Emerson ZBD58KCE, ZBD45KCE, ZBD38KCE, ZBD114K5E, ZBD30KCE Application Manuallines

...

Digital

Application Guidelines

Digital Scroll™ Compressors for Refrigeration

ZBD21K* to ZBD114K*

ZFD13KVE to ZFD25KVE

ZFD41K5E

About these guidelines .............................................................................................. 1

1 Safety instructions .......................................................................................... 1

1.1 Icon explanation ................................................................................................. 1

1.2 Safety statements............................................................................................... 1

1.3 General instructions ............................................................................................ 2

2 Product description ........................................................................................ 3

2.1 Common information about Copeland Scroll Digital™ compressors............................ 3

2.2 Nomenclature .................................................................................................... 4

2.3 Dimensions ....................................................................................................... 4

2.4 Application range ............................................................................................... 5

2.4.1 Qualified refrigerants and oils ..................................................................... 5

2.4.2 Application limits and operating envelopes ................................................... 6

3 Installation....................................................................................................... 7

3.1 Compressor handling .......................................................................................... 7

3.1.1 Transport and storage ............................................................................... 7

3.1.2 Positioning and securing............................................................................ 7

3.1.3 Installation location ................................................................................... 7

3.1.4 Mounting parts ......................................................................................... 7

3.2 Solenoid valves for models ZBD21K* to ZBD57K* and ZFD13KVE to ZFD25KVE ........ 8

3.2.1 Securing the filter screen in position ............................................................ 8

3.2.2 Solenoid valve installation – General recommendations ................................. 9

3.2.3 Solenoid valve installation – Tubing recommendations ................................... 9

3.3 Copeland Scroll Digital compressors ZFD13KVE to ZFD25KVE with vapour injection /

wet vapour injection ................................................................................................... 9

3.3.1 Vapour injection (EVI = Economized Vapour Injection) ..................................10

3.3.2 Wet vapour injection (vapour injection + liquid injection) ................................10

3.4 Discharge check valve .......................................................................................11

3.5 Brazing procedure .............................................................................................11

3.6 Shut-off valves and adaptors ...............................................................................12

3.7 Oil separator.....................................................................................................13

3.8 Accumulators....................................................................................................13

3.9 Screens ...........................................................................................................13

3.10 Mufflers............................................................................................................14

3.11 Suction line noise and vibration ...........................................................................14

4 Electrical connection .................................................................................... 15

4.1 General recommendations ..................................................................................15

4.2 Electrical installation ..........................................................................................15

4.2.1 Terminal box...........................................................................................17

4.2.2 Motor winding .........................................................................................17

4.2.3 Motor protection ......................................................................................18

C6.2.24/1014-0215/E

4.2.4 Protection devices ...................................................................................18

4.2.5 Crankcase heaters ..................................................................................18

4.3 Pressure safety controls .....................................................................................18

4.3.1 IPR valve (Internal Pressure Relief valve) ...................................................18

4.3.2 High-pressure control ...............................................................................18

4.3.3 Low-pressure control ...............................................................................19

4.4 Discharge temperature protection ........................................................................19

4.5 High potential testing .........................................................................................20

5 Starting up & operation................................................................................. 21

5.1 Strength pressure test ........................................................................................21

5.2 Tightness/pressure test ......................................................................................21

5.3 Preliminary checks – Pre-starting .........................................................................21

5.4 Charging procedure ...........................................................................................21

5.5 Initial start-up ....................................................................................................22

5.6 Rotation direction ..............................................................................................22

5.7 Pressure fluctuations .........................................................................................22

5.8 Starting sound ..................................................................................................22

5.9 Deep vacuum operation .....................................................................................23

5.10 Shell temperature ..............................................................................................23

5.11 Minimum run time ..............................................................................................23

5.12 Sound characteristics.........................................................................................23

5.13 Shut-off sound ..................................................................................................23

5.14 Frequency ........................................................................................................23

5.15 Oil level............................................................................................................24

