Page 1

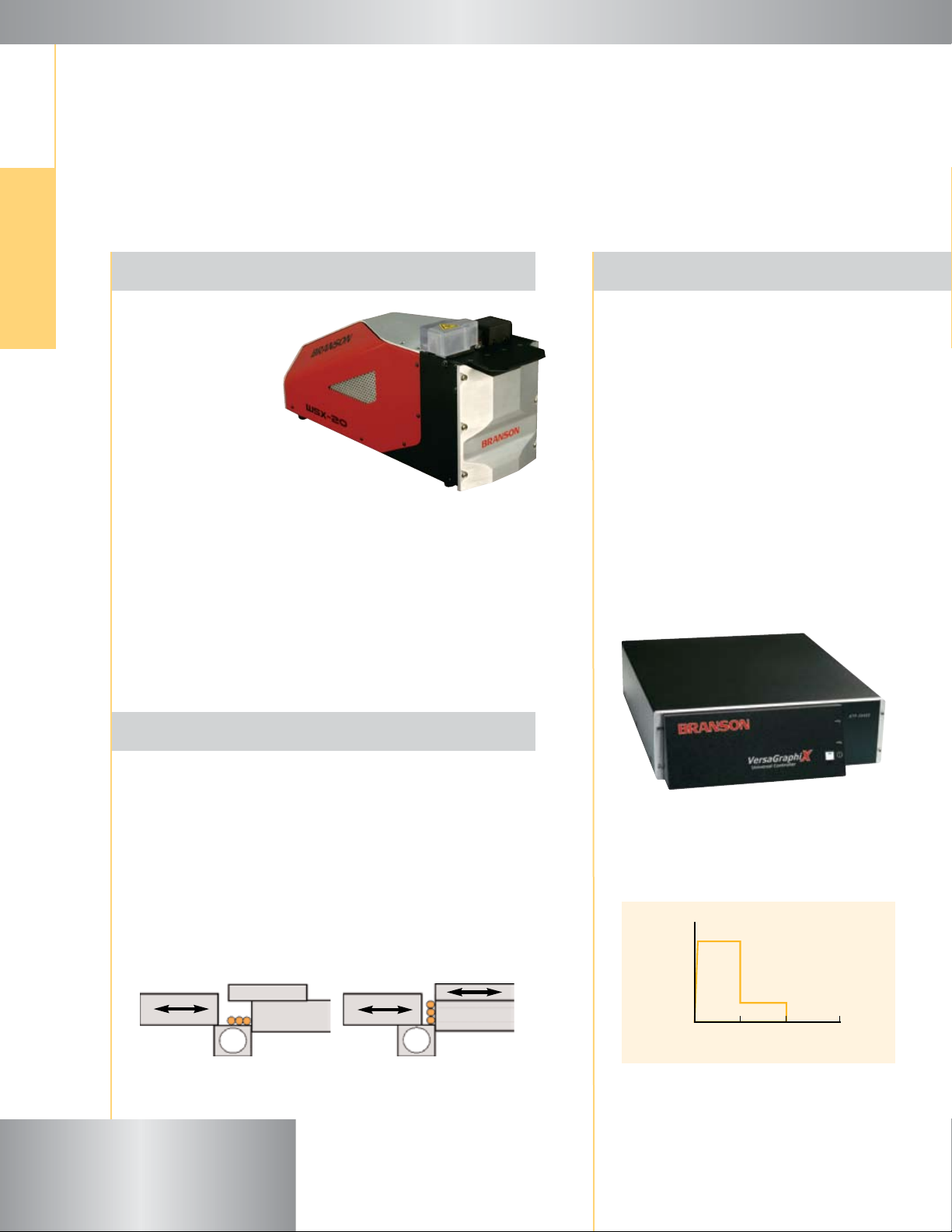

WSX-20

Ultrasonic Metal Welding

Assembly Systems

A full-range, fully programmable, and remarkably

economical wire splicing system

Page 2

Instantly adjustable parameters. More precise

and reliable splices. And a whole lot more!

WSX-20 Ultrasonic Splicing System

• Capable of splicing from

2

CSA

0.48 to 40 mm

(cross sectional area

• Flexibly designed

bench top unit can

be mounted in a

workstation table

• Automatically adjus

parameters and par

• Uniquely designed 4-lobe keyed tip and 4-surface

anvil provides longer tool life – and the lowest maintenance

cost in the industry!

