Page 1

Type VS-FL

Instruction Manual

0017EN-VSFL-IM

January 2010 - Rev. 03

D103654X012

TM

SUMMARY

Introduction ........................................................................ 1

P.E.D. Categories and Fluid Group ................................... 2

Characteristics ................................................................... 2

Labelling ............................................................................ 2

Overpressure Protection .................................................... 3

Transport and Handling ..................................................... 3

Atex Requirements ............................................................ 3

Pilots .................................................................................. 4

Operation ........................................................................... 4

Dimensions and Weights ................................................... 5

Installation ......................................................................... 5

Startup ............................................................................... 6

Pilot Adjustment ................................................................. 6

Shutdown ........................................................................... 7

Periodical Checks .............................................................. 7

Relief Valve Maintenance .................................................. 7

Type PRX/182 Pilot Maintenance ...................................... 8

Spare Parts ........................................................................ 9

Troubleshooting ................................................................. 9

Parts Lists .......................................................................... 10

Schematic Assemblies ....................................................... 11

INTRODUCTION

Scope of Manual

This manual provides instructions for installation, startup,

maintenance and spare parts ordering for the VS-FL Series

pilot operated relief valves and for PRX/182 pilot.

Product Description

The VS-FL Series relief valves are axial ow type with a

single seat and counterbalanced shutter.

They are used in reduction, distribution and conveying

stations using suitably ltered natural gas.

They can also be used for air, propane, butane, LPG, city

gas, nitrogen, carbon dioxide and hydrogen.

The following versions are available:

VS-FL-BP : For low and mid pressure applications

Pilot PRX/182

VS-FL : For mid and high pressure applications

Pilot PRX/182 or PRX-AP/182

Also available version with type SR silencer.

All standard gas pressure devices (relief valves) used

in assemblies will comply to EN 12186 and EN 12279

standards.

Any accessories (e.g. pilots) used on the Emerson Process

Management range of relief valves, must be manufactured

by one of the Emerson Process Management companies

and bear that manual.

If this is not respected, Emerson Process Management will

not be responsible in the case of any inefciency.

Pilot-Operated Relief Valves

Figure 1. Relief Valve Type VS-FL with PRX/182 Pilot

Page 2

Type VS-FL

2

P.E.D. CATEGORIES AND FLUID GROUP

The VS-FL/ Pilot-Operated Series relief valves are designed

as functional equipments and they are typically used in gas

pressure reducing stations for overpressure protection by

releasing small amounts of gas in the event of not perfect

pressure relief valve closing.

Table 1. P.E.D. Category for VS-FL Series Relief Valves

PRODUCT SIZE CATEGORY FLUID GROUP

DN 25 - 40 - 50 - 65 - 80 - 100 - 150 - 200 IV 1

If VS-FL/ series relief valve is used as full-capacity relief

device (according clause 8.3.2 EN 12186) , downstream

equipments protected by this products shall have technical

features such as not to be category higher than following

category (according Directive 97/23/EC “PED”).

Possible built-in pressure accessories (e.g. pilots PRX/

series or lters SA/2, FU/ and FD-GPL/) conform to Pressure

Equipment Directive (PED) 97/23/EC Article 3 section 3 and

were designed and manufactured in accordance with sound

engineering practice (SEP).

Per Article 3 section 3, these “SEP” products must not bear

the CE marking.

CHARACTERISTICS

Body Sizes and End Connection Styles

VS-FL-BP

DN 25 - 40 - 50 - 65 - 80 - 100 - 150

PN 16

ANSI 150 anged

VS-FL

DN 25 - 40 - 50 - 65 - 80 - 100 - 150 - 200

ANSI 300 - 600 anged

The pressure/temperature limits indicated

in this instruction manual or any applicable

standard or code limitation should not be

exceeded.

Maximum Operating Inlet Pressure

PN 16 : 16 bar

ANSI 150 : 20 bar

ANSI 300 : 50 bar

ANSI 600 : 100 bar

At average ambient temperature.

Outlet Set Pressure Ranges

VS-FL-BP PN 16 ANSI 150 DN 25-40-50 : 0.5 ÷ 8 bar

VS-FL-BP PN 16 DN 65-80-100-150 : 0.5 ÷ 16 bar

VS-FL-BP ANSI 150 DN 65-80-100-150 : 0.5 ÷ 19.3 bar

VS-FL ANSI 300 all sizes : 1 ÷ 50 bar

VS-FL ANSI 600 all sizes : 1 ÷ 80 bar

Minimum/Maximum Allowable Temperature (TS)

See label.

