Emerson XFAL-020Z-TFC, XFAL-030Z-TFC, XFAL-035Z-CFV, XFAL-040Z-CFV, XFAL-040Z-TFC Installation And Reference Manual

...Page 1

Copeland Scroll™ Outdoor Refrigeration Unit

Installation and reference manual

Models:

XFAL, XFAM, XFAP

1.5 to 6 HP

Page 2

AE5-1412 R1

AE5-1412 R1

August 2016

Copeland Scroll™ Outdoor Refrigeration Unit

X-Line User Manual

TABLE OF CONTENTS

Section Page Section Page

1. Introduction .......................................................4

2. Nomenclature ....................................................4

3. Electrical/Physical Data ...................................5

4. Installation/Piping Instructions .......................5

5. Quick Setup Guide ............................................6

6. User Interface ....................................................7

6.1. Button Descriptions and Key Combinations....... 8

6.2. Changing a Parameter Value ............................. 8

6.3. Entering the Advanced Options Menu ............... 8

6.4. Moving Parameters Between the Programming

Menu and the Advanced Options Menu ............. 8

6.5. Locking the Keypad ........................................... 8

6.6. Unlocking the Keypad ........................................ 8

6.7. Changing Clock Setting .................................... 9

6.8. Refrigerant Selection ......................................... 9

6.9. Fast Access Menu.............................................. 9

6.9.1 List of Fast Access Parameters ................9

6.10. Alarm Menu ...................................................... 10

6.11. How to Program a Hot Key From the Controller

(UPLOAD) ........................................................ 10

6.12. How to Program a Controller Using a Hot Key

(download) ....................................................... 10

6.13. Manual Stepper Control Mode for Vapor Injection

(Low Temp) or Liquid Injection (Medium Temp) 10

6.14. Controller Startup ............................................. 11

6.15. Bump Start Control Operation.......................... 11

6.16. Compressor Stop Program .............................. 11

6.17. Crankcase Heater ............................................ 12

6.18. Suction Pressure Control ................................. 12

6.19. Fan Control ...................................................... 12

6.19.1. Fan Overrides and Error Handling ....... 12

6.20. Defrost Controls ............................................... 13

6.20.1. Holiday Defrosts................................... 13

6.20.2. Defrost Functionality ............................ 13

6.20.3. Liquid Line Solenoid Control ................ 13

6.21. Enhanced Vapor Injection (EVI) for Low

Temperature Units............................................ 13

6.21.1. Low Temp EVI Discharge Line

Temperature Protection Mode.............. 13

6.21.1.1. Low Temp EVI Discharge Line

Temperature Protection Error

Handling ................................ 14

6.21.2. EVI SYSTEM CHECKS

(XFAL Units Only) ............................................ 14

6.21.3 Constant Liquid Temperature Mode for

Low Ambient EVI Injection .................... 14

6.22. Medium Temperature DLT Protection .............. 14

6.22.1. Medium Temperature DLT Protection

Error Handling .................................................. 14

6.23. Over-Current Protection ................................... 14

6.24. Incorrect Phase Sequence Protection (3 Phase

Only) ................................................................ 15

6.25. Loss of Phase Protection - Current (3 Phase

Only) ................................................................ 15

6.26. Open Run Circuit (Single Phase Only) ............ 15

6.27. Open Start Circuit ............................................ 15

6.28. Over/Under Voltage Protection ........................ 15

6.29. Phase Imbalance (3 Phase Only) .................... 15

6.30. Compressor Internal Thermal Protection ......... 15

6.31. Fixed High Pressure Control ............................ 16

6.32. Alarm Contact .................................................. 16

6.33. Anti-Floodback Warning ................................... 16

6.34. High Condensing Temperature Warning .......... 16

7. Condensing Unit Operational Control ..........16

8. Physical and Installation Requirements ......17

9. Wiring Diagrams .............................................20

10. Refrigerant Liquid Temperature Valve

Capacity Multiplier Correction Factors .........28

11. Alarm Codes ...................................................29

12. Sensor Values .................................................31

13. Parameters ...................................................... 32

© 2016 Emerson Climate Technologies, Inc.

552-7018-00

1

Page 3

AE5-1412 R1

Safety Instructions

Copeland Scroll™ compressors are manufactured according to the latest U.S. and European Safety

Standards. Particular emphasis has been placed on the user's safety. Safey icons are explained below

and safety instructions applicable to the products in this bulletin are grouped on Page 3. These

instructions should be retained throughout the lifetime of the compessor. You are strongly advised

to follow these safety instructions.

Safety Instructions

Copeland Scroll™ compressors are manufactured according to the latest U.S. and European Safety Standards.

Particular emphasis has been placed on the user's safety. Safey icons are explained below and safety instructions

applicable to the products in this bulletin are grouped on Page 3. These instructions should be retained throughout

the lifetime of the compressor. You are strongly advised to follow these safety instructions.

Safety Icon Explanation

DANGER

WARNING

CAUTION

NOTICE

CAUTION

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices

not related to personal injury.

© 2016 Emerson Climate Technologies, Inc.

2

Page 4

AE5-1412 R1

Instructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

WARNING

WARNING

WARNING

ELECTRICAL SHOCK HAZARD

• Disconnect and lock out power before servicing.

• Discharge all capacitors before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

•

• Failure to follow these warnings could result in serious personal injury.

PRESSURIZED SYSTEM HAZARD

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side before

removing compressor.

•

• Never install a system and leave it unattended when it has no charge,

a holding charge, or with the service valves closed without electrically

locking out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury.

BURN HAZARD

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of

the compressor.

• Use caution when brazing system components.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury or

property damage.

CAUTION

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

•

install, commission and maintain this equipment.

•

• All valid standards and codes for installing, servicing, and maintaining electrical and

refrigeration equipment must be observed.

© 2016 Emerson Climate Technologies, Inc.

COMPRESSOR HANDLING

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in personal injury or

property damage.

3

Page 5

AE5-1412 R1

1. Introduction

Copeland Scroll™ Outdoor Refrigeration Units provide

the many benets of scroll compressor technology,

coupled with advanced diagnostic controls, to ensure

reliable performance and operation in foodservice

applications.

Electronics are used extensively in its protection and

diagnostic features. These features are controlled by

an electronic integrated control module. The Dixell

XCM25D control module with CoreSense™ technology

provides control functions related to temperature and

pressure control, defrost, and compressor protection.

Units are available in 1.5 to 6 HP for coolers and 2 to

6 HP for freezers. All units are 208/230 volts and are

available in single or three phase. All -081 bill of material

units come factory equipped with a heated and insulated

receiver, service valves, pressure controls, defrost

control, lter drier, moisture indicator, crankcase heater,

variable speed condenser fan, CoreSense Protection,

CoreSense Diagnostics, and two-way communications

standard.

Low temperature XFAL units (-40°F to 0°F saturated

suction) also feature an accumulator and oil separator.

Discharge line temperature control is provided by

enhanced vapor injection (EVI).

™

Discharge line temperature control is accomplished by

suction line liquid injection.

Extended medium temp XFAP units (-25F to +45F

saturated suction) feature an accumulator. Discharge

line temperature control is accomplished by suction line

liquid injection.

The Dixell XCM25D Electronic Control Module with

CoreSense technology (control module) on Copeland™

condensing units provides many benefits to the

contractor and end-user. It is designed specically for

demanding refrigeration applications to ensure simple

installation and precision operation. While the control

module replaces existing adjustable low pressure

controls, fan cycle switches and other relays, it also

has additional features. These features include bump

start, data storage, communication, and short cycling

protection.

The control module is preprogrammed with the proper

settings, resulting in little to no setup time. The unit

comes with instructions showing how to adjust the low

pressure cut-in and cut out. See the label on the inside

of the enclosure for more information.

Condensing unit operating range: -40°F to +120°F

Medium temperature XFAM units (0°F to +45°F

saturated suction) include all the standard features.

2. Nomenclature

Nomenclature

X F A M – 0 2 0 Z – T F C – 0 8 1

Family = X-Line

F = Multi-refrigerant

Z = Scroll

60Hz

L = Low Temp

A = Air-Cooled

M = Medium Temp

P = Multiple Applications

1.5 to 6.0 = H.P.

CFV = 208/230V-1ph-

Base Model Electrical Bill of Material

TFC = 208/230V-3ph-

60Hz

81 = Standard

0 = UL Listed Product

© 2016 Emerson Climate Technologies, Inc.

