YARWAY TempLowHT DESUPERHEATER

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

MODEL 59/69/79

ATTENTION WHEN PUTTING INTO OPERATION

Readjust ‘Stuffing box’ immediately as required

(see separate section). Leakage is out of guarantee.

INSTALLATION OF THE TempLowHT

DESUPERHEATER

Before installation, check the TempLowHT

Desuperheater, actuator and accessories for any

visible damage.

Check that the information on the documentation,

identification plate and tag number complies with

the order specification. Remove the TempLowHT

Desuperheater carefully from its packaging,

liftingby means of straps around the body.

Do not use the water inlet connection, yoke,

actuator or any of its accessories for lifting. Leave

the flange covers

until ready to install in the pipework.

WARNING

The hoisting lug is for the actuator only,

NOT for a total assembly!

When installing the TempLowHT

Desuperheater use gaskets and bolting

material in accordance with the relevant piping

code, for example ASME B31.1 or AD 2000/EN.

Place the gasket onto the mounting flange

and carefully insert the nozzle into the branch

pipe. Ensure that the spray cylinder is pointed

with the direction of the steam flow before

tightening the mounting bolts (see figure 3).

in place during transportation,

RECOMMENDATIONS

(acid cleaning ofsteam boilers)

Remove TempLowHT Desuperheaters from

thepiping prior to acid cleaning!

UNPACKING

The Yarway TempLowHT Desuperheater is

packed with the greatest of care in wooden

boxes or cartons for protection during handling

and transit to site. After hydrostatic testing,

the TempLowHT Desuperhater is flushed

through with a high grade of preservative to

protect machined and internal surfaces from

corrosion. If it is found, however, that damage

has occurred during shipment, then this should

be reported immediately to your forwarder or

Yarway representative.

Particular care should be taken when removing

the TempLowHT Desuperheater from its packing

and your special attention is required to check

carefully that no damage has occurred to flange

faces, threading, actuators, connecting pipes, etc.

(See figure 1).

NOTE

The TempLowHT Desuperheaters should be installed

free of ‘forces, moments and torques’.

The TempLowHT Desuperheater is provided

with a standard lower body length, as specified

in the contract drawing and the mounting

branch for the steam pipework must be

manufactured to suit. The length of this branch

should be such, that the centerline of the spray

cylinder is located on the centerline of the

steam pipe (± 5 mm).

The mounting branch should be 3” (DN 80) for

Model 59, 4” (DN 100) for Model 69 and 5” (DN125)

for Model 79 nominal bore, maximum pipe

schedule 160 for clearance purposes (check the

applicable power piping code). Check the certified

drawing for flange details.

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-03239-EN 18/04

YARWAY TempLowHT DESUPERHEATER

InstallatIon and MaIntenance InstructIons

The minimum pipe run, required downstream

of the TempLowHT Desuperheater, varies

with each individual application and would

be specified by Yarway at the enquiry stage.