Temperature

Standard Version : Working -10° to 60°C

Low Temperature Version : Working -20° to 60°C

Materials

Flanges and covers: Steel

Diaphragms : Fabric Nitrile (NBR) + PVC

Nitrile (NBR) rubber

Pads : Nitrile (NBR) rubber

(FKM available on request)

LABELLING

Figure 2. Label for VS-FL Series Relief Valves

APPARECCHIOTIPO/DEVICE TYPE

Wau

DN2

DN1

MATRICOLA

bar

bar

SERIAL Nr.

°C

FLUIDO GRUPPO

FLUID GROUP

ANNO

YEAR

HARMONIZED STD.

bar

NORME ARMONIZ.

LEAKAGE CLASS

CLASSE DI PERDITA

FUNCTIONAL CLASS

CLASSE FUNZIONALE

bar

Wao

Wa

TS

bar

pao

Cg

PS

body

bar PT= xPS bar

PS

covers

EN

bar

pmax

xxxx

body

Notified

BOLOGNA ITALY

O.M.T.

1.5Nota4Nota3

Nota2

Nota1

1

-

!

WARNING

Page 3

Type VS-FL

3

Note 1: See “Characteristics”

Note 2: Year of manufacture

Note 3: Class 1: -10°/60°C

Class 2: -20°/60°C

Note 4: PN 16 PS : 16 bar

ANSI 150 PS : 19.3 bar

ANSI 300 PS : 50 bar

ANSI 600 PS : 100 bar

OVERPRESSURE PROTECTION

The recommended safety pressure limitations are stamped

on the valve label.

Downstream overpressure protection shall be also provided

if the inlet pressure can be greater than the PS (see label).

Equipment’s operation below the maximum pressure

limitations does not preclude the possibility of damage from

external sources or debris in the line.

The relief valve should be inspected for damage after any

overpressure condition.

TRANSPORT AND HANDLING

Established transport and handling procedures shall be

followed to avoid any damage on the pressure containing

parts by shocks or anomalous stresses.

Ringbolts are designed just for handling of equipment

weight.

Built-up sensing lines and pressure accessories (e.g. pilots)

shall to be protected by shocks or anomalous stresses.

ATEX REQUIREMENTS

If the provisions of EN 12186 & EN 12279, national

regulations, if any, and specic manufacturer

recommendations are not put into practice before

installation and if purge by inert gas is not carried out before

equipment’s start-up and shut-down operations, a potential

external and internal explosive atmosphere can be present

in equipment & gas pressure regulating/measuring stations/

installations.

If a presence of foreign material in the pipelines is foreseen

and purge by inert gas is not carried out, the following

procedure is recommended to avoid any possible external

ignition source inside the equipment due to mechanical

generated sparks:

• drainage to safe area via drain lines of foreign materials, if

any, by inow of fuel gas with low velocity in the pipe-work

(5m/sec)

In any case,

• provisions of Directive 1999/92/EC and 89/655/EC shall

be enforced by gas pressure regulating/measuring station/

installation’s end user

• with a view to preventing and providing protection against

explosions, technical and/or organizational measures

appropriate to the nature of the operation shall be taken

(e.g. : lling/exhausting of fuel gas of internal volume

of the isolated part/entire installation with vent lines

to safe area - 7.5.2 of EN 12186 & 7.4 of EN 12279 ;

monitoring of settings with further exhaust of fuel gas to

safe area ; connection of isolated part/entire installation to

downstream pipeline; ….)

• provision in 9.3 of EN 12186 & 12279 shall be enforced

by pressure regulating/measuring station/installation’s end

user

• external tightness test shall be carried out after each

reassembly at installation site using testing pressure in

accordance with national rules

• periodical check/maintenance for surveillance shall be

carried out complying with national regulations, if any, and

specic manufacturer recommendations.

Page 4

Type VS-FL

4

Table 2. Pilots Type PRX/182 and PRX-AP/182 Characteristics

Model

Allowable Pressure

PS (bar)

Set Range

Wd (bar)

Body and Covers

Material

PRX/182

100

0.5 - 40

Steel

PRX-AP/182 30 - 80

N.B.: 1/4” NPT female threaded connections

PILOTS

VS-FL relief valves are equipped with the PRX/ series pilots.