4

Page 6

AE5-1412 R1

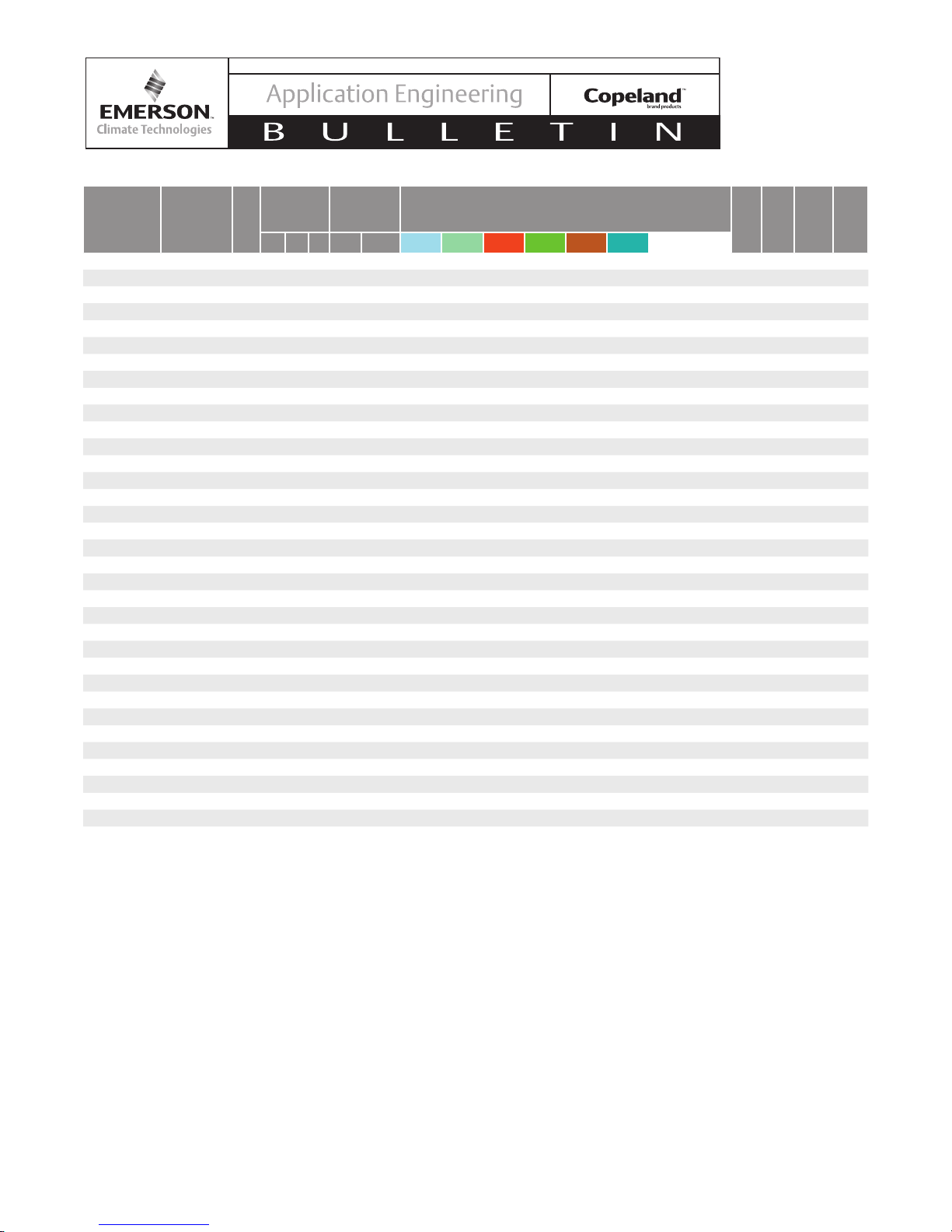

3. Electrical/Physical Data

Overall

Dimensions

Model Compressor

XFAL-020Z-CFV ZXI06KCE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S N/A N/A 9.1 10 10 9.1 NA NA 21.55 35 40 246

XFAL-020Z-TFC ZXI06KCE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S N/A N/A 9.1 10 10 9.1 NA NA 16.18 25 40 246

XFAL-030Z-TFC ZXI09KCE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S N/A N/A 9.1 10 10 9.1 NA NA 17.18 25 40 246

XFAL-035Z-CFV ZXI11KCE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S N/A N/A 9.1 10 10 9.1 NA NA 34.05 50 40 272

XFAL-040Z-CFV ZXI14KCE-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S N/A N/A 13.4 14.8 14.7 13.4 NA NA 40.1 60 40 274

XFAL-040Z-TFC ZXI14KCE-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S N/A N/A 13.4 14.8 14.7 13.4 NA NA 27.1 45 40 312

XFAL-050Z-TFC ZXI15KCE-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S N/A N/A 13.4 14.8 14.7 13.4 NA NA 28.85 45 40 323

XFAL-051Z-CFV ZXI16KCE-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S N/A N/A 13.4 14.8 14.7 13.4 NA NA 44.73 70 40 343

XFAL-060Z-TFC ZXI18KCE-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S N/A N/A 13.4 14.8 14.7 13.4 NA NA 33.98 50 40 341

XFAM-015Z-CFV ZS09KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 13.55 20 40 218

XFAM-015Z-TFC ZS09KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 11.05 15 40 219

XFAM-017Z-CFV ZS11KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 16.8 25 40 219

XFAM-017Z-TFC ZS11KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 14.05 20 40 219

XFAM-022Z-CFV ZS15KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 20.68 35 40 220

XFAM-022Z-TFC ZS15KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 14.3 20 40 219

XFAM-030Z-CFV ZS21KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 30.05 50 40 236

XFAM-030Z-TFC ZS21KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 20.05 30 40 236

XFAM-045Z-CFV ZS33KAE-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 37.35 60 40 285

XFAM-045Z-TFC ZS33KAE-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 29.98 50 40 280

XFAM-050Z-CFV ZS38K4E-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 41.85 70 40 292

XFAM-050Z-TFC ZS38K4E-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 28.85 45 40 292

XFAM-060Z-TFC ZS45K4E-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 31.98 50 40 299

XFAP-015Z-CFV ZS09KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 13.55 20 40 233

XFAP-015Z-TFC ZS09KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 11.05 15 40 234

XFAP-017Z-CFV ZS11KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 16.8 25 40 234

XFAP-017Z-TFC ZS11KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 14.05 20 40 234

XFAP-022Z-CFV ZS15KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 20.68 35 40 235

XFAP-022Z-TFC ZS15KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 14.3 20 40 234

XFAP-030Z-CFV ZS21KAE-PFV 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 30.05 50 40 251

XFAP-030Z-TFC ZS21KAE-TF5 1 16.7 40.5 33.1 1/2 S 7/8 S 10.7 10.5 9.1 10 10 9.1 9.7 9.7 20.05 30 40 251

XFAP-045Z-CFV ZS33KAE-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 37.35 60 40 300

XFAP-045Z-TFC ZS33KAE-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 29.98 50 40 295

XFAP-050Z-CFV ZS38K4E-PFV 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 41.85 70 40 307

XFAP-050Z-TFC ZS38K4E-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 28.85 45 40 307

XFAP-060Z-TFC ZS45K4E-TF5 2 16.7 40.5 48.9 1/2 S 7/8 S 15.7 15.5 13.4 14.8 14.7 13.4 14.2 14.3 31.98 50 40 314

Generator Requirements: In situations or locations where an electrical power generator is used for backup, the Copeland Scroll Outdoor Refrigeration Unit requires a supply voltage of 186-253 VAC.

# of

Fans

(in)

L W H Liquid Suction R-134a R-22 R-404A R-407A R-407C R-507A R-448A* R-449A*

Refrigerant

Connections

Receiver Capacity

(Lbs @ 90% Volume)

MCA

Max

Fuse*

Defrost

Relay

Rating

(Amps)

†

Ship

Weight

(lbs)

4. Installation/Piping Instructions

A clearance of 8 inches from the wall (or the next

unit) is required from the unit’s left and rear panel; a

clearance of 20 inches is required from the unit's right,

top and front panels. (See diagams in section covering

Physical and Installation Requirements) Ensure that

the hot discharge air from one unit does not circulate

to another unit.

The unit is designed to mount on the ground, on a roof,

or on a wall. For ground mounting, the units should be

placed on a level solid concrete slab with rubber strips

© 2016 Emerson Climate Technologies, Inc.

between the feet and concrete, or other raised support

structure. For wall mounting, use a wall bracket system

designed for mounting condensing units or universal

metal framing strut and follow the manufacturer's

instructions. All mounting options must follow local

zoning and building codes.

Pipes should be sized for optimum performance and

good oil return, and for the full capacity range through

which this particular unit will need to operate. Follow the

ASHRAE guidelines for proper piping practice.

