Page 1

VSG & VSSG

Single Screw Compressor

Software Manual

Compact Logix PLC

1

Page 2

2

Page 3

Important Note

Before applying power to the control panel, all wiring to the panel shall be installed per NEC. Specifically

check for proper voltage and that the neutral is grounded at the source. An equipment ground should also

be run to the panel.

*See Wiring Instructions and Diagrams before proceeding.

NOTES:

• Before start-up you need to enter all system values and options, see section on Setpoint Values.

• Power circuits entry on left side of enclosure

• Instrument circuits entry on right side of enclosure

Electrical installation shall be completed by a licensed electrician qualified in field wiring

located in Class 1 Div 2 Hazardous Locations per the National Electric Code (NEC).

3

Page 4

4

Page 5

Table of Contents

Important Note .................................................................................................3

VSG STANDARD VILTER WARRANTY STATEMENT

............................................... 6

Operational Flow Charts ....................................................................................7

Main Screen

.....................................................................................................15

Log On Screen .................................................................................................16

Set Up Screen ..................................................................................................17

Vilter Only Screen

............................................................................................19

Menu Screen ...................................................................................................20

Compressor Alarm and Trip

............................................................................. 24

Compressor Control Setpoints ......................................................................... 27

Additional Compressor Controls ...................................................................... 32

Compressor Setpoints and Alarms

Motor Speed Setpoints & Control Screen

................................................................... 34

.........................................................35

Diagnostics Force Output ................................................................................37

Instrument Calibration ....................................................................................38

Oil Mixing Valve ...............................................................................................43

Unit Start Screen (Start / Stop Logic)

Device Names

..................................................................................................50

................................................................47

Calibration Procedure of Optical Actuators ...................................................... 51

Calibration Procedure of Optical Actuators ...................................................... 52

Calibration Procedure of Optical Actuators ...................................................... 53

Installation Instructions For Replacement Of Optical Actuator

Slide Valve Actuator Theory of Operation

........................................................ 55

.........................54

Slide Valve Actuator Troubleshooting Guide ....................................................56

Slide Valve Actuator Troubleshooting Guide ....................................................57

Slide Valve Actuator Troubleshooting Guide ....................................................58

Command Shaft Rotation and Travel

Safety Failure Message

....................................................................................60

................................................................ 59

Safety Failure Message .................................................................................... 61

Safety Failure Message .................................................................................... 62

Version Screen .................................................................................................63

Trend Charts

....................................................................................................64

Trend Charts .................................................................................................... 65

Captured Data at Shutdown

............................................................................ 67

Appendix A: Slide Valve Actuator Troubleshooting Guide

Appendix B: Drawings and Parts Lists

5

Page 6

VSG STANDARD VILTER WARRANTY STATEMENT

Seller warrants all new single screw gas compression units and bareshaft single screw compressors

manufactured by it and supplied to Buyer to be free from defects in materials and workmanship for a period

of (a) eighteen (18) months from the date of shipment or (b) twelve (12) months from the date of

installation at the end user’s location, whichever occurs first.

If within such period any such product shall be proved to Seller’s satisfaction to be defective, such product

shall be repaired or replaced at Seller’s option. Such repair or replacement shall be Seller’s sole obligation

and Buyer’s exclusive remedy hereunder and shall be conditioned upon (a) Seller’s receiving written notice

of any alleged defect within ten (10) days after its discovery, (b) payment in full of all amounts owed by

Buyer to Seller and (c) at Seller’s option, Buyer shall have delivered such products to Seller, all expenses

prepaid to its factory. Expenses incurred by Buyer in repairing or replacing any defective product

(including, without limitation, labor, lost refrigerant or gas and freight costs) will not be allowed except by

written permission of Seller. Further, Seller shall not be liable for any other direct, indirect, consequential,

incidental, or special damages arising out of a breach of warranty.

This warranty is only applicable to products properly maintained and used according to Seller’s

instructions. This warranty does not apply (i) to ordinary wear and tear, damage caused by corrosion,

misuse, overloading, neglect, improper use or operation (including, without limitation, operation beyond

rated capacity), substitution of parts not approved by Seller, accident or alteration, as determined by Seller

or (ii) if the product is operated on a gas with an H2S level above 100 PPM. In addition, Seller does not

warrant that any equipment and features meet the requirements of any local, state or federal laws or

regulations. Products supplied by Seller hereunder which are manufactured by someone else are not

warranted by Seller in any way, but Seller agrees to assign to Buyer any warranty rights in such products

that Seller may have from the original manufacturer. Labor and expenses for repair are not covered by

warranty.

THE WARRANTY CONTAINED HEREIN IS EXCLUSIVE AND IN LIEU OF ALL OTHER REPRESENTATIONS AND

WARRANTIES, EXPRESS OR IMPLIED, AND SELLER EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Any description of the products, whether in writing or made orally by Seller or Seller’s agents,

specifications, samples, models, bulletins, drawings, diagrams, engineering sheets or similar materials used

in connection with Buyer’s order are for the sole purpose of identifying the products and shall not be

construed as an express warranty. Any suggestions by Seller or Seller’s agents regarding use, application or

suitability of the products shall not be construed as an express warranty unless confirmed to be such in

writing by Seller.

6

Page 7

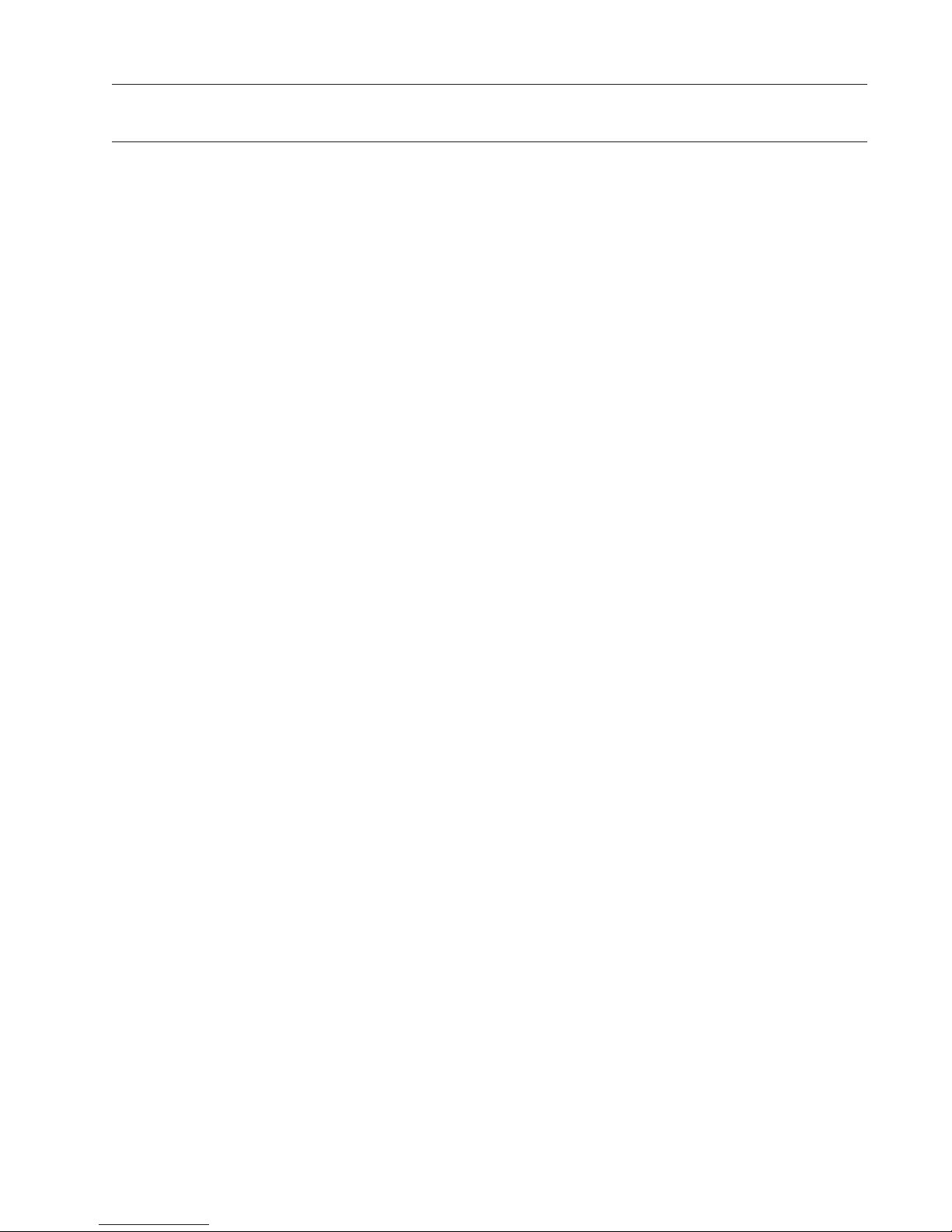

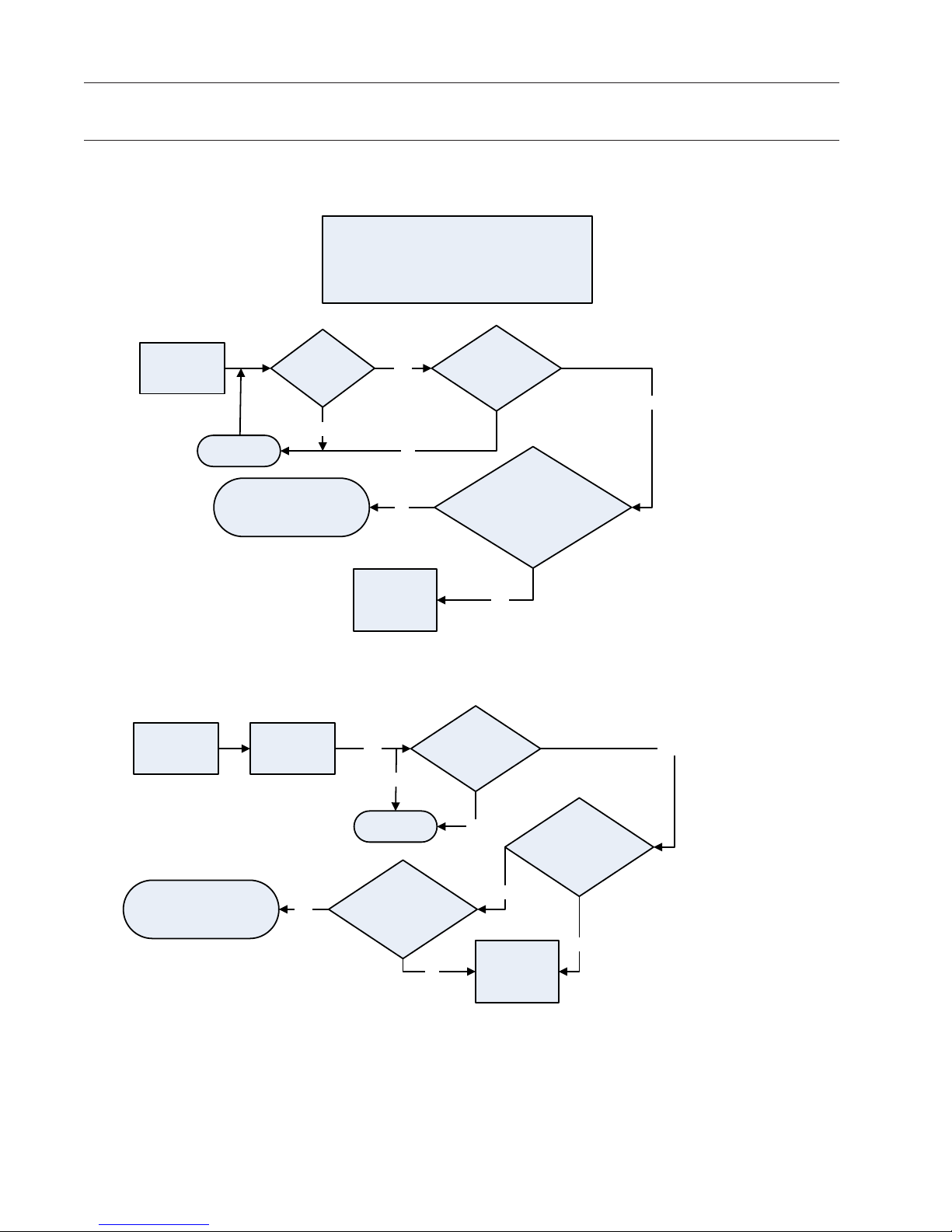

Requirements to Start Compressor

Operational Flow Charts

Volume and

Capacity slides are

less than 5 %.

Oil Separator Temp

> Oil Sep Start

Trip

Setpt.

Oil Pump On: Prelub Oil Press is > Prelub Oil

Press Reset Setpt for “Min Compressor Prelub

Timer” setting (Default 7 Seconds)

Critical Compressor Run Logic @ Compressor Start

Start

Compressor

Compressor

Start Mode

Prelube 5

Seconds

Satified Oil

Pressure

Filter Diff Press <

Filter Diff

Start

Trip Setpt

Is Run Oil Press >

Run Oil Press setpt?

Yes

Yes

Start Compressor

Is

Run Oil Press >

Run Oil Press

setpt?

Reset

(Default 40 PSI)

No

Run Oil Press Failure

“Filter Diff Press Safety

Changeover” timer expires

(60 sec after start).

Compressor Amperage Load Limiting

Is

Motor Amps >

FLA (ON

)

Setpt?

Yes

No

Capacity INC Disabled

No

Is

Motor Amps >

Max (OFF

)

Setpt?

Yes

Is

Filter Diff < Hi Filter

Diff Press Run Trip

setpt?

No

Oil Separator Temp

Safety Changeover

Yes Yes

Timer expires. (5 min

after start)

Is

Oil Sep Temp > Lo

Oil Sep Run Reset

setpt:?

No

Run Filter Diff Press Failure Lo Run Oil Sep Temp Failure

High Disch Pressure Load Limit

Is

Normal Loading &

Unloading

Disch Press >

Cutin (ON

)

Normal Loading &

No

Unloading

Setpt?

Yes

Capacity INC Disabled

No

Capacity Decrease

until Amps < FLA x

1.0625

Is

Disch Press >

Cutout (OFF

Setpt?

