Page 1

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

6081-P

Wireless pH/ORP Transmitter

Figure 1. 6081-P

Essential Instructions – Read this before proceeding

Rosemount Analytical designs, manufactures, and tests its products to meet many national and international standards.

Because these instruments are sophisticated technical products, you must properly install, use, and maintain them to

ensure they continue to operate within their normal specications. The following instructions must be adhered to and

integrated into your safety program when installing, using, and maintaining Rosemount Analytical products. Failure

to follow the proper instructions may cause any one of the following situations to occur: Loss of life; personal injury;

property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the

correct manual, telephone 1-800-654-7768 and the requested manual will be provided. Save this Instruction Manual

for future reference.

• If you do not understand any of the instructions, contact your Rosemount representative for clarication.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

Page 2

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

Essential Instructions (continued)

• Install your equipment as specied in the Installation Instructions of the appropriate Instruction Manual and per

applicable local and national codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualied personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualied people use replacement parts specied by Rosemount.

Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your process at

risk. Look alike substitutions may result in re, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being

performed by qualied persons, to prevent electrical shock and personal injury.

Note

The Rosemount 6081 and all other wireless devices should be installed only after the 1420 Wireless Gateway has been installed

and is functioning properly. Wireless devices should also be powered up in order of proximity from the 1420 Wireless Gateway,

beginning with the closest. This will result in a simpler and faster network installation.

Note

Shipping considerations for wireless products (Power Modules):

The unit was shipped to you without the power module installed. Please remove the power modules from the unit prior to

shipping.

Primary lithium power modules are regulated in transportation by the U. S. Department of Transportation, and are also covered

by IATA (International Air Transport Association), ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure compliance with these or any other local

requirements. Please consult current regulations and requirements before shipping.

The power module with the wireless unit contains two “C” size primary lithium/thionyl chloride power sources.

Each power module contains approximately 5 grams in each pack. Under normal conditions, the power module materials

are self-contained and are not reactive as long as the power modules and the pack integrity are maintained. Care should

be taken to prevent thermal, electrical or mechanical damage. Contacts should be protected to prevent premature

discharge.

Power module hazards remain when cells are discharged. Power modules should be stored in a clean and dry area. For

maximum power module life, storage temperature should not exceed 30 °C.

WARNING

Use only with Rosemount Smart Power Module PN 701PBKKF

WARNING

Potential Electrostatic Hazard – The plastic antenna may present a potential electrostatic ignition hazard and must not be rubbed

or cleaned with a dry cloth.

WARNING

Mechanical Spark Hazard – The 6081 enclosure is made of aluminum alloy and given a protective polyurethane paint nish.

However, care should be taken to protect it from impact or abrasion if located in Zone 0.

This applies to any Intrinsically Safe installation, whether the Class, Division or Zone system is used.

2

Page 3

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

Quick Start Guide - 6081 Wireless pH Transmitter

1. Install the Power Module inside the rear enclosure. Follow the installation instructions on p.9 “Power Module

Installation”.

2. Wire the pH or ORP sensor to the transmitter. Refer to the sensor instruction sheet for details.

3. Once the connections are secure and veried, install the Power Module to power to the transmitter.

4. When the transmitter is powered up for the rst time, Quick Start screens appear. Using Quick Start is easy.

a. A blinking eld shows the position of the cursor.

b. Use the or key to move the cursor left or right. Use the or key to move the cursor up or down or to

increase or decrease the value of a digit. Use the or key to move the decimal point.

c. Press ENTER to store a setting. Press EXIT to leave without storing changes. Pressing EXIT also returns the

display to the previous screen.

5. Choose a local language.

6. Choose measurement: pH, ORP, or Redox.

7. Choose preamplier location. Select Xmtr to use the integral preamplier in the transmitter.

8. Choose Off or On for displayed diagnostics.

9. Select measurement update rate. Select ENTER to choose an update rate of 1 minute or enter a value from 1 second to

10 minutes.

10. Choose temperature units: °C or °F

11. Choose Yes to Setup the Wireless Network or No if the Network ID and the Join Key have already been entered.

12. Enter the 5-digit Wireless Network ID. This ID number must match the Network ID of the 1420 Wireless Gateway.

13. Enter the 8-digit Network Join Key number 1 of 4 to match the 1420 Wireless Gateway. See the Note below for

clarication.

14. Enter Network Join Key numbers 2, 3, and 4 to match the 1420 Wireless Gateway.

15. The transmitter will exit Quick Start and display the live measurement screen.

16. To change the Network ID or Join Key, HART address, or measurement-related settings from the default values, and

to set security codes, press MENU. Select Program and follow the prompts. Refer to the appropriate menu tree.

17. To return the transmitter to default settings, choose Reset Analyzer in the Program menu.

Note regarding Wireless Device Configuration

In order to communicate with the 1420 Wireless Gateway, and ultimately the Information System, the transmitter must

be congured to communicate with the wireless network. This step is the wireless equivalent of connecting wires from a

transmitter to the information system.

Using a Field Communicator or AMS, enter the Network ID and Join Key so that they match the Network ID and Join Key

of the gateway and other devices in the network. The Network Join Key consists of four (4) blocks, each with an eight

digit code. The code of each block must match its corresponding block in the 1420 in order for the 6081 to join the

network.

If the Network ID and Join Key are not identical, the transmitter will not communicate with the network. The Network ID

and Join Key may be obtained from the 1420 Wireless Gateway on the Setup>Network>Settings page on the web server.

The nal device network conguration piece is the Update Rate. This by default is one (1) minute. This may be changed at

commissioning, or at any time via AMS or the 1420 Wireless Gateway’s web server. The Update Rate should be between 1

second and 10 minutes.

When device conguration is completed, remove the power module and replace the rear cover of the transmitter until

the time of actual live installation in the process. Tighten the cover to the proper tension for safety approvals.

Note

For installation and operation at high elevations, slight convex bulging of the front keypad overlay is possible. If bulging occurs, it

is recommended to unscrew the two Philips head screws that faster the front cover to the central housing to release any internal

pressure. This will equalize the device’s internal pressure to the ambient atmospheric pressure. Re-tighten the two Philips head

screws to secure the front cover before device installation or operation. Make sure to perform the pressure equalization in a clean,

dry area.

