

TFD

ZBD30KCE

6.98

6.78

6.84

6.67

4.25

3.63

4.09

TFD

ZBD38KCE

8.59

8.46

8.37

8.33

5.29

4.48

5.04

TFD

ZBD45KCE

10.25

9.39

10.00

9.76

6.04

5.38

6.03

TFD

ZBD57KCE

13.22

12.86

12.84

7.63

TFD

ZBD58KCE

13.45

12.00

12.84

TFD

ZBD76KCE

17.85

15.95

17.24

10.20

TFD

ZBD76K5E

18.38

17.08

18.40

TFD

ZBD114K5E

26.19

24.10

24.09

TFD

Compressor

COP

Motor

R404A

R407A

R407F

R448A

R449A

R134a

R450A

R513A*

ZBD21KCE

2.23

2.28

2.01

2.15

2.24

2.14

PFJ/TFD

ZBD29KCE

2.20

2.14

2.09

2.07

TFD

ZBD30KCE

2.22

2.16

2.22

2.15

2.21

2.24

2.12

TFD

ZBD38KCE

2.23

2.20

2.22

2.15

2.23

2.25

2.14

TFD

ZBD45KCE

2.24

2.17

2.23

2.22

2.20

2.27

2.14

TFD

ZBD57KCE

2.26

2.17

2.17

2.36

1.99

TFD

ZBD58KCE

2.12

2.02

2.08

TFD

ZBD76KCE

2.16

2.08

2.16

2.18

2.08

TFD

ZBD76K5E

2.14

2.11

2.19

TFD

ZBD114K5E

2.07

2.08

2.08

TFD

Compressor

R404A

R407A

R407F

R448A, R449A

Motor

kW

COP

kW

COP

kW

COP

kW

COP

kW

ZFD13KVE

3.96

1.35

3.15

1.16

3.31

1.16

3.27

1.45

TFD

ZFD18KVE

5.91

1.49

4.92

1.44

4.92

1.29

4.83

1.43

TFD

ZFD25KVE

7.68

1.62

6.12

1.43

6.43

1.43

6.16

1.58

TFD

ZFD41K5E

8.56

1.35

7.32

1.18

7.32

1.18

TFD

ZFD41K5E EVI

12.46

1.58

10.02

1.55

10.02

1.55

TFD

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

2 Product description

2.1 Common information about Copeland Scroll Digital™ compressors

The Scroll compressor has been under development at Emerson Climate Technologies since

1979. It is the most efficient and durable compressor Emerson Climate Technologies has ever

developed for air conditioning and refrigeration.

These application guideline s dea l with Copeland Scroll Digital™ compressors for

refrigeration from ZBD21K* to ZBD114K*, ZFD13K* to ZFD41K*. These compressors

include a wide range of capacities, electrical options and features.

Table 1: Cooling capacity for medium tempera ture compressors @EN 12900 Medium temp.

Table 2: Coefficient of performance (COP) for medium temperature compressors @EN 12900 Medium temp.

Table 3: Cooling capacity in kW and COP for low temperature compressors @EN 12900 Low temp

EN 12900 MT: Evaporating: -10°C, Condensing: 45°C, Suction gas: 20°C, Sub-cooling: 0K

Except for R513A*, Suction Superheat = 10K

EN 12900 LT: Evaporating: -10°C, Condensing: 45°C, Suction gas: 20°C, Sub-cooling: 0K

Copeland Scroll Digital compressors have one Scroll compression set driven by a single or

three-phase induction motor. The Scroll set is mounted at the upper end of the rotor shaft of the

motor. The rotor shaft axis is in the vertical plane.

C6.2.24/0215-0515/E 3

A B C D

E

ZBD21KCE

432.4

414.3

363.6

261.6

218.9

ZBD29KCE

463.2

445.2

394.3

291.3

249.7

2.2 Nomenclature

The model designation contains the following technical information about the compressor:

2.3 Dimensions

Figure 1: Dimensions ZBD21KCE & ZBD29KCE Figure 2: Dimensions ZBD30K* to ZBD57K*

& ZFD13KVE to ZFD25KVE

4 C6.2.24/1014-0215/E

A

mm

B

mm

C

mm

D

mm

E

mm

H

mm

ZBD58KCE

476.3

444.3

211.7

93.6

201.5

74.3

ZBD76KCE

533.2

501.2

253

122.1

242.8

92.3

ZBD76K5E

533.6

501.8

253.7

277.3

245.7

93

ZBD114K5E

881.5

519.5

271.3

295

263.3

93

IMPORTANT

It is essential that the glide of refrigerant blends (primarily R407A and

R407F) is carefully considered when adjusting pressure and superheat

controls.

Compressor

ZBD21K* to ZBD114K*

ZFD13K* to ZFD41K*

Qualified refrigerants

R404A, R407A, R407F, R448A,

R449A, R134a, R450A, R513A, R507;

R22 for ZBD30K* & ZBD45K* only

R404A, R407A, R407F,

R448A, R449A, R507

Copela nd brand products

standard oil

Emkarate RL 32 3MAF

Servicing oils

Emkarate RL 32 3MAF / Mobil EAL Arctic 22 CC

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

Figure 3: Dimensions ZBD58KCE & ZBD76KCE Figure 4: Dime nsions ZBD76K5E & ZBD114K5E

2.4 Application range

2.4.1 Qualified refrigerants and oils

Oil recharge values can be taken from Copeland Scroll compressors brochures or Copeland™

brand products Select software at

Table 4: Qualified refrigerants and oils

www.emersonclimate.eu.

C6.2.24/0215-0515/E 5

CAUTION

Inadequate lubrication! Compressor breakdown! The superheat at the

compressor suction inlet must always be sufficient to ensure that no

refrigerant droplets enter the compressor. For a typical evaporator-expansion

valve configuration a minimum stable superheat of at least 5K is required.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

2.4.2 Application limits and operating envelopes

The application envelopes for Digital refrigeration Scroll compressors are for various refrigerants,

you can find them in the Copeland brand products Select software, which can be downloaded for

free on our website

www.emersonclimate.eu.