This straight run is needed to prevent erosion

due to impingement of water droplets against

pipewalls, valves and fittings and is normally

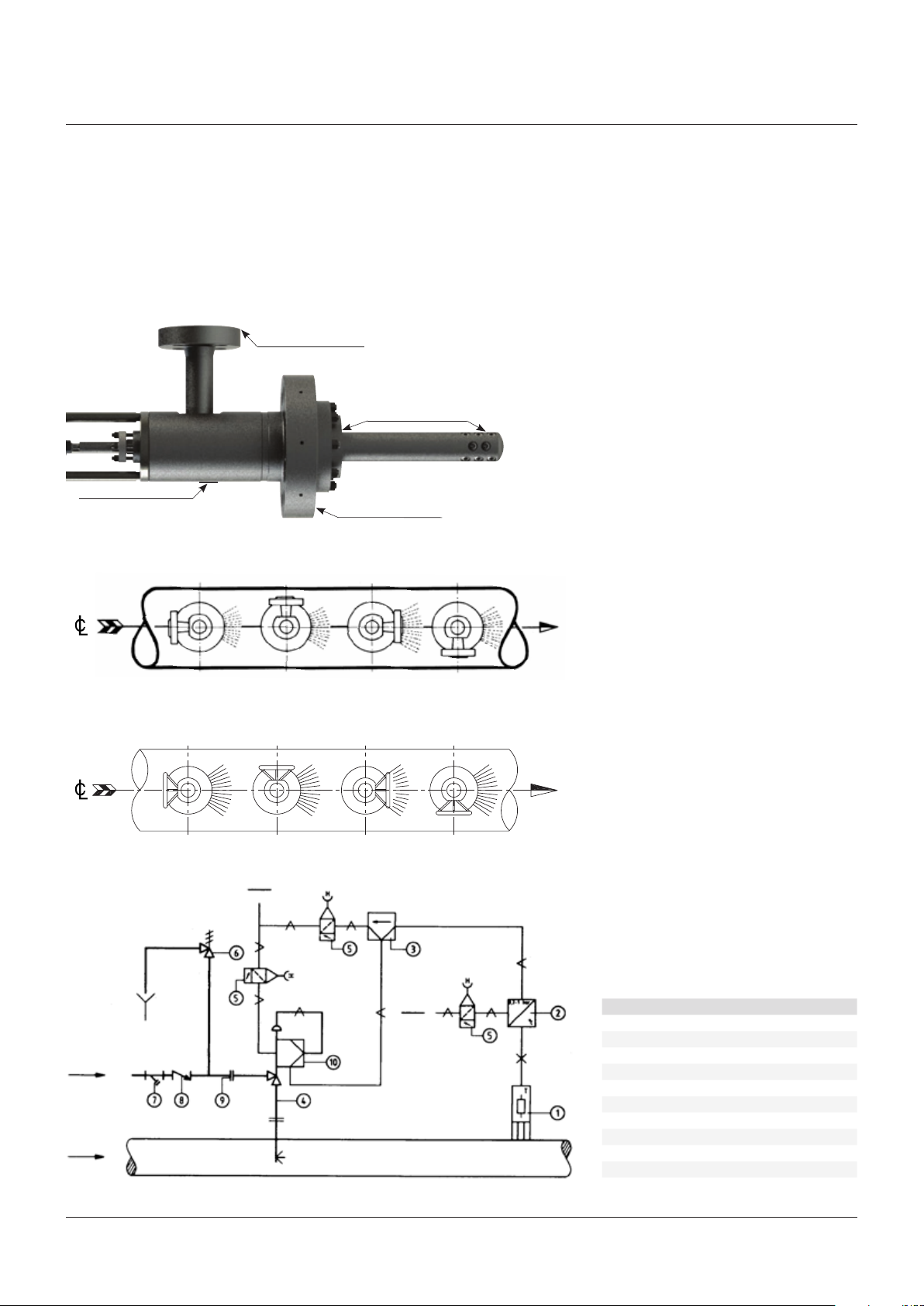

FIGURE 1 - MODEL 59/69/79

Check for damages

Identification plate

FIGURE 3

Water flange positions

Steam line

inthe order of 4 to 6 meters, as a minimum (no

upstream straight length is normally required).

The distance from the TempLowHT Desuperheater

to the temperature sensor is nominally 12to

15meters, although the distance specific to

theapplication would be advised by Yarway at

the enquirystage. Longerdistances will ensure

Check for damages

Check for damages

Steam flow

that full evaporation of the water will take place

at lowersteam velocities.

The temperature sensor should be located in

the upper half of the pipe, avoid branching of

the steam pipework between the TempLowHT

Desuperheater and the sensor (see figure 4).

Steam line

FIGURE 4

Water

Steam

FP9 FP12 FP3 FP6

Handwheel positions

HWW HWN HWE HWS

Air

Air

Steam flow

Item Description

1 Temperature sensor

2 Temperature transmitter

3 Temperature controller

4 TempLowHT Desuperheater

5 Air filter regulator

6 Safety relief valve

7 Strainer

8 Check valve

9 Flange

10 E/P-positioner

2

YARWAY TempLowHT DESUPERHEATER

InstallatIon and MaIntenance InstructIons

Pipe bends should always be of the long radius

type to assist in keeping the water droplets in

suspension, until complete evaporation has

taken place. Installation may be in vertical or

horizontal piping, but the direction of water

injection should always be with the steam flow.

The TempLowHT Desuperheater may be

mounted at 90° to the steam pipe, for all steam

flow orientations, but avoid installation in

the vertically downwards position, wherever

possible (see figure 5).

Yarway supplies the TempLowHT

Desuperheater as follows:

Identification number:

xx. 59. xxxxx - Forged type with 3” (DN 80)

mounting flange

xx. 69. xxxxx - Forged type with 4” (DN 100)

mounting flange

xx. 79. xxxxx - Forged type with 5” (DN 125)

mounting flange

NOTE

Horizontal orientated TempLowHT Desuperheater has

to be installed with a support for weightcompensation.

The water supply should be of a good quality;

clean and filtered, for example boiler feed

water and should have a constant pressure as

specified in the order documents. Each water

supply line should be protected with its own

individual strainer with a maximum element

perforation size of 0.1 mm (0.4 mm acceptable

for nozzles ‘E’ size and up).

Where there are positive shut-off components

in the water supply (including electric actuators)

then a safety relief valve of an approved type

should be fitted. As in the case of thesteam

pipework,

accordance with the relevant piping code.

Flushout the water line before connecting

to the TempLowHT Desuperheater mounting

flange (see figure 6).

use gasketing and bolting in

START-UP

Ensure that all components are installed

correctly. Connection of electrical supplies and

instrument air piping should be in accordance

with the manufacturer’s instruction manual.