3

Page 4

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

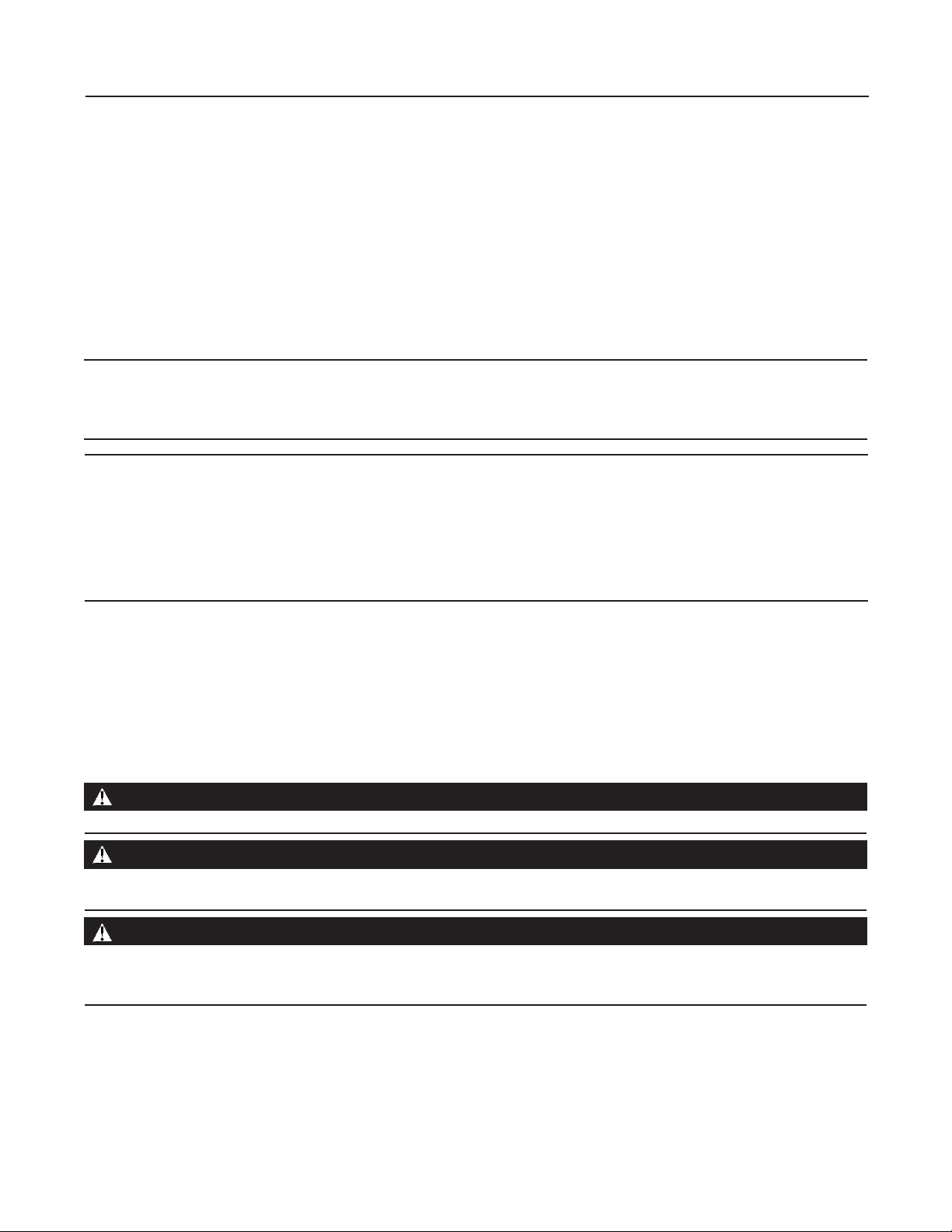

Figure 2. Menu Tree for 6081 pH Wireless Transmitter

4

Page 5

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

Product Description

When used with appropriate sensors, the 6081-P can measure pH or ORP (oxidation reduction potential) of a liquid and

transmit data wirelessly with a radio transceiver which uses HART 7 communication protocol. The instrument has a

local operator interface consisting of a keyboard and LCD display which can be used to observe process parameters or to

congure the 6081. This instrument is available with approvals for use in hazardous areas.

General Specifications

Enclosure: Cast aluminum. NEMA 4X, IP66

Dimensions: 6.55” x 5.40” x 5.15” (166mm x 137mm x 131mm)

Conduit Openings: ¾” FNPT

Ambient Temperature: -4 to 149 °F (-20 to 65 °C)

Storage Temperature: -22 to 158 °F (-30 to 70 °C)

Relative Humidity: 0 to 95% (non-condensing)

Weight/Shipping Weight: 7 lbs/8 lbs (3.2/3.6 kg)

Digital Communications: HART 7 Wireless HART™

Functional Specifications

pH Range: 0 to 14

ORP Range: -1400 to +1400mV

Compatible with Rosemount Analytical SMART pH sensors

Calibrations/standardization: The automatic buffer recognition uses stored buffer values and their temperature curves

for the most common buffer standards available worldwide. The transmitter also performs a stabilization check on the

sensor in each buffer.

A manual two-point calibration is made by immersing the sensor in two different buffer solutions and entering the pH

values. The microprocessor automatically calculates the slope which is used for self-diagnostics. An error message will

be displayed if the pH sensor is faulty. This slope can be read on the display and/or manually adjusted if desired. An online one-point process standardization is accomplished by entering the pH or ORP value of a grab sample.

The following calibration methods are supported:

- Two point calibration with Low and High buffer (pH only)

- Two point calibration with Automatic Buffer recognition (pH only)

- Single point standardization

- Single point Temperature Adjustment

- Automatic calibration upon live connection to RAI SMART pH sensors and upload of stored cal data to transmitter

Automatic Temperature Compensation: External 3-wire Pt100 RTD or Pt1000 RTD located in the sensor, compensates

the pH reading for temperature uctuations. Compensation covers the range -10 to 150 °C (14 to 302 °F). Manual

temperature compensation is also selectable.

Accuracy: ±1 mV @ 25 °C ±0.01 pH

Repeatability: ±1 mV @ 25 °C ±0.01 pH

Information and Status: Information screens display faults and warnings, radio transmission status, network ID number,

Power Module voltage, transmitter model, and software version.

Diagnostics: The internal diagnostics can detect:

RTD Failure

Glass Low Failure

Glass High Failure

Broken Glass Fault

Reference High Failure

CPU Error

High Temperature Warning

Low Temperature Warning

Glass Impedance High Warning

Glass Impedance Low Warning

Reference Impedance High Warning

5

Page 6

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

EEPROM Warning

Sense Line Open Warning

Factory Cal Warning

Keyboard Warning

Once a fault or warning is detected, the display will show a message describing the problem.

Sensor Temperature Range: -10 to 150°C (PT100 and PT1000)

Display: 2-line, 16 character display supports display of pH and mV units. Display shows temperature.

