Page 1

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N Smart Pressure Transmitter for Nuclear Service

www.rosemountnuclear.com

Page 2

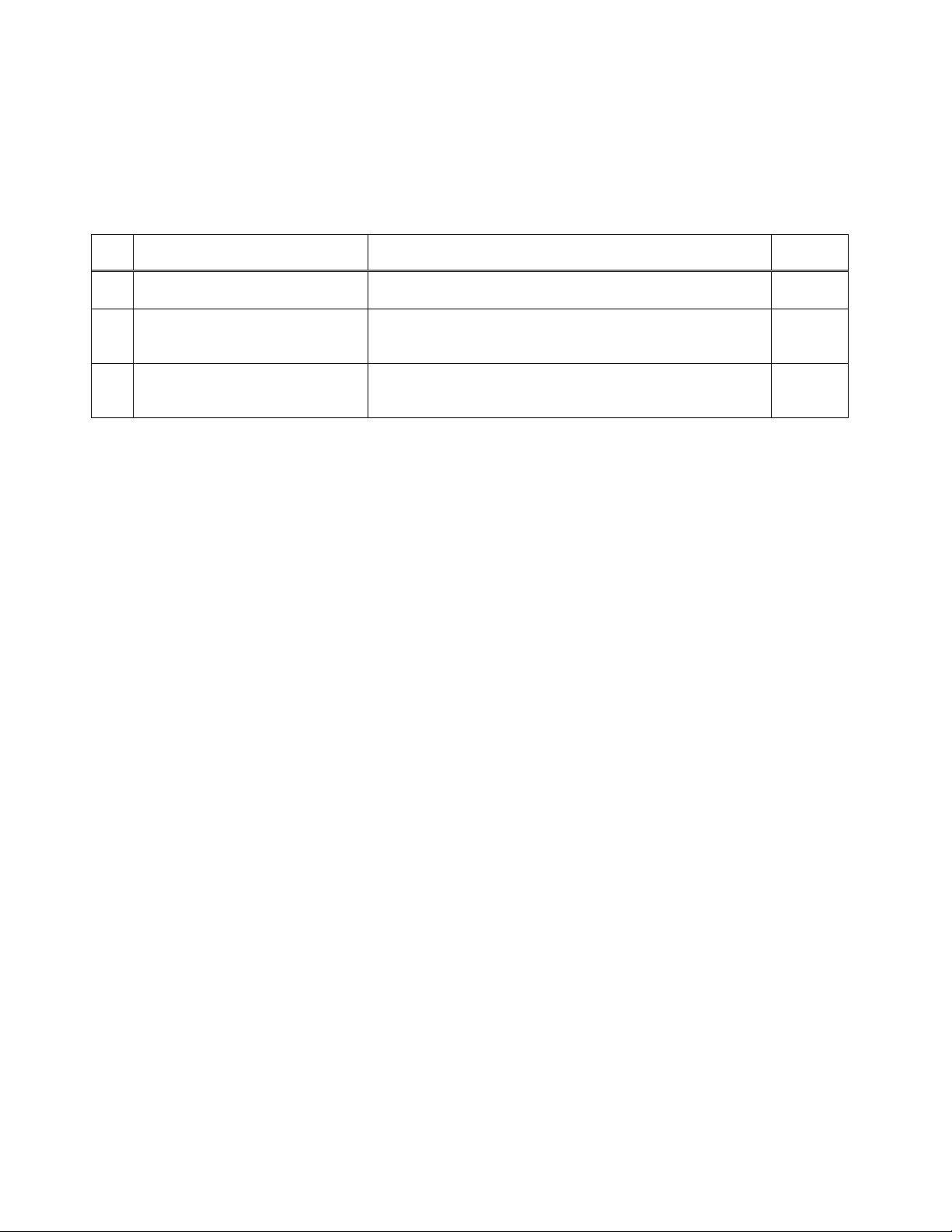

IMPOR TANT NOTICE -- ERRATA

Model 3051N Product Manual 00809-0100-4808 Rev CA (6/2008)

No. Affected Pages Description of Change

1 5-8 Flange Bolts and Mounting Bolts - Carbon steel, per

ASTM A449 Type 1 or SAE J429 Grade 5…

2 5-8 Electronics Housing – Low copper aluminum with

polyurethane paint, or CF-8M (cast version of 316

SST)...

3 5-8

Mounting Bracket – AISI 1010 steel or JIS G3131

SPHC P/O Steel with polyurethane paint (Option Code

B2)...

Effect.

Date

12/3/07

11/18/08

1/24/11

12/5/07

Page 3

Reference Manual

Rosemount Nuclear Instruments, Inc.

8200 Market Blvd.

Chanhassen, Mn 55317

Tel 952-949-5210

Fax 952-949-5201

©Rosemount Nuclear Instruments, Inc.

www.rosemountnuclear.com

Rosemount Nuclear Instruments, Inc.

satisfies all obligations coming from

legislation to harmonize product

requirements in the European Union.

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Rosemount 3051N Smart Pressure Transmitter for Nuclear Service

Rosemount 3051 HART Universal Revision 5

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

Within the United States, contact Rosemount Nuclear Instruments, Inc. at

1-952-949-5210 for assistance.

Outside of the United States, contact your local Emerson Process

Management Sales Representative.

The Rosemount logotype, and SMART FAMILY are registered trademarks of Rosemount Inc.

Coplanar is a trademark of Rosemount Inc.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

D.C. 200 is a registered trademark of Dow Corning Corporation.

HART is a registered trademark of the HART Communication Foundation.

www.rosemountnuclear.com

Page 4

Reference Manual

00809-0100-4808, Rev CA

Rosemount 3051N

June 2008

Rosemount Nuclear Instruments, Inc. Warranty and Limitations of Remedy

The warranty and limitations of remedy applicable to this Rosemount equipment are as stated on the reverse of the

current Rosemount quotation and customer acknowledgment forms.

RETURN OF MATERIAL

Authorization for return is required from Rosemount Nuclear Instruments, Inc. prior to shipment. Contact Rosemount Nuclear Instruments,

Inc. (1-952-949-5210) for details on obtaining Return Material Authorization (RMA). Rosemount Nuclear Instruments will not accept

any returned material without a Returned Material Authorization. Material returned without authorization is subject to return to

customer.

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Nuclear Instruments, Inc.

8200 Market Blvd.

Chanhassen, MN 55317

USA

IMPORTANT

The Rosemount 3051N Pressure Transmitter is qualified for nuclear use per IEEE Std 344-1987 and IEEE Std 323-1983 (mild

environment) as documented in Rosemount Report D2001019, and is supplied in accordance with 10CFR50 Appendix B and ISO

9001:2000 quality assurance programs. To ensure compliance with 10CFR Part 21, the transmitter must comply with the requirements

herein and in Report D2001019 throughout its installation, operation, and maintenance. It is incumbent upon the user to ensure that the

Rosemount Nuclear Instruments, Inc. component traceability program where applicable is continued throughout the life of the transmitter.

Where the manual uses the terms requirements, mandatory, must, or required, the instructions so referenced must be carefully followed.

Rosemount Nuclear Instruments, Inc. expressly disclaims all responsibility and liability for transmitters for which the foregoing has not

been complied with by the user.

ii

Page 5

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

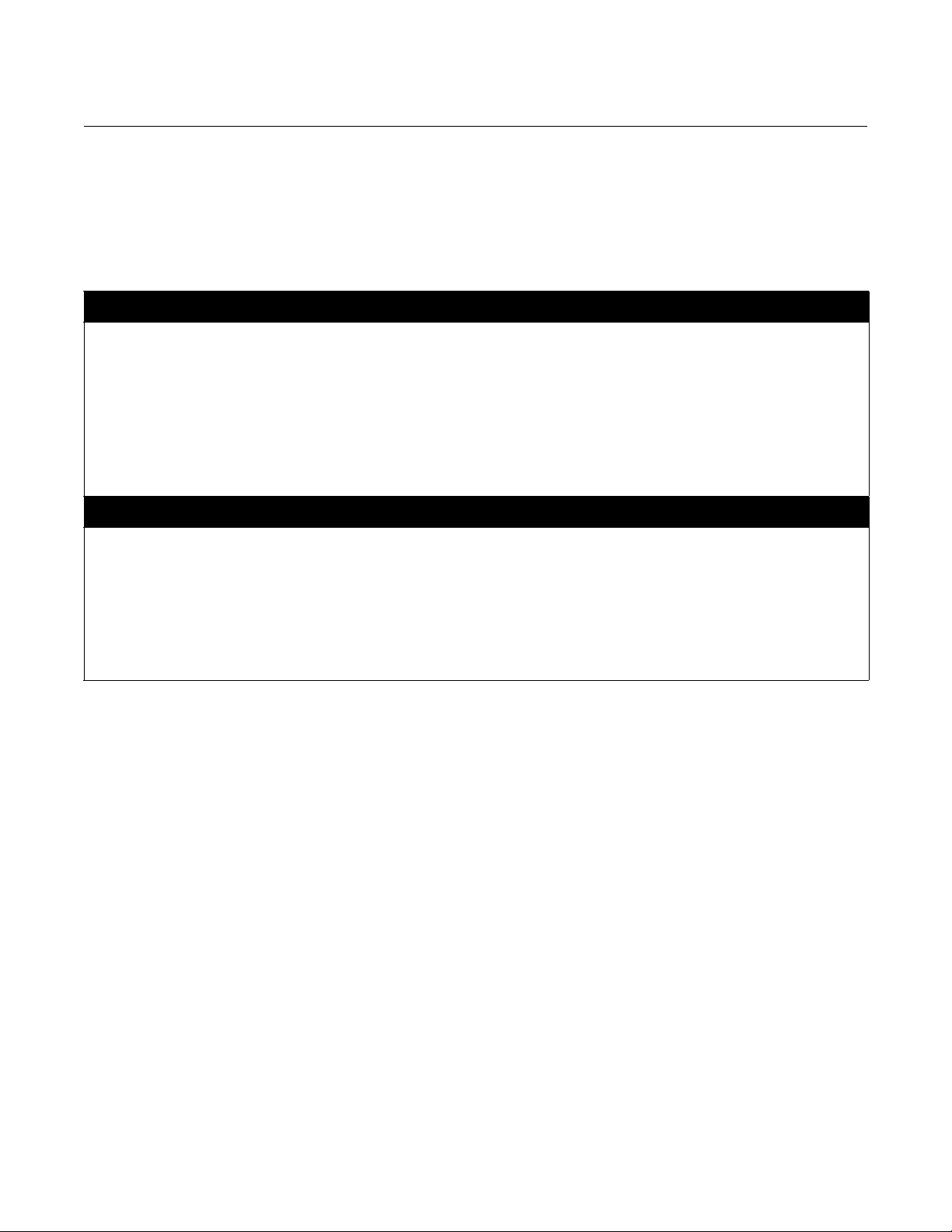

Revision Status

Changes from June 2006 to June 2008

Page (Old) Page (New) Changes

Cover,

throughout

TOC-1 Page i, back

- Page iii Add Revision Status page

TOC-1 to TOC-8 i to iv and TOC-1

Throughout Throughout Manual number corrected to 00809-0100-4808

3-6 and 3-8 3-6 and 3-8 Changed significant digits to conform to standard

3-12 3-12 Removed word ‘process’ from sentences indicating user responsibility for qualifying the connection

5-7 5-8 Reworded flange bolt description to reflect qualification configuration

NOTE

The above Revision Status list summarizes the changes made. Please refer to both manuals for complete

comparison details.

Cover,

throughout

cover

to TOC-4

Document revision date change from June 2006 to June 2008,

rev from BA to CA

CE mark added with Rosemount Nuclear Instruments, Inc.