)

Capacity Decrease until

Yes

DischPress < ON Setpt x

1.0625

Yes

Run

7

Page 8

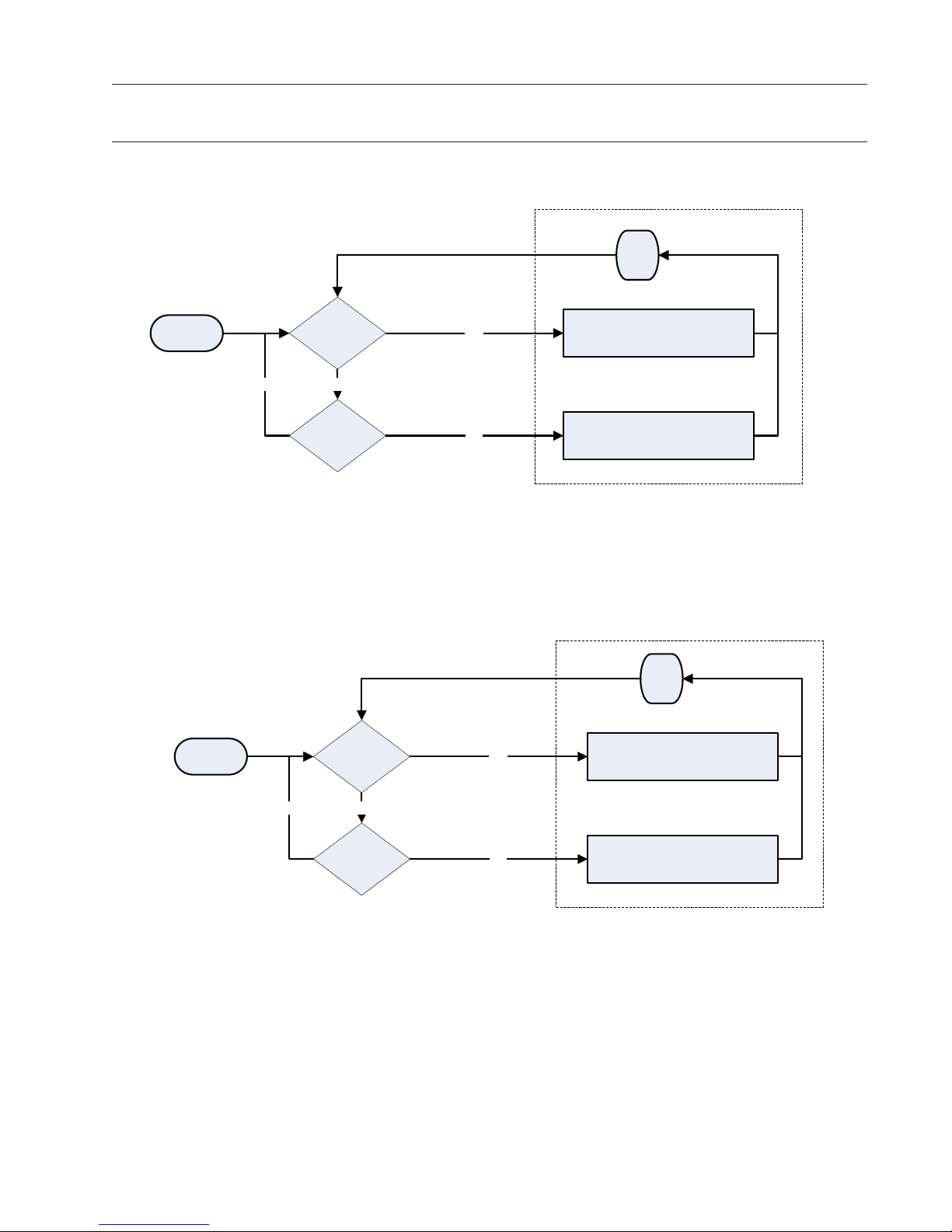

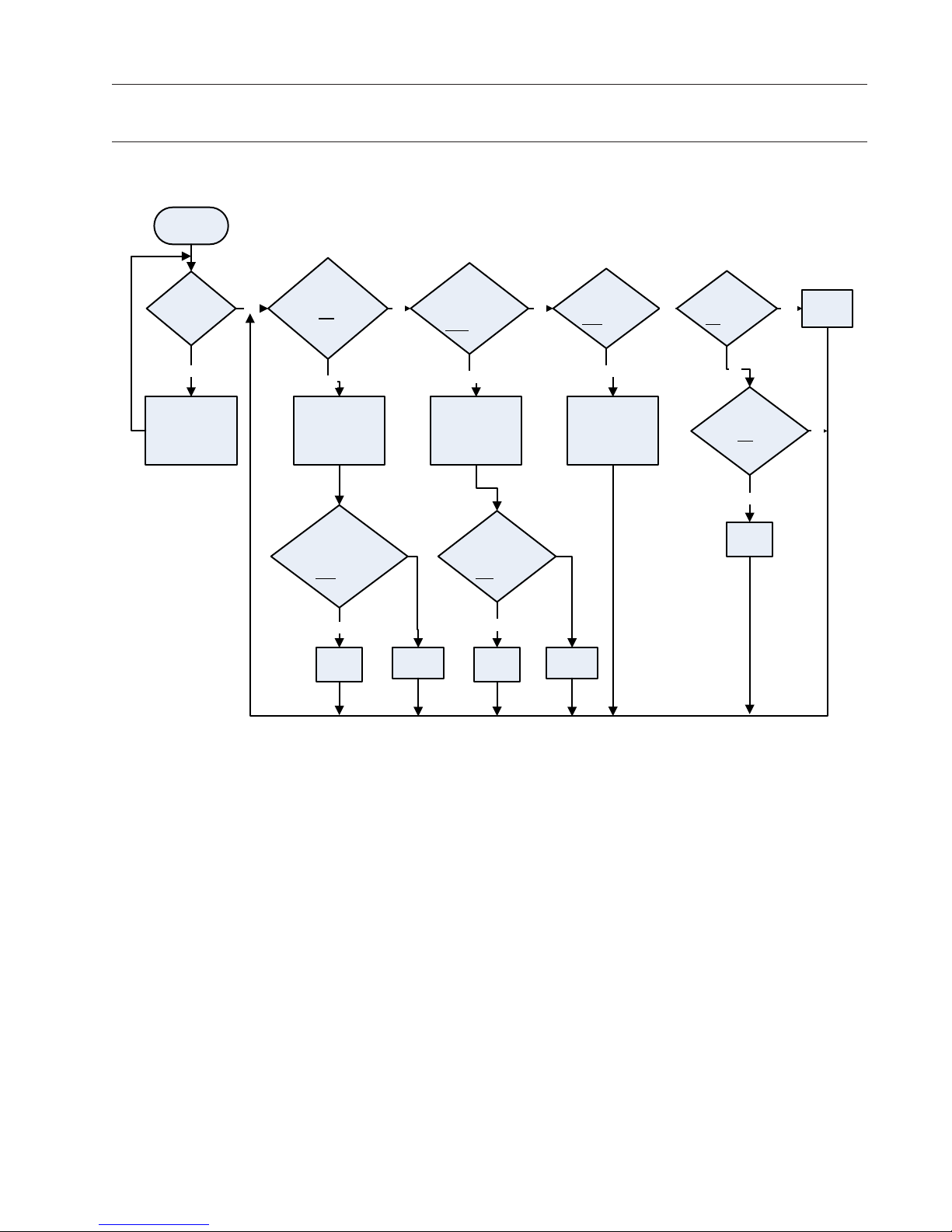

Suction Pressure Control

Is

Suction Press >

Suct Press Cap Inc

Setpt?

No

No

Is

Suction Press <

Suct Press Cap

Dec Setpt?

Suction Pressure Safety

Capacity Inc

No No

Yes Yes Yes

Is Cap Inc ON Timer

Timed Out?

No

WAIT

Is Cap Inc OFF Timer

Timed Out?

Capacity Dec

Is Cap Dec. ON Timer

Yes Yes Yes

Timed Out?

Is Cap Dec. OFF Timer

Timed Out?

No

Reset Cap Inc Timers

Reset Cap Dec Timers

Suct Press Alarm

No

Is

Suction Press <

Setpt?

No

Is

Suction Press <

Suct Press Trip

Setpt?

Yes

Yes

Lo Suction Press

Alarm

Lo Suction Press

Failure

8

Page 9

Oil Cooler Fan Control

(Selectable Control Optional)

Unit Start

Oil Cooler

outlet temp >

set pt?

NoNo

Oil Cooler

outlet temp <

set pt?

Yes

Yes

PID Control

30 sec

delay

Increase Speed

Decrease Speed

Oil Temperature Control Valve

Unit Start

No No

Oil injection

temp > set pt?

Oil injection

temp < set pt?

Yes

Yes

PID Control

30 sec

delay

Modulate valve

Modulate valve

9

Page 10

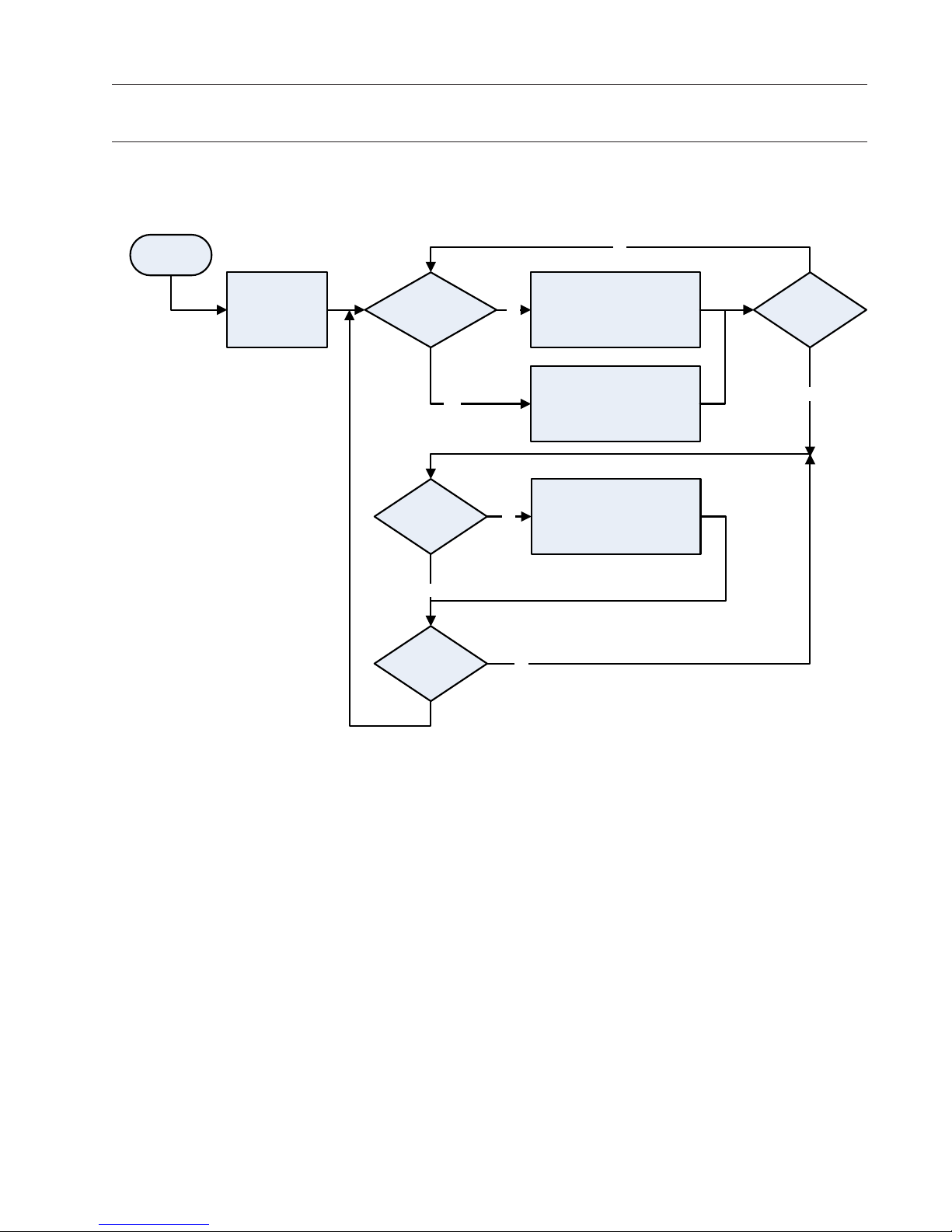

Delayed Lockout Timers

WARNING: FOR THE FOLLOWING SHUTDOWNS, A DELAYED RESTART MAY OCCUR:

High Discharge Pressure Failure

High Compressor Discharge Temp Failure

High Package Outlet Temp Failure

High Oil Injection Temp Failure

Shutdown due to

Operational

Failure

1 min Delay

Auto Restart if All Other Values

Are In Range

WARNING: INCASE OF A POWER FAILURE A DELAYED RESTART MAY OCCUR:

Shutdown Due

to Power Failure

Power Re-

establishing

Is

Shutdown Value

Below Reset

Value?

No

Yes

No

No

Lockout

Requires

Manual Restart

Yes Yes

No

Has

It been *H1

Hours Since

Shutdown?

Have

There Been 3 Shutdowns of “Any

of the Above Failure Conditions”

in H2 Hours

Yes

Has

It been *H3

Hours Since

Shutdown?

H1= Timer Set Between .5-6 Hours.

Default Value= .5 Hours

Yes

H2= Timer Set Between 4-100 Hours.

Minimum and Default Value= 4 Hours

H2 must be equal to or greater than 4 x H1

H3= Timer Set Between .5-6 Hours.

Default Value= .5 Hours

Auto Restart if All Other Values

Are In Range

Yes

10

1 min Delay

Was Compressor

Running During Power

Failure?

No

No

No

Lockout

Requires

Manual Restart

Have

There Been 3 Shutdowns

of This Same Condition

in H4 Hours

H4= Timer Set Between 4-100 Hours.

Minimum and Default Value= 4 Hours

H4 must be equal to or greater than 4 x H3

Yes

Page 11

Capacity Control Using Suction Pressure Control Setpoints

Start

Are Motor

Has

Decrease at Start

(Expired 15

sec.)

Yes No No Yes Yes

Amps >

Motor Amps Load

Setpt?

Limit ON

(Time Delay

10 sec)

Press > High Disch

Is Disch

Press Unload

OFF

Setpt?

Is Capacity

> Min Run Cap

OFF

Setpt?

Is Suct

Press > Cap Inc

ON

Setpt?

Inc Cap

(Timer)

No

Wait

Yes

Disable Cap Inc

Are Motor

Amps >

Motor Amp Load Limit

OFF

Setpt?

Yes

Dec Cap

(Timer)

Yes

Disable Cap Inc

Is Disch

Press > High Disch

Press Unload

ON

Setpt?

