Copeland Scroll

TM

ZB digital compressor

About Emerson Climate Technologies

Emerson Climate Technologies, a business segment of Emerson, is the world’s leading provider of heating, airconditioning and refrigeration solutions for residential, industrial and commercial applications. It combines best-in-class

technology with proven engineering, design, distribution, educational and monitoring services to provide customized,

integrated climate-control solutions for customers worldwide. Climate’s innovative solutions, which include industryleading brands such as Copeland ScrollTM, improve human comfort, safeguard food and protect the environment. For

more information, visit EmersonClimateAsia.com.

Emerson Climate Technologies, With Our Partners,

Will Provide Global Solutions To Improve Human Comfort,

Safeguard Food And Protect The Environment.

Our Vision:

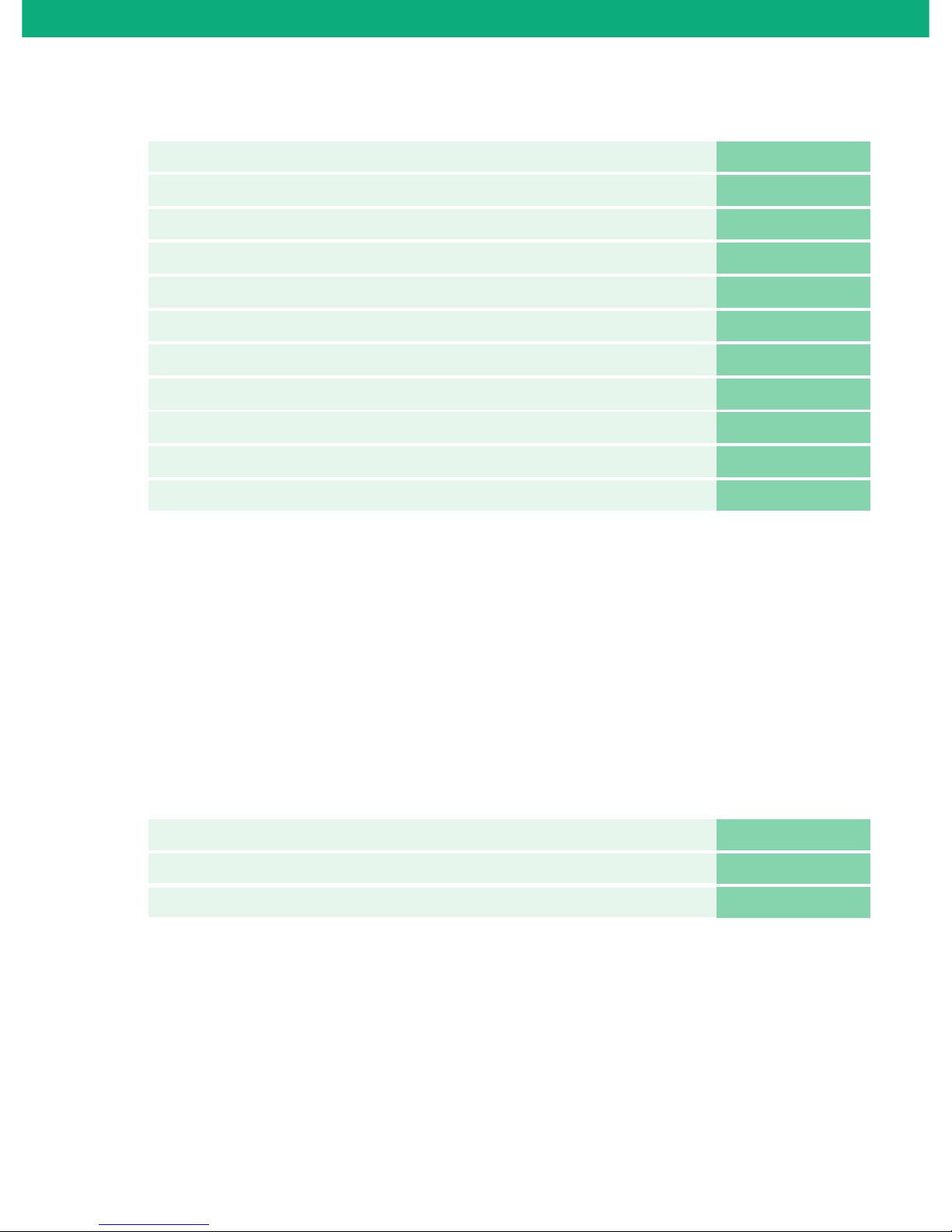

Index

Introduction 01

Digital Scroll Advantage for Rack Systems 02

Intelligent Store

TM

03

Nomenclature 04

Bill of Material 04

ZBD Rack Specication 05

Operating Envelope 06

Performance Table 07

Technical Data 13

Dimensional Drawings 14

Flow Controls Parts 21

OMB Crankcase Oil Level Protective Control 21

A-W/A-F Oil Separators 22

AOFD-553 Oil Filter Drier 24

STAS Steel Liquid and Suction Line Filter Drier 25

ADKS Liquid And Suction Line Filter Drier 26

Filter-Drier Cores And Filters 28

HMI-Hermetic Moisture Indicators 29

PS1 Single Pressure Controls 31

APD Pulsation Dampener/Mufer 33

Scroll Rack Application Guidelines 34

Digital Compressor Rack Controller-XC645CX 40

Contact List 49

1

Leading Innovations in Digital Scroll Technology

Emerson Climate Technologies has revolutionized the industry with the introduction of its scroll technology, which was launched in 1987.

In 2012, Emerson produced its 100 millionth scroll - a signicant achievement and further demonstrating Emerson’s position as a world

leader in the development and application of scroll technology.

Energy-efcient Refrigeration Through Capacity Modulation

Today, Emerson is the world’s largest manufacturer of refrigeration compressors, underscoring Emerson Climate Technologies’ thrust of

ensuring food safety and protecting the environment. Leveraging on Emerson’s vast global network and R&D resources, the company also

continues to develop the ultimate in climate technology for various businesses. Emerson helps provide solutions to achieve high efciency

systems for cold storage warehouses, supermarkets, quick service restaurants, meat trading and processing facilities, seafood import and

export establishments, agricultural depots and retail outlets - green technologies with less environmental impact.

With today’s growing need to address energy efciency and precise temperature control, Emerson developed ZBD compressors – digital

scroll technology in a simplied, compact design that is very reliable.

The ZBD features continuous capacity modulation range of 10-100%. This eliminates hot gas bypass, which causes waste of electricity,

and complications arising from variable speed drives. Precise capacity modulation control proves benecial in a number of applications,

including precise temperature control for precision cooling and humidity control as well as parallel compressor operations or rack systems

– intermediate and more precise part load operation of a compressor to perfectly match varying evaporator loads. Compared to cycling

compressors, smoother and more precise load matching is enabled by stepless capacity control with the ZBD.

Key Features and Benets

• Digital Scroll technology provides higher efciency compared to hot gas bypass systems or

compressor cycling

• Less complicated compared to variable speed technologies

• More reliable compared to other modulation technologies due to elimination of oil return issues

• Suitable for rack systems due to its varying load requirements

• Proven scroll technology paired with mechanical unloading system provides greater

reliability and efciency

2

Digital Scroll Advantage for Rack Systems

Digital scroll compressors having modulation capabilities from 10%–100% naturally t refrigeration rack systems. Rack systems need to

fulll varying evaporator load requirements due to changing case loads, not to mention variations due to cases undergoing routine defrost.

This can be attained by complementing xed-speed compressor racks with a digital scroll of the same capacity. The refrigeration load will

be matched by running xed-speed compressors to handle the base load and the peaks by the digital scroll. This leads to a smooth and

almost constant system suction pressure (see charts below). Compared to xed-speed scroll racks where unloading is achieved by cycling

the lead compressor, this results in a saw tooth prole of the system suction pressure and will reduce the life of the lead compressor due to

frequent on and off action. Fluctuating suction pressures lead to varying evaporator temperature and humidity conditions—a condition

that is not advisable for refrigerated products.

Compressor modulation by cycling compressor on and off

Saw tooth prole of suction pressure for

xed speed compressor

Compressor modulation by digital scroll

Smooth system suction pressure

Suction Pressure

Time

Suction Pressure

Time

3

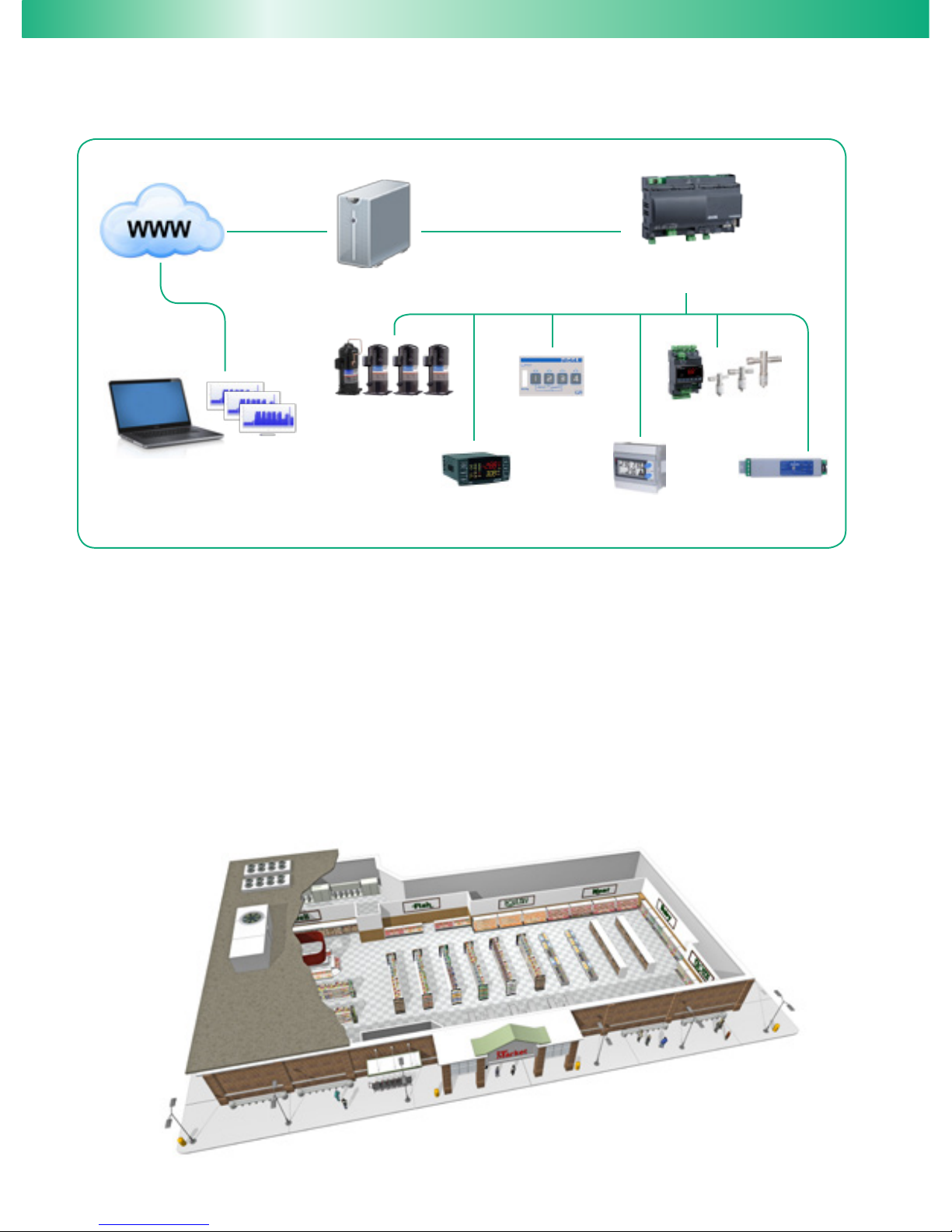

An innovative approach to enterprise facility management, Emerson’s Intelligent Store architecture integrates hardware and services

to help hyper mart, supermarket, convenience store, and box retail operators make better facility decisions while reducing operational

costs. The Intelligent Store architecture implements best practices for facility management and transforms data from store equipment

and controls into actionable insights. Designed to deliver value in both new and existing stores, the Intelligent Store architecture can help

retailers signicantly improve their bottom line results. The Intelligent Store solution constitutes:

• Energy efcient store infrastructure components

• State-of-the-art control technologies: XWeb Supervisory Platform

• Field services: Commissioning and project management

• Remote services: Alarm Management, Setpoint Management, Demand Response, Condition Based Maintenance, Energy Monitoring

and Targeting, Smart Dispatch, Food Quality Reports and Site Administration

Rack with

ZB Digital Scroll

Digital Compressor

Rack Controller

Power Meters

Dewpoint

Controller

Lighting and

HVAC Control

Superheat Controller

and EEV

ProAct Services

Intelligent Store

TM

XWeb Supervisory

Platform

4

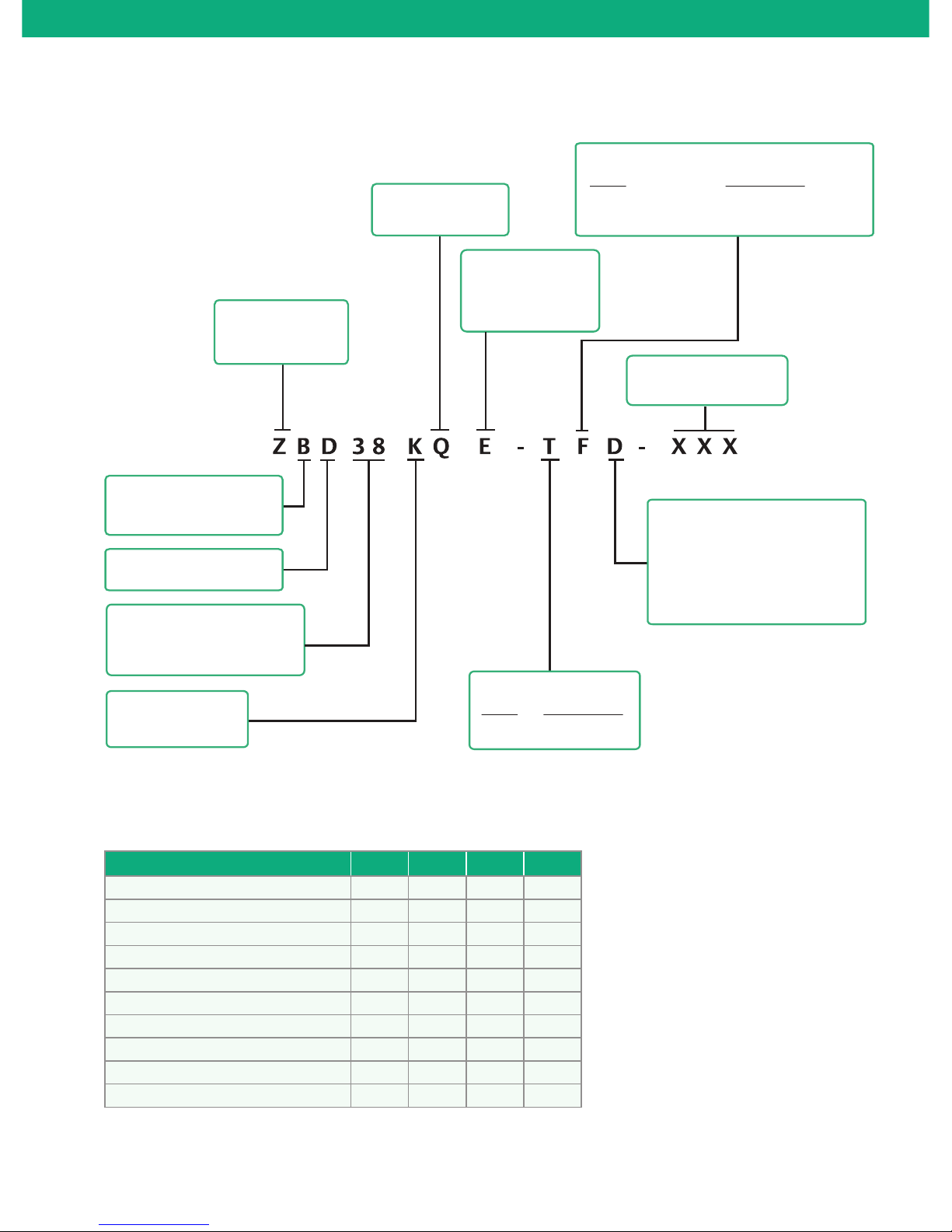

Nomenclature

Generation

Compressor

Family

High/Medium Temp

Refrigeration

Capacity at 60Hz

(Medium Temperature

Condition: Btu/h)

Base Capacity

K x 1000

Bill of Material

Lubricant

Blank: Mineral Oil

E: Ester Oil

Compressor Motor

Code Description

T: Three-phase

Motor Voltages

D

5

7

Compressor Motor Protection

Code Description

F: Inherent internal line break

motor protector

Digital Modulation

50 Hz 60Hz

380/420-3

200/220-3

460-3

200/230-3

380-3

Bill of Material

BOM 558 559 588 589

Sight Glass

✓ ✓ ✓ ✓

Stub Tube

✓

Rotalock

✓ ✓

Digital Valve

✓ ✓

Solenoid Coil

✓ ✓

Digital Rack Controller Kit

✓ ✓

Discharge Line Temperature Sensor

✓ ✓

Condenser Mid Coil Temperature Sensor

✓ ✓

OMB

✓ ✓

OMB Adaptor

✓ ✓

5

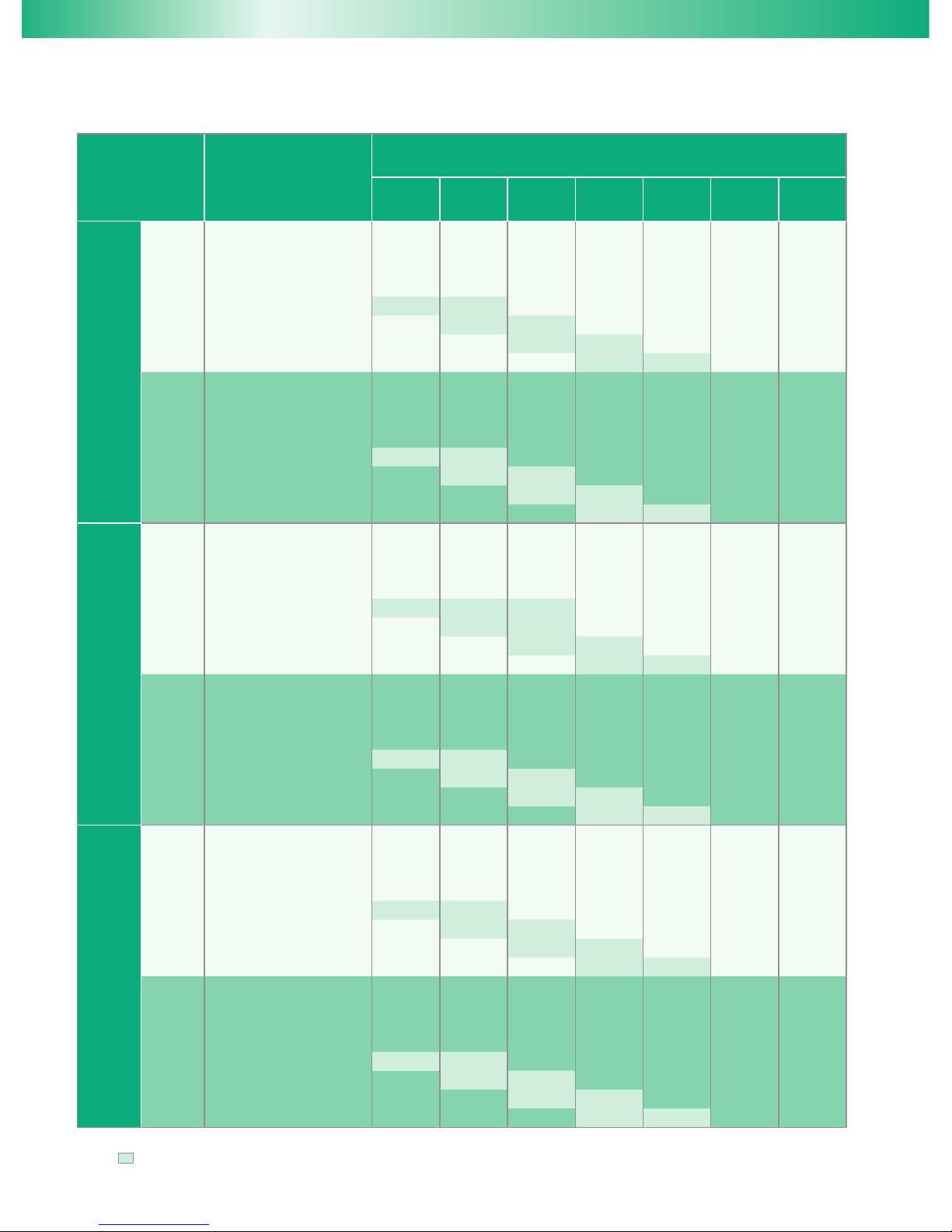

Family Items Unit

ZBD Rack Package ZBD Rack Recommendation

STD BOM 10HP 15HP

Compressor

Digital Scroll Compressor EA

✓

ZBD38KQ ZBD38KQ

Standard Scroll Compressor EA

- ZB38KQ ZB38KQ

- - ZB38KQ

Digital

Accessory

Thermistor

1

EA

✓

043-0130-00 043-0130-00

Valve Body EA

✓

010-0125-00 010-0125-00

Solenoid Coil

2

EA

✓

023-0088-00 023-0088-00

Rack Control

Kit

Controller (XC645CX) EA

✓

085-0254-00 085-0254-00

4-20mA Suction Pressure Transducer EA

✓

085-0233-00 085-0233-00

Condenser Mid Coil Temperature

Sensor

EA

✓

043-0168-02 043-0168-02

4-20mA Condenser Pressure

Transducer

3

EA - Optional Optional

TTL / RS485 Serial Converter

3

EA

✓

029-0502-00 029-0502-00

Hot Key EA - 085-0234-00 085-0234-00

Transformer EA

✓

037-0025-00 037-0025-00

Wiring Kit 3m

✓

029-0501-00 029-0501-00

Digital Input and Analog Out

Connector

3m

✓

029-0472-01 029-0472-01

System

Protector

Oil Regulator, OMB-JB1 ASC 2 24/50 EA

✓

085-0245-00 085-0245-00

Adapter for ZBD Sight Glass EA

✓

034-0236-00 034-0236-00

HP EA - PS1-A5A PS1-A5A

LP EA - PS1-A3A PS1-A3A

Oil Separator EA - A-W55877 A-W55889

Oil Filter Drier EA - AOFD553 AOFD553

Filter Drier EA - Shell STAS-487T Shell STAS-489T

EA - Core H-48 Core H-48

Sight Glass EA - HMI HMI

Pulsation Damper EA - APD APD

ZBD Rack Specication

Solenoid Coil Part Code

Part Code Description

023-0088-00 220V 50/60Hz

023-0088-04 240V 50/60Hz

023-0088-05 200V 50/60Hz

023-0088-07 24V 50/60Hz

Notes: 1. Thermistor: Only for ZBD29KQ, PCN 043-0130-00

2. Solenoid coil part code

3. Please contact Emerson sales representative if the part is required

6

Operating Envelope

ZBD29 - ZBD48

ZBD29 - ZBD48

60

70

50

40

30

20

10

-20 -15 -10 -5 0 5 10

Evaporating Temp. oC

Condensing Temp.

o

C

60

70

50

40

30

20

10

-15-10 -5 0510 15

Evaporating Temp. oC

Condensing Temp.

o

C

1. En

velope in unshaded region, max return gas temperature of 18.3°C

2. En

velope in shaded region, max superheat of 11K only

1. Envelope in unshaded region, max return gas temperature of 18.3oC

Notes:

Note:

R22

ZBD29 - ZBD48

60

70

50

40

30

20

10

-20 -15 -10 -5 0 5 10

Evaporating Temp. oC

Condensing Temp.

o

C

1. Envelope in unshaded region, max return gas temperature of 18.3oC

Note:

R404A

7

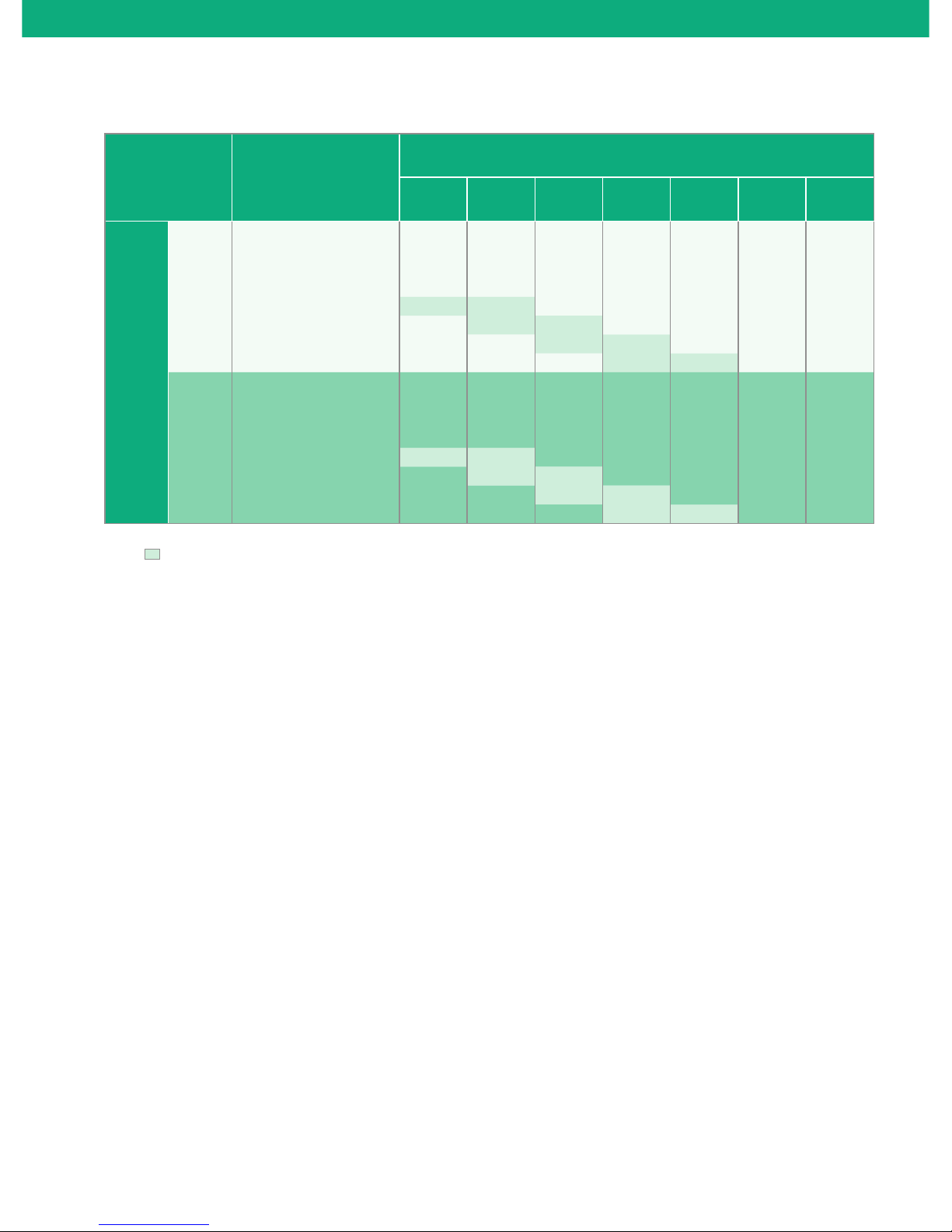

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R22 50 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-12 -10 -5 0 5 10 12.5

