Page 1

VSS/VSR/VSM single screw compressor

Operation and service manual

Page 2

Page 3

Important Message

READ CAREFULLY BEFORE INSTALLING AND STARTING YOUR COMPRESSOR.

The following instructions have been prepared to assist in installation, operation and removal of Vilter™ Single

Screw Compressors. Following these instructions will result in a long life of the compressor with satisfactory

operation.

The entire manual should be reviewed before attempting to install, operate, service or repair the compressor.

A compressor is a positive displacement machine. It is designed to compress gas. The compressor must

not be subjected to liquid carry over. Care must be exercised in properly designing and maintaining the

system to prevent conditions that could lead to liquid carry over. Vilter Manufacturing is not responsible

for the system or the controls needed to prevent liquid carry over and as such Vilter Manufacturing cannot warrant equipment damaged by improperly protected or operating systems.

Vilter screw compressor components are thoroughly inspected at the factory. However, damage can occur

in shipment. For this reason, the equipment should be thoroughly inspected upon arrival. Any damage

noted should be reported immediately to the Transportation Company. This way, an authorized agent

can examine the unit, determine the extent of damage and take necessary steps to rectify the claim with

no serious or costly delays. At the same time, the local Vilter representative or the home office should

be notified of any claim made.

All inquires should include the Vilter sales order number, compressor serial and model number. These can be

found on the compressor name plate on the compressor.

All requests for information, services or parts should be directed to:

Vilter Manufacturing LLC

Customer Service Department

P.O. Box 8904

5555 South Packard Ave

Cudahy, WI 53110-8904 USA

Telephone: 1-414-744-0111

Fax:1-414-744-3483

e-mail: info.vilter@emerson.com

Equipment Identification Numbers:

Vilter Order Number: _______________________Compressor Serial Number: _________________

Vilter Order Number: _______________________Compressor Serial Number: _________________

Vilter Order Number: _______________________Compressor Serial Number: _________________

Vilter Order Number: _______________________Compressor Serial Number: _________________

3

Page 4

4

Page 5

Table of Contents

Important Message ..............................................................................................................3

Standard VILTER Warranty Statement ..................................................................................6

Standard VILTER 5/15 Warranty Statement ..........................................................................7

Long Term Storage Requirements .........................................................................................8

Description .........................................................................................................................10

Foundation .........................................................................................................................12

Rigging and Lifting .............................................................................................................19

Installation .........................................................................................................................23

Slide Valve Actuator Installation & Calibration ...............................................................35

Slide Valve Operation ....................................................................................................38

Slide Valve Actuator Trouble Shooting Guide .................................................................39

Operation Section ..............................................................................................................43

Notice on using Non-Vilter Oils ......................................................................................43

Operation .....................................................................................................................44

Pre Start-Up Checklists ..................................................................................................52

Field Piping and Mechanical Requirements ....................................................................53

Field Wiring Requirements ............................................................................................54

Stop Check Valve Operation ..........................................................................................55

Service ..........................................................................................................................56

Maintenance .................................................................................................................87

VSS Parts Section ................................................................................................................88

Gate Rotor .....................................................................................................................89

Shaft Seal ......................................................................................................................93

Main Rotor ....................................................................................................................94

Slide Valve Cross Shafts and End Plate ............................................................................96

Slide Valve Carriage Assembly .......................................................................................98

Actuator & Command Shaft .........................................................................................102

Miscellaneous Frame Components ..............................................................................104

Replacement Tools ......................................................................................................108

VSM 301-701 Replacement Parts Section ..........................................................................111

Gaterotor Assembly ....................................................................................................112

Shaft Seal ....................................................................................................................115

Main Rotor, Slide Valve Cross Shafts & End Plate ..........................................................116

Slide Valve Carriage Assembly .....................................................................................120

Actuator & Command Shaft .........................................................................................122

Miscellaneous Frame Components ..............................................................................124

Replacement Tools ......................................................................................................128

Danfoss Liquid Injection Valve Setup .................................................................................129

Appendix A: Pre Start Up for Remote Oil Coolers ...............................................................143

5

Page 6

Standard VILTER Warranty Statement

Seller warrants the products it manufactures to be free from defects in material and workmanship for a period of

eighteen (18) months from the date of shipment from Seller’s manufacturing plant or twelve (12) months from

date of installation at the initial end users location, whichever occurs first. In addition, Seller provides the following

extended warranties: (a) three (3) years from the date of shipment on single screw compressor internal rotating

parts, (b) two (2) years from the date of shipment on reciprocating compressors and single screw and reciprocating compressor parts, and (c) two (2) years on all other parts on a single screw compressor unit. Such warranties

do not apply to ordinary wear and tear. Seller does not warrant that the product complies with any particular law

or regulation not explicitly set forth in the specifications, and Buyer is responsible for ensuring that the product

contains all features necessary to safely perform in Buyer’s and its customer’s plants and operations. Buyer must

notify Seller of any warranty claim within ten (10) days after such claim arises, otherwise Buyer waives all rights to

such claim. Products supplied by Seller, which are manufactured by others, are not warranted by Seller, but rather

Seller merely passes through the manufacturer’s warranty to Buyer.

SELLER EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Unless otherwise agreed in writing, Buyer’s sole remedy for breach of warranty is, at Seller’s option, the repair of

the defect, the correction of the service, or the providing a replacement part FOB Seller’s office. Seller will not be

responsible for costs of dismantling, lost refrigerant, reassembling, or transporting the product. Further, Seller will

not be liable for any other direct, indirect, consequential, incidental, or special damages arising out of a breach of

warranty. THESE WARRANTY REMEDIES ARE EXCLUSIVE AND ALL OTHER WARRANTY REMEDIES ARE EXCLUDED.

Products or parts for which a warranty claim is made are to be returned transportation prepaid to Seller’s factory.

Any improper use, corrosion, neglect, accident, operation beyond rated capacity, substitution of parts not approved

by Seller, or any alteration or repair by others which, in Seller’s judgement, adversely affects the Product, shall void

all warranties and warranty obligations. Further, Seller shall not be liable under the above warranties should Buyer

be in default of its payment obligations to Seller under this Agreement or any credit agreement.

6

Page 7

Standard VILTER 5/15 Warranty Statement

The seller extends warranty, from date of shipment, to a period of fifteen (15) years on all compressor bearings,

five (5) years on all internal compressor parts and two (2) years on the remainder of the parts on single screw

compressor units. If within such period any such product shall be proved to Seller’s satisfaction to be defective,

such product shall be repaired or replaced at Seller’s option. Such repair or replacement shall be Seller’s sole

obligation and Buyer’s exclusive remedy hereunder and shall be conditioned upon Seller’s receiving written

notice of any alleged defect within ten (10) days after its discovery and, at Seller’s option, return of such parts to

Seller, F.O.B., freight prepaid to Seller’s factory. Expenses incurred by Buyer in repairing or replacing any defective product or any lost refrigerant will not be allowed except by written permission of Seller. This warranty is

only applicable to products properly maintained and used according to Seller’s instructions, the use of genuine

Vilter replacement parts and recommended oil in all repairs and replacements has demonstrated adherence to a

scheduled maintenance program as detailed in the Single Screw Compressor operating manual. This warranty

does not apply to normal wear and tear, or damage caused by corrosion, misuse, overloading, neglect, improper

operation, accident or alteration, as determined by Seller. Products supplied by seller hereunder, which are

manufactured by someone else, are not warranted by Seller in any way, but Seller agrees to assign to Buyer any

warranty rights in such products that the Seller may have from the original manufacturer. Labor and expenses

for repair are not covered by warranty.

THE WARRANTY CONTAINED IN THIS SECTION IS EXCLUSIVE AND IN LIEU OF ALL OTHER REPRESENTATIONS

AND WARRANTIES (EXCEPT OF TITLE), EXPRESS OR IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Any description of the product, whether in writing or made orally by Seller or Seller’s agents, specifications,

samples, models, bulletins, drawings, diagrams, engineering sheets or similar materials used in connection with

Buyer’s order are for the sole purpose of identifying the products and shall not be construed as an express warranty. Any suggestions by seller or Seller’s agents regarding use, application or suitability of the products shall

not be construed as an express warranty unless confirmed to be such in writing by Seller. The 5/15 Extended

Warranty shall be applicable only if the specific maintenance guidelines as outlined in the technical manual are

followed. This includes the compressor inspections, completing periodic oil analysis and the change out of the

oil and oil filters, and related components as required with only genuine Vilter parts. The customer is required to

keep a maintenance log and receipts demonstrating the use of Genuine Vilter parts for validation of a warranty

claim, if requested.

Note: The 5/15 warranty applies to NEW compressors only, and does NOT include used or remanufactured compressors.

7

Page 8

Long Term Storage Requirements

The procedure described is a general recommendation for long term storage (over one month of no operation)

of Vilter Manufacturing packages and compressors. While this procedure is intended to cover most of the

commonly encountered situations, it is the responsibility of the installation fi rm and end user to address any

unusual conditions. We suggest using the accompanying Long Term Storage Log sheet for recording purposes

to validate the appropriate procedures.

Prior to start-up, Vilter recommends that a complete system pressure check be performed. Upon verifi cation

of the system integrity, a comprehensive evacuation procedure should be completed to ensure a dry system

before gas is introduced. The oil circuit of any compressor is to be primed at initial start-up through the prelube oil pump on screw compressors.

Warranty of the system remains in effect as described in Section 5, Product Warranty and Procedures.

* If the unit is designed for indoor duty, it must be stored in a heated building.

If the unit is designed for outdoor duty, and is to be stored outdoors, a canvas tarp is recommended for

protection until installation is imminent. Adequate drainage should be provided, by placing wood blocks

under the base skid, so that water does not collect inside the base perimeter or low spots in the tarp.

* All compressor stop valves are to be closed to isolate the compressor from the remainder of the system. All

other valves, except those venting to atmosphere, are to be open. It is essential that the nitrogen holding

charge integrity be maintained.

* Cover all bare metal surfaces (coupling, fl ange faces, etc.) with rust inhibitor.

* Desiccant is to be installed in the control panel. If the panel is equipped with a space heater, it is to be

energized. If the panel does not have a space heater, use a thermostatically controlled 50-watt light bulb.

Use an approved electrical spray-on corrosion inhibitor for panel components (relays, switches, etc.)

