Page 1

Instruction Manual

HASAxE-IM-HS

07/2006

Gas Analyzer Series

Instruction Manual

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and tests

its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when

installing, using and maintaining Emerson Process Management (Rosemount Analytical)

products. Failure to follow the proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to this

instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement

parts specified by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualified persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

Edition 2006-07

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Instruction Manual

HASAxE-IM-HS

04/2006

X-STREAM

PREAMBLE

This instruction manual provides information about X-STREAM series gas analyzers

concerning subassemblies, functions, procedures, installation, operation and maintenance.

This instruction manual covers several X-STREAM series analyzer variations and therefore

may describe configurations and/or options not part of your specific analyzer.

Installation and operation of instruments intended to be installed and operated in hazardous

areas is not covered by this instruction manual, but part of the specific instruction manual

shipped together with such analyzers because of the special requirements for working in

hazardous environments!

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in injury, death, or long-term health

hazards of personnel.

Safety Instructions

Highlights an operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in damage to or destruction of equipment,

or loss of effectiveness.

NOTE

Highlights an essential operating procedure, condition or statement.

Emerson Process Management GmbH & Co. OHG S-1

Page 4

Instruction Manual

X-STREAM

HASAxE-IM-HS

04/2006

IMPORTANT

Safety Instructions

Wiring and Installation of this Apparatus

The following safety instructions apply specifically to all EU member states. They should be strictly

adhered to in order to assure compliance with the Low Voltage Directive. Non-EU st ates should also

comply with the following unless superseded by local or National Standards.

1. Adequate earth connections should be made to all earthing points, internal and external, where

provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced. The

integrity of all earth terminals must be maintained at all times.

3. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

Circuit breakers or switches must comply with a recognized standard such as IEC947. All wiring

must conform with any local standards.

4. Where equipment or covers are marked with the symbol to the right, hazardous

voltages are likely to be present beneath. These covers should only be removed

when power is removed from the equipment — and then by trained service

personnel only .

5. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain

surfaces may remain hot to the touch.

6. Where equipment or covers are marked with the symbol to the right, refer to the

Instruction Manual for instructions.

7. Further graphical symbols used in this product:

Electrostatic discharge (ESD)

Harmful (to Health)!

Explosion Hazard!

Toxic!

Heavy Instrument!

Disconnect from Mains!

All graphical symbols used in this product are from one or more of the following standards:

EN61010-1, IEC417, and ISO3864.

Emerson Process Management GmbH & Co. OHGS-2

Page 5

Instruction Manual

HASAxE-IM-HS

04/2006

X-STREAM

Safety Instructions

Operating and Maintaining this Apparatus

This instrument has left the factory in compliance with all applicable safety regulations.

To maintain this operating condition, the user

must strictly follow the instructions and consider

the warnings in this manual or provided on the

instrument.

Before switching on the instrument, verify that

the electrical supply voltage matches the

instrument´s operating voltage as set in the

factory .

Any interruption in the instrument´s ground line,

whether inside or outside the instrument, or

removal or interruption of its ground line

connection, could result in hazardous operating

conditions. Intentionally interrupting the

instrument´s protective ground is strictly prohibited.

Opening cover panels could expose voltagecarrying components. Connectors may also be

under voltage. The instrument must be

disconnected from all electrical supplies before

attempting any calibrations, maintenance

operations, repairs or component

replacements requiring opening of the

instrument. Any calibrations, maintenance

operations, or repairs that need the instrument

to be opened while connected to electrical

supplies should be subject to qualified

technicians familiar with the hazards involved

only!

Observe all applicable regulations when

operating the instrument from an autotransformer or variac.

Substances hazardous to health may emerge

from the instrument‘s exhaust.

Please pay attention to the safety of your

operation personnel. Protective measures

must be taken, if required.

Safety Instructions

Use only fuses of the correct type and current

ratings as replacements. Using repaired fuses

and short circuiting of fuse holders is prohibited.

Emerson Process Management GmbH & Co. OHG S-3

Page 6

Instruction Manual

X-STREAM

Safety Instructions

HASAxE-IM-HS

04/2006

INTENDED USE STATEMENT

X-Stream series gas analyzers are intended to be used as analyzers for industrial purposes.

They must not be used in medical, diagnostic or life support applications nor as safety

devices, and no independent agency certifications or approvals are to be implied as

covering such applications!

AUTHORIZED PERSONNEL

If this equipment is used in a manner not specified in these instructions, protective systems

may be impaired.

SAFETY SUMMARY

T o avoid loss of life, personal injury and damage to this equipment and on-site property , do

not operate or service this instrument before reading and understanding this instruction

manual and receiving appropriate training. Save these instructions.

ELECTRICAL SHOCK HAZARD !

Do not operate without covers secure. Do not open while energized.

Installation requires access to live parts which can cause death or serious

injury .

For safety and proper performace this instrument must be connected to a

properly grounded three-wire source of power.

TOXIC GASES !

This unit’s exhaust may contain toxic gases such as sulfur dioxide.

These gases can cause serious injuries.

Aviod inhalation of the exhaust gases at the exhaust fitting.

Connect exhaust outlet to a safe vent. Check vent line and connections for

leakage.

Keep all fittings tight to avoid leaks. See section 7-2, page 7-2 for leak test

instructions.

Emerson Process Management GmbH & Co. OHGS-4

Page 7

Instruction Manual

HASAxE-IM-HS

04/2006

X-STREAM

Safety Instructions

EXPLOSION HAZARD !

Do not operate nor install these instruments in hazardous areas without additional measures!

HEAVY INSTRUMENTS !

The analyzer variation X-STREAM F, intended to be wall mounted and/or

outdoor installed, weighs up to approx. 26 kg (57 lbs), depending on

included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specified to be used for the weight of

the units!

T ake care the wall or stand the unit is intended to be inst alled at is solid and

stable to hold the units!

Safety Instructions

HIGH TEMPERATURES !

While working with photometers and/or thermostated components inside

the analyzers hot components may be accessible!

Emerson Process Management GmbH & Co. OHG S-5

Page 8

X-STREAM

GASES AND GAS CONDITIONING

Take care of the safety instructions applicable for the gases (sample

gases and test gases) and for the gas bottles containing these gases!

Instruction Manual

HASAxE-IM-HS

04/2006

Safety Instructions

INJURY HAZARD !

EXPLOSION HAZARD !

Supplying flammable gases of concentrations above the lower explosion

limit (LEL) we recommend to utilize one or more of the following measures:

• Purging the housing with inert gas

• Internal tubing with stainless steel

• Flame arrestors at gas input and output fittings

• Intrinsically safe paramagnetical or thermal conductivity sensors

Supplying explosive gases is not permitted ! (Explosive gases are mixtures

of flammable gases of concentrations between the explosion limits with air

or oxygen).

Before opening gas paths they must be purged with ambient air or

neutral gas (N2) to avoid hazards caused by toxic, flammable,

explosive or harmful to health sample gas components!

Emerson Process Management GmbH & Co. OHGS-6

Page 9

Instruction Manual

HASAxE-IM-HS

04/2006

POWER SUPPLY

V erify the mains voltage at site of inst allation corresponds to the analyzer´s

rated voltage as given on the nameplate label!

V erify the safety instruction given by power supply unit manufacturer !

CONNECTING INSTRUMENTS FOR FIXED INSTALLATION

X-STREAM

Safety Instructions

Safety Instructions

Installation and connecting mains and signal cables are subject to qualified

personnel only taking into account all applicable standards and legislative

requirements!

Failure to follow may cause warranty invalidation, property damage and/or

personal injury or death! Connecting mains and signal cables to internal

srew terminals requires working at open housing near life parts!

Installation of this instrument is subject to qualified personnel only , familiar

with the resulting potential risks!

The gas analyzers do not provide a mains power switch and are operable

when connected to power.

The gas analyzers do not provide a mains switch! A mains switch or circuit

breaker (to comply with IEC 60947-1 /-3) has to be provided in the building

installation. This switch has to be installed near by analyzer, must be easily

operator accessible and has to be assigned as disconnector for the analyzer.

Cables for external data processing must be double insulated for mains

voltage when used inside the instrument!

If double insulation is not available signal cables inside the analyzer must

be installed in a way that a distance of at least 5 mm is ensured permanently

(e.g. by utilizing cable ties).

Emerson Process Management GmbH & Co. OHG S-7

Page 10

X-STREAM

These instruments provide a protective earth terminal. To prevent electrical

shock hazards the instrument must be connected to a protective earth.

Therefore the instrument has to be connected to mains by using a three

wire mains cable with earth conductor!

Any interruption of the earth connector inside or outside the instrument or

disconnecting the earth terminal may cause potential electrical shock

hazzard! Intended interruption of protective earth connections is not

permitted!

Instruction Manual

HASAxE-IM-HS

04/2006

Safety Instructions

ELECTRICAL SHOCK HAZARD !

Emerson Process Management GmbH & Co. OHGS-8

Page 11

Instruction Manual

HASAxE-IM-HS

04/2006

General Operating Instructions

General Operating Instructions

X-STREAM

DANGER TO LIFE ! EXPLOSION HAZARD !

V erify all gas lines are connected as described within this manual and tight!

Improper gas connections may cause explosion, serious injury or death!

Exhaust may contain hydrocarbons and other toxic gases, e.g. carbon

monoxide. Carbon monoxide is toxic!