5

Page 7

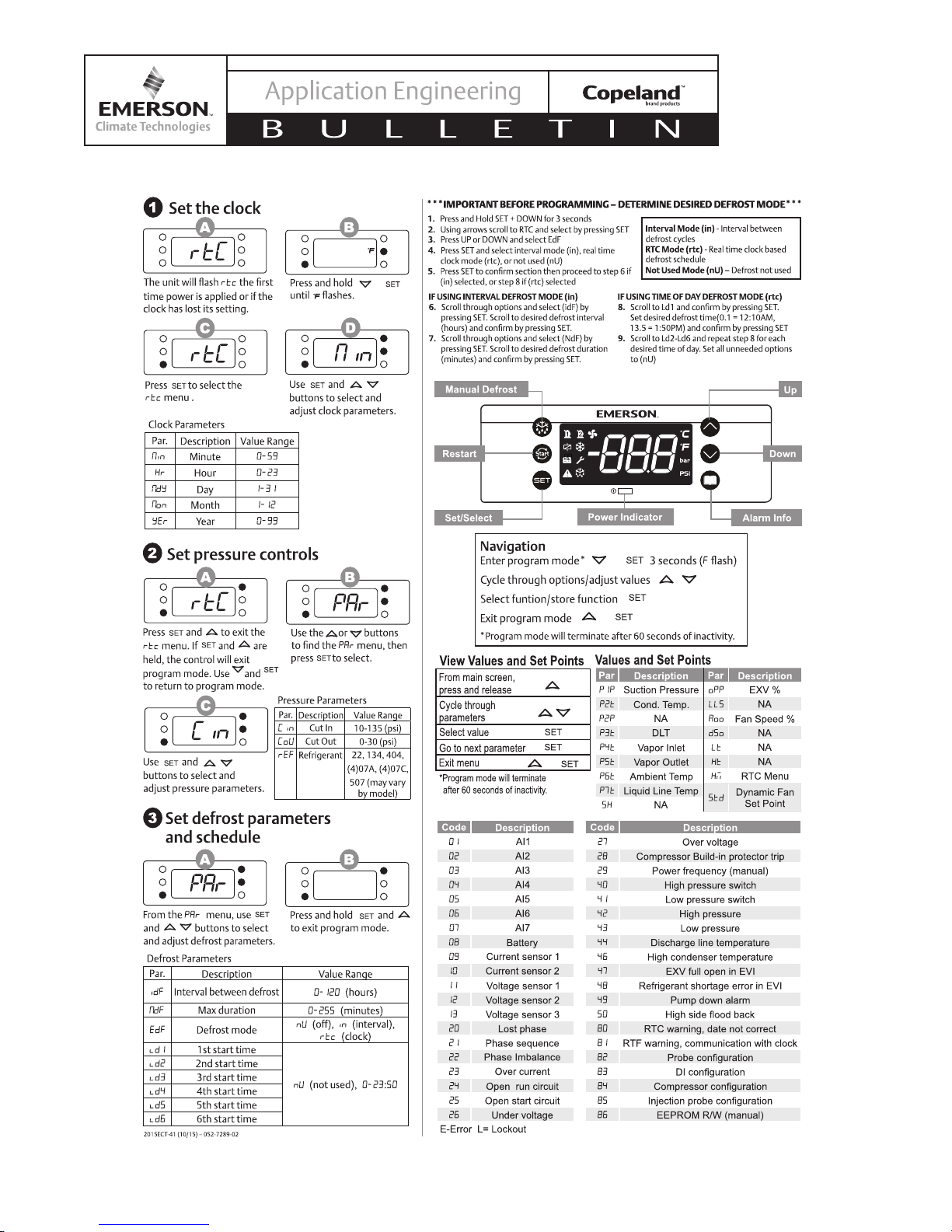

5. Quick Setup Guide

AE5-1412 R1

+

+

+

+

© 2016 Emerson Climate Technologies, Inc.

6

Page 8

AE5-1412 R1

6. User Interface

The controller display is shown below along with the function of each light. The controller displays the current suction

pressure to three digits in pounds per square inch gage (psig). The controller uses a 7-segment display for digits

and the following alpha characters:

The 7-segment alphabet and Roman equivalent:

A b C d E F H i L M n o P q r S T U Y 0 1 2 3 4 5 6 7 8 9

The letters G, J, K, Q, V, W, X and Z are not used on the 7-segment display.

LED MODE FUNCTION

ON Compressor enabled

Flashing Anti-short cycle delay enabled

ON Condensing fans enabled

ON Display temperature value in degrees F

Flashing Programming mode

ON Display pressure value in PSI

ON Browsing service menu

Flashing Fast access menu (Viewing set points and measured values)

ON Browsing the alarm menu

Flashing New alarm occurred

ON An alarm is occurring

ON In defrost or evap fan drip time when ON

ON Evaporator fans enabled

© 2016 Emerson Climate Technologies, Inc.

7

Page 9

AE5-1412 R1

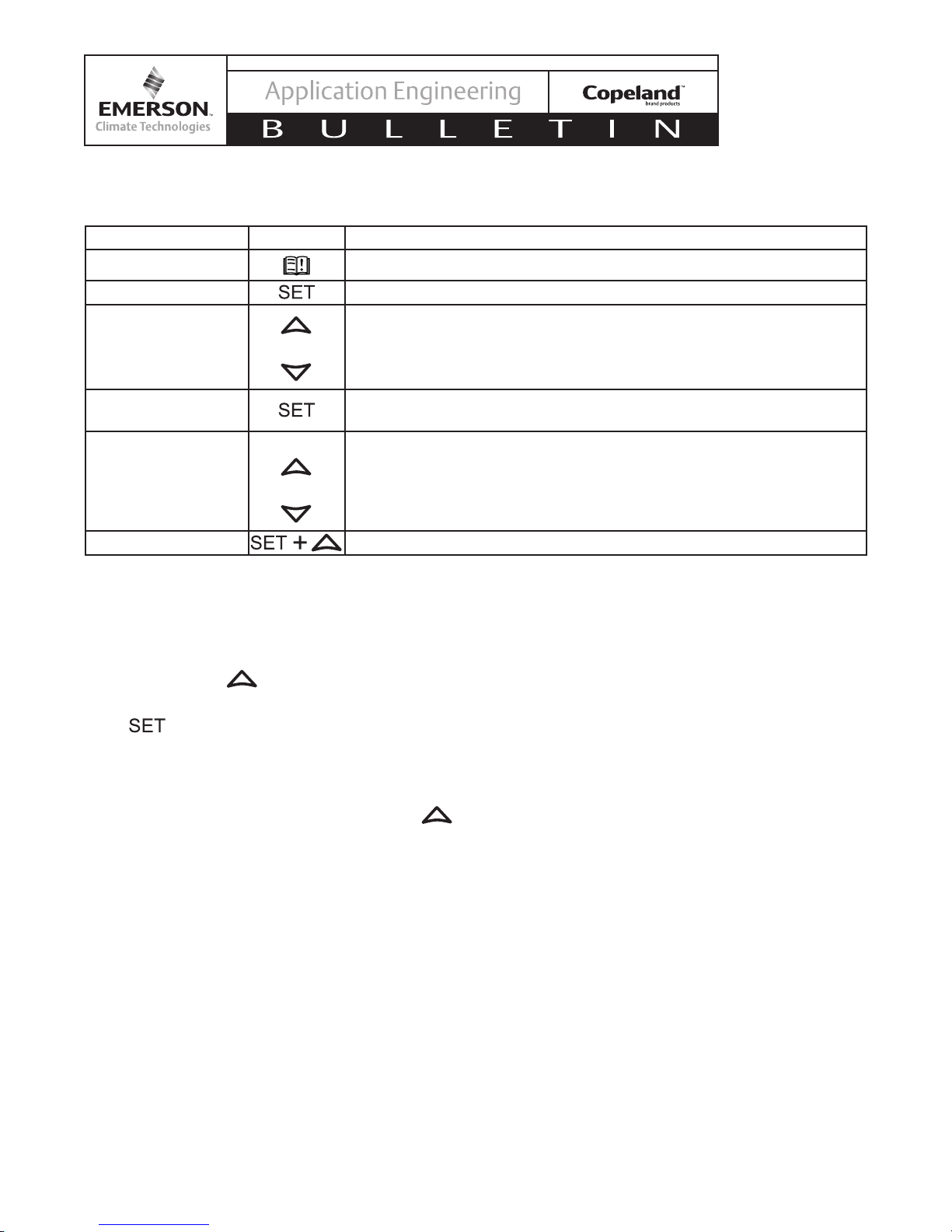

6.1. Button Descriptions and Key Combinations

(SET) Select a parameter or conrm an

operation when in programming mode.

(RESTART) Hold for 5 seconds to reset

any lockouts if the current state of the

controller allows for reset. Allows a

manual restart and a “dead band reset”.