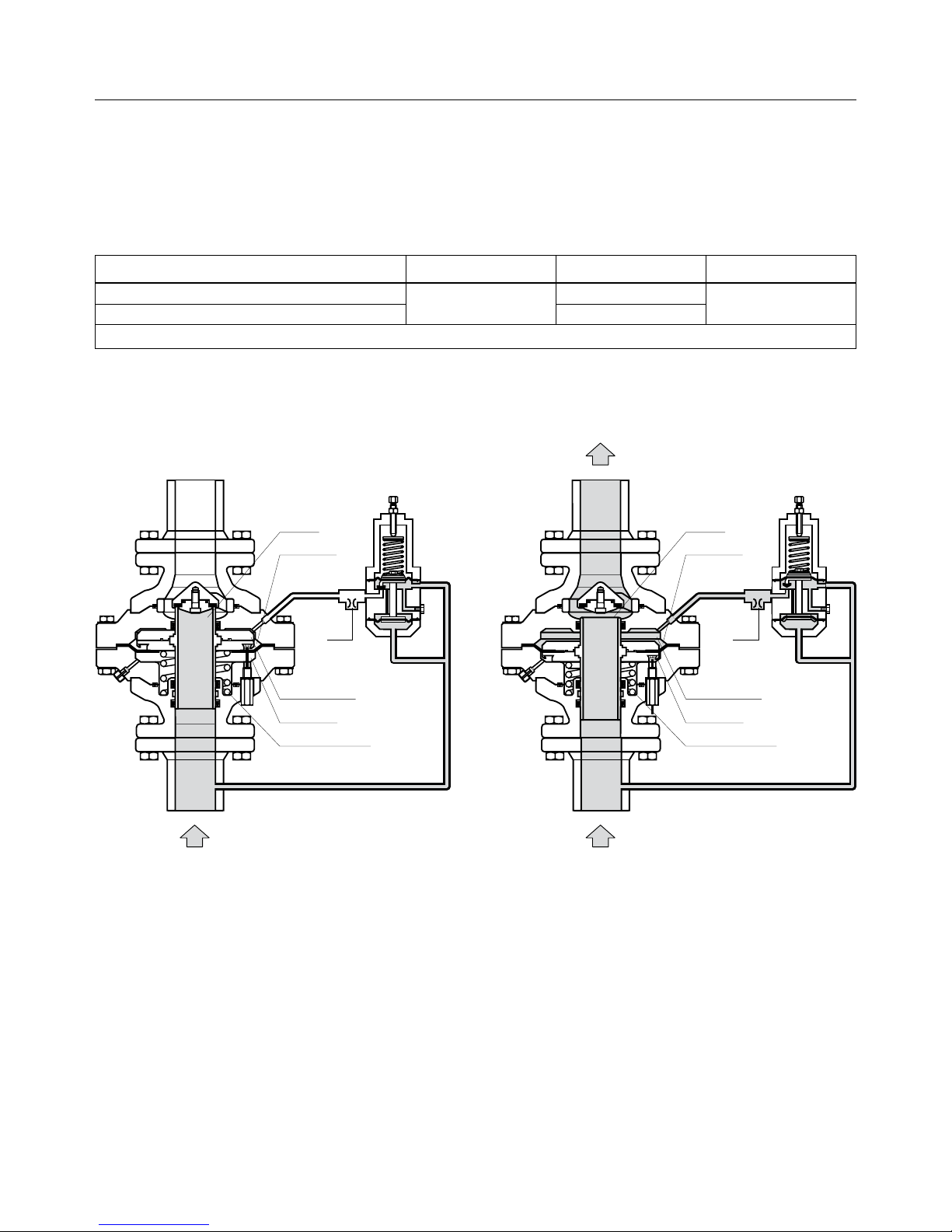

Figure 3. Closed VS-FL Relief Valve Figure 4. Opened VS-FL Relief Valve

OPERATION

The diaphragm unit (permanently connected to the shutter) divides the relief valve actuator into two chambers.

The chamber 1 is connected to the atmospheric pressure, chamber 2 is connected to the pilot.

In normal working conditions the two chambers are not containing pressure and the relief valve spring acts on the diaphragm unit

and closes the shutter.

If the line pressure exceeds the pilot set point, the pilot allows the gas to ow from the line to chamber 2.

The shutter moves to its open position when the force produced by gas pressure acting on the diaphragm unit becomes greater

than the load of the relief valve spring.

Once the excess gas is released and line pressure returns to normal working conditions, the pilot stops the pressure ow,

Chamber 2 is no longer being fed, it is emptied through the jet.

The diaphragm unit is pushed upward by the relief valve spring and the shutter moves to its closed position.