Page numbers changed

interface

www.rosemountnuclear.com

Page 6

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

iv

Page 7

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Table of Contents

SECTION 1

Introduction

SECTION 2

Transmitter Functions

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Failure Mode Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Alarm Level Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Security Jumper (Write Protect) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Local Zero and Span (Local Keys) Software Lock Out. . . . . . . . . . 2-3

Physical Removal of Local Zero and Span (Local Keys) . . . . . . . . 2-3

Configuring Transmitter Alarm

and Security Jumper Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Commissioning the Rosemount 3051N with a

HART-Based Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting the Loop to Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Wiring Diagrams (Bench Hook-up). . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Wiring Diagrams (Field Hook-up) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Check Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Process Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Sensor Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Set Process Variable Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Set Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Rerange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Rerange with a Communicator Only. . . . . . . . . . . . . . . . . . . . . . . . 2-9

Rerange with a Pressure Input Source and a Communicator . . . 2-10

Rerange with a Pressure Input Source and

the Local Zero and Span Buttons . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

LCD Meter Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Local Span and Zero Control (Local Keys). . . . . . . . . . . . . . . . . . 2-12

Sensor Temperature Output Unit Selection . . . . . . . . . . . . . . . . . 2-12

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Transmitter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Calibration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Deciding Which Trim Procedure to Use . . . . . . . . . . . . . . . . . . . . 2-16

Sensor Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

www.rosemountnuclear.com

Page 8

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

Zero Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Full Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Recall Factory Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Recall Factory Trim— Sensor Trim . . . . . . . . . . . . . . . . . . . . . . . 2-19

Recall Factory Trim— Analog Output. . . . . . . . . . . . . . . . . . . . . . 2-19

Analog Output Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Digital-to-Analog Trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Digital-to-Analog Trim Using Other Scale. . . . . . . . . . . . . . . . . . . 2-19

Compensating Rosemount 3051N Range 4 and

5 Differential Transmitters for Line Pressure . . . . . . . . . . . . . . . . 2-20

SECTION 3

Installation

SECTION 4

Troubleshooting

SECTION 5

Specifications and

Reference Data

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Special Draft Range Considerations . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Housing Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Grounding the Transmitter Case . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Access Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Returning Rosemount Products and Materials. . . . . . . . . . . . . . . . 4-2

Nuclear Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Quality Assurance Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Nuclear Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Hydrostatic Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Reference Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Ambient Temperature Effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Overpressure Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Static Pressure Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Power Supply Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Load Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Mounting Position Effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

TOC-2

Page 9

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Temperature Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Span and Zero, Zero Elevation, and Suppression . . . . . . . . . . . . . 5-6

Humidity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Volumetric Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Turn-on Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Maximum Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Static Pressure Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Overpressure Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Burst Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Rosemount 3051N 4-20 mA/HART Output Smart

Pressure Transmitters Typical Configuration Data Worksheet . . . . . 5-12

SECTION 6

Options

APPENDIX A

HART Communicator

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LCD Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Custom Meter Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Installing the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Traditional Flange (H2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Transient Protection Terminal Block (T1) . . . . . . . . . . . . . . . . . . . . . . 6-8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Connections and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Rosemount 275 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Communicator Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Action Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Function Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Alphanumeric and Shift Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Fast Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Fast Key Sequence Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Fast Key Sequence Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Menus and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Online Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Rosemount 375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Communicator Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Action Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Alphanumeric Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Function Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

TOC-3

Page 10

Rosemount 3051N

Glossary

Index

Reference Manual

00809-0100-4808, Rev CA

June 2008

Multifunction LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Using the Soft Input Panel (SIP) keyboard. . . . . . . . . . . . . . . . . . A-13

Menus and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

HART Application Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Fast Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Hot Key options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Diagnostic Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

TOC-4

Page 11

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Section 1 Introduction

USING THIS MANUAL The sections in this manual provide information on installing, operating, and

maintaining devices from the Rosemount 3051N Smart Pressure Transmitter

Family. The sections are organized as follows:

Section 2: Transmitter Functions

Provides instruction on commissioning and operating Rosemount 3051N

Pressure Transmitters. Information on software functions, configuration

parameters, and on-line variables is also included.

Section 3: Installation

Contains mechanical and electrical installation instructions.

Section 4: Troubleshooting

Provides troubleshooting techniques for the most common Rosemount 3051N

transmitter operating problems.

Section 5: Specifications and Reference Data

Supplies reference and specification data for the Rosemount 3051N Smart

Pressure Transmitter Family.

Section 6: Options

Describes the mounting and configuration options available for Rosemount

3051N transmitters.

Appendix A: HART Communicator

Gives an overview of the HART Communicator, defines its partial command

menu tree for the Rosemount 3051N family, and provides a table of typical

fast key sequences. A table of typical diagnostic messages is also included.

www.rosemountnuclear.com

Page 12

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

1-2

Page 13

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Section 2 Transmitter Functions

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Failure Mode Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-8

Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-12

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-12

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-13

OVERVIEW This section contains information on commissioning and operating

Rosemount 3051N Smart Pressure Transmitters. Tasks that should be

performed on the bench prior to installation are explained in this section.

When the HART Communicator is referenced, it refers to either the

Rosemount 275 or Rosemount 375 as documented in Rosemount Report

D2001019.

For your convenience, typical HART Communicator fast key sequences are

listed for most software functions. These fast key sequences are the same for

both the Rosemount 275 and Rosemount 375 Communicators. If you are

unfamiliar with the communicator or how to follow fast key sequences, please

refer to Appendix A for communicator operations.

A typical transmitter software configuration data worksheet is provided in

Section 5.

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the following safety messages before performing an operation preceded by

this symbol.

Warnings

Explosions can result in death or serious injury.

• Do not remove the transmitter covers in explosive environments when the

circuit is alive.

www.rosemountnuclear.com

Page 14

Reference Manual

00809-0100-4808, Rev CA

Rosemount 3051N

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present

on leads can cause electrical shock.

June 2008

FAILURE MODE ALARM Rosemount 3051N transmitters automatically and continuously perform

self-diagnostic routines. If the self-diagnostic routines detect a failure, the

transmitter drives its output outside of the normal saturation values. The

transmitter will drive its output low or high based on the position of the failure

mode alarm jumper. See Table 2-1 for failure mode and saturation output

levels. To select alarm position, see “Configuring Transmitter Alarm and

Security Jumper Procedure” in Section 2.

Table 2-1. Standard Alarm and Saturation Values.

Level

4–20 mA

Saturation

4–20 mA

Alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

NOTE

You can alter the actual transmitter mA output values by performing an analog

output trim.

NOTE

When a transmitter is in an alarm condition, the hand-held HART

Communicator indicates the analog output the transmitter would drive if the

alarm condition did not exist. The transmitter will alarm high in the event of

failure if the alarm jumper is removed.

Alarm Level Verification Transmitters allow verification testing of alarm current levels. If you replace

the LCD meter, reconfigure or make any changes to the transmitter, verify the

transmitter alarm level before you return the transmitter to service. This

feature is also useful in testing the reaction of your control system to a

transmitter in an alarm state. To verify the transmitter alarm values, perform a

loop test and set the transmitter output to the alarm value (see Table 2-1 and

“Loop Test” in Section 2).

TRANSMITTER

There are three security methods with the Rosemount 3051N transmitter:

SECURITY

2-2

Page 15

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

1. Security Jumper: prevents all writes to transmitter configuration.

2. Local Keys (Local Zero and Span) Software Lock Out: prevents changes to transmitter range points via local zero and span adjustment keys. With local keys security enabled, changes to configuration are possible via HART.

3. Physical Removal of Local Keys (Local Zero and Span) Magnetic Buttons: removes ability to use local keys to make transmitter range point adjustments. With local keys security enabled, changes to configuration are possible via HART.

NOTE

If the security jumper is not installed, the transmitter will continue to operate in

the security OFF configuration.

Security Jumper (Write Protect)

Local Zero and Span (Local Keys) Software Lock Out

Physical Removal of Local Zero and Span (Local Keys)

CONFIGURING TRANSMITTER ALARM AND SECURITY JUMPER PROCEDURE

You can prevent changes to the transmitter configuration data with the write

protection jumper. Security is controlled by the security (write protect) jumper

located on the electronics board or meter face. Position the jumper on the

transmitter circuit board in the “ON” position to prevent accidental or

deliberate change of configuration data.

If the transmitter write protection jumper is in the “ON” position, the transmitter

will not accept any “writes” to its memory. Configuration changes, such as

digital trim and reranging, cannot take place when the transmitter security is

on.

To enable this feature, see “Local Span and Zero Control (Local Keys)” in

Section 2.

To remove the magnetic buttons used to activate the local zero and span, use

a small slotted head screwdriver and pry off the small, plastic cap located

under the approval tag. Remove button assemblies and discard.

To reposition the jumpers, follow the procedure described below.

1. If the transmitter is installed, secure the loop and remove power.

2. Remove the housing cover opposite the field terminal side. Do not remove the transmitter covers in explosive atmospheres when the circuit is alive.

3. Reposition the jumpers as desired.

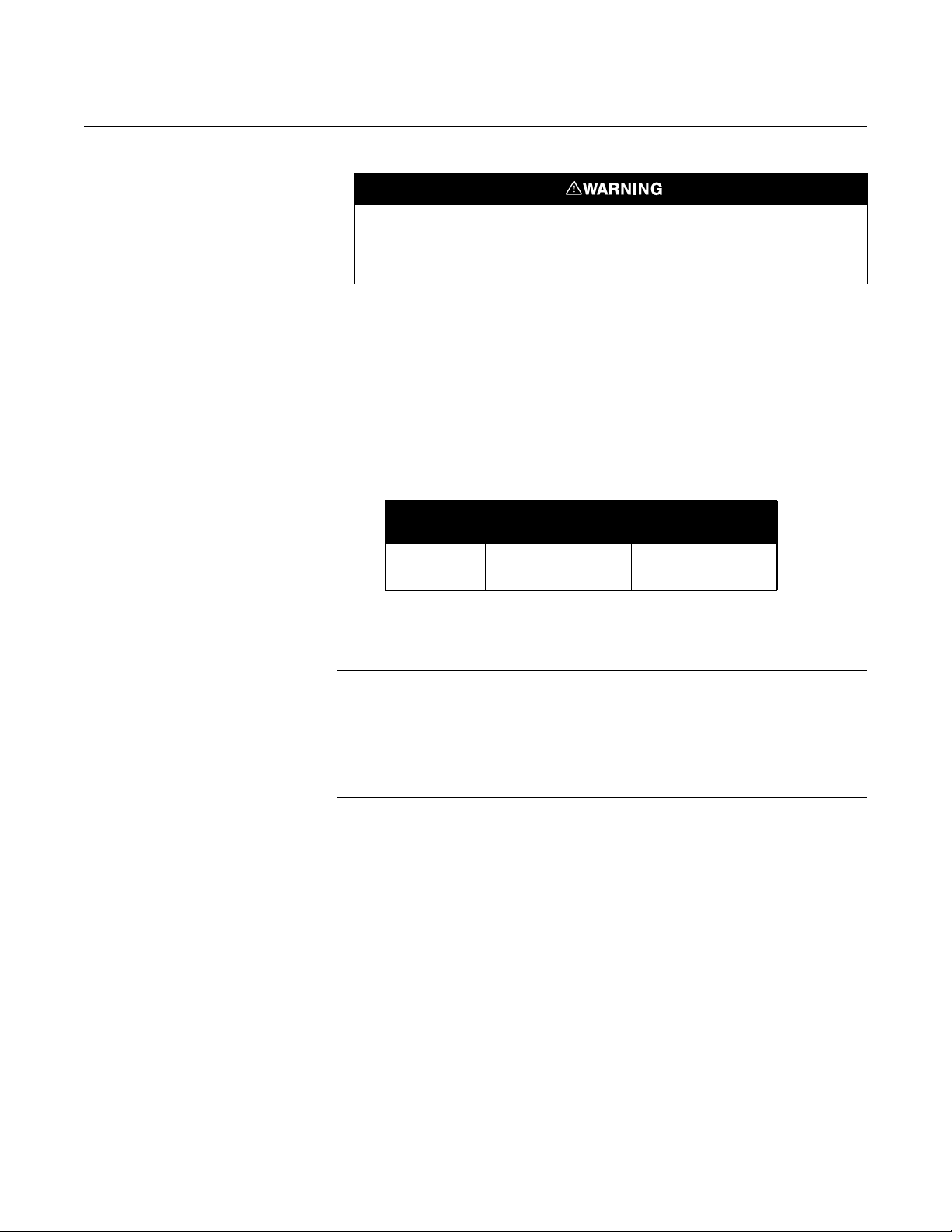

• Figure 2-1 shows the jumper positions for Electronics Boards.