(UP) View current measured values (Fast

Access Menu); in programming mode or

any menu to browse the parameter codes

or increase the displayed value.

(DOWN) in programming mode or any

menu to browse the parameter codes or

decrease the displayed value.

(SERVICE) To enter the service and

alarm menu.

Hold for 3 seconds to start a manual

defrost

+

Press and hold for about 3 sec to lock

(Pon) or unlock (PoF) the keyboard.

Press together to exit from programming

+

mode or from menu; on submenus to

return to previous level.

+

Press together for 3 sec to access to rst

level of programming mode.

6.2. Changing a Parameter Value

To change a parameter value:

1. Hold down keys for 3 seconds or until

the 'F' LED starts blinking to enter the module’s

programming menu.

2. Use or to select the rtC or PAr menu

3. Press to enter the menu.

4. Use or to select the required parameter.

5. Press the key to display its value.

6. Use or to change its value.

7. Press to store the new value.

TO EXIT: Press or wait 60 seconds

without pressing a key.

NOTE: The set value is stored even when the procedure

is exited by waiting for the time-out to expire.

6.3. Entering the Advanced Options Menu

1. Hold down keys for 3 seconds or

until the F LED starts blinking to enter the module’s

programming menu.

2. Use or to select the PAr menu

3. Press to enter the PAr menu

4. Use or to select the PAS parameter

5. Press to select PAS

6. The blinking PAS label will be showed for a few

seconds

7. Will be showed 0 - - with blinking 0: insert the

password [321] using the keys UP and DOWN and

conrming with SET key.

6.4. Moving Parameters Between the Programming

Menu and the Advanced Options Menu

While in the advanced options menu, certain parameters

will have a (.period) in between the 2nd and 3rd

character, for example Ci.n. These parameters are

in the Programming Menu as well as the Advanced

Options Menu.

To add or remove a parameter from the programming

menu, press the keys together while

the parameter name is on the display in the advanced

options menu. The (.period) between the 2nd and 3rd

parameter will either be added or removed.

TO EXIT: Press or wait 60 seconds

without pressing the keys.

6.5. Locking the Keypad

1. Press the keys for 3 seconds.

2. The POF message will be displayed and the

keyboard will be locked. The Fast Access Menu

will remain accessible whil the keyboard is locked.

3. If a key is pressed more than 3 seconds the POF

message will be displayed.

6.6. Unlocking the Keypad

Press the keys for 3 seconds until the

Pon message is displayed.

NOTE: If a menu does not have any parameters

available, noP will be displayed

© 2016 Emerson Climate Technologies, Inc.

8

Page 10

AE5-1412 R1

6.7. Changing Clock Setting

+

6.8. Refrigerant Selection

Using parameter REF set the refrigerant as follows

(refer to nameplate for approved refrigerants):

Refrigerant rEF

R-404A 404

R-507 507

R-134A 134

R-22 r22

R-407C 07C

R-407A 07A

R-407F 07F

R-448A 48A

R-449A 49A

6.9. Fast Access Menu

This menu allows viewing measured values from

various probes and view some outputs resulting from

these measurements. The values nP or noP stand for

probe not present or value not evaluated. Err means the

value is out of range, probe is damaged, not connected,

or incorrectly congured.

Press to enter the Fast Access Menu.

Use or arrows to select an entry, then press

to see the value or to go on with other value.

TO EXIT: Press or wait 60 seconds

without pressing the keys.

6.9.1. List of Fast Access Parameters:

P1P Suction pressure

P2t Condenser temperature

P2P Not Used

P3t Discharge line temperature

P4t EVI heat exchanger vapor inlet temperature

(XFAL only)

PSt EVI heat exchanger vapor outlet

temperature (XFAL only)

P6t Ambient temperature

P7t Liquid line temperature (XFAL only)

5H Not used

oPP Percentage of liquid injection (XFAP/

XFAM) or vapor injection (XFAL) valve

opening.

LLS Not used

Std Current condenser temperature target for

fan speed control

A00 Fan speed percent

d5o Not used

L t Not used

H t Not used

tU1 Line voltage (1-phase)

tU2 Line voltage (3-phase)

tU3 Line voltage (3-phase)

tA1 Current (1-phase)

tA2 Current (3-phase)

tA3 Current (3-phase)

HM Menu

© 2016 Emerson Climate Technologies, Inc.

9

Page 11

AE5-1412 R1

6.10. Alarm Menu

The controller time-stamps and stores the last 50 alarms. See Section 11 for alarm codes.

Action Button Notes

Enter alarm menu Push and release alarm key (Displays SEC when alarm menu is active)

Enter alarm list Press SET to conrm

Scroll through active

and recorded alarm

list

Or

Scroll the list of alarms and see the list of active alarms with the number

of the alarm (Letter+Number, A01-A50).

Push Down key and see the alarm Name or Code.

Push Down key and see the next active alarm

Select the alarm to

Enter the sub menu with alarm time details

see the date and time

Scroll through alarm

information data

Or

Successive presses of the down arrow button will display the clock

data label (hour, minute, day, month, year) followed by the value of the

preceding label. The up arrow will reverse this order and show the value

followed by the label. The displayed values record the start time of an

alarm.

Exit menu Press SET and UP together or wait about 10 seconds.

6.11. How to Program a HOT-KEY From the

Controller (UPLOAD TO OVERWRITE HOT-KEY)

Caution: Overwrites hot key. When the controller is ON,

insert the HOT-KEY into the 5-PIN receptacle (labeled

H-K) and push the button; the UPL message

appears followed a by a ashing End label.

Push button and the End will stop ashing.

Turn OFF the controller, remove the HOT-KEY and then

turn the controller ON again.

NOTE: the Err message appears in case of a failed

programming operation. In this case push the

again if you want to restart the upload again or remove

the HOT-KEY to abort the operation.

6.12. How to Program a Controller Using a HOT-KEY

(Download)

A hot key is included with each unit for factory reset

and replacement control programming. Remove power

from the unit.

Insert a pre-programmed HOT-KEY into the 5-PIN

receptacle (labeled H-K) and reapply power to the unit.

The parameter list of the HOT-KEY will be automatically

downloaded into the controller memory. The doL

message will blink followed by a ashing End label.

After 10 seconds the controller will restart and begin

working with the new parameters.

Remove the HOT-KEY

NOTE: The message Err is displayed for failed

programming. In this case turn the unit off and then on

if you want to restart the download again or remove the

HOT-KEY to abort the operation.

6.13. Manual Stepper Control Mode for Vapor

Injection (Low Temp) or Liquid Injection (Medium

Temp)

For troubleshooting purposes, the stepper setting can

temporarily be manually adjusted.

From the standard display screen, pressing SET and

SERVICE/ALARM key for 3 seconds will enter a manual

stepper control mode.

In the manual stepper control mode, the display shows

the current step count of the valve.

In manual stepper control mode, all algorithms

controlling the stepper valve are suspended, but the

rest of the functions operate normally

The up and down arrows on the keypad open and

close the valve, with the display showing the updated

step count

If the controller is left untouched for 60 seconds or

the set and up button are pressed together to exit, the

controller will resume normal operation.

© 2016 Emerson Climate Technologies, Inc.

10

Page 12

AE5-1412 R1

Condensing Unit Operational Control

The X-Line control module operates the condensing unit

and ensures the system remains in correct operating

conditions. It controls the follow items:

• Compressor

• Condenser Fan Motor(s)

• Crank Case Heater

• Receiver Heater

• Defrost Heater (If connected)

The X-line Unit will protect the system from the following

fault conditions (See Sections 6.23 through 6.31 for

further details):

• Discharge Line Temperature Protection

• Over-Current Protection

• Incorrect Phase Sequence Protection (3 Phase

Only)

• Loss of Phase Protection - Current (3 Phase Only)

• Open Run Circuit (Single Phase Only)

• Open Start Circuit (Single Phase Only)

• Over/ Under Voltage Protection

• Phase Imbalance (3 Phase Only)

• Compressor Internal Thermal Protection

• Fixed High Pressure Control

In addition, the X-Line unit has protection features

that will prevent it from reaching a fault condition. For

example, when the low temperature unit experiences

an extremely hot day, the control module decides to

switch from vapor-injection-optimization to discharge

gas temperature control to allow the compressor to run

safely and pass the extreme weather hours.

6.14. Controller Startup

At initial power up, the controller display will display the

following information:

All LEDs will light up for approximately 2 seconds.

For 3 seconds, the controller will display the

rmware version (EX: 1.0, 1.1, etc.)

For three seconds the controller will display the

program number (EX: 100, 101, 200, etc.)

The controller will then wait 6 seconds before turning

on the compressor or any other device.