• Replaceable tip technology provides high tool life at low cost

• P atented vertical stacking design prevents side splicing, a major

cause of field failures

• Patented closed-loop amplitude control helps ensure weld

consistency

)

table splice

ameter sequencing

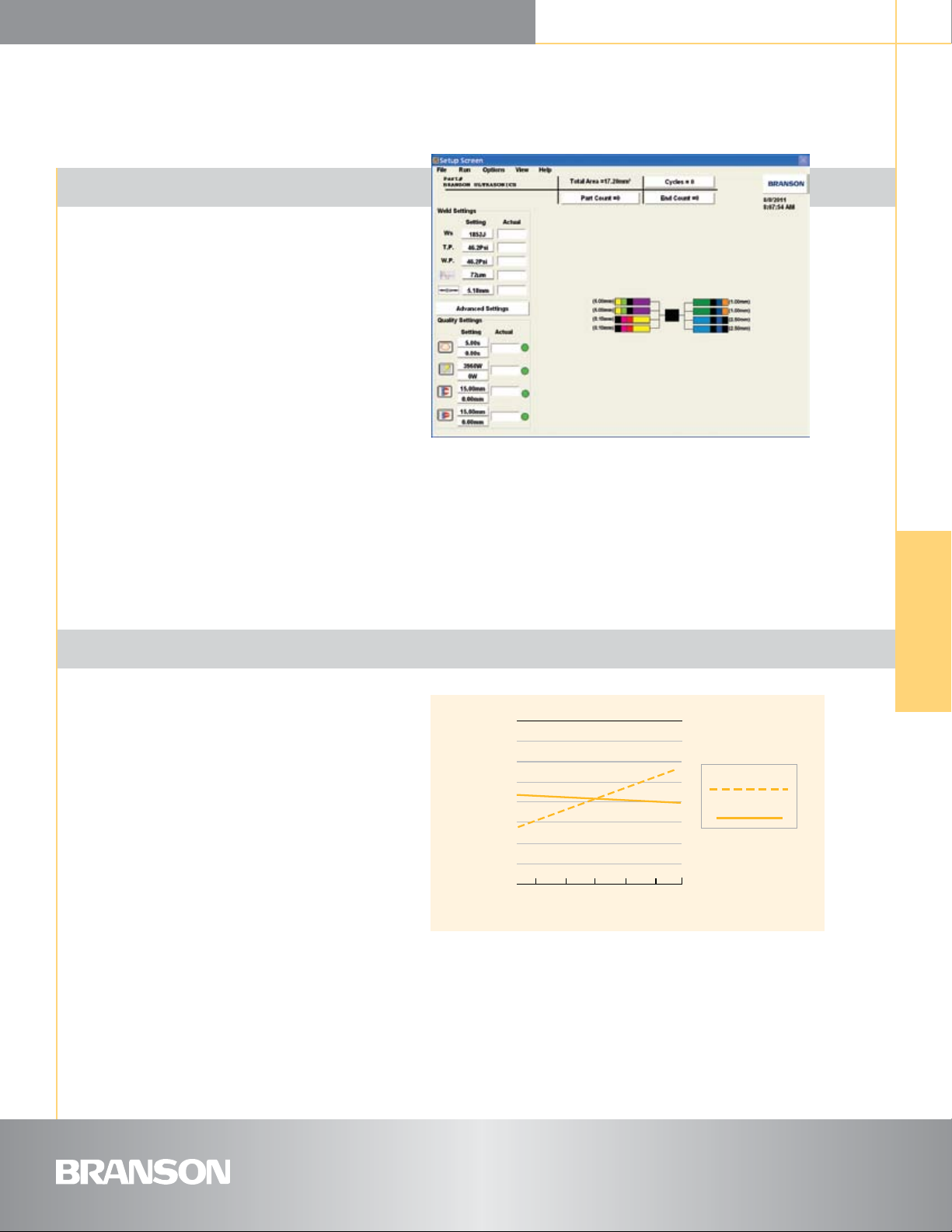

VersaGraphix Controller

• 20 kHz Ultrasonic Generator with Three

Teach Modes – Automatically calculates

your weld quality windows for Time, Power,

Pre-Height and Height.

• Four Weld Modes – Weld by Energy, Time,

Height (compaction), and Energy with

Height Compensation.

• Extensive Preset Library – Stores configu-

ration data for up to 1,000 parts for sequential

welding capability.

• Weld History – Weld results and graph are

stored on the hard drive in a date-stamped

folder and can be sent as needed via Ethernet.

