Page 1

Emerson Walk-In Solutions

Page 2

Walk-in coolers and freezers play an important part in your operation. Emerson is working

hard to ensure that your walk-in cooler or freezer is as reliable and energy-effi cient as possible.

We’re pioneering new refrigeration technologies, from compressors and condensing units to

electronicsand monitoring. And we have the resources to make sure the job gets done right.

Emerson offers a wide range of innovative products, solutions, support, training and tools –

all designed to make life more comfortable and your job easier. Our portfolio of brands offer

innovative, industry-leading solutions that combine technology and engineering for the

benefi t of our customers, our environment, and our future.

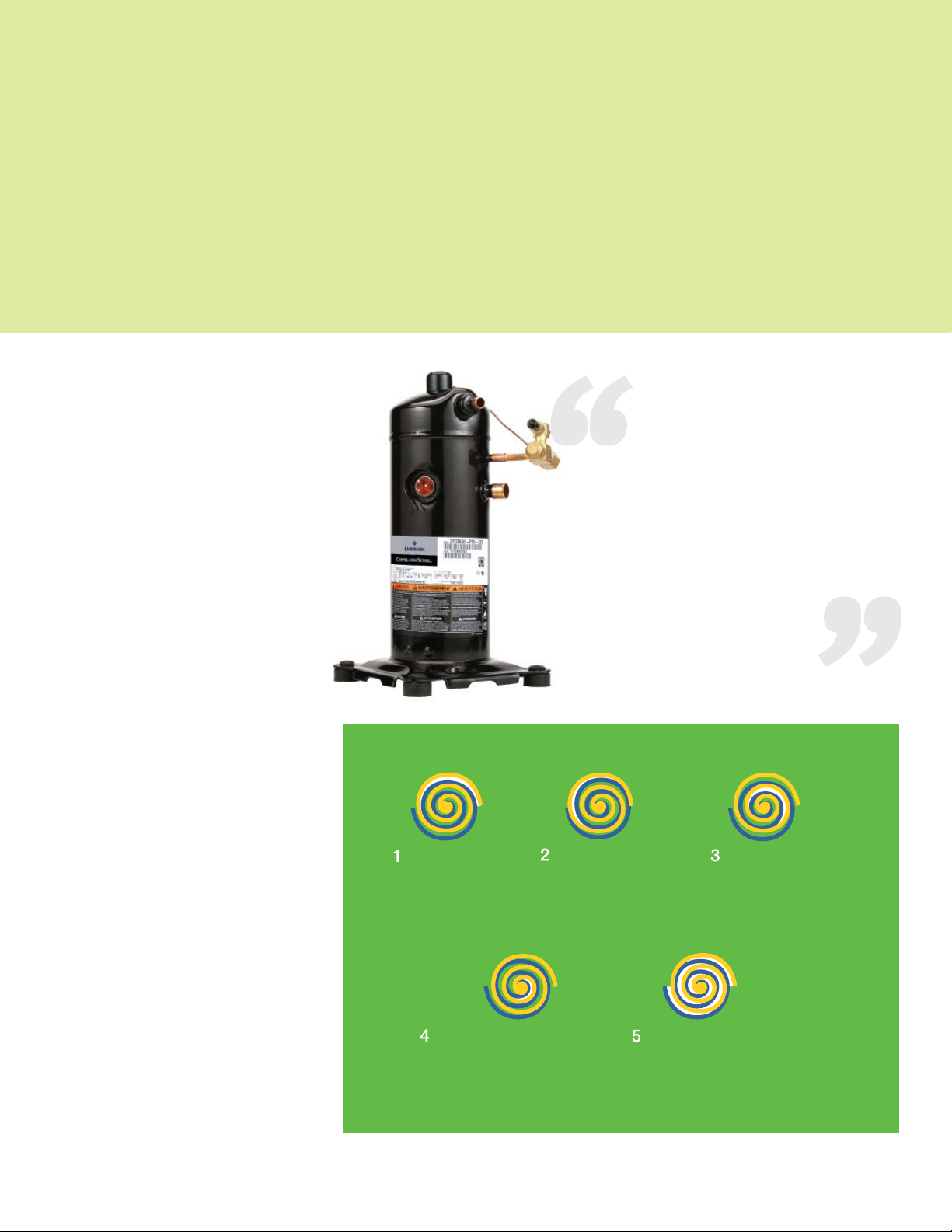

Copeland Scroll™ Compressors

for Refrigeration

The freezers in the newer

Copeland Scroll compressors have

earned a reputation for reliability and

lower energy costs. Unlike compressors

which use pistons (including hermetic

and semi-hermetic compressors), scroll

compressors have only two moving

scroll members. This difference results

in a more reliable, energy effi cient walk-

in, which translates into less downtime

and lower energy bills.

