Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

Oxygen Analyzer with HPS Heater

Power Supply Field Module

(for use with Existing Signal

Conditioning Electronics)

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective October, 1995 Rev. 3

Page Summary

Page 1-1 Updated art to reflect new probe configuration.

Page 1-3 Updated art to reflect new probe configuration.

Page 1-4 Updated art to reflect new probe configuration.

Page 2-1 Update installation procedure to include optional ceramic diffusor and

vee deflector.

Page 2-2 Updated art and dimensions to reflect new probe configurations.

Page 2-3 Updated art and dimensions to reflect new probe configurations.

Page 2-8 Updated art and dimensions to reflect new probe configurations.

Effective June, 1996 Rev. 3.1

Page Summary

Page 1-3 Added ambient air note.

Page 2-3 Updated Probe Installation, Figure 2-1, sheets 1 and 2 of 5.

Effective January, 1997 Rev. 3.2

Page Summary

Page iii Added "Safety instructions for the wiring and installation of this

apparatus".

Page 2-1 Added one WARNING to read new safety instructions and another

WARNING regarding protective covers and grounds.

Page 2-9 Added WARNING regarding protective covers and grounds and added

NOTE regarding HPS fuse locations and specifications.

Page 2-11 Added NOTE regarding HPS fuse specifications to Figure 2-7.

Page 3-1 Added WARNING regarding protective covers and grounds.

Page 4-1 Added WARNING regarding protective covers and grounds.

Page 7-1 Added fuses to index listing.

Effective May, 1997 Rev. 3.3

Page Summary

Page P-2 Added safety sheets.

Effective February, 1998 Rev. 3.4

Page Summary

Page 2-2 Figure 2-1. Changed calibration gas tube dimensions.

World Class 3000

PREFACE.........................................................................................................................P1

Definitions ......................................................................................................................... P1

Safety Instructions ........................................................................................................... P2

1-0 DESCRIPTION ................................................................................................................ 1-1

1-1 Component Checklist of Typical System (Package Contents) ........................................ 1-1

1-2 Overview.......................................................................................................................... 1-1

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Oxygen Analyzer (Probe) Installation .............................................................................. 2-1

2-2 Heater Power Supply Installation .................................................................................... 2-9

3-0 SETUP............................................................................................................................. 3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Models 218, 225, and 132 (Analog) Electronics Setup .................................................. 3-1

3-3 Model 218A Electronics Setup ....................................................................................... 3-2

3-4 Model TC200 VERITRIM Electronics Setup.................................................................... 3-3

3-5 Model 132 Digital Electronics Setup................................................................................ 3-4

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

TABLE OF CONTENTS

4-0 TROUBLESHOOTING .................................................................................................... 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 System Troubleshooting.................................................................................................. 4-1

5-0 RETURN OF MATERIAL .............................................................................................. 5-1

6-0 APPENDICES ................................................................................................................. 6-1

7-0 INDEX.............................................................................................................................. 7-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

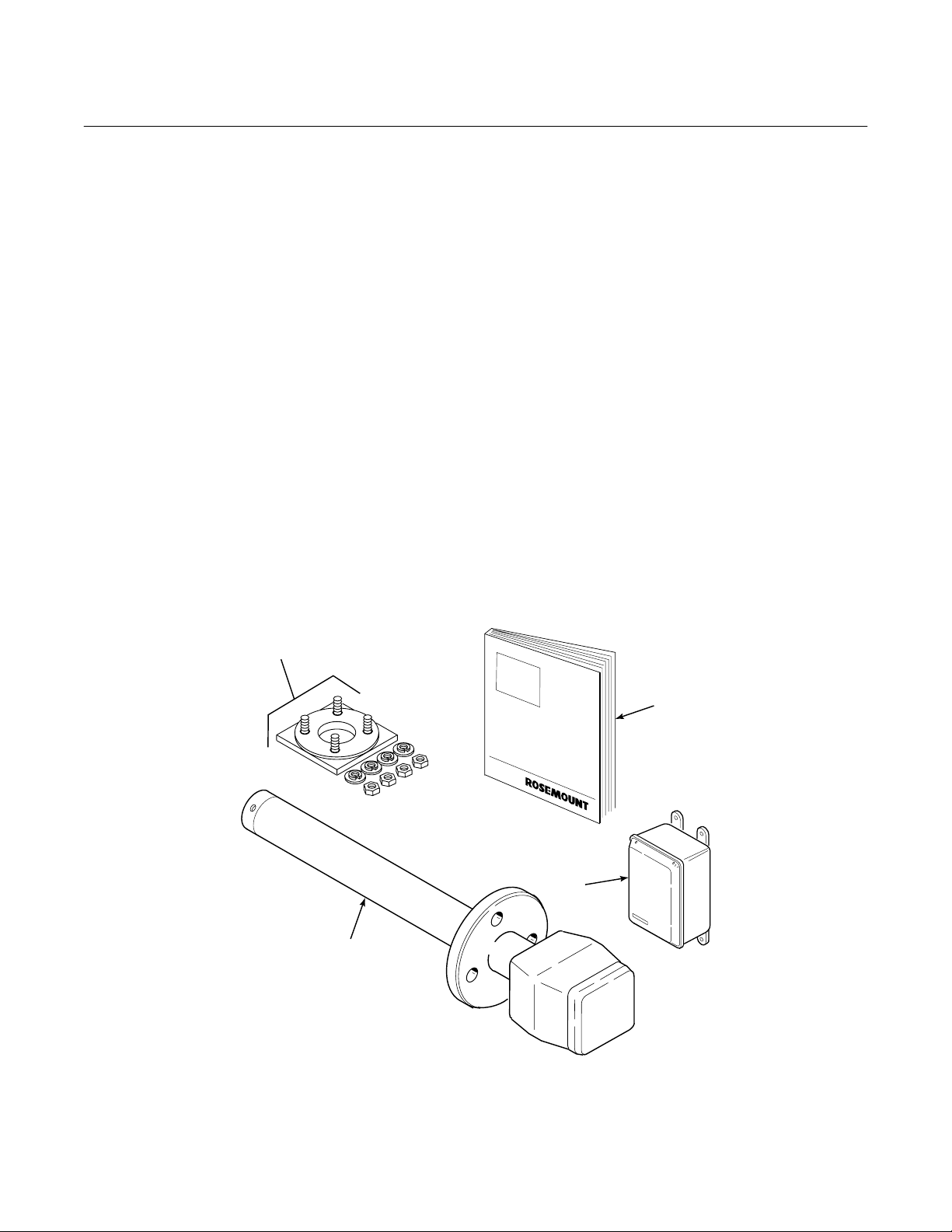

Figure 1-1. Typical System Package ....................................................................................... 1-1

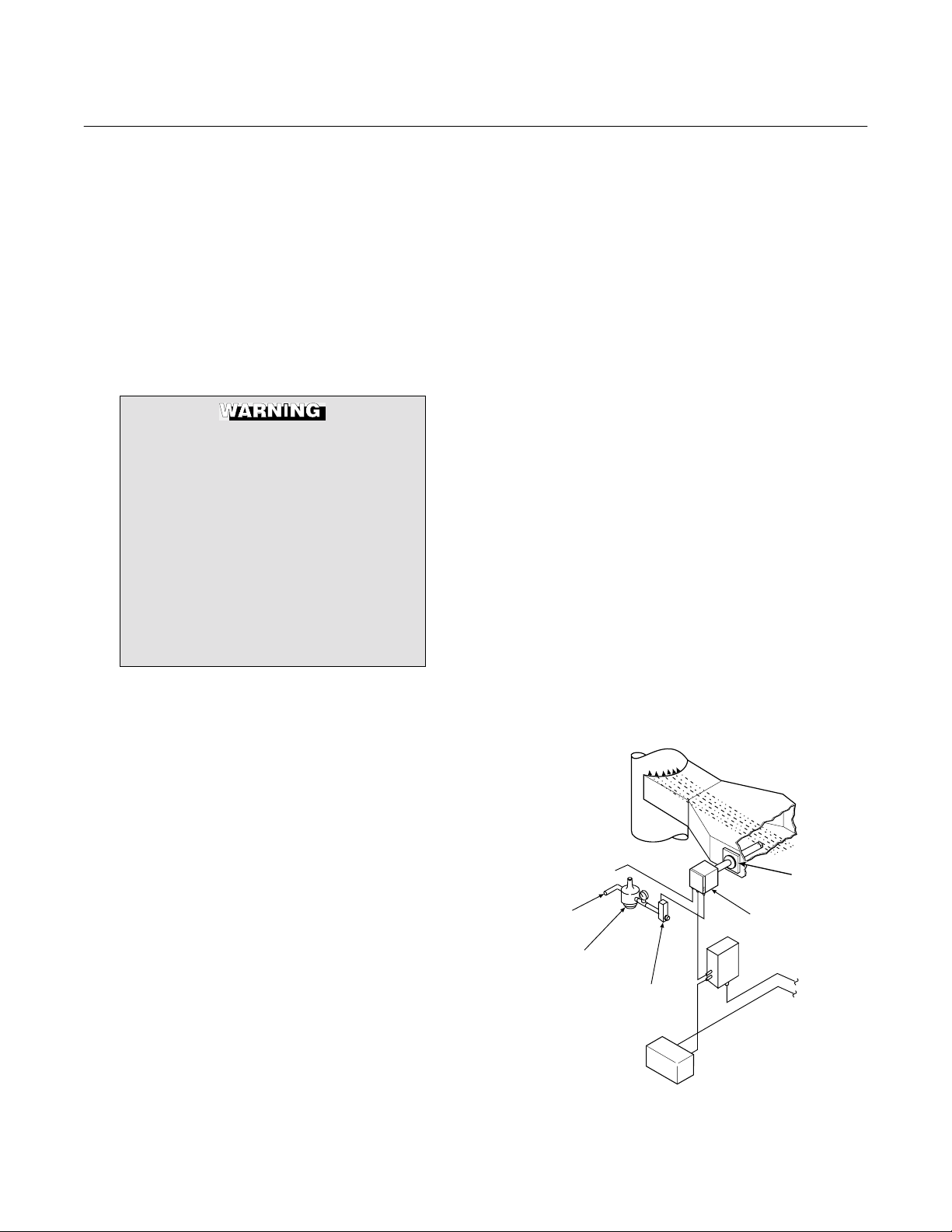

Figure 1-2. Typical System Installation .................................................................................... 1-3