Pilot

PRX/182

Jet

A

B

L

A

B

L

Chamber 1 Chamber 1

Diaphragm unit

Relief valve spring

Chamber 2

Shutter

Pilot

PRX/182

Jet

Diaphragm unit

Relief valve spring

Chamber 2

Shutter

Page 5

Type VS-FL

5

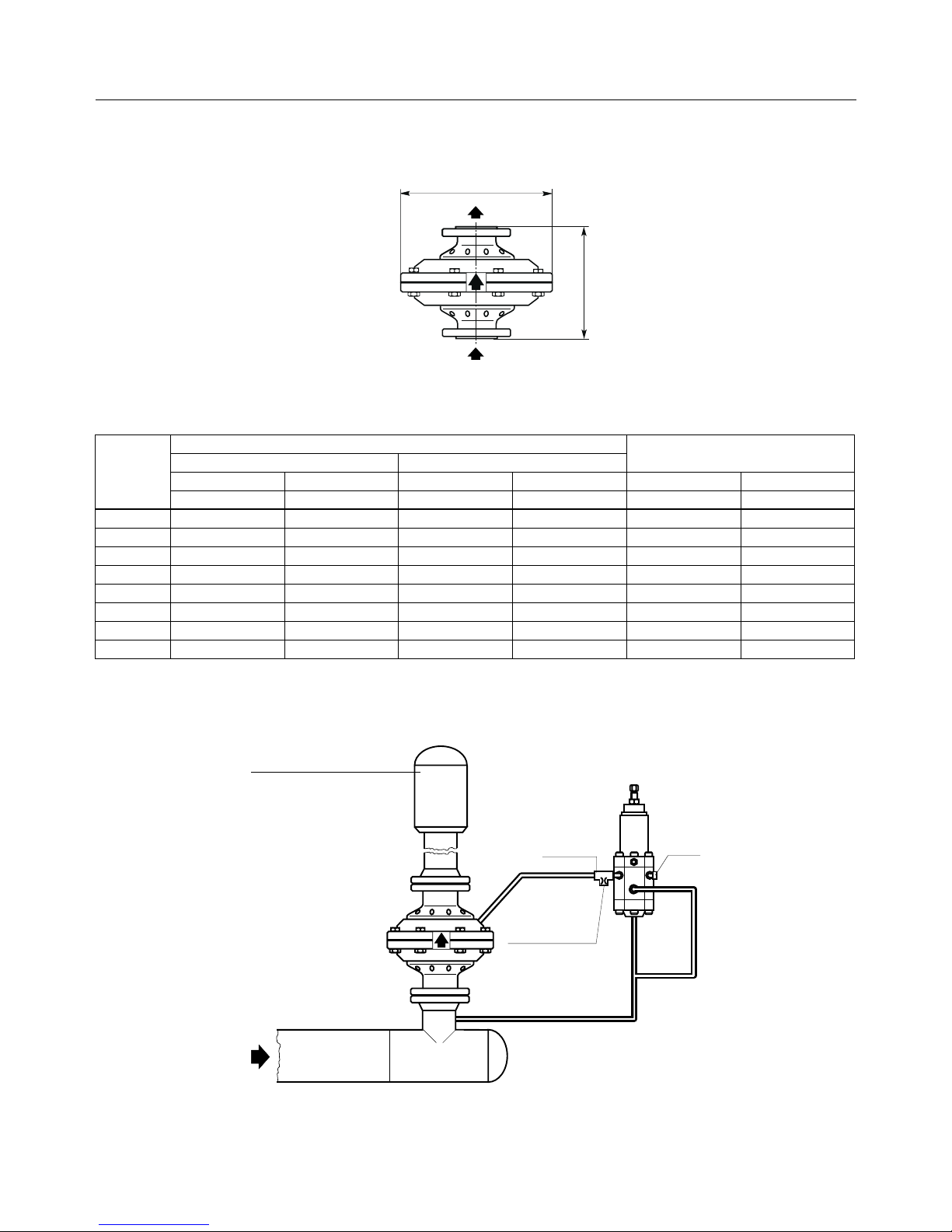

Figure 5. VS-FL Series Dimensions

Table 3. VS-FL Series Dimensions

DIMENSIONS AND WEIGHTS

DN

DIMENSIONS (mm)

WEIGHTS (Kg)

FACE TO FACE - I A

PN 16 - ANSI 150 ANSI 300 - ANSI 600 PN 16 - ANSI 150 ANSI 300 - ANSI 600 PN 16 - ANSI 150 ANSI 300 - ANSI 600

VS-FL-BP VS-FL VS-FL-BP VS-FL VS-FL-BP VS-FL

25 184 210 285 225 24 31

40 222 251 306 265 37 47

50 254 286 335 287 48 60

65 276 311 370 355 68 88

80 298 337 400 400 83 148

100 352 394 450 480 105 201

150 451 508 590 610 255 480

200* - 610 - 653 - 620

A

I

N.B.: (*) ANSI 300 I = 568 - 1/4” NPT female threaded connections

INSTALLATION

Figure 6. VS-FL Series Connection/Installation Schematic

NOTE: RECOMMENDED PIPING IS STAINLESS STEEL WITH 10 MM DIAMETER.