5.16 Digital system control .........................................................................................24

5.17 Power factor .....................................................................................................24

6 Maintenance & repair .................................................................................... 25

6.1 Exchanging the refrigerant ..................................................................................25

6.2 Rotalock valves .................................................................................................25

6.3 Replacing a compressor .....................................................................................25

6.3.1 Compressor replacement..........................................................................25

6.3.2 Start-up of a new or replacement compressor ..............................................25

6.4 Lubrication and oil removal .................................................................................26

6.5 Oil additives......................................................................................................26

6.6 Unbrazing system components............................................................................27

7 Dismantling & disposal ................................................................................. 27

DISCLAIMER............................................................................................................. 27

C6.2.24/0215-0515/E

WARNING

This icon indicates instructions to

avoid personal injury and material

damage.

CAUTION

This icon indicates instructions to

avoid property damage and possible

personal injury.

High voltage

This icon indicates operations with a

danger of electric shock.

IMPORTANT

This icon indicates instructions to

avoid malfunction of the compressor.

Danger of burning or frostbite

This icon indicates operations with a

danger of burning or frostbite.

NOTE

This word indicates a

recommendation for easier operation.

Explosion hazard

This icon indicates operations with a

danger of explosion.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

About these guidelines

The purpose of these application guidelines is to provide guidance in the application of Copeland

Scroll™ compressors in users’ systems. They are intended to answer the questions raised while

designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the compressors. Emerson Climate Technologies will not guarantee the

performance and reliability of the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications only. For mobile applications, contact

Application Engineering as other considerations may apply.

1 Safety instructions

Copeland Scroll compressors are manufactured according to the latest European and US Safety

Standards. Particular emphasis has been placed on the user’s safety.

These compressors are intended for installation in systems according to the Machinery Directive

MD 2006/42/EC and to the Pressure Equipment Directive PED 97/23/EC. They may be put to

service only if they have been installed in these systems according to instructions and conform

to the corresponding provisions of legislation. For relevant standards please refer to

Manufacturers Declaration, available at

www.emersonclimate.eu.

These instructions should be retained throughout the lifetime of the compressor.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

1.2 Safety statements

Refrigerant compressors must be employed only for their intended use.

Only qualified and authorized HVAC or refrigeration personnel are permitted to install,

commission and maintain this equipment.

Electrical connections must be made by qualified e lectrical personnel.

All valid standards for connecting electrical and refrige ration equipment must be

observed.

The national legislation a nd regula tions regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

C6.2.24/0215-0515/E 1

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only approved refrigerants and

refrigeration oils must be used.

WARNING

High shell temperature! Burning! Do not touch the compressor until it has

cooled down. Ensure that other materials in the area of the compressor do

not get in touch with it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

CAUTION

Contact with POE! Material damage! POE lubricant must be handled

carefully and the proper protective equipment (gloves, eye protection, etc.)

must be used at all times. POE must not come into contact with any surface

or material that it might damage, including without limitation, certain

polymers, eg, PVC/CPVC and polycarbonate.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid

collisions and tilting.