* All pneumatic controllers and valves (Fisher, Taylor, etc.) are to be covered with plastic bags and sealed with

desiccant bags inside.

* System and compressor pressures (unit is shipped with dry nitrogen holding charge approximately 5 psi

above atmospheric pressure) are to be monitored, on a regular basis, for leakage. It will be necessary to

add a gauge to monitor the system holding charge pressure. If a drop in pressure occurs, the source of

leakage must be found and corrected. The system must be evacuated and recharged with dry nitrogen to

maintain the package integrity.

* Motors – (NOTE: The following are general recommendations. Consult the manufacturer of your motor

for specifi c recommendations.)

1) Remove the condensation drain plugs from those units equipped with them and insert silica-gel into the

openings. Insert one-half pound bags of silica-gel (or other desiccant material) into the air inlets and outlets

of drip-proof type motors.

NOTE: The bags must remain visible, and tagged, so they will be noticed and removed when

the unit is prepared for service.

8

Page 9

Long Term Storage Requirements

2) Cover the unit completely to exclude dirt, dust, moisture, and other foreign materials.

3) If the motor can be moved, it is suggested that the entire motor be encased in a strong, transparent plastic bag.

Before sealing this bag, a moisture indicator should be attached to the side of the motor and several bags of

silica-gel desiccant put inside the bag, around the motor. When the moisture indicator shows that the desiccant

has lost its effectiveness, as by a change in color, the bag should be opened and fresh replacement desiccants

installed.

Whenever the motor cannot be sealed, space heaters must be installed to keep the motor at least 10°F above

the ambient temperature.

NOTE: There is a potential for damage by small rodents and other animals that will inhabit motors

in search of warm surroundings or food. Due to this, a possibility of motor winding destruction exists. Sealing motor openings should restrict access to the motor.

4) Rotate motor and compressor shafts several revolutions (approximately 6) per month to eliminate fl at spots on

the bearing surfaces. If the compressor unit is installed, wired and charged with oil, open all oil line valves and run the

oil pump for 10 seconds prior to rotating the compressor shaft. Continue running the oil pump while the compressor

shaft is being turned to help lubricate the surfaces of the shaft seal.

9

Page 10

Description

COMPRESSOR

The Vilter Single Screw Compressor is a positive displacement, capacity and volume controlled, oil fl ooded,

rotary compressor which uses a single main screw intermeshed by two opposing gate rotors. Gas compression

occurs when the individual fi ngers of each gate rotor sweep through the grooves, or fl utes, of the main screw as

the screw rotates. Compression occurs from the time the screw fl ute is fi rst closed off by the gate rotor fi nger,

until the time when the screw fl ute has rotated to the point of lining up with the discharge port in the compres-

sor housing. A labyrinth type seal is used to prevent gas at discharge pressure from leaking past the end of the

screw. Any discharge gas leakage past the labyrinth seal is vented back to suction via four longitudinal holes

drilled through the body of the screw.

By venting the discharge end of the main screw back to suction, forces on each end of the screw are equal. This

results in zero net axial forces on the main bearings. With twin opposing gate rotors, all radial forces are cancelled out also. Main shaft bearings have no net forces except the weight of the screw and the shaft assembly.

The compressors are comprised of three rotating assemblies: the main screw assembly and the two gate rotor assemblies. Each of these rotating assemblies use a common bearing confi guration consisting of a single,

cylindrical rolling element bearing at one end, and a pair of angular contact ball bearings at the other end. The

pair of angular contact ball bearings are used to axially fi x one end of the rotating shafts, and to absorb the small

amount of thrust loads on the shafts. The inner races of the ball bearings are securely clamped to the rotating

shafts, while the outer races are securely held in the bearing housing, thus fi xing the axial position of the shaft

in relation to the bearing housings. The cylindrical roller bearings at the opposite end of the shafts allow for

axial growth of the shafts while supporting the radial loads from the shafts.

The suction gas enters the compressor housing through the top inlet fl ange, at the driven end of the unit. The

driven end of the compressor housing is fl ooded with gas at suction pressure. The gas enters the open end of

the main screw fl utes at the driven end, and becomes trapped in the screw fl ute as the screw rotates and the

gate rotor tooth enters the end of the fl ute. At this point, the compression process begins. Directly after the

screw fl ute is closed off by the gate rotor tooth, oil is injected into the groove.

The oil enters the compressor through a connection at the top of the compressor. The purpose of the injected oil

is to absorb the heat of compression, to seal the gate rotor tooth in the groove, and to lubricate the moving parts.

Additional internal oiling ports are provided at the main and gate rotor bearings to cool and lubricate the bearings. The mechanical shaft seal housing also contains oiling ports to lubricate, cool and provide a sealing fi lm

of oil for the mechanical shafts seal. Excess oil fl ows through the check valves on the sealing baffl e plate. This

oil is directed at the main rotor roller bearing, which cools and lubricates the front roller bearing.

As the main screw rotates, the gate rotor is also driven, causing the gate rotor tooth to sweep the groove in the

main screw. This sweeping action reduces the volume of the groove ahead of the gate rotor tooth and causes

the trapped gas and oil to be compressed in the reduced volume. As the main screw continues to rotate, the

gate rotor tooth continues to reduce the groove volume to a minimum, thus compressing the trapped gas to

a maximum pressure. A labyrinth seal arrangement prevents the compressed gas from leaking past the end of

the screw. As the gate rotor tooth reaches the end of the groove, the groove rotates to a position that lines up

with the discharge port in the compressor housing and the gas/oil mixture is discharged from the screw at high

pressure. This completes the compression cycle for a single fl ute of the main screw.

Once the gas is swept from the main screw fl ute through the discharge port, it passes into the discharge manifold

of the compressor. From the discharge manifold, the gas/oil exits the compressor housing

10

Page 11

Description

The Vilter compressors feature the exclusive Parallex™ Slide System, which consists of a pair of slides for each

gate rotor assembly. These two independently operated slides are referred to as the capacity slide and the volume ratio slide. On the suction end of the screw, the capacity slide moves to vary the timing of the beginning

of the compression process. With the slide moved all the way out to the suction end of the screw (the 100%

position), the compression process begins immediately after the gate rotor tooth enters the screw fl ute and

closes off the end of the groove. In this situation, the maximum volume of gas is trapped in the screw fl ute at

the start of the compression process. As the slide is pulled back away from the suction end of the screw, the

start of the compression process is delayed as some of the suction gas is allowed to spill back out of the screw

fl ute until the screw rotates far enough to pass the end of the capacity slide and begin compressing. This causes

a reduced volume of gas to be trapped in the screw fl ute when the compression process begins. In this way, the

capacity of the compressor is reduced from 100% down to as low as 10% of the full rated capacity.

The capacity slide provides the means for controlling specifi c process set points. By continuously adjusting the

fl ow of gas through the compressor, either suction or discharge pressure in a particular process can be controlled.

When coupled with a microprocessor controller, the adjustable capacity slide allows for precise and continuous

automatic control of any parameter in the process to a chosen set point.

The second slide for each gate rotor is the volume ratio slide. The purpose of the volume ratio slide is to maximize

the effi ciency of the compressor by matching the gas pressure within the screw fl ute at the point of discharge

to the downstream process requirements. The volume ratio slide operates at the discharge end of the screw,

and acts to vary the position of the discharge port. When the slide is extended fully to the discharge end of the

screw (the 100% position), the compression process within the screw fl ute continues until the screw rotates

far enough for the fl ute to pass the end of the volume ratio slide. At this point, the screw fl ute lines up with the

discharge port and the compressed gas is expelled from the screw fl ute. As the volume ratio slide is pulled back

away from the discharge end of the screw, the position of the discharge port is changed and the gas is allowed

to escape the screw fl ute earlier in the compression process, at a reduced pressure.

The overall volume ratio within the compressor is determined by the distance between the front of the capacity slide (the start of compression) and the back of the volume ratio slide (the completion of compression).

Therefore, the volume ratio slide must respond to changes in the downstream pressure measured in the oil

separator and position itself for the required compression ratio based on the position of the capacity slide. By

only compressing the gas within the screw as far as required to match the pressure in the downstream receiver,

the compressor effi ciency is maximized. Proper positioning of the volume ratio slide prevents either over

compressing or under compressing of the gas within the screw fl ute. This allows the single screw compressor

to effi ciently handle a range of volume ratios from as low as 1.2 up to 7.0.

11

Page 12

Foundation

Introduction

Vilter Single Screw compressor units are low vibration machines. Under most conditions, no elaborate foundation is

necessary. However a sound foundation maintains motor alignment and proper elevation, and is therefore required.

Provided are recommendations for the foundation and anchoring of the compressor unit. The Vilter foundation supports the entire operating weight of the unit and is suitable for years of continuous duty. Included are specifi cations

for concrete, rebar, aggregate, anchors and grout.

Considerations Prior to Starting

Consult professionals, such as building inspectors, structural engineers, geotechnical engineers and/or construction

contractors prior to starting. Below are a few points to consider:

Site Characteristics:

• Soil information

• Site drainage

• Wind data

• Seismic zone

• Ingress and egress

• Power and power lines

Site Layout:

• Plant elevations, grading, drainage and erosion

• Accessibility to compressors for service

• Location of surrounding buildings

• Property lines and roadways

• Power

• Fire safety

Safety:

NOTE

Always check with a safety engineer before proceeding.

• Arranging equipment with adequate access space for safe operation and maintenance

• Wherever possible, arrange equipment to be served by crane. If not feasible, consider other handling methods

• Make all valves and devices safely accessible

• Use special bright primary color schemes to differentiate service lines

• Lightening protection for outdoor installations

• Relief valve venting

Foundation Materials

Materials needed to build the foundation are forms, concrete, sand, rebar, wire, grout, anchor bolts, expansion board

and shims. A set of concrete forms will need to be acquired; generally, these can be rented or constructed from

dimensional lumber. There should be enough 4,000 psi concrete with one inch aggregate to build the foundation.