With more than 170 million Copeland

Scroll™ compressors installed, you’re

not just choosing a compressor, you’re

choosing nearly 30 years of scroll innovation and expertise. And, protecting

your reputation by selecting a compressor that is of the highest quality in the

commercial refrigeration market. With

our complete lineup of compressors for

low-, medium- and extended mediumtemperature applications for walk-in

coolers and freezers, we’ll help you

select the confi gurable solution that fi ts

your needs. Since our compressors are

distributed in the US, we can help ensure

compressor and service availability for

our customers.

HOW SCROLL COMPRESSORS WORK

Gas enters an

outer opening as

one scroll orbits

the other.

Gas is continually compressed

to the center of the scrolls,

where it is discharged through

precisely machined ports and

returned to the system.

restaurant stores use mostly

scroll compressors and they are

extremely reliable. In fact, we’ve

been servicing Copeland Scroll

compressors in restaurants for

about nine years and had

only one go bad.

– Service Manager

Dayton, Ohio

The open passage is

sealed as gas is drawn

into the compression

chamber.

During actual operation, all

passages are in various stages

of compression at all times,

resulting in near-continuous

intake and discharge.

As one scroll

continues orbiting,

the gas is compressed

into an increasingly

smaller ‘pocket’.

To learn more visit Climate.Emerson.com/Copeland

Page 3

Copeland Scroll Outdoor Refrigeration Unit,

X-Line Series

Copeland Scroll Digital Outdoor Refrigeration Unit,

X-Line Series

The Copeland Scroll Outdoor Refrigeration Unit, X-Line Series

sets a new standard for energy effi ciency, reliability, and

installation fl exibility. With capacities now available from ¾ to

6 HP and expanded refrigerant approvals, its industry leading

onboard diagnostics and system protection are available for

more applications commonly found in today’s foodservice

establishments.

The Copeland Scroll Outdoor Refrigeration Unit was designed

with three factors in mind:

Energy Efficiency

Scroll compressor technology, variable speed fan motors,

large capacity condenser coils, and advanced control

algorithms, work together to signifi cantly reduce energy

consumption.

Reliability and Communications

Equipment reliability is greatly enhanced by combining

the proven reliability of Copeland Scroll compressors with

advanced CoreSense™ technology. Each unit has built-in

CoreSense Diagnostics and protection that can alert and

record alarms independently or communicate with building

management systems.

Building on the fi eld-proven Copeland Scroll and X-Line

Outdoor Refrigeration Unit platforms, the Digital X-Line

Series delivers superior food safety and energy effi ciency in

small-format supermarkets, convenience stores and

foodservice establishments.

Digital modulation enables tighter control of case temperatures, giving operators the security of knowing their food is

kept safe and at maximum quality. The Digital X-Line Series

combines compression technology with variable-speed fan

motor control, large-capacity condenser coils, and smart

protection and diagnostics to meet today’s challenging

refrigeration requirements.

Ideal for walk-in coolers and display cases, digital X-Line units

deliver more precise, reliable refrigeration, longer-lasting

equipment, and lower energy bills in medium-temperature

applications.

Energy Efficiency Advantages

• Substantial annual energy effi ciency improvements

• Reduced compressor cycling

• Longer equipment life

• Decreased electrical load at startup

Flexibility

The ultra-quiet variable-speed fan motor signifi cantly reduces

exterior sound levels and is combined with a lightweight

weather-resistant cabinet, slim footprint, and optional wall

mounting capability to deliver unmatched installation fl exibility.

Copeland Scroll Outdoor Refrigeration Unit, X-Line Series Copeland Scroll Digital Outdoor Refrigeration Unit, X-Line Series

To learn more, visit Climate.Emerson.com/X-Line

Refrigeration Reliability Improvements

• Precise setting and tight control over case temperatures

• Load matching from 20 to 100 percent

• Improved product integrity, which helps operators

maximize food quality and safety

Page 4

Copeland Scroll Water-Cooled and Air-Cooled

Condensing Units for Refrigeration

Complying with the DOE’s Mandate on

Walk-In Coolers and Freezers

Copeland Scroll air cooled refrigeration units (F-Line Series)

allow evaporator temperatures as low as -40° while using

today’s new high heat refrigerants. Available in nominal sizes

from ¾ to 5 horsepower, F-Line condensing units are ideal for

cooler and freezer applications including display cases, merchandisers, and walk-ins. Our low-temperature offering has

built-in liquid injection controls discharge temperatures and

expands the operating range of the compressor.