1.3 General instructions

2 C6.2.24/1014-0215/E

Compressor

Cooling Capacity kW

Motor

R404A

R407A

R407F

R448A

R449A

R134a

R450A

R513A*

ZBD21KCE

5.09

4.88

4.67

3.14

2.67

3.00

PFJ/TFD

ZBD29KCE

6.83

6.35

6.77

3.97

TFD

ZBD30KCE

6.98

6.78

6.84

6.67

4.25

3.63

4.09

TFD

ZBD38KCE

8.59

8.46

8.37

8.33

5.29

4.48

5.04

TFD

ZBD45KCE

10.25

9.39

10.00

9.76

6.04

5.38

6.03

TFD

ZBD57KCE

13.22

12.86

12.84

7.63

TFD

ZBD58KCE

13.45

12.00

12.84

TFD

ZBD76KCE

17.85

15.95

17.24

10.20

TFD

ZBD76K5E

18.38

17.08

18.40

TFD

ZBD114K5E

26.19

24.10

24.09

TFD

Compressor

COP

Motor

R404A

R407A

R407F

R448A

R449A

R134a

R450A

R513A*

ZBD21KCE

2.23

2.28

2.01

2.15

2.24

2.14

PFJ/TFD

ZBD29KCE

2.20

2.14

2.09

2.07

TFD

ZBD30KCE

2.22

2.16

2.22

2.15

2.21

2.24

2.12

TFD

ZBD38KCE

2.23

2.20

2.22

2.15

2.23

2.25

2.14

TFD

ZBD45KCE

2.24

2.17

2.23

2.22

2.20

2.27

2.14

TFD

ZBD57KCE

2.26

2.17

2.17

2.36

1.99

TFD

ZBD58KCE

2.12

2.02

2.08

TFD

ZBD76KCE

2.16

2.08

2.16

2.18

2.08

TFD

ZBD76K5E

2.14

2.11

2.19

TFD

ZBD114K5E

2.07

2.08

2.08

TFD

Compressor

R404A

R407A

R407F

R448A, R449A

Motor

kW

COP

kW

COP

kW

COP

kW

COP

kW

ZFD13KVE

3.96

1.35

3.15

1.16

3.31

1.16

3.27

1.45

TFD

ZFD18KVE

5.91

1.49

4.92

1.44

4.92

1.29

4.83

1.43

TFD

ZFD25KVE

7.68

1.62

6.12

1.43

6.43

1.43

6.16

1.58

TFD

ZFD41K5E

8.56

1.35

7.32

1.18

7.32

1.18

TFD

ZFD41K5E EVI

12.46

1.58

10.02

1.55

10.02

1.55

TFD

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

2 Product description

2.1 Common information about Copeland Scroll Digital™ compressors

The Scroll compressor has been under development at Emerson Climate Technologies since

1979. It is the most efficient and durable compressor Emerson Climate Technologies has ever

developed for air conditioning and refrigeration.

These application guideline s dea l with Copeland Scroll Digital™ compressors for

refrigeration from ZBD21K* to ZBD114K*, ZFD13K* to ZFD41K*. These compressors

include a wide range of capacities, electrical options and features.

Table 1: Cooling capacity for medium tempera ture compressors @EN 12900 Medium temp.

Table 2: Coefficient of performance (COP) for medium temperature compressors @EN 12900 Medium temp.

Table 3: Cooling capacity in kW and COP for low temperature compressors @EN 12900 Low temp

EN 12900 MT: Evaporating: -10°C, Condensing: 45°C, Suction gas: 20°C, Sub-cooling: 0K

Except for R513A*, Suction Superheat = 10K

EN 12900 LT: Evaporating: -10°C, Condensing: 45°C, Suction gas: 20°C, Sub-cooling: 0K

Copeland Scroll Digital compressors have one Scroll compression set driven by a single or

three-phase induction motor. The Scroll set is mounted at the upper end of the rotor shaft of the

motor. The rotor shaft axis is in the vertical plane.

C6.2.24/0215-0515/E 3

A B C D

E

ZBD21KCE

432.4

414.3

363.6

261.6

218.9

ZBD29KCE

463.2

445.2

394.3

291.3

249.7

2.2 Nomenclature

The model designation contains the following technical information about the compressor:

2.3 Dimensions

Figure 1: Dimensions ZBD21KCE & ZBD29KCE Figure 2: Dimensions ZBD30K* to ZBD57K*

& ZFD13KVE to ZFD25KVE

4 C6.2.24/1014-0215/E

A

mm

B

mm

C

mm

D

mm

E

mm

H

mm

ZBD58KCE

476.3

444.3

211.7

93.6

201.5

74.3

ZBD76KCE

533.2

501.2

253

122.1

242.8

92.3

ZBD76K5E

533.6

501.8

253.7

277.3

245.7

93

ZBD114K5E

881.5

519.5

271.3

295

263.3

93

IMPORTANT

It is essential that the glide of refrigerant blends (primarily R407A and

R407F) is carefully considered when adjusting pressure and superheat

controls.