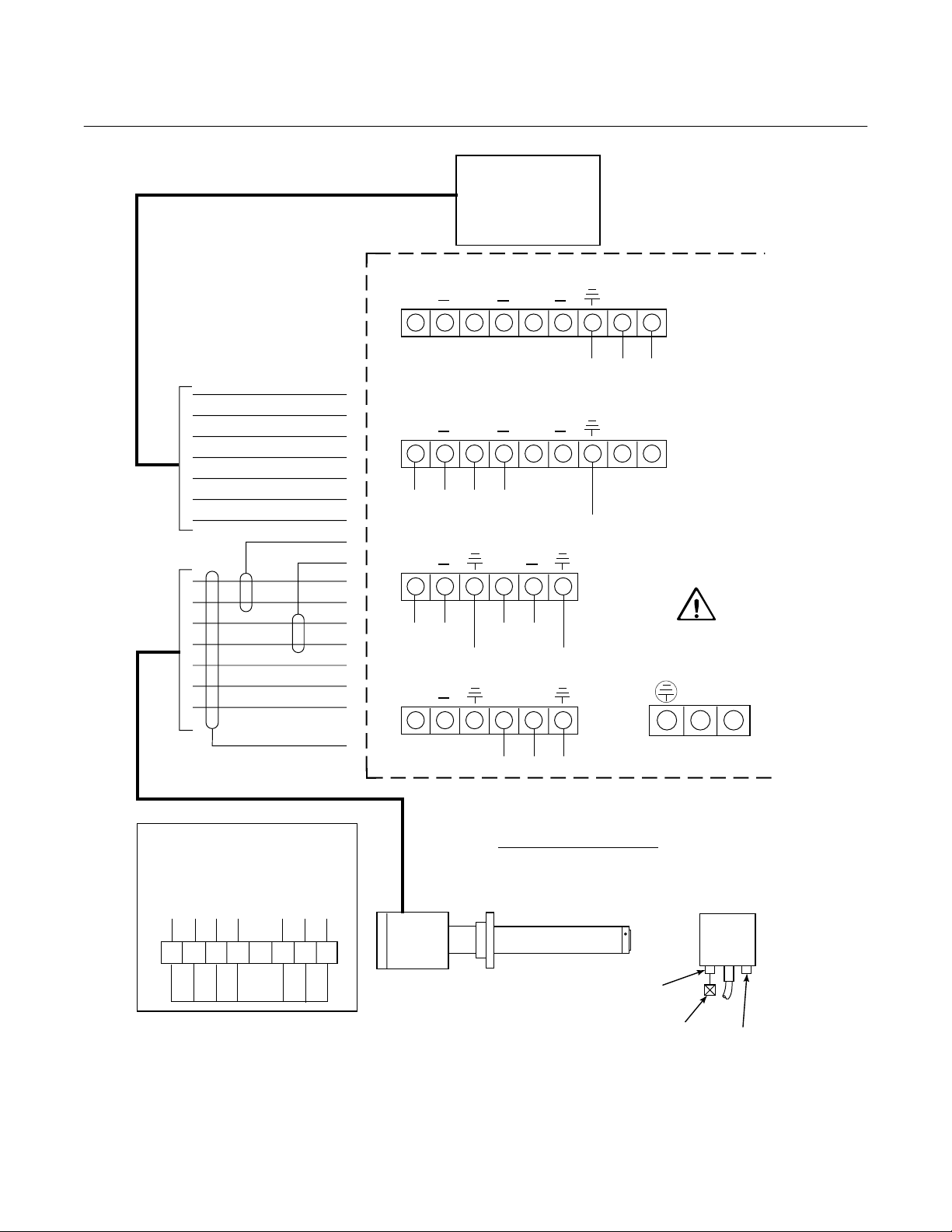

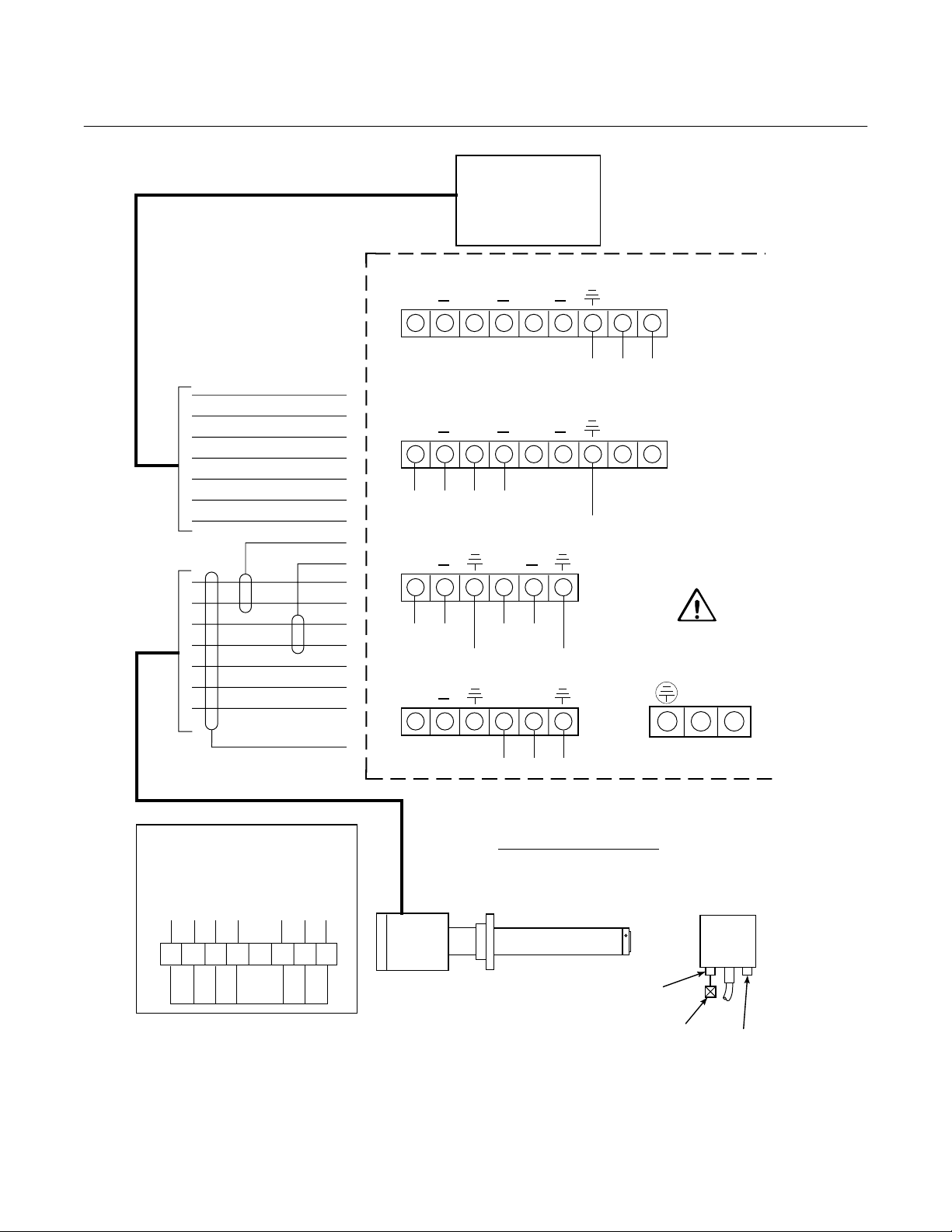

Figure 1-3. Typical System Wiring ........................................................................................... 1-4