ZBD29KQ

Q

15

7.90 8.53 10.30 12.40

20 7.58 8.19 9.89 11.90 14.20

30 6.99 7.55 9.11 10.90 13.00 15.45 16.75

40 6.37 6.89 8.32 9.98 11.90 14.10 15.30

50 5.60 6.09 7.45 8.96 10.70 12.70 13.80

55 5.62 6.91 8.41 10.05 11.95 13.00

60 6.34 7.75 9.38 11.20 12.20

65 7.07 8.62 10.35 11.30

P

15 1.46 1.48 1.52 1.57

20 1.62 1.64 1.68 1.74 1.80

30 1.98 2.01 2.06 2.11 2.17 2.24 2.28

40 2.44 2.46 2.52 2.57 2.62 2.67 2.69

50 3.05 3.08 3.14 3.18 3.21 3.24 3.25

55 3.46 3.52 3.56 3.58 3.60 3.60

60 3.96 3.99 4.01 4.01 4.00

65 4.49 4.50 4.49 4.47

ZBD38KQ

Q

15 8.72 9.20 10.60 12.30

20 9.12 9.69 11.30 13.25 15.50

30 8.86 9.55 11.45 13.60 16.10 18.95 20.50

40 7.95 8.64 10.50 12.70 15.15 17.95 19.50

50 7.20 7.79 9.48 11.35 13.50 16.00 17.40

55 7.71 9.12 10.80 12.75 14.95 16.20

60 9.10 10.45 12.15 14.05 15.15

65 10.50 11.80 13.35 14.25

P

15 2.24 2.35 2.65 3.00

20 2.21 2.28 2.48 2.70 2.97

30 2.55 2.58 2.65 2.72 2.81 2.92 2.99

40 3.14 3.17 3.23 3.27 3.29 3.32 3.34

50 3.65 3.73 3.90 4.01 4.09 4.15 4.17

55 3.90 4.16 4.36 4.51 4.62 4.67

60 4.32 4.63 4.88 5.08 5.16

65 4.79 5.17 5.48 5.62

ZBD45KQ

Q

15 10.25 10.85 12.50 14.50

20 10.75 11.45 13.35 15.60 18.30

30 10.50 11.30 13.55 16.10 19.00 22.40 24.20

40 9.48 10.30 12.50 15.05 17.95 21.30 23.10

50 8.70 9.40 11.40 13.60 16.15 19.10 20.70

55 9.35 11.00 13.00 15.30 17.90 19.40

60 11.05 12.65 14.65 16.90 18.20

65 12.80 14.30 16.15 17.20

P

15 2.63 2.76 3.12 3.52

20 2.61 2.70 2.93 3.19 3.50

30 3.02 3.06 3.15 3.23 3.34 3.48 3.57

40 3.73 3.77 3.85 3.90 3.94 3.98 4.00

50 4.36 4.46 4.66 4.80 4.91 4.98 5.01

55 4.68 4.99 5.23 5.42 5.56 5.62

60 5.20 5.57 5.88 6.12 6.22

65

5.79 6.24

6.62 6.79

Notes: Suction Return Temperature 18.3oC

Suction Superheat 11.0K

Liquid subcooling 0.0K

8

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R22 50 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-12 -10 -5 0 5 10 12.5

ZBD48KQ

Q

15

11.55 12.20 14.05 16.30

20 12.10 12.85 15.05 17.60 20.60

30 11.80 12.75 15.25 18.15 21.40 25.20 27.30

40 10.65 11.60 14.10 17.00 20.30 24.00 26.00

50 9.79 10.60 12.85 15.35 18.25 21.60 23.40

55 - 10.55 12.45 14.70 17.30 20.30 22.00

60 - - 12.50 14.35 16.60 19.15 20.60

65 - - - 14.45 16.20 18.30 19.50

P

15 2.96 3.11 3.51 3.97

20 2.92 3.01 3.28 3.58 3.93 - -

30 3.35 3.39 3.49 3.59 3.71 3.86 3.96

40 4.11 4.16 4.24 4.29 4.33 4.37 4.40

50 4.76 4.87 5.10 5.25 5.37 5.45 5.48

55 5.07 5.43 5.70 5.90 6.06 6.13

60 5.62 6.04 6.38 6.65 6.77

65

6.23 6.74

7.17 7.35

Notes: Suction Return Temperature 18.3oC

Suction Superheat 11.0K

Liquid subcooling 0.0K

9

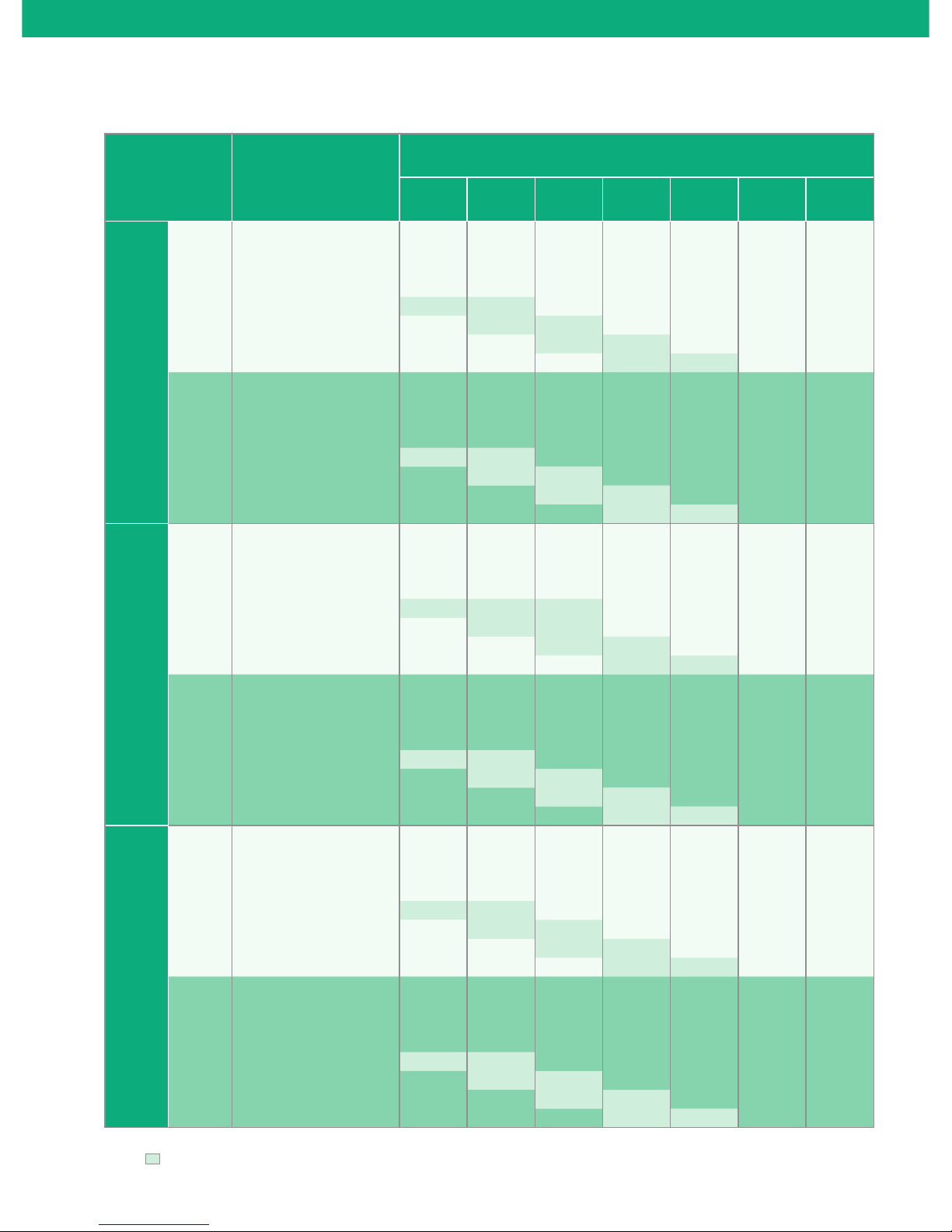

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R404A 50 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-20 -15 -10 -5 0 5 10