Also, there should be enough sand to provide a base of compacted sand four inches thick for the foundation to rest

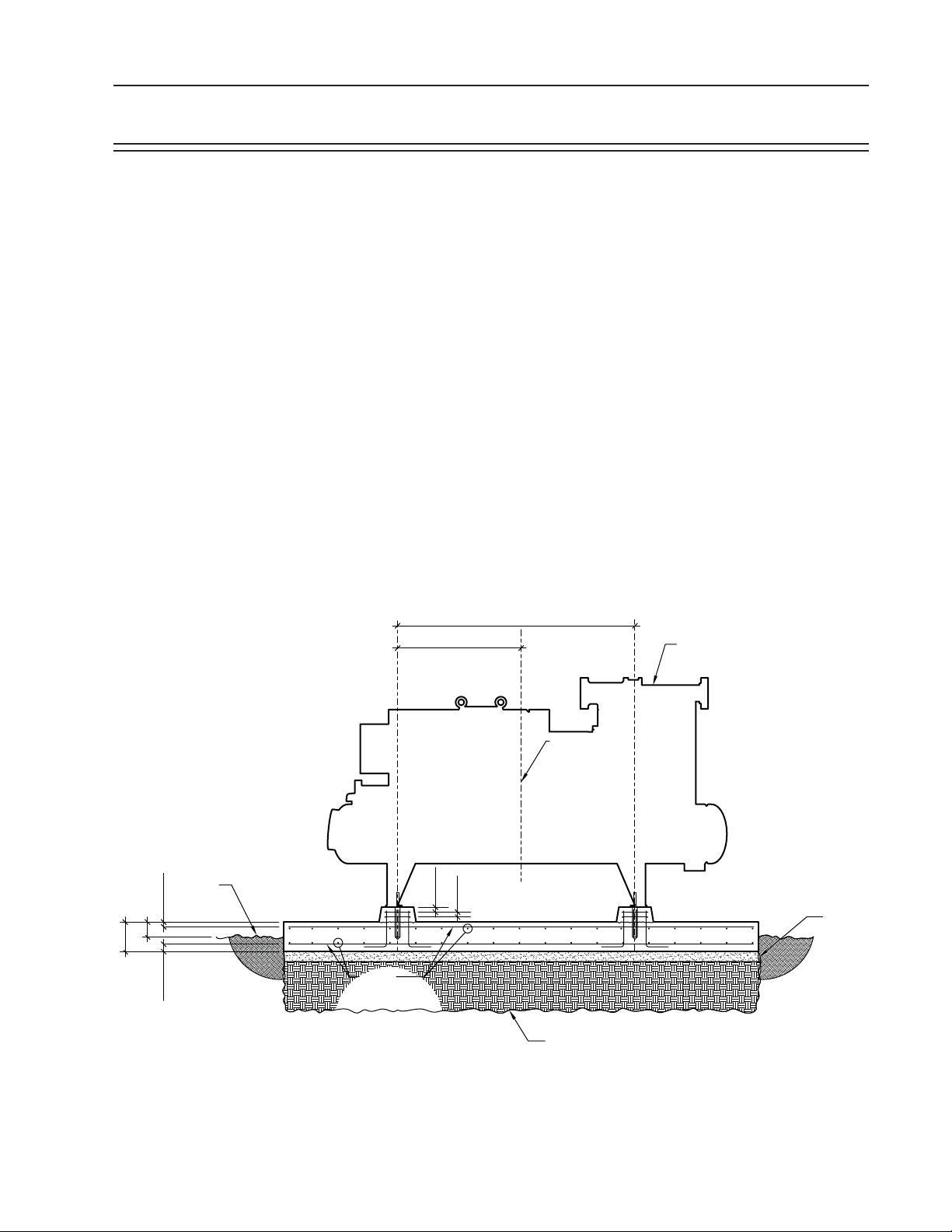

on, see Figure 1 - Concrete Pad with Compressor Unit Dimensions - Side View. The rebar required is ASTM 615, grade

60, sizes #4 and #6. Wires will also be needed to tie the rebar together. The recommended grout is Masterfl ow 648CP

high performance non-shirk grout to provide at least a 1” thick pad under each foot. The recommended anchors are

5/8” Diameter HILTI HAS SS threaded rod for outdoor installations or HAS-E rods for indoor installations. Anchor bolts

shall have a fi ve inch projection and 12-3/8” embedment. The required adhesive is HIT-ICE/HIT/HY 150 anchoring

system. There should be enough one inch expansion boards to go around the perimeter of the foundation. Finally

there should be enough shim stock and extra anchor bolt nuts to level the compressor unit.

12

Page 13

Foundation

Building the Foundation

Use the Vilter General Arrangement (GA) and foundation drawings to help secure a building permit and foundation

construction. The Vilter GA drawing will have the necessary dimensions required to determine the overall foundation size and where to locate the compressor unit on the foundation. It will also show the dimensions required to

form up the housekeeping piers that the compressor unit rests on. The Vilter foundation drawing lists the necessary

information to construct a suitable foundation. It includes the rebar requirements and locations. It also shows anchor

bolt locations, grouting and the concrete specifi cations. Using the Vilter GA drawing, Vilter foundation drawing and

the information from site characteristics, site layout and safety studies will provide enough data to allow building

the foundation to proceed.

The foundation is to be cast and permanently exposed against the earth. Therefore, if constructing on an existing

fl oor, typically indoors, the fl oor will need to be broken up to get to the earth. If starting from undisturbed soil, it

must be also be prepared accordingly. In either case, these are some check points to consider:

• Check the depth of your frost line to ensure the foundation extends below it

• Ensure the foundation rests entirely on natural rock or entirely on solid earth, but never on a combination

of both

• Check the ability of the soil to carry the load

• Check wet season and dry season soil characteristics for static loading limits and elasticity

• Check local codes for Seismic Design requirements

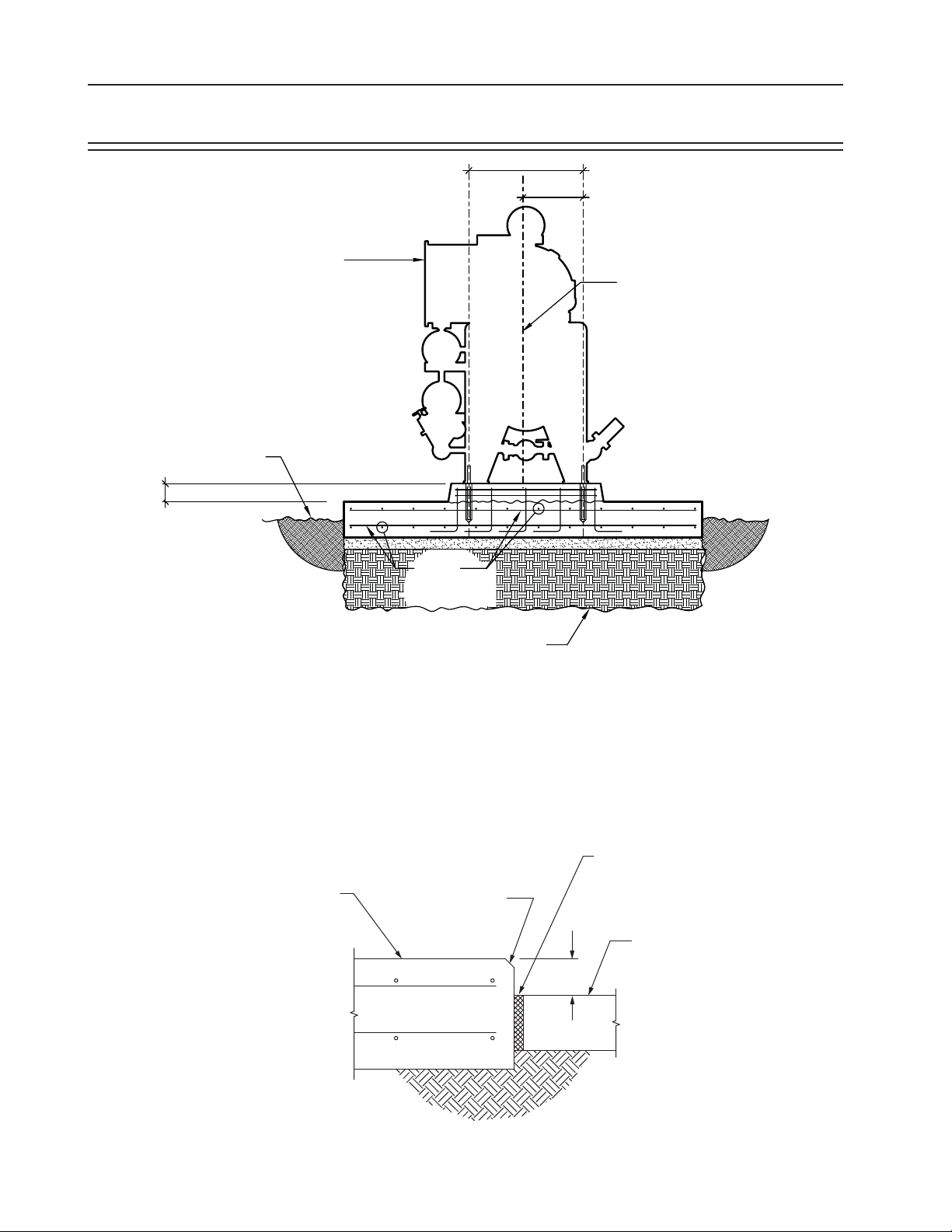

For examples of foundation diagrams, refer to Figure 1 - Concrete Pad with Compressor Unit Dimensions - Side View

and Figure 2 - Concrete Pad with Compressor Unit Dimensions - Front View

1'-0"

6"

EL. TOP OF

GRADE

3" CLR. 2" CLR.

G.A.

# 6 @ 12"

EACH WAY

TOP & BOTTOM

G.A.

CENTER LINE OF

GAS COMPRESSION

SYSTEM

2" (TYP.)

2" (TYP.)