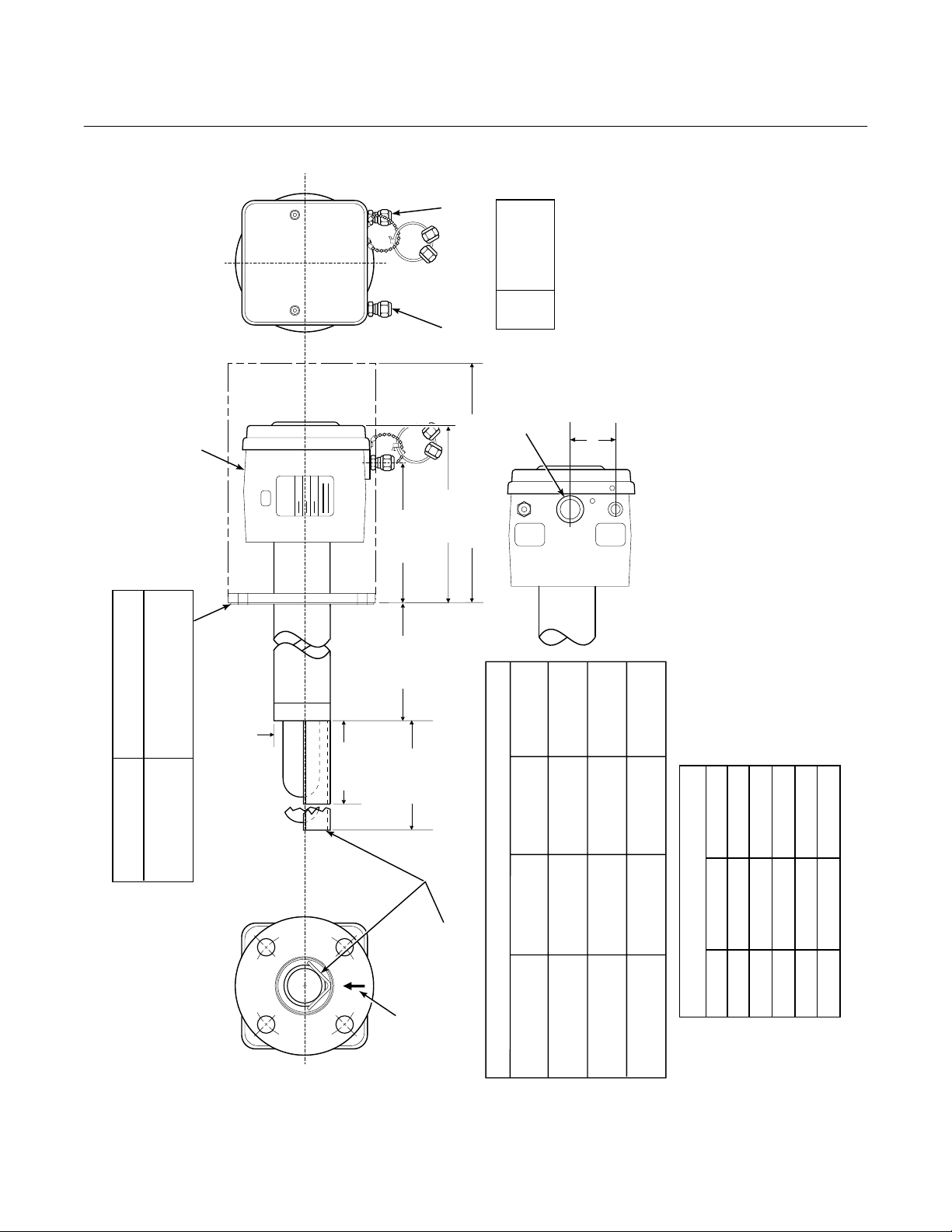

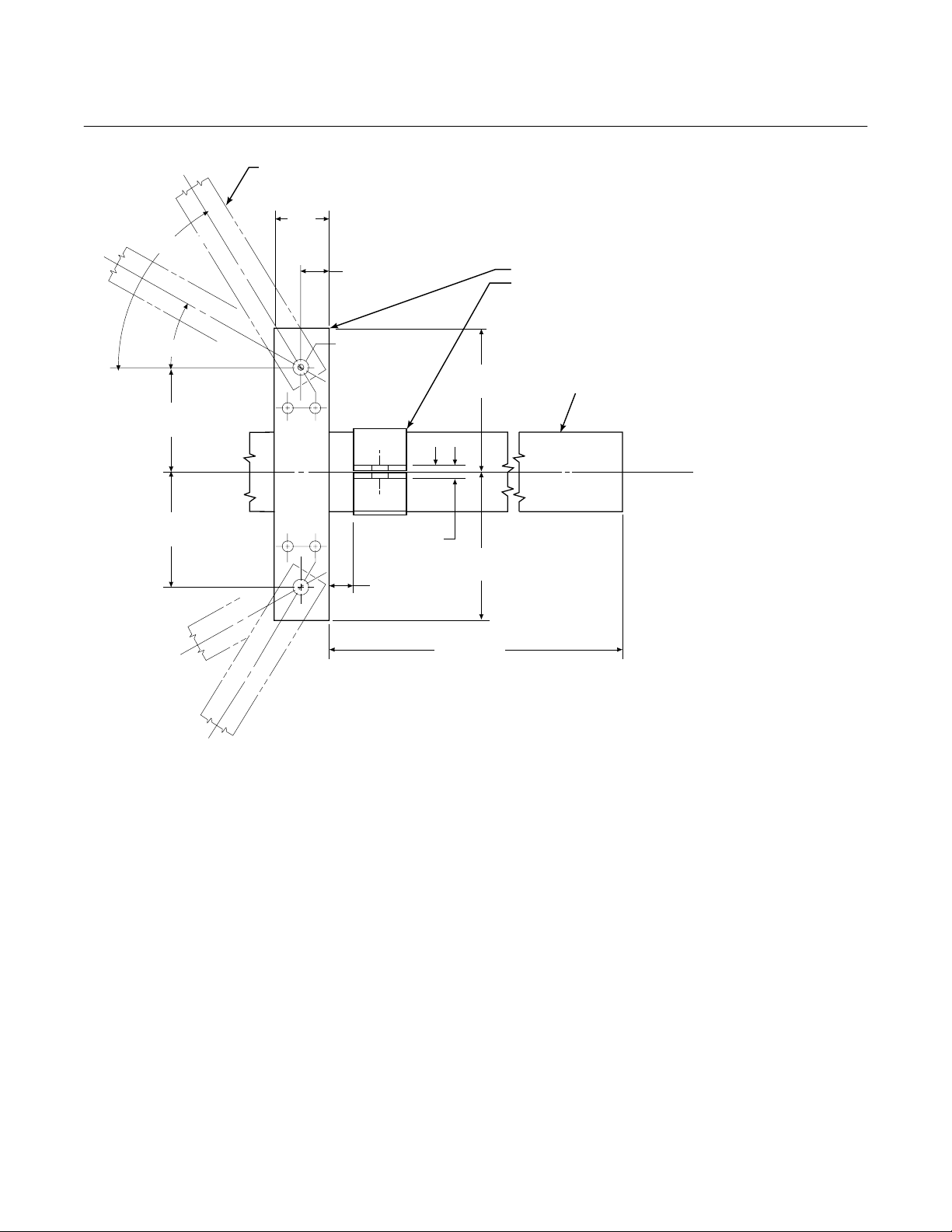

Figure 2-1. Probe Installation ................................................................................................... 2-2

Figure 2-2. Orienting the Optional Vee Deflector..................................................................... 2-7

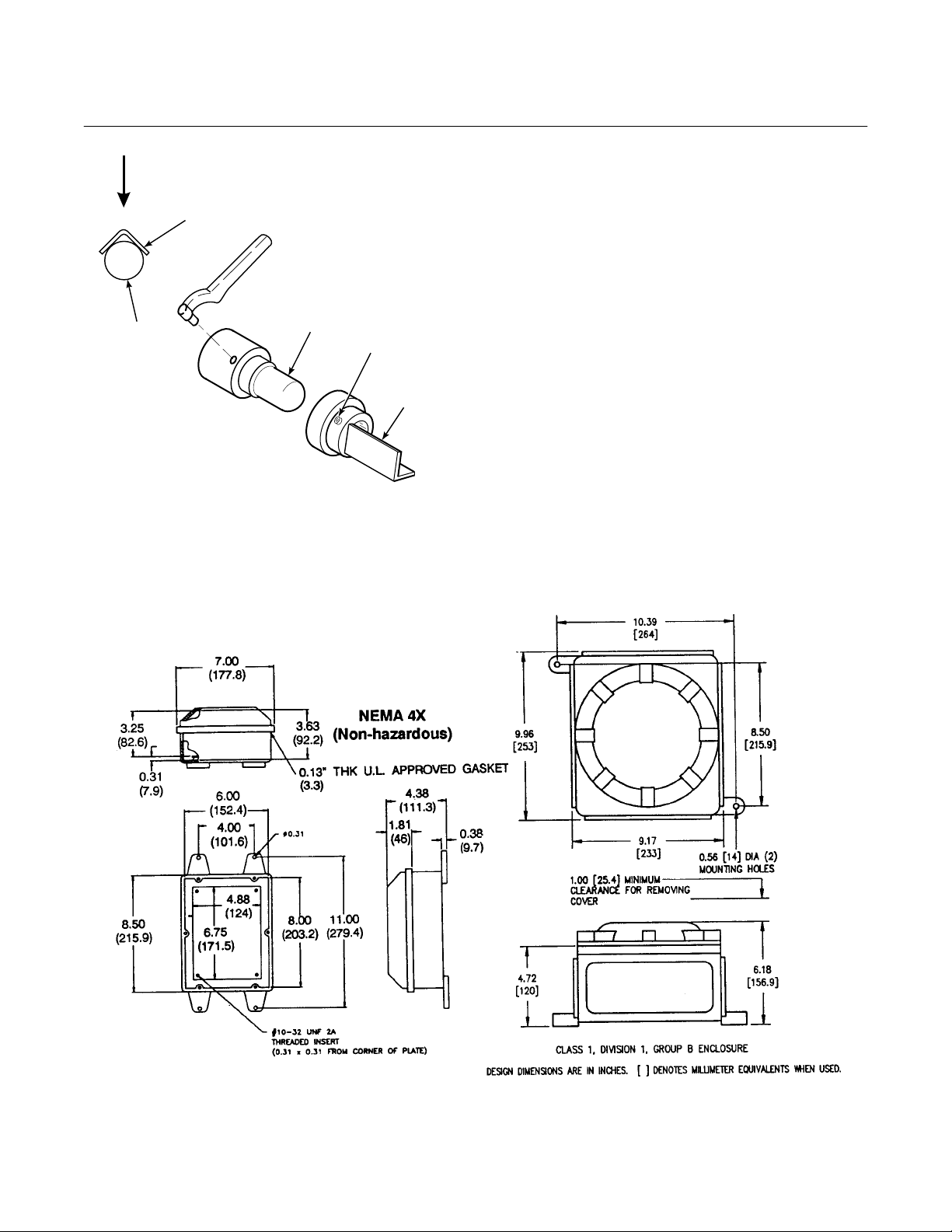

Figure 2-3. Outline of Heater Power Supply ............................................................................ 2-7

Figure 2-4. Electrical Installation of Heater Power Supply....................................................... 2-8

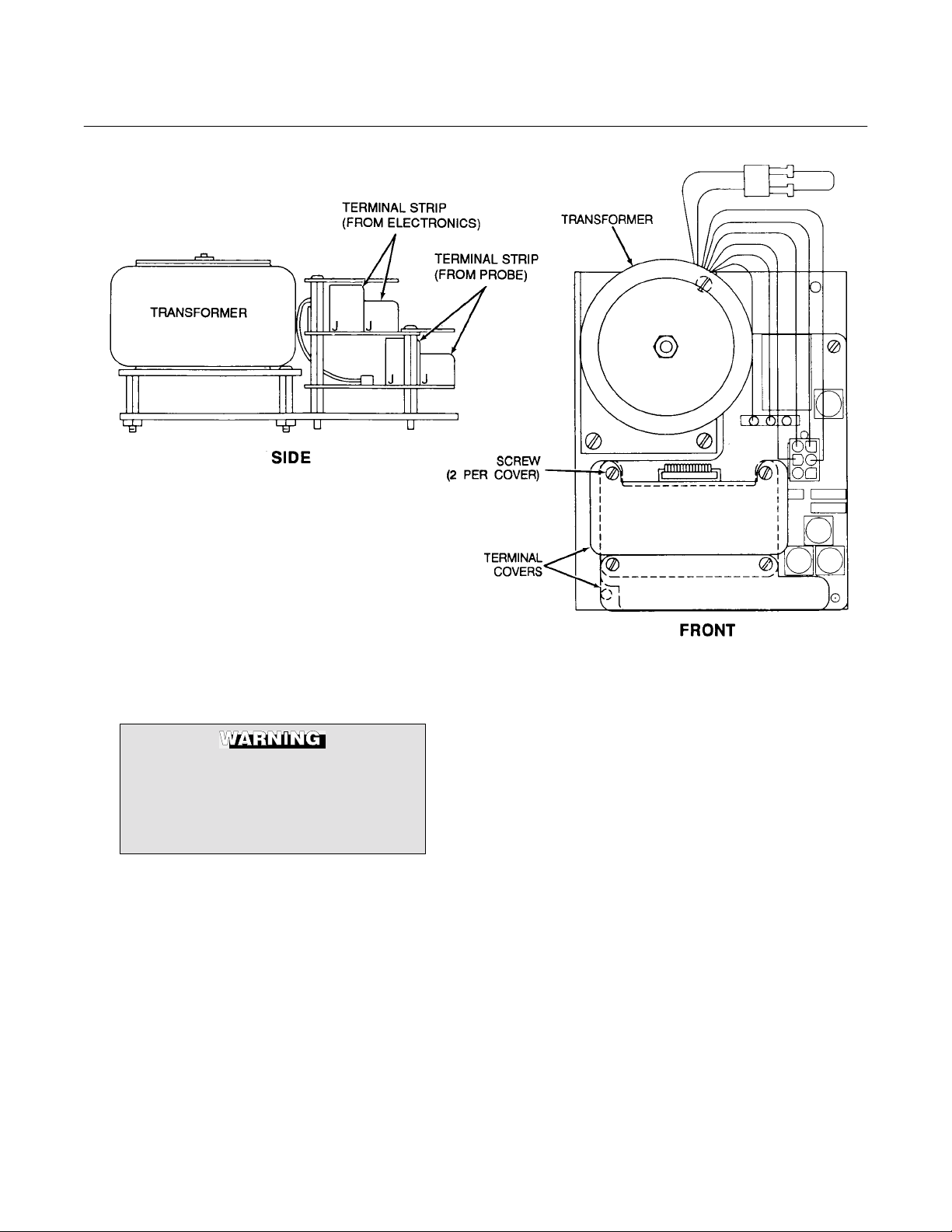

Figure 2-5. Heater Power Supply Wiring Connections ............................................................ 2-9

Figure 2-6. Jumper Selection Label ....................................................................................... 2-10

Figure 2-7. Jumpers on HPS Mother Board........................................................................... 2-11

Figure 3-1. Temperature Controller Card Calibration Points ................................................... 3-1

Figure 3-2. Main PCB (Model 218A) EPROM Replacement ................................................... 3-2

Figure 3-3. Main PCB (Model TC200) EPROM Replacement ................................................. 3-3

Figure 3-4. Main PCB (Model 132) EPROM Replacement...................................................... 3-4

World Class 3000

LIST OF ILLUSTRATIONS

ii Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

If the HPS 3000 and World Class 3000 probe are used with any of the following model

electronics; 218, 225, 218A, and TC200, read appropriate set point adjustment in Instruction

Bulletin (IB) 106-300NE to prevent damage to the World Class 3000 probe.

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of this particular oxygen analyzer.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

CAUTION

!