ZBD29KQE

Q

10 7.13 8.67 10.45

20 6.49 7.90 9.54 11.45 13.65

30 5.80 7.06 8.53 10.20 12.15 14.40 17.00

40 5.04 6.14 7.40 8.86 10.55 12.50 14.75

50 4.21 5.11 6.15 7.36 8.76 10.40 12.30

60 3.97 4.77 5.70 6.80 8.10 9.62

P

10 1.39 1.36 1.35

20 1.83 1.85 1.86 1.87 1.91

30 2.19 2.25 2.29 2.32 2.35 2.42 2.52

40 2.63 2.72 2.78 2.82 2.86 2.91 2.98

50 3.28 3.41 3.50 3.55 3.58 3.61 3.66

60 4.47 4.57 4.63 4.66 4.67 4.69

ZBD38KQE

Q

10 9.18 11.00 13.10

20 8.14 9.82 11.85 14.15 16.75

30 7.19 8.75 10.55 12.65 15.05 17.70 20.80

40 6.28 7.64 9.23 11.05 13.15 15.50 18.20

50 5.33 6.46 7.77 9.29 11.05 13.05 15.30

60 6.15 6.14 7.30 8.66 10.25 12.05

P

10 1.84 1.88 1.90

20 2.37 2.46 2.53 2.58 2.60

30 2.85 2.97 3.09 3.18 3.25 3.30 3.31

40 3.37 3.52 3.67 3.79 3.90 3.99 4.05

50 4.01 4.18 4.35 4.50 4.64 4.75 4.84

60 5.03 5.21 5.38 5.53 5.67 5.79

ZBD45KQE

Q

10 10.90 13.05 15.60

20 9.69 11.70 14.05 16.80 19.90

30 8.56 10.40 12.55 15.05 17.85 21.10 24.70

40 7.47 9.09 10.95 13.15 15.65 18.45 21.60

50 6.35 7.69 9.24 11.05 13.15 15.50 18.20

60 6.12 7.30 8.68 10.30 12.15 14.30

P

10 2.20 2.25 2.27

20 2.82 2.93 3.01 3.07 3.10

30 3.40 3.55 3.68 3.79 3.88 3.93 3.95

40 4.02 4.20 4.37 4.52 4.65 4.76 4.82

50 4.78 4.99 5.18 5.37 5.53 5.67 5.78

60 6.01 6.22 6.42 6.61 6.77 6.91

ZBD48KQE

Q

10 12.30 14.70 17.50

20 10.90 13.15 15.85 18.90 22.40

30 9.63 11.70 14.15 16.90 20.10 23.70 27.80

40 8.40 10.25 12.35 14.80 17.60 20.80 24.30

50 7.14 8.65 10.40 12.45 14.75 17.45 20.50

60 6.89 8.21 9.77 11.60 13.70 16.10

P

10 2.42 2.47 2.50

20 3.10 3.22 3.31 3.38 3.41

30 3.73 3.90 4.04 4.17 4.26 4.32 4.34

40 4.41 4.61 4.80 4.97 5.11 5.23 5.30

50 5.25 5.48 5.69 5.89 6.07 6.23 6.35

60 6.60 6.83

7.05 7.25

7.43 7.58

Notes: Suction Return Temperature 18.3oC

Liquid subcooling 0.0K

10

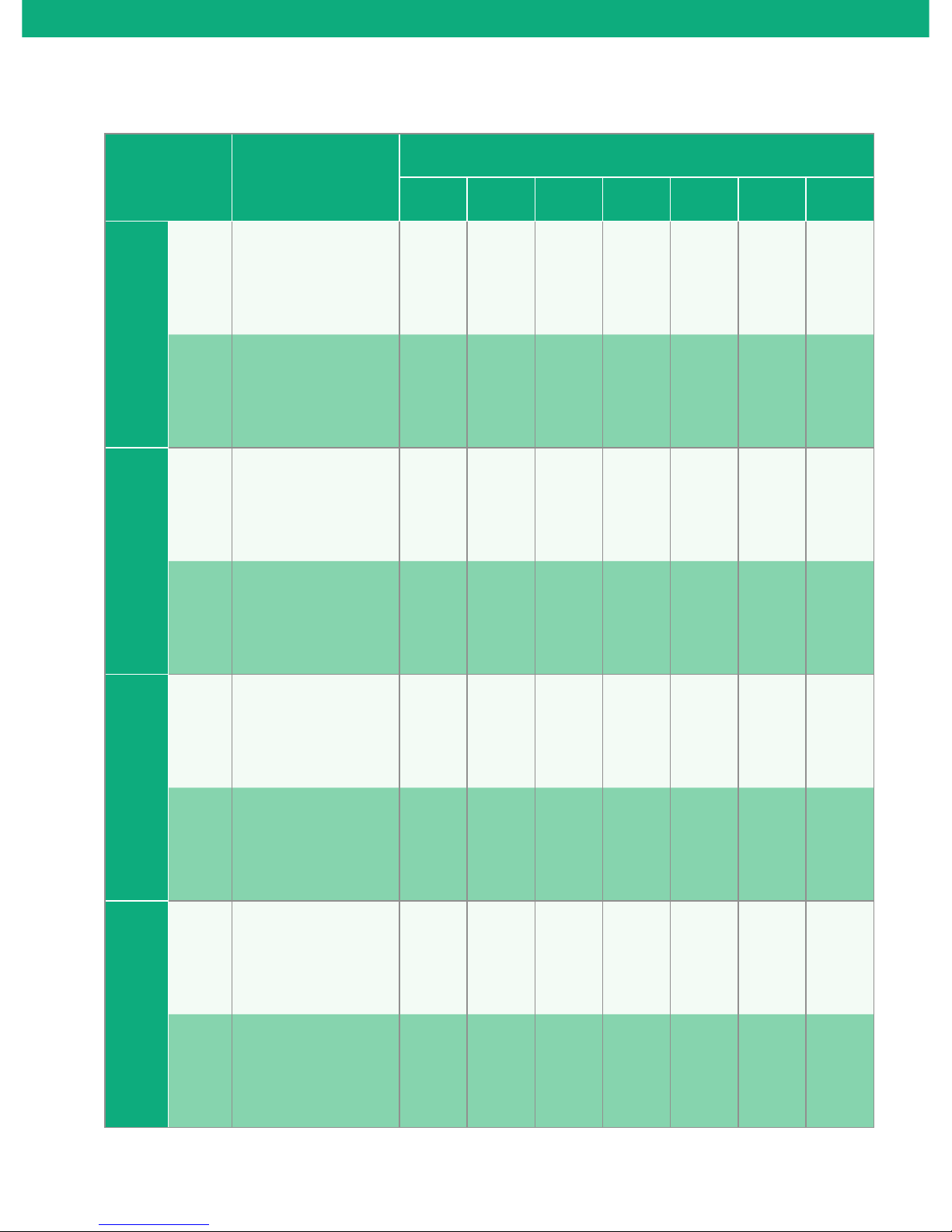

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R22 60 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-12 -10 -5 0 5 10 12.5

ZBD29KQ

Q

15 9.49 10.25 12.35 14.85

20 9.11 9.84 11.90 14.25 17.00

30 8.40 9.07 10.95 13.10 15.60 18.50 20.10

40 7.66 8.27 9.98 11.95 14.25 16.90 18.35

50 6.75 7.32 8.94 10.75 12.80 15.20 16.55

55 6.79 8.30 10.10 12.05 14.35 15.60

60 7.65 9.31 11.25 13.40 14.60

65 8.52 10.35 12.45 13.55

P

15 1.76 1.77 1.82 1.89

20 1.95 1.97 2.02 2.09 2.17

30 2.38 2.41 2.47 2.54 2.61 2.69 2.74

40 2.93 2.96 3.03 3.09 3.15 3.21 3.24

50 3.67 3.70 3.77 3.82 3.86 3.90 3.91

55 4.16 4.23 4.28 4.31 4.33 4.33

60 4.76 4.80 4.82 4.82 4.82

65 5.40 5.41 5.40 5.38

ZBD38KQ

Q

15 10.45 11.05 12.70 14.75

20 10.95 11.65 13.60 15.90 18.65

30 10.65 11.45 13.75 16.35 19.35 22.80 24.70

40 9.56 10.40 12.65 15.25 18.20 21.60 23.40

50 8.67 9.39 11.40 13.70 16.30 19.30 21.00

55 9.29 11.00 13.05 15.40 18.10 19.60

60 11.00 12.65 14.65 17.00 18.30

65 12.70 14.25 16.15 17.25

P

15 2.68 2.81 3.17 3.58

20 2.65 2.74 2.97 3.24 3.55

30 3.06 3.09 3.18 3.27 3.38 3.52 3.60

40 3.76 3.80 3.88 3.93 3.96 4.00 4.02

50 4.38 4.48 4.68 4.82 4.92 5.00 5.03

55 4.68 5.00 5.24 5.42 5.57 5.62

60 5.20 5.57 5.87 6.12 6.22

65 5.77 6.22 6.61 6.77

ZBD45KQ

Q

15 12.45 13.10 15.10 17.55

20 13.00 13.85 16.15 18.90 22.10

30 12.65 13.65 16.35 19.45 23.00 27.10 29.30

40 11.40 12.40 15.10 18.15 21.70 25.70 27.90

50 10.40 11.25 13.65 16.35 19.45 23.00 25.00

55 11.15 13.20 15.65 18.40 21.60 23.40

60 13.20 15.20 17.60 20.30 21.90

65 15.30 17.15 19.40 20.70

P

15 3.17 3.33 3.75 4.23

20 3.15 3.25 3.53 3.84 4.22

30 3.64 3.69 3.79 3.90 4.03 4.20 4.30

40 4.49 4.54 4.63 4.69 4.74 4.79 4.82

50 5.23 5.35 5.59 5.77 5.89 5.99 6.03

55 5.61 5.98 6.28 6.50 6.67 6.75

60 6.23 6.68 7.05 7.34 7.47

65

6.94 7.48

7.94 8.14

Notes: Suction Return Temperature 18.3oC

Suction Superheat 11.0K

Liquid subcooling 0.0K

11

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R22 60 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-12 -10 -5 0 5 10 12.5

ZBD48KQ

Q

15 13.85 14.60 16.85

19.55

20 14.45 15.40 17.95 21.00 24.60

30 14.05 15.15 18.15 21.60 25.60 30.10 32.60

40 12.55 13.65 16.70 20.10 24.00 28.50 31.00

50 11.30 12.30 14.90 18.00 21.50 25.40 27.70

55 12.10 14.40 17.15 20.20 23.80 25.80

60 14.35 16.55 19.25 22.30 24.10

65 16.60 18.65 21.20 22.60

P

15 3.69 3.88 4.39 4.96

20 3.64 3.77 4.10 4.47 4.92

30 4.20 4.25 4.38 4.50 4.65 4.85 4.97

40 5.19 5.24 5.35 5.41 5.47 5.52 5.55

50 6.04 6.18 6.46 6.66 6.81 6.91 6.96

55 6.46 6.90 7.24 7.51 7.71 7.79

60 7.17 7.70 8.13 8.48 8.63

65

7.97 8.62

9.16 9.40

Notes: Suction Return Temperature 18.3oC

Suction Superheat 11.0K

Liquid subcooling 0.0K

12

Performance Table

Q=Capacity (kW) P=Power input (kW) 3-Phase

R404A 60 Hz

Compressor

Condensing

Temperature

o

C

Evaporating Temperature (oC)

-20 -15 -10 -5 0 5 10

ZBD29KQE

Q

10 8.57 10.45 12.60

20 7.76 9.46 11.45 13.70 16.35

30 6.98 8.51 10.25 12.30 14.60 17.30 20.30

40 6.13 7.47 8.99 10.75 12.75 15.05 17.65

50 5.10 6.24 7.51 8.97 10.65 12.55 14.75

60 4.71 5.72 6.87 8.19 9.70 11.45

P

10 1.66 1.63 1.61

20 2.18 2.21 2.22 2.25 2.30

30 2.63 2.70 2.75 2.79 2.84 2.92 3.06

40 3.17 3.29 3.36 3.41 3.45 3.50 3.59

50 3.96 4.12 4.21 4.27 4.29 4.31 4.35

60 5.36 5.47 5.53 5.53 5.52 5.50

ZBD38KQE

Q

10 11.15 13.35 15.95

20 9.91 12.00 14.40 17.20 20.40

30 8.75 10.65 12.85 15.40 18.30 21.60 25.30

40 7.63 9.30 11.25 13.45 16.00 18.90 22.10

50 6.49 7.86 9.46 11.30 13.45 15.85 18.65

60 6.27 7.47 8.89 10.55 12.45 14.70

P

10 2.22 2.27 2.30

20 2.85 2.96 3.05 3.11 3.14

30 3.43 3.59 3.72 3.83 3.92 3.98 3.99

40 4.06 4.25 4.42 4.57 4.71 4.81 4.88

50 4.83 5.04 5.24 5.43 5.59 5.73 5.84

60 6.07 6.28 6.49 6.67 6.84 6.98

ZBD45KQE

Q

10 13.30 45.90 18.95

20 11.80 14.25 17.10 20.40 24.20

30 10.40 12.65 15.30 18.30 21.70 25.60 30.00

40 9.08 11.05 13.35 16.00 19.00 22.40 26.30

50 7.71 9.35 11.25 13.45 16.00 18.85 22.10

60 7.45 8.88 10.55 12.55 14.80 17.45

P

10 2.66 2.74 2.75

20 3.41 3.54 3.64 3.72 3.75

30 4.11 4.29 4.45 4.59 4.69 4.75 4.77

40 4.86 5.08 5.29 5.47 5.63 5.75 5.84

50 5.78 3.03 6.27 6.49 6.69 6.86 6.99

60 7.26 7.52 7.76 7.99 8.19 8.35

ZBD48KQE

Q

10 14.75 17.65 21.00

20 13.10 15.80 19.00 22.70 26.90

30 11.55 14.05 16.95 20.30 24.10 28.50 33.30

40 10.10 12.25 14.80 17.75 21.10 24.90 29.20

50 8.57 10.40 12.50 14.95 17.75 20.90 24.60

60 8.27 9.86 11.75 13.90 16.45 19.36

P

10 2.92 2.99 3.02

20 3.75 3.89 4.01 4.09 4.13

30 4.52 4.72 4.89 5.04 5.16 5.23 5.25

40 5.34 5.59 5.81 6.02 6.19 6.33 6.42

50 6.36 6.63 6.90 7.14 7.35 7.54 7.68

60 7.99 8.27

8.53 8.78

9.00 9.18

Notes: Suction Return Temperature 18.3oC

Liquid subcooling 0.0K

13

Technical Data 3-Phase

Model

ZBD29KQ

ZBD29KQE

ZBD38KQ

ZBD38KQE

ZBD45KQ

ZBD45KQE

ZBD48KQ

ZBD48KQE

Motor type

50Hz

TF5 TF5 TF5 TF5

TFD TFD TFD TFD

60Hz

TF5 TF5 TF5

TF7 TF7 TF7 TF7

TFD TFD TFD TFD

Displacement (m³/hr)

50Hz 11.4 14.4 17.1 18.8

60Hz 13.8 17.3 20.6 22.6

LRA

50Hz

TF5 115.0 150.0 156.0

TFD 48.0 64.0 74.0 100.0

60Hz

TF5 110.0 137.0 172.0

TF7 54.0 64.0 70.0 78.0

TFD 46.0 62.0 70.0 100.0

Max Operating Current

50Hz

TF5 18.5 24.7 22.7

TFD 7.9 12.8 12.5 15.2

60Hz

TF5 18.5 24.7 22.7

TF7 10.0 12.8 13.6 18.1

TFD 10.0 12.8 12.5 15.2

Max Continuous Current

50Hz

TF5 22.0 29.0 29.0

TFD 10.8 14.0 14.0 17.0

60Hz

TF5 24.0 29.0 29.0

TF7 13.0 15.0 17.5 20.0

TFD 11.0 14.0 14.0 18.0

RLA

KQ

TF5 17.1 20.7 20.7

TF7 9.3 10.7 12.5 14.3

TFD 7.9 10.0 10.0 12.9

KQE

TF5 16.7 23.7 25.4

TF7 9.6 11.6 12.9 14.7

TFD 7.7 11.3 9.6 12.8

Oil Charge, L

TF5 1.36 1.89 1.89 1.89

TF7 1.36 1.89 1.89 1.89

TFD 1.36 1.89 1.89 1.89

Oil Recharge, L

TF5 1.24 1.77 1.77 1.77

TF7 1.24 1.77 1.77 1.77

TFD 1.24 1.77 1.77 1.77

Nominal power(HP) 4 5 6 7

Crankcase Heater(W) 70 70 70 70

Connection Tube size(inch)

Discharge Tube outer Diameter 1/2 1/2 1/2 3/4

Suction Tube outer Diameter 7/8 7/8 7/8 7/8

Dimension(mm)

Length 241 241 241 241

Width 241 246 246 246

Height 479 494 494 494

Mounting parts installation size (hole size, mm) 190 x 190 (8.5)

Net Weight(kg) 72 84 88 90

Sound Power (dBA) 78 78 78 78

14

Dimensional Drawings

ZBD29KQ/E (BOM558)

15

Dimensional Drawings

ZBD38-45KQ/E (BOM 558)

16

ZBD48KQ/E (BOM 558)

Dimensional Drawings

17

ZBD29KQ/E (BOM 559)

Dimensional Drawings

18

ZBD38-48KQ/E (BOM 559)

Dimensional Drawings

19

ZBD38-45KQ/E (BOM 458 & 459)

Dimensional Drawings

20

ZBD48KQ/E (BOM 458 & 459)

Dimensional Drawings

21

Flow Controls Parts

The OMB is a compressor crankcase oil level protective control

ideal for use with Copeland Scroll® models ZF, ZB, ZR and ZS. It

is also recommended for Copeland® brand products, Carlyle,

Bitzer, and other semi-hermetic compressors.