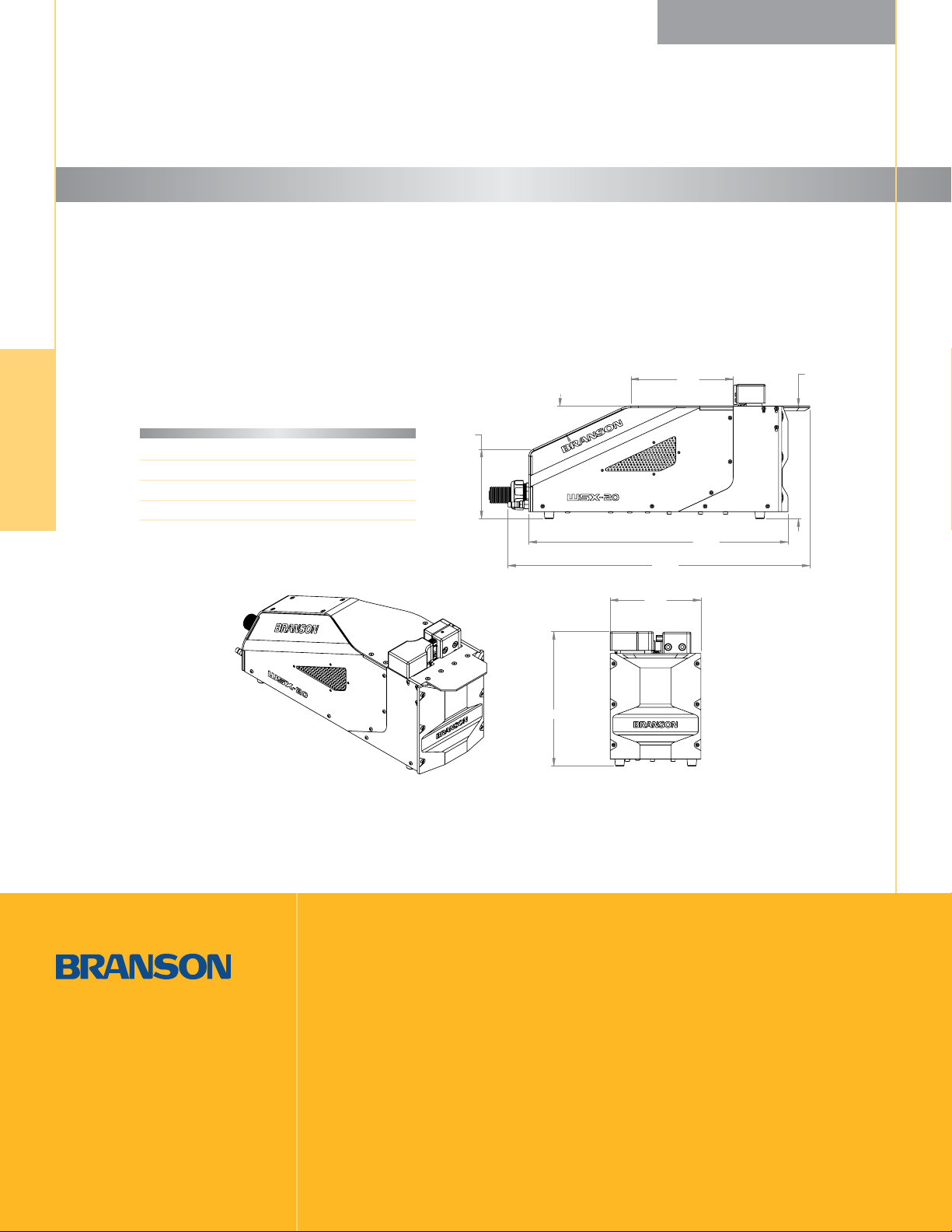

Patented Anti-Side-Splice Feature

• Prevents Side Spicing – One of the most common causes of

poor splices and field failure. When operators place the wires flat

on the tip (as shown in Figure 1a), only the tangent point of each

cable can be welded together.

• Vertical Stacking Fixes the Problem – By allowing operators to

vertically stack the wires (as shown in Figure 1b), a consistently

high-quality splice is ensured. The WSX-20 is the only ultrasonic

splicing system to offer this critical feature.

Figure 1a Figure 1b

• Patented Amplitude Stepping – Built-in

digital amplitude control for optimization of

weld strength and aluminum welding.

See Figure 2.

100

80

60

40

20

Amlitude (um)

0

0 500 1000 1500

Time (mS)

Figure 2

• Propor tioned Cooling Air — Automatically

applies the correct amount of cooling air,

based upon wire size, for optimum tool life

at minimum cost.