PREFACE

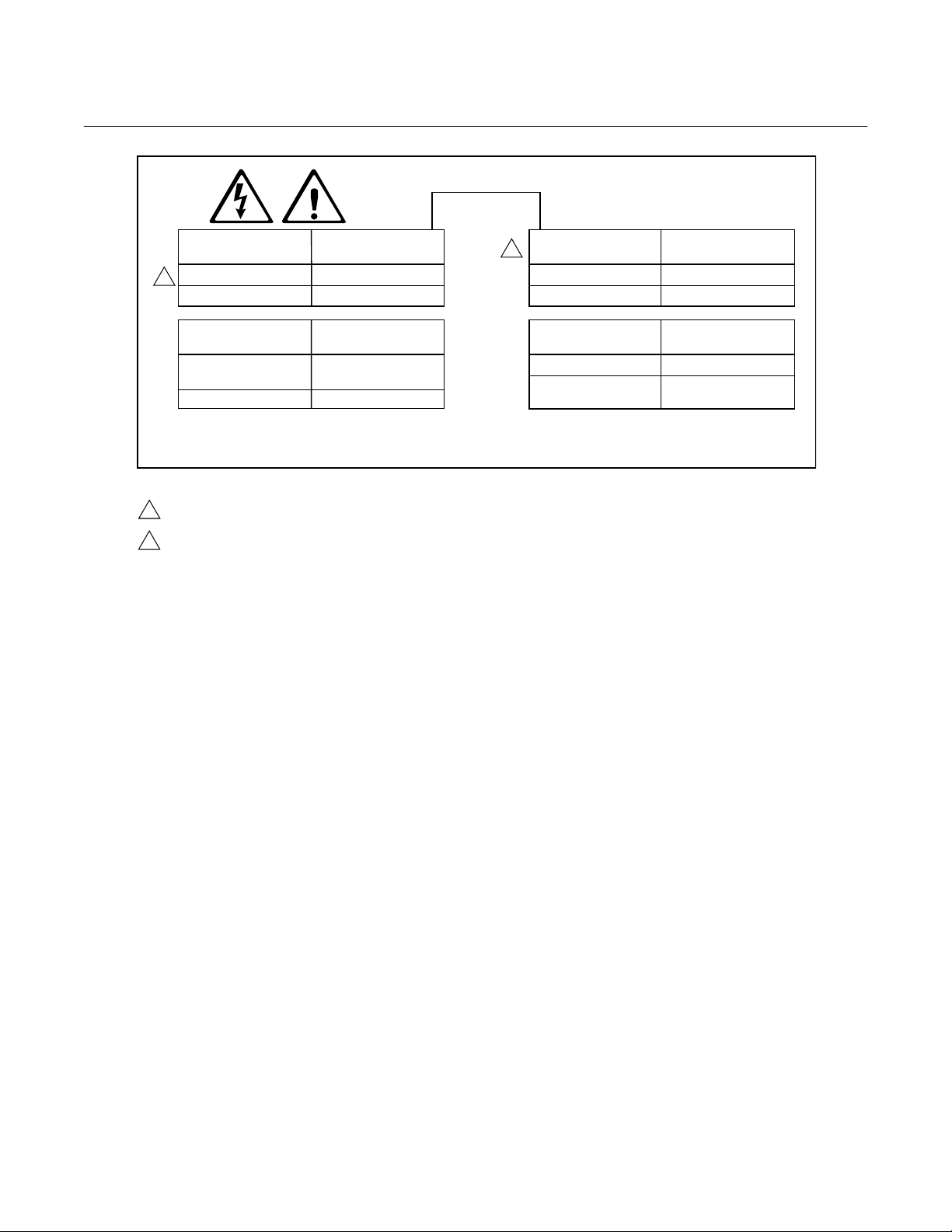

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

NOTE

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

World Class 3000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

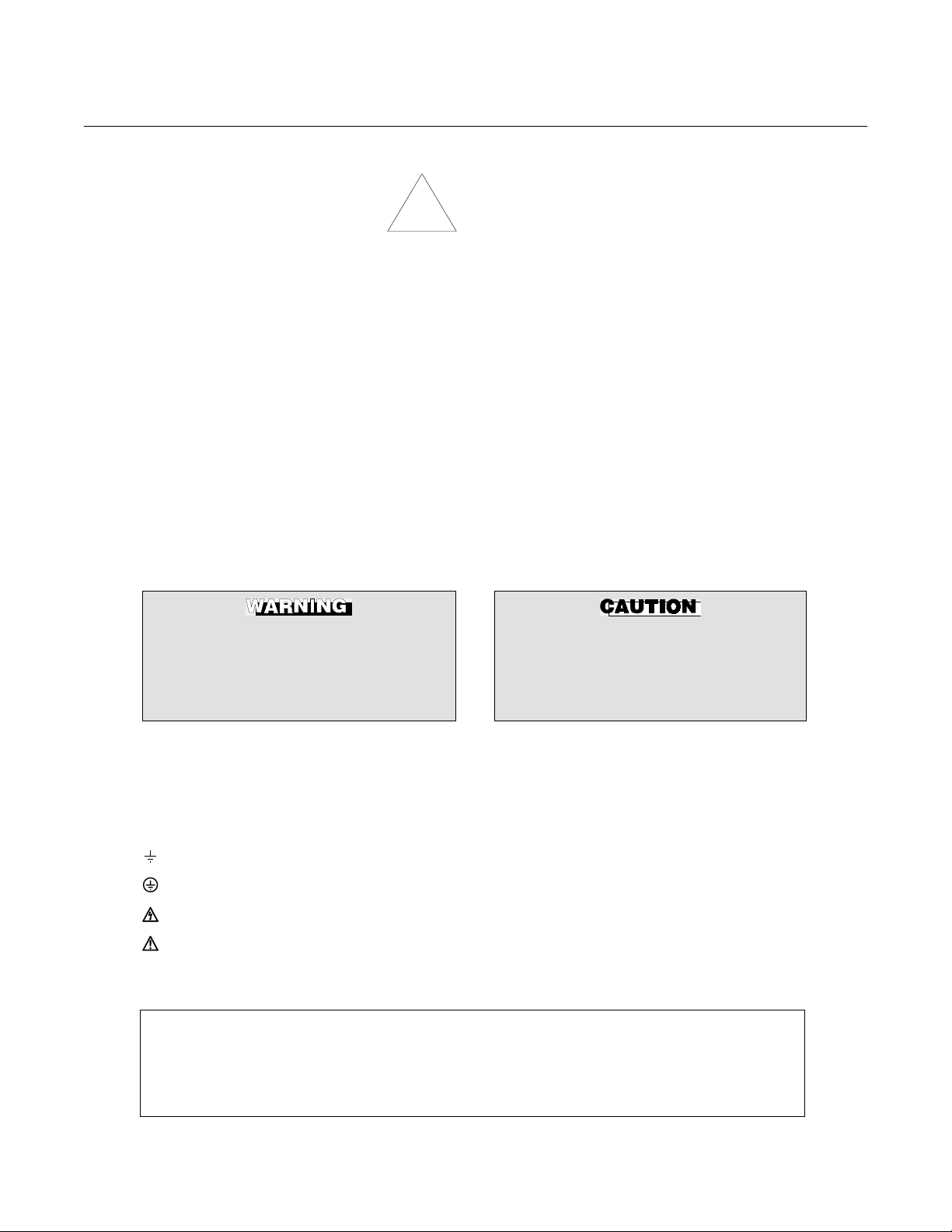

7. Where equipment or covers are marked with the symbol to the right, hazard-

ous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the follow-

ing standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

SECTION 1

DESCRIPTION

1-1 COMPONENT CHECKLIST OF TYPICAL

SYSTEM (PACKAGE CONTENTS)

A typical Rosemount World Class 3000 Oxygen

Analyzer with HPS 3000 Heater Power Supply

package should contain the items shown in

Figure 1-1. Record the Part Number, Serial

Number, and Order Number for each

component of your system in the table located

on the first page of this manual.

1-2 OVERVIEW

a. Scope

This Instruction Bulletin has been designed

to supply details needed to install, start up,

and troubleshoot the Rosemount World

Class 3000 Oxygen Analyzer with HPS

3000 Heater Power Supply Field Module.

4

The Heater Power Supply allows the

World Class 3000 Oxygen Analyzer (Probe)

to be interfaced to a number of different and

earlier model electronic packages. These

electronic packages are not covered in this

manual. For specific information concerning

calibration and operation of the system,

refer to the Instruction Bulletin applicable to

your electronics package.

b. System Description

The Rosemount Oxygen Analyzer (Probe) is

designed to measure the net concentration

of oxygen in an industrial process; i.e., the

oxygen remaining after all fuels have been

oxidized. The probe is permanently positioned within an exhaust duct or stack and

performs its task without the use of a sampling system.

1. Oxygen Analyzer (Probe)

2. Heater Power Supply

3. Instruction Bulletin

4. Mounting Adaptor Plate

with Mounting Hardware

and Gasket

3

2

1

19260001

Figure 1-1. Typical System Package

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-1

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

The equipment measures oxygen percentage by reading the voltage developed

across a heated electrochemical cell, which

consists of a small yttria-stabilized, zirconia

disc. Both sides of the disc are coated with

porous metal electrodes. When operated at

the proper temperature, the millivolt output

voltage of the cell is given by the following

Nernst equation:

EMF = KT log

10(P1/P2

) + C

Where:

1. P

is the partial pressure of the oxygen

2

in the measured gas on one side of the

cell,

2. P

is the partial pressure of the oxygen

1

in the reference gas on the other side,

3. T is the absolute temperature,

4. C is the cell constant,

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry,

instrument air (20.95% oxygen) as a

reference gas.

When the cell is at operating temperature

and there are unequal oxygen concentrations across the cell, oxygen ions will travel

from the high partial pressure of oxygen

side to the low partial pressure side of the

cell. The resulting logarithmic output voltage

is approximately 50 mV per decade. Because the magnitude of the output is proportional to the logarithm of the inverse of

the sample of the oxygen partial pressure,

the output signal increases as the oxygen

concentration of the sample gas decreases.

This characteristic enables the oxygen

analyzer to provide exceptional sensitivity at

low oxygen concentrations.

Oxygen analyzer equipment measures net

oxygen concentration in the presence of all

the products of combustion, including water

vapor. Therefore, it may be considered an

analysis on a "wet" basis. In comparison

with older methods, such as the Orsat apparatus, which provides an analysis on a

"dry" gas basis, the "wet" analysis will, in

general, indicate a lower percentage of

oxygen. The difference will be proportional

to the water content of the sampled gas

stream.

c. System Configuration

The equipment discussed in this manual

consists of two major components; the oxygen analyzer (probe), and the heater power

supply.

Probes are available in five length options,

giving the user the flexibility to use an in situ

penetration appropriate to the size of the

stack or duct. The options on length are 18

inches (457 mm), 3 feet (0.91 m), 6 feet

(1.83 m), 9 feet (2.74 m), or 12 feet

(3.66 m).

The heater power supply (HPS) provides an

interface to the electronics package and

contains a transformer for supplying proper

voltage to the 44 Vac and 115 Vac probe

heaters. The enclosure has been designed

to meet NEMA 4X (IP56) specifications for

water tightness; an optional enclosure to

meet Class 1, Division 1, Group B (IP56)

explosion-proof is also available.

The oxygen analyzer is connected to the

HPS and electronics package using seven

wires housed within the connecting system

cable.

d. Features

1. Unique and patented cell protection

action that automatically protects

sensor cell when analyzer detects

reducing atmospheres.

2. Output voltage and sensitivity increase

as the oxygen concentration

decreases.

3. In situ, non-sampling analyzer.

4. Field replaceable cell.

5. Analyzer constructed of rugged 316

LSS for all wetted parts.

1-2 Description Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

6. Suitable for use in temperatures up to

1300°F (700°C).

7. Heater power supply allows World

Class 3000 probe to be interfaced with

existing analog and 218A digital

electronic packages.