EXCAVATE TO FROST DEPTH AS REQ'D AND BACKFILL

WITH CLSM OR NON-FROST SUSCEPTIBLE FILL

COMPRESSOR UNIT

Figure 1. Concrete Pad with Compressor Unit Dimensions - Side View

4" COMPACTED

SAND

13

Page 14

6"

Foundation

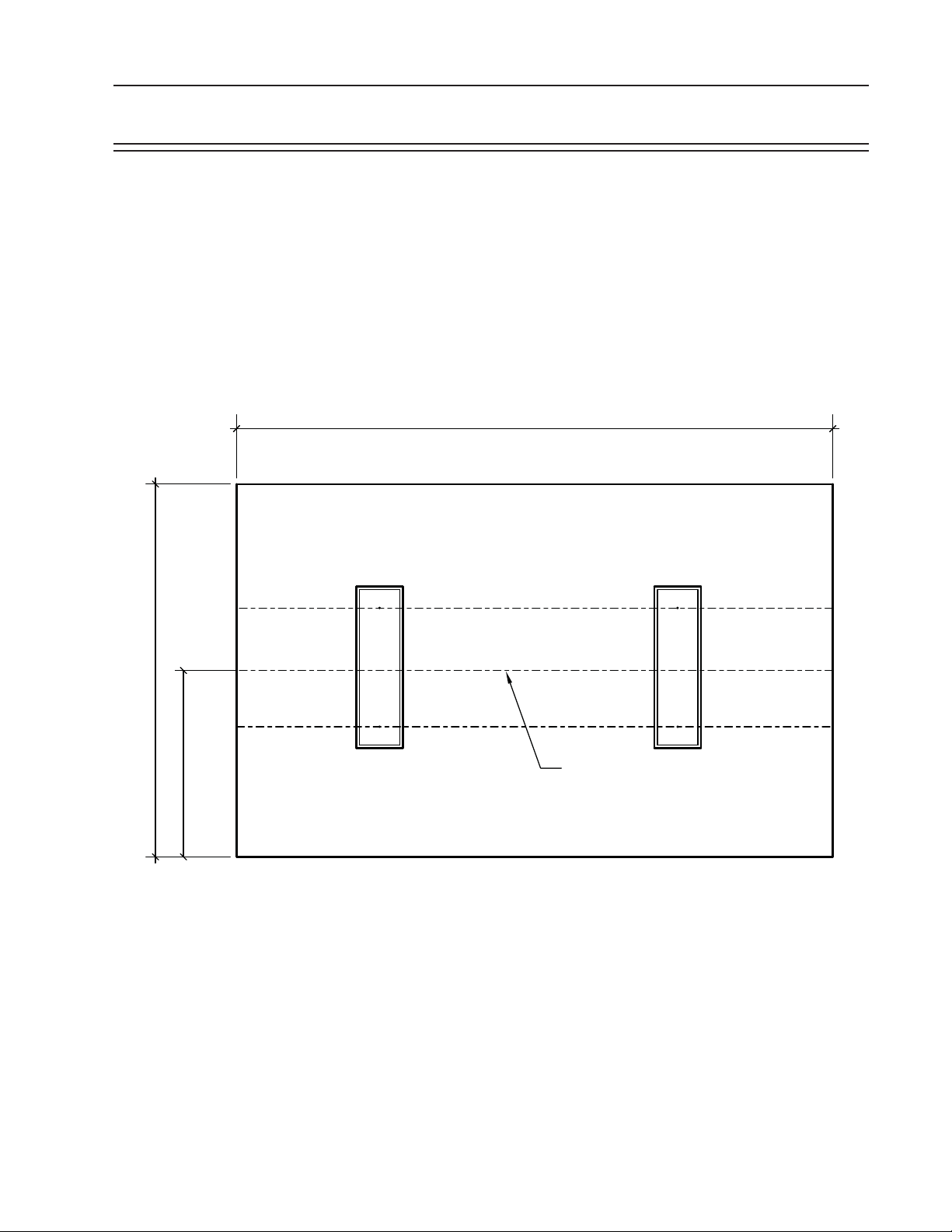

G.A.

G.A.

COMPRESSOR UNIT

CENTER LINE OF

GAS COMPRESSION

SYSTEM

EL. TOP OF

GRADE

# 6 @ 12"

EACH WAY

TOP & BOTTOM

EXCAVATE TO FROST DEPTH AS REQ'D AND BACKFILL

WITH CLSM OR NON-FROST SUSCEPTIBLE FILL

Figure 2. Concrete Pad with Compressor Unit Dimensions - Front View

Once the site has been excavated and prepared, place four inches of sand down on the bed where the foundation will

rest. The sand must be compacted before placing the forms and rebar. After the sand is compacted, use the Vilter GA

drawing to construct the forms for the foundation. With forms in place, install expansion boards on the inside of the

forms, for example, see Figure 3 - Interior Foundation Isolation. Next, place your rebar in the forms as per the Vilter

foundation drawing. When all rebars are in place the concrete can be poured. The concrete must then be trolled level

and a surface texture etched in place. Leave the concrete to cure for at least 28 days.

ISOLATION JOINT,

1" MINIMUM

COMPRESSOR UNIT

CHAMFER EDGE

THICKNESS

FOUNDATION

CONCRETE

SLAB IN

6”

BUILDING

14

Figure 3. Interior Foundation Isolation

Page 15

Foundation

Compressor Unit Installation

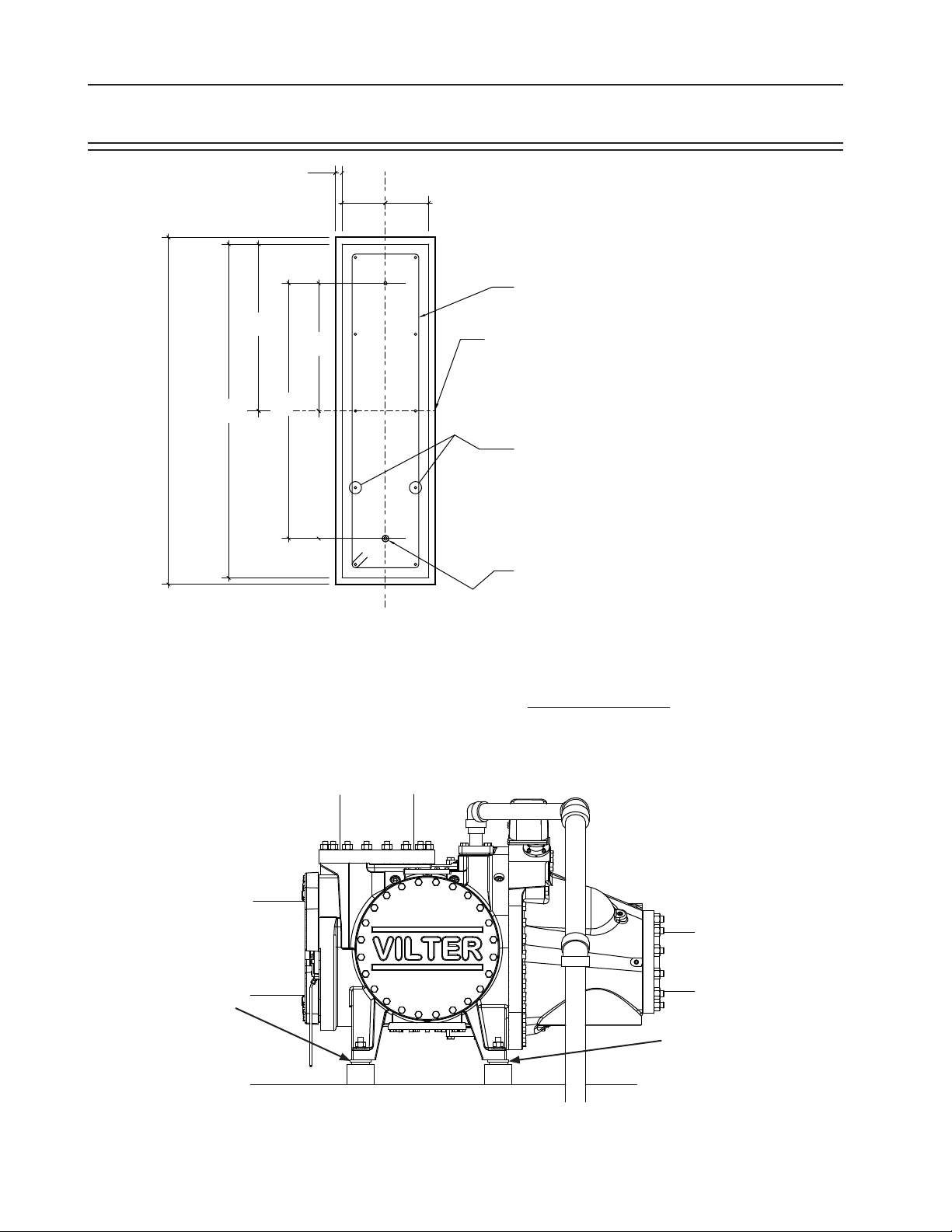

Once the foundation has cured, the compressor unit can be placed on the foundation, see Figure 4. Foundation with

Housekeeping Pads Dimensions - Top View and Figure 5. Housekeeping Pad Dimension Detail - Top View. With the

appropriate material handling equipment, lift the compressor unit by locations shown on the Vilter GA drawing and

slowly place it on the foundation housekeeping piers. As per the Vilter GA drawing, ensure the compressor unit is

correctly placed on the foundation. Once placed, use the spherical washers directly under the compressor as the

surface to level the compressor unit, see Figure 6 - Compressor with Spherical Washers. Place shims under the feet

of the compressor unit, as needed, until it is leveled, see Figure 7 - Concrete Pad Housekeeping Detail. Select the

correct drill bit and drill thru the anchor bolt hole in the mounting feet of the compressor unit to the depth called

for on the Vilter foundation drawing. Finally using the HILTI instructions, put your anchor bolts in place and wait for

them to cure. Then place the nuts on the anchor bolts to fi nger tight and prepare to grout.

OVER ALL G.A. LENGTH + 4'-0"

10'-0"

5'-0"

CENTER LINE GAS

COMPRESSION

SYSTEM

Figure 4. Foundation with Housekeeping Pads Dimensions - Top View

15

Page 16

G.A.

1" (TYP.)

G.A.

Foundation

G.A.G.A.

(2) - # 4

CLOSED TIES

CENTER LINE

G.A. + 2"

G.A.

G.A.

(5) - # 6 VERT.

WITH STD. 90° HOOK

AT BOTTOM EACH

FAC E

5/8" DIA. HILTI HAS SS THREADED ROD

(HAS-E RODS ARE ACCEPTABLE FOR INTERIOR

INSTALLATIONS) INSTALLED USING

HIT-ICE/HIT-HY 150 ADHESIVE ANCHORING

SYSTEM.

(5" PROJECTION, 12 3/8" EMBEDMENT.)

HOLES TO BE INSTALLED WITH HAMMER DRILL.

DO NOT DIAMOND CORE.

Figure 5. Housekeeping Pad Dimension Detail - Top View

(TYP.)