Jet

(0,75 mm)

A

B

L

PRX/182

VS/FL

Plug

To the atmosphere or in a safe area

To the atmosphere

or in a safe area

Page 6

Type VS-FL

6

INSTALLATION (CONTINUED)

• Ensure that the data found on the valve label are

compatible with usage requirements.

• Ensure that the valve is mounted in accordance with the

direction of ow indicated by the arrow.

• Make the connections as indicated in gure 6.

!

WARNING

Only qualied personnel should install or

service a relief valve.

Relief valves should be installed, operated,

and maintained in accordance with international and applicable codes and regulations.

Failure to take the relief valve out of service

immediately may create a hazardous

condition.

Personal injury, equipment damage, or

leakage due to escaping uid or bursting of

pressure-containing parts may result if this

relief valve is over-pressured or is installed

where service conditions could exceed the

limits given in the Specications section, or

where conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-limiting devices (as required by the

appropriate code, regulation, or standard) to

prevent service conditions from exceeding

limits.

Additionally, physical damage to the relief

valve could result in personal injury and

property damage due to escaping uid.

To avoid such injury and damage, install the

relief valve in a safe location.

Before installation, check shall be done if

service conditions are consistent with use

limitations.

All means for draining must be provided in

the equipment installed before relief valves

(ENs 12186 & 12279).

If using a VS-FL/ series relief valve on

hazardous or ammable gas service,

personal injury and property damage could

occur due to re or explosion of vented gas

that may have accumulated.

To prevent such injury or damage, provide

piping or tubing to vent the gas to a safe,

well-ventilated area in accordance also

with international and applicable codes and

regulations.

In particular, when venting a hazardous gas,

the piping or tubing should be located far

enough away from any buildings or windows

so to not create a further hazard, and the

vent opening should be protected against

anything that could clog it.

If installing the relief valve at an outside location, adequate protection, such as rain caps

or elbow piping, must be attached to the

outlet to keep the relief valve from getting

plugged or from collecting moisture, corrosive chemicals, or other foreign materials.

For outdoor installations, the relief valve

should be located away from vehicular trafc.

Further the ENs 12186 & 12279, where this product is used:

• provide the cathodic protection and electrical isolation to

avoid any corrosion and

• in accordance with clause 7.3/7.2 of aforesaid

standards, the gas shall be cleaned by proper lters/

separators/scrubbers to avoid any technical &

reasonable hazard of erosion or abrasion for pressure

containing parts

Pressure equipment in subject shall be installed in non-

seismic area and hasn’t to undergo re and thunderbolt action.

Clean out all pipelines before installation of the relief valve

and check to be sure it has not been damaged or has

collected foreign material during shipping.

For anged bodies, use suitable line gaskets and approved piping and bolting practices. Install the relief valve in any position

desired, unless otherwise specied, but be sure ow through

the body is in the direction indicated by the arrow on the body.

Installation must to be done avoiding anomalous stresses on

the body and using suitable joint means (bolts, anges, …)

according equipment dimensions and service conditions.

Note: It is important that the relief valve and relief valve be

installed so that the pilots vent holes are unobstructed at all

times.

For outdoor installations, the relief valve should be located

away from vehicular trafc and positioned so that water, ice,

and other foreign materials cannot enter through the valve pilot.

Avoid placing the equipment beneath eaves or downspouts,

and be sure it is above the probable snow level.

START-UP

The relief valve’s pilot is factory set at approximately the

midpoint of the spring range or at the pressure requested,

so an initial adjustment may be required to give the desired

results.

With proper installation completed and relief valves properly

adjusted, slowly open the upstream and downstream line

valves.

Page 7

Type VS-FL

7

PILOT ADJUSTMENT

Mount upstream of the relief valve a unit capable of

generating the pressure at which the valve is to release gas

(a pressure regulator, a compressed air or gas cylinder or

the like) and a pressure gauge with appropriate scale.

Adjust the load of spring by means of adjusting screw

proceeding as follows:

• Fully tighten adjusting screw.

• Bring pressure upstream of relief valve up to set point.

• Slowly loosen adjusting screw until relief valve opens.

This is revealed by the escape of gas through vent.

• Decrease and subsequently increase pressure a few

times to check for proper valve operation and make any

adjustment in setting, if necessary.

SHUTDOWN

!

WARNING

To avoid personal injury resulting from

sudden release of pressure, isolate the relief

valve from all pressure before attempting

disassembly and release trapped pressure

from the equipment and pressure line.