8. Optional explosion-proof HPS enclosure allows use in hazardous gas

areas.

e. Handling the Oxygen Analyzer

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to

prevent possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from

ceramics, which are susceptible to

shock when mishandled.

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in

case any components are to be

shipped to another site. This packaging has been designed to protect the

product.

f. System Considerations

Prior to installation of your Rosemount

World Class 3000 Oxygen Analyzer with

Heater Power Supply Field Module, make

sure you have all of the components necessary to make the system installation. Ensure

all components are properly integrated to

make the system functional.

Once you have verified you have all the

components, select mounting locations and

determine how each component will be

placed in terms of available power supply,

ambient temperatures, environmental considerations, convenience, and serviceability.

A typical installation is illustrated in Figure

1-2 and Figure 1-3.

After selecting the probe mounting location,

provision should be made for a platform

where the probe can be easily serviced.

The heater power supply can be located up

to 150 feet (45 m) cable distance from the

probe.

A source of instrument air is required at the

probe for reference gas use. Since the

probe is equipped with an in place calibration feature, provision should be made for

connecting test gas tanks to the oxygen

analyzer when the probe is to be calibrated.

NOTE

Ambient air is not recommended for

use as high test gas. An 8% O

ance in nitrogen is recommended for

high test gas.

If test gas bottles will be hooked up permanently, a check valve is required next to the

calibration fittings on the probe junction box.

This is to prevent breathing of calibration

gas line and subsequent flue gas condensation and corrosion. The check valve is in

addition to the stop valve in the test gas kit

or the solenoid valve in the multiprobe test

gas sequencer units.

GASES

STACK

CALIBRATION

INSTRUMENT

AIR SUPPLY

(REF. GAS)

GAS

PRESSURE

REGULATOR

ELECTRONICS

PACKAGE

FLOWMETER

Figure 1-2. Typical System Installation

bal-

2

DUCT

ADAPTER

PLATE

OXYGEN

ANALYZER

(PROBE)

HEATER POWER

SUPPLY

}

LINE

VOLTAGE

19260002

Rosemount Analytical Inc. A Division of Emerson Process Management Description 1-3

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

EXISTING

ELECTRONICS

YE

RD

OR

BL

BK

WH

GN

SHIELD

YE

RD

OR

BL

BK

WH

GN

SHIELD

SHIELD

*TRIAC RELAY

}

+

J9

PROBE

MV

}

+

J8

BL

OR

PROBE

MV

}

+

J3

BL

OR

STACK

TC

}

+

J2

}

+

PROBE

TC

}

+

YE

PROBE

+

SHIELD

PROBE

HEATER

STACK

TEMP

+

AD590

+

RD

TC

}

YE

RD

}

RH

BK

WH

}

}

SHIELD

GN

ANALOG

HEATER

}

BK WH

BK

GN

SHIELD

WH

(SEE PARAGRAPH 2.2.b)

MAINS

J1

LINE VOLTAGE

BY CUSTOMER

}

NL

HEATER POWER SUPPLY

*GATE VOLTAGE CONTROLLING TRIAC OUTPUT

STANDARD PROBE CABLE

6 M (20 FT)

HEATER

}

BL CELL -VE

OR CELL +VE

YE CHROMEL

RD ALUMEL

GN

BK

BK

1234567

BL

1-4 Description Rosemount Analytical Inc. A Division of Emerson Process Management

YE

RD

OR

PROBE HEAD

WIRING

GN

8

BK

WH

Figure 1-3. Typical System Wiring

12 M (40 FT)

18 M (60 FT)

PROBE

24 M (80 FT)

30 M (100 FT)

45 M (150 FT)

TEST GAS INPUT

AT 2-3 L/MIN

(4-7 SCFH)

CHECK

VALV E

REF. GAS SUPPLY

INPUT AIR AT

1 L/MIN (2 SCFH)

19260003

World Class 3000

2

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

SECTION 2

INSTALLATION

2-1 OXYGEN ANALYZER (PROBE)

INSTALLATION

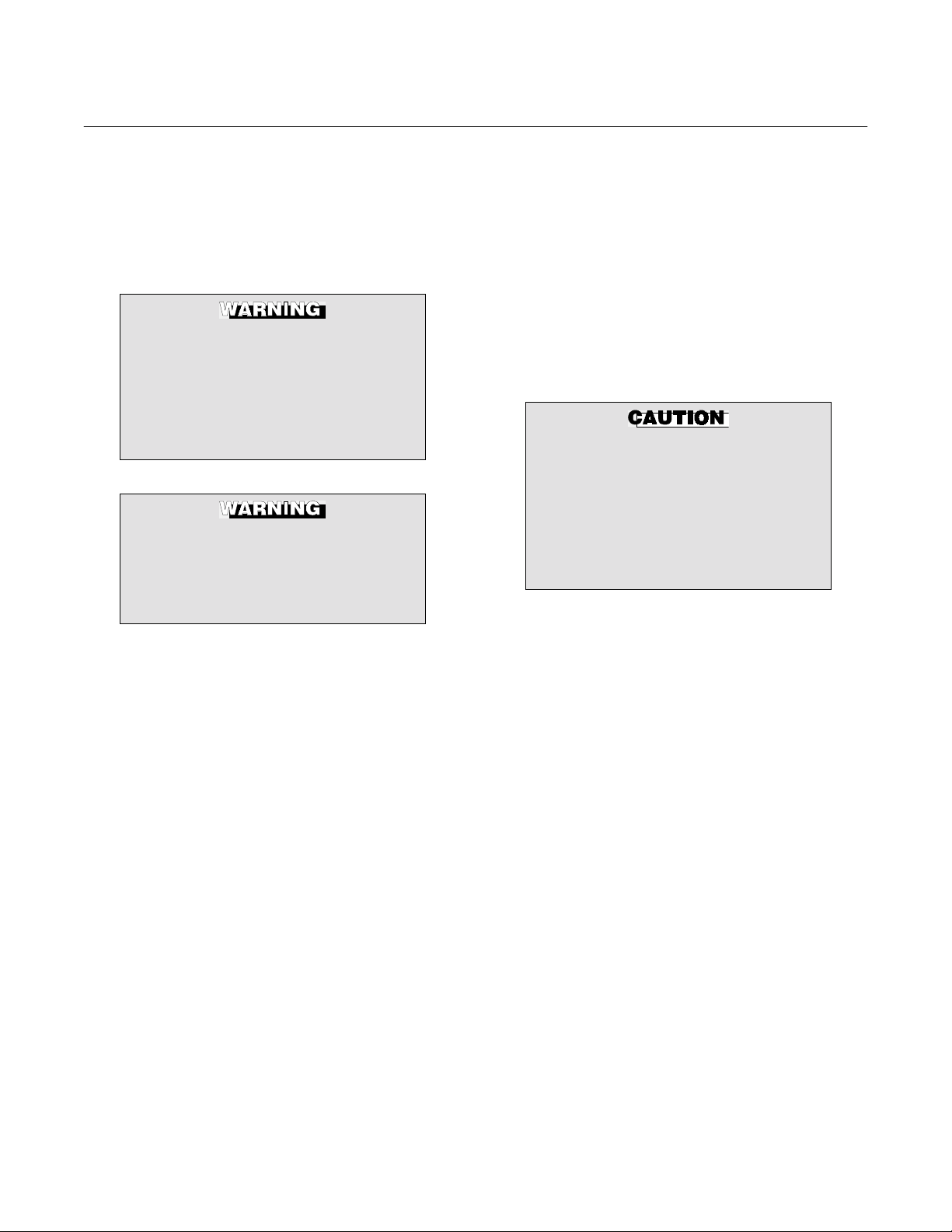

Before starting to install this equipment, read the "Safety instructions for

the wiring and installation of this apparatus" at the front of this Instruction

Bulletin. Failure to follow the safety

instructions could result in serious

injury or death.

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

a. Selecting Location

1. The location of the probe in the stack

or flue is most important for maximum

accuracy in the oxygen analyzing process. The probe must be positioned so

that the gas it measures is representative of the process. Best results are

normally obtained if the probe is positioned near the center of the duct (40

to 60% insertion). A point too near the

edge or wall of the duct may not provide a representative sample because

of the possibility of gas stratification. In

addition, the sensing point should be

selected so that the process gas temperature falls within a range of 50° to

1300°F (10° to 704°C). Figure 2-1 provides mechanical installation

references.

2. Check the flue or stack for holes and

air leakage. The presence of this condition will substantially affect the accuracy of the oxygen reading. Therefore,

either make necessary repairs or install

the probe upstream of any leakage.

3. Ensure that the area is clear of obstructions internal and external that will

interfere with installation. Allow adequate clearance for removal of probe

(Figure 2-1).

Do not allow the temperature of the

probe junction box to exceed 300°°°°F

(149°°°°C) or damage to the unit may re-

sult. If the probe junction box temperature exceeds 300°°°°F (149°°°°C), the user

must fabricate a heat shield or provide

adequate cooling air to the probe junction box.

b. Mechanical Installation

1. Ensure that all components are available for installation of the probe.

Ensure that the system cable is the required length. If applicable, check the

ceramic filter to ensure that it is not

damaged.

2. The probe may be installed intact as it

is received. It is recommended that you

disassemble the adapter plate for each

installation.

NOTE

An abrasive shield is recommended

for high velocity particulate in the flue

stream (such as those in pulverized

coal kilns and recovery boilers). Vertical and horizontal brace clamps are

provided for 9 ft and 12 ft (2.75 m and

3.66 m) probes to provide mechanical

support of the probe. Refer to Figure

2-1, Sheet 5.

3. Weld or bolt adapter plate (Figure 2-1)

onto the duct.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

FURNISHED IN - XIT

4512C34

ADAPTER & ACCESSORY

TO AMBIENT

INSULATE IF EXPOSED

WEATHER CONDITIONS

4512C35

4512C36

2.27 (58)

DIA MAX

ROSEMOUNT

5.85 (148.6)

DIM "A"

WITH STANDARD

REF GAS

CAL GAS

7.58 (192)

SNUBBER

DIFFUSER

ELEC

DIM "B" REMOVAL ENVELOPE

1/4 IN. TUBE

6 MM TUBE

6 MM TUBE

ANSI

DIN

JIS

1/2"

CONN

CONDUIT

GAS

CAL

JIS

4512C18H01

6.10

(155)

1.88 (48)

(15)

0.59

GAS

REF

AT THE BOTTOM

BOTTOM VIEW

INSTALL WITH CONNECTIONS

5.12

(130)

THESE FLAT FACED FLANGES ARE MANUFACTURED

TO ANSI, DIN, AND JIS BOLT PATTERNS AND ARE NOT

DIMENSIONS ARE IN INCHES WITH MILLIMETERS IN

PARENTHESES.

PRESSURE RATED.

2.

NOTES: 1.

24610001

3.80 (96.5)

DIFFUSER

FOR PROBE

WITH CERAMIC

4.90 (124.5)

ADD TO DIM "A" FOR

ARRESTOR

DIFFUSER AND FLAME

PROBE WITH CERAMIC

DIN

7.28

4512C19H01

ANSI

6.00

4512C17H01

(185)

(153)

0.71

0.75

(18)

(20)

5.71

(145)

4.75

(121)

DIM "B"

DIM "A"

27.3 (694)

16 (406)

45.3 (1151)

34 (864)

81.3 (2065)

117.3 (2980)

70 (1778)

106 (2692)

153.3 (3894)

142 (3607)

3535B18H02

3635B48H01

ANSI

JIS

0.062 THK GASKET

ADD TO DIM "A"

3535B45H01

DIN

TABLE I MOUNTING FLANGE

3FT

6FT

9FT

12 FT

PROCESS FLOW MUST

BE IN THIS DIRECTION

WITH RESPECT TO

DEFLECTOR 3534848G01

FLANGE

DIA.