• Indoor installation area has to be clean, free from moisture, excessive vibration and frostprotected.

• T ake care to meet the permissible ambient temperatures as given in the technical data section!

Instruments must not be exposed to direct sunlight nor sources of heat. Do not cover venting

openings and take care to mount the instrument in a distance to walls not affecting venting.

• Do not interchange gas inlet and outlet! All gases must be conditioned before supplying! When

supplying corrosive gases ensure that gas path components are not affected!

• Max. permissible gas pressure: 1,500 hPa (7.5 psig), except with paramagnetic Oxygen sensor

(atmospheric pressure;

page 3-17)!

Safety Instructions

• Exhaust lines must be installed in a descending way , need to be pressureless, frost-protected

and in compliance with applicable legislative requirements!

• When it is necessary to open gas paths seal the analyzer‘s gas fittings by using PVC caps to

avoid pollution of the internal gas path by moisture, dust, etc.

• T o stay in compliance with regulations regarding electromagnetic compatibility it is recommended

to use only shielded cables, as optionally available from Emerson Process Management or

equivalent. Customer has to take care that the shield is connected in proper way ( section

4-5, page 4-29). Shield and signal connector enclosure need to be conductively connected,

submin-d plugs and sockets must be screwed to the analyzer .

• Using external submin-d-to-terminal adaptor elements (option) affects electromagnetic

compatibility . In this case the customer has to take measures to stay in compliance and has to

declare conformity , when required by legislation (e.g. European EMC Directive).

Emerson Process Management GmbH & Co. OHG S-9

Page 12

X-STREAM

Magnetically Operated Front Panel

Magnetically Operated Front Panel

Persons with cardiac pacemakers should absolutely avoid magnetic

fields !

Negative effects on persons beyond those described above caused by

magnetic fields are not known. It is presumed that persons showing allergic

reaction on contact with ceramic or metallic material show the same

behavior on contact with magnetic material.

Instruction Manual

HASAxE-IM-HS

04/2006

DANGER TO LIFE !

Permanent magnets are surrounded by magnetic fields. These magnetic

fields can disturb and even destroy sensitive electronic measuring devices,

but also mechanical watches, credit cards, etc.

Usually a distance of 20 inch (0.5 m) is enough to avoid damages. All sintered

permanent magnets are hard and brittle. Hitting of sintered permanent

magnets by the magnetic attraction causes splitting into fragments with many

sharp edges. This especially occurs with high energy magnets, and can

also cause skin bruises by high attraction.

High energy magnets made of rare-earth materials have to be stored dry,

otherwise the surfaces would oxidise. Unprotected operation in a humid

environment may cause corrosion. Avoid damaging the protective galvanic

coating.

A storage in a hydrogen atmosphere destroys these magnets. A

demagnetisation is caused when permanent magnet materials have been

exposed in a radioactive radiation for a long time.

For air transportation of magnetic material the IATA instructions have to be

observed:

Magnetic fields are not allowed to penetrate the package, if necessary the

magnets have to be shorted using a metal plate.

Emerson Process Management GmbH & Co. OHGS-10

Page 13

Instruction Manual

HASAxE-IM-HS

05/2006

To find information about see chapter

Safety measures ................................................ S

The different instruments designs .................. 1

The instruments technical data ....................... 2

Measuring principles characteristics ............. 3

How to install the instruments.......................... 4

X-STREAM

SHORT FORM GUIDE FOR THIS MANUAL

Software menu structure, how to navigate

and menu entries descriptions ........................ 5

st

1

startup procedures,

checking the instrument‘s setup..................... 6

Basic procedures .............................................. 7

Maintenance procedures ................................. 7

Status messages and troubleshooting .......... 8

Modbus Parameters .......................................... 9

Table of Contents

Emerson Process ManagementGmbH & Co. OHG

T-1

Page 14

Instruction Manual

X-STREAM

HASAxE-IM-HS

05/2006

TABLE OF CONTENTS

Preamble S-1

Definitions S-1

Safety Instructions S-2

General Operating Instructions ............................................................................................ S-9

Magnetically Operated Front Panel.................................................................................... S-10

Chapter 1 Technical Description 1-1

1-1 Overview .....................................................................................................................1-1

1-2 X-STREAM General Purpose Tabletop or Rack Mount Version ............................ 1-4

1-3 X-STREAM F (Field Housing).................................................................................... 1-6

1-4 Reserved For Future Use ........................................................................................ 1-11

1-5 Gaspath Design ........................................................................................................1-12

1-5-1 Gas Paths Materials .............................................................................................1-12

1-5-2 Safety Filter........................................................................................................... 1-12

1-5-3 Fittings .................................................................................................................. 1-12

1-5-4 Piping.................................................................................................................... 1-12

1-5-5 Gas Path Variations ............................................................................................. 1-13

1-6 Optional Gas Path Components............................................................................. 1-15

1-6-1 Internal Sample Gas Pump ................................................................................. 1-15

1-6-2 Internal Valve Block.............................................................................................1-15

1-6-3 Internal Flow Monitor...........................................................................................1-15

1-6-4 Internal Barometric Pressure Sensor ................................................................ 1-15

1-6-5 Optional Heated Compartment...........................................................................1-16

1-7 Interfaces ..................................................................................................................1-17

1-7-1 Analog Outputs .................................................................................................... 1-17

1-7-2 Modbus Interface ................................................................................................. 1-17

1-7-3 Status Signals (NAMUR) .....................................................................................1-17

1-8 Optional Interfaces................................................................................................... 1-18

1-8-1 Digital Outputs ..................................................................................................... 1-18

1-8-2 Digital Inputs ........................................................................................................ 1-18

1-8-2-1 Remotely Activating a Calibration Procedure using IN 1 to IN 3................. 1-19

1-8-2-2 V alve Control.................................................................................................... 1-20

1-8-2-3 Remote Pump Control .................................................................................... 1-20

T-2

Emerson Process Management GmbH & Co. OHG

Page 15

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

Table of Contents

Chapter 2 Technical Data 2-1

2-1 Common Technical Data ........................................................................................... 2-2

2-2 Model Specific Technical Data.................................................................................. 2-5

2-2-1 X-STREAM GP, GPS Tabletop or Rack Mount Version....................................... 2-5

2-2-1-1 Terminals Version.............................................................................................. 2-6

2-2-1-2 Sockets Version .................................................................................................2-8

2-2-2 X-STREAM F Field Housing................................................................................2-10

2-3 Information on the Nameplate Label ......................................................................2-13

Chapter 3 Measuring Principles 3-1

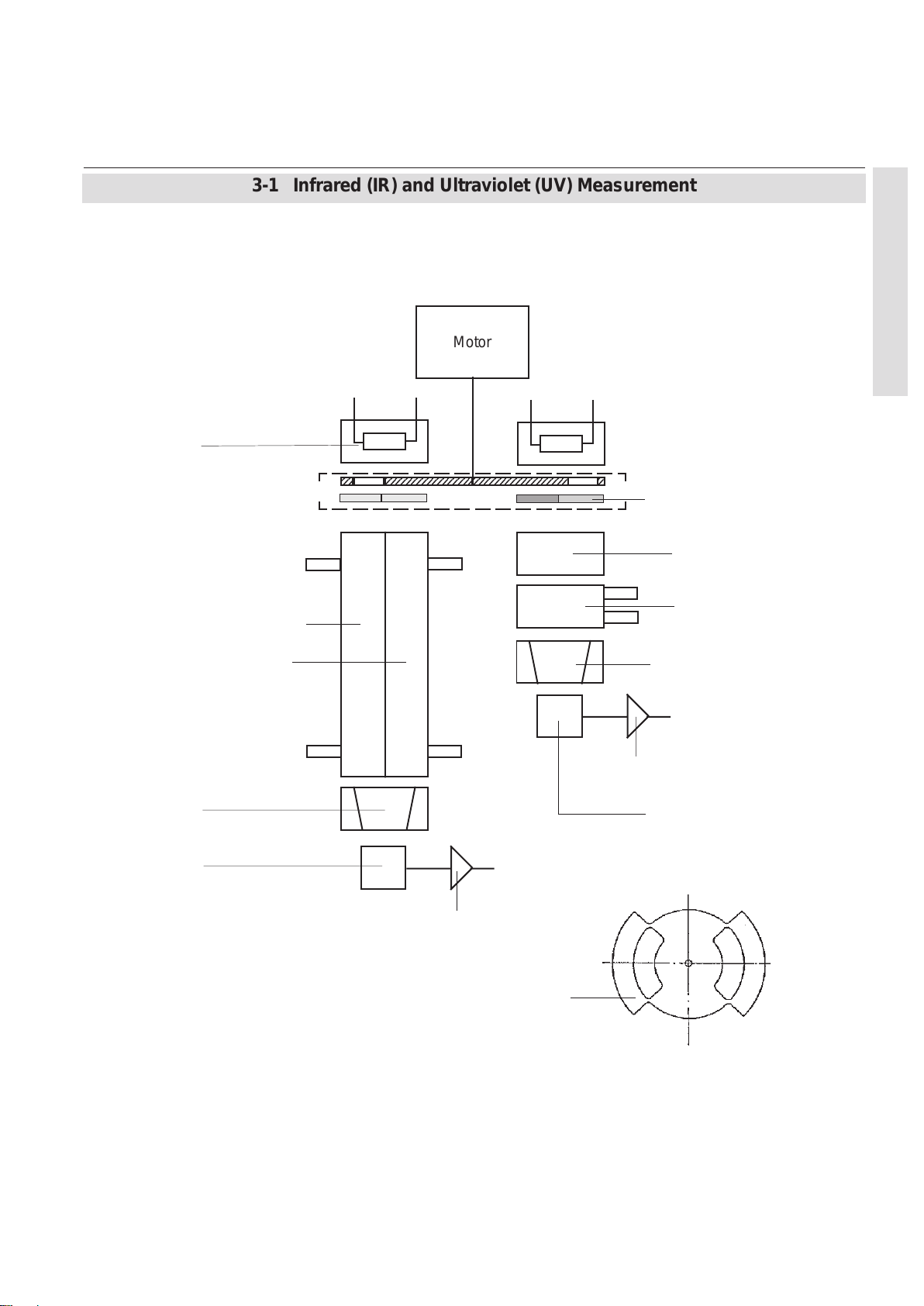

3-1 Infrared Measurement (IR), Ultraviolet Measurement (UV).....................................3-1