Once the controller calls for the compressor to run and

there are no active alarms, the controller will then turn

on the compressor utilizing bump start (if needed per

Section 6.15) and control the fans and compressor.

6.15. Bump Start Control Operation

If the ambient temperature sensor reads less than

95°F when the controller is rst turned on or after the

compressor has been off for 4 hours and now is being

turned on, the compressor will initiate a bump start. If

the ambient temperature sensor is not functioning, the

mid-coil temperature sensor will determine if the unit

will initiate a bump start or not.

The compressor and fans will run for 2 seconds then

turn off for 15 seconds three times. Once this sequence

is completed, the unit resumes normal operation.

The crank case heater will remain off during the bump

start sequence.

If liquid injection, vapor injection, or a system EXV is

present, the stepper valve will remain closed until the

bump start has nished.

In the event of a power loss, the controller can be

programmed to enter a defrost at power up if dPo is

set to YES. It is turned off by default, but is adjustable

from the advanced options menu.

6.16. Compressor Stop Program

When the compressor needs to turn off, either based

on an error or loss of demand, the following items will

occur:

• Liquid or Vapor Injection Only: If a non-error

shutdown occurs, compressor runs for 5 seconds

before turning off to allow the liquid of vapor

injection valves to fully close.

• Compressor turns off

• Condenser fans turn off

Crankcase heater turned on (See Section 6.17)

NOTE: During the pump down process with the 5

second delay the compressor may run down into

a vacuum. There are no reliability issues in this

application.

© 2016 Emerson Climate Technologies, Inc.

11

Page 13

AE5-1412 R1

6.17. Crankcase Heater

The crankcase heater is energized when the ambient

temperature is below 50°F and the compressor is off.

If an ambient sensor fails, the crankcase heater is

energized when the compressor is off.

6.18. Suction Pressure Control

The compressor is operated based on the suction

pressure cut-in (Cin) and cut-out (CoU). If the suction

pressure rises above the cut-in, the compressor is

turned on using the startup procedure (See Section

6.14). If the suction pressure then falls below the cut-

out, it turns the compressor off using the shutdown

procedure (See section 6.16).

The compressor remains off for a minimum 120

seconds (2oF) after shutdown, which is adjustable in

the advanced options menu (See section 6.3).

If the suction pressure transducer fails, the compressor

will run in limp along mode. The compressor will stay

off for 3 minutes (CoF) then run for 3 minutes (Con).

These values are adjustable from the advanced options

menu (See section 6.3).

The cut-in and cut-out settings are adjustable between

0 PSIG and 135 PSIG.

10 seconds before turning off and stay off for at least

10 seconds before being turned back on.

Since the X-Line controller knows the current suction

pressure, the controller can determine the minimum

condensing point for the condition the unit is actually

running, and will adjust the fan control set point to

maintain that temperature or higher.

The XFAP/XFAM and XFAL models have different

compressors and different refrigerant options.

Therefore, during commissioning, it is important to

identify the seleted refrigerant so the controller will

operate the fans properly.

Low ambient operation

The condensing unit can operate in outdoor ambient

temperatures as low as -40°F. The unit will automatically

adjust condenser fan speed to maintain head pressure.

At extremely low ambient temperature the condenser

fan might not run, but the condenser coil is still

discharging heat. Parameter LAS sets the ambient

temperature required to initiate low ambient on time.

The default value is -20°F. Parameter LMO sets the

low ambient minimum on time. The default value is 6

seconds. Below -20°F ambient, when the condensing

unit runs it will run for a minimum of 6 seconds.

IMPORTANT: At initial power up, depending on the

suction pressure transducer, the suction pressure

could be higher than the rating of the transducer. For

15 minutes after power up, any over pressure errors

generated by the suction pressure transducer should be

ignored, and the display will ash 135. If the transducer

is still in an error state after the time has expired, the

control will alarm that the suction pressure transducer

signal is lost, and go into limp along mode.

6.19. Fan Control

The The X-line uses variable speed PSC condenser

fan motors to maintain the head pressure values that

allow the system to operate within the compressor

operating envelope and maintain the minimum pressure

differential across the expansion device to allow it to

operate properly.

The controller uses a Proportional-Integral (PI) control

algorithm to determine the fan speed. The fans will

not run any slower than 40% before turning off. When

a fan rst turns on it will run for 3 seconds at full speed

before it begins modulating. Fans will run for at least

IMPORTANT NOTE: To fully utilize low condensing

options below 70°F condensing, an electronic

expansion valve (EXV) is normally required to handle

the larger variation in mass ows. As a result, the unit

is shipped with a default minimum condensing override

value of 70°F (80°F for XFAL). The fans will still follow

the map of the selected refrigerant, but the map will

not be allowed to run below the override value. If you

have a system with an EXV installed, you can adjust

the value by changing parameter MCS in the advanced

options menu.

6.19.1. Fan Overrides and Error Handling

If the discharge line temperature is above 205°F the

fans will run at full speed.

If the condenser mid-coil temperature sensor fails, the

fan speed is determined by outdoor ambient. If both

the outdoor ambient sensor and the condenser mid-coil

temperature sensor fail, all fans will run at full speed.

© 2016 Emerson Climate Technologies, Inc.

12

Page 14

AE5-1412 R1

6.20. Defrost Controls.

6.20.1. Holiday Defrosts

If you are using real time clock mode (rtc), holiday

defrosts can be set in the advanced options menu. To

set a holiday, change Hd1 from nU to whatever day

of the week you would like to have a different defrost

schedule. (An example would be if a store is closed

on Sundays and needs less defrosts). You can set a

second holiday by changing Hd2. The defrosts for the

set holidays are controlled by parameters 5d1 through

5d6.

The controller will terminate defrost after 45 minutes

MDF (Pr1 parameter) or after the defrost termination

input (Terminal 'X') is closed.

6.20.3. Liquid Line Solenoid Control

By default, the unit assumes that a liquid line solenoid

is used to pump down the system during a defrost.

When the unit enters a defrost, the evaporator power

(Connection 3 on the terminal strip) will turned off,

turning off the liquid line solenoid as well. The unit will

then run until the suction pressure drops below the

cut out value, then turn off the compressor. When the

defrost is complete, the unit will apply power to the

evaporator, opening the solenoid and the compressor

will start running once the suction pressure is above

the cut in.

If a pump down solenoid is not present or the unit should

not pump down when entering a defrost, parameter tLS

should be set to no. TLS is set to YES by default.

6.21. Enhanced Vapor Injection (EVI)

For Low Temperature Units

The injection valve is a key part of the EVI system.

It regulates vapor injection flow to optimize the

performance of system and cool the scroll set. When

the compressor rst calls for power, the injection valve

opens a preset amount before the compressor turns

on. After startup, the EVI injection valve is controlled

using a proportional-integral (PI) algorithm to control

the differential between the vapor inlet temperature

and the vapor outlet temperature. The differential is

9°F for R404A, R507, R134a, and R22. It is 18°F for

other approved refrigerants. The PI algorithm for the

EVI injection valve control is auto-adaptive, so it does

not need to be adjusted.

6.20.2. Defrost Functionality

During a defrost the controller will display dEF.

To manually initiate a defrost, press and hold the defrost

button for 3 seconds.

© 2016 Emerson Climate Technologies, Inc.

6.21.1. Low Temp EVI Discharge Line

Temperature Protection Mode

If during normal operation the DLT temperature reaches

225°F the control changes to act as a liquid injection

valve to control the DLT temperature. Once the DLT

temperature falls below 200°F, normal vapor injection

control resumes.

If the discharge temperature goes above 250°F, the

compressor trips off and the control displays an E44

error. The compressor cannot turn back on until the

temperature drops below 170°F and has been off for

3 minutes.

13

Page 15

AE5-1412 R1

If the compressor trips more than 4 times per hour (dLn),

the controller will lock out the compressor, requiring a

manual reset or the controller power to be reset. The

controller will display L44 showing the compressor has

tripped on high DLT and locked out. If parameter dLn,

which is available in the advanced options menu, is set

to 0, the unit will always automatically reset.

6.21.1.1. Low Temp EVI Discharge Line

Temperature Protection Error Handling

In case of DLT failure, the injection valve operates based

on the mid coil and ambient sensor.

If the DLT sensor fails and a mid-coil temperature sensor

is available, the injection valve will be opened based

on the mid coil temperature. If the mid coil sensor fails

in addition to the DLT sensor, the injection valve is

controlled by the ambient temperature.