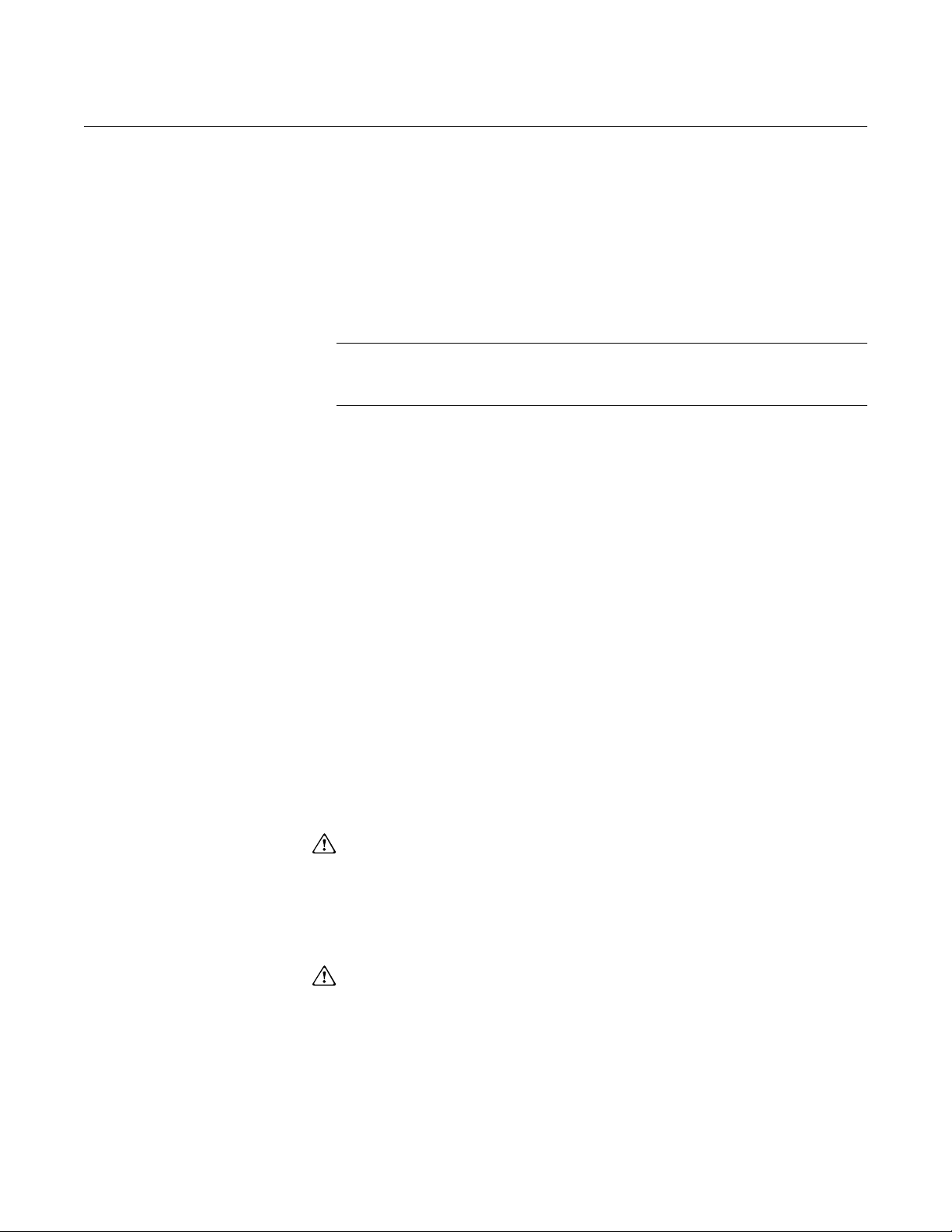

• Figure 2-2 shows transmitters with an optional LCD meter.

4. Reattach the transmitter cover. Transmitter covers must be fully engaged to meet explosionproof requirements.

2-3

Page 16

Rosemount 3051N

ELECTRONICS BOARD

Alarm

Security

HI

LO

OFF

ON

NOTE

Security jumper not installed = Not Write Protected.

Alarm jumper not installed = High Alarm.

FIGURE 2-1. Electronics Board.

Reference Manual

00809-0100-4808, Rev CA

June 2008

FIGURE 2-2. Rosemount 3051N with Optional LCD Meter.

COMMISSIONING THE ROSEMOUNT 3051N WITH A HART-BASED COMMUNICATOR

Commissioning consists of testing the transmitter and verifying transmitter

configuration data. You may commission Rosemount 3051N transmitters

either before or after installation. Commissioning the transmitter on the bench

before installation using a HART-based Communicator ensures that all

transmitter components are in good working order and acquaints you with the

operation of the device.

2-4

Page 17

Reference Manual

See “Safety Messages” on page 2-1 for warning information.