Yes

No Change No Change

Dec Cap

(Timer)

No

Increase Cap

(Timer)

No

Is Suct Press< Cap

Dec ON

Setpt?

Yes

Dec Cap

(Timer)

No

11

Page 12

Capacity Control Using Discharge Pressure Control Setpoints

Start

Are Motor

Has

Decrease at Start

(Expired 15 sec.)

Yes Yes

Amps >

Motor Amps Load

Limit ON

Setpt?

(Time Delay

10 sec)

No

Is Disch Press > Cap

Dec ON

Setpt?

Dec Cap

(Timer)

No

Wait

Yes

Disable Cap Inc

Are Motor

Amps >

Motor Amp Load Limit

OFF

Setpt?

Yes

Dec Cap

(Timer)

No

No

Change)

No

Is Disch Press < Cap

Inc ON

Setpt

No

Yes

Inc Cap

(Timer)

No

change

12

Page 13

Compressor Operation with VFD Drive

Start

Compressor

Check/Adjust Capacity Slide

No

Start VFD at

Minimum Speed

(30 Hz Typ.)

Is Control Press.

Within Setpt

Deadbands?

Yes

Check/Adjust VFD

Is Control Press @

Setpoint?

Yes

Is Motor Speed @

Min?

No

No

Increase or Decrease the

Compressor Capacity Slides to

Match Setpoints

Increase or Decrease the

Compressor Capacity Slides to

Match Setpoints

Increase or Decrease Motor Speed

@ Rate Defined by VFD PID

Parameters

No

Is Capslide @

100%

Yes

13

Page 14

14

Page 15

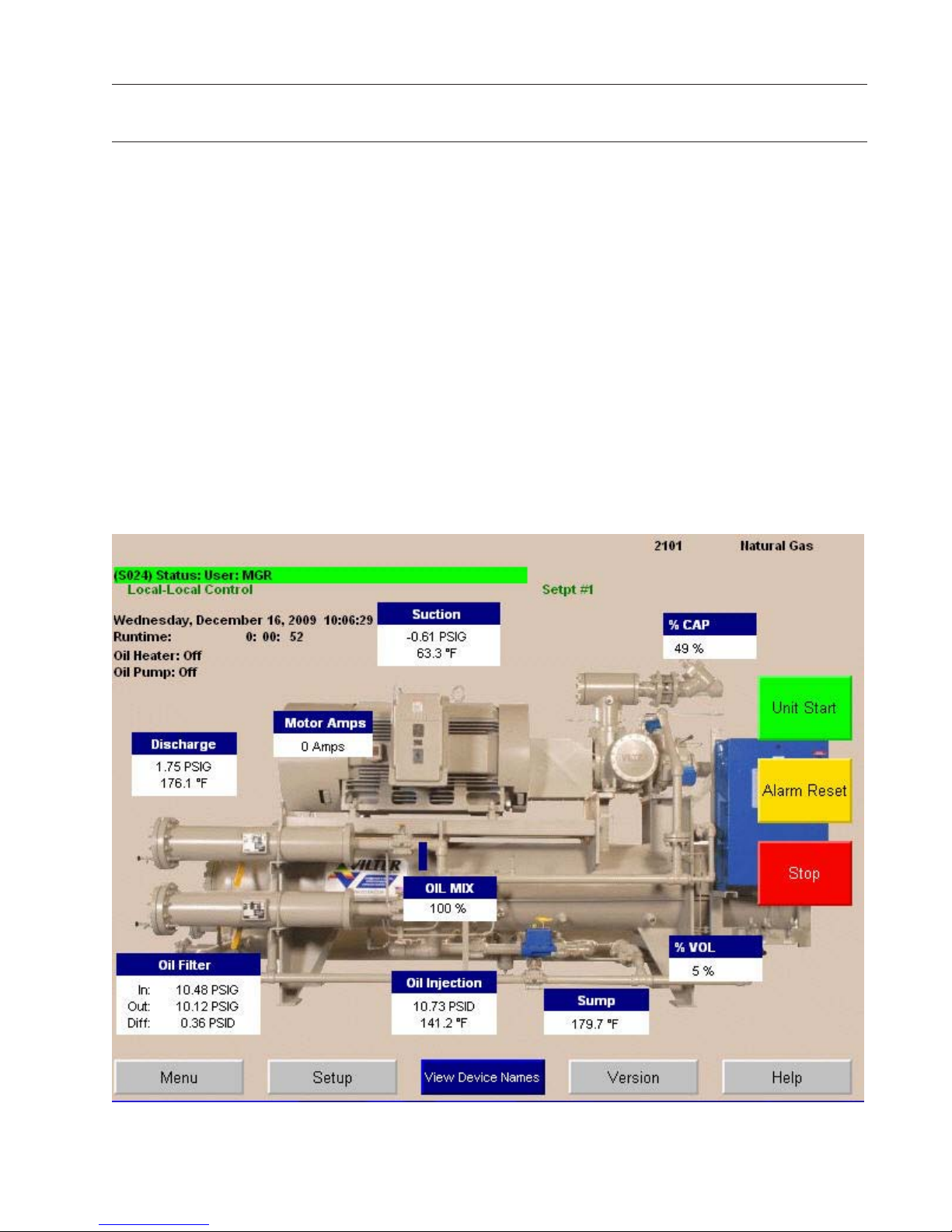

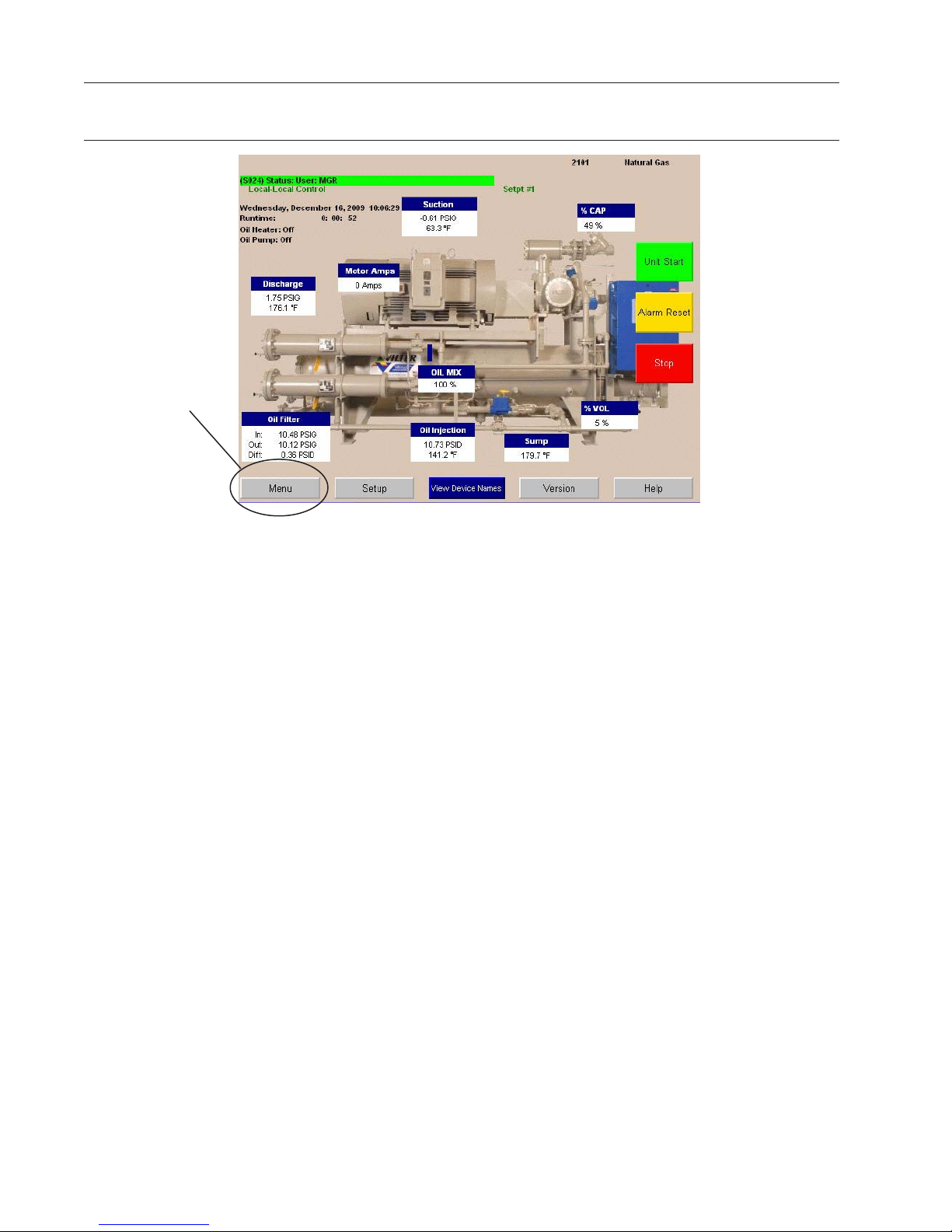

Main Screen

Main Screen

This screen has been designed to give the operator

an overall view of all operating parameters affecting the compressor package. This screen should

always be displayed when maintenance items and

setpoint items are not being performed.

Status information such as Alarms and Trips are

displayed on the screen.

This screen contains buttons to navigate to setpoint

setup screens.

Status information on the compressor, oil pump,

oil heater and run mode.

Start/Stop buttons.

Hour meter.

Motor amperage.

Compressor operating conditions.

15

Page 16

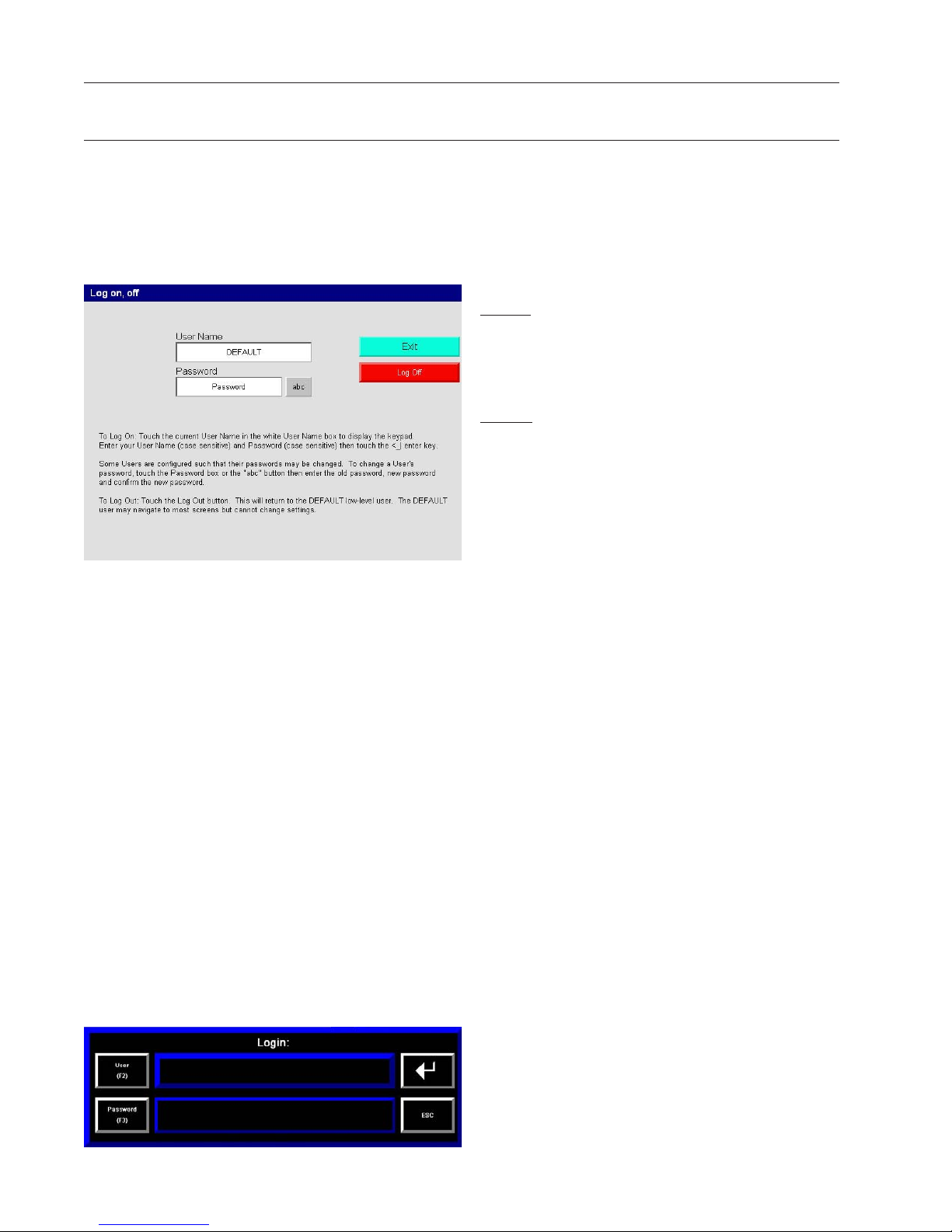

Log On or Off

Log On Screen

Note: An operator will be automatically

logged off after 10 minutes of inactivity.

Note: The machine can be run and monitored without logging on. To change the

setup or parameters of the machine, the

operator must log on.

Press Log on Button and the above screen will appear. When altering setpoints, log on is necessary.

Select appropriate user name and enter password

to change/access setpoints.

To Log On: Touch the current User Name in the white

User Name box to display the keypad. Enter your User

Name (case sensitive) and Password (case sensitive)

then touch the <_| enter key.

Some Users are configured such that their passwords

may be changed. To change a User’s password,

touch the Password box or the “abc” button then

enter the old password, new password and confirm

the new password.

To Log Off: Touch the Log Off button. This will return

to the DEFAULT low-level user. The DEFAULT user

may navigate to most screens but cannot change

settings.