In case of disassembly of main pressure retaining parts for checks and maintenance procedures, external and internal tightness tests

have to be done according applicable codes.

PERIODICAL CHECKS

CAUTION

It is recommended that relief valve and pilot

are checked periodically.

In order to check the efciency of the relief valve, line

pressure increase must be simulated using the same

procedure as described in previous “Pilot Adjustment”

paragraph.

Valve is in proper working order if gas release is noticed

upon pressure increase. Gas release must cease

immediately as pressure is brought back to its normal

working value.

It is also recommended that both pilot’s and relief valve’s

seal pads are checked periodically as described in the

following paragraphs.

RELIEF VALVE MAINTENANCE

(SEE FIGURES 7 TO 11)

!

WARNING

All maintenance procedures must be carried

out only by qualied personnel.

If necessary, contact our technical support

representatives or our authorized dealers.

VS-FL Series Relief valve and its pressure accessories are

subject to normal wear and must be inspected periodically

and replaced as necessary.

The frequency of inspection/checks and replacement

depends upon the severity of service conditions and upon

applicable National or Industry codes, standards and

regulations/recommendations.

In accordance with applicable National or Industry codes,

standards and regulations/recommendations, all hazards

covered by specic tests after nal assembling before

applying the CE marking, shall be covered also after every

subsequent reassembly at installation site, in order to ensure

that the equipment will be safe throughout its intended life.

Before proceeding with any maintenance work, shutoff the

gas upstream and downstream from the valve, also ensure

that there is no gas under pressure inside the body by

loosening the upstream and downstream connections.

Replacing Seal Pad

a. Disconnect all ttings preventing removal of outlet stub

pipe and take the latter off.

b. Loosen screws (key 5) and slide out outlet ange

(key 22), replace O-ring (key 18).

c. Remove pad holder (key 19) from the outlet cover

(key 13). Only for the DN 200 size the pad holder remain

attached to the outlet ange and it is not necessary

dismount it.

d. Loosen screw (key 25), pad retainer (key 21), remove and

replace pad unit (key 20).

e. Check that the part of sleeve (key 16) that touches

pad unit (key 20) is intact. If not, carry out general

maintenance and replace sleeve.

f. Reassemble by reversing the above sequence, being

careful not to damage O-ring (key 18). To facilitate tting

of pad holder (key 19), use an air pump that, when

connected to tting (key 17), causes sleeve (key 16) to

open fully.

Page 8

Type VS-FL

8

Relief Valve General Maintenance

a. Disconnect all ttings, remove regulator from the line and

place it in upward vertical position.

b. Mark the position of inlet and outlet anges (key 1 and 22)

and cover (key 11 and 13) to keep the correct alignment

during the following reassembly phase.

c. Separate covers (key 11 and 13) by removing screws

(key 9).

!

WARNING

Spring (key 6) is compressed between

covers (key 11 and 13); its sudden release

could cause them to y apart dangerously.

To prevent this, replace the two screws

(key 9) with threaded rods and their nuts,

remove the remaining screws and use nuts

to slowly release spring tension.

d. Slide sleeve-diaphragm assembly (key 16 and 10) out of

inlet cover (key 11) and remove indicator (key 34).

e. Loosen screws (key 27), axially slide out of sleeve

(key 16) plates (key 8 and 12) and diaphragm (key 10).

Replace O-rings (key 26 and 28).

f. Loosen screws (key 5 or 64 for DN 150 and DN 200

sizes) and dismount inlet ange (key 1). Replace anti-

friction rings (key 2) and O-ring (key 3).

g. Unscrew travel indicator support (key 36) from inlet cover

(key 11), dismount parts, replace O-rings (key 35 and 37)

and O-ring (key 4) on the inlet cover (key 11).

h. Loosen screws (key 5) and axially slide out outlet ange

(key 22). Replace O-ring (key 18), anti-friction rings

(key 2) and O-ring (key 3).

i. Remove pad holder (key 19) from the outlet cover

(key 13). Only for the DN 200 size the pad holder remain

attached to the outlet ange and it is not necessary

dismount it.

j. Loosen screw (key 25), pad retainer (key 21), remove and

replace pad unit (key 20).

k. Check that the part of sleeve (key 16) that touches pad

unit (key 20) is intact. If not replace sleeve.

l. Check all moving parts, paying special attention to nickel

plated surfaces. Replace any that are worn or damaged.

m. Clean all stripped-down parts with petrol and dry with

compressed air.

Reassembly

Lubricate all seals with MOLYKOTE 55 M, being very careful

not to damage them when reassembling. Reassemble the

parts by reversing the above steps.