6 C6.2.24/1014-0215/E

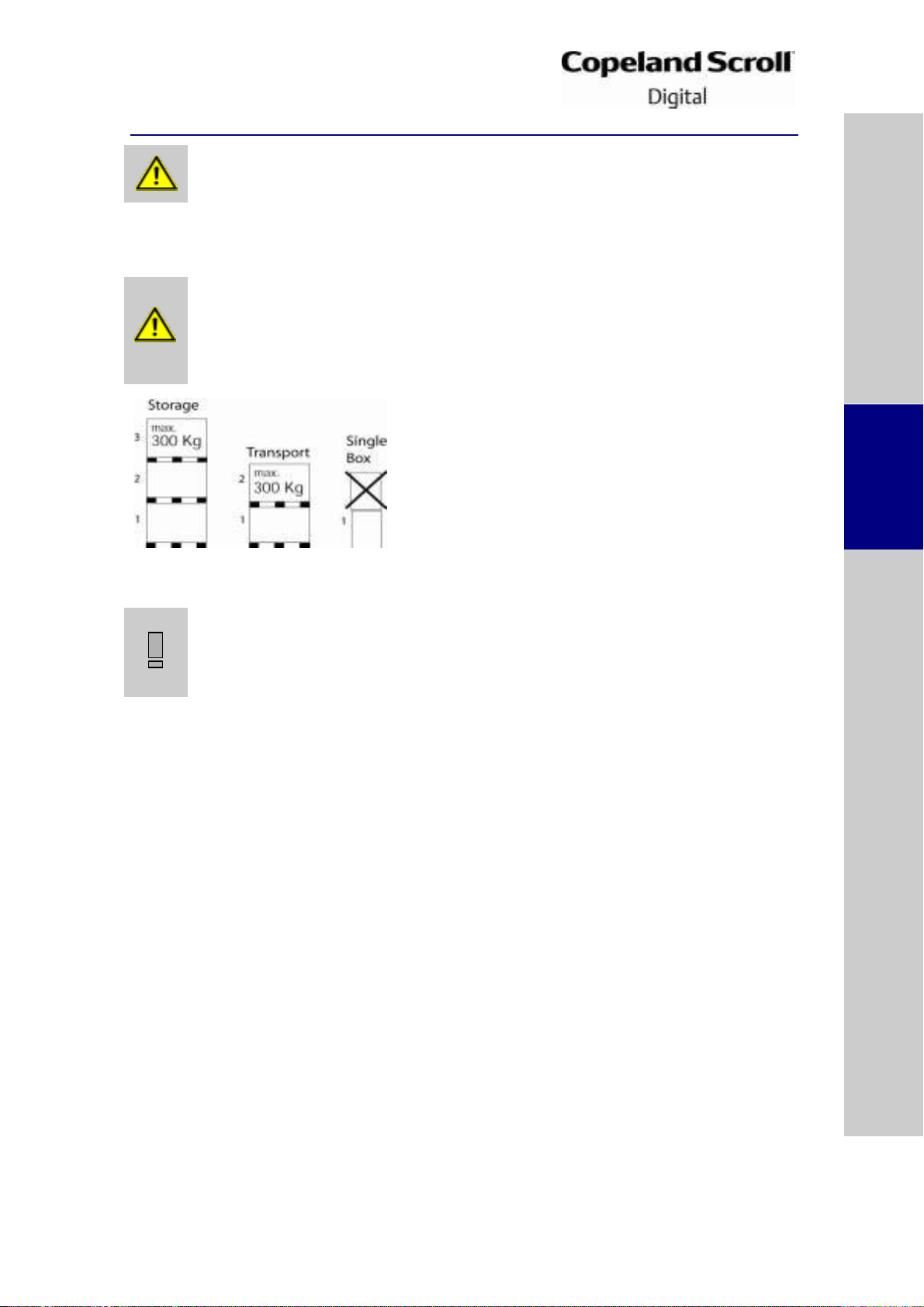

WARNING

High pressure! Injury to skin and eyes possible! Be careful when

opening connections on a pressurized item.

WARNING

Risk of collapse! Personal injuries! Move compressors only with

appropriate mechanical or handling equipment according to weight. Keep in

the upright position. Stack pallets on top of each other when not exceeding

300 kg. Do not stack single boxes on top of each other. Keep the packaging

dry at all times.

IMPORTANT

Handling damage! Compressor malfunction! Only use the lifting eyes

whenever the compressor requires positioning. If the compressor has two

lifting tabs, both must be used for lifting. Using discharge or suction

connections for lifting may cause damage or leaks.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

3 Installation

3.1 Compressor handling

3.1.1 Transport and storage

Figure 5

3.1.2 Positioning and securing

For models ZBD58K* to ZBD114K* and ZFD41K5E, because oil might spill out of the suction

connection located low on the shell, the suction connection plug must be left in place until the

compressor is set into the unit. If possible, the compressor should be kept vertical during

handling. The discharge connection plug should be removed first before pulling the suction

connection plug to allow the dry air pressure inside the compressor to escape. Pulling the plugs

in this sequence prevents oil mist from coating the suction tube making brazing difficult. The

copper-coated steel suction tube should be cleaned before brazing. No object, eg, a swaging

tool should be inserted deeper than 51 mm into the suction tube or it might damage the suction

screen and motor.

3.1.3 Installation location

Ensure the compressors are installed on a solid level base.

3.1.4 Mounting parts

Four vibration absorber grommets are supplied with each compressor. They dampen the start-up

surge of the compressor and minimise sound and vibration transmission to the compressor base

during operation. The metal sleeve inside is a guide designed to hold the grommet in place. It is

not designed as a load-bearing member, and application of excessive torque to the bolts can

crush the sleeve. Its inner diameter is approximately 8.5 mm to fit, eg, an M8 screw. The

mounting torque should be 13 ± 1 Nm. It is critically important that the grommet is not

compressed.

If the compressors are mounted in tandem or used in parallel, then the hard mountings (bolt M9

5/16”) are recommended. The mounting torque should be 27 ± 1 Nm. It is possible to deliver

these hard mounting parts as a kit, or on request to deliver the compressor with these parts

instead of the rubber grommets.

C6.2.24/0215-0515/E 7

Mounting parts ZBD21K* to ZBD114K* & ZFD13K* to ZFD41K* - Soft mountings

IMPORTANT

The external solenoid valve is a critical component for proper function of this

compressor. Only the Copeland brand solenoid valve supplied as a

requested accessory must be used.

Figure 6

3.2 Solenoid v alv e s for models ZBD21K* to ZBD57K* and ZFD13KVE to

ZFD25KVE

Care must be taken during the brazing process that no solid parts can enter the control piston

compartment or the solenoid valve tubing. To prevent solid parts from entering the control valve

seat, the solenoid valve kit contains a filter screen, which has to be placed into the horizontal

tube of the valve before brazing the tube connections as shown in Figure 10 below.

The solenoid valve has to be fitted in such a way that the sleeve with the stem inside – which

supports the solenoid coil – is fixed and aligned in the upright position.

3.2.1 Securing the filter screen in position

The filter screen should be placed into the small tube running

at 90° to the solenoid valve stem. A narrow washer fixed on

the filter screen will sit on the end of the tube preventing it

falling inside (see photos). The tube running from the top

centre of the compressor down to the previous tube needs to

be swaged at the solenoid valve end so that it covers the filter screen/tube and is

then brazed into position.

Filter screen with washer

To solenoid valve end From top o From compressor

Swaged tube

Swaged tube

Figure 7

Figure 8: Position of external s olenoid v a lv e Figure 9: Recommended piping

8 C6.2.24/1014-0215/E

IMPORTANT

This tube has been tested and qualified at 50 and 60 Hz operation for

running stresses and resonance in a single compressor lab environment.

However, in some compressor applications such as racks and transport

applications, the OEM is strongly advised to re-confirm the acceptability of

the tube when the compressor is subject to additional vibration inputs.