16

Page 17

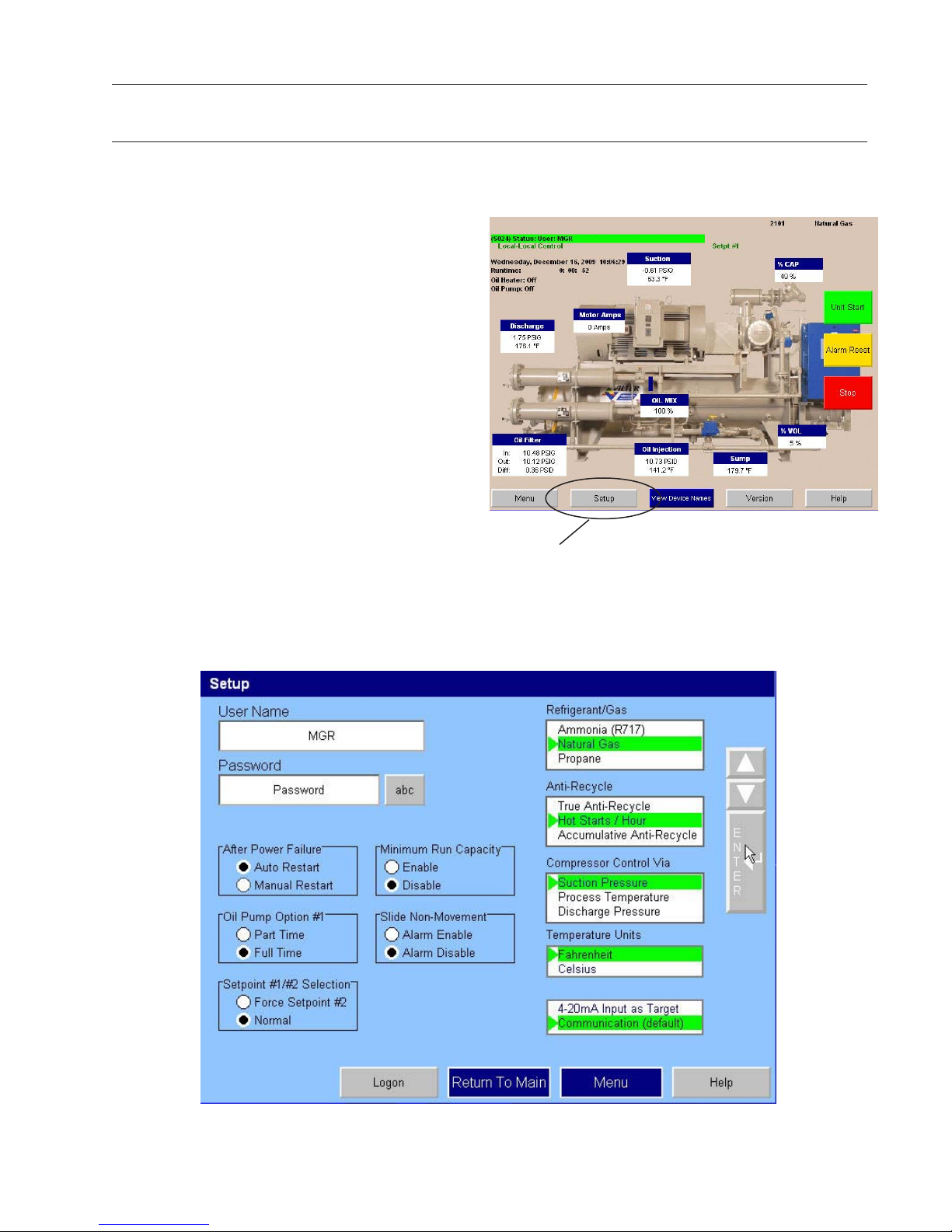

Set Up Screen

From the Main screen, touch the Setup button. After

entering an authorized user name and password, the

screen pictured below will appear.

Pressure units,Temperature units and Suction/

Discharge Pressure control configurations are list

selectable.

To choose a configuration from a list: 1.) Touch the

list. 2.) Touch the Up or Down Arrow to move the

green cursor “>” along side of the desired configuration. 3.) Touch the Enter button. This will highlightgreen the chosen configuration.

Touch Here

17

Page 18

· Pressure Units – Select units of measure for pres-

sure readings. Choices are psi, kg cm2 and kPa.

· Temperature Units – Select units of measure

for temperature. Choices are Fahrenheit or Celsius.

· Anti-Recycle – The operator can select from the

following Anti-Recycle options: True, Accumulative, Modified, or Hot Starts. These select the

strategy used to prevent excessive start/stop

cycles of the compressor. Timers and counters

used to enforce anti-recycling are adjusted and

monitored in the Compressor Timer Settings

screen, reached from the Menu screen. Help

for the Timer Settings screen explains how the

different settings and strategies operate.

· Compressor Control Via – Operator can choose

the method or mode of compressor control.

This determines which measured variable is used

in making loading (capacity control) decisions.

The choice selected here determines which

setpoints are made available for adjustment on

the Compressor Control Setpoints screen.

· Slide Non-Movement – Alarm enable and dis-

able buttons permit selecting whether an alarm

should be generated when failure of slides to

move is detected.

· Reset After Power Fail – When Auto is selected,

the compressor will attempt to restart on powering up if it was running in ‘Auto’ when powered

down and enabling conditions are met. When

‘Manual’ is selected, the compressor powers up

into the ‘Stop’ mode and an explicit command

to run is required from an operator or comms

channel.

· Min Run Capacity – When enabled, the Minimum

Run Capacity setting on the Addition Compressor Setpoints screen operates as described in the

help for that screen. When multiple compressor

sequencing is used, selecting Disable here does

not interfere with use of the Min Run Capacity

setting in the sequencing logic.

18

Page 19

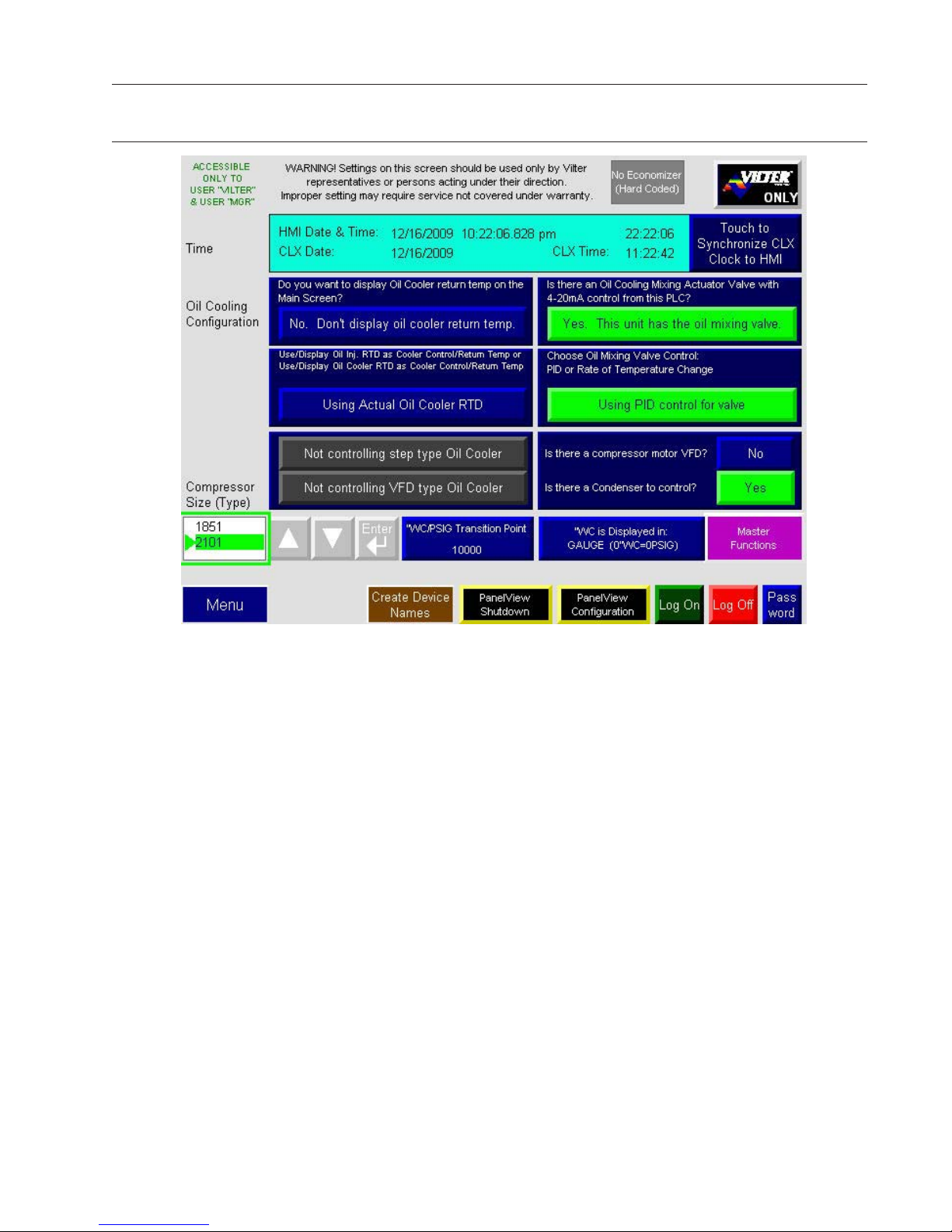

Vilter Only Screen

To set and synchronize the date and time for the HMI and ControlLogix or CompactLogix processor, first configure the PanelView date and time then, move the PanelView’s date and time to the processor

To set the date, time and regional settings in the PanelView Plus HMI:

1. Display the Vilter Only Screen (This screen has restricted access).

2. Touch the PanelView Configuration button.

3. Wait approximately 30 seconds while the PanelView application shuts down then loads.

4. Touch the Thermal Settings button.

5. Scroll to or touch the Time/Date/ Regional Settings field then touch the Enter button.

6. Set the Date, Regional Settings. Time and Time Zone as applicable. Touch OK after setting each

screens’ values to accept the new values.

7. When finished, touch the Close button to exit the Time/Date/Regional Settings screen.

8. IMPORTANT: Clear the log files of the PanelView after changing the PanelView Date and/or time.

a. Touch or scroll to the File Management field then touch the Enter Button.

b. Touch or scroll to the Delete Files field then touch the Enter button.

c. Touch or scroll to the Delete Log Files field then touch the Enter button.

DO NOT DELETE APPLICATIONS! DO NOT DELETE FONTS!

d. Touch “Yes” to delete the log files.

e. Touch the Close button twice to return to the Terminal Settings screen.

9. Touch the Close button twice again to return to the Terminal Settings screen.

10. Touch the Reset button then “Yes” button to reset the PanelView.

To synchronize the ControlLogix or CompactLogix date and time to the PanelView date and time:

1. Display the Vilter Only Screen (This screen has restricted access).

2. Touch the “Touch to Synchronize CLX Clock to HMI” button.

19

Page 20

Touch Here

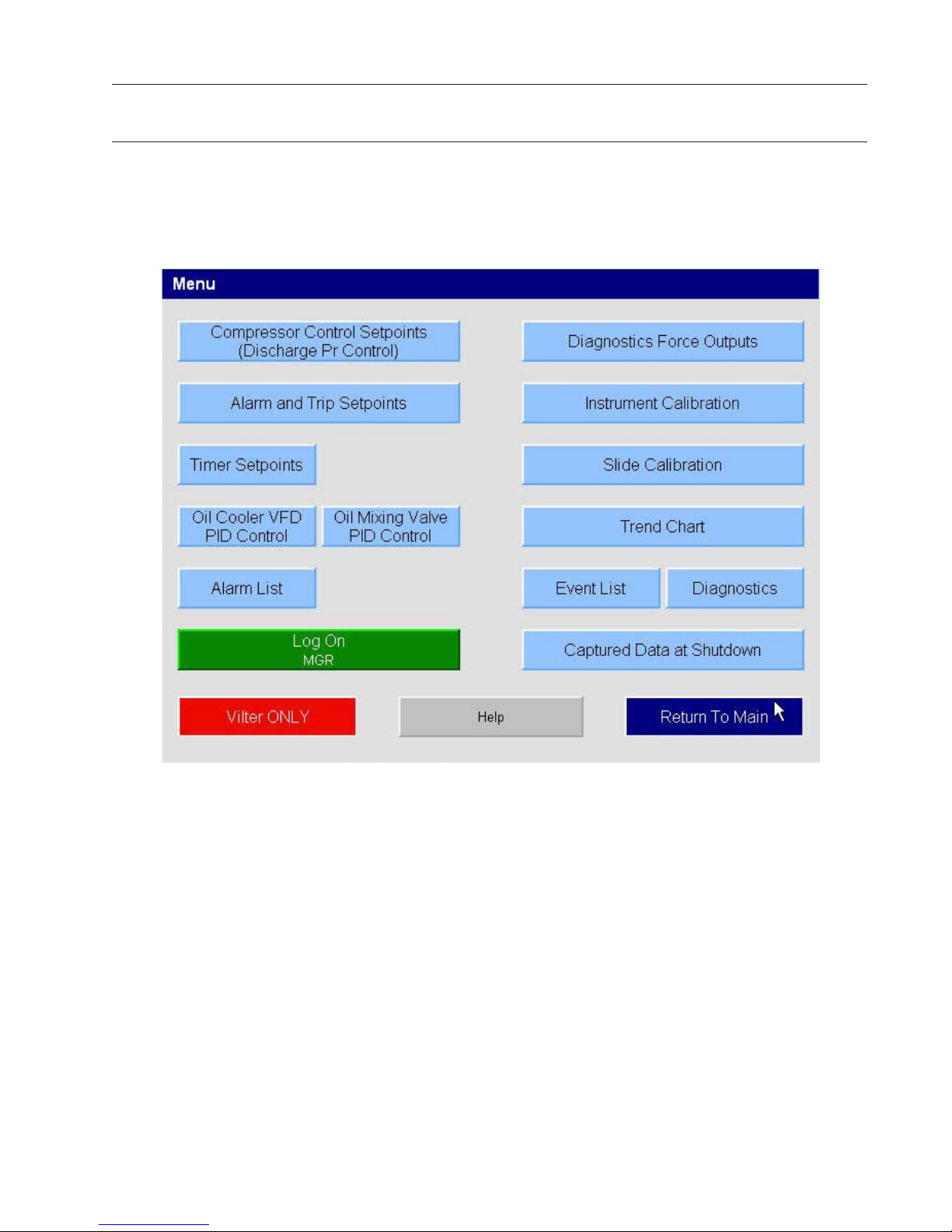

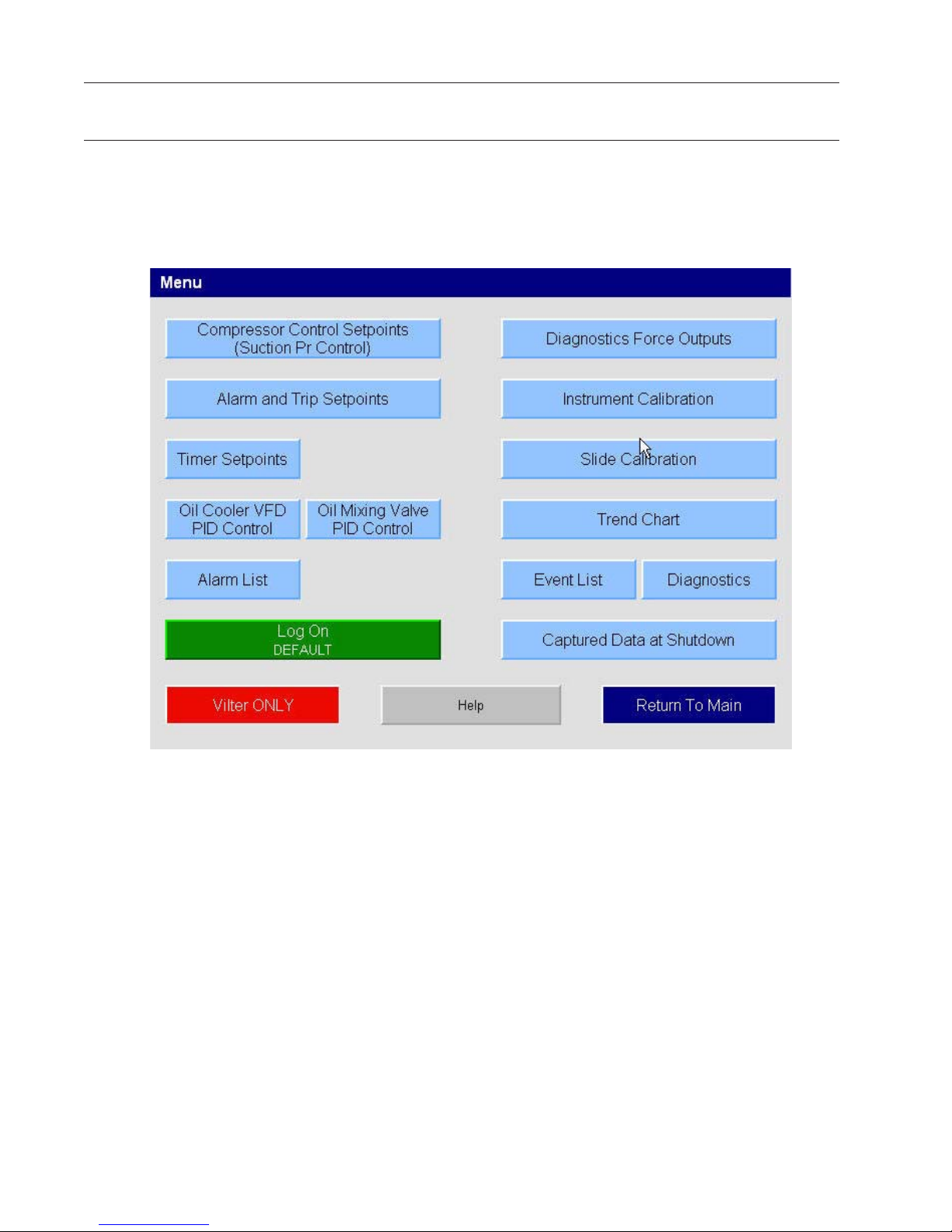

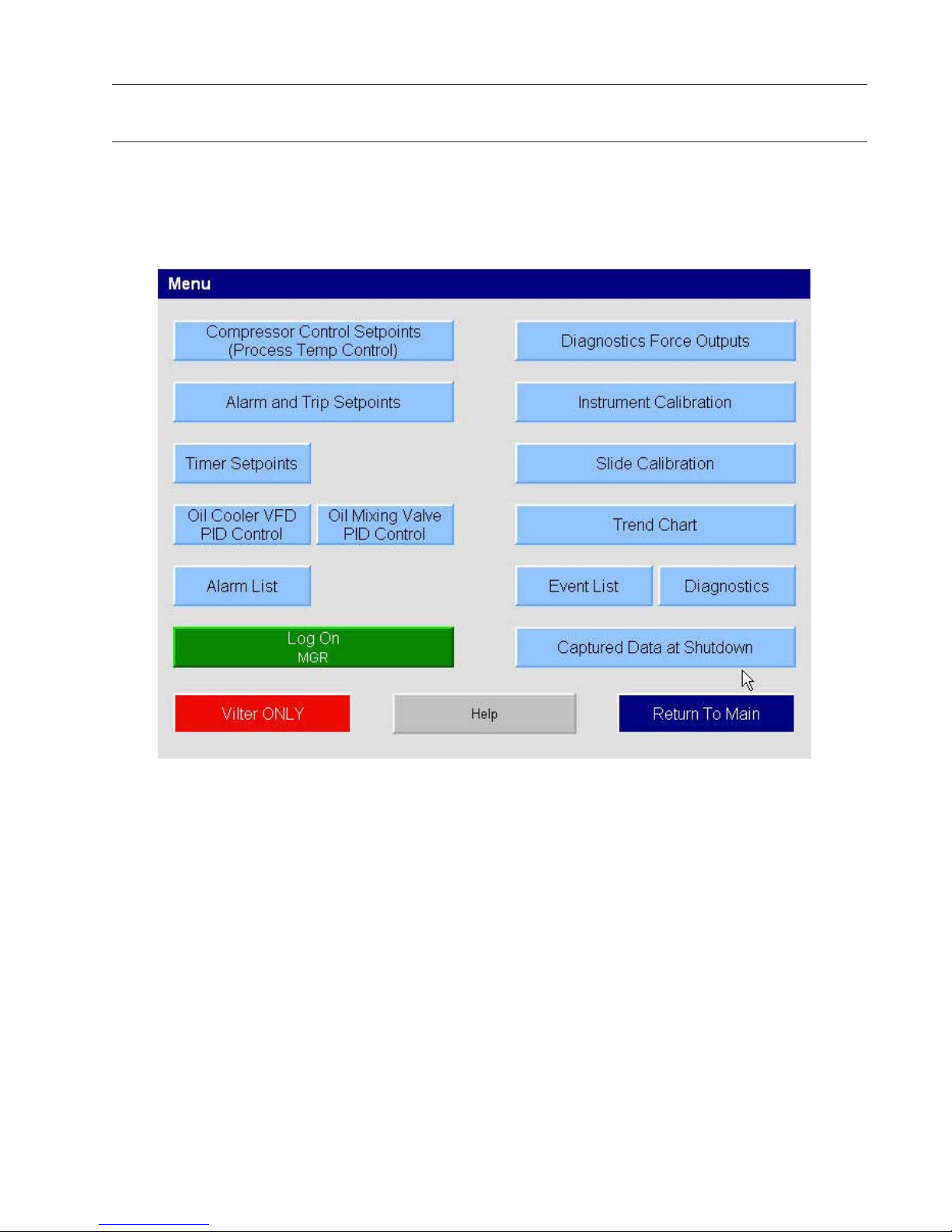

Menu Screen

At the bottom of the Main screen touch the Menu button to bring up the screen shown in Figures below.

Use this screen to navigate to the other setpoint screens contained within the program. Each screen has a help

button to describe the function of the screen.

There are several buttons that are common for all menu screens:

Return to Menu – This button always returns you to the Menu screen

Logon To Edit – The user is allowed to view data at all screen levels but cannot edit data until a login has occurred.

Refer to the Logon Instructions on page 21.

Set – To change a value, the operator must first press the SET button and then the text field of the value they

want to modify. A number pad will pop up for ease in entry.

Help – This screen will provide more information to the user about the operation of the microprocessor.

Event List – provides a chronological event listing.

Chart – Provides a line graph showing process values over a range of time.

Auto – Places the capacity slides into automatic mode. In automatic mode, the capacity slide moves according

to control setpoint information.

Manual – Places the capacity slides into manual mode. In manual mode, the capacity slide moves moves based

on input from the operator.

20

Page 21

There are three options for the Compressor Control Setpoints:

Discharge Pressure Control

21

Page 22

22

Suction Pressure Control

Page 23

Process Temperature Control

23

Page 24

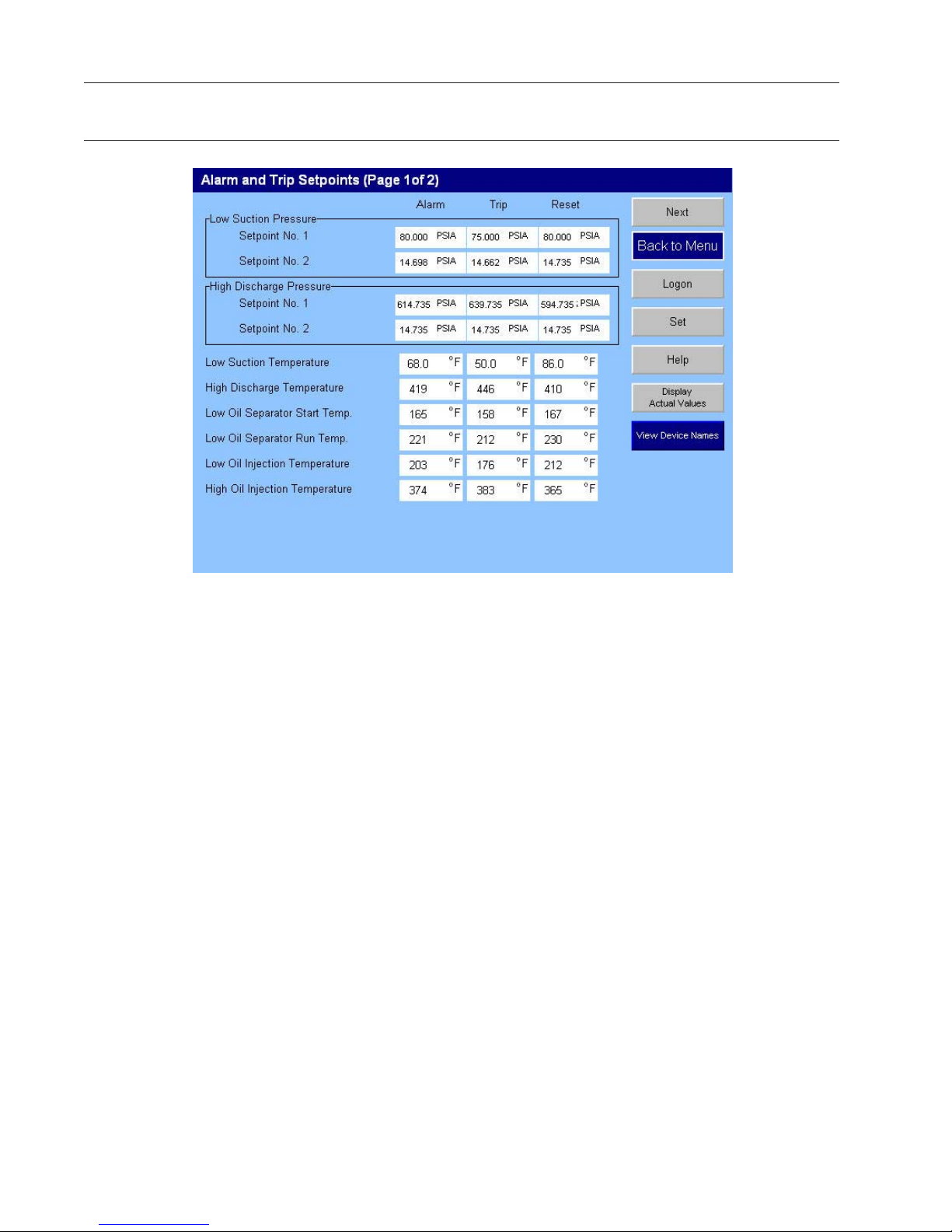

Compressor Alarm and Trip

· Low Suction Pressure Setpoints 1&2 – This is

the low suction pressure safety. This safety is

active in both temperature and pressure control

modes. An alarm or trip will be active on a drop

in suction pressure below the setpoint value.

· High Discharge Pressure Setpoints 1&2 This is

the high discharge pressure safety. The alarm or

trip will be active on a rise in discharge pressure

above the setpoint value.

· Low Suction Temperature – This is the lowest

allowable Suction temperature. The compressor will not be allowed to run if the Suction

Temperature is below the trip setting.

· High Discharge Temperature – This is the high

discharge temperature safety. The alarm or

trip will be active if the discharge temperature

should rise above the setpoint value.

· Low Oil Separator Start Temperature – This is the

starting low oil separator temperature safety.

The compressor is prevented from starting or

running if the oil in the separator is below the

trip value. After a time delay (Oil Separator

Temperature Safety Changeover), this safety is

deactivated and the Lo Oil Separator Run Temperature is the active setpoint.

· Low Oil Separator Run Temperature – This is the

running low oil separator temperature safety.

After a time delay (Oil Separator Temperature

Safety Changeover), the Lo Oil Separator Start

Temperature is bypassed and Lo Oil Separator

Run Temperature is the active setpoint. The

alarm or trip will be active if the oil temperature

of the separator drops below the setpoint value.

· Low Oil Injection Temperature – This is the low

oil injection safety. The alarm or trip will be

active if oil injection temperature drops below

setpoint value after a time delay (Oil Injection

Temperature Safety Changeover).

· High Oil Injection Temperature – This is the high

oil injection temperature safety. The alarm or

trip will be active on a rise in oil injection temperature above the setpoint value.