As you proceed, make sure that parts move freely and

without friction.

In addition:

a. Before tting sleeve-diaphragm assembly (key 16 and

10), recompose indicator group (key 34, 35, 36, 37, 38

and 40) and mount it on inlet cover (key 11).

Attach spring collet (key 33) to plate (key 8) upon

completion of reassembly. Don’t execute this assembly

for the DN 200 size.

b. Complete reassembly and make sure to tighten all screws

uniformly.

c. Remove cap (key 40) and tap with a rubber or wooden

hammer indicator (key 34) so as to couple spring collet

(key 33) and plate (key 8).

Only for DN 200 size insert indicator (key 34) and hook it

to plate (key 8), recompose indicator group (key 35, 36,

37, 38 and 40) and mount it on inlet cover (key 11).

d. Use an air pump connected to tting (key 7) to check

proper regulator working order.

e. After the reassembly completion, check the proper

functioning of all parts. Check the regulator with soapy

water, making sure there are no leaks.

f. Remount regulator on the line and reestablish all

connections.

TYPE PRX/182 PILOT MAINTENANCE

(SEE FIGURE 12)

Installation

a. Make sure that specications on the pilot plate comply

with the intended use.

b. Make sure that all connections are correctly made.

Startup

Refer to the relief valve startup instructions.

Periodical Checks

Pilot tightness should be tested regularly by referring to the

following procedure:

a. Supply tting A with normal operating pressure.

b. Make sure there is no gas outow from tting B.

Page 9

Type VS-FL

9

Maintenance

CAUTION

Maintenance should be carried out by skilled

personnel to ensure good servicing results.

Contact our technical support representatives

or our authorized dealers for any information.

Let gas under pressure ow out of the

relevant part of the system before servicing.

General Maintenance

a. Disconnect and remove the pilot from the line.

b. Fully unscrew the adjusting screw (key 1).

c. Unscrew the cap (key 3), for the AP version also the

extension (key 35), remove the spring holder (key 6) and

the spring (key 7). Replace the O-rings (key 4 and 5).

d.

Loosen screws (key 10), remove the upper cover (key 8)

and the lower cover (key 21). Replace the O-ring (key 18).

e. Lock the stem (key 23) by inserting a key into the notches

and unscrew nuts (key 20 and 26).

f. Disassemble the parts and replace the diaphragm

(key 14) and the pad (key 22).

g.

Unscrew the seat (key 19) and replace the O-ring (key 17).

h. Use petrol to cleanse the pilot body and all metal parts. Blow

them thoroughly with compressed air and check for clear

holes along the gas conduits. Replace any worn parts.

Reassembly

Reassemble all parts by following in reverse order the

assembly as described above (see General Maintenance

section).

As parts are assembled, make sure they move freely

causing no friction.

Make sure to:

a. O-rings and diaphragms should be lubricated by applying

a thin layer of ‘Molykote 55 M’ grease.

Pay attention not to damage them during reassembly. All

other pilot parts require no lubrication.

b. The cover clamping screws (key 10) should be tightened

evenly to ensure proper tightness.

c. Pilot operation, calibration and tightness should be tested

as described in the Periodical Checks paragraph.

d. Previously disassembled ttings must be connected.

Check for leaks by using suds.

Calibration

See the paragraph Pilot Adjustment on page 6.

SPARE PARTS

Spare parts storage shall be done by proper procedures

according to national standard/rules to avoid over aging or

any damage.

TROUBLESHOOTING

Table 4. General Troubleshooting for VS-FL Series Relief Valves

SYMPTOMS CAUSE ACTIONS

The valve does not open

Lack of incoming gas Check the station feeding

Pilot is not being supplied Check pilot connections

Valve diaphragm is broken To be replaced

Pilot setting is higher than required Check pilot setting

The valve is not sealed properly

Tight shutoff gaskets are worn To be replaced

Deposits of grime on the tight shutoff pad are

obstructing proper positioning of the shutter

Clean or replace it

Pilot setting is lower than required Check pilot setting

Page 10

Type VS-FL

10

PARTS LISTS

VS-FL Relief Valve

(See Figures 7 to 11)