Compressor family

Liquid injection

Vapour injection

Wet vapour injection

(vapour + liquid injection)

ZFD13KVE to ZFD25KVE

X

X

ZFD41KE

X

X

X

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

3.2.2 Solenoid valve installation – General recommendations

The solenoid must be mounted vertically, within ± 15° of vertical. Horizontal mounting is not

permitted.

If a suction rotalock fitting is used, the threaded shipping plug in the rotalock fitting must be

removed prior to brazing in the vertical solenoid line.

The valve operation is directional. See Figures 13 & 14 below for inlet and outlet locations.

Do not restrict the line size coming from or leaving the solenoid. Use 3/8” soft drawn

copper.

Figure 10: Control v alv e w ithout coil Figure 11: Control v alv e pipe connection

3.2.3 Solenoid valve installation – Tubing recommendations

The tube from the solenoid to the suction, marked “A” (see Figure 12), should be as short as

possible (less than 7.5 cm). Dimensions for a typical tube going from the top of the compressor

are shown in Figures 13 & 14.

3.3 Cope land Scroll Digital compressors ZFD13KVE to ZFD25KVE with v apour

inje ction / we t v apour injection

The following injection systems can be used:

Table 5

C6.2.24/0215-0515/E 9

Copeland Scroll compressors ZFD13KVE to ZFD25KVE are vapour injection only. Liquid

injection alone is not possible. For compressor model ZFD41K5E both liquid injection and

vapour injection are possible.

Dedicated discharge temperature thermostats (DLT) shall be used for R407A, R407F, R448A

and R449A applications and can also be used for R404A. The R407A/R407F/R448A/R449A

dedicated discharge thermostat has a cut-out setting of 130°C ± 4K with closing at 101°C ± 8K.

It should be installed approximately 120 mm from the discharge valve outlet.

3.3.1 Vapour injection (EVI = Economized Vapour Injection)

Compressor models ZFD13KVE to ZFD25KVE and ZFD41K5E can be used with R404A,

R407A, R407F, R448A and R449A refrigerants and vapour injection.

These compressors are equipped with a vapour injection connection for economizer operation.

Economizing can be achieved by using a subcooling circuit similar to the circuit shown in

Figure 15. This increases the refrigeration capacity and the system efficiency.

The line diagram shows a system configuration for the economizer cycle. A heat exchanger is

used to provide additional subcooling to the refrigerant before it enters the evaporator. This

subcooling process provides the increased capacity gain measured in the system.

The evaporated refrigerant through the heat exchanger (economizer) is injected into the

compressors and provides additional cooling at higher compression ratios.

Figure 12: Vapour inj e ction line diagram

The application envelopes for the use of R407A and R407F refrigerants with vapour injection are

significantly limited, because of possible high discharge temperatures. Special attention should

be paid to the maximum suction gas temperature / superheat values.

NOTE: For further informa tion on vapour injection see Technical Information C7.19.2

"ZF* Refrigeration Copeland Scroll™ Compressors Using R407A and R407F in Low

Temperature Applications".

3.3.2 Wet vapour injection (vapour injection + liquid injection)

Compressor models ZFD13KVE to ZFD25KVE and ZFD41K5E can be used with R407A and

R407F refrigerants and wet vapour injection.

The operating envelopes for R407A and R407F low temperature applications can be enlarged

thanks to the use of wet vapour injection, ie, a combination of vapour injection and liquid

injection (DTC valve) (see Figures 6 & 7 in Chapter 2.4.2).

The wet vapour injection cycle showing the main components is shown in Figure 16 next page:

10 C6.2.24/1014-0215/E

IMPORTANT

Blockage! Compre ssor brea kdown! Maintain a flow of oxygen-free

nitrogen through the system at very low pressure during brazing. Nitrogen

displaces the air and prevents the formation of copper oxides in the system.

If allowed to form, the copper oxide material can later be swept through the

system and block screens such as those protecting capillary tubes, thermal

expansion valves, and accumulator oil return holes.

Contamination or moisture! Bearing failure! Do not remove the plugs

until the compressor is set into the unit. This minimises any entry of

contaminants and moisture.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

Figure 13: Wet v apour injection cycle for R407 A & R407F low temperature applications

NOTE: For Digital compressors ZFD13KVE and ZFD25KVE, the DTC valve bulb must

replace the existing NTC sensor located at the side of the compressor top cap. The

previous NTC sensor has to be removed and the controller, eg, ALCO EC3-D*, has to be

modified (disable discharge sensor input). A new thermostat must be installed on the

discharge line. DO NOT use the previous solution NTC sensor + controller as a discharge

tempera ture protection since its rating is not suitable for R407A and R407F.

3.4 Discharge che ck v alve

There is no discharge check valve at the discharge port of Copeland Scroll Digital compressors

ZBD21K* to ZBD57K* and ZFD13KVE to ZFD25KVE since the high-side pressure is needed to

support the operation of the unloader mechanism.

To avoid by-passing during the unloading process back to suction, a dynamic discharge valve is

fitted internally on the discharge port of the fixed scroll. This discharge valve cannot be used with

recycling pump down because it is not leak-proof during the off period.

Models ZBD58K* to ZBD114K* work with an internal unloader mechanism and are equipped

with a check valve in the discharge fitting that will prevent backward flow of gas through the

scroll when the compressor shuts off.

3.5 Brazing proce dure

C6.2.24/0215-0515/E 11

CAUTION

Lea king system! System breakdown! It is strongly recommended to

periodically re-torque all pipe and fixing connections to the original setting

after the system has been put into operation.

Figure 14: Suction tube brazing

Copeland Scroll compressors have copper-plated

steel suction and discharge tubes. These tubes are

far more robust and less prone to leaks than copper

tubes. Due to the different thermal properties of

steel and copper, brazing procedures may have to

be changed from those commonly used.

Figure 17 shows the proper procedure for brazing

the suction and discharge lines to a scroll

compressor.

The copper-coated steel tubes on scroll compressors can be brazed in approximately the

same manner as any copper tube.

Recommended brazing materials: any silfos material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is acceptable.

Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

Using a double-tipped torch, apply heat in area 1.

As the tube approaches brazing temperature, move the torch flame to area 2.

Heat area 2 until braze temperature is attained, moving the torch up and down and rotating

around the tube as necessary to heat the tube evenly. Add braze material to the joint while

moving the torch around the joint to flow braze material around the circumference.

After the braze material flows around the joint, move the torch to heat area 3. This will draw

the braze material down into the joint. The time spent heating area 3 should be minimal.

As with any brazed joint, overheating may be detrimental to the final result.

To disconnect:

Heat joint areas 2 and 3 slowly and uniformly until the braze material softens and the tube

can be pulled out of the fitting.

To reconnect:

Recommended brazing materials: Silfos with minimum 5% silver or silver braze used on

other compressors. Due to the different thermal properties of steel and copper, brazing

procedures may have to be changed from those commonly used.

NOTE: Since the discharge stub contains a check valve, care must be taken not to

overheat it to prevent brazing material from flow ing into it.