24 V dc

Supply

R

L

≥ 250Ω

Current

Meter

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

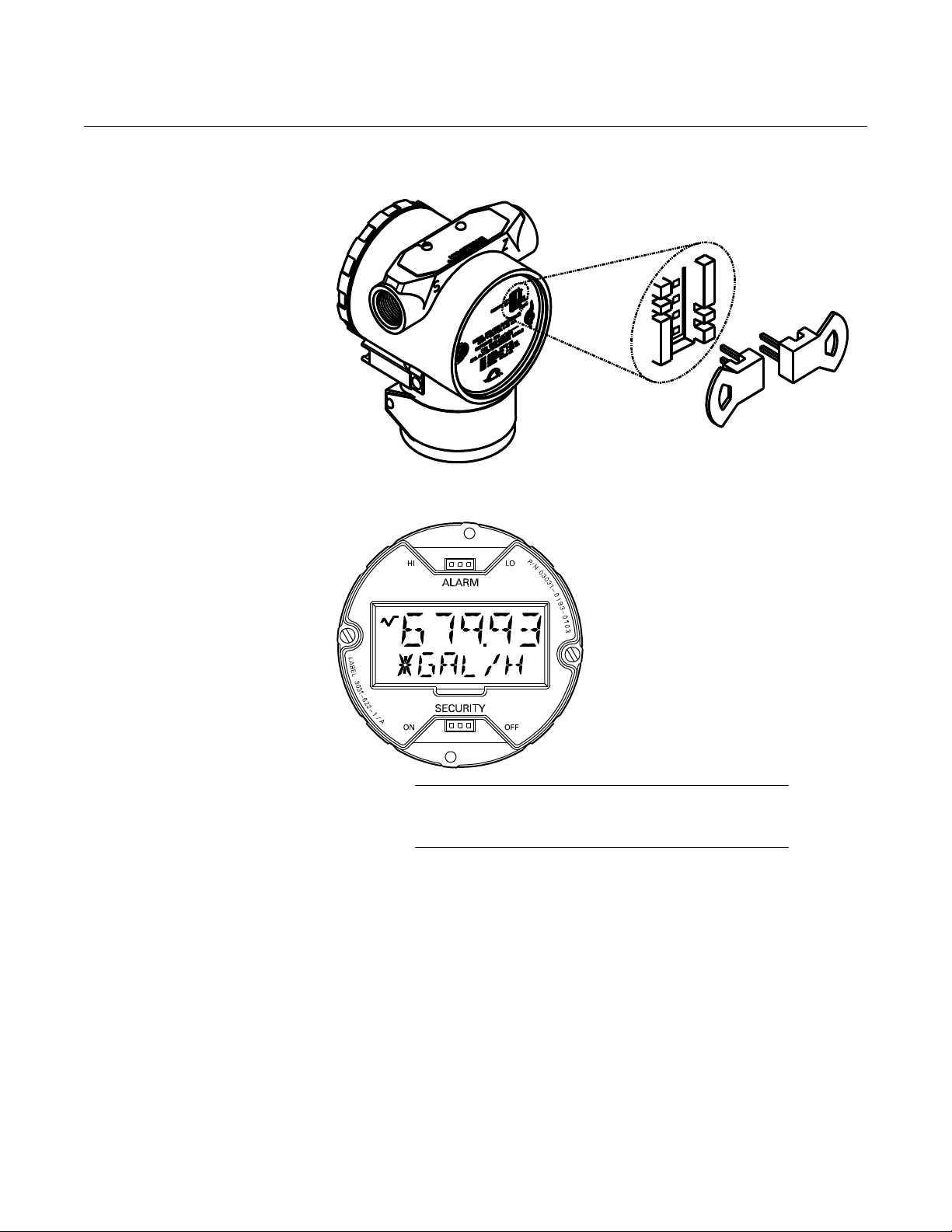

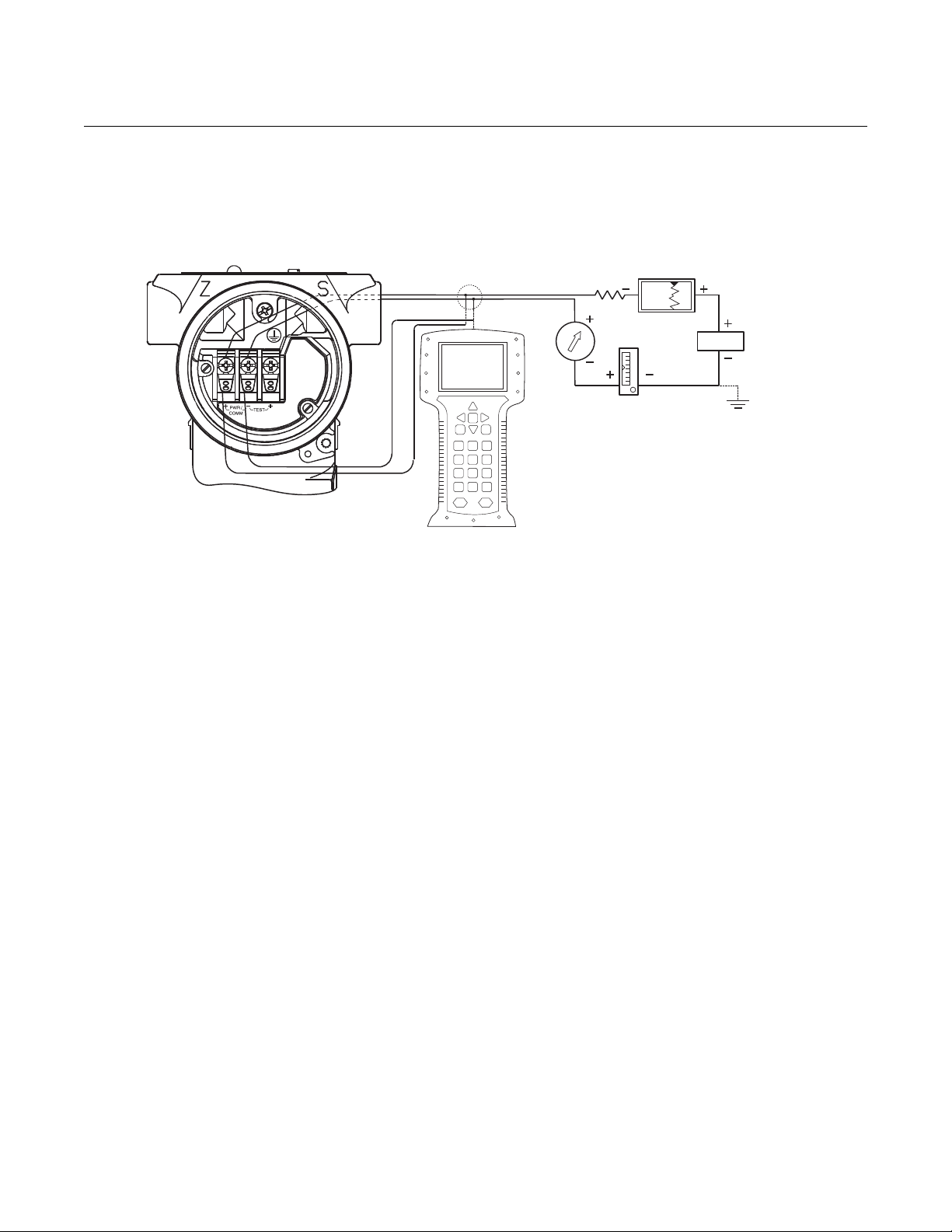

To commission on the bench, connect the transmitter and the communicator

as shown in Figure 2-3. Make sure the instruments in the loop are installed in

accordance with intrinsically safe or nonincendive field wiring practices before

connecting a communicator in an explosive atmosphere. Connect the

communicator leads at any termination point in the signal loop. It is most

convenient to connect them to the terminals labeled “COMM” on the terminal

block. Connecting across the “TEST” terminals will prevent successful

communication. To avoid exposing the transmitter electronics to the plant

environment after installation, set all transmitter jumpers during the

commissioning stage on the bench.

For 4–20 mA transmitters, you will need a power supply capable of providing

10.5 to 55 V dc at the transmitter, and a meter to measure output current. To

enable communication, a resistance of at least 250 ohms, but within the

transmitter load limitations (see Figure 3-7 “Power Supply Load Limitations.”

in Section 3) must be present between the communicator loop connection and

the power supply. Do not use inductive-based transient protectors with the

Rosemount 3051N.

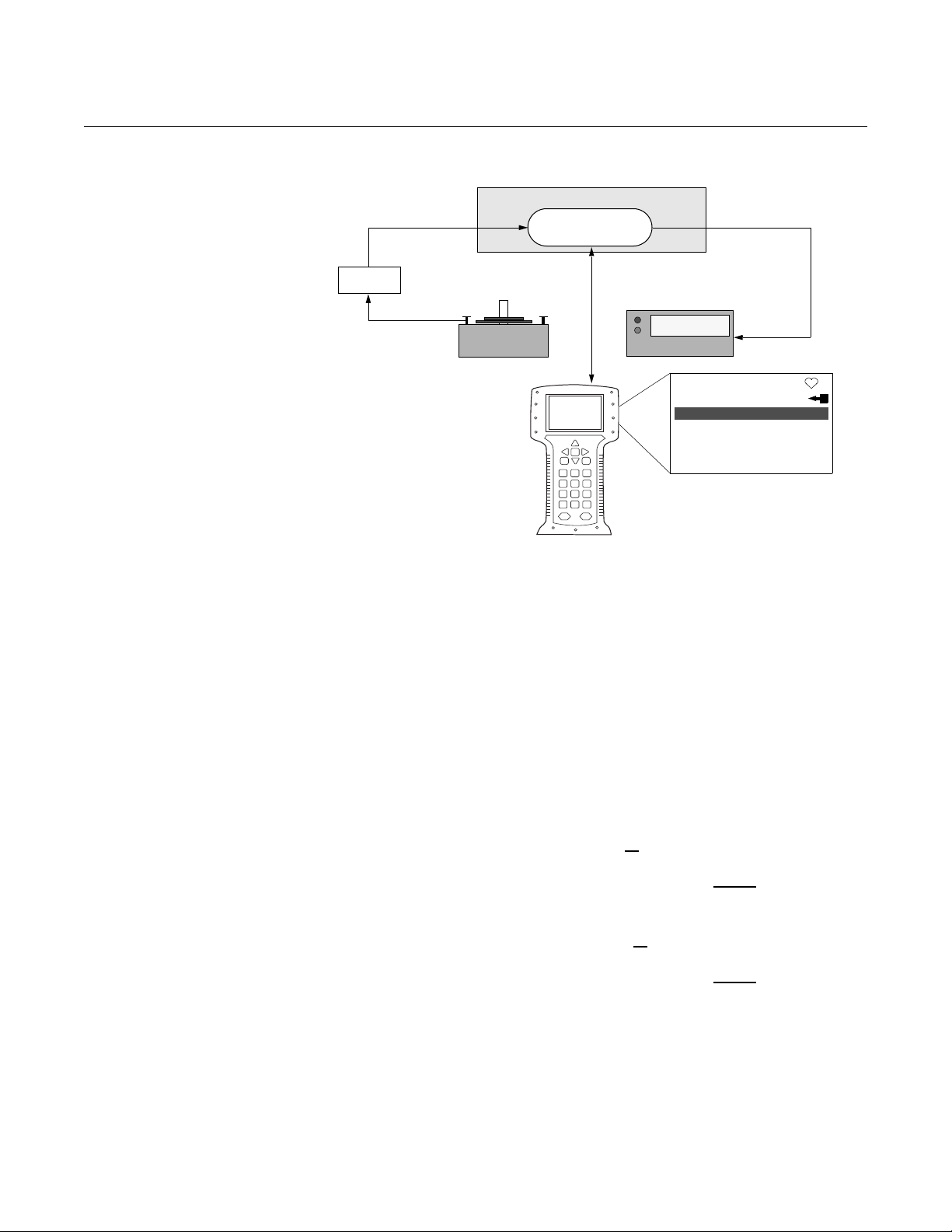

Setting the Loop to Manual

Wiring Diagrams (Bench Hook-up)

FIGURE 2-3. Bench Hook-up (4–20 mA Transmitters).

Whenever you are preparing to send or request data that would disrupt the

loop or change the output of the transmitter, you must set your process

application loop to manual. The HART Communicator will prompt you to set

the loop to manual when necessary. Keep in mind that acknowledging this

prompt does not set the loop to manual. The prompt is only a reminder; you

have to set the loop to manual yourself as a separate operation.

Connect the bench equipment as shown in Figure 2-3 and turn on the

HART-based Communicator by pressing the ON/OFF key. The communicator

will search for a HART-compatible device and will indicate when the

connection is made. If the communicator fails to connect, it will indicate that

no device was found. If this occurs, refer to Section 4: Troubleshooting.

2-5

Page 18

Rosemount 3051N

Power

Supply

R

L

≥250Ω

Current

Meter

Signal point may be grounded at any

point or left ungrounded.

CAUTION

Do not use inductive-based

transient protectors.

Reference Manual

00809-0100-4808, Rev CA

June 2008

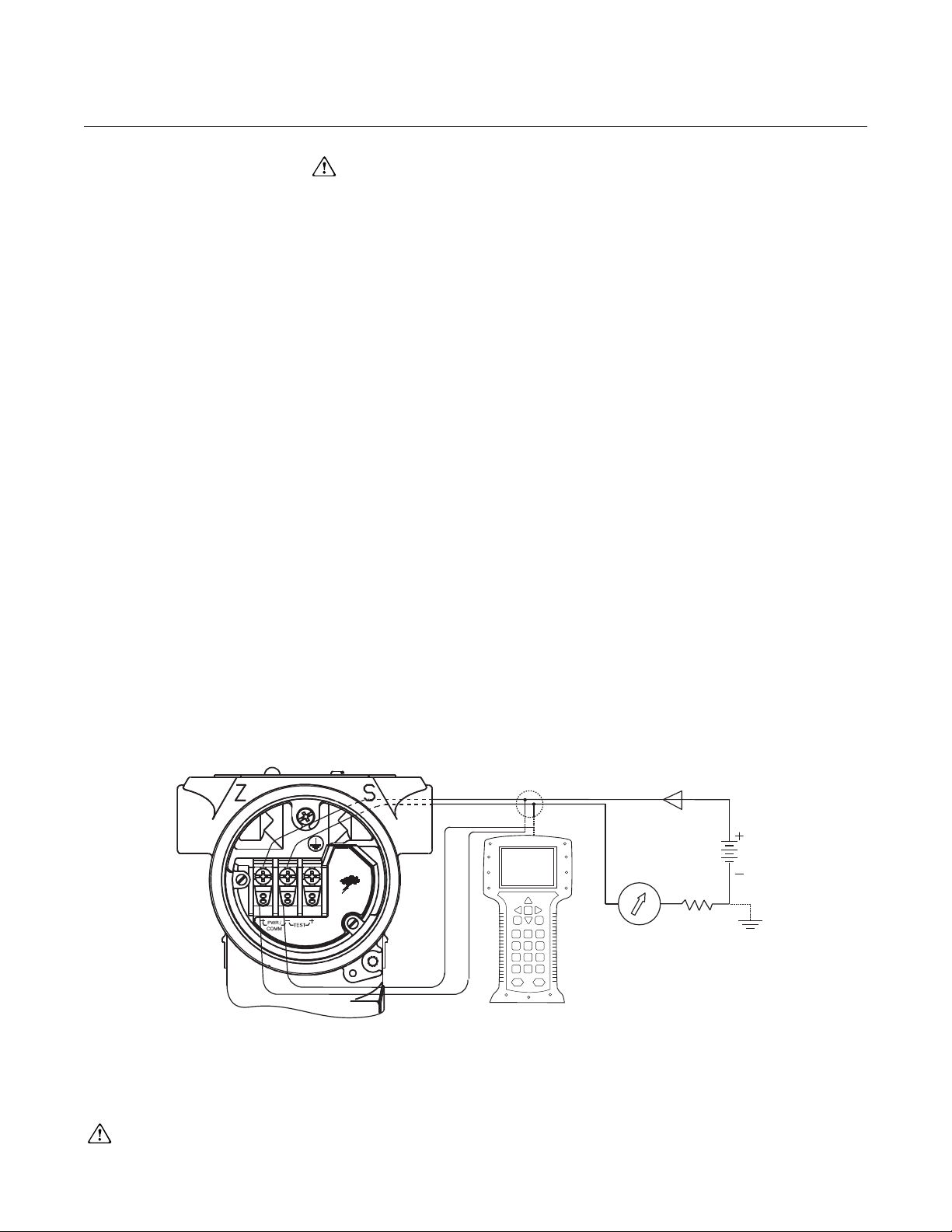

Wiring Diagrams (Field Hook-up)

FIGURE 2-4. Field Hook-up (4–20 mA Transmitters).

The following diagrams illustrate wiring loops for a field hook-up with a

HART-based Communicator.

2-6

Page 19

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

REVIEW CONFIGURATION DATA

HART Comm 1, 5

NOTE

Information and procedures in this section that make use of HART

Communicator fast key sequences assume that the transmitter and

communicator are connected, powered, and operating correctly. If you are not

familiar with the HART Communicator or fast-key sequences, refer to

Appendix A: HART Communicator.