Key Description

1 Inlet ange

2* Anti-friction ring

3* O-ring

4* O-ring

5 Screw

6 Spring

7 Fitting

8 Inlet plate

9 Screw

10 Diaphragm

11 Inlet Cover

12 Outlet plate

13 Outlet cover

14 Washer

15 Nut

16 Sleeve

17 Fitting

18* O-ring

19 Pad holder

20* Pad unit

21 Pad retainer

22 Outlet ange

25 Screw

26* O-ring

27 Screw

28* O-ring

29 Label support

30 Label

31 Rivet

32 Label

33 Spring collet

34 Indicator

35* O-ring

36 Support

37* O-ring

38 Bush

39 Indicator label

40 Cap

43 SR silencer

46* O-ring

47* O-ring

48 Washer

59 Eyebolt

61 Special screw

62 Screw

63 Elastic washer

64 Screw

64 Screw

65 Elastic pin

400 Plate

401 Bush

Key Description

402* O-ring

403 Support

404* O-ring

405 Spring collet

406 Indicator

407 Nut

408 Bracket

409 Support

410 Proximity switch

411 Fitting

Type PRX/182 Pilot

(See Figure 12)

Key Description

1 Adjusting screw

2 Nut

3 Cap

4* O-ring

5* O-ring

6 Spring carrier plate

7 Spring

8 Upper cover

9 Spring carrier plate

10 Screw

11 Washer

12 Filter

13 Plate

14* Diaphragm

15 Plate

16 Body

17* O-ring

18* O-ring

19 Seat

20 Nut

21 Lower cover

22* Pad holder unit

23 Stem

24 Plate

25* O-ring

26 Nut

28* O-ring

29 Plate

31 Screw

33 Plug

34 Plug

35 Extension

Rubber parts marked with (*) are supplied in the “spare parts

kit”, recommended as stock.

To order the kit it is necessary to communicate to us the type

of the relief valve or pilot and its serial number.

Page 11

Type VS-FL

11

181622

13 14 15

4

10

3

2

3

2

2

2

12

1

7

22

3

178

6

11

5

9

5

26

27

28

31

30 2932313334353637383940

Figure 7. VS-FL Relief Valve DN 25 to DN 150

SCHEMATIC ASSEMBLIES

LM/1403

Page 12

Type VS-FL

12

LM/1403

Figure 8. Pad Holder for VS-FL Relief Valve DN 25 to DN 150

19

19

20

21

47

20

25

PAD HOLDER

DN 25 TO DN 50

PAD HOLDER

DN 25 TO DN 50

PAD HOLDER

DN 65 TO DN 150

PAD HOLDER

DN 65 TO DN 150

19

20

21

19

20

21

C

43

46

48

25

47

46

48

25

43

21

25

SILENCED VS-FL

NOT SILENCED VS-FL

Page 13

Type VS-FL

13

1

2

2

3

2

4

6

8

9

10

11 12

13 14 15

16

18

2

3

5

2

19

20

21

47

26

27

28

31 30 29

31

32

33

34

35

36

3738

3940

25

22

65

62

63

59

3

2

64

59

Figure 9. VS-FL Relief Valve DN 200

Page 14

Type VS-FL

14

LM/1403

Figure 10. VS-FL Relief Valve DN 150 Various Versions

Figure 11. VS-FL Relief Valve DN 25 to DN 150 with Proximity

LM/1403

5

VS-FL/150 ANSI 300-600 DETAIL

61

64

5

64

VS-FL/150 ANSI 300-600 DETAIL

VS-FL-BP/150 DETAIL

VS-FL-BP/150 DETAIL

59

VS-FL/ AND VS-FL-BP/ WITH PROXIMITY SWITCH VERSION

411

409

407

410

400

408 407 402 403

401

404 406 405

Page 15

Type VS-FL

15

B

A

A

L

B

S

33

28

31 29

28

34

34

22

19

14

17

16

18

1413

1

2

3

4

5

6

7

8

9

10

11

12

13

15

11

20

10

11

21

22

23

24

18

11

26

25

35

4

4

LM/1390

Figure 12. Type PRX/182 and PRX-AP/182 Pilots

AP VERSION

A B L

To the controlled

pressure

To Chamber 2 of the

relief valve

To the controlled

pressure

PRX/182

SECTION A-A

Table 5. Type PRX/182 and PRX-AP/182 Connections

Page 16

Type VS-FL

©Emerson Process Management Regulator Technologies, Inc., 2009, 2013; All Rights Reserved

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6777 8337

Europe

O.M.T. Tartarini s.r.l. Via P. Fabbri 1,

I-40013 Castel Maggiore (Bologna), Italy

Tel: +39 051 419 0611

Francel SAS, 3 ave Victor Hugo, CS 801215

Chartres 28008, France

Tel: +33 2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shangai 201206, China

Tel: +86 21 2892 9499

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Tartarini is a mark of O.M.T. Ofcina Meccanica Tartarini s.r.l.,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such products at any

time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson Process

Management product remains solely with the purchaser.

Loading...

Loading...