24

Page 25

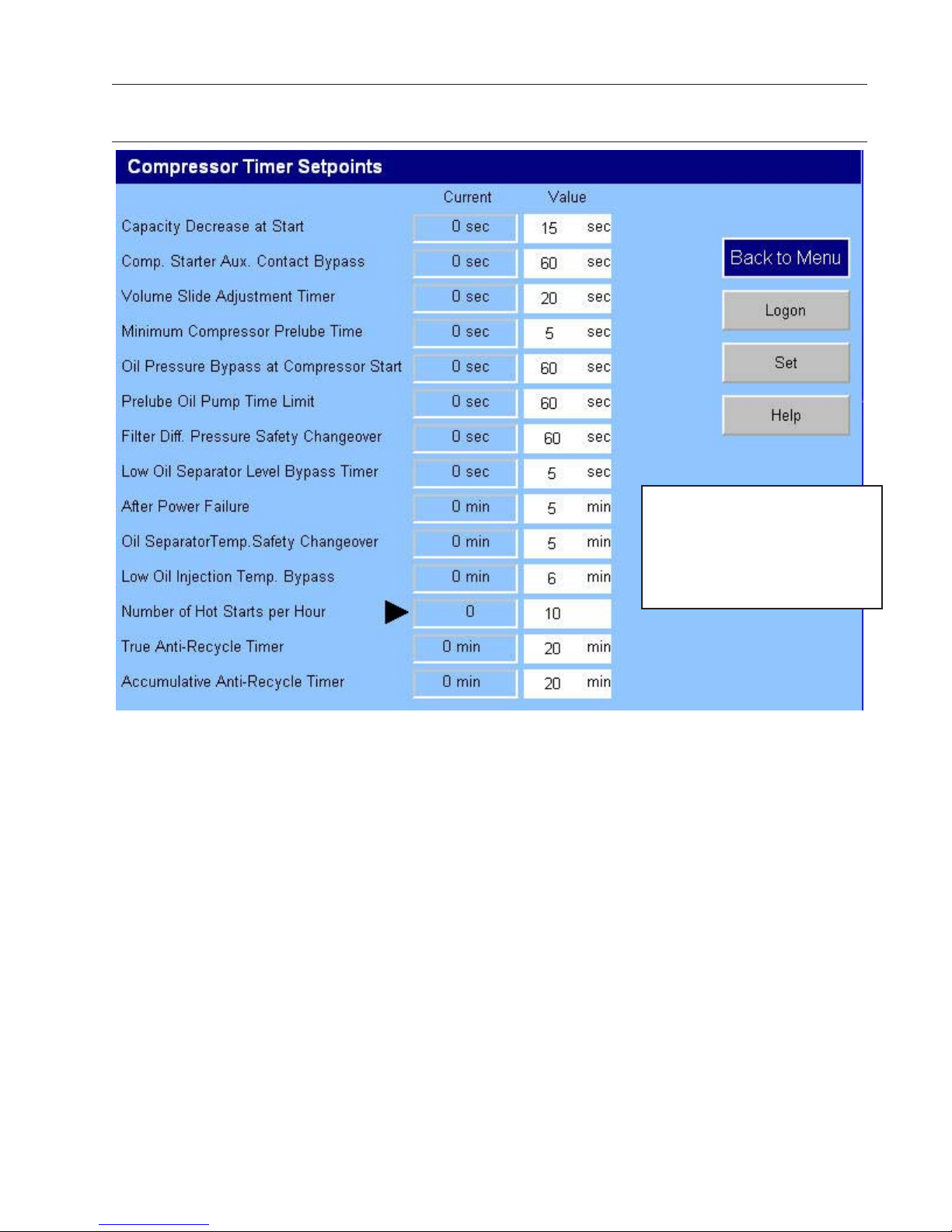

Compressor Timer Setpoints

To change a timer setting, a user with high

access level must be

logged on.

· Capacity Decrease At Start – At compressor

startup, the capacity motor is held at minimum

position for this time period. After the timer

expires, the slide is free to move in accordance

to the system demands.

· Compressor Starter Auxiliary Contact Bypass –

This timer is used to bypass the motor amperage

input at start. After the timer times out, the

program determines if the motor starter has

pulled in by testing the amperage channel. If

the program determines that the starter did not

“pull in”, then the compressor will fail on “Motor

Starter Fail” message.

· Volume Slide Adjustment Timer – This timer

determines the intervals the volume slide is

adjusted. If the volume slide is between 2½% &

7% away from the desired volume ratio, the motor is pulsed once toward the desired volume.

If the volume slide is more than 7% away from

the desired value, the volume slide motor is

continuously energized until the valve is within

2½% of the desired value. If the actual position

is within 2½% of the desired value, no adjustment will be made.

· Minimum Compressor Prelube Timer – This is

the length of time the oil pump will run after

establishing the Prelube Oil Pressure, to prime

oil circuit before starting the compressor.

· Oil Pressure Bypass At Compressor Start – This

timer bypasses the Low Oil Pressure limits.

The timer starts when the compressor starts.

After the timer has cycled, the Low Oil Pressure

setpoint is active.

· Prelube Oil Pump Time Limit – This timer puts

a limit on how long the prelube oil pump is allowed to run without establishing the Prelube

Oil Pressure.

25

Page 26

· Filter Differential Pressure Safety Changeover

– This timer bypasses the Hi Run Filter Differential Pressure setting during start, to allow the

Hi Start Filter Differential Pressure to protect

against High Filter Differential during start. After the timer has cycled, the Hi Run Differential

Pressure Safety is active.

· Low Oil Separator Level Bypass Timer – This

timer bypasses the low oil level switch for momentary drops in the oil level. If the switch is still

open after the Low Oil Separator Level Bypass

Timer has timed out, the compressor will be shut

down and an alarm will be displayed. This timer

is available if the unit is equipped with a low oil

separator float switch. The oil level switch is

standard on all liquid injection units and optional

on all others.

· Auto Restart After Power Failure – This timer

forces the microprocessor to wait for the set

time period after a power failure before starting the compressor unit. By staggering the

time settings, the compressors can be allowed

to start automatically, one at a time, after a

power failure. This prevents excessive loads on

the power system that could be caused by all of

the equipment coming online at the same time.

The Power-Up Auto Start operator option must

be selected on the Setup screen for this option

to be active.

· Oil Separator Temperature Safety Changeover

– This timer allows Low Oil Separator Start

Temperature Safety setpoint to protect the

compressor against cold oil during starting.

After the timer has cycled, the Low Oil Separator

Run Temperature is then active.

· Low Oil Injection Temperature Bypass – This

timer bypasses the Low Oil Injection Temperature Safety Setpoint during start-up. After the

timer cycles, the Low Oil Injection Temperature

Safety is set.

· Hot Starts / Hr Counter – This counter counts

compressor starts. After every start, a one-hour

timer is reset and starts timing. If the timer

times out, the hot starts counter is reset. When

the counter reaches it’s preset value, it will not

allow another compressor start until the onehour timer times out and resets the counter.

In other words, the hot starts counter will be

reset when the time between compressor starts

total one hour. This counter allows repetitive

compressor starts, but once the counter has

reached its set point, it requires a one-hour

window between compressor starts in order

for the counter to be reset. Note: if this option

is chosen an arrow will appear alongside its

current value. When active a point will appear.

· True Anti-Recycle Timer – Once the compressor

turns off, the timer will keep the compressor

off for the setting of True Anti-Recycle Timer.

This timer is used to prevent short cycling of the

compressor. Note: if this option is chosen an

arrow will appear alongside its current value.

When active a point will appear.

· Accumulative Anti-Recycle Timer – This timer

also forces a specified time between compressor starts. When the compressor starts, the

timer resets then starts timing and accumulates

running time. Once the compressor shuts

down, it will not be allowed to restart for the

remainder of the time left on the Accumulative Anti-Recycle Timer. Unlike the True AntiRecycle Timer, if the compressor has run for a

time period that exceeds the setpoint of the

Accumulative Anti-Recycle Timer, then when

the compressor shuts down, it will be allowed

to restart immediately. The compressor restart

options (Hot Starts or Anti-Recycle Timers) are

selected from the Setup screen. One additional

Anti-Recycle Timer that can be selected from

the Setup screen is the Modified Anti-Recycle

Timer. Note: if this option is chosen an arrow

will appear alongside its current value. When

active a point will appear.

26

Page 27

Compressor Control Setpoints

From the Menu screen, press the Compressor Control setpoints button. The compressor control setpoints

screen will be shown.

These screens enable the operator to view and adjust settings that affect compressor control.

From the Setup screen, the operator can choose the method or mode of compressor control:

Compressor Control Via:

1. Discharge Pressure

2. Suction Pressure

3. Process Temperature Control

Once the method is chosen, the appropriate setpoints are then displayed on the Compressor Control Setpoints

screen.

The compressor will decide when to increase or decrease capacity by comparing the controlled variable to

the setpoints. The maximum on time and minimum off time settings for slide actuator motors can be used

to reduce hunting or improve response time. The default settings of 3 and 20 seconds respectively, provide

good operation over a wide range of conditions.

From the Menu screen, press the Compressor Control setpoints button. The compressor control setpoints

screen will be shown.

Level 1 Access – Compressor Control Setpoints

27

Page 28

Discharge Pressure Control

Setpoints on this screen:

· Discharge Pressure On/Off – The compressor will automatically cycle ON and OFF at the setpoints entered.

Discharge Pressure On/Off control is only active if the Compressor Control Via Discharge Pressure option

is selected on the Setup screen. If a compressor shutdown is desired on a discharge pressure drop and a

manual reset is required, set the OFF value below the Low Discharge Pressure Safety Trip value. This will

shut down the unit and a reset will be required to restart it.

· Discharge Pressure Capacity Increase – The capacity of the compressor will increase when suction pressure

is at or above the Increase ON setpoint, and the increase “off” timer has cycled. Capacity will continue to

increase until the Discharge Pressure Capacity Increase OFF setpoint is reached. If closer system control

is desired, set the ON and OFF setpoints at the same values. This will essentially eliminate any differential

between the ON and OFF setpoints.

· Discharge Pressure Capacity Decrease – The capacity of the compressor will decrease when discharge

pressure is at or below the ON setpoint, and the decrease “off” timer has cycled. Capacity will continue

to decrease until the Discharge Pressure Capacity Decrease OFF setpoint is reached. If closer system

control is desired, set the ON and OFF setpoints at the same values. This will essentially eliminate any

differential between the ON and OFF setpoints. While this setting is only available for adjustment on the

Control Setpoints screen when the Compressor Control Via Suction Discharge option is selected on the

Setup screen, it has an override effect when control is via process temperature as described below.

28

Page 29

Suction Pressure Control

Setpoints on this screen:

· Suction Pressure On/Off – The compressor will automatically cycle ON and OFF at the setpoints entered.

Suction Pressure On/Off control is only active if the Compressor Control Via Suction Pressure option is

selected on the Setup screen. If a compressor shutdown is desired on a suction pressure drop and a

manual reset is required, set the OFF value below the Low Suction Pressure Safety Trip value. This will

shut down the unit and a reset will be required to restart it.

· Suction Pressure Capacity Increase – The capacity of the compressor will increase when suction pressure

is at or above the Increase ON setpoint, and the increase “off” timer has cycled. Capacity will continue to

increase until the Suction Pressure Capacity Increase OFF setpoint is reached. If closer system control is

desired, set the ON and OFF setpoints at the same values. This will essentially eliminate any differential

between the ON and OFF setpoints.

· Suction Pressure Capacity Decrease – The capacity of the compressor will decrease when suction pressure

is at or below the ON setpoint, and the decrease “off” timer has cycled. Capacity will continue to decrease

until the Suction Pressure Capacity Decrease OFF setpoint is reached. If closer system control is desired,

set the ON and OFF setpoints at the same values. This will essentially eliminate any differential between

the ON and OFF setpoints. While this setting is only available for adjustment on the Control Setpoints

screen when the Compressor Control Via Suction Pressure option is selected on the Setup screen, it has

an override effect when control is via process temperature as described below.

29

Page 30

Process Temperature Control

Setpoints on this screen:

· Process Temperature Control – Provides for a Suction Pressure Override feature. If the suction pressure

should drop below the Suction Pressure Capacity Decrease OFF setpoint, the Suction Pressure Capacity

Decrease OFF setpoint will override the Capacity Control F Increase and prevent the compressor capacity

from increasing (loading). If the suction pressure should continue to decrease below the Suction Pressure Capacity Decrease ON setpoint, the compressor capacity will be forced to decrease until the suction

pressure is just above the Suction Pressure Capacity Decrease ON setpoint. This will help stabilize the

suction pressure, allowing for the process temperature to be gradually pulled down. The Suction Pressure Capacity Decrease ON and OFF setpoints can viewed or adjusted by temporarily selecting “Processor

Control Via Suction Pressure” on the Setup screen.

Note: Capacity Control for Refrigeration Only.

· Capacity Control °F On/Off – The compressor will automatically cycle ON and OFF at the setpoints entered.

Capacity Control °F On/Off is only active if the Compressor Control Via Process Temperature option is

selected on the Setup screen. If compressor shutdown is desired on a process temperature drop and a

manual reset is required, set the OFF value below the Low Control Temperature Safety trip valve. This

will shut down the unit and a reset will be required to restart.

30

Page 31

· Capacity Control °F Increase – The capacity of the compressor will increase when process temperature is at

or above the ON setpoint, and the increase “off” timer has cycled. Capacity will continue to increase until the

Capacity Control °F Increase OFF setpoint is reached. If closer system control is desired, set the ON and OFF

setpoints at the same values. This will essentially eliminate and difference between the ON and OFF setpoints.

Process temperature control of the capacity is active only if the Compressor Control Via Process Temperature

option is selected on the Setup screen.

· Capacity Control °F Decrease – The capacity of the compressor will decrease when process temperature is at

or below the ON setpoint, and the increase “off” timer has cycled. Capacity will continue to decrease until the

Capacity Control °F Decrease OFF setpoint is reached. If closer system control is desired, set the ON and OFF

setpoints at the same values. This will essentially eliminate and difference between the ON and OFF setpoints.

Process temperature control of the capacity is active only if the Compressor Control Via Process Temperature

option is selected on the Setup screen.

31

Page 32

Additional Compressor Controls

· High Discharge Pressure Unloading Setpoints

– Active in Suction Pressure or Process Temperature Capacity Control mode. These setpoints

limit the compressor from loading at high

discharge pressure conditions. They override

the Suction Pressure or Process Temperature

Capacity Control setpoints. The capacity of the

compressor will decrease when the discharge

pressure is at or above the ON set point. When

the OFF setpoint is reached, the compressor will

stop from unloading any further.

· Motor Amp. Load Limit Setpoints – This control

limit is the motor full load current draw and the

maximum current draw. This control limit will

only prevent the compressor from loading and

does not shut down the compressor if the maximum current draw setpoint is exceeded. The

actual values entered may depend on particular

circumstances. The function of the setpoint is

as follows:

If the motor is operating at the full load amperage (FLA) setting, the compressor is prevented

from loading. If the motor amps exceed the

MAX setpoint, the compressor is forced to unload until the current is at 1.0625 times above

the FLA setting. If the motor being used has a

service factor below 1.0625, use a value for the

FLA that is 10% lower than the MAX value.

· Oil Separator Heater Temperature – This con-

trol limit determines when the oil separator

heater is energized. A decrease in oil separator

temperature below the ONsetpoint energizes

the oil separator heater. On an increase in oil

separator temperature above the OFF setpoint,

the oil heater is de-energized.

· High Discharge Pressure Unloading Setpoints –

Active in Suction Pressure or Process Temperature Capacity Control mode. These setpoints

limit the compressor from loading at high

discharge pressure conditions. They override

the Suction Pressure or Process Temperature

Capacity Control setpoints. The capacity of the

compressor will decrease when the discharge

pressure is at or above the ON set point. When

the OFF setpoint is reached, the compressor will

stop from unloading any further.