Approvals:

RFI/EMI:

EN-61326

EN 301 489-1 V1.2 2002

EN 301 489-17: V1.4.1 2002

EN 60950-1: 2001

EN 300 328 V 1.6.1 (2004-11)

Hazardous Location Approvals

Intrinsic Safety:

Special Conditions of Use:

1. The 6081 enclosure is made of aluminum alloy and

given a protective polyurethane paint nish; however,

care should be taken to protect it from impact or

abrasion if located in zone 0. This applies to any

Intrinsically Safe installation, whether the Class, Division

or Zone system is used.

2. Potential Electrostatic Hazard – The plastic antenna may

present a potential electrostatic ignition hazard and

must not be rubbed or cleaned with a dry cloth.

Intrinsically Safe,

Class I, Division 1

Groups ABCD/T4

Ta = -20 °C to +65 °C – 1400322;

IP66

Class 1 Zone 0, AEx ia IIC T4

Ta = -20 °C to +65 °C – 1400322;

IP66

Non-Incendive:

Nonincendive, Class I,

Division 2, Groups ABCD/T4

Ta = -20˚C to +65 °C

Complies with FM standards:

FM3600:1998

FM3610: 2010, ISA60079-0:2009, ISA60079-11:2009.

FM3611: 2004

FM3810: 2005

ANSI/IEC 60529:2004

Class I, Division 1, Groups A/B/C & D

Class II, Division 1, Groups E/F& G

Class III

T4 Tamb : -20 to +65 °C

Type 4x, IP66

CE 1180 II1G

Baseefa 10 ATEX 0149X

Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +65 °C

(source CE cert-6081 Baseefa)

Complies with Standards: EN

60079-0:2009, EN 60079-11:2007

Class I, Division 2,

Groups A, B, D

Dust Ignition Proof

Class II, Division 2,

Groups F & G

T4 Tamb : -20 to +65 °C

Environmental: The operating atmosphere of the

transmitter must be consistent with the appropriate

hazardous location certications.

6

Page 7

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

pH Calibration Procedure – Auto Buffer Calibration

1. Obtain two buffer solutions. Ideally, the buffer values should bracket the range of pH values to be measured.

2. Remove the pH sensor from the process liquid. If the process and buffer temperatures are appreciably different place

the sensor in a container of tap water at the buffer temperature. Do not start the calibration until the sensor has reached

the buffer temperature. Thirty minutes is usually adequate.

3. Press MENU. The main menu appears. Choose Calibrate.

4. Choose pH.

5. Choose BufferCal.

6. Choose Auto.

7. To continue with the calibration, choose Buffer1.Then go to step 8. To change stability criteria, choose Setup and go to

step 19.

8. Rinse the sensor with water and place it in buffer 1. Be sure the glass bulb and the reference junction are completely

submerged. Swirl the sensor.

9. The screen at left is displayed with “Wait” ashing until the reading is stable. The default stability setting is <0.02

pH change in 10 sec. To change the stability criteria, go to step 19. When the reading is stable, the screen in step 10

appears.

10. The top line shows the actual reading. The transmitter also identies the buffer and displays the nominal buffer value

(buffer pH at 25 °C). If the displayed value is not correct press ▼ or ▲ to display the correct value. The nominal value

will change, for example from 7.01 to 6.86 pH. Press ENTER to store.

11. The screen at left appears momentarily.

12. The screen at left appears. Remove the sensor from Buffer 1, rinse it with water, and place it in Buffer 2. Be sure the

glass bulb and the reference junction are completely submerged. Swirl the sensor. Choose Buffer2.

13. The screen is displayed with “Wait” ashing until the reading is stable. When the reading is stable, the screen in step

14 appears.

14. The top line shows the actual reading. The transmitter also identies the buffer and displays the nominal buffer value

(buffer pH at 25 °C). If the displayed value is not correct, press ▼ or ▲ to display the correct value. The nominal value

will change, for example from 9.91 to 10.02 pH. Press ENTER to store.

15. The screen at the left appears momentarily.

16. If the calibration was successful, the transmitter will display the offset and slope (at 25°). The display will return to the

screen in step 6.

17. If the slope is out of range (less than 45 mV/pH or greater than 60 mV/pH) or if the offset exceeds the value

programmed in Section 8.4, an error screen appears. The display then returns to the screen in step 6.

18. To return to the main display, press MENU then EXIT.

19. Choosing Setup in step 7 causes the Buffer Stabilize screen to appear. The transmitter will not accept calibration data

until the pH reading is stable. The default requirement is a pH change less than 0.02 units in 10 seconds. To change

the stability criteria:

a. Enter the desired stabilization time

b. Enter the minimum amount the reading is permitted to change in the time specied in step 19a.

20. To return to the main display, press MENU then EXIT.

7

Page 8

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

Sensor Wiring

Note

For additional wiring information on this product, including sensor combinations not shown here, please refer to either our online

wiring programs or the Manual DVD enclosed with each product.

1056, 1057, 56, 5081, 6081, 54e, and XMT :

http://www3.emersonprocess.com/raihome/sp/liquid/wiring/XMT/ 1066 and sensors with SMART preamps:

http://www2.emersonprocess.com/en-US/brands/rosemountanalytical/Liquid/Sensors/Pages/ Wiring_Diagram.aspx

1055:

http://www3.emersonprocess.com/raihome/sp/liquid/wiring/1055/

General Information

pH and ORP sensors without preamps manufactured by Rosemount Analytical can be wired directly to the 6081-P

wireless transmitter.

Sensor Wiring

To assist in sensor wiring, please refer to the one of the following resources:

1. Sensor Instruction Sheet – provided with each shipped sensor. Detailed wiring drawings show terminal block

connections for each sensor lead.

2. Online wiring program available at http://www.emersonprocess.com/raihome/liquid/products/wiring/Xmt displays

wiring schematics for all compatible pH sensors.

Note

All sensor wiring must be rated for ≥70 °C.