HOLE

DIA.

(4) HOLES

EQ SP ON BC

TABLE II INSTALLATION/REMOVAL

18 IN.

PROBE

Figure 2-1. Probe Installation (Sheet 1 of 5)

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

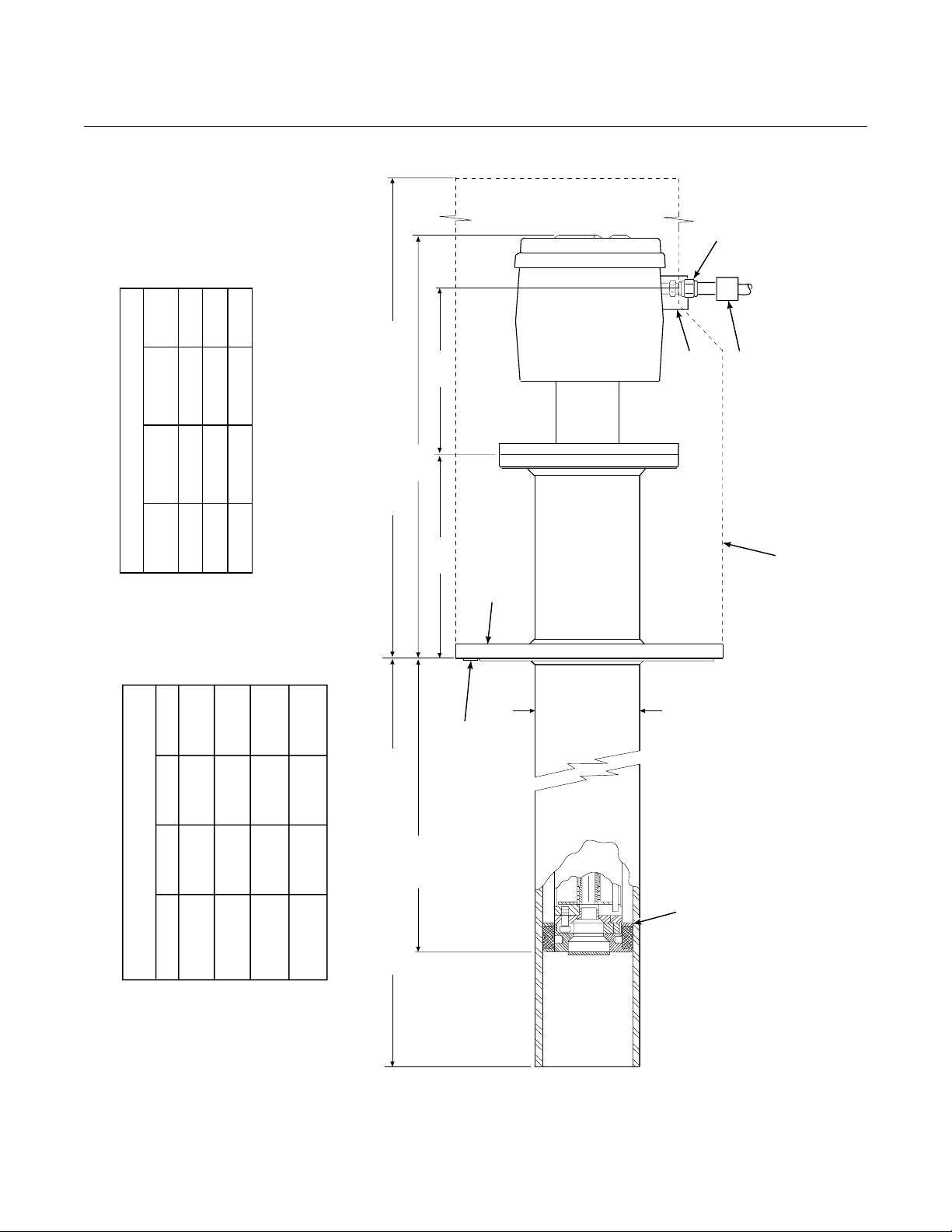

2

7.50

7.48

0.75

9.25 (235)

*

JIS

7.48

0.945

9.25 (235)

*

DIN

* FLANGE ARE MANUFACTURED TO ANSI,

TABLE IV. FLANGE SIZE

BOLT

CIRCLE

0.75

(8) HOLES

DIAMETER

FLANGE

9.00 (153)

DIAMETER

*

ANSI

DIN, AND JIS BOLT PATTERNS AND ARE

FLAT FACED. THESE FLANGES ARE NOT

PRESSURE RATED.

5.7

(145)

14.5

(369)

DIM "D" REMOVAL ENVELOPE

7.00

(178)

SEE TABLE IV

FOR FLANGE

SIZES

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

21190008

REF AND

CAL GAS

CONNECTOR

ELECTRICAL

CONNECTOR

CAL GAS LINES

CHECK VALVE FOR

INSULATE IF

CONDITIONS

EXPOSED TO

AMBIENT WEATHER

31.1

(790)

45.3

(1151)

DIM "D" DIM "E"

27

(686)

DIM "C"

NOMINAL MEASUREMENTS

TABLE III. REMOVAL / INSTALLATION

3FT

67.1

81.3

63

6FT

(1704)

(2065)

(1600)

103.1

(2619)

117.3

(2980)

99

(2515)

9FT

139.1

(3533)

153.3

(3894)

(P/N 3535B58G04 - JIS)

135

12 FT

(3429)

DIM "C"

0.06 THK GASKET FURNISHED

DIM "E" (WITH FLAME ARRESTOR)

(P/N 3535B58G06 - DIN)

(P/N 3535B58G02 - ANSI)

IN HARDWARE PACKAGE

Figure 2-1. Probe Installation (Sheet 2 of 5)

3.6

NOMINAL

(P/N 4843B38G02)

SNUBBER DIFFUSION/

DUST SEAL ASSEMBLY

DIMENSIONS ARE IN INCHES WITH

MILLIMETERS IN PARENTHESES.

NOTE:

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Bulletin

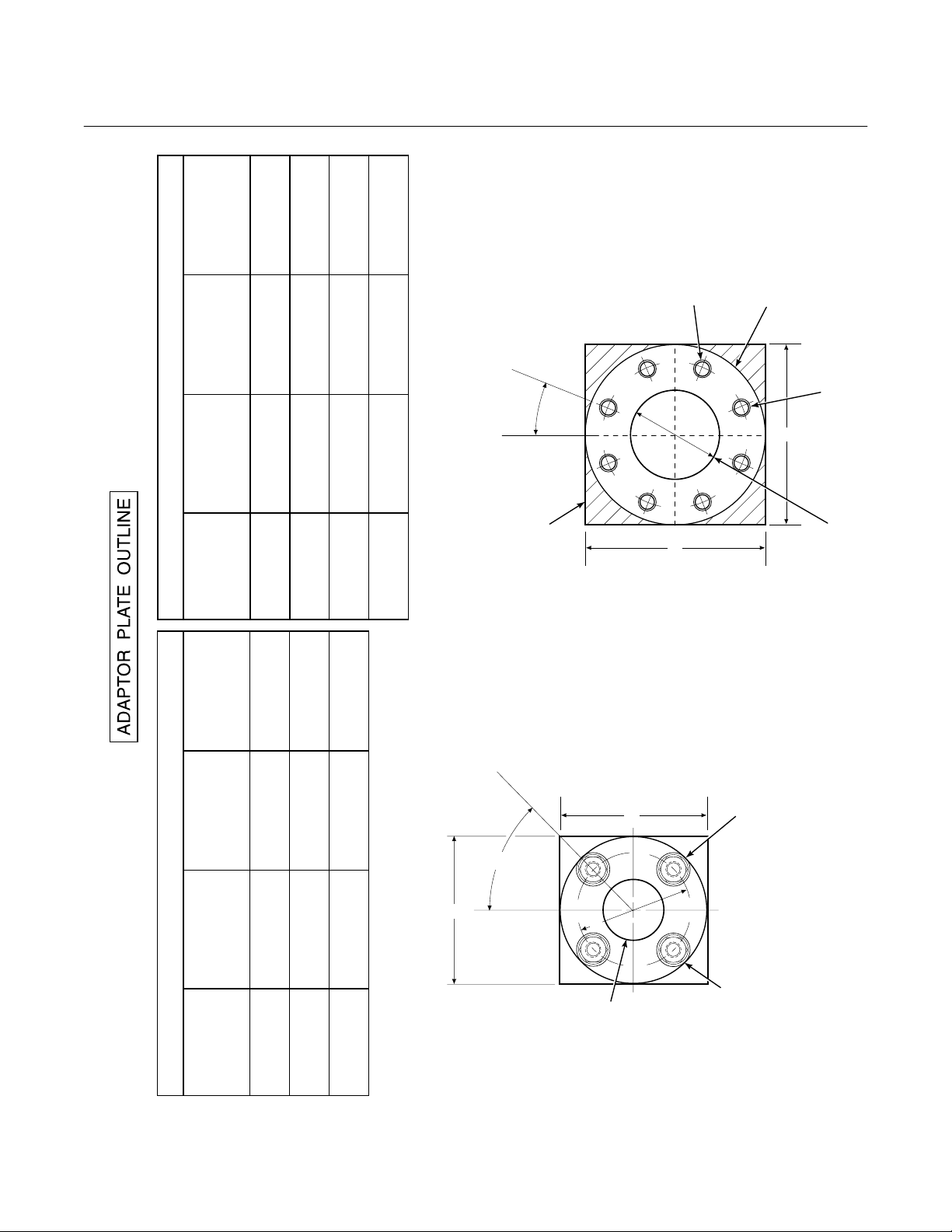

106-300NE Rev. 3.4

May 2000

JIS

(P/N 3535B58G04)

9.25

(235)

4.92

(125)

(M-20 x 2.5)

(200)

7.894

World Class 3000

16860021

8 THREADED HOLES

EQUALLY SPACED ON

D DIA B.C.

ABRASIVE SHIELD

FLANGE O.D.

TABLE VI. ADAPTOR PLATE DIMENSIONS FOR ABRASIVE SHIELD

DIN

ANSI

IN.

DIMENSIONS

JIS

9.25

(P/N 3535B58G06)

9.00

(P/N 3535B58G02)

"A"

(mm)

6.50

(P/N 4512C35G01)

(235)

(229)

(165)

3.94

(100)

4.75

(121)

"B"

DIA

(M-12 x 1.75)

(M-16 x 2)

0.625-11

"C"

THREAD

(130)

5.118

7.48

7.50

"D"

(190)

(191)

DIA

ATTACHING HARDWARE.

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

o

22.5

A

CORNERS MAY BE USED TO

FIELD BOLTING OF PLATE TO

PROVIDE ADDITIONAL HOLES FOR

OUTSIDE WALL SURFACE.

AND 12 FT ABRASIVE SHIELD

ADAPTOR PLATE FOR 3, 6, 9,

INSTALLATIONS. SEE SHEET 2.

CROSSHATCHED AREA IN 4

C

A

B

4 STUDS,

LOCKWASHERS AND

NUTS EQUALLY

SPACED ON

C DIA B.C.