Compressor

ZBD21K* to ZBD114K*

ZFD13K* to ZFD41K*

Qualified refrigerants

R404A, R407A, R407F, R448A,

R449A, R134a, R450A, R513A, R507;

R22 for ZBD30K* & ZBD45K* only

R404A, R407A, R407F,

R448A, R449A, R507

Copela nd brand products

standard oil

Emkarate RL 32 3MAF

Servicing oils

Emkarate RL 32 3MAF / Mobil EAL Arctic 22 CC

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

Figure 3: Dimensions ZBD58KCE & ZBD76KCE Figure 4: Dime nsions ZBD76K5E & ZBD114K5E

2.4 Application range

2.4.1 Qualified refrigerants and oils

Oil recharge values can be taken from Copeland Scroll compressors brochures or Copeland™

brand products Select software at

Table 4: Qualified refrigerants and oils

www.emersonclimate.eu.

C6.2.24/0215-0515/E 5

CAUTION

Inadequate lubrication! Compressor breakdown! The superheat at the

compressor suction inlet must always be sufficient to ensure that no

refrigerant droplets enter the compressor. For a typical evaporator-expansion

valve configuration a minimum stable superheat of at least 5K is required.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

2.4.2 Application limits and operating envelopes

The application envelopes for Digital refrigeration Scroll compressors are for various refrigerants,

you can find them in the Copeland brand products Select software, which can be downloaded for

free on our website

www.emersonclimate.eu.

6 C6.2.24/1014-0215/E

WARNING

High pressure! Injury to skin and eyes possible! Be careful when

opening connections on a pressurized item.