3.6 Shut-off v alv es and adaptors

Copeland Scroll compressor models ZBD58K* to ZBD114K* and ZFD41K5E are delivered with a

discharge check valve fitted inside the discharge port and rubber plugs fitted to the suction and

discharge port as standard. There are options to fit either Rotalock valves or Rotalock adaptors,

or just make brazing connections.

Figure 15

12 C6.2.24/1014-0215/E

Torque [Nm]

Rotalock 3/4" – 16UNF

40-50

Rotalock 1" – 14UNS

70-80

Rotalock 1 ¼" – 12UNF

110-135

Rotalock 1 ¾" – 12 UNF

135-160

CAUTION

Inadequate lubrication! Bearing destruction! Minimise liquid refrigerant

returning to the compressor. Too much refrigerant dilutes the oil. Liquid

refrigerant can wash the oil off the bearings leading to overheating and

bearing failure.

CAUTION

Scree n blocking! Compressor breakdown! Use screens with at least

0.6 mm openings.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

Braze connections can be converted to Rotalock by means of adaptors. Rotalock shut-off valves

are available for the suction as well as discharge side. Using either straight or angled adaptors

provides a way to convert a Rotalock into a brazing connection.

Refer to Table 6 for proper tightening torques:

Table 6

NOTE: More information about adaptors and shut-off valves can be found in the "Spare

parts list".

3.7 Oil se parator

During any operating cycle of Copeland Digital Scroll compressors, there is a loaded state during

which the compressor operates at full capacity. The velocity of gas during this loaded state is

sufficient to return oil back to the compressor. Laboratory tests have established that there is no

problem in oil return, even when the length of interconnecting pipe used is

100 metres and the vertical elevation is 30 metres. Based on such performance, we do not

strictly recommend the use of an oil separator.

3.8 Accumulators

Irrespective of system charge, oil dilution may occur if large amounts of liquid refrigerant

repeatedly flood back to the compressor during:

normal off cycles;

defrost;

varying loads.

In such a case an accumulator must be used to reduce flood-back to a safe level that the

compressor can handle. The use of accumulators is dependent on the application. If an

accumulator must be used, the oil-return orifice should be from 1 to 1.4 mm in diameter for

models ZBD21K* to ZBD57K* and ZFD13KVE to ZFD25KVE and 2.0 mm for models ZBD58K*

to ZBD114K* and ZFD41K5E, depending on compressor size and compressor flood-back

results.

The size of the accumulator depends upon the operating range of the system and the amount of

subcooling and subsequent head pressure allowed by the refrigerant control.

3.9 Scree ns

The use of screens finer than 30 x 30 mesh (0.6 mm openings) anywhere in the system should

be avoided with these compressors. Field experience has shown that finer mesh screens used

to protect thermal expansion valves, capillary tubes, or accumulators can become temporarily or

permanently plugged with normal system debris and block the flow of either oil or refrigerant to

the compressor. Such blockage can result in compressor failure.

C6.2.24/0215-0515/E 13

Figure 16: Suction tube design

3.10 Mufflers

External mufflers, normally applied to piston compressors in the past, may not be required for

Copeland Scroll compressors.

Individual system tests should be performed to verify acceptability of sound performance. If

adequate attenuation is not achieved, use a muffler with a larger cross -sectional area to inlet

area ratio. A ratio of 20:1 to 30:1 is recommended.

A hollow shell muffler such as the Alco APD-1 will work quite well. Locate the muffler at minimum

15 cm to maximum 45 cm from the compressor for the most effective operation. The farther the

muffler is placed from the compressor within these ranges, the more effective. Choose a muffler

with a length of 10 to 15 cm.

3.11 Suction line noise and v ibration

Copeland Scroll compressors inherently have low sound

and vibration characteristics. However in some respects

the sound and vibration characteristics differ from

reciprocating compressors and in rare instances could

result in unexpected sound generation. One difference is

that the vibration characteristic of the scroll compressor,

although low, includes two very close frequencies , one of

which is normally isolated from the shell by the

suspension of an internally-suspended compressor.

These frequencies, which are present in all compressors,

may result in a low-level "beat" frequency that can be

detected as noise coming along the suction line into the

building under some conditions. Elimination of the beat

can be achieved by attenuating either of the contributing

frequencies. This is easily done by using one of the

common combinations of recommended design

configurations. The scroll compressor makes both a rocking and twisting motion and enough

flexibility must be provided in the line to prevent vibration transmission into any lines attached to

the unit. In a split system, the most important goal is to ensure minimal vibration in all directions

at the service valve to avoid transmitting vibrations to the structure t o which the lines are

fastened.

A second difference of the Copeland Scroll compressor is that under some conditions the normal

rotational starting motion of the compressor can transmit an "impact" noise along the suction

line. This may be particularly pronounced in three-phase models due to their inherently higher

starting torque. This phenomenon, like the one described previously , also results from the lack of

internal suspension and can be easily avoided by using standard suction line isolation

techniques as described below. The sound phenomena described above are not usually

associated with reversible air conditioning / heat pump systems because of the isolation and

attenuation provided by the reversing valve and tubing bends.

Recommended configuration

Tubing configuration: ...... small shock loop

Service valve: ................ "angled valve" fastened to unit / wall

Suction muffler: ............. not required

Alternative configuration

Tubing configuration: ...... small shock loop

Service valve: ................ "straight through" valve fastened to unit / wall

Suction muffler: ............. may be required (acts as dampening mass)

14 C6.2.24/1014-0215/E

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

4 Electrical connection

4.1 General recommendations

The compressor terminal box has a wiring diagram on the inside of its cover. Before connecting

the compressor, ensure the supply voltage, the phases and the frequency match the nameplate

data.

4.2 Electrical installation

Single-phase (PF*) compressors:

Pow e r circuit Control circuit

Motor terminal connections

Single-phase compressors are connected to the

Common (C), Start (S) and Run (R) connections

Lege nd

B1 ....Room thermostat F4 .... LP switch

B3 ....Discharge gas thermostat K1.... Contactor

C2 ....Run capacitor R2.... Crankcase heater

F1 ....Fuse S1.... Auxiliary switch

F3 ....HP switch

Figure 17

C6.2.24/0215-0515/E 15

Three -phase compressors (TF*) with internal motor protection:

Power circuit Control circuit

Motor terminal connections

Three-phase compressors are connected to the T1,

T2 and T3 connections

Lege nd

B1 ....Room thermostat K1.... Contactor

B3 ....Discharge gas thermostat R2.... Crankcase heater

F1 ....Fuse S1.... Auxiliary switch

F3 ....HP switch Y5.... Solenoid valve for refrigerant injection

F4 ....LP switch

Figure 18

16 C6.2.24/1014-0215/E

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

4.2.1 Terminal box

The standard terminal box is IP21 for all models with internal motor protection (TF*/PF*),

enclosure class according to IEC 60034-5.