B

ADAPTOR PLATE FOR

STD WORLD CLASS 3000

PROBE INSTALLATION.

SEE SHEET 1.

TABLE V. ADAPTOR PLATE DIMENSIONS FOR PROBE

DIN

ANSI

IN.

DIMENSIONS

7.5

(P/N 4512C36G01)

6.00

(P/N 4512C34G01)

"A"

(mm)

(191)

(153)

(M-16 x 2)

0.625-11

"B"

THREAD

(145)

5.708

4.75

(121)

"C"

DIA

A

o

45

A

C

ATTACHING HARDWARE.

2.500 DIA

NOTE: PART NUMBERS FOR ADAPTOR PLATES INCLUDE

Figure 2-1. Probe Installation (Sheet 3 of 5)

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

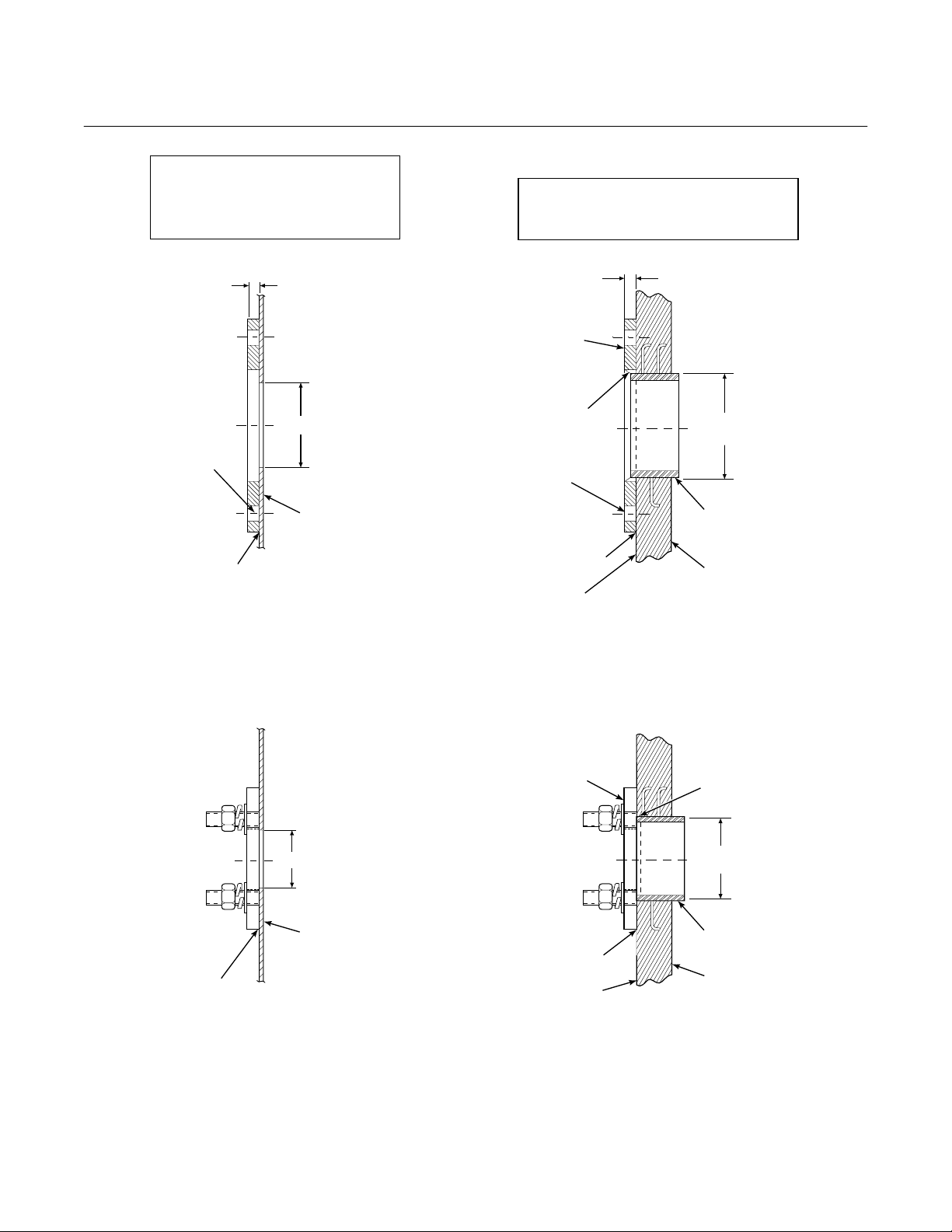

World Class 3000

2

INSTALLATION FOR METAL

WALL STACK OR DUCT

CONSTRUCTION

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

INSTALLATION FOR MASONRY

WALL STACK CONSTRUCTION

MTG HOLES

SHOWN ROTATED

o

22.5 OUT OF

TRUE POSITION

WELD OR BOLT MOUNTING

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIRTIGHT.

0.50 (13)

3.75 (95)

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

BOLT ADAPTOR

PLATE TO OUTSIDE

WALL SURFACE

FIELD WELD

PIPE TO

ADAPTOR PLATE

MTG HOLES

SHOWN ROTATED

o

22.5 OUT OF

TRUE POSITION

JOINT MUST

BE AIRTIGHT

OUTSIDE WALL

SURFACE

NOTE: ALL MASONRY STACK WORK AND JOINTS EXCEPT

ADAPTOR PLATE NOT FURNISHED BY ROSEMOUNT.

ABRASIVE SHIELD MOUNTING

0.50 (13)

4.50 (114)

O.D. REF

PIPE 4.00 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

WELD OR BOLT MOUNTING

PLATE TO METAL WALL

OF STACK OR DUCT.

JOINT MUST BE AIRTIGHT.

3.25 (82.5)

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

BOLT MOUNTING

PLATE TO OUTSIDE

WALL SURFACE

OUTSIDE WALL

PROBE MOUNTING

JOINT MUST

BE AIRTIGHT

SURFACE

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARENTHESES.

FIELD WELD

PIPE TO

ADAPTOR PLATE

4.0 (102)

O.D. REF

PIPE 3.5 SCHED 40

PIPE SLEEVE (NOT

BY ROSEMOUNT)

LENGTH BY CUSTOMER

MASONRY

STACK WALL

P0038

Figure 2-1. Probe Installation (Sheet 4 of 5)

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

o

60 MAX.

o

30 MIN.

4.12

(105)

4.12

(105)

BRACE BARS

(NOT BY ROSEMOUNT)

2.00

(51)

1.00

(25)

2 HOLES - 0.625

(16) DIA. FOR

0.50 (12) DIA.

BOLT

1.00

(25) MAX.

0.375

(10)

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARETHESES.

VERTICAL BRACE CLAMP ASSY.

HORIZONTAL BRACE CLAMP ASSY.

(BOTH BRACE CLAMP ASSEMBLIES ARE THE SAME.

INSTALLATION AND LOCATION OF CLAMP ASSEMBLIES

AND BRACE BARS TO BE DONE IN FIELD.)

5.62

(143)

5.62

(143)

ABRASIVE SHIELD

BY ROSEMOUNT

}

NOTE: BRACING IS FOR VERTICAL AND HORIZONTAL PROBE INSTALLATION.

EXTERNAL BRACING REQUIRED FOR 9 FT AND 12 FT

(2.75 M AND 3.66 M) PROBES AS SHOWN ABOVE.

Figure 2-1. Probe Installation (Sheet 5 of 5)

4. If using the optional ceramic diffusor

element, the vee deflector must be correctly oriented. Before inserting the

probe, check the direction of gas flow

in the duct. Orient the vee deflector on

the probe so that the apex points upstream toward the flow (Figure 2-2).

This may be done by loosening the

setscrews, and rotating the vee deflector to the desired position.

Retighten the setscrews.

5. In horizontal installations, the probe

junction box should be oriented so the

system cable drops vertically from the

probe junction box. In a vertical installation, the system cable can be oriented in any direction.

36.00 (914)

P0039

6. If the system has an abrasive shield,

check the diffusion element dust seal

packings. The joints in the two packings must be staggered 180°. Also,

make sure that the packings are in the

hub grooves as the probe slides into

the 15° forcing cone in the abrasive

shield.

7. Insert the probe through the opening in

the mounting flange and bolt the unit to

the flange. When probe lengths selected are 9 or 12 feet (2.74 or 3.66 m),

special brackets are supplied to provide additional support for the probe

inside the flue or stack. See Figure 2-1,

sheet 5.

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

GAS FLOW

DIRECTION

VEE

FILTER

DEFLECTOR

DIFFUSION

ELEMENT

SETSCREW

DEFLECTOR

VEE

P0017

APEX

Figure 2-2. Orienting the Optional Vee Deflector

c. Service Required

1. Power input: 100, 115 or 220 Vac single phase, 50 to 60 Hz, 3 amp

minimum. (See label.)

2. Compressed air: 10 psig (68.95 kPag)

minimum, 225 psig (1551.38 kPag)

maximum at 2 scfh (56.6 L/hr) maximum; supplied by one of the following

(less than 40 parts-per-million total hydrocarbons). Regulator outlet pressure

should be set at 5 psi (35 kPa).

(a) Instrument air - clean, dry.

(b) Bottled standard air with step-down

regulator.

(c) Bottled compressed gas mixture

(20.95% oxygen in nitrogen).

(d) Other equivalent clean, dry, oil-free

air supply.

Figure 2-3. Outline of Heater Power Supply

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

World Class 3000

EXISTING

ELECTRONICS

YE

RD

OR

BL

BK

WH

GN

SHIELD

YE

RD

OR

BL

BK

WH

GN

SHIELD

SHIELD

*TRIAC RELAY

}

+

J9

PROBE

MV

}

+

J8

BL

OR

PROBE

MV

}

+

J3

BL

OR

STACK

TC

}

+

J2

}

+

PROBE

TC

}

+

YE

PROBE

+

SHIELD

PROBE

HEATER

STACK

TEMP

+

AD590

+

RD

TC

}

YE

RD

}

RH

BK

WH

}

}

SHIELD

GN

ANALOG

HEATER

}

BK WH

BK

GN

SHIELD

WH

(SEE PARAGRAPH 2.2.b)

MAINS

J1

LINE VOLTAGE

BY CUSTOMER

}

NL

HEATER POWER SUPPLY

*GATE VOLTAGE CONTROLLING TRIAC OUTPUT

STANDARD PROBE CABLE

6 M (20 FT)

HEATER

}

BL CELL -VE

OR CELL +VE

YE CHROMEL

RD ALUMEL

1234567

BL

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

YE

RD

OR

PROBE HEAD

WIRING

GN

BK

BK

8

BK

GN

WH

Figure 2-4. Electrical Installation of Heater Power Supply

12 M (40 FT)

18 M (60 FT)

PROBE

24 M (80 FT)

30 M (100 FT)

45 M (150 FT)

TEST GAS INPUT

AT 2-3 L/MIN

(4-7 SCFH)