To review our AWEF compliant lineup, visit Emerson Online Product Information (OPI) or Climate.Emerson.com/AWEFCatalog

The DOE’s energy effi ciency mandate will take aim at walk-in

coolers and freezers (WICFs) — requiring 20–40 percent energy reductions in WICFs smaller than 3,000 square feet that

are manufactured after the following enforcement dates:

• January 1, 2020, for dedicated condensing systems

applied in walk-in coolers

• July 10, 2020, for dedicated condensing systems applied

in walk-in freezers

As a manufacturer of condensing units for a wide range of

commercial refrigeration applications, we have released our

condensing units for walk-in applications according to the

DOE’s minimum AWEF requirements with respect to the

above compliance dates. For OEMs, these certifi ed condensing

units will help you achieve compliance in one of your primary

refrigeration system components. Simply combine a Copeland

AWEF-rated condensing unit with an AWEF-rated unit cooler in

order to achieve compliance in a dedicated system.

Dixell™ XW60K Walk-In System Controller

The Dixell XW60K Walk-In System Controller from Emerson

replaces the following devices on a walk-in cooler or freezer:

• Mechanical thermostat

• Defrost time clock (with On-Demand Defrost)

• Fan control

• Klixon defrost termination

• Temperature and door open alarm

• Thermometer

• Light Timer

Standard Features

• On-Demand® Defrost Algorithm

• Remote Keypad (100 ft) w/ buzzer- J-Box

• Display Update Delay

• Confi gurable Inputs and Outputs

• Pump Down feature (fan on)

• Evaporator Fan Cycling

• Auto-On/ Off Light timer / Manual light switch

• Blast Chill Mode (with optional product probe)

• Energy Saver mode SetPoint shift (up or down) with auto

time out

Remote Power Board Walk-In Box Keypad

Page 5

Supervisory Controls

Complete facility control made simple

Control Controlled facility Facility insight

For retailers, providing fresh, quality food while maintaining

a convenient shopping experience for their customers is a

constant challenge. It means keeping close watch over every

store system and piece of equipment impacting that experience — from refrigeration and lighting to heating and cooling.

Emerson’s family of Supervisory controls delivers the right

control system and power for every operation and enterprise.

Supervisory controls, a fl exible facility control platform, man-

ages refrigeration, HVAC, lighting and other critical equipment and systems. It also collects data on important performance indicators, including refrigerated case temperatures,

energy usage and HVAC discharge and space temperatures,

so store managers can quickly respond to issues that may

impact the customer experience and food safety.

While powerful and feature-rich, Supervisory Controls are still

easy enough to use at the local levels, giving store managers

and service technicians enterprise-level visibility to systems

and equipment through a simple, intuitive interface.

Supervisory Controls are optimized for use with our Connect+

Enterprise Management System and can also seamlessly

connect to Emerson’s ProAct™ Services to diagnose alarms,

resolve problems, and maintain systems .

White-Rodgers™ Electrical Control Valves

EX valves from White-Rodgers are stepper motor designed

to ensure stable operation at low condensing pressures.

The valve seat and slider are made of solid ceramic for long

life, low operating force and low internal leak rates. The

positive shut off function and fast response time eliminate

the need for an additional solenoid valve. The tear drop

shape of the ceramic slide enables linear capacity characteristics between 10% and 100% maximum capacity.

EXD-SH1, EX4-EX8 Stepper

Motor Driven Valves

Stepper Motor

Controller EXD-U

Control valves EX4 ... EX8 for capacities

from .5 to 290 tons. (R-410A @ to=+4/tc = -36F)

Superheat Controller EC3-X33 with built-in backup

battery and display unit ECD-002

White-Rodgers Electronic Temperature Control

The 16E09-201 from White-Rodgers is a

single stage control that utilizes a SPDT

relay to achieve output and provides

superior temperature control for

refrigeration or heating applications.

• Multiple input voltages - 120/208/240

Volts AC

• Adjustable differential settings - 1° to 30°F

• Broad set-point range - 40° to 220°F

ProAct Services

Tablet Smartphone PC Optional display

Site Supervisor connects with a number of 3rd party devices. For a complete list of these devices please visit Emerson.com/RetailSolutions

Authorized technician

Cloud/WAN

Store router

Corporate offi ce

System

Supervisor

Lighting control

HVAC control

Refrigeration monitoring and control (optional)

Optional

lighting

expansion

modules

Optional

HVAC

expansion

modules

Optional

refrigeration

expansion

monitoring/

control

Page 6

Emerson System Protectors

When it comes to the refrigeration systems you install and maintain, what matters the most? It’s keeping them running at peak

effi ciency. Keeping your reputation intact and your customers satisfi ed. It’s the kind of protection you can only get from Em-

erson. Our EK fi lter driers, HMI hermetic moisture indicators, along with many other high-performance products, provide you

with a total package that delivers more reliable and longer lasting protection from moisture and contaminants.