16

SPHERICAL

WASHER

SPHERICAL

WASHER

Figure 6. Compressor with Spherical Washers

Page 17

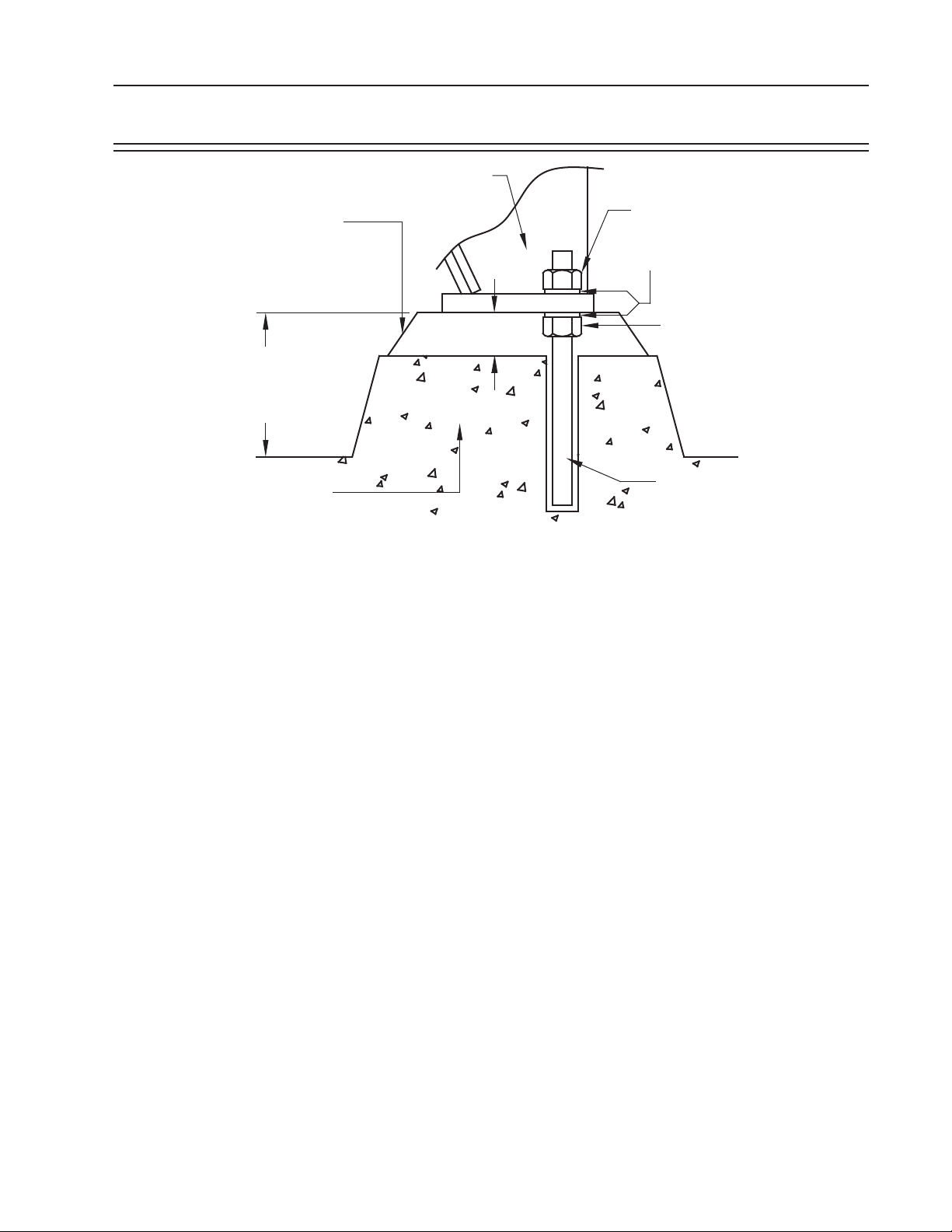

Foundation

70+6.')

010Ä5*4+0-

'21:;)4176

/+0

4'%1//'0&'&

(14

*175'-''2+0)

%10%4'6'

$#5'

Figure 7. Concrete Pad Housekeeping Detail

Leveling and Grouting

The unit should be level in all directions. Wet the concrete pad according to the grout manufacturer’s directions. Mix

a suffi cient amount of grout. The grout must be an expanding grout rather than shrinking to provide a tighter bond.

Follow the manufacturer’s recommendations for setting, precautions, mixing, and grout placement, fi nishing and

curing. The grout must be worked under all areas of the feet with no bubbles or voids. If the grout is settled with a

slight outside slope, oil and water can run off of the base. Once the grout has cured, torque the anchor bolts as per

HILTI instructions.

*1.&&190076

9#5*'4

.'8'.+0)076

#0%*14$1.6

Piping Connections

Piping Stress

Once the screw compressor package has been installed, properly grouted and anchored, it is imperative that the

piping bolted to the screw compressor not impose excessive forces on the compressor. Suction and discharge lines

should be supported so the lines will not move if disconnected from the compressor.

Additional Information

Codes and Standards

Vilter followed the following codes and standards when designing your foundation:

• ACI

• ASTM

• ASCE 7

• IBC 2006

17

Page 18

Foundation

Operation and Performance

The foundation was designed for:

• Outside environment severe exposure

• Ambient temperature -10 degrees F to 105 degrees F

• Unit weight 20,000 lbs

• RPM 3600

• Soil bearing capacity 1,500 lbs/sq.ft.

• Wind speed 120 MPH

• Exposure factor D

• Wind importance factor 1.15

• Concrete poured on and permanently cast against the earth

General Design Requirements

The compressor foundation is designed to:

• Maintain the compressor in alignment and at proper elevation.

• Minimize vibration and prevents its transmission to other structures

• Provide a permanently rigid support

• Provide suffi cient depth to dampen vibrations.

18

Page 19

Rigging and Lifting

Thank you for purchasing a gas compressor (the “Compressor”) from Vilter Manufacturing LLC (“Vilter”). Rigging

and Lifting a large piece of equipment like the Compressor is extremely dangerous.

**DISCLAIMER**

Notice

This rigging and lifting manual (this “Manual”) is provided to you as a courtesy by Vilter and is not intended to be a

comprehensive guide to rigging and lifting the Compressor. Vilter shall not be liable for errors contained herein or

for incidental or consequential damages (including any injury to persons performing the rigging or lifting) in connection with the furnishing, performance, or use of this Manual. This Manual is only a set of suggestions and you

may not rely solely on the information contained in this Manual to conduct the lift. In addition, information in this

Manual is subject to change without notice.

Limited Warranty

The information is this Manual does not constitute any warranty as to the Compressor. The warranty provision

contained in the terms and conditions pursuant to which the Compressor was sold serves as the sole and exclusive

warranty.

Safety

To correctly and safely operate the Compressor, you must consult all of the documentation that was provided to

you with the purchase of the Compressor (including all information sheets, warning notices and any other documents). This Manual is not intended to summarize or supplant any directions regarding how to safely operate or

move the Compressor.

BEFORE LIFTING AND RIGGING THE COMPRESSOR

In order to minimize the inherent risk involved in rigging and lifting a large piece of equipment, before attempting

to lift the Compressor, the actions of all parties involved in the lift must be carefully planned.

The following is provided merely to encourage purchasers to think about all of the steps necessary to rig and lift

the Compressor. Vilter can neither anticipate all of the dangers involved in a particular lift, nor evaluate the particular capabilities of each of person who will participate in the lift.

Educate and Select Lift Participants

To rig and lift the Compressor in a safe manner, you will need to select experienced, trained people (“Participants”)

to take on (and successfully perform) at a minimum the tasks associated with each of the following positions:

• Crane Operator;

• Crane Owner;

• Lift Coordinator;

• Lift Engineer;

• Rigging Specialist;

• Riggers; and

• Safety Signaler.

19

Page 20

Rigging and Lifting

Training curriculum for Participants, at a minimum, should include:

• A review of safe operating practices;

• A review of who each person is and their specifi c role in the lift;

• A tutorial on how to read lift charts;

• A demonstration on how to use and inspect rigging hardware;

• A review of the company’s general lift plans and procedures;

• A tutorial on hand signals normally used to communicate with crane operators (a copy of such hand signals

may be obtained from machine safety vendors); and

• A review of the Compressor’s specifi c rig and lift plan (the “Plan”) (developed by the Lift Coordinator and Lift

Engineer); please see the section immediately below entitled “Create and Communicate the Plan.”

Individuals participating in the lift should fully understand the scientifi c principles pursuant to which a successful

lift is dependent—for example, center of gravity, equilibrium, and mechanics of load stabilization, critical angle

considerations and force.

All Participants should undergo a fi tness-for-duty program, including drug testing and medical examinations.

Create and Communicate the Plan

Well in advance of the planned lift date, lift planning meetings and hazard assessment meetings should be held

with all Participants in attendance. In addition, the Plan should be fi nalized and distributed for review and com-

ment.

The Plan should clearly defi ne requirements, expectations and specifi cations for lifting the Compressor. At a mini-

mum, the Plan should include:

• Standard lifting and rigging procedures in place at the lift site (including proper classifi cation of the lift as a

“critical lift” a “serious lift” or a “standard lift”);

• Drawings of the Compressor;

• A description of the lifting task;

• An evaluation of the hazards;

• The rigging plan and sketches of rigging to be attached to the Compressor;

• The roles and responsibilities of all Participants;

• An emergency plan; and

• The contact information of the Plan preparer

It is important to confi rm that each Participant understands both the broader Plan and their specifi c responsibilities

during the lift. Participants should be encouraged to contact the Plan preparer at any time if they have questions.

In addition, the Plan preparer should be on-site during the lift to ensure that the lift is being executed in accordance with the Plan. Finally, well in advance of the lift date, it should be confi rmed that all necessary permits have

been obtained.

Inspect and Use the Appropriate Lifting Equipment

Verify Crane Operator and Crane Owner Credentials

Prior to rigging and lifting the Compressor, certain precautions should be taken with regards to the crane, the

crane operator and the crane owner.