3-1-1 Interference Filter Correlation (IFC) .....................................................................3-1

3-1-2 Opto Pneumatic Measuring Principle .................................................................. 3-3

3-1-3 Technical Implementation..................................................................................... 3-4

3-2 Oxygen Measurement ................................................................................................3-9

3-2-1 Paramagnetic Measurement................................................................................. 3-9

3-2-2 Electrochemical Measurement ........................................................................... 3-11

3-2-3 Special Hints on Oxygen Sensors ..................................................................... 3-13

3-3 Thermal Conductivity Measurement ......................................................................3-14

3-3-1 Principle of Operation.......................................................................................... 3-14

3-3-2 Technical Implementation................................................................................... 3-15

3-4 Measurement Specification ....................................................................................3-16

Table of Contents

Chapter 4 Installation 4-1

4-1 Abstract....................................................................................................................... 4-1

4-2 Gas Conditioning .......................................................................................................4-2

4-3 Electrical Connections ..............................................................................................4-5

4-4 Detailled Installation Instructions ............................................................................. 4-6

4-4-1 X-STREAM GP, X-STREAM GPS...........................................................................4-6

4-4-1-1 Plugs & Sockets Version .................................................................................. 4-7

4-4-1-2 Terminals Version............................................................................................ 4-13

4-4-2 X-STREAM F......................................................................................................... 4-20

4-5 Hints on Wiring Signal Inputs and Outputs........................................................... 4-29

4-5-1 Electrical Connections in General...................................................................... 4-29

4-5-2 Wiring Inductive Loads .......................................................................................4-31

4-5-3 Driving Multiple Loads ........................................................................................ 4-31

4-5-4 Driving High Current Loads................................................................................ 4-32

Emerson Process Management GmbH & Co. OHG

T-3

Page 16

Instruction Manual

X-STREAM

HASAxE-IM-HS

05/2006

Table of Contents

Chapter 5 User Interface and Software Menus 5-1

5-1 Abstract....................................................................................................................... 5-1

5-2 The User Interface...................................................................................................... 5-1

5-2-2 The Status LEDs .................................................................................................... 5-2

5-2-1 The Display............................................................................................................. 5-2

5-2-3 The Keys ................................................................................................................. 5-3

5-2-3-1 Magnetically Operated Front Panel ................................................................. 5-4

5-3 Software...................................................................................................................... 5-5

5-3-1 Power-On Sequence ............................................................................................. 5-5

5-3-2 Measuring Screen .................................................................................................. 5-5

5-3-3 Menu Structure ......................................................................................................5-6

5-3-4 Navigating and Editing..........................................................................................5-6

5-3-5 Access Levels ........................................................................................................ 5-8

5-3-6 Special Screens ..................................................................................................... 5-9

5-4 Menu System ............................................................................................................5-10

5-4-1 Power-On and Measuring Screen ...................................................................... 5-11

5-4-2 Control Menu ........................................................................................................ 5-13

5-4-2-1 Zero Calibration Menu.....................................................................................5-14

5-4-2-2 Span Calibration Menu ................................................................................... 5-15

5-4-2-3 Advanced Calibration Menu ........................................................................... 5-16

5-4-2-4 Calibration Status Screen...............................................................................5-17

5-4-2-5 Apply Gas Menu............................................................................................... 5-18

5-4-2-6 Acknowledgements Menu .............................................................................. 5-19

5-4-3 Setup Menu .......................................................................................................... 5-20

5-4-3-1 Display Setup Menu ........................................................................................5-21

5-4-3-1-1 Display Language Setup Menu .................................................................5-23

5-4-3-1-2 Menu Access Setup Menu..........................................................................5-24

5-4-3-1-3 Component Setup Menu ............................................................................5-25

5-4-3-2 Calibration Setup Menu ..................................................................................5-26

5-4-3-2-1 Calibration Gases Setup Menu ..................................................................5-27

5-4-3-2-2 Interval Time Setup Menu...........................................................................5-28

5-4-3-3 Measurement Setup Menu..............................................................................5-29

5-4-3-3-1 Signal Damping Setup Menu .....................................................................5-30

5-4-3-3-2 Cross Interference Setup Menu.................................................................5-31

5-4-3-3-3 AD Conversion Setup Menu ......................................................................5-32

5-4-3-4 In/Outputs Setup Menu ...................................................................................5-33

5-4-3-4-1 Analog Output Setup Menu........................................................................5-34

T-4

Emerson Process Management GmbH & Co. OHG

Page 17

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

Table of Contents

5-4-3-4-1-1 Analog Output Signal Setup ..................................................................5-35

5-4-3-4-1-2 Analog Output Range Setup..................................................................5-36

5-4-3-4-1-3 Analog Output Signal Scaling Setup ....................................................5-38

5-4-3-4-1-4 Analog Output Signal Trimming ............................................................5-39

5-4-3-4-2 V alve Assignment........................................................................................5-40

5-4-3-5 Installed Options Setup Menu ........................................................................ 5-41

5-4-3-6 Communication Setup Menu..........................................................................5-42

5-4-3-7 Alarms Setup Menu ......................................................................................... 5-43

5-4-3-8 Save-Load Menu ..............................................................................................5-44

5-4-3-9 Miscellaneous Screen.....................................................................................5-46

5-4-4 Status Menu .........................................................................................................5-47

5-4-4-1 Failure Status Screen......................................................................................5-48

5-4-4-2 Check Requests Status Screen..................................................................... 5-49

5-4-4-3 Function Check Status Screen ...................................................................... 5-50

5-4-4-4 Off Spec Status Screen...................................................................................5-51

5-4-4-5 Calibration Status Screen...............................................................................5-52

5-4-4-6 Measurement Status Screen .......................................................................... 5-53

5-4-4-7 Alarms Status Screen .....................................................................................5-54

5-4-5 Info Menu ..............................................................................................................5-55

5-4-5-1 Measuring Range Info Screen........................................................................ 5-56

5-4-5-2 Factory Settings Screen .................................................................................5-57

5-4-5-3 Installed Options Info Screen .........................................................................5-58

Table of Contents

Chapter 6 Initial Startup 6- 1

6-1 Abstract....................................................................................................................... 6-1

6-2 Checking the Instrument's Setup.............................................................................6-2

6-2-1 Instrument's Language Setup.............................................................................. 6-3

6-2-2 Display Information Setup ....................................................................................6-4

6-2-3 Calibration Data Setup ..........................................................................................6-4

6-2-4 Analog Output Setup............................................................................................. 6-7

6-2-5 Concentration Alarms Setup ..............................................................................6-12

Chapter 7 Maintenance 7-1

7-1 Abstract....................................................................................................................... 7-1

7-2 Performing a Leak Test.............................................................................................. 7-2

Emerson Process Management GmbH & Co. OHG

T-5

Page 18

Instruction Manual

X-STREAM

HASAxE-IM-HS

05/2006

Table of Contents

7-3 Calibration Procedures ............................................................................................7-3

7-3-1 Preparing a Calibration .........................................................................................7-4

7-3-2 Manual Calibration................................................................................................. 7-7

7-3-2-1 Manual Zero Calibration.................................................................................... 7-7

7-3-2-2 Manual Span Calibration ..................................................................................7-8

7-3-3 Advanced Calibration..........................................................................................7-10

7-3-3-1 Additional Preparations for Advanced Calibration ...................................... 7-11

7-3-3-2 Zero All Calibration .......................................................................................... 7-14

7-3-3-3 Span All Calibration .........................................................................................7-16

7-3-3-4 Zero & Span All Calibration............................................................................. 7-18

7-3-4 Auto Calibration ................................................................................................... 7-21

7-3-4-1 Additional Preparations for Auto Calibration................................................ 7-21

7-3-4-2 Zero Auto Calibration ......................................................................................7-24

7-3-4-3 Span Auto Calibration .....................................................................................7-26

7-3-4-4 Unattended Auto Calibration.......................................................................... 7-28

7-3-5 Resetting a Calibration........................................................................................7-30

7-3-6 Verifying a Calibration .........................................................................................7-30

7-3-7 Cancelling an Ongoing Calibration....................................................................7-31

7-3-8 Cross Interference Compensation ..................................................................... 7-33