6.21.2. EVI System Checks (XFAL units only)

An E47 warning code means that the injection valve has

been fully open longer than 3 minutes. An E48 warning

code means that the temperature difference across

the EVI heat exchanger is higher than expected for 3

minutes. These are only warnings, but are likely due to

loss of refrigerant charge or undercharge

6.21.3. Constant Liquid Temperature Mode For

Low Ambient EVI Injection

Subcooling is generally good, but liquid refrigerant

that is too cold can create sizing problems for TXVs.

If the ambient is below 30°F, discharge temperature

is generally well under control and so the controller

disables vapor injection to operate in constant liquid

temperature mode. The low ambient temperature will

generate enough subcooling for the system without the

need for injection. Emerson recommends a balanced

port TXV (or EXV) for low ambient operation.

6.21.4. Low Temperature Units With EVI TXV

Selection

For use with low temperature units with EVI, Emerson

recommends a balanced port TXV because it offers a

wider operating range for oating liquid temperatures.

In addition, the unit liquid line should be insulated since

the liquid line temperature will be lower than the ambient

temperature.

See the table on page 28 for specics regarding

balanced port sizing recommendations. Applied with the

low temp units it is recommended that a balanced port

expansion valve be used along with a complete review

of the distributor and nozzle (orice) that is supplied with

the evaporator coil being matched with the applicable

condensing unit. Typically nozzles are selected for

standard TXV sizing using 100°F liquid, with the low

temperature X-Line units those typical selections could

be grossly oversized. See the table on page 28 for the

liquid correction safety factors when selecting those

components.

6.22. Medium Temperature DLT Protection

Medium Temperature units have liquid injection through

the suction line to prevent compressor overheat during

extreme ambient operations. The liquid injection will

keep discharge temperatures below 235°F.

If the discharge temperature goes above 255°F, the

compressor trips and the controller shows an E44 error.

The compressor cannot turn back on until the discharge

line temperature drops below 170°F and has been off

for at least 3 minutes.

If the compressor trips more than 4 times in an hour

(dLn) on DLT, the controller will lock out the compressor,

requiring a manual reset or the controller power to

be reset. The controller will display L44 showing the

compressor has tripped on high DLT and is locked

out. If parameter dLn, which is available in the

advanced options menu, is set to 0, the unit will always

automatically reset.

See Section 12 for 86k Thermistor probe resistance

values. Discharge line sensor is 86k, all other

temperature sensors on this unit are 10k.

6.22.1. Medium Temperature DLT Protection Error

Handling

In case of DLT sensor failure, injection is determined by

the mid coil and ambient sensor.

If the DLT sensor fails and a mid-coil temperature sensor

is available, the injection valve will be opened based on

the mid coil temperature. If the mid coil sensor fails in

addition to the DLT sensor, the injection is determined

by the ambient temperature.

© 2016 Emerson Climate Technologies, Inc.

14

Page 16

AE5-1412 R1

6.23. Over-Current Protection

Current is measured using the two current transducers

installed on the controller. If the current exceeds

the compressor MCC, the controller will stop the

compressor for 3 minutes and signal error E23. A

separate parameter MC2 is available to allow adjust

the maximum current value down, but not up, in the

advanced options menu.

To avoid any fault triggering during the compressor

startup period caused by the high inrush current,

current sensing in not processed by the controller until

6 seconds after compressor startup.

If the compressor trips more than 5 times in an hour

(default) on high current, the controller will lock out

the compressor and display an L23 lockout, requiring

a manual reset or the controller power to be reset. If

the parameter oCn, which is available in the advanced

options menu, is set to 0, then the unit will always reset.

6.24. Incorrect Phase Sequence Protection

(3 Phase Only)

The controller determines whether the sequence of

three phase supply lines is proper or not. The voltage

sensing terminals are connected to the 3-phase supply

of the compressors. If an incorrect phase (L1, L2, and

L3) is detected, the controller will trip compressor

immediately and display an L21 lockout code. The

compressor will not restart until the power to the unit is

turned off and L1 and L2 are switched. The reset button

will not work with this error.

6.25. Loss of Phase Protection - Current (3 Phase

Only)

The unit controller detects whether or not all the three

phase supplies are available. If a phase is missing, the

controller will shut down the compressor and display

an E20 error code and prevent the compressor from

restarting for 3 minutes. If the unit is shut down more

than 5 times in an hour (default), then unit will lock out

and display an L20 lockout code. If the parameter (PEn)

is set to 0, the unit will always automatically reset.

6.26. Open Run Circuit (Single Phase Only)

After the compressor is started and runs for 6 seconds, if

the there is no run circuit current and the start current is

still greater than 1 amp, the controller will display an E24

error for open run circuit and shut down the compressor.

The compressor will not restart for 3 minutes in the

event of a trip.

If the unit is shut down more than 5 times in an hour

(oCn), then the unit locks out and display a L24 lockout

code. If the parameter (oCn) is set to 0, the unit will

always automatically reset.

6.27. Open Start Circuit (Single Phase Only)

Immediately after startup, if there is no start current for

the rst 500ms and the run current is greater than 1 amp,

the controller will display an E25 error for open start

circuit and shut down the compressor. The compressor

will not restart for 3 minutes in the event of a trip. If the

unit is shut down more than 5 times in an hour (oCn),

then the units locks out and display an L25 lockout code.

If the parameter (oCn) is set to 0, the unit will always

automatically reset.

6.28. Over/ Under Voltage Protection

If the voltage drops below 10% of the minimum rated

voltage or above 10% of the maximum rated voltage for

1 second, the controller will shut off the compressor and

display an E26 (under voltage) or E27 (over voltage)

error code until the voltage is back within acceptable

range and the compressor has been off for 3 minutes

(oCn).

If the compressor trips more than 5 times per hour

(Default), the controller will lock out the compressor,

requiring a manual reset or the controller power to be

reset. If the parameter (PEn) is set to 0, then the unit will

always reset. The controller will display an L26 (lockout,

under voltage) or L27 (lockout over voltage).

6.29. Phase Imbalance (3 Phase Only)

If the voltage in a given leg drops below 5% of the

average voltage of the 3 legs for 1 second, the controller

will display E22 and shut the unit down (based on

a parameter PiC) for 5 minutes and until the phase

imbalance is corrected.

© 2016 Emerson Climate Technologies, Inc.

15

Page 17

AE5-1412 R1

6.30. Compressor Internal Thermal Protection

If the compressor’s internal thermal protector trips,

the contactor fails, or the contactor is miswired, the

controller will detect the loss of current and display an

E28 warning code. This happens if both of the current

transducers do not sense current for 1 second when

the controller sends a compressor run signal. To avoid

any fault triggering during the compressor startup period

caused by the high inrush current, current sensing is

not processed by the controller until 6 seconds after

compressor startup.

6.31. Fixed High Pressure Control

The high pressure control is a nonadjustable pressure

switch that opens at 440 +/- 10 psig and resets at

348psig in the event of high discharge pressure. If the

high pressure switch is open, the compressor shuts off

immediately, ignoring any overrides. As long as the high

pressure switch is open, the compressor will not run.

The compressor will stay off for 3 minutes regardless of

when the pressure switch resets. E40 will be displayed

while the unit is shut down.

If the compressor trips more than 5 times per hour,

the controller will lock out the compressor, requiring a

manual reset or the unit power to be reset. Error code

L40 means the compressor tripped on high pressure

and is locked out. If the parameter HPn is set to 0, the

unit will always automatically reset.

6.33. Anti-Flood Back Warning

System Liquid Flood Back Warning Logic:

High-side superheat is the discharge line temperature

minus the mid-coil temperature. If high-side superheat

is less than 18°F for longer than 30 minutes during

the last 45 minutes, the controller will display E50,

but continue running the system. When the high-side

superheat climbs above 18°F for 30 minutes, then the

warning signal stops.

6.34. High Condensing Temperature Warning

An E46 warning means the condensing temperature

exceeded 150°F. The fans will run at full speed but the

compressor does not shut down. The warning clears

when the temperature drops below 140°F.

7. Local and Remote Displays and

Communication

The controller can communicate with Modbus RTU

RS485 supervisory controllers. An optional remote

display is available. The display can be mounted up

to 30 feet from the unit. To connect and congure the

remote display, follow the instructions included with

the remote display

6.32. Alarm Contact

The alarm contact (A1 and A2 on terminal block) is a dry

contact that can be wired to an external warning device

such as a buzzer or light. This relay has a 5 Amp limit,

up to 250V. The alarm contact will close in the event of

an alarm or lockout.

© 2016 Emerson Climate Technologies, Inc.

16

Page 18

8. Physical and Installation Requirements

Single Fan Unit

1.5-3 HP

AE5-1412 R1

Dual Fan Unit

4- 6 HP

Figure 1

Bottom View

All Models

© 2016 Emerson Climate Technologies, Inc.