Verify and adjust, ifnecessary, set points for

filter regulators and valve positioners, following

the manufacturer’s recommendations.

Similarly, calibrate thetemperature

transmitter/controller, verifying automatic

response to temperature changes.

Warm the steam main and open the

valve in the water supply. Check the

water pressure at the TempLowHT

Desuperheater. Verifytheoperation of the

temperature transmitter and controller by

manually increasing and decreasing the

output signal and observing indicated and

recordedtemperatures.

When satisfactory coordination between

instrument signals and temperature are

attained, adjustment of the set point can

be made and the system transferred to

automaticoperation.

It is recommended to record the various steam

coordinates, over a sustained period, to verify

operation, adjusting where necessary.

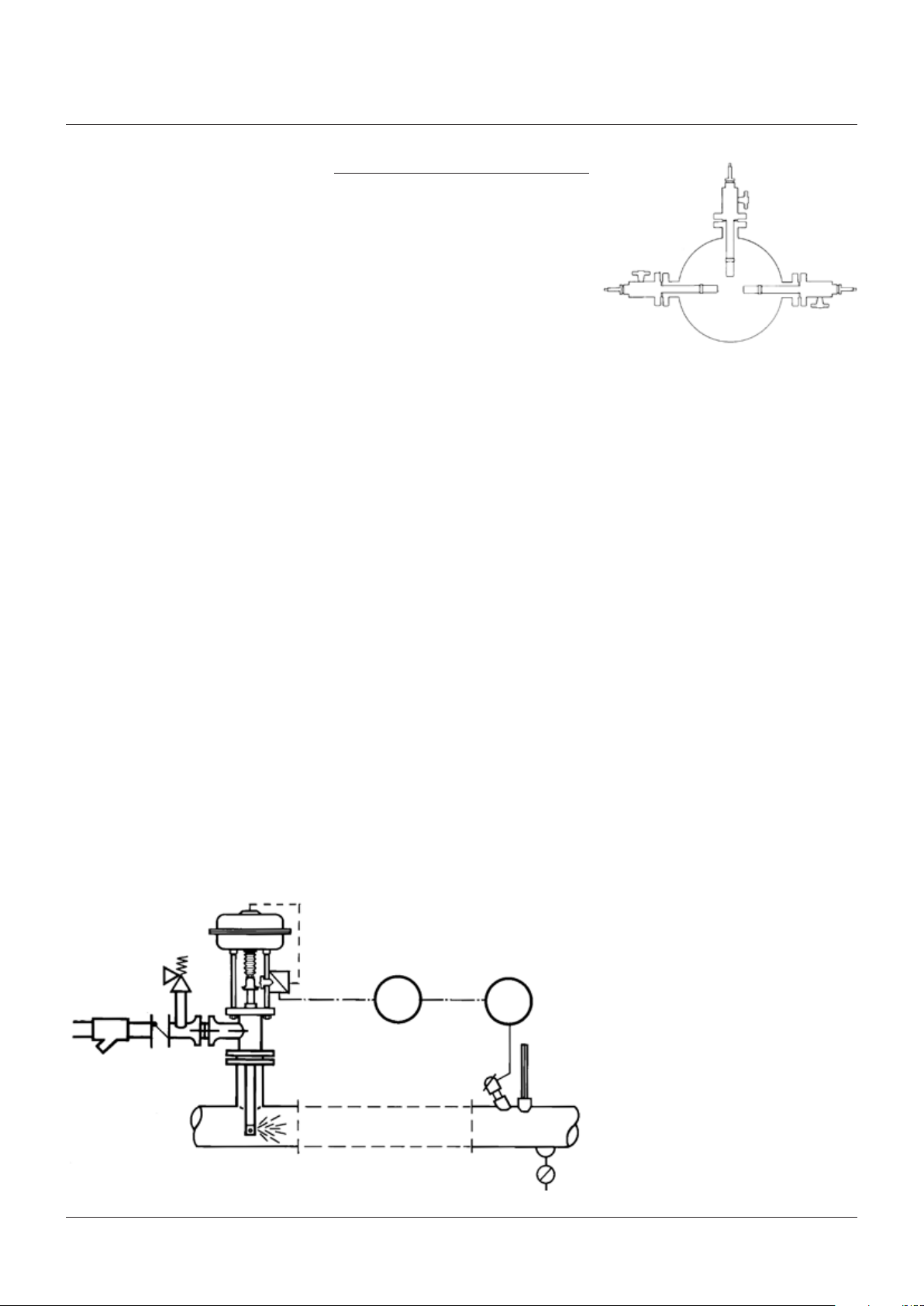

FIGURE 5

FIGURE 6

Check valve

Strainer

Safety valve

TC TT

3

Loading...

Loading...