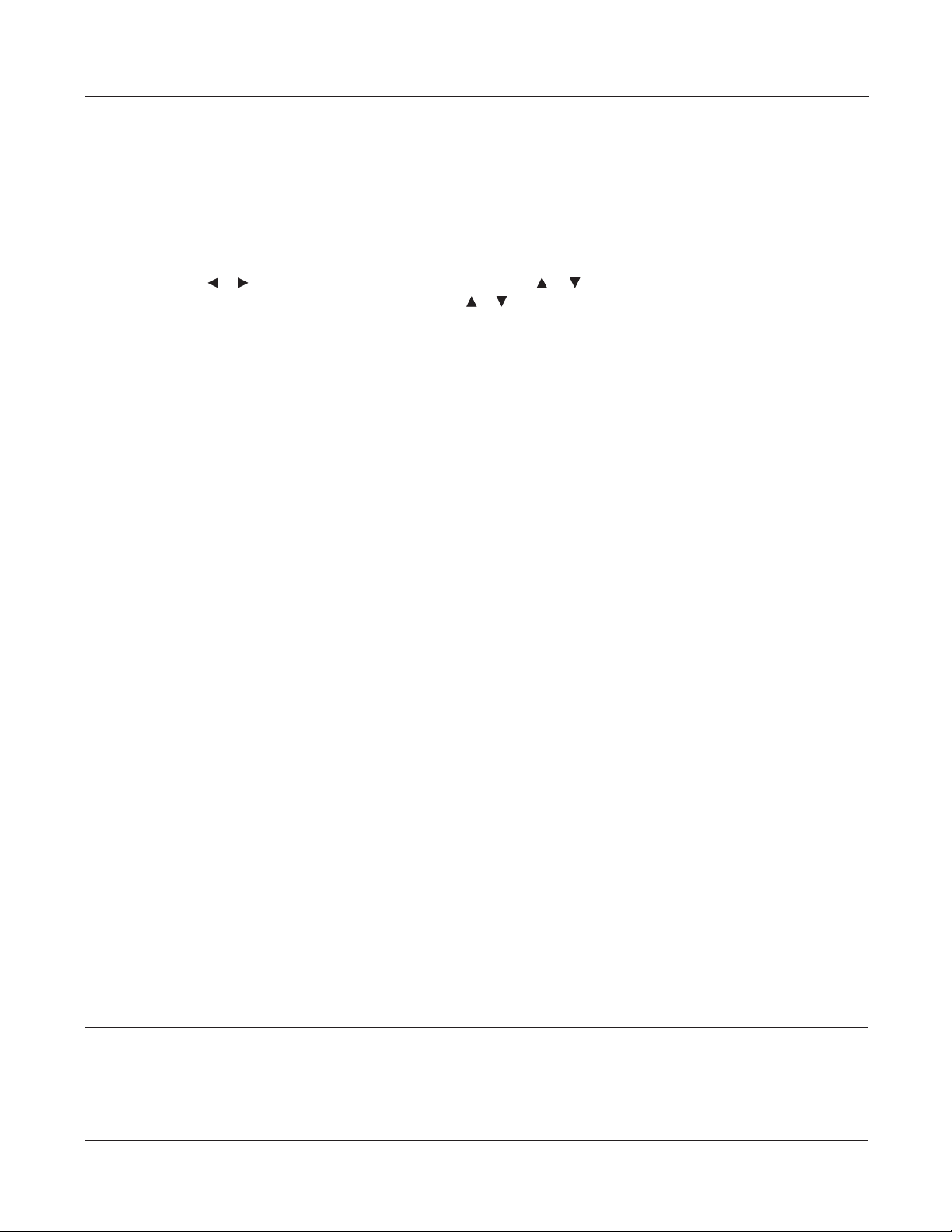

The following drawing identies each terminal block lead position for pH sensors.

Figure 3. 6081 Sensor Wiring and Connection Points

8

Page 9

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

Power Module Installation / Replacement

The expected life of the power module (PN 701PBKKF) is a minimum of four years at reference conditions. This section

describes the procedure for initial installation and replacement of the power module (PN 701PBKKF). The new power

module should be stored in a safe place with a controlled environment until the 6081 is ready for live operation. Note that

the power module is packed separately from the 6081 wireless transmitter upon delivery and must be installed initially.

For initial installation or replacement of the power module, follow these steps using a Philips-head screwdriver:

1. Unscrew the two long machine screws to remove the rear cover of the 6081. Separate the rear cover from the central

housing by manually prying the sections apart. Do not use screwdrivers or tools to separate these housing parts. The

parts are sealed with an o-ring.

2. Before installation, note the safety warning, disposal instructions and part information on the connection side label of

the power module.

3. With the 6081 front display section facing away from you, align the power module pack with the curved surface of

the pack facing towards you and the small protruding connector facing away from you. Make sure to align the power

module and its keyed connector with the connection receptacle in the middle of the instrument’s terminal block area.

4. With gentle pressure, insert the keyed connector on the power module into the receptacle (labeled Power Module

Connection on the drawing). The power module seats in the connection receptacle with an o-ring.

5. Conrm that the power module is fully inserted in the receptacle and properly aligned with the surrounding terminal

block.

6. Replace the rear cover of the 6081 with the two screws to secure it to the central housing. Tighten screws and verify

operation. Correct installation the rear cover will ensure that the power module is properly secured to power the

transmitter.

7. DO NOT RETURN SHIP THE USED POWER MODULE to Rosemount Analytical. Dispose of spent power modules as a

hazardous material in accordance with government regulations.

WARNING

Use only with Rosemount SMART Power Module (PN 701PBKKF)