17

Page 19

AE5-1412 R1

Figure 2 – Controller

NOTE: There is no eld wiring to this controller except for communications. The transformer wired in the unit is for

the controller only. Do not tap off the transformer to power any other devices. When removing a connector, do not

pull on the wire.

High Voltage Connections

Label Connector(s)

C1 ¼” Spade Connectors (2)

Electrical Limit

(250VAC Max)

25A Max Current

(16A Max Each Spade)

Function

Provides Power for Defrost Heater and

Evaporator Fan Relays

D01 ¼” Spade Connector 16A Relay Operates 40A Evaporator Fan Relay

D02 ¼” Spade Connector 16A Relay Operates 40A Defrost Heater Relay

C2 ¼” Spade Connector 16A Max Current

Provides Power to Compressor Relay

and CCH/RH Relays

D03 ¼” Spade Connector 5A Relay Operates Compressor Contactor

D04 ¼” Spade Connector 8A Relay

Powers Crankcase Heater and Receiver

Heater

D05 ¼” Spade Connectors (2) 5A Relay Dry (Switch Only) Alarm Contact

DI1 250VAC Max

Left Terminal – Defrost Termination Input

Right Terminal – L2

© 2016 Emerson Climate Technologies, Inc.

18

Page 20

High Voltage Connections (continued)

AE5-1412 R1

Label Connector(s)

Neutral ¼” Spade Connectors (6)

Electrical Limit

(250VAC Max)

25A Max Current

(16A Max Each Spade)

Function

L1 Common Terminal Strip

R ¼” Spade Connector 480V Max L1 Voltage Sensing

S ¼” Spade Connector 480V Max L2 Voltage Sensing

T ¼” Spade Connector 480V Max L3 Voltage Sensing (3 Phase Only)

SUPPLY 24VAC, 40VA Controller Power Supply

T01

2A Wave Form

Chopping Triac

Variable Speed PSC Fan Motor Control

T02 Not Used For Future Use

Sensor Connections

Label Function Type

AI1 Suction Pressure Transducer 0.5 to 4.5 VDC Ratio metric

AI2 Condenser Temperature Sensor 10k NTC (See Section 12 for values)

AI3 Discharge Line Temperature Sensor 86k NTC (See Section 12 for values)

AI4

AI5

EVI Heat Exchanger Inlet Vapor Temperature

Sensor (Low Temp Only)

EVI Heat Exchanger Outlet Vapor Temperature

Sensor (Low Temp Only)

10k NTC (See Section 12 for values)

10k NTC (See Section 12 for values)

AI6 Ambient Temperature Sensor 10k NTC (See Section 12 for values)

AI7 Liquid Line Temperature Sensor (Low Temp Only) 10k NTC (See Section 12 for values)

DI3 Future Use Future Use

EV Liquid or Vapor Injection Valve 12VDC Stepper

Other Connections

Label Functions

VNR Remote Display Connection

Connect + to + and – to -

RS485 RS-485 Communications

CANBUS Future Use

B.BKP Future Use

H-K

© 2016 Emerson Climate Technologies, Inc.

Hotkey programming

(use with part # 043-0171-01 to reset control)

19

Page 21

9. Wiring Diagrams

AE5-1412 R1

L1 L2

© 2016 Emerson Climate Technologies, Inc.

A

3

X

G

4 N

A

1

2

052-7287-00

Low Temp 1-Phase 2.0-3.5 HP

1 Condenser Fan

20

Page 22

AE5-1412 R1

L1 L2

© 2016 Emerson Climate Technologies, Inc.

A

G

3 X

4 N

A

1

2

052-7287-01

Low Temp 1-Phase 4-5 HP

2 Condenser Fans

21

Page 23

AE5-1412 R1

© 2016 Emerson Climate Technologies, Inc.

052-7287-02

Medium Temp 1-Phase 1.5-3 HP

1 Condenser Fan

22

Page 24

AE5-1412 R1

L2

L1

© 2016 Emerson Climate Technologies, Inc.

A

L3

3

X

4 N

G

A

1

2

052-7287-04

Medium Temp 3-Phase 4.5-6 HP

2 Condenser Fans

23

Page 25

AE5-1412 R1

L2

L1

© 2016 Emerson Climate Technologies, Inc.

L3

3

4 N

G

A

X

1

052-7287-05

Low Temp 3-Phase 2-3 HP

1 Condenser Fans

24

A

2

Page 26

AE5-1412 R1

L1

© 2016 Emerson Climate Technologies, Inc.

L2

A

L3

3

X

4 N

G

A

1

2

052-7287-13

Low Temp 3-Phase 4-6 HP

2 Condenser Fans

25

Page 27

AE5-1412 R1

L2

L1

© 2016 Emerson Climate Technologies, Inc.

A

L3

3

4 N

G

A

X

2

1

052-7287-14

Medium Temp 3-Phase 1.5-3 HP

1 Condenser Fan

26

Page 28

AE5-1412 R1

L1 L2

© 2016 Emerson Climate Technologies, Inc.

A

G

3 X

4 N

A

1

2

052-7287-15

Medium Temp 1-Phase 4.5-5 HP

2 Condenser Fans

27

Page 29

Evaporator Wiring

Typical Unit Cooler

AE5-1412 R1

10. Refrigerant Liquid Temperature Valve Capacity Multiplier Correction Factors

Refrigerant Liquid Temperature Entering TXV

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

R-22 1.56 1.51 1.45 1.40 1.34 1.29 1.23 1.17 1.12 1.06 1.00 0.94 0.88 0.82 0.76

R-404A 2.00 1.90 1.80 1.70 1.60 1.50 1.40 1.30 1.20 1.10 1.00 0.90 0.80 0.70 0.50

R-507 2.00 1.90 1.80 1.70 1.60 1.50 1.40 1.30 1.20 1.10 1.00 0.90 0.80 0.70 0.50

R-134a 1.70 1.63 1.56 1.49 1.42 1.36 1.29 1.21 1.14 1.07 1.00 0.93 0.85 0.78 0.71

R-407A 1.75 1.68 1.61 1.53 1.46 1.39 1.31 1.24 1.16 1.08 1.00 0.92 0.84 0.76 0.68

R-407C 1.69 1.62 1.55 1.49 1.42 1.35 1.28 1.21 1.14 1.07 1.00 0.93 0.86 0.79 0.72

These factors include corrections for liquid refrigerant density and net refrigerating effect and are based on an

average evaporator temperature of 0°F. However, they may be used for any evaporator temperature from - 40°F

to + 40°F since the variation in the actual factors across this range is insignicant.

© 2016 Emerson Climate Technologies, Inc.

28

Page 30

11. Alarm Codes

Code Description Alarm Level Diagnostic Resolution Possible Fix

Check wire connection to the

E01

E02

E03

E04

E05

E06

E07

E09-E10 Current sensor error Alarm

E11-E13 Voltage sensor error Alarm

E20

L20

E21

L21

E22

E23

L23

E24

L24

Suction pressure

transducer error

Condenser

temperature sensor

error

Discharge line

temperature sensor

error

EVI heat exchanger

vapor inlet temperature

error (XFALs only)

EVI heat exchanger

vapor outlet

temperature error

(XFALs only)

Ambient temperature

sensor error

Liquid line temperature

sensor error (XFALs

only)

Lost phase error/

lockout (Three phase

only)

Phase sequence error

/ lockout (Three phase

only)

Phase imbalance

(Three phase only)

Over current error/

lockout

Open run circuit error/

lockout

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Lockout

Alarm

Lockout

Alarm Check incoming electrical power Correct incoming voltage supply

Alarm

Lockout

Alarm

Lockout

top of the controller (A1)

Check to ensure suction

pressure is below 135 PSIG

Check wire connection to the

top of the controller (A2)

Check wire connection to the

top of the controller (A3)

Check wire connection to the

top of the controller (A4)

Check wire connection to the

top of the controller (A5)

Check wire connection to the

top of the controller (A6)

Check wire connection to the

top of the controller (A7)

Check wires are properly routed

through controller current

transducers per wiring diagram

Check wires are connected to

voltage sensing connections (R,

S, T) per wiring diagram

Check power to unit

Reverse two phases incoming

power to unit

Conrm system operation to

nd out what is causing the

compressor to pull excessive

current

Check run capacitor

Replace faulty suction pressure

transducer

Replace faulty temperature

sensor

Replace faulty temperature

sensor

Replace faulty temperature

sensor

Replace faulty temperature

sensor

Replace faulty temperature

sensor

Replace faulty temperature

sensor

Replace faulty controller

Replace faulty controller

Check wires are connected to

voltage sensing connections (R,

S, T) per wiring diagram

Check wires are connected to

voltage sensing connections (R,

S, T) per wiring diagram

Check start component wiring

per diagram

Check wires are properly routed

through controller current

transducers per wiring diagram

AE5-1412 R1

© 2016 Emerson Climate Technologies, Inc.