Before you place the transmitter into operation, it is recommended that you

review the transmitter configuration data that was set at the factory. You

should review the following configuration data:

Transmitter Model Type

Tag Range

Date Descriptor

Message Minimum and Maximum

Sensor Limits

Minimum Span Units

4 and 20 mA points Output (linear or sq. root)

Damping Alarm Setting (high, low)

Security Setting (on, off) Local Zero/Span Keys

(enabled, disabled)

Integral Meter Sensor Fill

Isolator Material Flange (type, material)

O-Ring Material Drain/Vent

Remote Seal (type, fill fluid,

isolator material, number)

Address Sensor S/N

Transmitter S/N

CHECK OUTPUT Before performing other transmitter on-line operations, review the digital

output parameters to ensure that the transmitter is operating properly and is

configured to the appropriate process variables.

Process Variables The process variables for the Rosemount 3051N provide the transmitter

HART Comm. 2

output, and are continuously updated. The process variable menu displays

the following process variables:

• Pressure

• Percent of Range

• Analog Output

The pressure reading in both Engineering Units and Percent of Range will

continue to track with pressures outside of the defined range from the lower to

the upper range limit of the sensor module.

2-7

Page 20

Reference Manual

00809-0100-4808, Rev CA

Rosemount 3051N

June 2008

NOTE

Regardless of the range points, the Rosemount 3051N will measure and

report all readings within the digital limits of the sensor. For example, if the

4 and 20 mA points are set to 0 and 10 in H

3051N, and the transmitter detects a pressure of 25 inH

the 25 inH

O reading and a 250% of span reading. However, there may be up

2

O on a range code 1 Rosemount

2

O, it digitally outputs

2

to ±5.0% error associated with output outside of the range points.

Sensor Temperature The Rosemount 3051N contains a temperature sensor just above its pressure

HART Comm. 1, 1, 4

sensor in the sensor module. When reading this temperature, keep in mind

that this is not a process temperature reading.

BASIC SETUP

Set Process Variable Units

HART Comm. 1, 3, 2

The PV Unit command sets the process variable units to allow you to monitor

your process using the appropriate units of measure. Select from the following

engineering units:

•inH2O•bar

• inHg • mbar

•ftH

O • g/cm

2

•mmH2O • kg/cm

2

2

•mmHg •Pa

•psi •kPa

• torr • atm

•inH

O at 4 °C • mmH2O at 4 °C

2

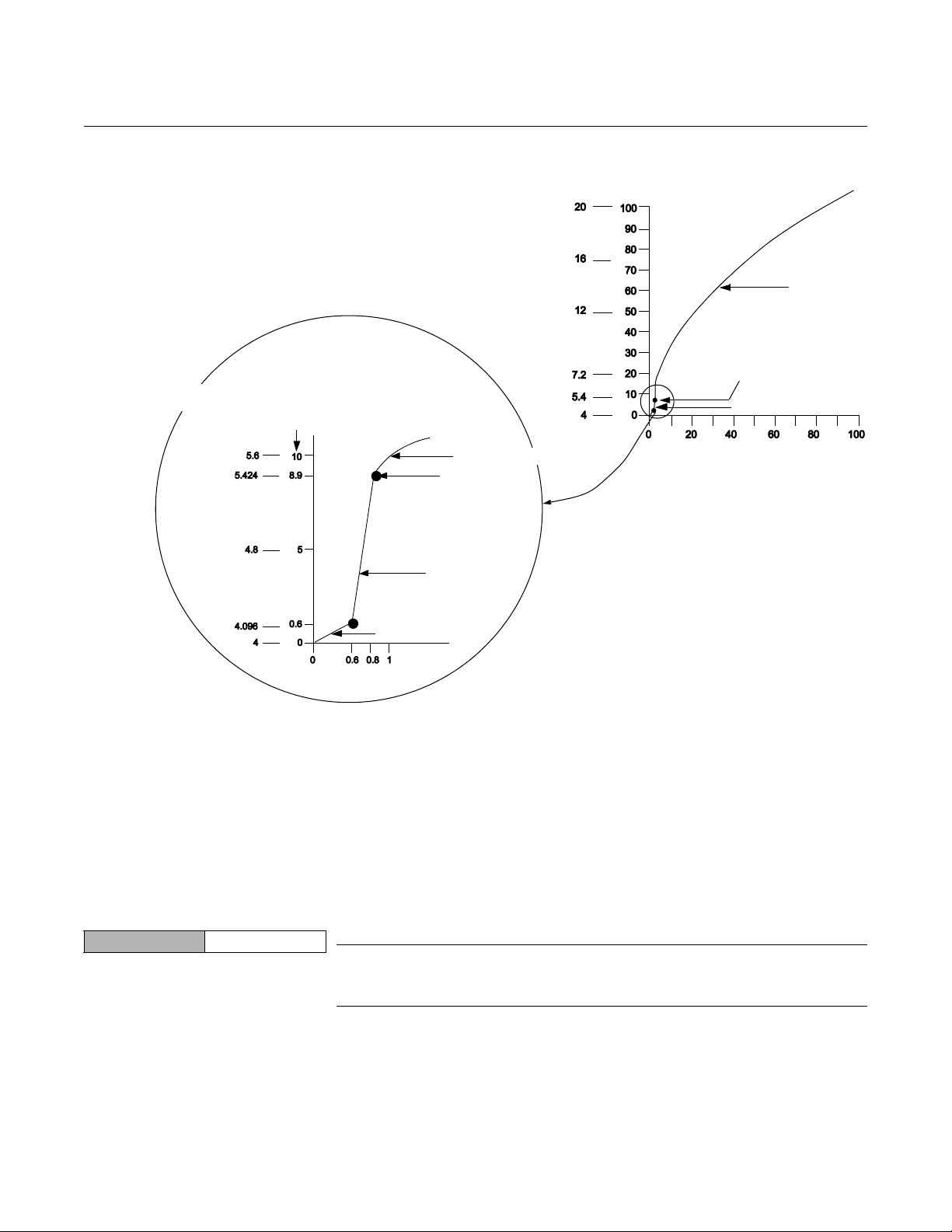

Set Output Activate the transmitter square root output option to make the analog output

HART Comm. 1, 3, 5

proportional to flow. As the input approaches zero, the Rosemount 3051N

automatically switches to a linear output in order to ensure a more smooth,

stable output near zero. See Figure 2-5.

The transition from linear to square root is not adjustable. It occurs at 0.8% of

ranged pressure input or 8.9% of full-scale flow output.

From 0 percent to 0.6 percent of the ranged pressure input, the slope of the

curve is unity (y = x). This allows accurate calibration near zero. Greater

slopes would cause large changes in output for small changes at input. From

0.6 percent to 0.8 percent, the slope of the curve equals 42 (y = 42x) to

achieve continuous transition from linear to square root at the transition point.

2-8

Page 21

Reference Manual

Sq. Root

Curve

Transition Point

Linear Section

Slope=1

Slope=42

Transition

Point

Sq. Root Curve

Full Scale

Flow (%)

Full Scale Output

(mA dc)

00809-0100-4808, Rev CA

June 2008

FIGURE 2-5. Square Root Output Transition Point.

Rosemount 3051N

Rerange The Range Values command sets the 4 and 20 mA points (lower and upper

range values). Setting the range values to the limits of expected readings

maximizes transmitter performance. In practice, you may reset the transmitter

Rerange with a Communicator Only

HART Comm. 1, 2, 3, 1, 1

range values as often as necessary to reflect changing process conditions.

You may use one of three methods to rerange the transmitter. Each method is

unique; examine all three closely before deciding which method to use.

Reranging using only the communicator changes the values of the analog 4

and 20 mA points independently without a pressure input.

NOTE

Changing the lower or upper range point results in similar changes to the

span.

To rerange using only the communicator, enter the fast-key sequence above,

select 1 Keypad input, and follow the on-line instructions. Or enter the values

directly from the ONLINE screen.

2-9

Page 22

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

NOTE

If the transmitter security jumper is in the ON position, you will not be able to

make adjustments to the zero and span. Refer to Figure 2-1 for the

appropriate placement of the transmitter security jumper.

Rerange with a Pressure Input Source and a Communicator

HART Comm. 1, 2, 3, 1, 2

Rerange with a Pressure Input Source and the Local Zero and Span Buttons

Reranging using the communicator and a pressure source or process

pressure is a way of reranging the transmitter with a pressure input. When

specific 4 and 20 mA points are not known process input can be used. This

method changes the values of the analog 4 and 20 mA points.

NOTE

When you set the 4 mA point the span is maintained; when you set the 20 mA

point the span changes. If you set the lower range point to a value that causes

the upper range point to exceed the sensor limit, the upper range point is

automatically set to the sensor limit, and the span is adjusted accordingly.

To rerange using the communicator and a pressure source or process

pressure, enter the fast-key sequence above, select 2 Apply values, and

follow the on-line instructions.

NOTE

If the transmitter security jumper is in the ON position, you will not be able to

make adjustments to the zero and span. Refer to Figure 2-1 for the

appropriate placement of the transmitter security jumper.

Reranging using the local zero and span adjustments (see Figure 2-6) and a

pressure source or process pressure is a way of reranging the transmitter with

a pressure input and when a communicator is not available. When specific 4

and 20 mA points are not known process input can be used.

2-10

NOTE

When you set the 4 mA point the span is maintained; when you set the 20 mA

point the span changes. If you set the lower range point to a value that causes

the upper range point to exceed the sensor limit, the upper range point is

automatically set to the sensor limit, and the span is adjusted accordingly.

Page 23

Reference Manual

Span and Zero Adjustment Buttons

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

To rerange the transmitter using the span and zero buttons, perform the

following procedure:

1. Loosen the screw holding the label on top of the transmitter housing, and rotate the label to expose the zero and span buttons (see Figure 2-6).

2. Using a pressure source with an accuracy three to ten times the desired calibrated accuracy, apply a pressure equivalent to the lower range value to the high side of the transmitter.

3. To set the 4 mA point, press and hold the zero button for at least two seconds, then verify that the output is 4 mA. If a meter is installed, it will display ZERO PASS.

4. Apply a pressure equivalent to the upper range value to the high side of the transmitter.

5. To set the 20 mA point, press and hold the span button for at least two seconds, then verify that the output is 20 mA. If a meter is installed, it will display SPAN PASS.

NOTE

If the transmitter security jumper is in the ON position, or if the local zero and

span adjustments are disabled through the software, you will not be able to

make adjustments to the zero and span using the local buttons. Refer to

Figure 2-1 for the proper placement of the transmitter security jumper. Or refer

to “Local Span and Zero Control (Local Keys)” in Section 2 for instructions on

how to enable the span and zero buttons.

FIGURE 2-6. Local Zero and Span Adjustments.

After you rerange the transmitter using the span and zero adjustments, it is

possible to disable the adjustments to prevent further reranging. Refer to

“Local Span and Zero Control (Local Keys)” below for

more information.

2-11

Page 24

Reference Manual

00809-0100-4808, Rev CA

Rosemount 3051N

June 2008

Damping The process variable (PV) Damp command changes the response time of the

HART Comm. 1, 3, 6

transmitter to smooth variations in output readings caused by rapid changes

in input. Determine the appropriate damping setting based on the necessary

response time, signal stability, and other requirements of the of loop dynamics

of your system. The default damping value is 0.4 seconds,

to any of eleven pre-configured, nominal damping values between 0 and 25.6

seconds.