9

Page 10

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

Mounting

Mounting on a Flat Surface

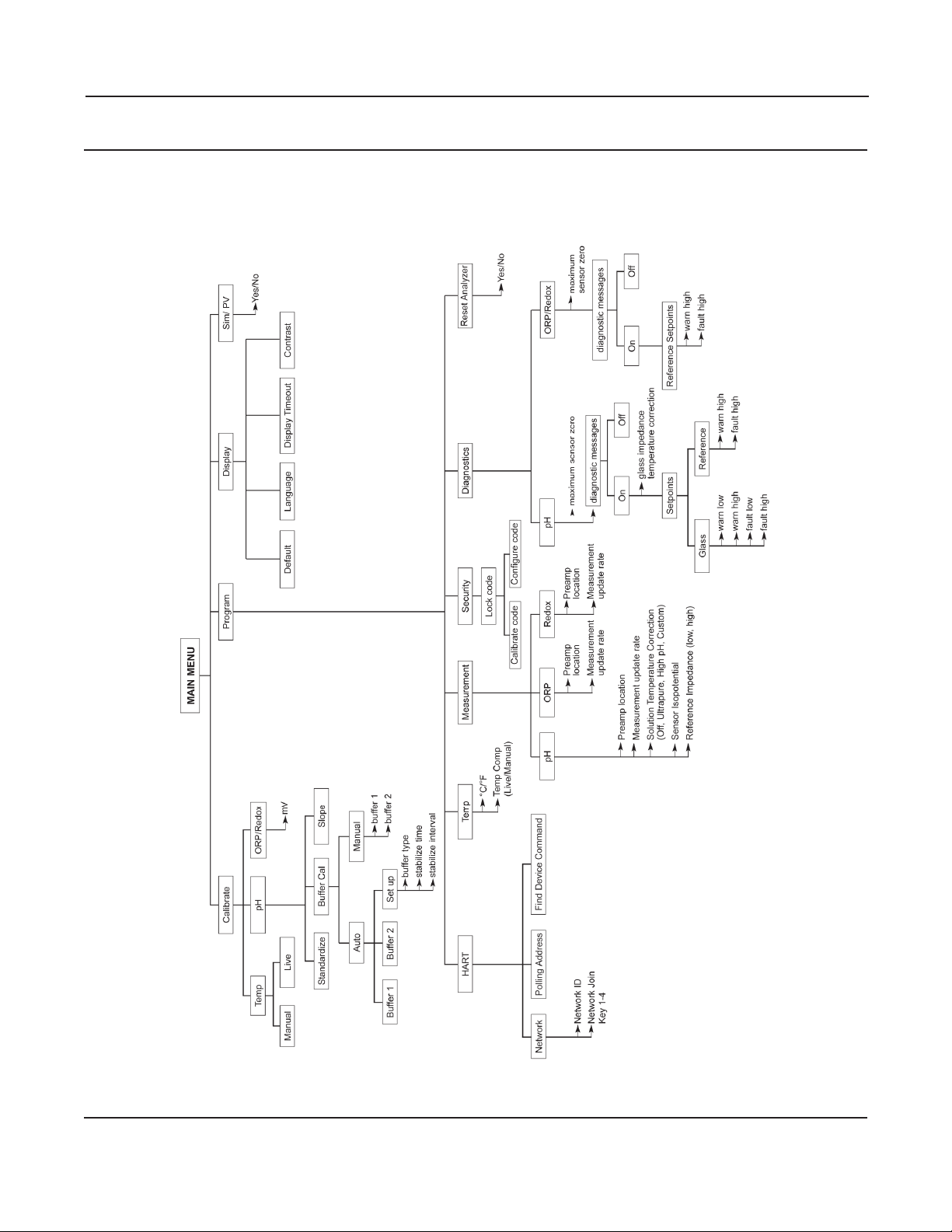

Figure 4. Wall Mounting Installation for 6081.

Use Pipe/Wall Mounting Bracket Kit, PN23820-00

Note: PN 23820-00 mounting bracket kit includes mounting hardware for pipe mounting only. Wall mounting hardware to be pro-

vided by customer. Only use suitable fasteners and hardware to securely fasten the bracket and transmitter to the wall surface

10

Page 11

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

Pipe Mounting

The pipe mounting kit (PN 23820-00/01) accommodates 1–½ in. pipe

Figure 5. Pipe Mounting Installation for 6081.