· Motor Amp. Load Limit Setpoints – This control

limit is the motor full load current draw and the

maximum current draw. This control limit will

only prevent the compressor from loading and

does not shut down the compressor if the maximum current draw setpoint is exceeded. The

actual values entered may depend on particular

circumstances. The function of the setpoint is as

follows: If the motor is operating at the full load

amperage (FLA) setting, the compressor is prevented from loading. If the motor amps exceed

the MAX setpoint, the compressor is forced to

unload until the current is at 1.0625 times above

the FLA setting. If the motor being used has a

service factor below 1.0625, use a value for the

FLA that is 10% lower than the MAX value.

32

Page 33

· Oil Separator Heater Temperature – This con-

trol limit determines when the oil separator

heater is energized. A decrease in oil separator

temperature below the ON setpoint energizes

the oil separator heater. On an increase in oil

separator temperature above the OFF setpoint,

the oil heater is de-energized.

· Oil Pump Restart – To determine the ON and

OFF values for the pressure ratios, take the absolute discharge pressure (PSIA), and divide it

by the absolute suction pressure (PSIA). If the

pressure ratio is below the ON setpoint value,

the oil pump will restart and stay on until the

pressure ratio increases above the OFF setpoint.

This enables a high stage compressor with a part

time oil pump to temporarily operate under

conditions requiring a full time oil pump.

EXAMPLE: To calculate the OFF value, if the

absolute discharge pressure is 200 PSIA and the

desired absolute suction pressure of the cut-out

point is 67 PSIA, the discharge pressure is divided

by the suction pressure. The result is a OFF value

of approximately 3.0. This would then be entered

for the OFF pressure. Now determine the ON value,

take the absolute discharge pressure (200 PSIA) and

divide this by the desired absolute suction pressure

(71 PSIA). This results in a ON valve of 2.8.

· Capacity Slide Adjustment Range – This control

limit determines the capacity range the Capacity Slide Adjustment factor will be active. The

factor will be active from 0% capacity and will be

deactivated when the OFF setpoint is reached.

On a decrease in capacity below the ON set

point, the factor will be active.

· Minimum Run Capacity – The Minimum Run

Capacity is the minimum capacity the compressor will be allowed to run at. When the

compressor is started, it will be loaded to the

Minimum Run Capacity control setpoint minus

5%. This is done to prevent the capacity control

from hunting if the load is not great enough to

keep the compressor capacity at the Minimum

Run Capacity setpoint. On a call for unloading,

the compressor will unload until it reaches the

Minimum Run Capacity control setpoint. It will

remain there until the suction pressure reduces

and the compressor cycles off on the Suction

Pressure On/Off control setpoint.

· Volume Slide Adjustment Factor – This value is

normally zero (0) and will not require changing.

However, if the system operating conditions

show the volume ratio is not at the optimum

value for the system, this value can be adjusted

up or down to permit the most efficient positioning of the volume slide valves. To determine the

value to enter, first ensure that the system is in

a steady operating state and place the volume

side in manual. NOTE: The volume position setting and increase the volume side position slowly

until the lowest amperage level is achieved. If the

amperage level rises instead of falls, decrease the

volume slide position until the lowest amperage

is achieved.

Record the differential from the original position.

This will then be adjustment factor to enter for

our system. NOTE: Negative numbers can be

used for this setting. This setpoint is active on a

drop in capacity below the Capacity Slide Adjustment Range cut-in (ON) setting. The adjustment

is disabled when capacity rises above the Adjustment Range OFF setting. Normally, the “ON-Off”

set points should both be set at 100%, so the

volume side adjustment factor will be applied

over the full range of 0 to 100%

· Current Transformer Ratio – The value entered

must agree with the Current Transformer Ratio

on the current transformer being used. The

current transformer is mounted in the compressor motor conduit box. The ratio is stated as

the ratio of measured current to a nominal full

scale current in the secondary of 5 amps; only

the first of these is entered. For example, if the

ratio reads 250/5, enter 250.

· Low Suction Pressure Load Limit – Active in

Discharge Pressure Capacity Control mode only.

These setpoints limit the compressor from loading at low suction pressure conditions. They

override the discharge pressure capacity control

setpoints. When the OFF setpoint is reached

(at or below setpoint), the compressor will not

be allowed to load any further. If the suction

pressure continues to fall, the capacity of the

compressor will decrease when the suction

pressure is at or below the ON set point. It will

stop decreasing when the suction pressure rises

to a point that is just below the ON set point.

33

Page 34

Compressor Setpoints and Alarms

· Prelube Oil Pressure – If the oil pressure does not

rise above the reset setting for a time exceeding

the Minimum Compressor Prelube Time and

the pump runs longer than the Prelube Pump

Time Limit, an alarm or trip will occur. These

time limits are set on the Compressor Timer

Setpoints screen. Prelube oil pressure is defined

as the amount that the oil pump drives manifold

pressure above the discharge pressure.

· Low Oil Pressure – This is the running oil pressure safety. An alarm or trip will be active if the

oil pressure should drop below the setpoint

value. This occurs once the Oil Pressure Bypass

timer has expired. The time limit is set on the

Compressor Timer Setpoints screen. For the

single screw compressor, oil pressure is defined

as manifold pressure minus suction pressure.

· High Filter Differential Pressure Start – This

safety setpoint is active when the compressor is

in the start cycle. An alarm or trip will be active

if the filter inlet pressure exceeds the filter outlet

pressure by the setpoint value.

· High Filter Differential Pressure Run – This safety

setpoint is active when the compressor is in

the run cycle. An alarm or trip will be active if

the filter inlet pressure exceeds the filter outlet

pressure by the setpoint value.

· High Motor Amps – This safety setpoint is active after the Volume Decrease At Start Timer

expires. This timer is not user settable, and in

standard applications, is 15 seconds. A trip will

occur if the motor amperage exceeds the safety

setpoint value. The setpoint should be set at

125% of the motor full load amperage.

34

Page 35

Motor Speed Setpoints & Control Screen

VFD SCREEN SETTINGS

Settings:

Auto Button:

Choosing Auto will do the following:

1. While the fan is off the Output Mode will be forced to Manual Mode.

2. When the fan starts, it will remain in Manual Mode at the Initial Speed for the period defined as

Delay Auto.

3. After the Delay Auto time expires, the Output Mode will change to Auto Mode.

4. In Auto Mode, the VFD is enabled to increase and decrease speed to maintain the temperature set tings.

5. Increase At: High setting where an increase of speed is desired.

6. Decrease At: Low setting where a decrease of speed is desired

7. Initial Speed: Desired forced speed to start the fan at as described above. Note: The PLC will auto-

matically keep this value to at least the Minimum Speed setting.

35

Page 36

8. Max Speed Detect: Setting for PLC program detection of maximum speed. This setting will not limit

the speed of the VFD. Generally, this setting is useful only when sequencing of multiple devices is

used.

9. Minimum Speed: This is the minimum speed that the PLC will send to the VFD. This is active in

Manual Mode and in Auto Mode.

Adjustment Limit: This is the maximum amount of change in speed per adjustment. If the Calculated Adjust-

ment is greater than the Adjustment Limit value, the PLC output will only change the amount of the Adjust-

ment Limit. If the Calculated Adjustment is less than the Adjustment Limit value, the PLC output will change

the amount of the Calculated Adjustment. The Adjustment Limit is used in conjunction with the Gain to

prevent target overshooting.

10. Gain: This value is factory set to 2.50 but may be set from 0.1 to 99. For VFDs, Gain is a multiplica-

tion factor used in a calculation to determine an adjustment to the speed each set interval. This

interval is defined as the Increase Rate or Decrease Rate. Factory settings for Increase Rate and De-

crease Rate are 2 to 5 seconds.

Manual Button:

Choosing Manual will do the following:

1. The fan Output Mode will remain Manual Mode.

2. Manual Speed: This setting becomes accessible only when the Manual Button is chosen. Enter the

desired speed (%) for the VFD.

Stop Button:

Choosing Stop will remove the fan from Auto and from Manual. The VFD will ramp down to a stop. Note:

The On/Off status of a VFD is based on a nominal speed feedback from the VFD. Therefore, the VFD Status

will display “On” until the drive is near zero speed.

Bypass Button:

Choosing Bypass will remove the fan from VFD speed control. The bypass contactor will be used in lieu of

the VFD.

36

Page 37

Diagnostics Force Output

WARNING: Be sure to remove all outputs from Forced-On mode before exiting this screen!

To force an output, a user with high level access must be logged on first. Without sufficient access, the outputs display without force buttons. Touch the Logon button or Set button to prompt the Logon screen. At

the Logon screen, enter the user name (case sensitive) then the user’s password (case sensitive) then press

the <-| enter button. The currently logged in user’s name displays on the Logon screen, on the Logon button

(on the main menu and on the Setup screen.

Once a user with sufficient access is logged on, force buttons appear.

To force an output on, touch its button. The “Main Compressor Motor Starter*” button and “Starter Reset”

button are momentary-on buttons while the others are maintained buttons. Forced-on buttons display green.

On/Off output status displays to the right of each button.

Return all maintained buttons to their off (grey color) state before exiting this screen. Exiting this screen does

not automatically remove forces.

37

Page 38

Instrument Calibration

To calibrate, a user with high level access must be logged on first. Without sufficient access, the raw input

values and calibrated values display without “Calibrate” buttons. Touch the Logon button or Set button to

prompt the Logon screen. At the Logon screen, enter the user name (case sensitive) then the user’s password

(case sensitive) then press the <-| enter button. The currently logged in user’s name displays on the Logon

screen, on the Logon button (on the main menu and on the Setup screen.

Once a user with sufficient access is logged on, Calibrate buttons appear.

The following items can be calibrated from this screen: Suction Pressure Transducer, Discharge Pressure

Transducer, Oil Manifold Pressure Transducer, Oil Filter Inlet Pressure Transducer, Motor Amperage, Oil Cooling Fan Feedback, Suction Temperature RTD, Discharge Temperature RTD, Oil Separator Temperature RTD,

Oil Injection RTD.

The “Calibrated Values” reflect the values used for control of the system. The user can perform calibration by

pressing the respective Calibrate button alongside the value prompting the Calibration screen.

Calibration Instructions are provided on each Instrument Calibration screen.

38

Page 39

Instrument Calibration

39

Page 40

Instrument Calibration Pressures

Confirm the “mA Reading” value (the raw mA value at the analog module) is correct and stable.

If not already done, set the Minimum mA to 4.00

If not already done, set the Maximum mA to 20.00

Set the Minimum Pressure to the actual minimum pressure at 4mA as marked on the transducer.

Set the Maximum Pressure to the actual maximum pressure at 20mA as marked on the transducer.

Set the Offset to zero unless required otherwise. The offset value adds to the resultant linearly scaled value

and results in the Calibrated Value which is used for control

40

Page 41

Instrument Calibration Motor Amps

Confirm the “mA Reading” value (the raw mA value at the analog module) is correct and stable.

If not already done, set the Minimum mA to 4.00. This is the minimum mA expected from the current

transmitter at 0 motor amps.

If not already done, set the Maximum mA to 20.00. This is the maximum mA possible from the current

transmitter.

Set the Minimum Ratio value of the current transformer. Enter a 0 for zero amps.

Set the Maximum Ratio value of the current transformer. For example, if the CT has a 250:5 rating, enter

250 as the Maximum Ratio value.

Set the Offset to zero unless required otherwise. The offset value adds to the resultant linearly scaled value

and results in the Calibrated Value which is used for control.

41

Page 42

Instrument Calibration Temperatures

All RTDs are 100 ohm Pt and are scaled as such via hard-coded configuration in the PLC input module. The

Raw T Reading is defined as the scaled value from the RTD input module.

Set the Offset to zero unless required otherwise. The offset value adds to the raw temperature reading

scaled value to result in the Calibrated Value which is used for control.

42

Page 43

Oil Mixing Valve

Various types of oil coolers can be used to maintain the oil injection temperature, usually

either a water-cooled shell-&-tube heat exchanger mounted locally or a remotely located aircooled fan-coil unit. In either case, the oil temperature control valve operates the same.

A two-way ball valve is located in the main oil line between the oil separator and the

compressor. The oil cooler is piped in parallel to the oil temperature control valve, which acts

as a by-pass valve.

1.0 Installation & Position Indication

1.1 The ball valve is installed with the ball closed.

1.2 The actuator mounts on the ball valve stem. Flats on the ball valve stem indicate the

position of the ball:

OPEN – stem flats are with the flow

CLOSED – stem flats are across the flow

1.3 On smaller valves, the ball valve stem flats are nearly hidden between the stem

extension and the stem lock nut. The locking tabs on the stem lock nut are across the

flow.

1.4 The actuator position indicator stem flats are oriented in the same direction as the ball

valve stem flats.

1.5 There is a mechanical position indicator on the top of the actuator cover.

NOTE: The oil temperature control valve comes from the vendor already assembled with the

ball closed and the actuator in the CLOSED position.

43

Page 44

2.0 Control Action

2.1 The ball valve can rotate through a full 360° arc.

2.2 The actuator restricts the ball to a 90° arc of travel.

2.3 The actuator is powered (120V or 24V) all the time.

2.4 The position target signal from the compressor controller is a 4-20mA analog value.

2.5 There is no feedback position from the actuator.

3.0 Initial Position

3.1 With the electrical power to the valve de-energized, the valve is set to its initial position

by ensuring that the ball is in the closed position and that the actuator indicator

displays CLOSED.

3.2 When the electrical power to the valve is energized, the valve should rotate to fully

OPEN.

4.0 Operation

4.1 When initially installed, the ball must be in the closed position.

4.2 When electrically energized, if the compressor is not running, the compressor

controller will turn the valve fully open (100%).

4.3 When the compressor starts, the valve remains fully open (100%) until the oil injection

temperature rises above the control setpoint.

4.4 When the oil injection temperature rises above the control setpoint, the oil

temperature control valve will begin to close.

4.5 The hot oil from the oil separator begins to divert to the oil cooler, mixing the hot and

cooled oil flow streams together downstream of the oil temperature control valve. The

valve can fully close (0%) diverting the entire oil flow stream to the oil cooler.

4.6 As the oil injection temperature drops below the setpoint, the oil temperature control

valve begins to open so that the oil injection temperature does not become too cold.

4.7 When the compressor stops, the valve returns to fully open (100%).

5.0 Fail Position

The actuator remains in its last position when power is removed.