29

Page 31

Code Description Alarm Level Diagnostic Resolution Possible Fix

Check start component wiring

E25

L25

E26

L26

E27

L27

E28

E40

L40

E44

L44

E46

E47

E48

E50

E80

E81

E82-E85 Conguration Errors Alarm

L86

Open start circuit error/

lockout

Under voltage alarm/

lockout

Over voltage alarm/

lockout

Compressor protector

trip

High pressure switch

trip/ lockout

Discharge line

temperature alarm/

lockout

High condenser

temperature alarm

Over injection (XFALs

only)

Refrigerant shortage

(XFALs only)

High side ood back

alarm

Rtc warning, date not

correct

Rtf warning,

communication error

EEPROM Memory

Error

Alarm

Lockout

Alarm

Lockout

Alarm

Lockout

Warning

Alarm

Lockout

Alarm

Lockout

Alarm

Warning

Warning Check refrigerant charge

Warning

Warning Set the real time clock

Warning

Lockout

Check start capacitor

Check incoming power

Check incoming power

Check to see if compressor is

tripped on protector

Check system cause of high

pressure trip

Check if circuit breaker is

tripped (It provides power to the

high pressure switch)

Check system cause of high

DLT

Check to see what is causing

the system to run at a higher

condensing temperature

Check to see if proper

superheat is being maintained

Reload factory settings with the

hotkey and reset the real time

clock

Reload factory settings with the

hotkey

Reload factory settings with the

hotkey

Check wires are properly routed

transducers per wiring diagram

Check to see if contactor is

Check contractor control circuit

Ensure wiring to terminal C2

of the controller is correct per

the wiring diagram and C2 is

is working properly or needs

Check sensor values versus

Check sensor values versus

EVI injection valve may not be

per diagram

through controller current

functioning properly

wiring per wiring diagram

receiving power.

Verify high pressure switch

replaced

Faulty temperature sensor.

section 12.

Faulty temperature sensor.

section 12.

clogged or blocked

Replace faulty controller

Replace faulty controller

Replace faulty controller

AE5-1412 R1

© 2016 Emerson Climate Technologies, Inc.

30

Page 32

12. Sensor Values

Discharge Line

Temperature Sensor Resistance

°F

-40 2889.60

-31 2087.22

-22 1522.20

-13 1121.44

-4 834.72

5 627.28

14 475.74

23 363.99

32 280.82

41 218.41

50 171.17

59 135.14

68 107.44

77 86.00

86 69.28

95 56.16

104 45.81

113 37.58

122 30.99

131 25.68

140 21.40

149 17.91

158 15.07

167 12.73

176 10.79

185 9.20

194 7.87

203 6.77

212 5.85

221 5.09

230 4.45

239 3.87

248 3.35

257 2.92

266 2.58

275 2.28

284 2.02

293 1.80

302 1.59

311 1.39

320 1.25

329 1.12

338 1.01

347 0.92

356 0.83

Resistance

(kOhms)

Temperature Sensor Resistance

(Excludes DLT)

°F

-55 302.2

-50 254.9

-45 221.7

-40 188.5

-35 160.2

-30 140.4

-25 120.2

-20 105.7

-15 90.8

-10 80.3

-5 69.4

0 61.5

5 53.4

10 46.5

15 41.5

20 36.3

25 32.4

30 28.5

35 25.6

40 22.5

45 20.3

50 18.0

55 15.9

60 14.4

65 12.8

70 11.6

75 10.4

80 9.46

85 8.47

Resistance

(kOhms)

AE5-1412 R1

°F

90 7.73

95 6.94

100 6.25

105 5.73

110 5.17

115 4.75

120 4.30

125 3.96

130 3.59

135 3.32

140 3.02

145 2.75

150 2.55

155 2.33

160 2.16

165 1.98

170 1.84

175 1.69

180 1.58

185 1.45

190 1.34

195 1.25

200 1.15

205 1.08

210 0.998

215 0.937

220 0.868

225 0.816

230 0.758

Resistance

(kOhms)

© 2016 Emerson Climate Technologies, Inc.

31

Page 33

13. Parameters

Label Description Default Range

Default Display Value

Current Suction Pressure (PSIG)

Adjustable in Programming Menu

Compressor

Cin / Compressor cut in pressure set point (PSIG) 25.0 Cou - 135

CoU / Compressor cut out pressure set point (PSIG) 15.0 0 - Cin

rEF / Refrigerant Selection for Regulation R404A All unit Refs

Low Side Control

idF / interval between defrost cycles (hour) 8 0 - 120

MdF / Maximum length for defrost (min) 45 0 - 255

EdF / Defrost interval mode in nu, in, RTC

Ld1 / Workday defrost start 1 (hour) 6:00 nu, 0:00 - 23:50

Ld2 / Workday defrost start 2 (hour) 13:00 nu, 0:00 - 23:50

Ld3 / Workday defrost start 3 (hour) 21:00 nu, 0:00 - 23:50

Ld4 / Workday defrost start 4 (hour) nu nu, 0:00 - 23:50

Ld5 / Workday defrost start 5 (hour) nu nu, 0:00 - 23:50

Ld6 / Workday defrost start 6 (hour) nu nu, 0:00 - 23:50

Real Time Clock

Min / Current minute 0 - 59

Hr / Current hour 0 - 23

MdY / day of month 1 - 31

Mon / month 1 - 12

YEr / year 0 - 99

Password

PAS / Enter into PR2 level 321 (blank)

Adjustable from Advanced Options Menu

Probe Conguration

P1F / Probe P1 calibration (PSIG) 0.0 -12.0 - 12.0

Display

Lod / Remote Display visualization P1 P1 - P7

Compressor

LAS /

LMO / Low ambient minimum on time (sec) 6 0 - 255

Ambient temperature required to initiate low

ambient on time (°F)

-20 -40 - 230

AE5-1412 R1

© 2016 Emerson Climate Technologies, Inc.

32

Page 34

AE5-1412 R1

Label Description Default Range

Compressor Safety

odS / Output delay at start up (sec) 6 0 - 255

Con / Compressor On time with faulty probe (min) 3 0 - 255

CoF / Compressor OFF time with faulty probe (min) 3 0 - 255

2oF / Compressor Minimum Off Time (sec) 120 1 - 900

HPn /

bMP / Bump start enable YES no, yes

dLn /

MCS / Minimum Condenser set point (°F)

dFd / Display during defrost dEF

Fdt / Drip time (min) 0 0 - 120

dPo / Defrost at power-on NO no, yes

Sd1 / Holiday defrost start 1 (hour) 6:00 nu, 0:00 - 23:50

Sd2 / Holiday defrost start 2 (hour) 13:00 nu, 0:00 - 23:50

Sd3 / Holiday defrost start 3 (hour) 21:00 nu, 0:00 - 23:50

Sd4 / Holiday defrost start 4 (hour) nu nu, 0:00 - 23:50

Sd5 / Holiday defrost start 5 (hour) nu nu, 0:00 - 23:50

Sd6 / Holiday defrost start 6 (hour) nu nu, 0:00 - 23:50

Hd1 / First Weekly holiday nu Sun - Sat

Hd2 / second weekly holiday nu Sun - Sat

FnC / Fans operating mode on cn, on, cy, oy

MC2 / Adjustable current limit before trip (Amps) MCA 0 - MCA

oCn / Over Current Trips before lockout 5

PEn / loss of phase trips number before lockout 5

Utn / compressor trips before lockout 5

PiC /

Adr / Serial address 1 1 - 247

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its afliates (collectively "Emerson"),

as applicable, reserve the right to modify the design or specications of such products at any time without notice. Emerson does not assume responsibility for the

selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson product remains solely with the purchaser

or end user.

© 2016 Emerson Climate Technologies, Inc.

Number of high pressure switch activation

before compressor lock

Number of activation of DLT in a hour to lock

compressor

Condenser Fan

Low Side Control

Compressor Protection

Generate warning or shut the regulation when

phase imbalance

Serial Address

33

5 0 - 15

4 0 - 15

70 - XFAP

80 - XFAL

-40 - 230

DEF, Setpoint, Initial

Pressure, End Pressure

0 - 15; 0 = always

automatic restart

0 - 15; 0 = always

automatic restart

0 - 15; 0 = always

automatic restart

Trip Warning, Trip

Page 35

2015ECT-53 R1 (4/17) Emerson, Copeland Scroll and CoreSense are trademarks of Emerson Electric Co. or one of its affi liated companies.

©2017 Emerson Climate Technologies, Inc. All rights reserved.

Emerson.com

Loading...

Loading...