Use Pipe/Wall Mounting Bracket Kit, PN23820-00

11

Page 12

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

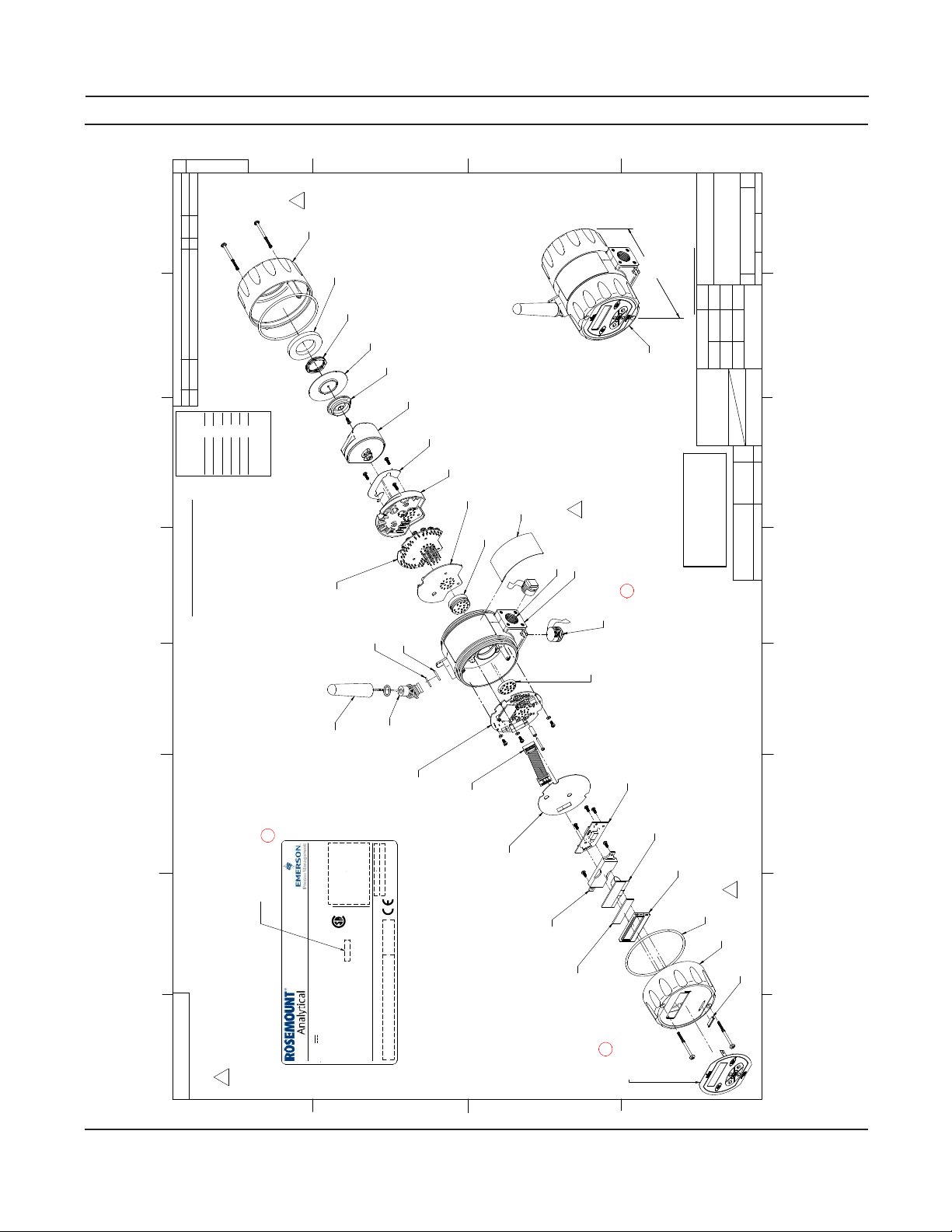

Figure 6. FM IS Installation

1

2

3

4

D

1700672

CHECKED/APPROVED

DATE

BY

REVISION

LTR ECO DESCRIPTION

THIS DOCUMENT IS

JP/ SP

5-18-11

LQD10215 SEE ECO CH

D

CERTIFIED BY

C

2

ALUMINUM

REAR COVER

PN 34182-00

POLYURETHANE

RING PN 9160626

ALUMI NUM WAVE RING

PN 9160627

NORYL BUSHING

PN 9160630

NEOPRENE SPACER RING

PN 34149-00

POWER MO DULE

PN 00753-9220-0001

REV

REV

REV

REV

REV

REV

W/O AGENCY APPROVAL

REVISIONS NOT PERMITTED

NORYL TERMINAL

BLOCK PN 34145-00

INTERFACE PCB

PN 24356-00 OR

PN 24357-00

NORYL TERMINAL

INS ULATOR

PN 34146-00

MYLAR WIRING DIAGRAM LABEL

PN 9241688-00

SILICONE PIN SEAL

PN 34150-00

NEOPRENE

O-RING

PN 9550343

B

6.55

4.80

121.92

O

POLYESTER AGENCY

CERTIFICATION LABEL

PN 9241685-01

2

3/4 -14NPT

ALUMINUM BASE

PN 34181-00

D1

OPTIONALLY INSTALLED ALUMINUM

OR BRASS PLUG WITH TEFLON TAPE

(2X)

A

D

REV

ANALYTICAL

ROSEMOUNT

166.44

Emerson

PROCESS MANAGEMENT

DATE

OVERALL DIMENSIONS

APPROVALS

DIMENSIONS ARE IN INCHES

MACHINE FILLET RADII .020 MAX

REMOVE BURRS & SHARP EDGES

THIS DRAWING HAS BEEN SUBMITTED

FOR HAZARDOUS LOCATION

APPROVAL. ANY CHANGES TO THIS

SHEET 1 OF 1

1

WEIGHT:

1700672

6081 XMTR I.S. (FM)

CERT PROD, MODEL

1:1

DWG NO

SIZE

D

TITLE

SCALE:

5-1-08

4-30-10

4-30-10

B. JOHNSON

DRAWN

ANGLES ± 1/2°.

NOMINAL SURFACE FINISH: 125

DRAWING REQUIRE AGENCY

APPROVAL.

2

J. PERKINS

S. PACI S

THIS FILE CREATED USING

SOLID EDGE

ENG APPR

CHECKED

.XX ± .03 .XXX ± .010

FINISH

MATERIAL

C

3

REV

LQD10112

ECO NO

APR 29, 10

RELEASE DATE

4

NORYL

PIN GUIDE

PN 34148-00

5

MAR KED AS 6081-A-BB-CCC

WHERE:

A = P (pH) OR C (CONDUCTIVITY)

BB = 67 (FM APPROVED)

APPROVED MODELS

6

7

8

Rosemount Analytical, and is not to be made available

to those who may compete with Rosemount Analytical.

This document contains information proprietary to

CCC = ANY 3 DIGIT NUMBER (COUNTRY CODE)

2X NEOPRENE

O-RING

POLY CARBONATE

ANTEENA

PN 9160628

POLY CARBON ATE

ADAPTE R

PN 9160629

OPTI ONAL

SPECTRUM APPROVAL

INFORMATION

3. ENCLOSURE MEETS THE REQUIREMENTS OF IP66.

1. PCB MATERIALS HAVE CTI> 175. ALL OTHER INSULATING MATERIALS HAVE CTI >100.

2 ALUMINUM FRONT COVER, ALUMINUM BASE AND ALUMINUM REAR COVER ARE MADE OF ALUMINUM

356C OR ALUMINUM ALLOY A413.0 OR ALUMINUM ALLOY A3 600.0 . THESE MATERI ALS CONT AIN LES S THAN

6 % MAGNESSIUM. PAINT MANUFACTURER: CADINAL, PART NO. 6442, BLUE.

NOTES: UNLESS OTHERWISE SPECIFIED

4. THE PAINT ON THE OUTER SURFACE OF THE ENCLOSURE IS LESS THAN 0.2mm THICK.

D

ASSEMBLY LOCATION

C

PN 9550342

DIS PLAY INT ERFACE PCB

PN 24298-00

WIRELE SS PCB W/2.4 GHz

HART 7 RADIO

PN 24295-00 OR

PN 24296-00

MODEL NUMBER

('ASSEMBLED IN MEXICO'

OR 'MADE IN USA')

POLYCARBONATE

14 PIN RBBON CABLE

PN 24224-00

POLY CARBONATE

INS ULATOR

PN 34183-00

RETAINER, LCD

PN 34254-00

GENCY CERTIFICATION LABEL

A

SERIAL NUMBER INCLUDES DATE CODE

WINDOW, F ILLER

PN 34255-00

B

LCD MODULE

PN 9010443

FRONT NORYL LCD FRAME

PN 34163-00

2X NEOPRENE O-RING

PN 9550344

(Mc MASTER-CARR PART NO. 4679T281

MADE OF BLACK BUNA-N,

-65°C TO +275°F COT)