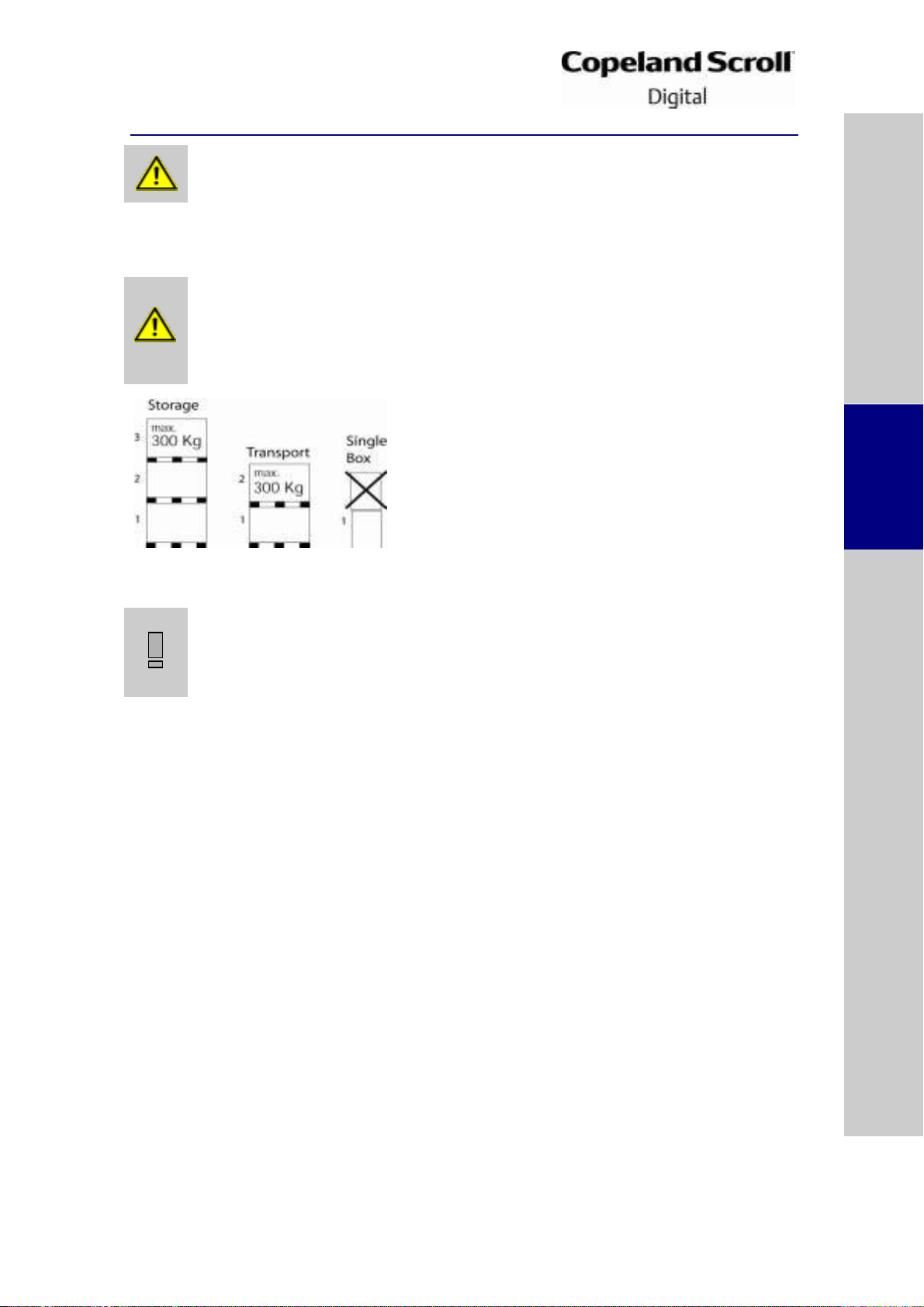

WARNING

Risk of collapse! Personal injuries! Move compressors only with

appropriate mechanical or handling equipment according to weight. Keep in

the upright position. Stack pallets on top of each other when not exceeding

300 kg. Do not stack single boxes on top of each other. Keep the packaging

dry at all times.

IMPORTANT

Handling damage! Compressor malfunction! Only use the lifting eyes

whenever the compressor requires positioning. If the compressor has two

lifting tabs, both must be used for lifting. Using discharge or suction

connections for lifting may cause damage or leaks.

Safety

instructions

Product

description

Installation

Electrical

connection

Starting up &

operation

Maintenance &

repair

Dismantling &

disposal

3 Installation

3.1 Compressor handling

3.1.1 Transport and storage

Figure 5

3.1.2 Positioning and securing

For models ZBD58K* to ZBD114K* and ZFD41K5E, because oil might spill out of the suction

connection located low on the shell, the suction connection plug must be left in place until the

compressor is set into the unit. If possible, the compressor should be kept vertical during

handling. The discharge connection plug should be removed first before pulling the suction

connection plug to allow the dry air pressure inside the compressor to escape. Pulling the plugs

in this sequence prevents oil mist from coating the suction tube making brazing difficult. The

copper-coated steel suction tube should be cleaned before brazing. No object, eg, a swaging

tool should be inserted deeper than 51 mm into the suction tube or it might damage the suction

screen and motor.

3.1.3 Installation location

Ensure the compressors are installed on a solid level base.

3.1.4 Mounting parts

Four vibration absorber grommets are supplied with each compressor. They dampen the start-up

surge of the compressor and minimise sound and vibration transmission to the compressor base

during operation. The metal sleeve inside is a guide designed to hold the grommet in place. It is

not designed as a load-bearing member, and application of excessive torque to the bolts can

crush the sleeve. Its inner diameter is approximately 8.5 mm to fit, eg, an M8 screw. The

mounting torque should be 13 ± 1 Nm. It is critically important that the grommet is not

compressed.

If the compressors are mounted in tandem or used in parallel, then the hard mountings (bolt M9

5/16”) are recommended. The mounting torque should be 27 ± 1 Nm. It is possible to deliver

these hard mounting parts as a kit, or on request to deliver the compressor with these parts

instead of the rubber grommets.

C6.2.24/0215-0515/E 7

Loading...

Loading...