Cable glands have an influence on the protection class of the terminal box. It is strongly

recommended to use appropriate cable glands in order to reach the rated protection class. We

advise installers/service providers to pay attention to this aspect every time they install or

replace a Copeland Scroll compressor and to use cable glands according to EN 50262 or any

other relevant standard of application in their country/region. Examples of correct electrical

installations are shown in Figures 22 & 23 below.

Figure 19: Correct ele ctric al installation w ith ca ble glands for IP2 1 T-box (compressors ZBD21K* & ZBD29K*)

Figure 20: Correct ele ctric al installation with cable glands for IP21 T-box (compressors ZBD30K* to ZBD114K*,

ZFD13KVE to ZFD25KVE & ZFD41K5E)

4.2.2 Motor winding

Compressor model ZBD21K* is available in single-phase (PF*). ZBD and ZFD compressors are

offered with three-phase (TF*) induction motors. Single-phase motors need a run capacitor while

all three-phase motors are connected in star.

The motor insulation material is class "B" for compressor models covered in these guidelines.

This is according to VDE 0530, IEC 34-18-1 or DIN 57530.

C6.2.24/0215-0515/E 17

Figure 21: Crankcase hea ter location

IMPORTANT

Oil dilution! Bearing malfunction! Turn the crankcase heater on 12 hours

before starting the compressor.

Compressor

Refrigerant charge

limit

ZBD21K* & ZBD29K*

3.6 kg

ZBD30K* to ZBD57K*

ZFD13KVE to ZFD25KVE

4.5 kg

ZBD58K* to ZBD114K* & ZFD41K5E

7.5 kg

4.2.3 Motor protection

For ZBD21K* to ZBD114K*, ZFD13KVE to ZFD25KVE and ZFD41K5E compressors,

conventional inherent internal line break motor protection is provided.

4.2.4 Protection devices

Independently from the internal motor protection, fuses must be installed before the compressor.

Selection of fuses has to be carried out according to VDE 0635, DIN 57635, IEC 269-1 or

EN 60-269-1.

4.2.5 Crankcase heaters

A crankcase heater is used to prevent refrigerant migrating into the shell during standstill

periods. Due to the Copeland scroll’s inherent ability to handle liquid refrigerant in flooded

conditions a crankcase heater is not required when the system charge does not exceed the

charge limits shown in Table 7.

Table 7

If a crankcase heater is fitted it is recommended

that the heater be turned on for a minimum of 12

hours prior to starting the compressor. This will

prevent oil dilution and bearing stress on initial

start-up. The crankcase heater must remain

energised during compressor off cycles.

The crankcase heater must be mounted below the

oil Schraeder valve located on the bottom shell (see

Figure 24).

The crankcase heater should be wired in such a way that it is turned on whenever the

compressor is switched off.

4.3 Pressure safe ty controls

4.3.1 IPR valve (Internal Pressure Relief valve)

The internal pressure relief valves for models ZBD21K* to ZBD57K* and ZFD13KVE to

ZFD25KVE are located between the high and low sides of the compressor. They are designed to

open when the discharge-to-suction differential pressure exceeds 26-31 bar. When the valve

opens, hot discharge gas is routed back into the area of the motor protector to cause a trip.

During developmental blocked fan testing, it is sometimes noted that the valve opens, but the

compressor does not shut off while the discharge pressure continues to climb. This condition is

normally caused by flood back and may be corrected by using a more restrictive expansion

device or reducing the refrigerant charge.

ZBD58K* to ZBD114K* and ZFD41K5E compressors do not have internal pressure relief valves.

To ensure safe operation, a high-pressure control must be used in all applications with this

compressor. This pressure control will act independently of the digital controller.

4.3.2 High-pressure control

A high-pressure control with a maximum cut-out setting of 28 bar(g) is required.

The high-pressure control should have a manual reset feature for the highest level of system

protection.

18 C6.2.24/1014-0215/E

IMPORTANT!

Loss of system charge! Bearing malfunction! A low-pressure control is

highly recommended for loss of charge protection. Do not bridge or by-pass

the low-pressure cut out.

Temperature

(°C)

Resistance

(kOhm)

Temperature

(°C)

Resistance

(kOhm)

-40 2889.60 75 12.73

-35 2087.22 80 10.79

-30 1522.20 85 9.20

-25 1121.44 90 7.87

-20 834.72 95 6.77

-15 627.28 100 5.85

-10 475.74 105 5.09

-5 363.99 110 4.45

0 280.82 115 3.87

5 218.41 120 3.35

10 171.17 125 2.92

15 135.14 130 2.58

20 107.44 135 2.28

25 86.00 140 2.02

30 69.28 145 1.80

35 56.16 150 1.59

40 45.81 155 1.39

45 37.58 160 1.25

50 30.99 165 1.12

55 25.68 170 1.01

60 21.40 175 0.92

65 17.91 180 0.83

70 15.07

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

4.3.3 Low-pressure control

Even though these compressors require a discharge temperature sensor, loss of system charge

etc. will result in overheating and recycling of the motor protector. Prolonged operation in this

manner could result in oil pump-out and eventual bearing failure.

A minimum cut-out setting of 0.3 bar(g) is required for the ZFD compressors using R404A. For

ZBD compressors, the low-pressure cut-out should be set as high as possible. The normal

minimum is 2.6 bar(g).

The low-pressure cut-out should have a manual reset feature for the highest level of system

protection.

4.4 Discharge tempe rature protection

Internal discharge temperatures can reach unacceptable values under some extreme operating

conditions (such as operation outside the approved application limits, improper control operation

or loss of refrigerant injection charge). This could cause compressor damage.

Discharge gas temperature protection is required for any application with Copeland brand

compressors in order to guarantee positive compressor protection. This protection must not be

used as an operating envelope controller but as a safety device.

Compressors ZBD21K* & ZBD29K*: These compressors have no internal temperature

protection. Therefore they are supplied with a discharge temperature thermostat.

Compressors ZBD30K* to ZBD57K* and ZFD13KVE to ZFD25KVE: These compressors are

equipped with a discharge temperature sensor (NTC thermistor) that is embedded in the top cap

of the compressor. The output of the NTC thermistor is used in the protection module of the

Digital Scroll controller. The resistance curve for the NTC thermistor is provided in Table 8

hereunder.

Table 8: Digital Scroll thermistor temperature / re sistance v alues

C6.2.24/0215-0515/E 19

WARNING

Conductor cable s! Electrical shock! Shut off power supply before high-

potential testing.

CAUTION

Internal arcing! Motor destruction! Do not carry out high-voltage or

insulation tests if the compressor housing is under vacuum.

Figure 22: Discharge temperature protection

recommended position

X

Compressors ZBD58K* to ZBD114K* a nd ZFD41K5E: These models have no internal

temperature protection and therefore require an external thermostat or a discharge temperature

sensor (NTC thermistor) mounted as close as possible to the discharge fitting in order for the

Digital Scroll controller to operate properly. For best response the sensor should be insulated.

Compressors ZFD13KVE to ZFD25KVE: For low temperature applications with R404A, these

compressors could be used with the NTC thermistor, connected to the digital Scroll controller.