6.0 Screen Display

The oil temperature control valve, identified as “OIL MIX” on the main HMI display screen,

shows a numerical value with “%” as units. This is to be understood as “% OPEN.” It is a direct

indication of the position of the ball valve.

44

Page 45

6.1 100% OPEN

Oil flow stream is entirely bypassing the oil cooler

6.2 99% to 1% OPEN

Oil flow stream is partially by-passing the oil cooler and partially diverted to the oil

cooler

6.3 0% OPEN

Oil flow stream is entirely diverted to the oil cooler

7.0 Control Settings

The oil temperature control setpoints are entered on the compressor controller screen “Oil

Mixing Valve PID (Oil Return from Cooler)”.

8.0 Rotating the Actuator for Convenience of Installation

The actuator can be rotated to any one of four positions.

8.1 Remove both 120V and 24V power from the actuator.

8.2 Disconnect electrical leads at actuator.

8.3 Remove four cap screws that fasten the actuator to the valve mounting bracket.

8.4 Lift the actuator off the valve stem.

8.5 Rotate the actuator to the desired position.

8.6 Slide actuator down on the valve stem.

8.7 Secure the actuator to the valve mounting bracket with four cap screws.

8.8 Re-connect the electrical leads at the actuator.

8.9. Restore 120V and 24V power to the actuator.

NOTE: The ball valve and the actuator must always be assembled in the CLOSED position. See

Section 3.0 Calibration above.

CAUTION: Be careful not to move the ball stem during this operation. Turning the ball

valve 90° in either direction will reverse the control action of the valve and the compressor

will experience high oil temperature within minutes. Turning the ball valve 180° has no

detrimental effect.

9.0 Manual Override

The actuator has a handwheel that can be engaged to override the electrically determined

position of the ball valve.

Push and rotate to engage.

Push a second time to de-clutch.

45

Page 46

46

Page 47

Unit Start Screen (Start / Stop Logic)

Unit Start Button

Pressing this button will invoke a floating button panel, called Unit Start. The operational

mode of the compressor unit can be selected from the Unit Start button panel. The

compressor unit does not start when the green Unit Start button, on the main screen, is

pressed.

Unit Start Window

Local Button

The Local button is used to put the compressor controller into Local mode. This is the default

mode for the compressor controller. In Local mode the compressor unit must be operated in

Auto or Manual mode.

47

Page 48

Auto Button

In this mode the compressor will respond to its on-board settings for start, stop, load and

unload commands.

Manual Button

In this mode the compressor will respond to operator inputs from the HMI screen. They

Capacity and Volume Slide Valve Position can be adjusted by the up and down arrows that

appear on the main screen. The Position is a value 0% to 100%.

Remote Digital Button

The Compressor Controller must be in Local-Auto in order to activate Remote mode. In

Remote Digital Mode the compressor is controlled by digital input signals.

1. Remote Start Input: Permissive Start/Stop for the compressor.

2. Remote Increase Input: Increases the Capacity Slide Valve.

3. Remote Decrease Input: Decrease the Capacity Slide Valve.

Remote Capacity Hold Button

From Local mode, Remote Caphold button can be pressed to put the compressor controller in

Central mode. Central mode allows for external capacity control via communications link.

Central Mode

The remote PLC must maintain the Central mode operation by setting a tag in the compressor

controller memory at least every 60 seconds. If the Central mode signal is lost during

operation, the compressor controller reverts to Local Auto mode.

48

Page 49

Stop Button

Pressing this button will stop the compressor unit. If the compressor unit is in Central mode

when the Stop button is pressed, the compressor controller enters Local-Stop-Lock mode.

The central system controller will no longer be able to command the compressor controller.

To return to any operational mode, see the description of Local-Stop-Lock Release Button

below.

NOTE: If the compressor unit does not stop, use the Emergency Stop button which is

hardwired to the compressor controller. If this does not stop the compressor, then the main

power disconnect must be opened.

Local-Stop-Lock Release Button

If the Stop key is pressed when in Central mode, the controller goes into Local-Stop-Lock

mode. In Local-Stop-Lock the controller prevents the compressor from being remotely

started. Press Local-Stop-Lock Release to take the Controller out of Local-Stop-Lock mode.

The controller must then be set to the desired mode from the Unit Start button.

Alarm Reset Button

Pressing this button will reset the Alarms.

Exit Button

Pressing this button will close the Unit Start box.

Help Button

Pressing this button will open an additional help screen.

49

Page 50

Device Names

To change Device Name, go into the “vilter Only” screen and press “Create Device Names.”

From the Device Name Screen, press the corresponding text window to change the name of

the device.

50

Page 51

Calibration Procedure of Optical Actuators

ACTUATOR MOTOR CONTROL MODULE CALIBRATION PROCEDURE

1. Open the plastic cover of the capacity motor by removing the four #10 screws. Cau-

tion: there are wires attached to the connector on the plastic cover. Handling the

cover too aggressively could break the wires.

2. Gently lift the cover and tilt it toward the Turck

connectors. Raise the cover enough to be

able to press the blue calibrate button and be

able to see the red LED on the top of assembly.

3. Press “Menu” on the main screen and then press

the “Slide Calibration” button, to enter the slide

calibration screen. Logging on with high-level access will prompt the following buttons to appear:

Press to Calibrate, Inc. and Dec. (Capacity and

Volume.) Touch the Press to Calibrate button – it

turns green and states “Calibrate.” Set Min and

Set Max buttons appear (Capacity and Volume.)

If you are re-installing a new optical actuator reconnect the yellow and gray cables.

4. Press INC and DEC to move the slide valve and

check for the correct rotation. See Table 1 for Actuator/command shaft rotation specifications.

5. Note: If the increase and decrease buttons

do not correspond to increase or decrease

shaft rotation, swap the blue and brown

wires of the “power cable”. This will reverse

the rotation of the actuator/command shaft.

6. Quickly press and release the blue push

button on the actuator one time. This places the ac tuator in calibration mode. The

red L ED will b egin flashing r apidly.

7. Note: When the actuator is in calibration mode,

it outputs 0V when the actuator is running and

5V when it is still. Thus, as stated earlier, the

actuator voltage will fluctuate during calibration. After the actuator has been calibrated, 0V

output will correspond to the minimum position

and 5V to the maximum position.

51

Page 52

Calibration Procedure of Optical Actuators

Remove Cover

Press Down On

Photochopper

8. Note: The “Slide calibration” screen on the Control Panel has a “Current” window, which displays

twice the actuator output voltage. This value,

(the % volume and the % capacity) displayed in

the “Current Vol” and Current Cap” Windows are

meaningless until calibration has been completed.

9. Use the DEC button on the Control panel to drive

the slide valve to its minimum “mechanical stop”

position. Do not continue to run the actuator in

this direction after the slide valve has reached

the stop. Doing so may cause damage to the

actuator or the slide valve.

Press down on the photochopper shaft to disen-

gage the brake, releasing tension from the motor

mount. Use the INC button to pulse the actuator

to where the slide is just off of the mechanical

stop and there is no tension on the motor shaft.

10. Quickly press and release the blue button on the

actuator again. The red LED will now flash at a

slower rate, indication that the minimum slide

valve position (zero position) has been set.

11. Use the INC button on the Control Panel panel

to drive the slide to its maximum “mechanical

stop” position. Do not continue to run the ac-

tuator in this direction after the slide valve has

reached the stop. Doing so may cause damage to the actuator or the slide valve. Press

down on the photochopper shaft to disengage

the brake, releasing tension from the motor

mount. Use the DEC button to pulse the actuator to where the slide is just off of its mechanical

stop and there is no tension on the motor shaft.

Do not touch wires, may cause an

electrical shock!

12. Quickly press and release the blue button on the

actuator one more time. The red LED will stop

flashing. The actuator is now calibrated and

knows the minimum and maximum positions

of the slide valve it controls. Now the capacity

or volume channel of the PLC can be calibrated.

13. Use the DEC button to move the actuator towards its minimum position while watching the

millivolt readout on the Control Panel screen.

Discontinue pressing the DEC button when the

millivolt reading the “Current” window above

the “Set Min” button is approximately 500 millivolts.

14. Now use the DEC and INC buttons to posi-

tion the slide valve until a value close to 300

millivolts is on the screen. Then, press the

“Set Min” button in the capacity or volume

slide valve window to tell the controller that

this is the minimum millivolt position. Note:

The value in the “Current Cap” or “Current

Vol” window has no meaning right now.

52

Page 53

Calibration Procedure of Optical Actuators

15. Use the INC button to rotate the actuator

towards its maximum position while watching the millivolt readout on the controller

screen. Discontinue pressing the INC button

when the millivolt reading in the “Current”

window is approximately 4800 millivolts. You

are nearing the mechanical stop position.

16. Pulse the INC button to carefully move the slide

valve until the millivolt readout “saturates”,

or stops increasing. This is around 4800 millivolts Record millivolt maximum reading.

17. Pulse the DEC button until the millivolts just

start to decrease. (This is the point where

the channel drops out of saturation). Adjust millivolt value to 300 millivolts below

recorded maximum millivolts in step #17.

18. Press the “Set Max” button.

19. Press the “Main” button to complete calibration and exit the “Slide Calibration” screen.

The controller will automatically energize

the actuator and drive it back to its minimum position (below 5%) for pre-start-up.

20. Note: Now the “Current Cap” or the “Current

Vol” value will be displayed in the window on the

“Main” screen and the “Slide Calibration” screen.

21. Gently lower the plastic cover over the top

of the actuator to where it contacts the

base and O-ring seal. After making sure the

cover is seated properly, gently tighten the

four #10 screws. Caution: The plastic cover

will crack if the screws are over tightened.

22. Enable the “Slide Non-Movement Alarm” by going to the “Setup” menu and choosing “Alarm

Enable” for the “Slide Non-Movement Option”.

23. This completes the calibration for this channel either capacity or volume. Repeat the

same pro ce dure to t he other chann el.

53

Page 54

Installation Instructions For Replacement Of Optical Actuator

CAUTION: WHEN INSTALLING THE OPTICAL SLIDE

MOTOR, LOOSEN LOCKING COLLAR BEFORE SLIDING THE COLLAR DOWN THE SHAFT. DO NOT USE

A SCREWDRIVER TO PRY LOCKING COLLAR INTO

POSITION.

OVERVIEW

Calibration of an optical slide valve actuator is

a two step process that must be done for each

actuator installed on the compressor. The steps

are as follows.

1. The actuator motor control module, located

inside the actuator housing, is calibrated so

that it knows the minimum and maximum rotational positions of the slide valve it controls.

The calibrated actuator will output 0 VDC at the

minimum position and 5 VDC at maximum position.

2. After the actuator motor control module has been

calibrated for 0-5 Volts, the controlling channel

corresponding to the actuator motor (either the

capacity or volume) has to be calibrated. This instructs the PLC to learn the rotational 0% position

& rotation 100% position of the slide valve travel.

Please Note:

Because there is an optical sensor on this motor,

DO NOT attempt to calibration in direct sunlight.

3. Before applying power to the PLC disconnect the

gray and yellow cable.

4. Power the PLC back on.

5. Refer to Calibration Procedure of Optical Actua-

tors.

54

Page 55

Slide Valve Actuator Theory of Operation

Slide Valve Actuator Theory of Operation

The slide valve actuator is a gear-motor with a position sensor. The motor is powered in the forward

and reverse directions from the main computer in

the control panel. The position sensor tells the main

computer the position of the slide valve. The main

computer uses the position and process information

to decide where to move the slide valve next.

The position sensors works by optically counting

motor turns. On the shaft of the motor is a small

aluminum “photochopper.” It has a 180 degree

fence that passes through the slots of two slotted

optocouplers. The optocouplers have an infrared

light emitting diode (LED) on one side of the slot and

a phototransistor on the other. The phototransistor

behaves as a light controlled switch. When the photochopper fence is blocking the slot, light from the

LED is prevented from reaching the phototransistor

and the switch is open. When photochopper fence

is not blocking the slot, the switch is closed.

This scheme is not foolproof. If the motor is moved

manually while the power is off or the motor brake

has failed, allowing the motor to free wheel for too

long after the position sensor looses power, the

actuator will become lost.

A brake failure can sometimes be detected by the

position sensor. If the motor never stops turning

after a power loss, the position sensor detects this,

knows it will be lost, and goes immediately into

calibrate mode when power is restored.

As the motor turns, the photochopper fence alternately blocks and opens the optocoupler slots,

generating a sequence that the position sensor microcontroller can use to determine motor position

by counting. Because the motor is connected to the

slide valve by gears, knowing the motor position

means knowing the slide valve position.

During calibration, the position sensor records the

high and low count of motor turns. The operator

tells the position sensor when the actuator is at the

high or low position with the push button. Refer to

the calibration instructions for the detailed calibration procedure.

The position sensor can get “lost” if the motor is

moved while the position sensor is not powered. To

prevent this, the motor can only be moved electrically while the position sensor is powered. When

the position sensor loses power, power is cut to the

motor. A capacitor stores enough energy to keep

the position sensor circuitry alive long enough for

the motor to come to a complete stop and then save

the motor position to non-volatile EEPROM memory.

When power is restored, the saved motor position

is read from EEPROM memory and the actuators

resumes normal function

55

Page 56

Slide Valve Actuator Troubleshooting Guide

The actuator cannot be calibrated

Dirt or debris is blocking one or

both optocoupler slots

The photochopper fence extends

less than about half way into the

optocoupler slots

The white calibrate wire in the grey

Turck cable is grounded

Dirt and/or condensation on the

position sensor boards are causing

it to malfunction

The cali brate button is stu ck

down

The position sensor has failed

Push button is being held down for

more that ¾ second when going

through the calibration procedure

Clean the optocoupler slots with

a Q-Tip and rubbing alcohol.

Adjust the photochopper so that

the fence extends further into the

optocoupler slots. Make sure the

motor brake operates freely and

the photochopper will not contact

the optocouplers when the shaft

is pressed down.

Tape the end of the white wire in

the panel and make sure that it

cannot touch metal

Clean the boards with an electronics cleaner or compressed air.

Try to free the stuck button.

Replace the actuator.

Depress the button quickly and

then let go. Each ¾ second the

button is held down counts as

another press.

The actuator goes into calibration mode spontaneously

The actuator goes into calibration mode every time power is

restored after a power loss

56

The white calibrate wire in the grey

Turck cable is grounding intermittently

A very strong source of electromagnetic interference (EMI), such

as a contactor, is in the vicinity of

the actuator or grey cable

There is an intermittent failure of

the position sensor

The motor brake is not working properly (see theory section

above.)