2

ALUMINUM

FRONT COVER

PN 34180-00

D2

POLYESTER

KEYPAD/OVERLAY

PN 34259-00

A

5

6

7

NORYL DISPLAY

FRAME PN 34175-00

8

12

Page 13

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

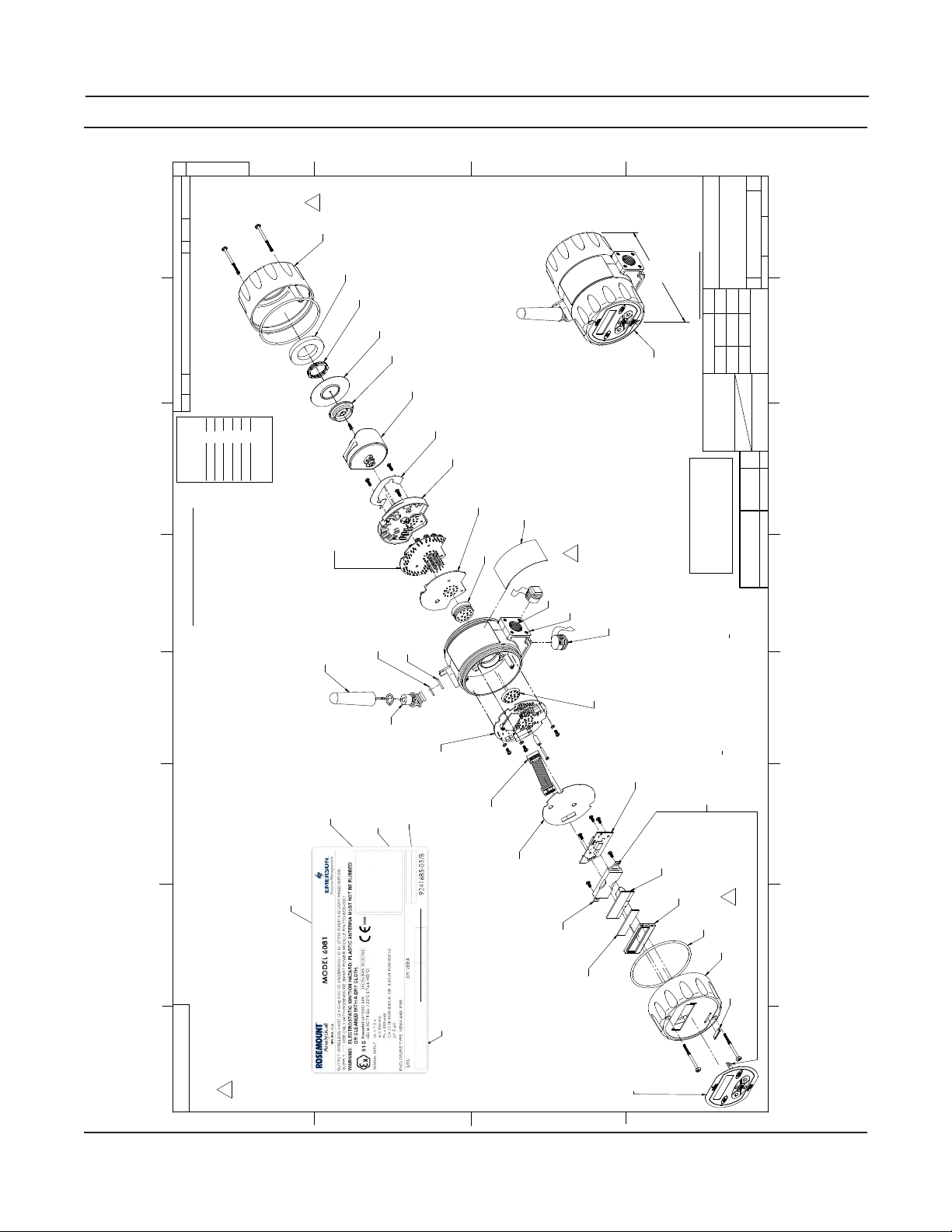

Figure 7. CSA IS Installation

1

2

3

4

D

1700673

CHECKED/APPROVED

DATE

BY

REVISION

LTR ECO DESCRIPTION

THIS DOCUMENT IS

APPROVED MODELS

C

JP/DOC

5-18-11

LQD10215 SEE ECO CH

D

REV

REV

REV

REV

REV

REV

CERTIFIED BY

6081-P-69-XXX

6081-C-69-XXX

WHERE XXX=COUNTRY CODE

EXAMPLE:108=BRAZIL

2

ALUMINUM

REAR COVER

POLYURETHANE

RING

ALUMINUM

WAVE R ING

NORYL BUSHING

NEOPRENE

SPACER RING

POWER MO DULE

PN 00753-9920-0001

MYLAR WIRING

DIAGR AM LABE L

NORYL TERMINAL

W/O AGENCY APPROVAL

REVISIONS NOT PERMITTED

INTERFACE PCB

PN 24356-00 OR

PN 24357-00

NEOPRENE

O-RING

2X NEOPRENE

BLOCK

NORYL TERMINAL

INS ULATOR

SILICONE

PIN S EAL

O-RING

B

6.55

4.80

121.92

O

POLYESTER AGENCY

CERTIFI CATION LABEL

2

3/4-14NPT

ALUMINUM BASE

D1

OPTIONALLY INSTALLED ALUMINUM

OR BRASS PLUG WITH TEF LON TAPE

(2X)

A

D

REV

ANALYTICAL

ROSEMOUNT

166.44

Emerson

PROCESS MANAGEMENT

DATE

OVERALL DIMENSIONS

APPROVALS

DIMENSIONS ARE IN INCHES

MACHINE FILLET RADII .020 MAX

REMOVE BURRS & SHARP EDGES

THIS DRAWING HAS BEEN SUBMITTED

FOR HAZARDOUS LOCATION

APPROVAL. ANY CHANGES TO THIS

SHEET 1 OF 1

1

WEIGHT:

1700673

6081 XMTR I.S.(CSA)

CERT PROD, MODEL

1:1

DWG NO

SIZE

D

TITLE

SCALE:

5-9-10

5-5-08

5-5-10

J. PERKINS

DRAWN

ANGLES ± 1/2°.

NOMINAL SURFACE FINISH: 125

DRAWING REQUIRE AGENCY

APPROVAL.

2

C. HOANG

D, CROWLEY

THIS FILE CREATED USING

SOLID EDGE

ENG APPR

CHECKED

.XX ± .03 .XXX ± .010

FINISH

MATERIAL

C

3

REV

LQD10154

ECO NO

MAY 21, 10

RELEASE DATE

4

NORYL

PIN GUIDE

5

POLY CARBON ATE

POLY CARBONATE

ANTENNA

6

D3

IN THIS AREA, PRINT:

1400335 IF 6081P,

1400336 IF 6081C

®

7

MODEL 6081

8

1. PCB MATERIALS HAVE CTI> 175. ALL OTHER INSULATING MATERIALS HAVE CTI >100.

3. ENCLOSURE MEETS THE REQUIREMENTS OF NEMA 4X AND IP66.

2 MATERIAL: ALUMINUM ALLOY CONTAINING LESS THAN 6% BY WEIGHT OF M AGNESIUM.

NOTES: UNLESS OTHERWISE SPECIFIED

Rosemount Analytical, and is not to be made available

to those who may compete with Rosemount Analytical.

This document contains information proprietary to

D

HAZARDOUS AREA WHEN CONNECTED PER DWG

GROUPS A, B, C, D, E, F & G

INTRINSICALLY SAFE FOR CLASS I, II & III, DIVISION 1,

WARNING: COMPONENT SUBSTITUTION MAY IMPAIR INTRINSIC SAFETY

OR SUITABILITY FOR DIVISION 2

SUPPLY: USE ONLY WITH ROSEMOUNT SMART POWER MODULE P/N 753-9220-0001

OUTPUT: WIRELESS HART (2.4 GHz) FCC ID: LW2R M2510 / IC ID: 2731A-RM2510 IS CONTAINED WITHIN.