Features

• Precision oil level measurement for maximum protection

• Easy monitoring with alarm and status lights

• Foam resistant design prevents nuisance trips unlike optical

sensor designs

• Contaminant proof operation ensures accurate control

• Only approved oil level control for Copeland Scroll® Compressors

• 5-time lockout feature protects compressor from repeated

low oil level condition

• Self-contained unit with oil lever sensor and integral

solenoid to manage oil level supply

• Reverse Hall-effect sensor for precise measurement of

oil level and protection from sensor magnetic debris

contamination

• SPDT output contact for compressor shut-down and alarming

• Easy installation by sightglass replacement

• Adapters suitable for various types of scroll compressors

(not required for reciprocating compressors)

• UL Recognized (File Number: MP604)

• Fluorescent oating ball

• Integral sight glass

• Debris retention magnet for reliable operation

OMB Series

Nomenclature example: OMB-JB1 ASC2 24 50/60

OMB JB1 ASC 2 24 50/60

Oil Management

Control

JB1 - Junction Box

MO1 - Series Relief

Connector

Solenoid Coil

Model

Number Voltage,

Frequency

(Included)

Ordering Information:

PCN Description

Oil Management Control

065365 OMB-JB1 ASC 2 24/50-60 - STD

065366 OMB-MO1 ASC 2 24/50-60 - STD

Adapters

(to attach OMB to Copeland Scroll® compressor

for new installation only)

065668

OMB-ACA ADAPTER (3/4” x 14 NPTF) Copeland®

Glacier, ZF, ZS, ZB

065667

OMB-ACB ADPATER (1 1/8” x 12 UNF) Copeland®

A/C ZR

066077

OMB-ACD ADAPTER (1 1/4” x 12 UNF) Copeland®

A/C Summit Series

066078

OMB-ACE ADAPTER (1 3/4” x 12 UNF) Copeland®

Specter Series

063521 OMB-AUA Copeland® 6D Semi-Hermetic

065982

OMB-ASA Carlyle Compressors DA, DR, 5F, 5H,

06D and 06E

Service parts

048638 Inlet Flare Screen

020877 Sight Glass O-Ring

064812 Mounting O-Rings (3 pieces)

049191 KS-30112 Solenoid Repair Kit

Dimensional Data (mm):

60.2

62.0

98.3

2.3

3.0

2.3

68.3

2.3

OMB Crankcase Oil Level Protective Control

Specications

• Maximum working pressure: 640 psi

• Solenoid MOPD: 350 psi

• Supply voltage: 24 VAC, 50/60 Hz

• Solenoid coil: ASC 2 L 24 VAC,

50/60 Hz

• Current consumption: 0.6A

• Time delay for low level signalling: 5–10 seconds

• Time delay for after setpoint recovery: 5–10 seconds

• Alarm delay time: 120 seconds

• Alarm switch: SPDT

• Alarm contact rating: 10A at 125;

5A at 220 VAC

50/60 Hz

• Refrigerant compatibility: HFC, HCFC, CFC

• Oil temperature: 180°F Max.

• Storage and transport temperature: 140°F Max.

• Operating ambient temperature: 120°F Max.

• Oil supply tting: 1/4" Male SAE

• UL/CUL le number: SA8547

• Transformer VA requirements* 25"

*NOTE: Field supplied transformer should always be of the same primary voltage

as the electrical supply system.

22

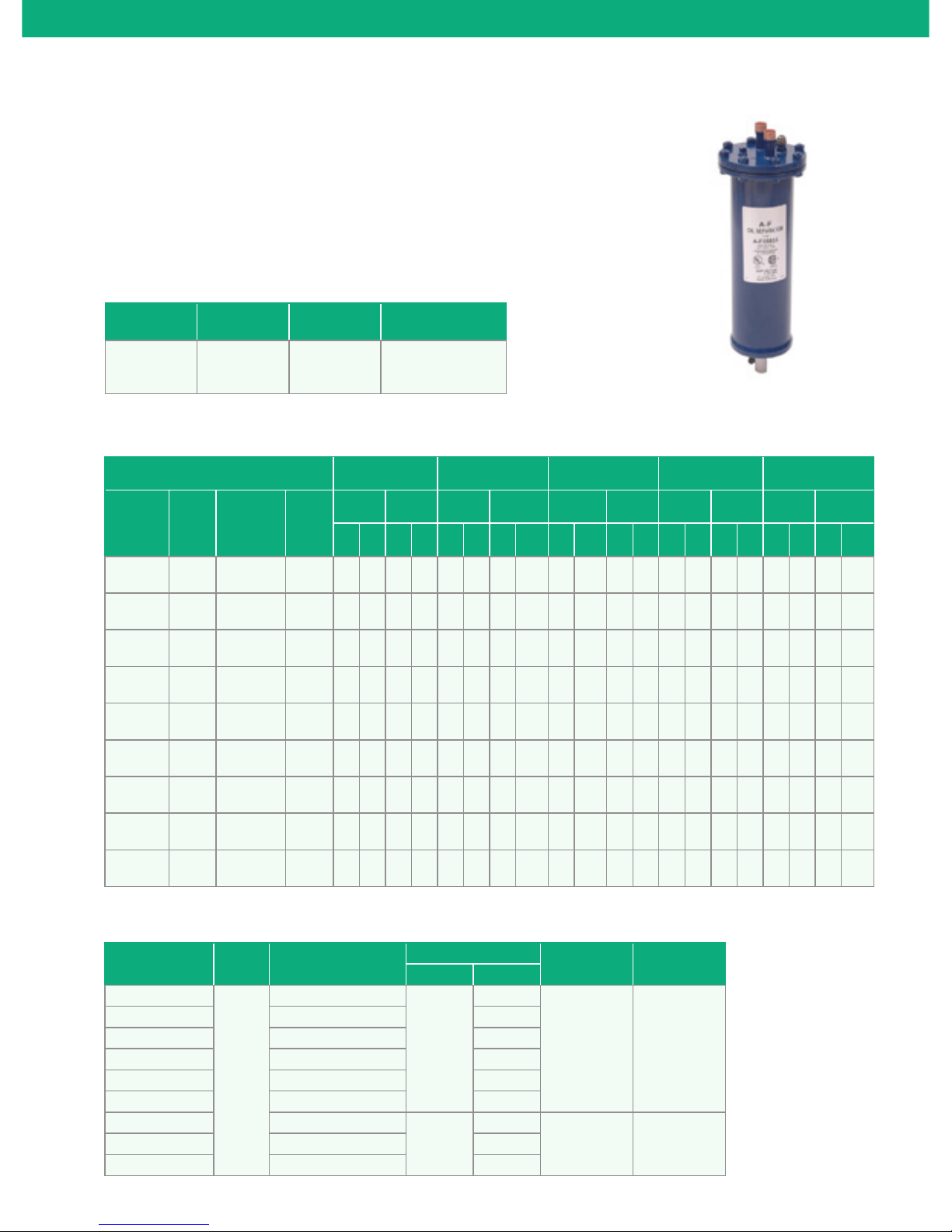

Seal Units: A-W

Description

Style

No.

Connection

Size (inch)

Dimensions (in)

Replaceable

Float

PCN

Oil Pre-charge

Amount

(0%)

A B

A-W 55824

1.0

1/2 ODF

4.0

10.8

N/A 17.0

A-W 55855 5/8 ODF 13.2

A-W 55877 7/8 ODF 15.0

A-W 55889 1-1/8 ODF 16.3

A-W 559011 1-3/8 ODF 19.5

A-W 569213 1-5/8 ODF 19.9

A-W 569011 1-3/8 ODF

6.0

15.8

N/A 20.0A-W 569213 1-5/8 ODF 19.0

A-W 569417 2-1/8 ODF 495.3

The A-W and A-F are used for multiple compressor racks in supermarkets and air conditioning

systems for use with HCFCs, HFCs and their lubricants.

Features

• Hermetic welded or accessible bolted ange construction

• Solid copper connections

• Corrosion resistant epoxy powder paint

Nomenclature:

A W 5582 4

Series

W = Welded

F = Flanged

Model Number

Connection Size

( in 1/8")

Ordering Information and Capacity Table:

Description R-12 R-22/R-407C R-502 R-134a R-404A/R-507

FLANGED PCN SEALED PCN

-40oC 40F (4C) -40F/C 40F (4C) -40F/C 40F (4C) -40F/C 40F (4C) -40F/C 40F (4C)

Tons kW Tons kW Tons kW Tons kW Tons kW Tons kW Tons kW Tons kW Tons kW Tons kW

A-F 58824 060877 A-W 55824 060933 1.0 3.5 1.5 5.3 1.5 5.3 2.0 7.1 1.5 5.3 2.0 7.1 1.0 3.5 1.8 6.2 1.5 5.3 2.0 7.0

A-F 58855 060878 A-W 55855 060934 3.0 10.6 4.0 14.2 4.5 15.9 5.5 19.5 4.8 16.8 5.8 20.4 3.3 11.5 4.5 15.9 4.0 14.2 5.5 19.0

A-F 58877 060879 A-W 55877 060931 4.5 15.9 5.5 19.5 7.0 24.8 8.0 28.3 7.5 26.6 8.5 30.1 4.8 16.8 6.5 23.0 6.5 23.0 8.5 30.0

A-F 58889 060759 A-W 55889 060974 6.0 21.2 7.5 26.6 9.0 31.9 11.0 37.2 9.5 33.6 11.5 11.5 6.5 23.0 8.5 30.1 8.5 30.1 11.0 38.0

A-F 589011 060760 A-W 559011 060930 7.5 26.6 10.0 35.4 11.5 40.7 14.0 47.8 12.0 42.5 14.5 14.5 8.0 28.3 11.5 40.7 10.5 37.2 14.0 49.0

A-F 589213 060761 A-W 559213 060975 9.0 31.9 11.5 40.7 14.0 49.6 18.0 62.0 16.0 56.6 17.5 17.5 9.5 33.6 13.3 46.9 14.0 49.6 17.0 60.0

– – A-W 569011 060978 9.0 31.7 12.0 42.3 13.0 45.8 14.0 49.8 15.0 52.8 20.0 20.0 9.5 33.4 13.7 48.2 11.0 38.7 19.0 66.9

A-F 579213 060875 A-W 569213 060979 11.0 38.9 14.0 49.6 16.0 56.6 18.0 63.7 20.0 70.8 24.0 24.0 11.8 41.6 16.0 56.6 17.5 62.0 23.0 81.0

A-F 579417 060876 A-W 569417 060980 17.0 60.2 22.0 77.9 25.0 88.5 30.0 106.0 30.0 106.035.0 35.0 18.0 63.7 25.6 89.4 26.0 92.0 34.0121.0

*See replacement parts page. Repair kits for style 2 only.

A-W/A-F Oil Separators

A-F Series

23

127

228.6

3/8 SAE FLARE FOR OIL

RETURN ON ALL UNITS

INLET AND OUTLET

IS ON TOP OF UNIT

STYLE NO. 1

STYLE NO. 2

INLET AND OUTLET

IS ON TOP OF UNIT

STYLE NO. 3

Dimensional Data (mm):

Flanged Units: A-F

Description

Style

No.

Connection

Size (inch)

Dimensions (in)

Replaceable

Float

PCN

Oil Pre-charge

Amount

(0%)

A B C

A-F 58824

3.0

1/2 ODF

4.0

10.5

5.5 N/A 17.0

A-F 58855 5/8 ODF 15.0

A-F 58877 7/8 ODF 18.0

A-F 58889 1 1/8 ODF 21.3

A-F 589011 1 3/8 ODF 21.4

A-F 589213 1 5/8 ODF 21.8

A-F 579213

2.0

1 5/8 ODF

6.0

20.1 4.4

065847 20.0

A-F 579417 2 1/8 ODF 20.3 4.6

24

The AOFD is designed specifically for refrigerant systems that use

POE oil. POE oil is hygroscopic in nature, which means that it attracts

and absorbs water. Moisture in a closed system can produce acid

and will harm the compressor. The AOFD protects compressors by

removing moisture and trapping contaminants.