CHECK

VALV E

REF. GAS SUPPLY

INPUT AIR AT

1 L/MIN (2 SCFH)

19260003

World Class 3000

2

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

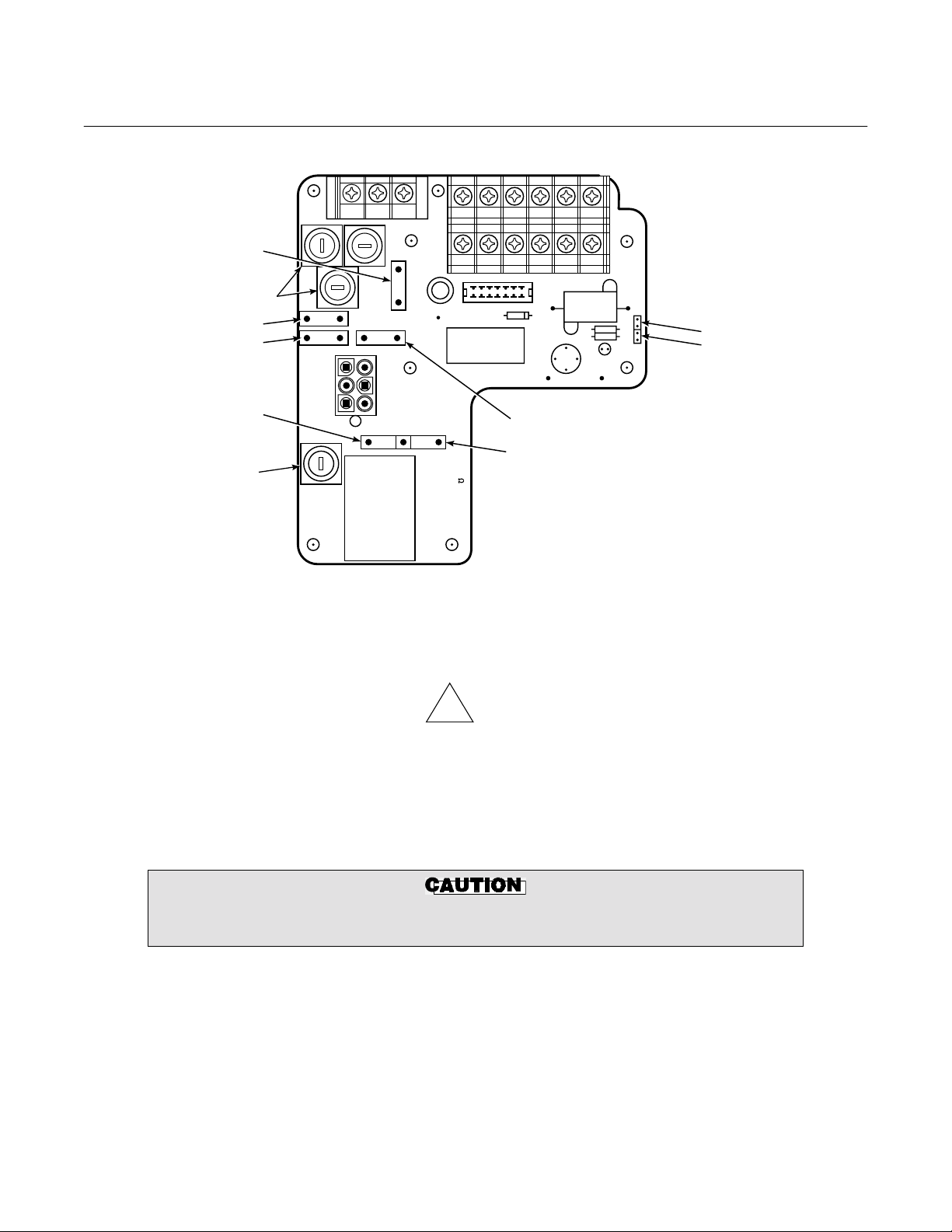

Figure 2-5. Heater Power Supply Wiring Connections

2-2 HEATER POWER SUPPLY INSTALLATION

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

a. Mechanical Installation

The outline drawing of the heater power

supply enclosure, Figure 2-3, shows

mounting centers and clearances. The

NEMA 4X enclosure is designed to be

mounted on a wall or bulkhead. The heater

power supply should be installed no further

than 150 feet (45 m) from the probe. The

heater power supply must be located in a

location free from significant ambient tem-

perature changes and electrical noise.

Ambient temperature must be between -20°

to 140°F (-30° to 60°C).

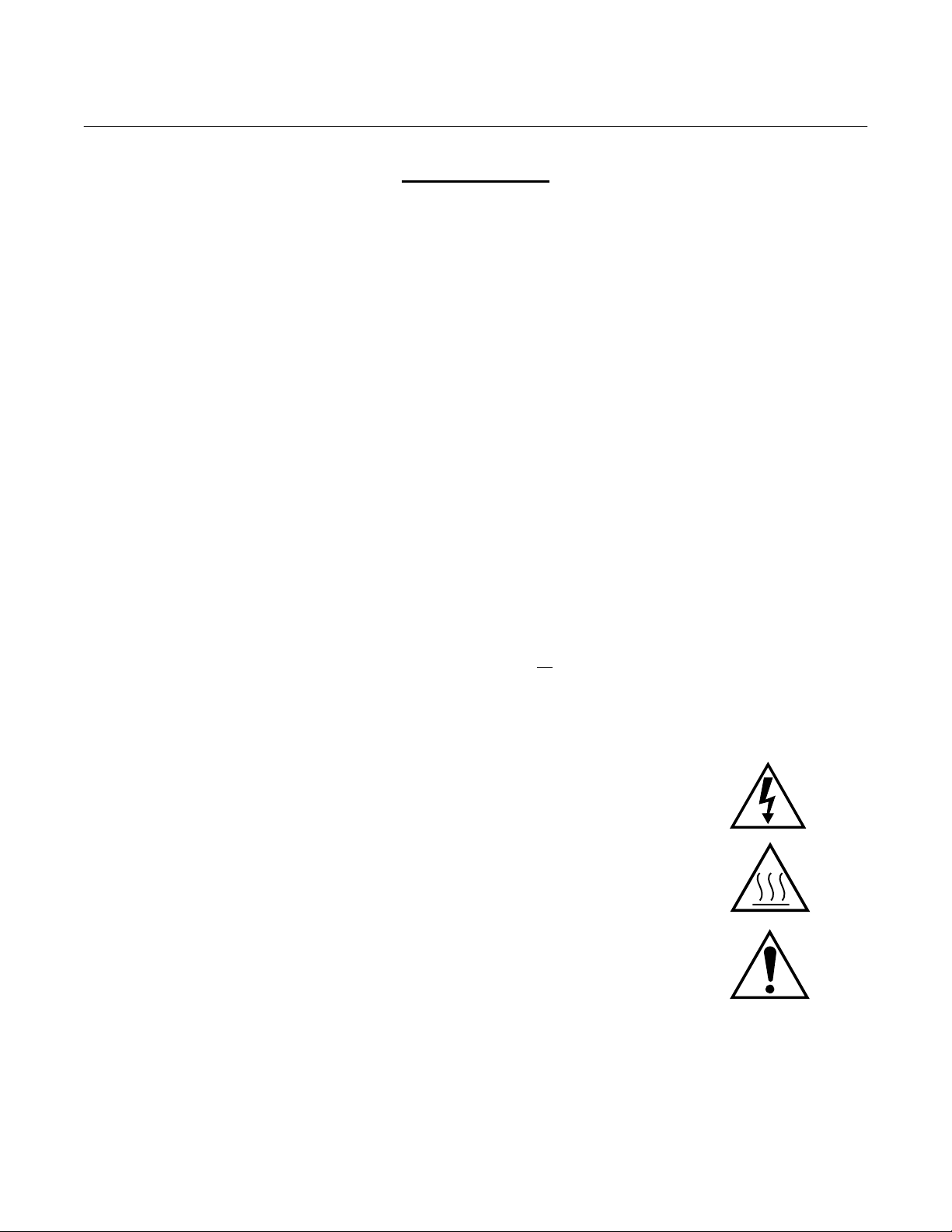

b. Electrical Connections

1. Electrical connections should be made

as described in the electrical installation diagram, Figure 2-4. The wiring

terminals are divided into two layers;

the bottom (FROM PROBE) terminals

should be connected first, the top

(FROM ELECTRONICS) terminals

should be connected (Figure 2-5).

Each terminal strip has a protective

cover which must be removed when

making connections. To remove the

terminal covers, remove two slotted

screws holding the cover in place. Always reinstall terminal covers after

making connections.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-9

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

LINE VOLTAGE

SELECTION

1

100/120 V.A.C.

220/240 V.A.C.

JUMPER

(INSTALL)

JM4, JM1

JM5

JUMPER

CONFIGURATIONS

2

World Class 3000

ALWAYS DISCONNECT LINE VOLTAGE

FROM HEATER POWER SUPPLY AND

ANALOG ELECTRONICS (IF USED)

BEFORE CHANGING JUMPERS.

HEATER

POWER

REMOTE

*ON

JUMPER

REMOVE JM2

INSTALL JM2

PROBE HEATER

VOLTAGE SELECTION

*WORLD CLASS PROBE

(44V)

218 PROBE (115V)

DENOTES JUMPERS THAT MUST BE INSTALLED WHEN USING THE WORLD CLASS 3000 OXYGEN ANALYZER

*

PROBE AND THE HPS 3000 HEATER POWER SUPPLY WITH EXISTING ANALOG, MODEL 218A, AND TC 2000

ELECTRONICS.

NOTES:

1

100 V.A.C. OPERATION REQUIRES TRANSFORMER PART NUMBER 1M02961G02.

2

HEATER POWER IS ALSO REFERRED TO AS LINE VOLTAGE RELAY.

JUMPER

(INSTALL)

JM7

JM8

ELECTRONICS

SELECTION

*ANALOG (EXISTING)

(NEXT GENERATION)

Figure 2-6. Jumper Selection Label

NOTE

Refer to Figure 2-7 for HPS unit fuse

locations and specifications.

NOTE

Before supplying power to the heater

power supply, verify that jumpers JM2,

JM3, JM6, and JM7 are installed.

2. Power Input: 120, 220 or 240 Vac. For

"ANALOG" under ELECTRONICS SELECTION on the label refers to Models

218, 225, TC200, and Model 218A electronics.

120 Vac usage, install jumpers JM4

and JM1. For 220 or 240 Vac usage,

install jumper JM5 (See label, Figure

2-6).

For 100 Vac usage, the heater power

supply is factory-supplied with a different transformer. When using the HPS

with 100 Vac transformer, install

jumpers JM1 and JM4.

JUMPER

INSTALL JM3, JM6

DIGITAL

REMOVE JM3, JM6

3. The power cable should comply with all

applicable codes and safety regulations in the user's country and should

not be smaller than 16 gauge, 3 amp.

NOTE

4. Before supplying power to the heater

power supply, verify that the jumpers

on the mother board, Figure 2-7, are

properly configured. Jumpers JM2,

JM3, JM6, and JM7 should be installed. Additionally, make sure that the

proper jumper for your line voltage is

installed, Figure 2-6.

2-10 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

2

JM1

FUSES

JM2

JM4

JM7

FUSE

3D3 080G REV

JM5

JM8

NOTE:

Instruction Bulletin

106-300NE Rev. 3.4

May 2000

JM3

JM6

ALL FUSES ARE 5A @ 250 VAC,

ANTI-SURGE, CASE SIZE

5 X 20 MM, TYPE T TO IEC127,

SCHURTER.

22540005

Figure 2-7. Jumpers on HPS Mother Board

NOTE

!

Upon completing installation, make sure that the probe is turned on and operating

prior to firing up the combustion process. Damage can result from having a cold

probe exposed to the process gases.

During outages, and if possible, leave all probes running to prevent condensation and

premature aging from thermal cycling.

If the ducts will be washed down during outage, MAKE SURE to power down the

probes and remove them from the wash area.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-11

Loading...

Loading...