ADAPTE R

WIRELE SS PCB

W/2.4 GHz

HART 7 RADIO

PN 24295-00 OR

PN 24322-00

POLY CARBON ATE

14 PIN RBBON CABLE

9241685-02/B

POLY CARBON ATE

INS ULATOR

-LR 34186

DWG 1700673

2:1

AGENCY CERTIFICATION LABEL

°CT4 Tamb = 65

S/N: SW VER#

ENCLOSURE TYPE: NEMA 4/4X IP66

DUST IGNITION PROOF CLASS II AND III, DIVISION 1, GROUPS E, F & G

NON-INCENDIVE CLASS I, DIVISION 2 GROUPS A, B, C & D

C

RETAINER, LCD

PN 34254-00

WINDOW, FILLER

B

DIS PLAY INT ERFACE PCB

PN 24298-00

LCD MODULE

FRONT NORYL

LCD F RAME

2X NEOPRENE O-RING

ALUMINUM

PN 34255-00

D2

POLY CARBONATE

OR POLYESTER

KEYPAD/OVERLAY

A

5

6

2

7

FRONT COVER

NORYL

DISPLAY

FRAM E

8

13

Page 14

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

Figure 8. ATEX IS Installation

1

2

3

4

D

1700674

CHECKED/APPROVED

DATE

BY

REVISION

LTR ECO DESCRIPTION

THIS DOCUMENT IS

APPROVED MODELS

CERTIFIED BY

C

2

ALUMINUM

REAR COVER

POLYURETHANE

RING

ALUMINUM

WAVE R ING

NORYL BUSHING

NEOPRENE

SPACER RING

POWER MODULE

PN 00753-9220-0001

MYLAR WIRING

REV

REV

REV

REV

REV

REV

W/O AGENCY APPROVAL

REVISIONS NOT PERMITTED

INTERFACE PCB

PN 24356-00 OR

PN 24357-00

6081-P-73-XXX

6081-C-73-XXX

WHERE XXX=COUNTRY CODE

EXAMPLE:108=BRAZIL

NEOPRENE

POLY CARBONATE

ANTENNA

O-RING

DIAGR AM LABE L

NORYL TERMINAL

BLOCK

NORYL TERMINAL

INS ULATOR

SILICONE

PIN SEAL

2X NEOPRENE

O-RING

B

6.55

4.80

121.92

O

POLYESTER AGENCY

CERTIFICATION LABEL

(SILVER POLYESTER

THERMfilm SELECT 22970)

2

3/4-14NPT

ALUMINUM BASE

OPTIONALLY INSTALLED ALUMINUM

OR BRASS PLUG WITH TEFLON TAPE

(2X)

A

D

REV

ANALYTICAL

ROSEMOUNT

166.44

Emerson

PROCESS MANAGEMENT

DATE

OVERALL DIMENSIONS

APPROVALS

DIMENSIONS ARE IN INCHES

MACHINE FILLET RADII .020 MAX

REMOVE BURRS & SHARP EDGES

THIS DRAWING HAS BEEN SUBMITTED

FOR HAZ ARDOUS LOC ATION

APPR OVAL. ANY CHANGES TO THIS

SHEET 1 OF 1

1

WEIGHT:

1700674

CERT PROD, MODEL

6081 XMTR I.S.(ATEX)

1:1

DWG NO

SIZE

D

TITLE

SCALE:

8-9-10

8-9-10

7-20-10

C. HOAN G

DRAWN

ANGLES ± 1/2°.

NOMINAL SURFACE FINISH: 125

DRAWING REQUIRE AGENCY

APPR OVAL.

2

J. PERKINS

D. CROWLEY

THIS FILE CREATED USING

SOLID EDGE

ENG APPR

CHECKED

.XX ± .03 .XXX ± .010

FINISH

MATERIAL

D

3

REV

LQD10235

ECO NO

AUG 10, 2010

RELEASE DATE

4

NORYL

5

POLY CARBON ATE

ADAPTE R

WIRELE SS PCB

W/2.4 GHz

HART 7 R ADIO

PN 24295-00 OR

PN 24296-00

OPTI ONAL

6

SPECTRUM APPROVAL INFORMATION

OMIT THE IECEx NUMBER IF ONLY

ATEX APP ROVAL IS WAN TED.

MODEL NUMBER

ASSEM BLY L OCATION

POLYCARBONATE

14 PIN RBBON CABLE

POLYCARBONATE

INSU LATOR

7

> 175. ALL OTHER INSULATING MATERIALS HAVE CTI >100.

AGENCY CERTIFICATION LABEL

SERIAL NUMBER INCLUDES DATE CODE

PIN GUIDE

DISP LAY INTE RFACE PCB

PN 24298-00

NOTE: THE STATIC GUARD LAYER GROUNDING TAB IS SECURED

TO THE HOUSING USING INDICATED SCREW. THE STATIC GUARD

LAYER MUST BE < 0.2mm FROM TOP SURFACE OF OVERLAY.

ANY VOID AREA IN THE STATIC GUARD LAYER MUST BE < 4 cm²

LCD MODULE

FRONT NORYL

LCD FRAME

2X NEOPRENE O-RING

ALUMINUM

FRONT COVER

RETAINER, LCD

PN 34254-00

WINDOW, F ILLER

PN 34255-00

8

POLY CARBON ATE

OR POLYESTER

3. ENCLOSURE MEETS THE REQUIREMENTS OF NEMA 4X AND IP66.

1. PCB MATERIALS HAVE CTI

2 MATERIAL: ALUMINUM ALLOY CONTAINING LESS THAN 6% BY WEIGHT OF MAGNESIUM.

NOTES: UNLESS OTHERWISE SPECIFIED

Rosemount Analytical, and is not to be made available

to those who may compete with Rosemount Analytical.

This document contains information proprietary to

D

C

B

KEYPAD/OVERLAY

A

5

6

2

7

NORYL

DIS PLAY

FRAM E

8

14

Page 15

Instruction Sheet 6081-P

LIQ_MAN_ABR_6081-P October 2013

15

Page 16

6081-P Instruction Sheet

October 2013 LIQ_MAN_ABR_6081-P

facebook.com/EmersonRosemountAnalytical

AnalyticExpert.com

twitter.com/RAIhome

youtube.com/user/RosemountAnalytical

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

rosemountanalytical.com

© Rosemount Analytical Inc. 2013

Credit Cards for U.S. Purchases Only.

©2013 Rosemount Analytical, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark of one

of the Emerson Process Management family of companies. All other marks are the property of their

respective owners.

The contents of this publication are presented for information purposes only, and while effort has been

made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request. We reserve the right to modify

or improve the designs or specications of our products at any time without notice.

Loading...

Loading...