Features

• Designed to clean and dry POE Oil

• 3/8” male are connections for easy replacement

• Large lter surface area to provide maximum ltration

• Contains desiccant for moisture removal

• Designed to operate at a very low pressure drop

• 10 micron ltration for optimum oil cleaning

• Dual access valves for pressure drop monitoring

Specications

• UL/CUL le number: SA3124

• Maximum working pressure: 680 psig

AOFD Water Capacity Table

Refrigerant Type Drops at 125°F

R-22 497

R-134A 518

R-404A 518

R-407C 435

AOFD-553 Oil Filter Drier

Ordering Information

PCN Description

062829 AOFD-553 Oil Filter Drier

Dimensional Data

9.62"

7.50"

3.17"

AOFD-553 Series

25

PCN Description

Size (mm)

Number of

48 in3 Cores

A B C D

053001 STAS-485T 252.5 152.4 96.0 16.0

1

053003 STAS-487T 246.1 158.8 95.3 19.8

053005 STAS-489T 247.7 160.3 97.5 23.9

053007 STAS-4811T 249.9 163.6 100.8 23.9

053043 STAS-4813S-V1 251.0 152.9 102.3 28.7

053044 STAS-4817S-V1 255.5 166.6 115.8 34.0

053045 STAS-4821S-V1265.2 178.6 120.7 26.4

053375 STAS-4813T 251.0 165.1 102.4 28.7

053938 STAS-4811SV 250.0 163.6 100.8 23.9

053010 STAS-967T 385.8 297.7 95.3 19.8

2

053012 STAS-969T 386.6 299.2 97.5 23.9

053014 STAS-9611T 388.9 302.5 100.8 26.2

053017 STAS-9613T 390.7 304.0 102.4 28.7

053018 STAS-9617T 395.2 305.6 115.8 34.0

053047 STAS-9617S-V1 395.2 305.6 115.8 34.0

053048 STAS-9621S-V1 404.9 317.5 120.7 38.1

059739 STAS-9625 SV 420.1 320.8 138.2 42.2

053020 STAS-1449T 539.8 441.5 97.5 23.9

3

053022 STAS-14411T 542.0 445.3 100.8 26.2

053024 STAS-14413T 543.1 446.8 102.4 28.7

053025 STAS-14417T 547.6 447.8 115.8 34.0

053028 STAS-19211T 683.5 584.2 100.8 26.2

4

053030 STAS-19213T 684.3 588.5 102.4 28.7

053031 STAS-19217T 689.1 587.5 115.8 34.0

056213 STAS-1927/5T 673.1 152.4 93.7 19.8/16.0

Note: 1. SV style include stainless steel bolts and access valve

The STAS is a replaceable core Filter Drier for CFC, HCFC, and HFC

refrigerants for use in large commercial air conditioning and

refrigeration systems.

Features

• Slotted cover/unique internal hardware for hassle-free installation

• Full ow ttings for low pressure drop

• Corrosion resistant epoxy powder paint nish

• Sturdy steel shells for long life

• Solid copper connections

• 100 mesh outlet screen

• Filtration (with core): 40 microns

• Maximum working pressure: SV version= 34.5 bar T version = 47 bar

• UL/CUL le number: SA7175

Ordering Information And Dimensional Data (mm):

Nomenclature:

STAS 48 9 T

Steel

Take-Apart

Series

Unit Size

(in3 )

Connection Size

(in 1/8")

System Service

T = Liquid Line Service

SV = Suction Line Service

STAS Steel Liquid and Suction Line Filter Drier

STAS Series

6.19

26

The ADKS is a replaceable core Filter Drier for use with CFC, HCFC,

and HFC refrigerants in very large commercial air conditioning and

refrigerant systems

Features

• Full ow ttings for low pressure drop

• Corrosion resistant epoxy powder paint nish

• Sturdy steel shells for long life durability

Nomenclature:

ADKS 300 13 T

System

Protector

Series

Unit Size

(in cu. in.)

Connection

Size

(in 1/8")

T = Tap Access

Connection

Ordering Information

PCN Description

Connection

Size

Number

Of 100 in3

Cores

Dimensions (mm)

Weight

(kg)

A B C D E F

2

G H

1

026570 ADKS-30013T 1 5/8 ODF

3.0

647.7 494.5 106.4 28.7

589.0

152.4 192.0

565.2 17.7

037978 ADKS-30017T 2 1/8 ODF 650.0 482.6 96.0 42.9

032105 ADKS-40017T 2 1/8 ODF

4.0

815.1 647.7 96.0 42.2

761.2 733.6 20.9

037570 ADKS-40021T 2 5/8 ODF 841.5 678.7 122.2 37.3

Notes: *Does not include weld bead

1

“H” Dimension is the clearance required to change the internal hardware assembly

T = 1/4” FPT access connection

ADKS Liquid And Suction Line Filter Drier

Dimensional Data

ADKS Models are shipped without fi lter cores or filter drier cores.

See filter or filter drier cores for availability.

Specications

• Filtration (with core): 40 microns

• Maximum working pressure: 500 psig*

• UL/CUL le number: SA 3124

• Bolt Torque: 35 ft-lbs

*Note: Not suitable for R-410A applications above 500 psig.

ADKS Series

27

Capacity Table (in Tons)

Liquid Line for Replaceable Block Type ADKS Filter Driers

Typ e

Connection

Size (inch)

Flow Capacity at 0.07 bar pressure drop

1,2

(kW)

R-12 R 134a R 22/R 410A R 407C R 404/507 R-502

ADKS 30013T

1 5/8 ODF

83

102

110

108

73

49

ADKS 30017T 2 1/8ODF 121 148 160 157 107 59

ADKS 40017T 2 1/8ODF 128 157 170 167 114 63

ADKS 40021T 2 5/8ODF 136 166 180 177 120 71

Notes: 1All ratings in accordance with ARI Standard 710-04. 86°F liquid refrigerant temperature

5oF saturated vapor temperature

3.1 lbs./min./ton for R-134a

2.9 lbs./min./ton for R-22 and R-407C

4.0 lbs./min./ton for R-404A/507 and R-12

2For 2 PSI ΔP. Multipy values by 1.4

Replacement Parts

Flange Cover Description PCN

ADKS-300

ADKS-400

X12176-2 027467

ADKS 30017T 2 1/8ODF 121

Shell Strainer Assembly

ADKS-300 X10574-5 039967

ADKS-400 X10574-6 038315

Miscellaneous Parts

Gasket Set

(Includes cover

gasket)

X-11983-2 027454

SHELL STRAINER

ASSEMBLY

FILTER-DRIER

BLOCK

FILTER-DRIER

BLOCK GASKET

INLET BLOCK

RETAINER

FILTER-DRIER

BLOCK

Exploded View

28

Universal replacement cores and lter cores for use in our ADKS and

STAS shells and similar competitive Take-Apart type Filter Drier shells.

May not be used for BTAS.

Features

• Water capacities to suit specic system conditions

• Exceptional acid capacities for normal system protection,

or to effectively clean-up following a compressor burnout

• Activated carbon blend for soluble contaminant and wax removal

(W-HH Series)

Nomenclature:

H 48

Series (in3)

Ordering Information:

PCN Type Refrigerant Function

Water Capacity1 (g)

R 134a R 22 R 407C

R 404A

/R 507

R 410A

24oC 52oC 24oC 52oC 24oC 52oC 24oC 52oC 24oC 52oC

059541 D-48 HCFC High Acid Removal 20.8 17.0 18.2 12.7 11.3 4.8 22.9 17.2 10.5 4.3

059542 H-48 HCFC

High Acid and Water

Removal

33.8 26.9 29.9 21.8 22.3 14.3 36.1 26.8 19.0 11.3

061235 W-48-HH HCFC, HFC Burnout Cleanup 19.4 14.7 16.8 11.3 14.5 8.3 20.9 14.5 12.5 6.5

061617 UK-48

CFC, HCFC,

HFC

Universal Replacement 1272 1168 1181 1072 1033 786 1319 1241 976 707

089338 H-100 HCFC

High Acid and Water

Removal

55.6 41.7 48.1 33.7 36.3 20.9 60.0 42.0 33.6 18.2

043582 W-100-HH HCFC, HFC Burnout Cleanup 53.9 40.6 46.9 31.1 31.5 18.2 58.1 39.6 28.7 15.4

089559 F-48 HCFC, HFC Filter (Suction Only) -

095762 F-100 HCFC, HFC Filter (Suction Only) -

Note: 1. Water Capacities are based on Equilibrium Point Dryness (EPD) of:

50 parts per million for R 134a, R 404A/R 410A and R 407C, 60 parts per million for R 22

Filter drier

block size

Dimensions (mm)

Weight (kg)

A B C

42 152.4 40.1 79.2 0.5

48 139.7 45.0 94.5 0.7

100 165.1 52.3 122.2 2.0

Filter drier

block size

Dimensions (mm)

Weight (kg)

A B C

F48/F48R 140.0 71.4 98.6 0.3

F100 165.0 95.3 122.2 0.7

Cores And Filters

Filter-Drier Cores And Filters

Dimensional Data (mm):

29

HMI-Hermetic Moisture Indicators

The HMI is designed to provide an accurate method of determining the

moisture content of a system's refrigerant. The HMI has a unique high

accuracy moisture indicator for CFC, HCFC, and HFC refrigerants.

Features

• Highest sensitivity moisture indicator available

• Hermetic, leak-free construction

• Single indicator for all common refrigerants

• Accurate color calibration at low ppm levels and higher temperatures

• Wide angle viewing/high visibility window for ease of monitoring

• All brass corrosion resistant body for fewer leaks

• Solid copper connections

Specications

• Maximum working pressure: 680 psig

• UL/CUL file number: SA 9566

HMI Series

FEMALE FLARE X MALE FLARE

TYPE "FM"

A

MALE FLARE X MALE FLARE

TYPE "MM"

A

B

D

C

F

C

TUBE STUB MALE X TUBE STUB FEMALE

TYPE "TTMF"

TUBE STUB X TUBE STUB

TYPE "TT"

A

G

F

E

F

D

C

A

D

C

B

E

B

D

Nomenclature:

HMI 1 TT 4

Hermetic

Moisture

Indicator

Series

Connection Style

TT = Sweat x

Sweat

Connection

Size

(in 1/8")

Dimensional Data

30

Dimensional Data (mm):

PCN Description Series

Connection Size

(inch)

065391 HMI-1MM2

Male Flare x Male Flare

1/4

065392 HMI-1MM3 3/8

065393 HMI-1MM4 1/2

065394 HMI-1MM5 5/8

065395 HMI-1MM6 3/4

065405 HMI1-1TT2

Sweat x Sweat (ODF)

1/4

065406 HMI1-1TT3 3/8

065407 HMI1-1TT4 1/2

065408 HMI1-1TT5 5/8

065409

HMI1-1TT6

3/4

065410 HMI1-1TT7 7/8

065411 HMI1-1TT9 1 1/8

065396 HMI-1FM2

Female Flare x Male Flare

1/4

065397 HMI-1FM3 3/8

065398 HMI-1FM4 1/2

065622 HMI-1TT2MF

Sweat x Sweat (ODM x ODF)

1/4

065814 HMI-1TT3MF 3/8

065979 HMI-1TT4MF 1/2

065980 HMI-1TT5MF 5/8

Moisture Content Color Code (ppm H2O):

Indication Liquid

Temperature

Dry (Dark Blue) Caution (Purple) Wet (Salmon)

75°F 100°F 125°F 75°F 100°F 125°F 75°F 100°F

125°F

R-12 1.4 2.5 4 5 9 15 25 43 70

R-134A 20 35 60 35 55 85 130 160 190

R-22 25 35 50 40 65 90 145 205 290

R-407C 26 40 64 42 68 109 150 230 370

R-410A 30 55 75 50 85 120 165 290 420

R-404A/507 15 25 45 33 50 80 120 150 180

31

PS1 Single Pressure Controls are designed for use on high and low

pressure applications in refrigeration, airconditioning, and heat pump

systems, providing single-device control of the compressor or other

electrical device.

Features

• Adjustable pressures and differentials

• Narrow adjustable differential depending on model

• Range and differential pointer in units bar and psig

• Range and differential individually lockable by tab

• High rated SPDT contacts for all versions

• Captive terminal and cover screws

• Manual toggle for system checkout and override

Options

• Different pressure connections

• Automatic and manual reset versions

• Factory set to customer specication

PS1 Series

PS1 Single Pressure Controls

Nomenclature:

PS1 A 5 K

Product Name Housing Variant/function Pressure Range Sensor Type

PS1 = Adjustable

single

Pressostat

A = Pressure control,

automatic

B = Pressure cut out, external

manual reset EN 12263

R = Pressure control, external

manual reset

W = Pressure limiter,

automatic, DIN/EN 12263

3 = -0.3 to 7 bar

4 = 2 to 20 bar

5 = 6 to 31 bar

A = 7/16” - 20 UNF male for 1/4” SAE

male are

K*= 7/16” - 20 UNF are nut with 1

meter (3 ft.) cap tube

U = 6mm ODF solder, 80mm length

R = 1/4" male, brass for 1/4" BSPP Fitting

Specications

• SPDT switch rated for 12FLA and 72LRA at 240VAC and 16FLA

and 96LRA at 120VAC

• Agency approvals include:

UL/CUL le number E85974

CE per (LVD) low voltage directive

32

Dimensions and Drawings mm(in):

Ordering Information

Single Pressure

Control

PCN Pressure Range (bar) Differential (bar)

Factory

Setting (bar)

Function

Pressure

Connection

PS1 - A3A 99035 -0.3 to 7 1 to 5 3.4 Automatic 1/4" SAE male are

PS1 - A3K 99041 -0.3 to 7 1 to 5 3.4 Automatic 1m cap tube with nut

PS1 - A3R 99014 -0.3 to 7 1 to 5 3.4 Automatic 1/4" BSPP tting

PS1 - A3U 99015 -0.3 to 7 1 to 5 3.4 Automatic 6mm tube, 80mm length

PS1 - A4A 99016 2 to 20 3 to 15 10 Automatic 1/4" SAE male are

PS1 - X4A 99043 2 to 20 3 to 15 10 Automatic 1/4" SAE male are

PS1 - A5A 99036 6 to 31 3 to 15 20 Automatic 1/4" SAE male are

PS1 - A5K 99039 6 to 31 3 to 15 20 Automatic 1m cap tube with nut

PS1 - B5U 99020 6 to 31 3 to 15 20

External Manual

Reset

6mm tube, 80mm length

PS1 - R5A 99037 6 to 31 Fixed 20

External Manual

Reset

1/4" SAE male are

PS1 - W5U 99033 6 to 31 3 to 15 20 Automatic 6mm tube, 80mm length

Bracket 99019 — — — — —

Note: Bracket not included with controls. Sold separately. 100 brackets per box.