7-4 Replacing the ElectrochemicalSensor .................................................................7-35

7-4-1 Precautions for Sensor Handling ......................................................................7-37

7-4-2 Opening the Analyzer.......................................................................................... 7-38

7-4-2-1 Opening X-STREAM GP / GPS ....................................................................... 7-39

7-4-2-2 Opening X-STREAM F.....................................................................................7-39

7-4-3 Locating the Sensor ...........................................................................................7-40

7-4-4 Sensor Unit Disassembly ................................................................................... 7-41

7-4-5 Sensor Amplifier Adjustment ..............................................................................7-42

7-4-6 Finalizing the Sensor Replacement................................................................... 7-43

7-5 Cleaning the Instrument's Outside.........................................................................7-44

7-6 Save / Restore Configuration Data Sets ................................................................ 7-45

7-6-1 Save CfgData to UserData .................................................................................. 7-46

7-6-2 Restore UserData to CfgData ............................................................................. 7-47

7-6-3 Restore FactData to CfgData..............................................................................7-48

7-6-4 Save / Restore to an External Device................................................................. 7-49

7-6-4-1 Save CfgData to COMPort ..............................................................................7-50

7-6-4-2 Restore COMPort to CfgData .........................................................................7-52

T-6

Emerson Process Management GmbH & Co. OHG

Page 19

Instruction Manual

HASAxE-IM-HS

05/2006

Table of Contents

X-STREAM

Chapter 8 Troubleshooting 8-1

8-1 Abstract....................................................................................................................... 8-1

8-2 Solving Problems Indicated by Status Messages ..................................................8-2

8-3 Solving Problems Not Indicated by Status Messages ...........................................8-8

8-4 Troubleshooting on Components..........................................................................8-12

8-4-1 Opening X-STREAM GP / GPS............................................................................8-12

8-4-2 Opening X-STREAM F ......................................................................................... 8-12

8-4-3 Measuring Points................................................................................................. 8-13

8-4-3-1 Measuring Points at BKS Board ....................................................................8-13

8-4-3-1-1 Supply voltage +6 V ....................................................................................8-13

8-4-3-1-2 Positive reference voltage..........................................................................8-13

8-4-3-1-3 Negative reference voltage............................................................................. 8-15

8-4-3-1-4 Temperature sensor....................................................................................8-15

8-4-3-1-5 Light barrier signal ......................................................................................8-15

8-4-3-1-6 Analog Preamplifier.....................................................................................8-16

8-4-3-2 Measuring Points at OXS Board (Electrochemical Oxygen Measurement)8-17

8-4-3-2-1 Sensor Signal ..............................................................................................8-17

8-4-4 BKS 20 Board Jumper Configuration................................................................8-18

8-4-5 Fuse on BKS 20 Board .......................................................................................8-19

Table of Contents

Chapter 9 Modbus Functions 9-1

9-1 Abstract....................................................................................................................... 9-1

9-2 Supported Functions ................................................................................................ 9-2

9-3 List of Parameters and Registers ............................................................................. 9-2

9-4 Comparison of Registers and Parameters ............................................................9-17

Chapter 10 Service Information 10-1

10-1 Return of Material..................................................................................................... 10-1

10-2 Customer Service .................................................................................................... 10-2

10-3 T raining ..................................................................................................................... 10-2

Appendix A-1

A-1 Modbus Implementation........................................................................................... A-2

A-2 EC Declaration of Conformity................................................................................ A-12

A-3 Block Diagrams ....................................................................................................... A-13

Emerson Process Management GmbH & Co. OHG

T-7

Page 20

Instruction Manual

X-STREAM

HASAxE-IM-HS

05/2006

Index of Figures

Index of Figures

Fig. 1-1: X-STREAM GP, GPS, front side view......................................................................................................1-4

Fig. 1-2: X-STREAM GP, terminals version, rear side view .................................................................................1-5

Fig. 1-3: X-STREAM GPS, plugs and sockets version, rear side view................................................................1-5

Fig. 1-4: X-STREAM F, front side view & rear side view at carrying handle ......................................................1-7

Fig. 1-5: X-STREAM F, front panel........................................................................................................................1-8

Fig. 1-6: X-STREAM F, bottom view .....................................................................................................................1-9

Fig. 1-7: X-STREAM F, mains and signal terminals (front door removed).......................................................1-10

Fig. 1-8: Single channel or serial tubing ............................................................................................................1-13

Fig. 1-9: Dual channel parallel tubing.................................................................................................................1-12

Fig. 1-10: Single channel or serial tubing, with options ...................................................................................1-14

Fig. 1-1 1: Dual channel parallel tubing, with options ........................................................................................1-15

Fig. 1-12: Optional Heated Compartment ...........................................................................................................1-16

Fig. 1-13: Digital Outputs - Schematic ................................................................................................................1-18

Fig. 1-14: Digital Inputs - Priorities ......................................................................................................................1-19

Fig. 2-1: X-STREAM GP, GPS - dimensions [approx. mm (inch)] .......................................................................2-5

Fig. 2-2: X-STREAM GP , (terminals version) - terminals and fuse holders........................................................2-7

Fig. 2-3: X-STREAM GPS, (sockets version) - power and signals connectors ..................................................2-8

Fig. 2-4: X-STREAM F - dimensions (approx. mm [inch]) .................................................................................2-10

Fig. 2-5: X-STREAM F - mains terminals / fuse holders ....................................................................................2-11

Fig. 2-6: X-STREAM F - signals terminals ..........................................................................................................2-12

Fig. 2-7: Analyzer Nameplate Label (example)...................................................................................................2-13

Fig. 3-1: Absorption Bands of Measured Gases and Transmission of Interference Filters ................................3-2

Fig. 3-2: Gas Detector Design Principle ................................................................................................................3-3

Fig. 3-3: IR Photometer Assembly Principle .........................................................................................................3-5

Fig. 3-4: Photometer Assembly with Pyroelectrical Detector ..............................................................................3-7

Fig. 3-5: IR & UV Photometer Assemblies with Gas Detectors.............................................................................3-8

Fig. 3-6: Paramagnetic Oxygen Detector, Assembly Principle .......................................................................... 3-10

Fig. 3-7: Electrochemical Sensor - Assembly Principle..................................................................................... 3-11

Fig. 3-8: Electrochemical reaction of Oxygen Sensor .......................................................................................3-12

Fig. 3-9: Wheatstone Bridge ................................................................................................................................3-15

Fig. 3-10a: TC cell, exterior view .........................................................................................................................3-15

Fig. 3-10b: TC cell - sectional view......................................................................................................................3-15

Fig. 4-0: Example of gas fittings label...................................................................................................................4-3

Fig. 4-1: Bypass Mode Installation.........................................................................................................................4- 5

Fig. 4-2:Frontal view...............................................................................................................................................4-6

Fig. 4-3: Rear panel - plugs & sockets version .....................................................................................................4-7

Fig. 4-4: Socket X1 - pin assignment ....................................................................................................................4-8

Fig. 4-5: Socket X2 - pin assignment ....................................................................................................................4-9

Fig. 4-7: Plug X3 - pin assignment ......................................................................................................................4-10

Fig. 4-6: Relay status signals, block diagram .....................................................................................................4-10

Fig. 4-8: Socket X4 - pin assignment ..................................................................................................................4-11

T-8

Emerson Process Management GmbH & Co. OHG

Page 21

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

Index of Figures

Fig. 4-9: IEC mains input plug .............................................................................................................................4-12

Fig. 4-10: Rear panel - terminals version ............................................................................................................4-13

Fig. 4-1 1: Analog Signal Output Terminals ........................................................................................................4-14

Fig. 4-12: Modbus Interface Terminals ................................................................................................................4-15

Fig. 4-14: Relay Status Terminals ........................................................................................................................4-16

Fig. 4-13: Relay status signals, block diagram ...................................................................................................4-16

Fig. 4-15: Digital Input & Output Terminals ........................................................................................................4-17

Fig. 4-16: Mains terminals....................................................................................................................................4-18

Fig. 4-17: X-STREAM F ........................................................................................................................................4-20

Fig. 4-18: X-STREAM F -Allocation of terminals and gas fittings.....................................................................4-21

Fig. 4-19: X-STREAM F - Analog output terminals ............................................................................................4-23

Fig. 4-20: X-STREAM F - Modbus interface terminals .......................................................................................4-24

Fig. 4-22: X-STREAM F - Relay Status Terminals ..............................................................................................4-25

Fig. 4-21: Relay status signals, block diagram ...................................................................................................4-25

Fig. 4-23: Digital Input & Output Terminals ........................................................................................................4-26

Fig. 4-24: Power terminals ...................................................................................................................................4-27

Fig. 4-25: Shielded Signal Cable, shield connected at both ends ....................................................................4-28

Fig. 4-26: Shielded Signal Cable, shield connected at one end .......................................................................4-30

Fig. 4-27: Double-shielded Signal Cable, shields connected at both sides......................................................4-30

Fig. 4-28: Suppressor Diode for Inductive Loads ...............................................................................................4-31

Fig. 4-29: ”Serial” Wiring ....................................................................................................................................4-31

Fig. 4-30: Running Supply Lines "parallel”........................................................................................................4-32

Fig. 4-31: Driving High Current Loads ................................................................................................................4-32