For low temperature applications with R407A, R407F, R448A and R449A the DTC valve bulb

(for the wet vapour injection system) must replace the existing NTC sensor located at the side of

the compressor top cap. Since there is no more connection possibility for the NTC sensor bulb,

the previous NTC sensor has to be removed and the controller, eg, ALCO EC3-D*, has to be

modified (disable discharge sensor input). A new discharge gas thermostat must be installed on

the discharge line. DO NOT use the previous solution NTC sensor + controller as a discharge

temperature protection since its rating is not suitable for R407A, R407F, R448A and R449A.

The R404A, R407A, R407F, R448A and R449A

dedicated discharge thermostat has a cut-out

setting of 130°C ± 4K with closing at 101°C ± 8K.

The thermostat should be installed approximately

120 mm from the discharge valve outlet (see

Figure 25). It must be insulated in order to avoid

improper functioning due to false readings (see "X"

in Figure 25).

4.5 High pote ntial te sting

Emerson Climate Technologies subjects all Scroll compressors to a high-voltage test after final

assembly. Each motor phase winding is tested, according to EN 0530 or VDE 0530 part 1, at a

differential voltage of 1000V plus twice the nominal voltage. Since high-voltage tests lead to

premature ageing of the winding insulation further additional tests of that nature are not

recommended.

If it has to be done for any reason, a lower voltage must be used. Disconnect all electronic

devices, eg, motor protection module, fan speed control, etc prior to testing.

20 C6.2.24/1014-0215/E

WARNING

Diesel effect! Compressor destruction! The mixture of air and oil at high

temperature can lead to an explosion. Avoid operating with air.

IMPORTANT

Oil dilution! Bearing malfunction! Turn the crankcase heater on 12 hours

before starting the compressor.

WARNING

High pressure! Personal injuries! Consider personal safety requirements

and refer to test pressures prior to test.

WARNING

System explosion! Personal injuries! DO NOT USE other industrial

gases.

CAUTION

System contamina tion! Bearing malfunction! Use only dry nitrogen or

dried air for pressure testing.

CAUTION

Low suction pressure operation! Compressor damage! Do not operate

with a restricted suction. Do not operate with the low-pressure cut-out

bridged. Do not operate compressor without enough system charge to

maintain at least 0.3 bar suction pressure. Allowing pressure to drop below

0.3 bar for more than a few seconds may overheat scrolls and cause early

drive bearing damage.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

5 Starting up & operation

5.1 Stre ngth pressure test

The compressor has been strength-tested in the factory. It is not necessary for the customer to

strength- or leak-test the compressor again although the compressor will normally be exposed to

the testing made as part of system testing.

5.2 Tightness/pressure test

If using dry air do not include the compressor in the pressure test – isolate it first. Never add

refrigerant to the test gas (as leak indicator).

5.3 Preliminary checks – Pre-starting

Discuss details of the installation with the installer. If possible, obtain drawings, wiring diagrams,

etc.

It is ideal to use a check-list but always check the following:

Visual check of the electrics, wiring, fuses etc.

Visual check of the plant for leaks, loose fittings such as TXV bulbs etc.

Compressor oil level

Calibration of HP & LP switches and any pressure actuated valves

Setting and operation of all safety features and protection devices

All valves in the correct running position

Pressure and compound gauges fitted

Correctly charged with refrigerant

Compressor electrical isolator location & position

5.4 Charging proce dure

The system should be liquid-charged through the liquid-receiver shut-off valve or through a valve

in the liquid line. The use of a filter drier in the charging line is highly recommended. Because

R404A is a blend and scrolls have discharge check valves, systems should be liquid-charged on

both the high and low sides simultaneously to ensure a positive refrigerant pressure is present in

C6.2.24/0215-0515/E 21

CAUTION

Oil dilution! Bearing malfunction! It is important to ensure that new

compressors are not subjected to liquid abuse. Turn the crankcase heater on

12 hours before starting the compressor.

CAUTION

High discharge pressure operation! Compressor damage ! Do not use

compressor to test opening set point of high-pressure cut-out. Bearings are

susceptible to damage before they have had several hours of normal

running in.

the compressor before it runs. The majority of the charge should be placed in the high side of the

system to prevent bearing washout during first-time start on the assembly line.

5.5 Initial start-up

Liquid and high pressure loads could be detrimental to new bearings. It is therefore important to

ensure that new compressors are not subjected to liquid abuse and high-pressure run tests. It is

not good practice to use the compressor to test the high-pressure switch function on the

production line. Switch function can be tested with nitrogen prior to installation and wiring can be

checked by disconnecting the high-pressure switch during the run test.

5.6 Rotation dire ction

Copeland Scroll compressors, like several other types of compressors, will only compress in one

rotational direction. Three-phase compressors will rotate in either direction depending upon

phasing of the power. Since there is a 50-50 chance of connecting power in such a way as to

cause rotation in the reverse direction, it is important to include notices and instructions in

appropriate locations on the equipment to ensure proper rotation direction is achieved

when the system is installed a nd operated.

Observing that suction pressure drops and discharge pressure rises when the compressor is

energized allows verification of proper rotation direction. There is no negative impact on

durability caused by operating three-phase Copeland Scroll compressors in the reversed

direction for a short period of time (under one hour) but oil may be lost. Oil loss can be prevented

during reverse rotation if the tubing is routed at least 15 cm above the compressor. After several

minutes of operation in reverse, the compressor's protection system will trip due to high motor

temperature. The operator will notice a lack of cooling. However, i f allowed to repeatedly restart

and run in reverse without correcting the situation, the compressor will be permanently

damaged.

All three-phase scroll compressors are identically wired internally. Therefore, once the correct

phasing is determined for a specific system or installation, connecting properly phased power

leads to the identified compressor terminals will ensure proper rotation direction.

5.7 Pressure fluctuations

During the normal operation of the Copeland Scroll Digital compressor, there is a fluctuation in

the suction and the discharge pressures. This fluctuation will be in the range of 2 to 3.5 bar.

During the unloaded state, discharge pressure will start to drop and suction pressure will start to

rise. This is normal. This pressure fluctuation has no effect on the reliability of any system

components.

NOTE: Models ZBD21K* to ZBD57K* require a minimum 3.5 bar differential betwee n the

suction pressure and the discharge pressure to unload properly.

5.8 Starting sound

During the very brief start-up, a clicking sound is audible, resulting from initial contacting of the

spirals and is normal. Due to the design of the Copeland Scroll compressors, the internal

compression components always start unloaded even if system pressures are not balanced. In

addition, since internal compressor pressures are always balanced at start -up, low-voltage

starting characteristics are excellent for Copeland Scroll compressors.

22 C6.2.24/1014-0215/E

CAUTION

Vacuum operation! Compressor damage! Scroll compressors should

never be used to evacuate a refrigeration or air-conditioning system.