(1)

and can be reset

LCD Meter Options The Meter Options command allows you to customize the LCD meter for use

HART Comm. 1, 4, 3, 4

in your application. You can configure the meter to display the

following information:

• Engineering Units

• Percent of Range

• User-Configurable LCD Scale

• Alternating between any two of the above

The user-configurable scale is a feature that enables you to configure the

LCD meter to a custom scale using a HART Communicator. With this feature

you can define the decimal point position, the upper range value, the lower

range value, the engineering units, and the transfer function. Refer to

“Custom Meter Configuration” in Section 6 for complete configuration

information.

DETAILED SETUP

Local Span and Zero Control (Local Keys)

HART Comm. 1, 4, 4, 1, 7

Sensor Temperature Output Unit Selection

HART Comm. 1, 4, 1, 2, 2

DIAGNOSTICS AND SERVICE

The Local keys command allows software control over the use of the local

span and zero adjustments. To enable or disable the span and zero

adjustment buttons on your transmitter, perform the fast key sequence at left.

NOTE

Disabling the local keys does not disable all transmitter configuration

changes. With the local keys disabled, you can still make changes to the

transmitter configuration—including range values—using a HART

Communicator.

The Sensor Temperature Output Unit Selection command selects between

Celsius and Fahrenheit units for output of the sensor temperature. The sensor

temperature output is accessible via HART only.

The diagnostics and service functions listed here are primarily for use after

you install the transmitter in the field. The transmitter test feature is designed

to verify that the transmitter is operating properly, and can be performed either

on the bench or in the field. The loop test feature is designed to verify proper

loop wiring and transmitter output, and should only be performed after you

install the transmitter.

2-12

(1) Rosemount 3051ND0 default damping is 3.2 seconds. Rosemount 3051ND1, with calibra-

tions below 2.5 inH

O (0,62 kPa), have damping set at 3.2 seconds.

2

Page 25

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Transmitter Test The transmitter Self Test command initiates a more extensive diagnostics

HART Comm. 1, 2, 1, 1

routine than that performed continuously by the transmitter. The transmitter

test routine can quickly identify potential electronics problems. If the

transmitter test detects a problem, messages to indicate the source of the

problem are displayed on the communicator screen.

Loop Test The Loop Test command verifies the output of the transmitter, the integrity of

HART Comm. 1, 2, 2

the loop, and the operations of any recorders or similar devices installed in the

loop. To initiate a loop test, perform the following procedure:

1. Connect a reference meter to the transmitter. To do so, either connect the meter to the test terminals on the transmitter terminal block, or shunt the power to the transmitter through the meter at some point in the loop.

2. From the ONLINE screen, select 1 Device Setup, 2 Diagnostics and

Service, 2 Loop Test, to prepare to perform a loop test.

3. Select OK after you set the control loop to manual (see “Setting the

loop to Manual”). The communicator displays the loop test menu.

4. Select a discreet milliamp level for the transmitter to output. At the

CHOOSE ANALOG OUTPUT prompt, select 1 4mA, 2 20mA, or

select 3 other to manually input a value. IF

test to verify the output of a transmitter, THEN

4 and 20 mA. IF

transmitter alarm levels, THEN

an alarm state (see Table 2-1).

5. Check the electrical current meter installed in the test loop to verify

that it reads the value you commanded the transmitter to output. IF

the readings match, THEN

configured and functioning properly. IF

THEN

you may have the current meter attached to the wrong loop,

there may be a fault in the wiring or elsewhere in the loop, the

transmitter may require an output trim, or the electrical current meter

may be malfunctioning.

you are performing a loop test to verify the

enter the milliamp value representing

the transmitter and the loop are

you are performing a loop

enter a value between

the readings do not match,

After completing the test procedure, the display returns to the loop test screen

and allows you to choose another output value or to exit loop testing.

NOTE

If the HART Communicator is disconnected from the process loop or loses

power prior to exiting loop testing, output will remain fixed at the loop test

value.

CALIBRATION Calibrating a smart transmitter is different from calibrating an analog

transmitter. The one-step calibration process of an analog transmitter is done

in three steps with a smart transmitter:

• Rerange—sets the 4 and 20 mA points at the desired pressures;

• Sensor T rim—Adjusts the position of the factory characterization curve

to optimize the transmitter performance over a specified pressure

range or to adjust for mounting effects

• Analog Output Trim—Adjusts the analog output to match the plant

standard or the control loop.

2-13

Page 26

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

Smart transmitters operate differently than analog transmitters. A smart

transmitter uses a microprocessor and sensor memory that contains

information about the sensor’s specific characteristics in response to pressure

and temperature inputs. A smart transmitter compensates for these sensor

variations. The process of generating the sensor performance profile is called

factory characterization. Factory characterization also provides the ability to

readjust the 4 and 20 mA points without applying pressure to the transmitter.

The trim and rerange functions also differ. Reranging sets the transmitter

analog output to the selected upper and lower range points and can be done

with or without an applied pressure. Reranging does not change the factory

characterization curve stored in the microprocessor. Sensor trimming requires

an accurate pressure input and adds additional compensation that adjusts the

position of the factory characterization curve to optimize transmitter

performance over a specific pressure range.

NOTE

Sensor trimming adjusts the position of the factory characterization curve. It is

possible to degrade the performance of the transmitter if the sensor trim is

done improperly or with inaccurate equipment. Contact Rosemount Nuclear

Instruments, Inc. at 952-949-5210 if you have questions.

Table 2-2. Recommended Calibration Tasks.

Transmitter Bench Calibration Tasks Field Calibration Tasks

3051ND

3051NG

3051NA

1. Set output configuration parameters: a. Set the process variable units. b. Set the output type. c. Set the range points. d. Set the damping value.

2. Optional: Perform a full sensor trim. (Accurate multimeter required.)

3. Optional: Perform an analog output trim. (Accurate multimeter required.)

1. Set output configuration parameters: a. Set the process variable units. b. Set the output type. c. Set the range points. d. Set the damping value.

2. Optional: Perform a full sensor trim if equipment available (accurate absolute pressure source required), otherwise perform the low trim value section of the full sensor trim procedure.

3. Optional: Perform an analog output trim (accurate multimeter required).

1. Reconfigure parameters if necessary.

2. Zero trim the transmitter to compensate for mounting effects or static pressure effects.

1. Reconfigure parameters if necessary.

2. Perform low trim value section of the full sensor trim procedure to correct for mounting position effects.

Notes:

• A HART Communicator is required for all sensor and output trim procedures.

• Rosemount 3051N Range 4 and Range 5 transmitters require a special calibration procedure when used

in differential pressure applications under high static line pressure (see “Compensating Rosemount 3051N

Range 4 and 5 Differential Transmitters for Line Pressure” on page 2-20).

2-14

Page 27

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Calibration Overview Complete calibration of the Rosemount 3051N Pressure Transmitter involves

the following tasks:

Configure the Analog Output Parameters

• Set Process Variable Units (page 2-8)

• Set Output Type – Linear or Square Root (page 2-8)

• Set the Range Points (page 2-9)

• Set Damping (page 2-12)

Calibrate the Sensor

• Full Trim (page 2-18)

• Zero Trim (page 2-17)

Calibrate the 4–20 mA Output (Digital-to-Analog [D/A] Signal Conversion)

• 4–20 mA Output Trim (page 2-19) or

• 4–20 mA Output Trim Using Other Scale (page 2-19)

Figure 2-7 illustrates the Rosemount 3051N transmitter data flow. This data

flow can be summarized in four major steps:

1. A change in pressure is measured by a change in the sensor output (Sensor Signal).

2. The sensor signal is converted to a digital format that can be understood by the microprocessor (Analog-to-Digital Signal Conversion).

3. Corrections are performed in the microprocessor to obtain a digital representation of the process input (Digital PV).

4. The Digital PV is converted to an analog value (Digital-to-Analog Signal Conversion).

Figure 2-7 also identifies the approximate transmitter location for each

calibration task. Note that the data flows from left to right, and a parameter

change affects all values to the right of the changed parameter.

Not all calibration procedures should be performed for each Rosemount

3051N transmitter. In addition, some procedures are appropriate for bench

calibration but should not be performed during field calibration. Table 2-2

identifies the recommended calibration procedures for each type of

Rosemount 3051N transmitter for both bench and field calibration.

2-15

Page 28

Rosemount 3051N

Transmitter Electronics Module

Microprocessor

Digital PV

Sensor

Input Device

Output Device

20.00 mA

3051:PT-4001

1 ➡ Device Setup

Online

2 PV 100.00 inH2O

3 AO 20.00 mA

4 LRV 0.00 inH2O

5 URV 100.00 inH2O

Transmitter Ranged 0 to 100 inH2O

Input

Pressure

Sensor

Signal

Analog Output

HART

Communicator

NOTE

Value on PV line should equal

the input pressure. Value on

AO line should equal the

output device reading.

FIGURE 2-7. Transmitter Data Flow with Calibration Options.

Reference Manual

00809-0100-4808, Rev CA

June 2008

Deciding Which Trim Procedure to Use

Sensor Trim You can trim the sensor using either the full trim or the zero trim function. The

2-16

To decide which trim procedure to use, you must first determine whether the

analog-to-digital section or the digital-to-analog section of the transmitter

electronics is in need of calibration. To do so, refer to Figure 2-7 and perform

the following procedure:

trim functions vary in complexity, and their use is application-dependent. Both

trim functions alter the transmitter’s interpretation of the input signal.

A zero trim is a single-point adjustment. It is useful for compensating for

mounting position effects and is most effective when performed with the

transmitter installed in its final mounting position. Since this correction

maintains the slope of the characterization curve, it should not be used in

place of a full trim over the full sensor range.

1. Connect a pressure source, a HART Communicator, and a digital readout device to the transmitter.

2. Establish communication between the transmitter and the communicator.

3. Apply pressure equal to the upper range point pressure (100 inH

0,

2

for example).

4. Compare the applied pressure to the Process Variable (PV) line on

the Communicator On-line Menu. IF

communicator does not match the applied pressure, and you are

confident that your test equipment is accurate, THEN

the PV reading on the

perform a

sensor trim.

5. Compare the Analog Output (AO) line on the communicator on-line

menu to the digital readout device. IF

the AO reading on the

communicator does not match the digital readout device, and you are

confident that your test equipment is accurate, THEN

perform an

output trim.

Page 29

Reference Manual

ZERO-BASED FLOW

APPLICATION

ZERO-BASED LEVEL

APPLICATION

NONZERO-BASED

LEVEL APPLICATION

20 mA Point

4 mA Point

20 mA Point

4 mA Point

00809-0100-4808, Rev CA

June 2008

FIGURE 2-8. Typical Zero vs. Non-zero-Based Application Illustrations.

Rosemount 3051N

When performing a zero trim, ensure that the equalizing valve is open and all

wet legs are filled to the correct levels.

NOTE

Do not perform a zero trim on Rosemount 3051N Absolute pressure

transmitters. A zero trim is zero-based, and absolute pressure transmitters

reference absolute zero. To correct mounting position effects on a Rosemount

3051N Absolute Pressure Transmitter, perform a low trim within the full

sensor trim function. The low trim function provides a “zero” correction similar

to the zero trim function but it does not require the input to be zero-based.

A full trim is a two-point sensor calibration where two end-point pressures

are applied, and all output is linearized between them. You should always

adjust the low trim value first to establish the correct offset. Adjustment of the

high trim value provides a slope correction to the characterization curve

based on the low trim value. The factory-established characterization curve is

not changed by this procedure. The trim values allow you to optimize

performance over your specified measuring range at the calibration

temperature.

Zero Trim To calibrate the sensor with a HART Communicator using the Zero Trim

HART Comm. 1, 2, 3, 3, 1

function, perform the following procedure.