Table of Contents

Fig. 5-1: X-STREAM user interface........................................................................................................................5-1

Fig. 5-2: X-STREAM magnetic tool .......................................................................................................................5-4

Fig. 5-3: X-STREAM Software menu structure ...................................................................................................5-12

Fig. 6-1: Thresholds defining a window..............................................................................................................6-15

Fig. 6-2: HIGH and HIGH-HIGH alarm mode ........................................................................................................6-16

Fig. 6-3: LOW and LOW-LOW alarm mode ........................................................................................................6-17

Fig. 7-1: Leak Testing with U-turn manometer .....................................................................................................7-2

Fig. 7-2: Calibration improvement by variable valve assignments ................................................................... 7-11

Fig. 7-3: Calibration improvement by variable valve assignments ................................................................... 7-21

Fig. 7-3: Graphical Explanation of Interval Time Settings.................................................................................7-28

Fig. 7-4: X-STREAM interior views......................................................................................................................7-38

Fig. 7-5: X-STREAM GP Interior View .................................................................................................................7-40

Fig. 7-6: Cardcage Detail ......................................................................................................................................7-41

Fig. 7-7: Allocation of eO2 Sensor Unit ..............................................................................................................7-40

Fig. 7-8: Purged Box Detail ..................................................................................................................................7-40

Fig. 7-9: Sensor Unit Assembly ...........................................................................................................................7-40

Fig. 7-10: Sensor Block Assembly ......................................................................................................................7-41

Fig. 7-1 1: OXS Board, top view............................................................................................................................7-43

Emerson Process Management GmbH & Co. OHG

T-9

Page 22

Instruction Manual

X-STREAM

HASAxE-IM-HS

05/2006

Index of Tables

Fig. 8-0: X-STREAM F interior view with flapped front panel.............................................................................8-8

Fig. 8-1: X-STREAM interior views......................................................................................................................8-12

Fig. 8-2: BKS Board (section), measuring points ...............................................................................................8-13

Fig. 8-3:Light barrier signal .................................................................................................................................8-15

Fig. 8-4: OXS board, assembled, top view..........................................................................................................8-17

Fig. 8-5: BKS board (section) ...............................................................................................................................8-18

Fig. 8-6: Allocation of fuse on BKS board ..........................................................................................................8-19

Index of Tables

Table 1-1: Digital Inputs IN4-IN7, array ................................................................................................................1-20

Table 3-1: Solvent Resistant Sensor: Approved Solvents....................................................................................3-9

Table 3-2: Medium affected Materials within Paramagnetic Oxygen Sensor ...................................................3-10

Table 3-3: Paramagnetic Oxygen Measurement, cross interference by accompanying gases........................3-13

Table 3-4: Electrochemical Oxygen Measurement, cross interference by accompanying gases ...................3-13

Table 3-5: Examples of Specific Thermal Conductivities ..................................................................................3-14

Table 3-6: Gas Components and Measuring Ranges, examples .......................................................................3-16

Table 3-7: Measurement Performance Specifications ........................................................................................3-17

Table 5-1: Analog Output Signal Selection ........................................................................................................5-35

Table 5-2: Analog Output Signal Setting & Operation Modes ..........................................................................5-37

Table 6-1: Analog Output Signals Settings & Operation Modes .......................................................................6-10

Table 6-2: Thresholds influenced by SpanRange parameter.............................................................................6-13

T-10

Emerson Process Management GmbH & Co. OHG

Page 23

Instruction Manual

HASAxE-IM-HS

05/2006

1-1 Overview

X-STREAM

Chapter 1

Technical Description

Emerson Process Management´s new XSTREAM gas analyzer series key features:

• compact design with easily accessible

internal components

• almost identical internal design supports

several housing variations covering a wide

range of applications

• highly integrated main board, containing

all necessary basic functions and

interfaces

• microprocessor based multi-language

user interface utilizing an alphanumeric liquid cristal display (LCD) or vacuum

fluorescence display (VFD) with measuring values and status messages. Outdoor

variations provide a magnetically operated

impact tested front panel.

• internal wide range power supply for

worldwide usage

X-STREAM series analyzers are designed to

measure 1 or 2 gas components combining

any of the following methods:

I R = non-dispersive infrared measurement

UV = ultraviolet measurement

PO

= paramagnetic Oxygen measurement

2

EO2= electrochemical Oxygen measurement

TC = thermal conductivity measurement

For applications with solvent and/or corrosive

components in the gas stream special resistant

measuring cells are available.

For measuring flammable gases special

solutions are available too (e.g. intrinsically safe

cells).

Standard General Purpose Applications

Several enclosure variations are available:

• T abletop and rack mount versions, full 19“

size, IP 20 protected (acc. to EN 60529).

• NEMA 4X / IP 66 protected field housing for

outdoor installation (ambient temperature

range +32 to +122°F; 0 to +50 °C, optional

-4 to +122°F; -20 to +50 °C). The analyzer

is intended to be wall mounted.

Installation in Hazardous Areas

For installation in hazardous areas the field

housing analyzer provides an adapted pressurization system (ATEX type approved for

Zone 1 or Zone 2 in Europe). Optionally

intrinsically safe signal couplers are available,

too.

A z-purge system permits installation in NorthAmerican Zone 2 environments.

A flameproof analyzer variation, designed to

be installed in hazardous areas, is suitable for

installation in rough environments, too and will

be available soon.

CSA-C/US and ATEX approvals

for installation in North-American and European hazardous

areas are pending!

Consult your local sales office

for more information.

Note!

This manual does not deal with special

conditions for analyzers in hazardous areas,

related to installation, operation, maintenance

etc. For such applications refer to the

separate instruction manuals, delivered

together with the analyzers.

1 Technical Description

1-1Emerson Process ManagementGmbH & Co. OHG

Page 24

X-STREAM

Instruction Manual

HASAxE-IM-HS

05/2006

1-1 Overview

The X-STREAM series analyzers offer a wide

range of available configurations and options,

to be combined according to the selected

model:

Measuring principles

Up to two out of all offered principles may be

combined within one analyzer model to provide

best adaption to the application.

For a detailled description of available

measuring principles: chapter 3.

Gas path design

Internal tubing with viton or, optional and

depending on application, PFA or stainless

steel.

In addition one or more of the following options

are available:

• Soleniod valve block

This option uses 4 internal solenoid valves

to control sample, zero, span gas 1 and

span gas 2. These gases are fed to the

analyzers to provide manual or controlled

automatic calibration (initialized by

keypad, serial interface or digital inputs).

• Sample pump

Maximum flow rate 2.5 l/min

• Barometric Pressure sensor

(Measuring range 800 to 1,200 hPa)

Facilitates compensation of atmospheric

pressure variations to improve precision

of results (

measurement specifications, page 3-17).

Special sensors for e.g. corrosive gas on

request.

• Flow measurement

A flow sensor (option) can be used to

monitor gas flow and set alarms.

• Heated box for physical components

All the physical components

*)

can

optionally be installed inside thermostatted

box to minimize influences from ambient

tem-perature fluctuations.

For a detailled description of optional gas path

components: page 1-16

Interfaces

All models may be configured to use several

interfaces:

St andard:

• analog outputs

• serial interface (RS 485 or RS 232) with

Modbus protocol

• status signals (NAMUR; relay outputs)

Optional:

• 8 digital outputs & 7 digital inputs

For a detailled description of optional interfaces:

page 1-18

1-2 Emerson Process Management GmbH & Co. OHG

Page 25

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

1-1 Overview

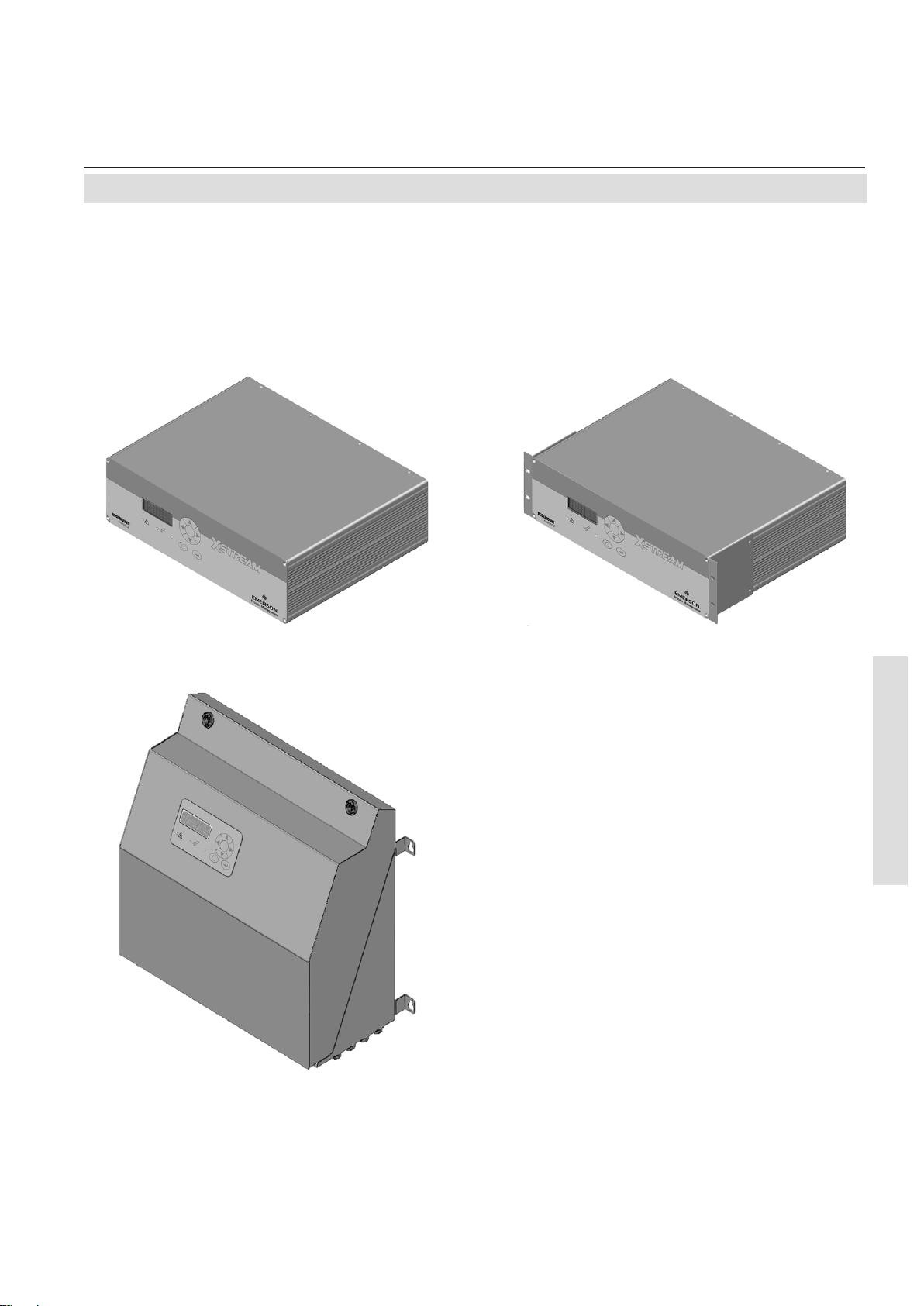

The different X-STREAM

their appearance.

T able top and rack mount version (see section 1-2, page 1-5)

series models and

The following sections 1-2 to 1-3 give detailed

descriptions for all available configurations.

Field housing (see section 1-3, page 1-7)

1 Technical Description

1-3Emerson Process ManagementGmbH & Co. OHG

Page 26

X-STREAM

1-2 X-STREAM GP, GPS

1-2 X-STREAM General Purpose

Tabletop or Rack Mount Version

Instruction Manual

HASAxE-IM-HS

05/2006

This basic general purpose version contains

all components within a full 19 inch housing and

is intended to either be used as rack mountable

analyzer or as tabletop instrument after removing

two mounting brackets and installing 4 feet (part

of an accessory kit).

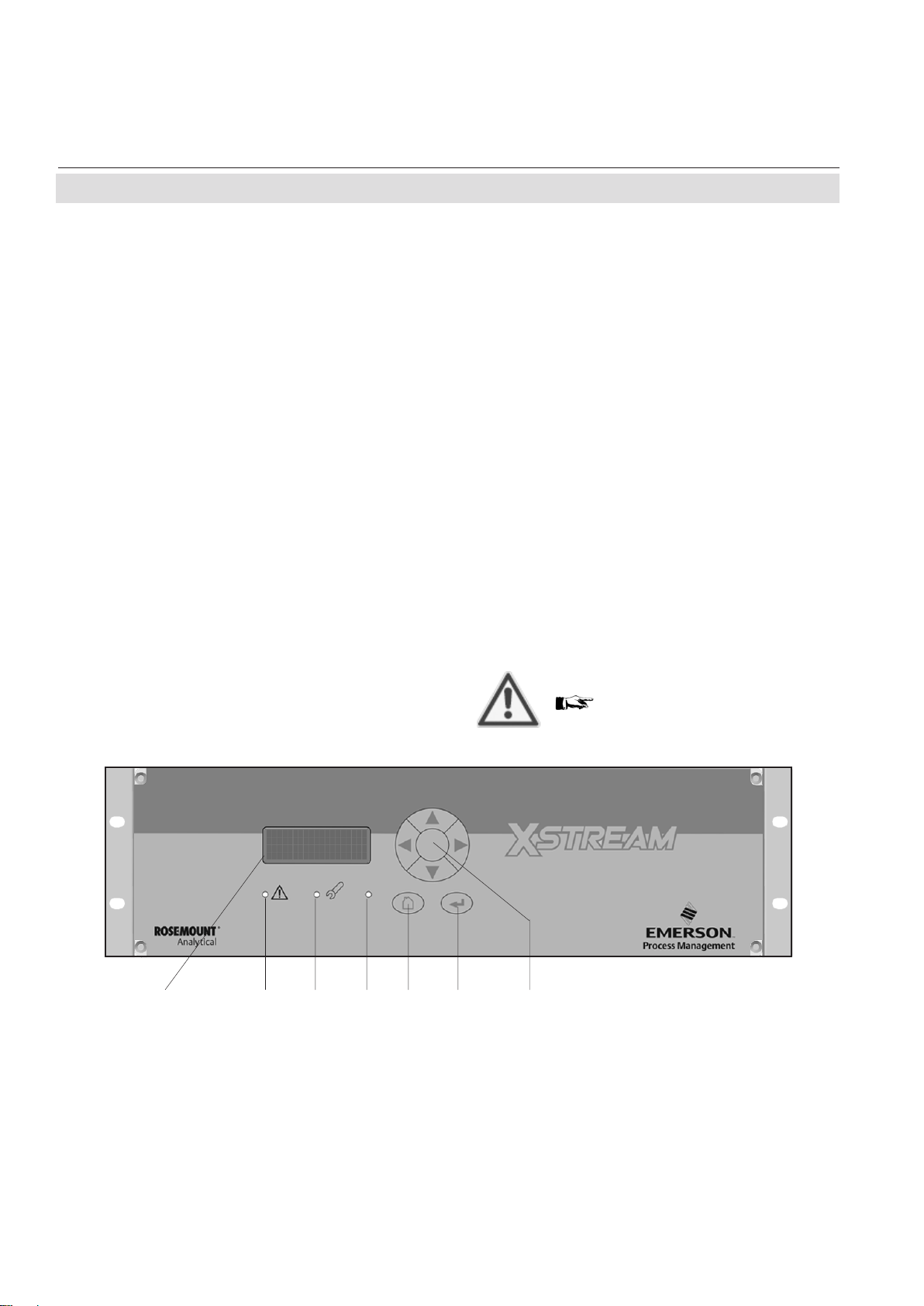

The front panel shows a 4x20 characters alphanumeric display, a membrane keypad and

3 status LEDs (fig. 1-1).

Electrical connections are provided by either

screw terminals (version GP , fig. 1-2) or plugs,

sockets and mains appliance (version GPS,

fig. 1-3) at the instrument's rear side.

Gas fittings are provided at the instrument's

rear side, too.

An optional fitting facilitates purging the

instrument with inert gas to minimize influences

caused by ambient air when measuring low

ranges of select gases (e.g. CO, CO

). The in-

2

ert gas may exhaust the analyzer through a

separate fitting (into an exhaust system) or

by leakages in the housing (into ambient).

Purging the physical components with air or

inert gas may also be needed when measuring aggressive and/or flammable gases: In

addition to the purge fitting an internal box is

installed, covering the physical components.

This forces the purge medium to flow around

all other (electronic) components before it

circulates around the physics and exhausts

the analyzer through a separate outlet fitting

into an exhaust system. In case of internal

leakage this ensures that the aggressive/

flammable gas is not flushed towards the

electronics causing hazards of corrosion and/

or explosion and provides operator safety .

Purge medium specifications:

2-1, page 2-4.