CAUTION

Vacuum operation! Bearing damage! Vacuum operation causes damage

to the drive bearing of the scrolls. Copeland Scroll compressors are able to

pull vacuum very quickly and this should be avoided.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

5.9 Deep v acuum ope ration

The scroll compressor can be used to pump down refrigerant in a unit as long as the pressures

remain within the operating envelope. Prolonged operation at low suction pressures will result in

overheating of the scrolls and permanent damage to the compressor drive bearing. ZB scrolls

incorporate internal low vacuum protection; the floating seal unloads when the pressure ratio

exceeds approximately 10:1 (ZF>20:1).

5.10 Shell te mperature

The top shell and discharge line can briefly but repeatedly reach temperatures above 177°C if

the compressor cycles on its internal protection devices. This only happens under rare

circumstances and can be caused by the failure of system components such as the condenser

or evaporator fan or loss of charge and depends upon the type of expansion control. Care must

be taken to ensure that wiring or other materials that could be damaged by these temperatures

do not come in contact with the shell.

5.11 Minimum run time

Emerson Climate Technologies recommends a maximum of 10 starts per hour. There is no

minimum off time because scroll compressors start unloaded even if the system has unbalanced

pressures. The most critical consideration is the minimum run time required to return oil to the

compressor after start-up. To establish the minimum run time obtain a sample compressor

equipped with a sight tube (available from Emerson Climate Technologies) and install it in a

system with the longest connecting lines that are approved for the system. The minimum on time

becomes the time required for oil lost during compressor start-up to return to the compressor

sump and restore a minimal oil level that will ensure oil pick-up through the crankshaft. Cycling

the compressor for a shorter period than this, for instance to maintain very tight temperature

control, will result in progressive loss of oil and damage to the compressor.

5.12 Sound characteristics

For the Copeland Scroll Digital compressor the sound spectrum of the loaded state and that of

the unloaded state are quite different. The unloaded sound power is normally 2 dB(A) higher

than the loaded sound power. If sound variability is an issue, we recomm end the usage of a

sound cover.

5.13 Shut-off sound

Scroll compressors incorporate a device that minimizes reverse rotation. The residual

momentary reversal of the scrolls at shut off will cause a clicking sound, but it is entirely normal

and has no effect on compressor durability.

5.14 Freque ncy

There is no general release of standard Copeland Scroll compressors for use with variable

speed AC drives. There are numerous issues that must be considered when applying Scroll

compressors with variable speed, including system design, inverter selection, and operating

envelopes at various conditions. Only frequencies from 50 Hz to 60 Hz are acceptable.

Operation outside this frequency range is possible but should not be done without s pecific

Application Engineering review. The voltage must vary proportionally to the frequency.

If the inverter can only deliver a maximum voltage of 400V, the amps will increase when the

speed is above 50 Hz, and this may give rise to nuisance tripping if operation is near the

maximum power limit and/or compressor discharge temperature limit.

C6.2.24/0215-0515/E 23

5.15 Oil le vel

The oil level should be maintained at mid-point of the sight glass. If an oil regulator is used the

level should be set within the top half of the sight glass.

5.16 Digital system control

Due to the pulsing characteristic of Copeland Scroll Digital compressors superheat control needs

to be performed by qualified solutions in order to assure the stability, reliability and good

performance of the system.

NOTE: For further information about these solutions see Technical Information C7.8.3

"Refrigeration – Controlling Digital Scroll".

5.17 Power factor

During the loaded state, when the Copeland Scroll Digital compressor operates at full capacity,

the power factor is almost the same as with a standard scroll. However, when the scrolls are

unloaded, the power factor is lower.

24 C6.2.24/1014-0215/E

CAUTION

Inadequate lubrication! Bearing destruction! Exchange the accumulator

after replacing a compressor with a burned out motor. The accumulator oil

return orifice or screen may be plugged with debris or may become plugged.

This will result in starvation of oil to the new compressor and a second

failure.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

6 Maintenance & repair

6.1 Exchanging the refrigerant

Qualified refrigerants and oils are given in section 2.4.1.

It is not necessary to replace the refrigerant with new unless contamination due to an error such

as topping up the system with an incorrect refrigerant is suspected. To verify correct refrigerant

composition, a sample can be taken for chemical analysis. A check can be made during shut

down by comparing the refrigerant temperature and pressure using precision measurements at a

location in the system where liquid and vapour phases are present and when the temperatures

have stabilised.

In the event that the refrigerant needs replacing, the charge should be recovered using a

suitable recovery unit.

6.2 Rotalock valv es

Rota lock valves should be periodically retorqued to ensure that leak tightness is maintained.

6.3 Replacing a compressor

6.3.1 Compressor replacement

In the case of a motor burnout, the majority of contaminated oil will be removed with the

compressor. The rest of the oil is cleaned through the use of suction and liquid line filter driers. A

100% activated alumina suction line filter drier is recommended but must be removed after

72 hours. It is highly recommended that the suction accumulator be replaced if the system

contains one. This is because the accumulator oil return orifice or screen may be plugged with

debris or may become plugged shortly after a compressor failure. This will result in starvation of

oil to the replacement compressor and a second failure. When a single compressor or tandem is

exchanged in the field, it is possible that a major portion of the oil may still be in the system.

While this may not affect the reliability of the replacement compressor, the extra oil will add to

rotor drag and increase power usage.

6.3.2 Start-up of a new or replacement compressor

Rapid charging only on the suction side of a scroll-equipped system or condensing unit can

occasionally result in a temporary no start condition for the compressor. The reason for this is

that, if the flanks of the compressor happen to be in a sealed position, rapid pressurisation of the

low side without opposing high-side pressure can cause the scrolls to seal axially. As a result,

until the pressures eventually equalise, the scrolls can be held tightly together preventing

rotation. The best way to avoid this situation is to charge on both the high and low sides

simultaneously at a rate which does not result i n axial loading of the scrolls.

A minimum suction pressure of 1.75 bar must be maintained during charging. Allowing pressure

to drop below 0.3 bar for more than a few seconds may overheat scrolls and cause early drive

bearing damage. Never install a system in the field and leave it unattended when it has no

charge, a holding charge, or with the service valves closed without securely electrically locking

out the system. This will prevent unauthorised personnel from accidentally operating the system

and potentially ruining the compressor by operating with no refrigerant flow. Do not start the

compressor while the system is in a deep vacuum. Internal arcing may occur when a scroll

compressor is started in a vacuum causing burnout of the internal lead connections.

C6.2.24/0215-0515/E 25

CAUTION

Chemical reaction! Compressor destruction! Do not mix up ester oils with

mineral oil and/or alkyl benzene when used with chlorine-free (HFC)

refrigerants.

6.4 Lubrication and oil removal

The compressor is supplied with an initial oil charge. The standard oil charge for use with

refrigerants R404A, R407A, R407F, R448A, R449A, R134a R450A, and R513A is a polyolester

(POE) lubricant Emkarate RL 32 3MAF. In the field the oil level could be topped up with Mobil

EAL Arctic 22 CC if 3MAF is not available. See nameplate for original oil charge shown in litres.

A field recharge is from 0.05 to 0.1 litre less.