1. Vent the transmitter and attach a communicator to the measurement loop.

2. From the communicator menu select 1 Device setup, 2 Diagnostics and service, 3 Calibration, 3Sensor trim, 1 Zero trim to prepare to adjust the zero trim.

NOTE

The transmitter must be within 3% of true zero (zero-based) in order to

calibrate it using the zero trim function.

3. Follow the commands provided by the communicator to complete the adjustment of the zero trim.

2-17

Page 30

Reference Manual

250 Ω Minimum Loop

Resistance

Rosemount 3051N

Transmitter

Precision Meter

24 V dc Power Supply

HART-Based

Communicator

Rosemount 275 or

Rosemount 375

Dead Weight Tester

Calibration Standard for

Sensor Trim Only

00809-0100-4808, Rev CA

Rosemount 3051N

June 2008

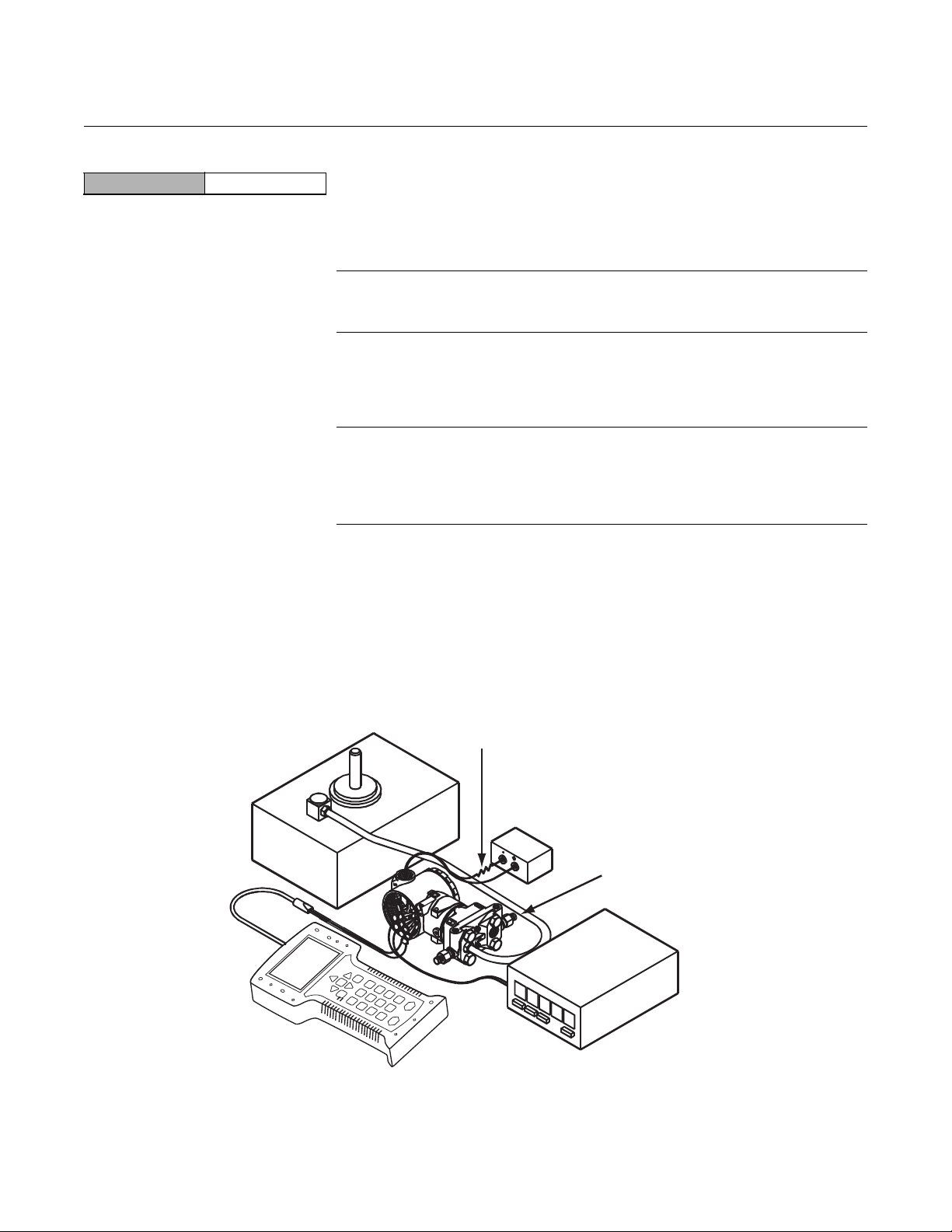

Full Trim To calibrate the sensor with a HART Communicator using the full trim

HART Comm. 1, 2, 3, 3

function, perform the following procedure:

1. Assemble and power the entire calibration system including a transmitter, HART Communicator, power supply, pressure input source, and readout device (see Figure 2-9).

NOTE

Use a pressure input source with sufficient accuracy and allow the input

pressure to stabilize for 10 seconds before entering any values.

2. From the communicator menu select 1 Device setup, 2 Diagnostics and service, 3 Calibration, 3Sensor trim, 2 Lower sensor trim to prepare to adjust the lower trim point.

NOTE

Select pressure input values so that the low and high values are equal to or

outside the 4 and 20 mA points. Do not attempt to obtain reverse output by

reversing the high and low points. The transmitter allows approximately a

5% URL deviation from the characterized curve established at the factory.

FIGURE 2-9. Digital Trim Connection Drawing (4–20 mA Transmitters).

3. Follow the commands provided by the communicator to complete the adjustment of the lower value.

4. Repeat the procedure for the upper value, replacing 2 Lower sensor trim with 3 Upper sensor trim in Step 2.

2-18

Page 31

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Recall Factory Trim The Recall Factory Trim commands allow the restoration of the as-shipped

factory settings of the sensor trim and analog output trim.

Recall Factory Trim— Sensor Trim

HART Comm. 1, 2, 3, 4, 1

Recall Factory Trim— Analog Output

HART Comm. 1, 2, 3, 4, 2

Resets the transmitter sensor trim to the as-shipped factory settings. The

Recall Factory Trim—Sensor Trim command can be useful for recovering

from an inadvertent zero trim of an absolute pressure unit.

Resets the transmitter analog output trim to the as-shipped

factory settings. The Recall Factory Trim—Analog Output Trim command can

be useful for recovering from an inadvertent zero trim on an absolute pressure

transmitter.

Analog Output Trim The Analog Output Trim commands allow you to adjust the transmitter’s

current output at the 4 and 20 mA points to match the plant standards. This

command adjusts the digital to analog signal conversion (see Figure 2-7).

Digital-to-Analog Trim To perform a digital-to-analog trim with a HART Communicator, perform the

HART Comm. 1, 2, 3, 2, 1

following procedure.

1. From the ONLINE screen, select 1 Device setup, 2 Diag/Service,

3 Calibration, 2 Trim Analog Output, 1 Digital-to-Analog Trim. Select

OK after you set the control loop to manual (see “Setting the Loop to

Manual” on page 2-5).

2. Connect an accurate reference ammeter to the transmitter at the

CONNECT REFERENCE METER prompt. To do so, connect the

positive lead to the positive terminal and the negative lead to the test

terminal in the transmitter terminal compartment, or shunt the

transmitter power through the reference meter at some point.

3. Select OK after connecting the reference meter.

4. Select OK at the SETTING FLD DEV OUTPUT TO 4 MA prompt. The

transmitter outputs 4.00 mA.

5. Record the actual value from the reference meter, and enter it at the

ENTER METER VALUE prompt. The communicator prompts you to

verify whether or not the output value equals the value on the

reference meter.

6. Select 1Yes if the reference meter value equals the transmitter

output value, or 2No if it does not.

you select 1Yes, THEN proceed to Step 7.

IF

IF

you select 2No, THEN repeat Step 5.

7. Select OK at the SETTING FLD DEV OUTPUT TO 20 MA prompt,

and repeat Steps 5 and 6 until the reference meter value equals the

transmitter output value.

8. Select OK after you return the control loop to automatic control.

Digital-to-Analog Trim Using Other Scale

HART Comm. 1, 2, 3, 2, 2

The Scaled D/A Trim command matches the 4 and 20 mA points to a

user-selectable reference scale other than 4 and 20 mA (1 to 5 volts if

measuring across a 250 ohm load, or 0 to 100 percent if measuring from a

DCS, for example). To perform a scaled D/A trim, connect an accurate

reference meter to the transmitter and trim the output signal to scale as

outlined in the Output Trim procedure.

2-19

Page 32

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

NOTE

Use a precision resistor for optimum accuracy. If you add a resistor to the

loop, ensure that the power supply is sufficient to power the transmitter to a

20 mA output with the additional loop resistance.

Compensating Rosemount 3051N Range 4 and 5 Differential Transmitters for Line Pressure

Rosemount 3051N Range 4 and Range 5 pressure transmitters require a

special calibration procedure when used in differential pressure applications.

The purpose of this procedure is to optimize transmitter performance by

reducing the effect of static line pressure (P

) in these applications.

s

Rosemount 3051N differential pressure transmitter ranges 0, 1, 2, and 3 do

not require this procedure because the optimization occurs in the sensor. See

“Static Pressure Effect” on page 5-3 for additional details.

Applying high static pressure to Rosemount 3051N Range 4 and Range 5

pressure transmitters causes a systematic shift in the output. This shift is

linear with static pressure; correct it by performing the “Full Trim” on

page 2-18, after determining the corrected input values as noted below.

The following specifications show the static pressure effect for Rosemount

3051N Range 4 and Range 5 transmitters used in differential pressure

applications:

Zero Effect:

±0.1% of the upper range limit per 1000 psi (6,9 MPa) for line pressures

(P

) from 0 to 2000 psi (0 to 13,8 MPa)

s

±[0.2 + 0.2 (P

-2000) / 1000]% of the upper range limit per 1000 psi

s

(6,9 MPa) for line pressures above 2000 psi (13,8 MPa) and ≤ 3626 psi

(25 MPa)

Span Effect:

Correctable to ±0.2% of reading per 1000 psi for line pressures from 0 to

3626 psi.

2-20

The systematic span shift caused by the application of static line pressure is

–1.00% of input reading per 1000 psi for 3051N Range 4 transmitters, and

–1.25% of reading per 1000 psi for Range 5 transmitters.

Use the following example to compute corrected input values.

Example

A Rosemount 3051ND4 transmitter will be used in a differential pressure

application where the static line pressure is 1200 psi. The transmitter is

ranged so that the output is 4 mA at 500 inH

O and 20 mA at 1500 inH2O.

2

To correct for systematic error caused by high static line pressure, first use

the following formulas to determine corrected values for the low trim and

high trim.

= LRV + S (LRV) Ps

LT

c

Where: LTc = Corrected Low Trim Value

LRV = Lower Range Value

S = –(Systematic Span shift per specification)

= Static Line Pressure

P

s

Page 33

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

HTc = URV + S (URV) P

Where: HTc = Corrected High Trim Value

In this example:

To calculate the corrected low trim (LT

To calculate the corrected high trim (HT

s

URV = Upper Range Value

S = –(Span shift per specification)

= Static Line Pressure

P

s

URV = 1500 inH

LRV = 500 inH

=1200psi

P

s

S = -(-0.01/1000 psi) = 0.01/1000psi

=500 in H

LT

c

=506in H

LT

c

HT

=1500 in H

c

=1518 in H

HT

c

O

2

O

2

) value:

c

0 + (0.01/1000 psi)(500 in H20)(1200 psi)

2

O

2

) value:

c

0 + (0.01/1000 psi)(1500 in H20)(1200 psi)

2

O

2

To complete a Rosemount 3051N full trim, enter the corrected values for low

trim (LT) and high trim (HT). Refer to “Full Trim” on page 2-18.