33

The APD series is designed to reduce noise and vibration on the

compressor discharge lines.

Features

• Compact size

• Full ow ttings

• Solid copper connections

• Corrosion resistant epoxy powder paint nish

• Rugged steel shells for vibration resistance

• Shock resistant steel shell construction

Specications

• Maximum working pressure: 680 psig

• Operating Range: -40°F to +250°F

• UL/CUL le number: SA 5760

APD Pulsation Dampener/Mufer

Nomenclature:

APD 05 3 S B

Pulsation

Dampener

Cubic

Inches

Fitting Size

in 1/8”

ODF

Fittings

With Bafes

(omit for

standard)

Flow Capacity

Fitting Size Tons

1/4 1–5

3/8 5–10

1/2 10–20

5/8 15–25

7/8 25–35

1 1/8 35+

Dimensional Data

Ordering Information

Fitting

Size

Tons

Dimensions (in)

A B C D E F

061862 APD 1R 6.00 5.00 4.47 3.02

0.50 0.50

049651 APD 054 S-B 4.56 3.56 3.00

2.63

059144 APD 163 S 6.25 5.38

4.75

0.38 0.38

060119 APD 165 S-B 6.56 5.31 0.63 0.63

056989 APD 309 S 10.25 8.44 7.50 3.13 1.13 0.88

APD Series

34

Scroll Rack Application Guidelines

1. Introduction

Parallel operation is when several compressors are operating on one common refrigeration system. These installations require a

special design to achieve a maximum possible operating capacity and reliability. Only the system design engineer can make the

decision which conguration of installation is to be used in view of the particular requirements. The concept of scroll compressors

for refrigeration in parallel operation brings several benets:

• Efcient capacity control

With several compressors in parallel, if one of the compressors is turned off, one can achieve a simple method of capacity control

combined with a maximum possible saving of energy. If the load or ambient conditions change, compressors can be switched on

and off to match capacity requirements. This method of capacity control provides the advantage that the application limitations

are not altered as when the plant is equipped with capacity control. The use of unequal compressors allows many capacity

possibilities.

• Standby operation

If one compressor cannot run for any reason, the load can often be met by the remaining compressors. If the stoppage is caused

by a compressor breakdown, the other compressors could be damaged as well. One has to take immediate action to protect the

whole installation if acid / dirt is generated. The cause has to be detected in order to be able to decide on the urgency of repair.

This is especially required on plants having oil and refrigerant vapour pressure equalization lines, and on plants having no oil level

regulating system with lters in the suction and oil return lines.

• Changing compressors

If a compressor needs to be changed for any reason the small lightweight nature of the scroll makes this a much less costly

operation and causes much less disruption. This is particularly true for the smaller models.

• Matching several evaporating conditions

If there are two or more temperatures to be controlled individual compressors can be matched to each evaporator while working

on a single condenser circuit. This will give power savings compared with an alternative system working at the lowest suction

pressure.

Scroll compressors have no positive displacement oil pump and therefore no oil pressure switch. The high performance Teon®

bearings provide protection for short periods in case of oil losses. However sustained running at high-pressure differences without

lubricant will fail the bearings. In order to ensure adequate protection it is necessary to observe the following guidelines.

2. Parallel application considerations

If compressors are required to operate in parallel it is normally necessary to stop and start them independently for capacity control

purposes. There are three major considerations in this type of application:

• Oil return

With all capacity controlled refrigeration plant the oil circulation has to be perfectly correct especially under part-load

operation. This means that the maximum possible capacity reduction will be limited by the means of guaranteeing the correct

oil circulation. An adequate oil level at all times is necessary to maintain lubrication of the bearings. Too much oil can result in

inefcient operation and excessive oil carry over to the system.

• Tubing stress

If compressors are mounted close together care must be taken to ensure that there is sufcient exibility in the tubing. If this

is not done the starting pulse may result in excess stress directed at the mounting positions and may give rise to a leak. Tube

resonance should be avoided.

• Running sequence

A certain logical sequence control is recommended so that each compressor runs for the same amount of time.

35

3. Active oil control

Individual oil control for each compressor can be attained when each compressor has Flow Controls OMB oil level regulator tted

using an adaptor at the sight glass location. The regulator is fed from an oil reservoir which is itself fed from an oil separator. Filters

can be installed in the oil feeding line. The reservoir allows variations in oil quantity in the system to be accommodated. Oil carried

over from the compressor to the system is replaced when insufcient oil is being returned. There is a sight glass on each oil level

regulator where the oil level can be visually checked approximately 10 seconds after switching off the compressor. This method is

recommended by Emerson Climate Technologies provided that certain design points are observed. Because the scroll compressor

has no positive displacement oil pump and therefore no oil pressure switch, it is recommended that the oil control system

incorporates protection. It will be necessary to add oil to the system and the Emerson Climate Technologies approved lubricants are

Emkarate RL 32-3MAF and Mobil EAL Arctic 22 CC. The oil level regulating system for applications should be installed on site. Well

tested oil level regulating systems are available from refrigeration wholesalers.

3.1 Low pressure oil reservoir

The oil reservoir is maintained at a pressure slightly above the compressor sump pressure and this limits the amount of refrigerant

dissolved in the oil in the reservoir. The pressure drop is low when the oil enters the compressor and the amount of ash gas formed

in the sump is small.

Float switches or other devices can be used as regulators. It is recommended that the regulator has an electrical output which

can be wired into the control circuit and stop the compressor if the oil level falls below the minimum level and remains below the

minimum level for a period of time (maximum 2 minutes). This protects against failure of the oil supply to the individual compressor.

A level switch in the reservoir will only protect against insufcient oil in the receiver, but not against loss of oil supply to an individual

compressor or against a fault on an individual regulator.

Regulators currently on the market which meet these requirements include Flow Controls OMB oil level regulator. The OMB requires

the oil reservoir to be pressurized to 3.5 bar above suction pressure for reliable operation.

When using a regulator care must be taken to set the oil level in the upper half of the sight glass. If an adapter is used to connect the

regulator this may have a smaller internal diameter than the glass and this could give rise to a false oil level reading.

When commissioning these systems it is important to allow sufficient time for equilibrium running conditions to be attained.

Because the oil carry over rate from the scroll compressors is low it may take some time for stable oil quantities to build up in the

coolers. Until this has happened the total oil requirement of the system cannot be determined.

3.1 High pressure oil reservoir

The need for a separate oil receiver may be avoided if a combined separator/receiver is used, but in this case the oil will be stored at

discharge pressure. It will therefore cause much more disturbance and foaming when it enters the compressor sump. For this reason

it is advisable to limit the quantity of oil entering the sump when the valve opens. Flow Controls OMB oil level regulator is suitable for

this type of application and has been proven to operate satisfactorily with a high-pressure oil supply.

4. Passive oil control

4.1 Equalisation lines with passive oil control

The need for a separate oil receiver may be avoided if a combined separator/receiver is used, but in this case the oil will be stored at

discharge pressure. It will therefore cause much more disturbance and foaming when it enters the compressor sump. For this reason

it is advisable to limit the quantity of oil entering the sump when the valve opens. Flow Controls OMB oil level regulator is suitable for

this type of application and has been proven to operate satisfactorily with a high-pressure oil supply.

Simple systems which link the compressor sumps via tubes with no control are obviously attractive. They are quite common

on air conditioning applications, but in refrigeration additional considerations apply. They can of course only be considered for

compressors working at a common suction condition.

If there are large variations in oil quantity in the system due to changing conditions or defrost, this may result in too much or too

little oil in the compressors. Usually the only means of checking oil level is via the sight glass connection. Once the oil level is above

the sight glass it is not possible to determine if the maximum oil quantity is reached. Likewise if no oil is visible in the sight glass there

is a danger of operation below the minimum quantity.

A tube connecting the oil level adjustment valves on the compressors is not adequate because when a compressor is stopped, the

pressure in the shell rises and oil will transfer to the running compressor(s). The adjustment valve is located below sight glass level

and therefore the stationary compressor will show no oil level. Even if all compressors run together at all times, there will be small

pressure differences which will cause the same effect.

36

4.3 Suction line conguration

An adequately sized suction header providing equal distribution of returning

refrigerant and oil to each individual compressor must be used. The nonsymmetrical design as shown below is acceptable and does not create oil level

problems between the compressors.

Figure 1: Scrolls in parallel

Figure 2: Oil return Figure 3: Suction line conguration

Table 2: Model applicability

Compressor models approved

Low temperature Medium temperature

ZF09K* to ZF48K* ZB15K* to ZB114K* ZS21K* to ZS11M*

Alternative methods using the sight glass connections for oil equalisation connections have been shown to work on specic systems.

Notes are given below on some possible methods, but because of wide variations in system design and operating conditions, these

methods cannot be given general approval by Emerson Climate Technologies. The user has to verify operation in each system type.

4.2 Gas and oil equalization tube at sight glass position

Emerson Climate Technologies has conducted tests to prove the satisfactory operation of up to three compressors in parallel using

a gas and oil equalising tube. The conguration of suction line and equalization line should be as described below (see sections 4.3

and 4.4).

This method can be used for:

• Two or three ZF, ZS, ZB refrigeration Scroll compressors

• They must all be the same model, not uneven sizes

• All voltages

• Refrigerants R404A, R507, R22

• Same operating envelope as single compressor with injection where required

• Adequate liquid oodback protection must be provided

• Any sequence of compressors is allowed

37

4.4 Oil equalization line

The oil equalization line between the two or three compressors must be at least 7/8” (22 mm) with a minimum inner diameter of 19

mm. On no account must the internal diameter of any tting in this line be less than 19 mm. It is strongly recommended that a sight

glass be tted using adaptors. Kits consisting of the adaptor shown below, plus conversion to brazed connections are available (see

spare parts lists for details). The equalization tube must be level, and the compressors must be mounted level. Tests have shown that

smaller tube diameters do not provide proper oil balancing. An oil separator may be used and the oil return line from the separator

should be connected to the oil equalization line.

If no oil separator is installed the oil returns into the suction header and is picked up there from the individual compressor suction lines.

11/4” – 12 UNF 3/4” – 14 NPTF

7/8”

Figure 4: Adaptor for oil sight glass connection

NOTE: Tightening torque: 41-54 Nm. Use Loctite string or Everseal 483 White Pipe Sealant.

4.5 Oil and gas equalization plus oil regulator

If the OMB or other device is fitted to the equalization line, one device serving 2 or 3 compressors, the proper functioning of

the system has to be checked to ensure that no nuisance tripping occurs. The OMB sight glass, remote from the sump, does not

always accurately follow the sump oil level. The oil separator must be of the combined separator/reservoir high-pressure type, or

alternatively a separate oil reservoir may be used if the separator has its own oat valve. The separator oat valve outlet must not be

connected directly to the OMB.

5. Oil return to running compressors

If oil returns to the compressor at approximately the same rate as it leaves then the oil level will be maintained. It is always preferable

to design the suction manifold in such a way that oil returning with the suction gas can only enter the running compressor(s). This

can be done in a number of ways. Perhaps the most common is to use a suction header with vertical pick-ups to each compressor

which induces sufficient velocity to lift the oil. Again certain designs have been shown to be satisfactory but each one has to be

proven by testing. With some system designs this is sufficient to ensure adequate oil level at all times but there is no fail-safe

pressure switch if one compressor loses oil.

Recommended

From evaporator(s)

From evaporator(s)

From evaporator(s)

Suction lines to compressors

Not recommended

Figure 5: Suction header/lines to compressors – Recommendation

38

Figure 6: Tubing recommendation

Compressors Ident Number Characteristics Drawing

ZB15K* to ZB45K*

ZF09K* to ZF18K*

ZF13KVE to ZF18KVE

ZS21K* to ZS45K*

8030450

527-0157-00

60-70

Durometer

ZB56K* to ZB11M*

ZF24K* to ZF48K*

ZF24KVE to ZF48KVE

ZS56K* to ZS11M*

8522911

527-0168-00

Variation = 8516741

Hard

steel

6. Tubing and mounting considerations

6.1 Starting pulse

The standard mount for the scroll compressor is a soft rubber mount. It is designed to transmit the lowest possible disturbance

to the mounting frame. Because of the flexibility of this mount, it is essential that tubing to each compressor be designed to

accommodate the movement which will occur, particularly upon start-up.