1 3456 72

1 4x20 characters alphanumeric display

2 LED (red)

3 LED (red)

4 LED (green)

Fig. 1-1: X-STREAM GP, GPS, front side view

1-4 Emerson Process Management GmbH & Co. OHG

5 "Home" key

6 "Enter" key

7 4 keys for editing and entering menus

Page 27

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

1-2 X-STREAM GP, GPS

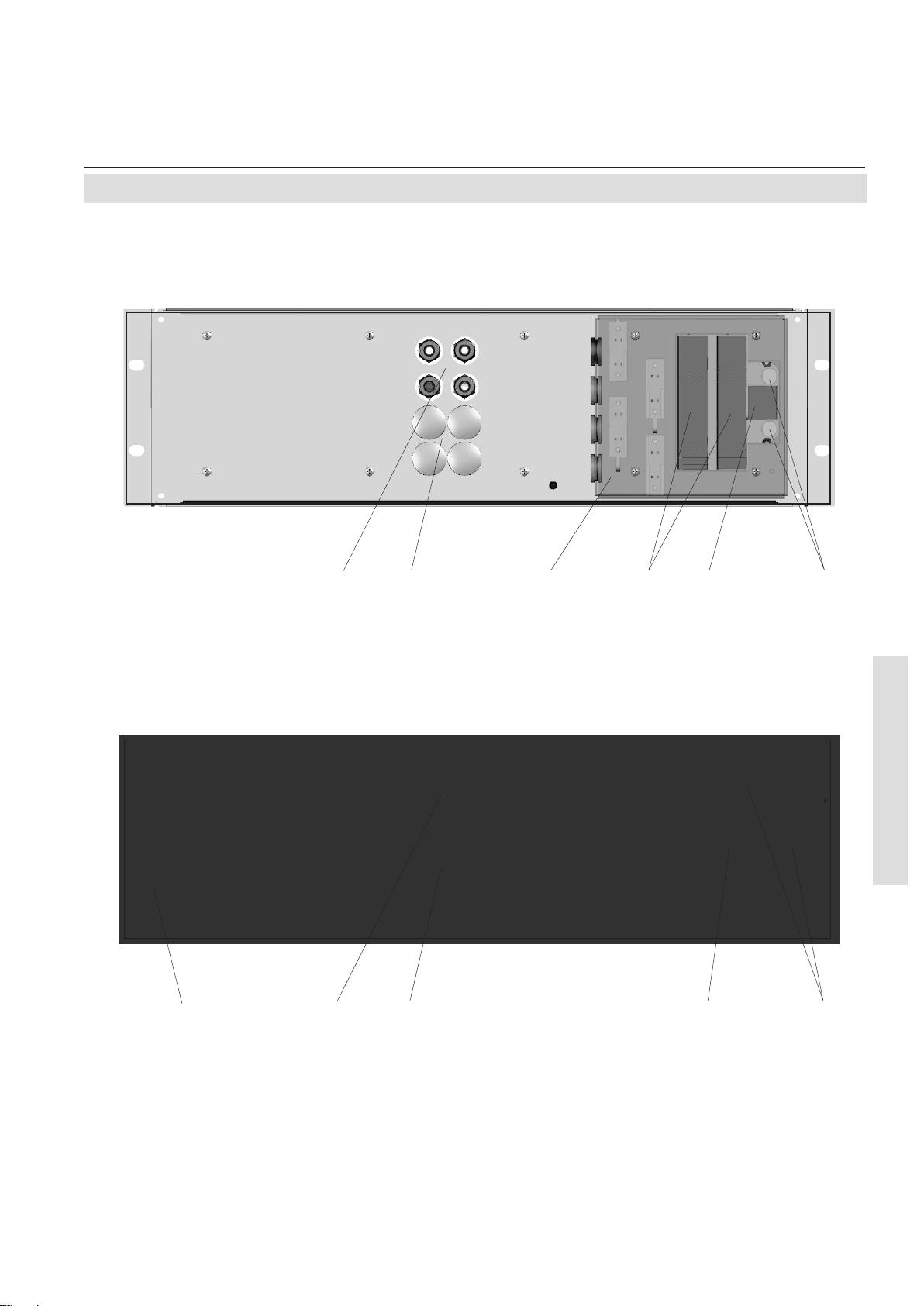

1 23456

1 Gas inlet fittings

2 Optional gas inlet fittings

3 Cover for terminals (shown with

transparency)

Fig. 1-2: X-STREAM GP, terminals version, rear side view

1 23 45

4 Input / output signal terminals

5 Mains terminals

6 Mains fuses

1 Technical Description

1 Gas inlet fittings

2 Optional gas inlet fittings

3 Optional purge gas inlet

Fig. 1-3: X-STREAM GPS, plugs and sockets version, rear side view

4 Mains appliance with fuses

5 Signals sockets

1-5Emerson Process ManagementGmbH & Co. OHG

Page 28

X-STREAM

1-3 X-STREAM F

1-3 X-STREAM F (Field Housing)

Instruction Manual

HASAxE-IM-HS

05/2006

This IP66 / NEMA 4X protected housing is

intended for outside wall mounting: The housing

(fig. 1-4) is made of painted stainless steel.

Gaskets protect against water and dust.

The front panel is located behind a safety glass

providing protection against mechanical impact

and shows a 4x20 characters alphanumeric

display and 3 status LEDs. The keypad as it is

used to operate the tabletop analyzer is replaced by sensor fields, operated with a magnetic tool (fig. 1-5).

Electrical connections are provided by internal

screw terminals, the cables enter the housing

via cable glands located at the instruments

bottom side (fig. 1-6).

Gas fittings are located at the instrument's

bottom side, too.

The front door opens vertically by 180° providing easy access to internal components.

Removing the hinge bolts even allows to

completely remove the front door.

inert gas may exhaust the analyzer through a

separate fitting (into an exhaust system) or by

leakages in the housing (into ambient).

Purging the physical components with air or

inert gas may also be needed when measuring aggressive and/or flammable gases: In

addition to the purge fitting an internal box is

installed, covering the physical components.

This forces the purge medium to flow around

all other (electronic) components before is

circulates around the physics and exhausts the

analyzer through a separate outlet fitting into

an exhaust system. In case of internal leakage

this ensures that the aggressive/flammable

gas is not flushed towards the electronics

causing hazards of corrosion and/or explosion

and provides operator safety .

Purge medium specifications:

see technical data section (2-1).

An optional fitting facilitates purging the

instrument with inert gas to minimize influences

caused by ambient air when measuring low

ranges of select gases (e.g. CO, CO2). The

Provided with an appropriate pressurization

system the X-STREAM F is suitable for installation in hazardous areas.

EXPLOSION HAZARD !

This instruction manual at hand does not deal with X-STREAM analyzers

intended to be used in hazardous areas!

Installation, startup and maintenance are described in detail in a separate

instruction manual, shipped together with each such analyzer, and are not

subject of this current instruction manual!

1-6 Emerson Process Management GmbH & Co. OHG

Page 29

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

1-3 X-STREAM F

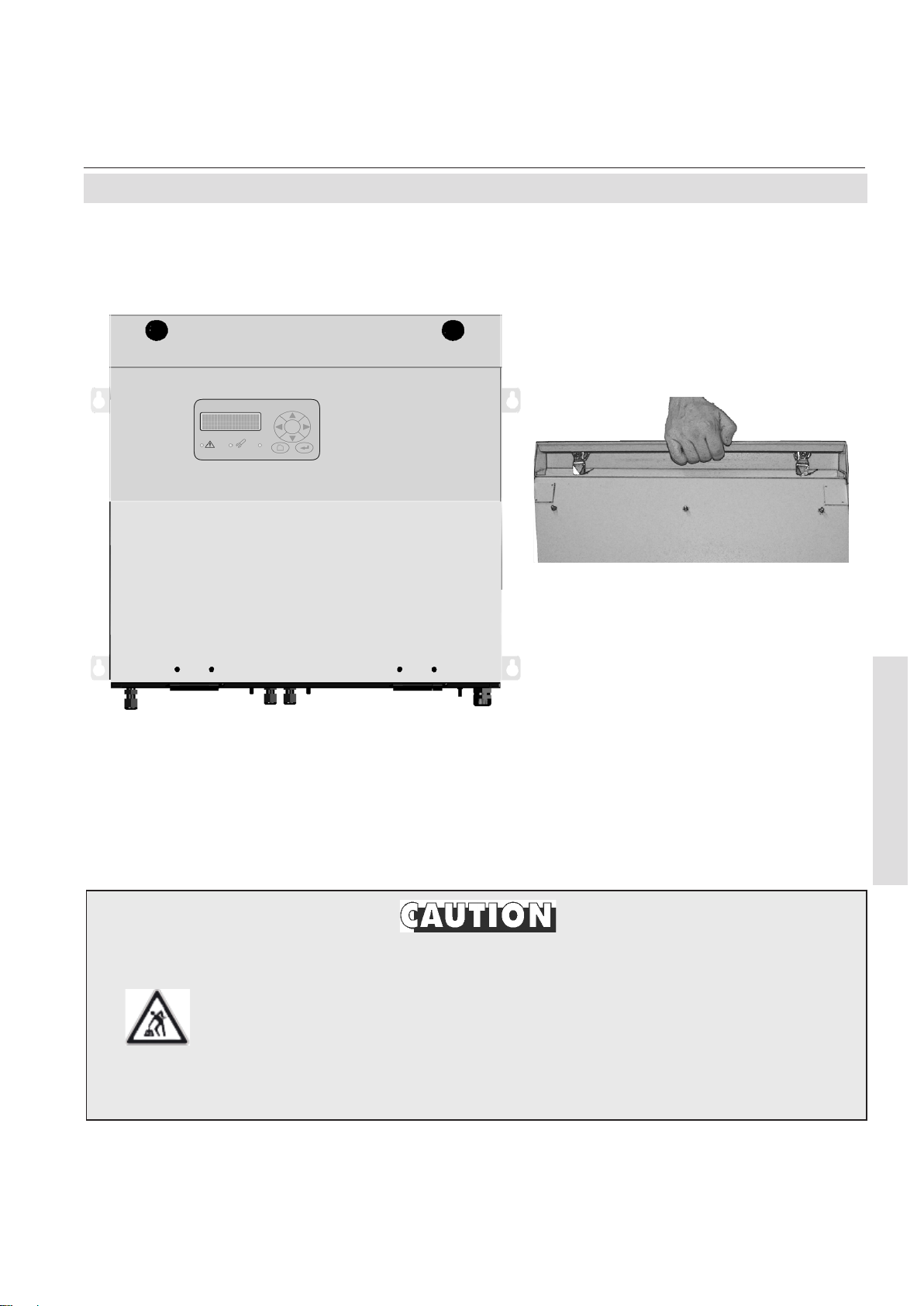

Fig. 1-4: X-STREAM F, front side view & rear side view at carrying handle

HEAVY INSTRUMENT!