Page 3

1200

1100

1000

900

800

700

600

500

400

100

80

60

40

20

0

-15 -10 -5 0 5 10 15

0 500 1000 1500

Weld Strength

(lbs)

Time (mS)

Amlitude (um)

Under Welded

Over Welded

Relative Line Voltage (%)

User Interface

100

80

60

40

20

0

0 500 1000 1500

Time (mS)

Amlitude (um)

Under Welded

Over Welded

Without Regulation With Regulation

Relative Line Voltage (%)

Time (mS)

• 15˝ (381 mm) LCD Touch Monitor –

Enables intuitively easy system navigation with

fingertip control. See Figure 3.

• Embedded Windows XP Operating System –

Minimizes the learning curve, so you can be up

and running sooner.

• Ethernet-Ready – For quick and easy dissemi-

nation of welding data.

• USB Connectivity – 4 USB ports and printer

interface allow peripheral devices to be easily

connected and facilitate file transfer.

• R S232 Connection – For easy interfacing with

Raychem shrink tube machine.

Power Supply

• True Auto-Tune with Memory (AT/M) –

Provides fully-automatic tuning and stores

horn frequency at the end of each weld.

• T otal Amplitude Control – Utilizing

Branson’s power supply technology, you have

complete control of amplitude throughout

the weld cycle: programmable starting ramp,

digital setting of weld amplitude and

patented amplitude stepping. See Figure 2.

• Progr ammable Starting Ramp – Adjustable

starting ramps from 10 milliseconds to 1.0

second to accommodate starting characteristics of a wide range of horns. This feature

makes it easier to start smaller horns.

Figure 3

• Supports Multiple Languages – Including English, French,

German, Italian, Spanish, Japanese, Korean, traditional and

simplified Chinese.

• Bar Code Readable – Automatically recalls presets or sequences

as specified on the bar code label. Helps reduce welding errors.

Figure 4

• Line/Load Regulation – Patented closed-loop amplitude control

corrects for variations due to power line fluctuations and varying

load conditions. Output amplitude will vary by only ±2% with line

voltage variations of ±10%, to ensure weld consistency. See Figure 4.

WSX-20

Page 4

WSX-20

10.74

7.25

REVISIONS

ZONE

ECN

REV.

DESCRIPTION

DATE

BY

APP

--1INITIAL RELEASE

DRAWN ON:

SCALE:

SHT QTY:

WORK ORDER:

DATE:

DIMENSIONS ARE IN INCHES [MM]

MATERIAL:

UNLESS OTHERWISE STATED

FOR ALL SPECIFICATIONS

AND TOLERANCES, REFER TO:

ENGINEERING SPECIFICATION

07/24/09

1:4

1 OF 1

C

B

E

D

A

6

3

2

4

1

5

8

7

REVISIONS

DESCRIPTION

DATE

BY

APP

1

INITIAL RELEASE

B

A

6

4

5

8

7

REVISIONS

ZONE

ECN

REV.

DESCRIPTION

DATE

BY

APP

--1INITIAL RELEASE

C

B

D

A

6

8

7

The Branson Advantage

Branson Ultrasonics is the world leader in materials joining and precision cleaning, with more than 1,800 employees

and 70 sales and service offices. We are committed to leading the industry in service and support excellence, too.

That means fast delivery, troubleshooting, parts replacement, samples testing, preventative maintenance and repair

services. We are certainly proud of our ISO 9001 (since 1994) and ISO 14001 (since 1998) certifications –

but we are equally proud to have the opportunity to serve you.

WSX-20 Specifications

Electrical

245 VAC, 15/60 Hz 1Ø 300 mp

Pneumatic

5.5 bar (80 psi) clean, dry air (0.5 µ coalescing filter)

5.56

ZONE

ECN

REV.

--

25°

10.74

7.25

24.15

8.18

20.73

9.0

Branson Ultrasonics Corp.

41 Eagle Road

Danbury, CT 06810, USA

T: 203-796-0400

F: 203-796-0450

www.bransonultrasonics.com

All specifications subject to change without notice. All dimensions are nominal. All units are CE compliant and

comply with FCC rules and regulations governing radio frequency interference.

Note: All sales shall be subject to the Supplier’s terms and conditions of sale as described in Branson’s quotations

and sales contracts.

WARRANTY: The Branson WSX-20 ultrasonic assembly systems carry a three-year warranty on materials or

workmanship.

Note: This warranty applies to equipment purchased and operated in North America. For warranty information

on units purchased and/or operated outside the U.S. contact your local representative.

WSX-20 © Branson Ultrasonics Corporation 2011

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Revised and printed in the U.S.A. 11/11

MW-0002-11-WSX-20

Loading...

Loading...