One disadvantage of POE is that it is far more hygroscopic than mineral oil (see Fig. 26). Only

brief exposure to ambient air is needed for POE to absorb sufficient moisture to make it

unacceptable for use in a refrigeration system. Since POE holds moisture more readily than

mineral oil it is more difficult to remove it through the use of vacuum. Compressors supplied by

Emerson Climate Technologies contain oil with low moisture content, and it may rise during the

system assembling process. Therefore, it is recommended that a properly sized filter drier is

installed in all POE systems. This will maintain the moisture level in the oil to less than 50 ppm. If

oil is charged into a system, it is recommended to use POE with a moisture content no higher

than 50 ppm.

Figure 23: Absorption of moisture in ester oil in comparison to mineral oil in ppm by w eight at 25 °C and 5 0%

relativ e humidity (h=hours)

If the moisture content of the oil in a refrigeration system reaches unacceptably high levels,

corrosion and copper plating may occur. The system should be evacuated down to 0.3 mbar or

lower. If there is uncertainty as to the moisture content in the system, an oil sample should be

taken and tested for moisture. Sight glass/moisture indicators currently available can be used

with the HFC refrigerants and lubricants; however, the moisture indicator will just show the

moisture content of the refrigerant. The actual moisture level of POE would be higher than the

sight glass specifies. This is due to the high hygroscopicity of the POE oil. To determine the

actual moisture content of the lubricant, samples have to be taken from the system and

analysed.

6.5 Oil additiv e s

Although Emerson Climate Technologies cannot comment on any specific product, from our own

testing and past experience, we do not recommend the use of any additives to reduce

compressor bearing losses or for any other purpose. Furthermore, the long term chemical

stability of any additive in the presence of refrigerant, low and high temperatures, and materials

commonly found in refrigeration systems is complex and difficult to evaluate without rigorously

controlled chemical laboratory testing. The use of additives without adequate testing may result

in malfunction or premature failure of components in the system and, in specific cases, in voiding

the warranty on the component.

26 C6.2.24/1014-0215/E

WARNING

Explosive flame! Burning! Oil-refrigerant mixtures are highly flammable.

Remove all refrigerant before opening the system. Avoid working with an

unshielded flame in a refrigerant charged system.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

6.6 Unbrazing system compone nts

Before opening up a system it is important to remove all refrigerant from both the high and low

sides of the system. If the refrigerant charge is removed from a scroll-equipped unit from the

high side only, it is possible for the scrolls to seal, preventing pressure equalization through the

compressor. This may leave the low side shell and suction line tubing pressurized. If a brazing

torch is then applied to the low side while the low side shell and suction line contain pressure,

the pressurized refrigerant and oil mixture could ignite when it escapes and contacts the brazing

flame. To prevent this occurrence, it is important to check both the high and low sides with

manifold gauges before unbrazing. Instructions should be provided in appropriate product

literature and assembly (line repair) areas. If compressor removal is required, the compressor

should be cut out of system rather than unbrazed.

7 Dismantling & disposal

Removing oil and refrigerant:

Do not disperse in the environment.

Use the correct equipment and method of removal.

Dispose of oil and refrigerant properly.

Dispose of compressor properly.

DISCLAIMER

1. The contents of this publication are presented for informational purposes only and are not to

be construed as warranties or guarantees, express or implied, regarding the products or

services described herein or their use or applicability.

2. Emerson Climate Technologies GmbH and/or its affiliates (collectively "Emerson"), as

applicable, reserve the right to modify the design or specifications of such products at any

time without notice.

3. Emerson does not assume responsibility for the selection, use or maintenance of any

product

remains solely with the purchaser or end user.

4. Emerson does not assume responsibility for possible typographic errors contained in this

publication.

. Responsibility for proper selection, use and maintenance of any Emerson product

C6.2.24/0215-0515/E 27

BENELUX

Josephinastraat 19

NL-6462 EL Kerkrade

Tel. +31 77 324 02 34

Fax +31 77 324 02 35

benelux.sales@emerson.com

UK & IRELAND

Unit 17, Theale Lakes Business Park

Reading, Berkshire RG7 4GB

Tel: +44 1189 83 80 00

Fax: +44 1189 83 80 01

uk.sales@emerson.com

BALKAN

Selska cesta 93

HR-10 000 Zagreb

Tel. +385 1 560 38 75

Fax +385 1 560 38 79

balkan.sales@emerson.com

GERMANY, AUSTRIA & SWITZERLAND

Senefelder Str. 3

DE-63477 Maintal

Tel. +49 6109 605 90

Fax +49 6109 60 59 40

ECTGermany.sales@emerson.com

FRANCE, GREECE & MAGHREB

8, Allée du Moulin Berger

FR-69134 Ecully Cédex

Tel. +33 4 78 66 85 70

Fax +33 4 78 66 85 71

mediterranean.sales@emerson.com

ITALY

Via Ramazzotti, 26

IT-21047 Saronno (VA)

Tel. +39 02 96 17 81

Fax +39 02 96 17 88 88

italy.sales@emerson.com

SPAIN & PORTUGAL

C/ LLull, 321 (Edifici CINC)

ES-08019 Barcelona

Tel. +34 93 412 37 52

Fax +34 93 412 42 15

iberica.sales@emerson.com

SWEDEN, DENMARK, NORWAY & FINLAND

Norra Koxåsvägen 7

SW-443 38 Lerum

Tel. +46 725 386486

nordic.sales@emerson.com

EASTERN EUROPE & TURKEY

Pascalstr. 65

DE-52076 Aachen

Tel. +49 2408 929 0

Fax +49 2408 929 525

easterneurope.sales@emerson.com

POLAND

Szturmowa 2

PL-02678 Warsaw

Tel. +48 22 458 92 05

Fax +48 22 458 92 55

poland.sales@emerson.com

RUSSIA & CIS

Dubininskaya 53, Build. 5, 4th floor

RU-115054 Moscow

Tel. +7 495 995 95 59

Fax +7 495 424 88 50

ECT.Holod@emerson.com

UKRAINE

Kurenevskiy lane, 12, build. A, office 302

UA-04073 Kiev

T +38 044 492 99 24 Ext. 232

F +38 044 492 99 28

Andrey.Gladchenko@emerson.com

ROMANIA

Tel. +40 374 13 23 50

Fax +40 374 13 28 11

Ancuta.Ionescu@Emerson.com

MIDDLE EAST & AFRICA

PO Box 26382

Jebel Ali Free Zone - South, Dubai - UAE

Tel. +971 4 811 81 00

Fax +971 4 886 54 65

mea.sales@emerson.com

ASIA PACIFIC

Suite 2503-8, 25/F., Exchange Tower

33 Wang Chiu Road, Kowloon Bay

Kowloon , Hong Kong

Tel: +852 2866 3108

Fax: +852 2520 6227

For more details, see www.emersonclimate.eu

C6.2.24/0215-0515/E

Connect with us: facebook.com/EmersonClimateEurope

Emerson Climate Technologies - European Headquarters - Pascalstrasse 65 - 52076 Aachen, Germany

Tel. +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.emersonclimate.eu