• The lift capacity of the crane must exceed the Compressor’s weight;

• Confi rm that the crane operator is qualifi ed to work on the site;

20

Page 21

Rigging and Lifting

• Get third-party confi rmation that the crane owner and the crane operator are in compliance with applicable

laws, regulations and internal safety standards;

• Consult with the crane owner to determine if any site preparation is required for outriggers—improper use of

outriggers is a signifi cant cause of crane failure;

• Determine the level of supervision to be supplied by the crane owner; and

• Review all crane maintenance and inspection records, including without limitation, the crane log book, maintenance records, inspection reports and the physical condition of the crane.

Take all Appropriate Measurements

• Understand and interpret the load charts;

• Review all Compressor drawings for unit size, weight, center of gravity and other specifi cations;

• Communicate incident response procedures in writing prior to the lift and verbally immediately before the lift;

• Determine the initial position, fi nal position, orientation and elevation of the Compressor;

• Ensure that adequate space is provided to safely assemble, erect, and operate the crane and materials (such as

timber mats, cribbing and blocks);

• Identify and communicate to all Participants the access points, lift radius, swing radius, clearances, and obstructions;

• Eliminate hazards and obstructions that may interfere with moving the Compressor; and

• Inform all Participants of water lines, sewer lines, power lines and other obstructions.

Use Proper Rigging Methods

• Determine diameter, length and quantity of necessary rigging hardware (design and detail the rigging hardware to suit lifting the Compressor at the supplied pad eyes);

• Review and inspect all hoisting, lifting and rigging equipment;

• Select shackle size and prepare sketches or drawings for rigging;

• Use proper, conservative rigging techniques—including spreader beams—needed to lift the Compressor;

• Pad sharp corners, check the orientation of chocker hitches and the orientation of hooks;

• Prevent the binding of hoist rings; and

• Verify pad eye information.

TEST AND BALANCE THE COMPRESSOR

It is essential to test and balance the compressor before executing the actual lift in order to identify potential

causes of injury to Participants and the Compressor.

Secure Rigging and the Lift Site

• Reiterate that no one should walk under the raised load;

• Secure and restrict access to the lift area (consider vacating all non-essential personnel from the area);

• Provide qualifi ed supervision for the duration of the lift;

• If applicable, assess the weather conditions and decide if it is safe to proceed;

• Stop the lift when any potentially unsafe conditions are recognized; and

• Ensure there are open channels for communications during the pre-lift, lift and post-lift phases (radio communications should be used if a direct line of sight is not possible).

Test and Balance the Compressor before the Lift

• Slowly raise the crane to take slack out of the rigging without actually lifting the load;

• Allow the rigging gear to settle into place;

• Check for twists and binds;

• Verify that all padding has remained in place and that all slings are protected from sharp edges;

• Begin to raise the load to verify balance and check the braking system; and

• If the Compressor is not balanced, lower and adjust as necessary.

21

Page 22

Rigging and Lifting

CONTACT VILTER

While Vilter will not offer any specifi c feedback on the Plan or provide a specifi c Plan for rigging and lifting the

Compressor, Vilter may be able to answer questions about the Compressor that are important in developing your

Plan.

Please contact Vilter at:

P.O. Box 8904

5555 S Packard Ave

Cudahy, WI 53110-8904

Telephone: 1-414-744-0111

Fax: 1-414-744-3483

email: info.vilter@emerson.com

www.vilter.com

22

Page 23

Installation

I. DELIVERY INSPECTION

Vilter screw compressor components are thoroughly inspected at the factory, assuring the

shipment of a mechanically perfect piece of equipment. Damage can occur in shipment, however.

For this reason, the units should be thoroughly

inspected upon arrival. Any damage noted should

be reported immediately to the transportation

company. This way, an authorized agent can examine the unit, determine the extent of damage

and take necessary steps to rectify the claim with

no serious or costly delays. At the same time,

the local Vilter representative or the home offi ce

should be notifi ed of any claim made.

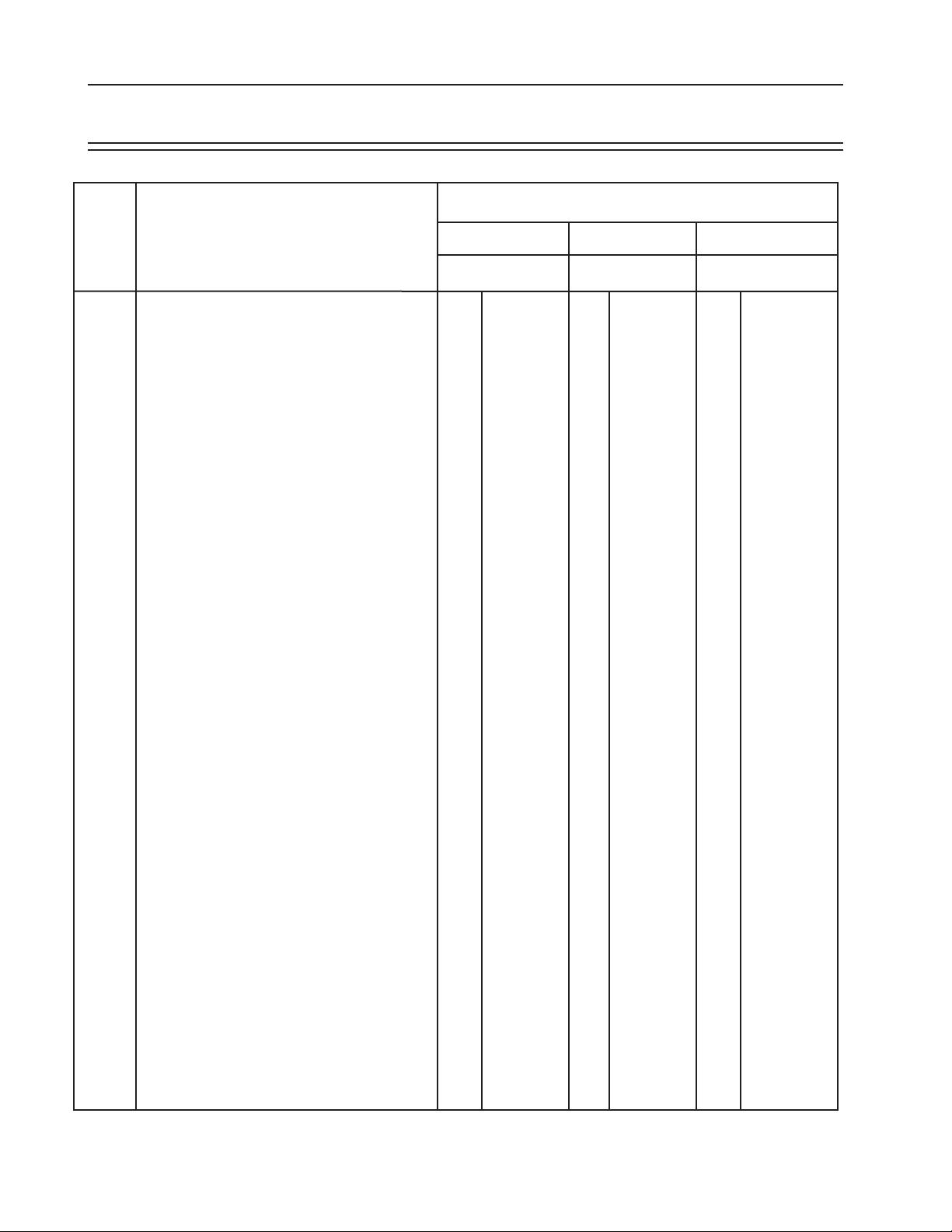

TABLE 1. UNIT WEIGHTS (LBS)*

MODEL STANDARD ECON-O MIZER

VSM 71 2,750 2,750

VSM 91 2,750 2,750

VSM 101 2,750 2,750

VSM 151 2,750 2,750

VSM 181 2,750 2,750

VSM 201 2,750 2,750

VSM 301 2,850 2,850

VSM 361 2,850 2,850

VSM 401 2,850 2,850

VSM 501 4,000 4,000

VSM 601 4,500 4,500

VSM 701 5,000 5,000

VSS 451 4,000 4,000

VSS 601 4,500 4,500

VSS 751 5,300 5,300

VSS 901 5,300 5,300

VSS 1051 6,600 6,600

VSS 1201 6,700 6,700

VSS 1301 6,750 6,750

VSS 1501 10,010 10,010

VSS 1801 10,010 10,010

VSS 1551 11,000 11,000

VSS 1851 11,000 11,000

VSS 2101 11,000 11,000

* Does not include motor.

II. FOUNDATIONS

Vilter single screw compressor units are basically vibration free machines, therefore, no

elaborate foundations are necessary. The fl oor

or foundation upon which the unit will be placed

should be designed to support the entire operating weight of the unit. See Table 1 for unit

weights. See Foundation, page 12, for additional

foundation instructions.

III. LOCATING UNIT - DRIVE

COUPLING ALIGNMENT

The single screw compressor units are shipped

with all major components mounted on structural steel. Place the entire unit on the fl oor

on a concrete pad and securely bolt in place.

Review local codes and ASHRAE Safety Code for

Mechanical Refrigeration. Bolt holes are located

in the unit’s mounting feet. When locating the

unit, provide adequate space for service work.

When the compressor unit is in place on the concrete pad, check both lengthwise and crosswise

to assure it is level. Use shims and wedges as

needed under the mounting feet to adjust the

level of the unit.

On single screw units, the motor and compressor have been roughly aligned at the factory.

The coupling center section was shipped loose

to allow a check of proper electrical phasing,

direction of rotation of the motor and final

coupling alignment. The dial indicator alignment method is recommended. Final alignment

should be within 0.004 inches total indicator

reading in all direction for the VSS models and

0.010 inches for the VSM models.

III. SYSTEM PIPING

Refer to the ANSI/ASME B31.5 Code for Refrigeration Piping. All compressor oil supply and oil

return piping has been completed at the factory.

The necessary connections to be made to the

screw compressor unit will vary depending on

the type of oil cooling method purchased. Main

line refrigerant suction and discharge connections are always necessary.

23

Page 24

Installation

Care must be taken to avoid trapping the lines except for specifi c purposes. When traps are used,

the horizontal dimensions should be as short as

possible to avoid excessive oil trapping.

Lines for ammonia systems must be of steel pipe

with specially designed ammonia service fi ttings.

Common pipe fi ttings must NEVER be used as

they will not provide the same service. Steel pipe

is generally used in large installations when joints

are welded.