Product Application Features

•Compacted bead fi lter drier that

provides long-lasting protection

from moisture and contaminants

•Premium universal replacement

for CFC, HCFC and HFC

Liquid line filter drier (EK)

•Replaceable core fi lter drier for

CFC, HCFC and HFC refrigerants

•Ideal for use in large commercial

air conditioning and refrigeration

systems

•High moisture and acid removal capacity

•Optimized to use with HFC refrigerants and POE

lubricants

• 680 psig maximum working pressure

• 20 micron outlet pad for maximum fi ltration

•Slotted cover/unique internal hardware for ease of

installation

• Full fl ow fi ttings for low pressure drop

• R-410A rated models available

Steel liquid and suction

filter drier (STAS)

Brass take-apart suction line

filter drier (BTAS)

Filter drier cores and filter s

• Replaceable core fi lter drier for

suction line service

• Ideal for commercial refrigeration

applications

•Universal replacement cores and

fi lter cores to remove moisture,

acid, and debris from the system

•For use in Emerson shells and

other take-a-part type fi lter drier

shells

•A unique high accuracy moisture

indicator for CFC, HCFC, and HFC

refrigerants

• Designed to accurately determine the moisture content of a

system’s refrigerant

• Corrosion resistant brass body with stainless steel

bolts

• Full fl ow fi ttings for low pressure drop

• Filter and fi lter drier cartridges available

• Water capacities to suit specifi c system conditions

• Exceptional acid capacities for normal system protection, or to clean up after a compressor burnout

• Activated carbon blend for soluble contaminant and

wax removal (W-HH Series)

•Highest sensitivity moisture indicator available provides best protection

• Hermetic, leak-free construction eliminates leaks

and refrigerant loss

•Single indicator for all common refrigerants

•Wide angle viewing/high visibility window for easy

monitoring

H e r m e t i c m o i s t u r e i n d i c a t o r s ( H M I )

Page 7

Cooper-Atkins™ NotifEye™

Wireless Monitoring System

The NotifEye monitoring system eliminates the time and

expense of manual monitoring. NotifEye sensors can be easily

mounted in any location, wirelessly monitoring temperatures

against preset conditions that are defi ned by the user and

foodservice industry today – especially when relating to food

safety. No longer will you need to visit and record temperatures

of equipment manually.

NotifEye™ is a low-cost wireless solution that is self-installable

and ready to use out-of-the-box. The online portal can also

be used to display data from certain wireless products using

Bluetooth® technology to allow digital integration within the

Cold Chain.

Box Load Calculator

This new tool allows you to calculate a room load and select

equipment based on the calculated load or known load value.

The Box Load Calculator is web-based – which means no

downloads are necessary.

This new tool allows you to select appropriate Copeland™

condensing units to match your load – which also means

there’s no longer a need for a separate calculation and manual

selection of equipment from our catalogs. You are also able

to choose evaporators from multiple manufacturers, which

makes it easy to select a complete equipment solution.

Access the Box Load Calculator at Climate.Emerson.com/BLC

• Refrigerator/Freezers

• Walk-ins/Reach-ins

• Prep Areas

• Dry Storage

• Salad/Deli Bars

• Steam Tables

• Open Air Cases

• Hot-holding Cabinents

Comprehensive Aftermarket Support Network

Emerson’s aftermarket services offer vast support

programs to support wholesalers by providing them

with the products and information they need to service

the installed base. These resources give contractors and

service technologies the tools and inventories to support

food retail operations:

• 32,000/year same-day shipments

• 850+ Authorized Wholesaler locations

• 160,000 Compressors and $6M Parts

• 540+ Copeland Technical Specialists

Page 8

About Emerson

Emerson (NYSE: EMR), headquartered in St.

Louis, Missouri (USA), is a global technology

and engineering company providing inno-

vative solutions for customers in industrial,

commercial, and residential markets. Our

Emerson Automation Solutions business helps

process, hybrid, and discrete manufacturers

maximize production, protect personnel and

the environment while optimizing their energy

and operating costs. Our Emerson Commer-

cial and Residential Solutions business helps

ensure human comfort and health, protect food

quality and safety, advance energy effi ciency,

and create sustainable infrastructure. For more

information visit Emerson.com.

Emerson.com

2020ECT-6 (1/20) Emerson, Cooper-Atkins, Copeland Scroll, Dixell, NotifEye and White-Rodgers are trademarks of

Emerson Electric Co. or one of its affi liated companies. ©2020 Emerson Climate Technologies, Inc. All rights reserved.

Loading...

Loading...