The three phase motors used in the refrigeration scroll compressors exhibit a high starting torque characteristic. The reaction of

the stator is directly on the shell because there are no internal spring mounts. This reaction causes easily observable movement of

the shell when the standard mounts are used and this is normal. However, if the suction and discharge tubing of the compressor is

closely clamped to the frame or linked to another compressor, the tubing will restrain the movement and the motor reaction force

will be taken by the tubing. This may cause excessive stress and premature failure of tubing joints.

6.2 Resonance

The discharge pulse can in some configurations give rise to resonance of tubing. It is advisable to avoid a natural frequency of

between 45 and 55 Hz for the section of tubing between the compressor and the rst clamp. It is often not possible to determine

this in advance but in the unlikely event of a resonance problem arising a change in tube conguration will usually resolve it.

6.3 Recommendations for tubing and mounting

Always allow some exibility in the tubing to the suction and discharge connections. If the standard mounts are used there should

be at least two bends and a vertical section before the tube joins a header. Test the nished assembly by rocking the compressor on

its mounts. Vibration eliminators may be used but are not essential if the tubing has sufcient exibility. Vibration eliminators should

be tted in the vertical plane.

An alternative harder mount as detailed in Figure 7 is recommended. This will allow more loads to be transmitted via the feet,

and the very small additional vibration transmission is not usually a problem in refrigeration applications. It is still advisable to

incorporate a vertical section of tube between the compressor and the rst rigid mount. This will give exibility and minimise the

risk of resonance.

39

7. Design points

7.1 Suction line header

The suction lines running from the evaporators to the compressors should be led to a common main suction header in which

the suction pressures can equalize. From the main suction header to the compressors, preferably short and similarly constructed

pipes have to be provided symmetrically arranged. This serves to achieve a most perfect pressure equalization necessary for the

crankcases already at the compressor inlet. Naturally, the lower the speed in the suction line header the more perfect the pressure

equalization. Pipes running into the suction line header must not be right opposite outgoing pipes, so that an equalization of the

returning oil quantities can take place in the suction line header.

According to the capacity requirement of the system, compressors will be switched on or off. Occasionally however liquid

refrigerant can possibly ow into the compressors operating. Therefore, the suction line header should be designed in a manner

to simultaneously serve as a liquid separator. Consequently, one has to construct each pipe from the suction line header to the

compressor so that the oil return is guaranteed by using additional bores or capillaries. Liquid refrigerant should not return to the

compressors when not operating via the oil returning device.

Since installations with parallel compressors mostly have long pipe runs fitted on site, suction filters are commonly used. These

lters may just as well be equipped with drier cores as with dust lters only. The lter housings will be rigidly tted into the system

during rst installation before the common suction line header. Thus one can employ the appropriate lter core according to the

individual requirement, ie, acid absorbing driers too if necessary.

7.2 Discharge line header

The discharge line should slope downwards from the compressor to a lower positioned discharge line header. This is so any liquid

returning to the compressor from the condenser on the off cycle does not enter the compressor discharge port.

7.3 Oil separator

One of the features of a parallel compressor installation is the higher refrigeration capacity. With an increasing capacity generally

the entire pipe work is extended, more complex and not easy to survey, sometimes resulting in problems with the oil return. It is

therefore recommended to install oil separators regardless of the refrigerant and evaporating temperature. Pay careful attention and

obey the rules on how to install the pipe work. With the installation using an oil level regulating system the oil separator is already

included in this system hence the oil return line has to be tted to the oil reservoir.

7.4 Oil supply

The more complex a system pipe work is the more inuence the installation has on oil return. The extreme possibilities of capacity

control resulting in frequent changes of gas velocities inside the suction line will render the oil return difficult as well. Particular

attention should be paid to the lubrication problems involved. The oil level in the compressor crankcase should be controlled by

using an OMB oil level regulator having oil level detection. This device interrupts the compressor control circuit when insufcient oil

is in the compressor crankcase.

7.5 Installation

All compressors should be installed as close as possible to each other in order to keep the lines as short as possible. By changing the

priority of compressors in operation and keeping running time constant the compressors oil temperature can be kept at a certain

level which will reduce the amount of refrigerant absorbed into the compressor oil. Refrigerant owback into the compressor during

standby periods is not possible because the suction line header is below the compressor inlet port. If there is a requirement for

isolating the installation against vibrations the frame should be mounted on vibration absorbers. Of course the connecting pipes on

suction and discharge sides have to be exible as well.

Figure 7: Mounting parts for multiple operation

Compressors Ident Number Characteristics Drawing

ZB50K* to ZB114K*

Summit

8609592

527-0206-03

Variation = 8602466

Hard

steel

40

General Description

The XC645CX is designed to manage both compressors and fans in a

condensing system such as a pack.

The compressors can be digital scroll, simple, multistage.

Control is by means of a neutral zone or proportional band and is based

on the pressure or temperature sensed in the LP suction (compressors)

and HP (condenser) circuits. A special algorithm balances the run hours

of the compressors to distribute the work load uniformly.

The controllers can convert both LP and HP pressures and displays them as temperatures.

The front panel offers complete information on the system’s status by displaying the suction and condenser pressure (temperatures),

the status of the loads, possible alarms or maintenance conditions.

Each load has its own alarm input that is able to stop it when activated. To guarantee the total system’s safety, there are also two

inputs for low and high pressure switches: when these are activated, the system is stopped.

By means of the HOT KEY the controller can be easy programmed at power on.

The controller can be connected to the X-WEB, controlling and monitoring system, thanks to the serial TTL output, using the

standard ModBus RTU protocol.

Components Related to the XC645CX

Digital Compressor Rack Controller-XC645CX

Name Description Part Number

Transformer TF5 230V/12Vac CD050010 00

Wiring kit 1.5m and 3m

CWC15-Kit (1,5m)

CWC30-Kit (3,0m)

DD500101 50

DD500103 00

Female disconnect able connector for digital input or

analog output (4pcs)

CABCJ15 (1,5m)

CABCJ30 (3,0m)

DD200101 50

DD200103 00

TTL /RS485 serial converter XJ485CX+CABRS02 J7MAZZZ9AA

4-20mA suction pressure transducer PP11 (-0.5–11bar) BE009302 07

4-20mA condenser pressure transducer PP30 (0–30bar) BE009302 04

Hot key for programming HOT KEY 4K DK00000100

• CWC15KIT and CWC30KIT: wiring kits

The XC645CX is provided with 2 socket connectors with 14 and 6 pins.

For the wiring the CWC15KIT (1.5m cable length) or CWC30KIT (3.0m cable

length) have to be used.

41

• NP4-67: pipe mounting temperature probe

The NP4-67 temperature probe can be used on the discharge line to

monitor the discharge temperature of the Digital Scroll compressor.

NP4-67 1.5MT NTC probe Measurement range: -40+110°C, Cable 1,5mt

Code BN609001 52

• CABCJ15 or CABCJ30: 2 PIN connectors

NOTE:

Use the connection cable CABCJ15 (1.5m lenght) or the CABCJ30 (3.0m

lenght) for the:

• HP digital input (25-26),

• i2F congurable digital input (27- 28),

• 0-10Vdc or 4-20mA analogue output (23-24)

• oA6, 12Vdc/40mA digital output (21- 22) :

• PP07, PP11, PP30 PP50: 4–20mA pressure transducers

• XJ485CX: TTL / RS485 serial converter

The XJ485CX is a TTL/RS485 external converter. Insert it into the TTL

receptacle to convert the TTL output into a RS485 (+) and (-) signal for

the monitoring system MODBUS_RTU compatible. (XWEB).

PP07 2,0MT -0.5 + 7bar rel FE

cod BE009302 00

PP11 2,0MT -0.5 + 11bar rel FE

cod BE009302 07

PP30 2,0MT 0 + 307bar rel FE

cod BE009302 04

PP50 2,0MT 0 + 507bar rel Male

cod BE009002 07

42

Wiring and Electrical Connections

• General warnings

Before connecting cables make sure the power supply complies with the instrument’s requirements.

Separate the probe cables from the power supply cables, from the outputs and the power connections.

Do not exceed the maximum current allowed on each relay 5A resistive, in case of heavier loads use a suitable external relay.

• Wiring connections

24Vac/dc supply: use terminals 1-2

• Always use a class 2 transformer with minimum power 5VA such as TF5.

• Terminals [21-22], [23-24], [25.26], [27-28] are provided with JST 2 PINS connectors, they require the CABCJ15 (1,5mt) or

CABCJ30 (3mt) wiring cables

• Probes connection

If using terminal ends be sure there are no bear parts which could cause short circuiting or introduce noise disturbance at high

frequencies. To minimize the induced disturbances use shielded cables with the shield connected to earth.

Pressure probe (4 - 20 mA): respect the polarity. If using terminal ends be sure there are no bear parts which could cause short

circuiting or introduce noise disturbance at high frequencies. To minimize the induced disturbances use shielded cables with the

shield connected to earth.

Temperature probe: it is recommended to place the temperature probe away from direct air streams to correctly measure the

temperature.

Low voltage side (14PINs connector): Keep the cables away from the power cables. Use shielded cable to lengthen the cables.

NOTE 1: The PIN 4 is the common line for the temperature probes

NOTE 2: The PIN 3 gives a 12Vdc supply for the 4-20mA pressure transducers

PP07 PP11, PP30, PP50 4÷20mA pressure transducers respect the polarity.

Suction (P1C = Cur)

Brown (+) to terminal 6 ; white (-) to terminal 5

Condenser (P2C = Cur)

Brown (+) to terminal 6 ; white (-) to terminal 7

35 7

46 8

12V

40mA

§

Pb1Pb2

43

• Safety Digital Inputs and Pressure Switches

!!!WARNING: free voltage inputs!!!!

NOTE: The PIN 10 is the common line for all the digital inputs.

• Load Connections

!!!WARNING: Digital Scroll valve coil MUST operate at main voltage (230Vac or 115Vac)!!!!

NOTE: Main voltage side (6PINs connector): the PIN 17 is the common line for all the relay outputs and for the TRIAC.

Temperature probes (NTC 10K)

Suction: 4-5 (P1C = NTC)

Condenser: 4-7 (P2C =NTC) Pb3 (P3C = NTC): 4-3

35 7

46 8

Pb

1

Pb3Pb2

15 16 17 18 19 20

0,5A250V

Tria c

DG S

Va lv e

Ma

in voltage

230

V or 120V

OA2

5

A

M

a

x

DGS OA3 OA4

44

78,

3

6

,

9

59,5

28,5

6

70

29

71

Mounting and Installation

The instruments are suitable only for internal use. Instruments shall be mounted on panel, in a 29x71 mm hole, and xed using the

special brackets supplied.

The ambient operating temperature range is between -10–60°C.

Avoid locations subject to heavy vibration, corrosive gases or excessive dirt. The same applies to the probes. Ensure ventilation

around the instrument.

First installation

At rst installation, it’s necessary the following:

1. Select the kind of gas.

2. Set the range of the pressure probes.

In the following paragraph a short cut for the above operations.

Chapters 10 Parameters programming and 16 will show in detail these operations.

• How to set the kind of gas

The controller has memorized the relation between temperature and pressure for some gases.

The pre-set gas is: R404.

If another gas is used, act as in the following:

1. Enter the Programming mode by pressing the Set and DOWN key for 3s.

2. Select the “Pr2” parameter. Then enter the password 3 2 1 0.

3. Select the FtyP, kind of gas, parameter.

4. Press the “SET” key: the value of the parameter will start blinking.

5. Use “UP” or “DOWN” to change the gas among the following: r22= R22; r404=R404A; 507=R507; 134=134; r717= ammonia.

6. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 30s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

45

• How to set the range of the pressure probes

If an instrument with the following part number is used: XC645CX – xxxxF, it is pre-set to work with pressure probe with the

following range:

Probe 1: -0.5 –11.0 bar (relative pressure);

Probe 2: 0–30.0 bar (relative pressure)

If the probes you’re using have a different range act as in the following:

To set the pressure range of the Probe 1 (suction probe) use the parameter:

PA04: Adjustment of read out corresponding to 4mA

PA20: Adjustment of read out corresponding to 20mA

Practically these parameters have to be set with the start and end scale of the probe range.

How to do:

1. Enter the Programming mode by pressing the Set and DOWN key for 3s.

2. Select the “Pr2” parameter. Then enter the password 3 2 1 0.

3. Select the PA04, adjustment of read out corresponding to 4mA, parameter.

4. Press the “SET” key: the value of the parameter will start blinking.

5. Set the lower value of the probe range.

6. Push the SET key to conrm the value. The PA20: adjustment of read out corresponding to 20mA parameter will be displayed.

7. Set the higher value of the range.

8. Push the SET key to conrm the value. Next parameter will be displayed.

Do the same things for the Probe 2, FA04, FA20 parameters.

User interface

• Displaying

Upper Display Lower Display Icons

Suction temperature or pressure Discharge temperature or pressure

- Working loads

- Measurement unit

- Alarm or status Icons

• Keyboard

SET

(SET)

Standard visualization: to see or modify the set point. In programming mode it selects a parameter or

conrms an operation.

Alarm menu: By holding it pressed for 3s, the current alarm is erased.

o

(UP)

In programming mode: it browses the parameter codes or increases the displayed value.

With Hot key inserted: it starts the Hot key programming procedure.

To access the INFO menu: push and release it to access the INFO menu.

n

(DOWN

)

In programming mode: it browses the parameter codes or decreases the displayed value.

46