Enter the corrected input values for low trim and high trim through the

communicator keypad after you apply the nominal value of pressure as the

transmitter input.

NOTE

After calibrating Rosemount 3051N Range 4 and Range 5 transmitters for

high differential pressure applications, rerange the 4 and 20 mA points using

the communicator to maintain the systematic static line pressure correction.

You may re-zero the 4 mA point at line pressure after installation using the

local zero button without affecting the completed calibration.

2-21

Page 34

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

2-22

Page 35

Reference Manual

00809-0100-4808, Rev CA

June 2008

Rosemount 3051N

Section 3 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-12

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . page 3-14

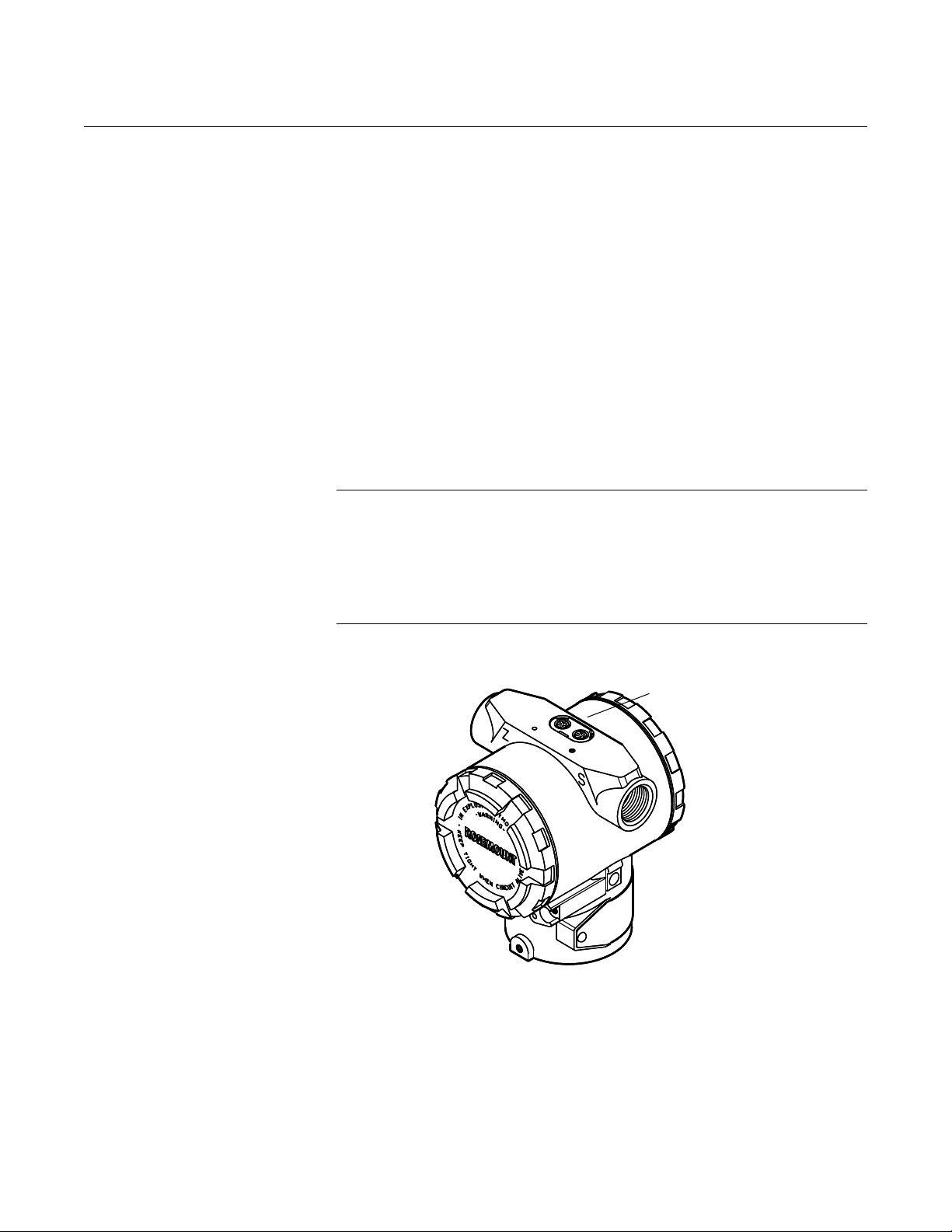

OVERVIEW The information in this section covers installation considerations. Dimensional

drawings illustrating the Rosemount 3051N and mounting brackets are

included in this section.

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operation. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the following safety messages before performing an operation preceded by

this symbol.

Warnings

Explosions can result in death or serious injury.

• Do not remove the transmitter covers in explosive environments when the

circuit is alive.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate qualification parameters.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals.

Process leaks could result in death or serious injury.

• Install and tighten all four flange bolts before applying pressure.

• Do not attempt to loosen or remove flange bolts while the transmitter is

in service.

www.rosemountnuclear.com

Page 36

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

Replacement equipment or spare parts not approved by Rosemount Nuclear

Instruments, Inc. for use as spare parts could reduce the pressure retaining

capabilities of the transmitter and may render the instrument dangerous or

adversely impact its qualification status.

• Use only components supplied with the Rosemount 3051N or sold by

Rosemount Nuclear Instruments Inc. as spare parts for the Rosemount 3051N.

Improper assembly of manifold or mounting bracket to traditional flange can

damage sensor module.

• For safe assembly of manifold or mounting bracket to traditional flange, bolts

must break back plane of flange web (i.e. bolt hole), but must not contact

module housing.

3-2

Page 37

Reference Manual

START HERE

Bench

Calibration?

Field Install

No

Configure

(Section 2)

Set Units

Set Range

Points

Set Output

Type

Set Damping

Verify

Apply Pressure

Yes

Within

Specifica-

tions?

Yes

No

Refer to

Section 4

Troubleshooting

Check Jumpers

and Switches

(page 2-2)

Mount

Transmitter

(pages 3-4–3-14)

Wire Transmitter

(pages 3-12–3-14)

Power

Transmitter

(page 3-12)

Check Process

Connection

for Leaks

(page 3-12)

Confirm

Transmitter

Configuration

(page A-4)

Trim Transmitter

for Mounting

Effects

(page 2-15)

Done

00809-0100-4808, Rev CA

June 2008

FIGURE 3-1. Typical Installation Flowchart.

Rosemount 3051N

3-3

Page 38

Rosemount 3051N

Reference Manual

00809-0100-4808, Rev CA

June 2008

GENERAL CONSIDERATIONS

Special Draft Range Considerations

Measurement accuracy depends upon proper installation of the transmitter

and impulse piping. Mount the transmitter close to the process and use a

minimum of piping to achieve best accuracy. Keep in mind the need for easy

access, personnel safety, practical field calibration, and a suitable transmitter

environment. Install the transmitter to minimize vibration, shock, and

temperature fluctuation.

Installation

It is best to mount the transmitter with the isolating diaphragms parallel to the

ground. Installing the transmitter in this way reduces oil head effect and

provides for optimal temperature performance.

Be sure the transmitter is securely mounted. Tilting of the transmitter may

cause a zero shift in the transmitter output.

Reducing Process Noise

It is often difficult to isolate the actual process variable from process noise in

draft range applications. Pressure fluctuations and air currents can make

accurate draft range measurements difficult to obtain.

There are two recommended methods of reducing process noise: output

damping and, in gage applications, reference side filtering.

Output Damping

The output damping for the Rosemount 3051ND0 is factory set to 3.2

seconds as a default. If the transmitter output is still noisy, increase the

damping time. If faster response is needed, decrease the damping time.

Damping adjustment information is available in Section 2: Transmitter

Functions.

MECHANICAL CONSIDERATIONS

Reference Side Filtering

In gage applications it is important to minimize fluctuations in atmospheric

pressure to which the low side isolator is exposed. One method of reducing

fluctuations in atmospheric pressure is to attach a length of tubing to the

reference side of the transmitter to act as a pressure buffer. Another method

is to plumb the reference side to a chamber that has a small vent to

atmosphere. If multiple draft transmitters are being used in an application, the

reference side of each device can be plumbed to a chamber to achieve a

common gage reference.

IMPORTANT

Install the enclosed pipe plug in unused conduit openings with a minimum of

five threads engaged to comply with explosion proof requirements.

The following figures show dimensional drawings and installation examples of

the Rosemount 3051N transmitters, including mounting brackets.

NOTE

For Rosemount 3051ND0 and 3051ND1, mount the transmitter solidly to

prevent tilting. A tilt in the physical transmitter may cause a zero shift in the

transmitter output.

3-4

Page 39

Reference Manual

7.1

(181)

6.2

(156)

4.8

(120)

4.3 (110)2.8 (72)

3

/8-16 x 11/4

Bolts for

Mounting to

Transmitter

5

/16 Bolts for Panel

Mounting (not supplied)

2.81

(71)

3.4

(85)

Note

Dimensions are nominal in inches (millimeters).

2.81

(71)

2.13

(54.1)

00809-0100-4808, Rev CA

June 2008

FIGURE 3-2. Coplanar Flange Mounting Configurations with Optional Bracket (Code B4) for Panel Mounting

Rosemount 3051N

NOTE

For steam service, do not blow down impulse piping through the transmitter.

Flush the lines with the blocking valves closed and refill the lines with water

before resuming measurement.

NOTE

When the transmitter is mounted on its side, position the Coplanar process

flange to ensure proper venting or draining. Keep drain/vent connections on

the bottom for gas service and on the top for liquid service.

NOTE

The Rosemount 3051N transmitter incorporates two independent seals

between the process connection and the conduit connection.

3-5

Page 40

Reference Manual

7.1

(181)

Note

Dimensions are nominal in inches (millimeters).

4.1 (105)

Terminal

Connections

0.75 (20)

Clearance

for Cover

Removal

1

/2-14 NPT Conduit

Connection

(two places)

5 (127)

4.3 (110)

Drain/vent

Valve

Nameplate

Transmitter

circuitry

0.75 (20)

Clearance

for Cover

Removal

Label

Meter

Cover

(optional)

6.4 (163)

Housing Rotation

Set Screw

1

/4-18 NPT on Coplanar Flange

for Pressure Connection

1

/4-18 NPT on Coplanar Flange

for Pressure Connection

00809-0100-4808, Rev CA

Rosemount 3051N

FIGURE 3-3. Rosemount 3051N Coplanar Flange Dimensional Drawing (Differential Pressure Transmitter Shown)

June 2008

3-6

Page 41

Reference Manual

2.63

(66.8)

9.4 (239)

6.3 (181)

5

/16 Bolts for Panel

Mounting (Not Supplied)

2.81 (71)

Note

Dimensions are nominal in inches (millimeters).

OPTION CODE BS:

TRADITIONAL FLANGE

UNIVERSAL PANEL MOUNTING

BRACKET (STAINLESS STEEL)

OPTION CODE B2:

TRADITIONAL FLANGE PANEL

MOUNTING BRACKET

(PAINTED CARBON STEEL)

9.5 (241)

2.75

(69.9)

4.93

(125)

3

/8 Bolts for Panel

Mounting (Not Supplied)

2.81 (71)

2.81

(71)

Nameplate

Nameplate

00809-0100-4808, Rev CA

June 2008

FIGURE 3-4. Traditional Flange Mounting Configurations with Optional Brackets for Panel Mounting

Rosemount 3051N

3-7

Page 42

Rosemount 3051N

Terminal connections

1.63 (41.4)

0.75 (20) Clearance for

Cover Removal

1