In making up joints for steel pipe, the following

procedures should be followed:

For threaded connections, all threads on the pipe

and fi tting should be carefully cleaned to remove

all traces of grease or oil. Threads should then be

wiped dry with a lintless cloth. Only thread fi ll-

ing compounds suitable for refrigeration service

should be used for making steel pipe joints. These

compounds should be used sparingly, and on the

pipe only. Do not put any on the fi rst two threads

to prevent any of the compound from entering

the piping system. Acetylene or arc welding

is frequently used in making steel pipe joints,

however, only a skilled welder should attempt this

kind of work. Take care to see no foreign materials

are left in the pipes and remove all burrs formed

when cutting pipe.

for tube sizes not larger than 1-3/8” in outside

diameter. These requirements are in accordance

with the mechanical code for refrigeration ANSI

B9.1-1971. The type of copper tubing to be used

for a given pressure is dependent on the strength

of the copper at the design temperature. Some

local codes forbid the use of Type “L”. Therefore,

before installation, be sure to check local requirements. Never use type “M” as it does not have

adequate wall thickness to withstand the operating pressures. In selecting fi ttings for Halocarbon

piping, only wrought copper fi ttings should be

used. Cast fi ttings as used for water service are

porous and will allow the refrigerant to escape.

Note this exception: In larger pipe sizes, wrought

fittings are not available. However, specially

tested cast fi ttings are available and these may

be used with complete safety.

In larger pipe sizes, wrought fi ttings are not avail-

able. However, specially tested cast fi ttings are

available and these may be used with complete

safety.

When soldering copper tubing joints, only silver

solder should be used for Refrigerant-22 service.

Soft solder such as “50-50” should never be used,

as its melting point is too low, lacks mechanical

strength, and tends to break down chemically in

the presence of moisture.

It is important to avoid short, rigid pipe lines that

do not allow any degree of fl exibility. This must

be done to prevent vibration being transmitted

through the pipe lines to the buildings. One

method of providing the needed fl exibility to

absorb the vibration is to provide long lines that

are broken by 90° Ells in three directions.

Smaller Halocarbon and Hydroflourocarbon

installations use copper pipes with solder type

fi ttings where possible. The use of screw type

fi ttings in Halocarbon systems should be held

to an absolute minimum, as these refrigerants,

due to their physical properties, will leak through

screw type joints.

When drawn copper tubing is used for Halocarbon lines, type “K” or “L” conforming to ASTM

B88 should be used. Soft annealed copper tubing conforming to ASTM B280 can also be used

24

A second method would be to install fl exible

pipe couplings as close to the compressor unit

as possible with connections run in two different

directions, 90° apart. These fl exible connections

should be installed on both the high and low side

lines of the compressor unit.

Hangers and supports for coils and pipe lines

should receive careful attention. During prolonged operation of the coils, they may become

coated with ice and frost, adding extra weight to

the coil. The hangers must have ample strength

and be securely anchored to withstand the

vibration from the compressor and adequately

support the pipe lines.

Water supply and drain connections, and equipment using water, should be installed so all the

water may be drained from the system after

the plant has been shut down in cold weather.

Page 25

Installation

These precautions will avoid costly damage to

the equipment due to freezing.

This information is taken from ASHRAE 15-89 and

ANSI B31.5. The installing contractor should be

thoroughly familiar with these codes, as well as

any local codes.

IV. ELECTRICAL CONNECTIONS

The single screw compressor units are shipped

with all package mounted controls wired. The

standard control power is 115 volts 60 Hertz,

single phase. If a 115 volt supply is not available, a

control transformer may be required. The power

source must be connected to the control panel

according to the electrical diagrams.

The units are shipped without the compressor

motor starter. Field wiring is required between

the fi eld mounted starters and package mounted

motors.

Additional control wiring in the fi eld is also re-

quired. Dry contacts are provided in the control

panel for starting the screw compressor motor.

These contacts are to be wired in series with the

starter coils. A current transformer is supplied

along with the compressor unit, and is located

in the motor junction box. This transformer is to

be installed around one phase of the compressor motor starter. A normally open auxiliary

contact from the compressor motor starter is

also required.

Terminal locations for this wiring can be found

on the wiring diagram supplied with this unit.

Additional aspects of the electrical operation of

the single screw units are covered in the start up

and operation section of this manual.

V. TESTING REFRIGERATION

SYSTEM FOR LEAKS

Vilter equipment is tested for leaks at the factory.

One the most important steps in putting a refrigeration system into operation is fi eld testing for

leaks. This must be done to assure a tight system

that will operate without any appreciable loss of

refrigerant. To test for leaks, the system pressure must be built up. Test pressures for various

refrigerants are listed in ANSI B9.1-1971 code

brochure entitle “Safety Code for Mechanical

Refrigeration”. These pressures will usually suffi ce, however, it is advisable to check local codes

as they may differ. Before testing may proceed,

several things must be done.

First, if test pressures exceed the settings of

the system, relief valves or safety devices, they

must be removed and the connection plugged

during the test. Secondly, all valves should be

opened except those leading to the atmosphere.

Then, open all solenoids and pressure regulators by the manual lifting stems. All bypass

arrangements must also be opened. Because

of differences in characteristics of the various

refrigerants, two different testing methods are

necessary.

A. Ammonia Systems

Dry nitrogen may be used to raise the pressure

in an ammonia system to the proper level for

the test. The gas may be put into the system

through the charging valve or any other suitable

opening. Adjust the pressure regulator on the

bottle to prevent over-pressurization. Do not

exceed the pressure rating on the vessel with

the lowest pressure rating.

Carbon Dioxide should NOT be used as a testing gas in a system where ammonia is already

dissolved in any moisture remaining. This will

cause ammonium carbonate to precipitate

when the CO2 is added. If heavy enough, this

precipitate may cause the machine to freeze

and clog the strainer.

A mixture of four parts water to one part liquid

soap, with a few drops of glycerin added, makes

a good solution. Apply this mixture with a one

inch round brush at all fl anges, threaded joints,

and welds. Repair all visible leaks. If possible,

leave the pressure on over night. A small pressure drop of 5 lbs. Over this period indicates a

very tight system.

Remember to note the ambient temperature,

as a change in temperature will cause a change

in pressure.

After the system is thoroughly tested, open all

25

Page 26

Installation

valves on the lowest part of the system so the gas

will fl oat away from the compressor. This pre-

vents any dirt or foreign particles from entering

the compressor and contaminating the working

parts. The oil should then be charged into the

compressor.

Charge a small amount of ammonia into the system and pressurize the system to its respective

design pressure. Pass a lit sulfur stick around all

joints and connections. Any leaks will be indicated by a heavy cloud of smoke. If any leaks are

observed during this test, they must be repaired

and rechecked before the system can be considered tight and ready for evacuation.

B. Halocarbon Refrigerant Systems

“Oil pumped” dry nitrogen, or anhydrous CO2 in

this order of preference may be used to raise the

pressure to the proper level for testing.

When the proper pressure is attained, test for

leaks with the soap mixture previously described.

After all leaks are found and marked, relieve the

system pressure and repair the leaks. Never attempt to repair soldered or welded joints while

the system is under pressure. Soldered joints

should be opened and re soldered.

Do not simply add more solder to the leaking

joint. After all the joints have been repaired and

the system is considered “tight” the system may

be tested with refrigerant.

Attach a drum of the refrigerant to be used in the

system and allow the gas to enter until a pressure

of 5 psig is reached.

Remove the refrigerant drum and bring the

pressure to the recommended test level with oil

pumped dry nitrogen or CO2. Then check the

entire system again for leaks, using a halide torch

or electronic leak detector. Be sure to check all

fl anged, welded, screwed and soldered joints, all

gasketed joints, and all parting lines on castings.

If any leaks are found, they must be repaired and

rechecked before the system can be considered

tight again, remembering that no repair should

be made to welded or soldered joins while the

system is under pressure.

C. Evacuating The System

A refrigeration system operates best when only

refrigerant is present. Steps must be taken to

remove all air, water, vapor, and all other noncondensables from the system before charging it

with refrigerant. A combination of moisture and

refrigerant, along with any oxygen in the system,

can form acids or other corrosive compounds that

corrode internal parts of the system.

To properly evacuate the system, and to remove

all non-condensables, air and water vapor, use a

high vacuum pump capable of attaining a blanked

off pressure of 50 microns or less. Attach this

pump to the system and allow it to operate until

system pressure is reduced somewhere below

1000 microns. Evacuation should not be done

unless the room temperature is 60F or higher.

Attach vacuum gauge(s), reading in the 20 to

20,000 micron gauge range, to the refrigerant

system. These gauge(s) should be used in conjunction with the high vacuum pump. The reading from the gauge(s) indicates when the system

has reached the low absolute pressure required

for complete system evacuation.

Connect the high vacuum pump into the refrigeration system by using the manufacturer’s

instructions. Connect the pump both to the high

side and low side of the system, to insure system

evacuation. Attach the vacuum gauge to the

system in accordance with the manufacturer’s

instructions.

A single evacuation of the system does not satisfactorily remove all of the non-condensable, air

and water vapor. To do a complete job, a triple

evacuation is recommended.

When the pump is fi rst turned on, bring system

pressure to as low a vacuum level as possible, and

continue operation for 5 to 6 hours.

Stop the pump and isolate the system. Allow

the unit to stand at this vacuum for another 5 to

6 hours. After this time, break, the vacuum and

bring the system pressure up to 0 psig with dry

nitrogen.

26

Page 27

Installation

To begin the second evacuation, allow the pump

to operate and reduce the pressure again to

within 50 to 1000 microns. After this reading is

reached, allow the pump to operate 2 or 3 hours.

Stop the pump and let the system stand with

this vacuum. Again using dry nitrogen, raise the

system pressure to zero.

For the third evacuation, follow the previous

procedure with the pump operating until system

pressure is reduced below the 1000 micron level.

Run the pump an additional 6 hours and hold the

system for approximately 12 hours at low pressure. After this, again break the vacuum with dry

nitrogen and allow the pressure in the system

to rise slightly above zero pounds (psig). Install

new drier cartridges and moisture indicators.

Charge the system once more below the 1000

micron level and use the refrigerant designed

for the system.

When properly evacuating the system as outlined

above, the system is dry, oxygen-free and free of

non-condensables. The piping should not be insulated before the evacuation process is started.