X-STREAM F

gas analyzers, designed for wall mounting and/or outdoor

installation may weigh up to 25 kg (57 lbs), depending on installed options!

The upper part of the front door is designed to work as a carrying handle,

see fig. 1-4.

Use two persons or a suitable lifting device to move or carry the instrument!

1 Technical Description

1-7Emerson Process ManagementGmbH & Co. OHG

Page 30

X-STREAM

Instruction Manual

HASAxE-IM-HS

05/2006

1-3 X-STREAM F

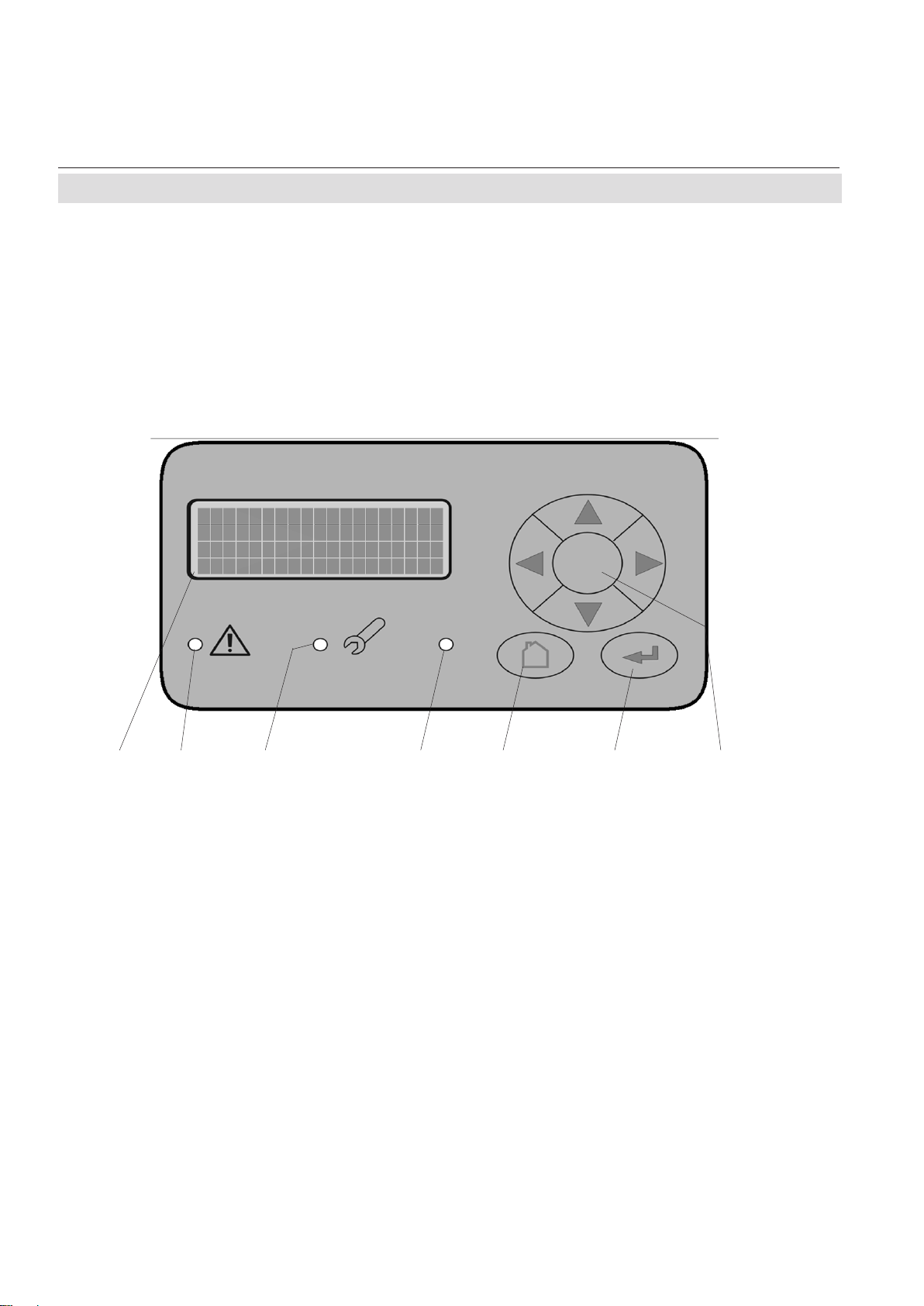

1 345672

1 4x20 characters alphanumeric display

2 LED (red)

3 LED (red)

4 LED (green)

Fig. 1-5: X-STREAM F, front panel

1-8 Emerson Process Management GmbH & Co. OHG

5 "Home" key

6 "Enter" key

7 4 keys for editing and entering menus

Page 31

Instruction Manual

HASAxE-IM-HS

05/2006

X-STREAM

1-3 X-STREAM F

2 134

1 Cable glands for mains and signal cables

2 Gas inlet and outlet fittings and purge gas outlet fitting

3 Purge gas inlet fitting

4 4 supports for wall mounting

Fig. 1-6: X-STREAM F, bottom view

1 Technical Description

1-9Emerson Process ManagementGmbH & Co. OHG

Page 32

X-STREAM

Instruction Manual

HASAxE-IM-HS

05/2006

1-3 X-STREAM F

1 423

1 Terminals for signal cables

2 Mains EMI filter

3 Cable glands for mains and signal cables

4 Mains terminals with integrated fuses

Fig. 1-7: X-STREAM F, mains and signal terminals (front door removed)

1-10 Emerson Process Management GmbH & Co. OHG

Page 33

Instruction Manual

HASAxE-IM-HS

05/2006

1-4 Reserved For Future Use

1-4 Reserved For Future Use

X-STREAM

1 Technical Description

1-11Emerson Process ManagementGmbH & Co. OHG

Page 34

X-STREAM

1-5 Gaspath Design

1-5 Gaspath Design

Various materials are available to provide a

best possible analyzer adaption to the application. Materials are selected taking into

account e.g. diffusion rate, corrosiveness,

temperature and pressure of the applied gas.

1-5-1 Gas Paths Materials

Physical and chemical characteristics of

applied gases and working conditions

(temperature and pressure) affect the available materials.

Instruction Manual

HASAxE-IM-HS

05/2006

1-5-2 Safety Filter

All analyzers provide an internal stainless steel

safety filter. This filter(s) is (are) not a substitute

for a dust filter to be installed in the sample

handling system!

1-5-3 Fittings

By default all analyzers are equipped with

PVDF fittings (ø 6/4 mm)

Alternatively Swagelok

®

or stainless steel

fittings(ø 6/4 mm or 1/4") or other fitting

materials (on request) may be used.

1-5-4 Piping

Analyzers are piped with Viton or PTFE

(ø 6/4 mm).

Other materials (e.g. stainless steel) are used

optionally , depending on application.

1-12 Emerson Process Management GmbH & Co. OHG

Page 35

Instruction Manual

HASAxE-IM-HS

05/2006

1-5-5 Gas Path Variations

X-STREAM

1-5 Gaspath Design

Depending on the application and the selected

options several gas paths configurations are

Analyzer

Gas inlet

(IN K1)

Fig. 1-8: Single channel or serial tubing

available, as shown in the following figures

(examples):

Gas outlet

(OUT K1)

Gas inlet

(IN K1)

Gas inlet

(IN K2)

Analyzer

Fig. 1-9: Dual channel parallel tubing

Gas outlet

(OUT K1)

1 Technical Description

Gas outlet

(OUT K2)

1-13Emerson Process ManagementGmbH & Co. OHG

Page 36

X-STREAM

V1

Instruction Manual

HASAxE-IM-HS

05/2006

1-5 Gaspath Design

Analyzer

V2

Sample gas

(V3)

V4

Solenoid

valves

(option)

Sample pump (option)

Fig. 1-10: Single channel or serial tubing, with options

Gas outlet

(OUT K1)

1-14 Emerson Process Management GmbH & Co. OHG

Page 37

Instruction Manual

HASAxE-IM-HS

05/2006

1-6 Optional Gas Path Components

1-6 Optional Gas Path Components

Optionally available for all analyzer variations

are:

• internal sample gas pump

• internal valve block

• internal flow monitor

• internal barometric pressure sensor

X-STREAM

1-6-1 Internal Sample Gas Pump

An optional sample gas pump may be required

if the process gas stream is without exerting

pressure. In this case the pump ensures the

sample gas stream through the instrument

remains constant.

If an internal sample gas pump is installed, the

associated software setup menu entry shows

Y es (

5-4-3-5, page 5-41). The valve may

be controlled either manually by a corresponding menu line or remotely by a digital input.

1-6-2 Internal Valve Block

An optional internal valve block allows to

directly connect sample gas as well as span

and zero calibration gases to the instrument,

e.g. enabling automatic calibration.

If an internal valve block is installed, the associated software setup menu entry shows

Internal or Int+Ext ( 5-4-3-5, page 5-41).

V alve control is supported by a corresponding

menu line, by selecting the autocal mode or

remotely by digital inputs.

1-6-3 Internal Flow Monitor

An optional internal flow meter allows to

monitor the gas flow and set an alarm in case

of a fault.

If an internal flow monitor is installed, the associated software setup menu entry shows Yes

(

5-4-3-5, page 5-41).

There will be a status message in the measuring screen if the gas flow is too low and the