If moisture is in the system before evacuating, it

condenses in low places and freezes. If this happens, it can be removed by gently heating the

trap farthest away from the vacuum pump. This

causes the ice to melt and water to boil. Water vapor collects in the next trap towards the vacuum

pump. This process should be repeated until all

pockets of water have been boiled off, and the

vacuum pump has had a chance to remove all the

water vapor from the system.

VI. UNIT OIL CHARGING

TABLE 2. OIL CHARGE

Oil Separator Size Approximate Oil

Charge (Gallons)

VSR 16” 20 to 27

VSR 20” 22 to 31

VSM 20” 20 to 25

VSM 30” 30 to 35

20” 30 to 40

24” 40 to 50

30” 60 to 75

36” 95 to 105

42” 145 to 165

The oil level may be above the top sight glass

at this time. Later, when the unit is placed in

operation, there will be some drop in the oil level

as the various oil lines, oil fi lter and other piping

becomes charged with the normal amount of

oil that will be in circulation. This drop in oil

level should bring the level in the oil receiver/

separator into the normal operating range. Do

not mix oils.

A. Oil For Single Screw Compressors

Due to the need for adequate lubrication, Vilter

recommends only the use of Vilter lubricants,

designed specifically for Vilter compressors.

With the extensive research that has been performed, we are able to offer refrigerant specifi c

lubricating oils. Use of oil not specifi ed or sup-

plied by Vilter will void the compressor warranty.

Please contact your local Vilter representative or

the Home Offi ce for further information.

The compressor unit is shipped from Vilter with

no oil charge. The initial oil charge can be made

through the drain valve at the oil receiver/separator. Vilter motor driven and manually operated

oil chargers are available for this purpose. Once

the unit has been started and is operating above

50% capacity, oil may have to be added to bring

the oil level to the normal operating point. With

the unit operating, oil should be added through

the charging connection at the suction strainer.

The normal operating level is between the (2)

sight glasses on the oil separator. See Table 2 for

approximate oil charge requirements.

VII. SYSTEM REFRIGERANT CHARGING

CAUTION

When charging the system, make sure the

compressor unit is pressurized from the discharge side of the compressor. Pressurizing the

compressor from the suction side may cause

rotation of the compressor, without oil supply,

which could lead to internal damage.

27

Page 28

Installation

After the system is leak-free and evacuation has

been completed, it is ready for charging. Before

actual charging, however, the entire operation

of the refrigeration system should be inspected

as outlined below:

A. Low Side Equipment

1. Fans on air handling equipment running.

2. Pumps on water cooling equipment running.

3. Proper location and attachment of thermostatic expansion valve bulb to suction line.

4. Correct fan and pump rotation.

5. Evaporator pressure regulators and solenoid

valves open.

6. Water pumps and motors correctly aligned.

7. Belt drives correctly aligned and tensioned.

8. Proper voltage to motors.

B. Compressors

1. Proper oil level.

2. Voltage agrees with motor characteristics.

3. Properly sized motor fuses and heaters.

4. Direct drivers aligned and couplings tight.

5. All suction and discharge valves open.

6. All transducers and RTD’s calibrated and

reading correctly.

C. Condensers

1. Water available at water cooled condensers

and supply line valve open.

2. Water in receiver of evaporative condenser

and makeup water available.

3. Correct rotation of pump and fan motors.

4. Belt drives aligned and tensioned correctly.

5. Pump, fans and motors lubricated.

D. Controls

Controls should be at the initial set points. See

microprocessor manual for further information.

E. Initial Charging – High Side Charging

There are two methods of charging refrigerant into the system, through the “high side” or

through the “low side”. High side charging is

usually used for initial charging as fi lling of the

28

system is much faster. Low side charging is

usually reserved for adding only small amounts

of refrigerant after the system is in operation.

High side charging of refrigerant into the system

is accomplished as follows:

1. Connect a full drum of refrigerant to the

liquid charging valve. This valve is generally located in the liquid line immediately

after the king or liquid line valve. Purge the

air from the charging line.

2. Invert the refrigerant drum if the drum is

not equipped with “Liquid” and “Vapor”

valves, and place in such a position so the

liquid refrigerant only can enter the system. Close the liquid line or king valve, if

it is not already closed. Open the “Liquid”

charging valve slowly to allow refrigerant

to enter the system. The vacuum in the

system will draw in the refrigerant.

It is important that, during this operation,

air handling units be running and water is

circulating through the chillers. The low

pressures on the system can cause the

refrigerant to boil at low temperature and

possibly freeze the water if it is not kept

circulating.

Water freezing in a chiller can rupture the

tubes and cause extensive damage to the

system. It would be desirable to charge

the initial amount of refrigerant without

water in the shell and tube equipment to

eliminate the possibility of freeze up.

3. After some refrigerant has entered the

system, the compressor unit starting procedure may be followed. See Start-Up and

Operation Section of this manual.

4. Continue charging refrigerant into the

system until the proper operating requirements are satisfi ed. Then, close the liquid

charging connection and open the liquid

line valve allowing the system to operate

normally. To check that enough refrigerant has been added, the liquid sight glass

Page 29

Installation

should show no bubbles, and there will be a

liquid seal in the receiver. If these two conditions are not satisfi ed, additional refrigerant

must be added.

5. When sufficient refrigerant has been

charged into the system, close the charging

and drum valves. Then remove the drum

from the system.

6. During the charging period, observe the

gauge carefully to insure no operating diffi culties. Watch head pressures closely to

make sure the condensers are functioning

properly.

Since it is usually necessary to use several drums

when charging a system, follow the procedures

in paragraphs E1 and E2 of the above description

when attaching a new drum. After charging,

the refrigerant drums should be kept nearby for

several days as it is sometimes necessary to add

more refrigerant as the system “settles down”.

VIII. MAINTENANCE SUGGESTIONS

Careful checking of a refrigeration system for

leaks and proper operation of all components

upon installation will start the system on its way

to a long life of satisfactory service. To ensure

the desired trouble-free operation, however, a

systematic maintenance program is a prerequisite. The following maintenance schedule is

suggested.

A. Daily

1. Check oil levels.

2. Check all pressure and temperature readings.

3. Check micronic oil fi lter inlet and outlet pres-

sures for excessive pressure drop. Change

fi lter when pressure drop exceeds 45 psi or

every six months, whichever occurs fi rst. For

proper procedure for changing micronic oil

fi lter and for charging oil into the system, see

Operation Section.

4. Clean strainers each time fi lter cartridge

if replaced.

5. Check compressor sound for abnormal

noises.

6. Check shaft seals for excessive oil leakage.

A small amount of oil leakage (approximately 10 drops/min) is normal. This

allows lubrication of the seal faces.

B. Weekly

(Items 1 thru 6 above plus 7 thru 9)

7. Check the refrigeration system for leaks

with a suitable leak detector.

8. Check oil pressures and review microprocessor log and log sheets.

9. Check refrigerant levels in vessels.

C. Monthly

(Items 1 thru 8 above plus 9 thru 13)

10. Oil all motors and bearings. Follow manufacturer’s instructions on lubrication.

11. Check calibration and operation of all

controls, particularly safety controls.

12. Check oil cooler for any evidence of corrosion, scaling or other fouling.

13. Operate compressor capacity and volume

ratio controls through their range both

automatically and manually.

D. Trimonthly

(About 2000 operating hours)

Check movement of compressor rotor at drive

coupling end to determine bearing fl oat. (Re-

fer to Service Section.)

E. Yearly

(Items 1 thru 13 and “D” above plus 14

thru 28)

14. Check entire system thoroughly for leaks.

29

Page 30

Installation

15. Remove all rust from equipment, clean and

paint.

16. Flush out sediment, etc. from water circuits.

17. Clean all oil strainers.

18. Clean suction strainer – compressors.

19. Check motors and fans for shaft wear and

end play.

20. Check operation and general condition of

microprocessor and other electrical controls.

21. Clean all water strainers.

22. Check drains to make sure water will fl ow

away from equipment.

23. Drain and clean entire oil system at receiver

drain. Recharge with new clean moisture

free oil. For proper procedure for changing

micronic oil fi lter and charging oil into the

system, see Start-Up and Operation section.

24. Check compressor coupling. For integrity

and alignment.

25. Check oil pump for wear.

26. Check the calibration of the microprocessor

pressure transducers and RTD’s for accuracy.

tightened, all plugs that were removed are replaced with a suitable thread fi lling compound,

all packing glands on valve stems are tightened,

and all valve caps are replaced. When operation

is restored, all joints opened or any valves moved

during the servicing should be checked for leaks.

G. Year Round Operation

On a continual basis:

1. Guard against liquid slugging of compressor.

2. Maintain unit in clean condition and paint

as necessary.

3. Grease valve stems and threads for the

valve caps.

When refrigeration equipment is operated 24

hours a day year round, it is highly recommended that a yearly check of all internal parts be

made (see Service Section). While the highest

material standards are maintained throughout

all Vilter compressors, continuous operation

and any presence of dirt may prove injurious to

the machine. To forestall needless shutdowns

or prevent possible machine breakdowns, the

side covers should be removed yearly, and a

visual inspection be made of the internal parts.

In this way, a small amount of time spent checking machine conditions once a year may prevent

extensive shutdowns later with subsequent

product loss and expensive repairs.

27. Check mounting bolts for compressor and

motor.

F. System Leaks

There are any number of reasons why leaks

develop in a refrigeration system (i.e. such as

drying out of valve packing, yielding of gaskets,

improper replacement of valve caps and loosening of joints due to vibration). For these reasons,

the need for periodic leak testing cannot be overemphasized. Similarly, when any service operations are performed on the system, care should

be exercised to insure all opened flanges are

30

Page 31

Stop Check Valve Installation

Correct

Correct

Wrong Wrong

Verify the location of the Spring and note the Vilter name.

Installation:

The new design will apply only to the 2” thru 4” stop valves. Retrofi tting a fi eld installation will

require replacing the bonnet assembly.

The bonnet must be installed with the spring towards the bottom (see illustrations above).

The drill fi xture is designed so that the hole for the spring will always be drilled on the oppo-

site side from the cast-in Vilter name on the bonnet. From the outside of the valve, the casting

numbers must always be towards the top of the valve.

See Operation Section on Stop Check Operation.

31

Page 32

Coupling Installation

COUPLING INFORMATION

COUPLINGS INSTALLATION AND ALIGNMENT

These instructions are intended to help you to install

and align the coupling. Covered here will be general