Page 1

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

Installation and Maintenance Instructions Vanessa Series 30,000 - Basic configuration

body style double flanged, wafer, lug and buttweld

All actuated valves must be securely

palleted or crated with particular attention,

in order to ensure that parts of actuator

(especially pneumatic piping or accessories)

do not extend beyond the skid/crate.

4 The type of packing must be defined in the

customer’s order and will be appropriate

to ensure safe transportation to final

destination and eventual conservation

before installation.

1.2 Handling requirements

Applicable product range

• Series 30,000 Basic configuration, double

flanged body style, which can be installed

between two flanges or stud-bolted to either

flange.

• Series 30,000 Basic configuration, lug-single

flange body style, which must be bolted to

either flange.

• Series 30,000 Basic configuration, wafer body

style, which can be installed between two

flanges.

• Series 30,000 Basic configuration, buttweld

ends, which must be welded to the line.

SECTION 1 - VALVE STORAGE

1.1 Preparation and preservation for shipment

All valves are properly packed in order

to protect the parts that are subject to

deterioration during transportation and storage

on site. In particular, the following precautions

should be taken:

1 The valves must be packed with the disc

in the closed position. The flange sealing

surfaces (raised faces) of the valves will be

protected with suitable protective grease.

The end faces of the valve must be protected

with plastic or wooden discs fixed with

straps.

2 Bare shaft valves: the ends of the shaft must

be protected with plastic tubes.

3 Valves with actuators: in case of “fail

open” pneumatic - hydraulic actuators

with manual override, the manual override

shall be used to manually close the valves

and to lock them in position. If there is no

manual override, cut outs are made in the

flange protectors for the disc, and the disc is

securely protected.

A - Packed valves

Crates: Lifting and handling of the packed

valves in crates will be carried out

by a fork lift truck, by means of the

appropriate fork hitches.

Cases: The lifting of packed valves in cases will

be carried out in the lifting points and

in the center of gravity position which

have been marked. The transportation

of all packed material must be carried

out safely and following the local safety

regulations.

B - Unpacked valves

1 The lifting and the handling of these valves

has to be carried out by using appropriate

means and by respecting the carrying limits.

The handling must be carried out on pallets,

protecting the machined surfaces to avoid

any damage.

2 With large dimension valves, the sling and

the hooking of the load must be carried out

by using the appropriate tools (brackets,

hook, fasteners, ropes) and load balancing

tools in order to prevent them from falling

or moving during the lifting and handling.

Emerson.com/FinalControl

© 2017 Emerson. All Rights Reserved.

VCIOM-00006-EN 18/04

Page 2

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

1.3 Storage and preservation before

installation

In case the valves have to be stored before

installation, the storage has to be carried out

in a controlled way, and has to be performed in

accordance to the following criteria:

1 The valves have to be stocked in a closed,

clean and dry storage room.

2 The disc must be in the closed position,

and the end faces must be protected with

plastic or wooden discs fixed with straps. If

possible, keep the original protection.

3 Periodical checks have to be carried out

in the storage area to verify that the above

mentioned conditions are maintained.

NOTE

Storage in an open area for a limited period can be

considered only in case the valves have appropriate

packing (packed in cases lined with tarred paper, and

contents well protected with barrier sacks).

CAUTION

For valve handling and/or lifting, the lifting

equipment (fasteners, hooks, etc.) must be sized and

selected while taking into account the valve weight

indicated in the packing list and/or delivery note.

Lifting and handling must be made only by

qualified personnel.

LIFTING AND HANDLING OF VALVES INSTALLED IN HORIZONTAL PIPELINE

FIGURE NO. 1A

Fasteners must be protected by plastic covers in

sharp corner areas.

Caution must be taken during the handling to

avoid that this equipment passes over the workers

or over any other place where a possible fall

could cause damage. In any case, the local safety

regulations must be respected.

NOTE

Solutions A and C are applicable when the protrusion

of the bottom hub from the flange or body is sufficient

to position securely the lifting strap.

Solutions B and D are applicable when the protrusion

of the bottom hub from the flanges is NOT sufficient to

position securely the lifting strap.

In presence of solution B, insert a stud bolt and fix it

securely with nuts as indicated in the drawing detail.

In presence of solution D, insert a lifting eyelet in the

flange threaded holes close to the bottom hub and fix

it securely as indicated in the drawing detail.

LIFTING AND HANDLING OF VALVES INSTALLED IN VERTICAL PIPELINE

FIGURE NO. 1B

2

Page 3

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

SECTION 2 - INSTALLATION

2.1 Valve inspection

1 Carefully remove the valve from the

shipping package (box or pallet) avoiding any

damage to the valve or, in case of automated

valves, to the electric or pneumatic/

hydraulic actuator or instrumentation.

2

The valves are shipped with the ends

protected with caps and a thin layer of

protective grease. Before installing the valve,

remove the caps and clean carefully, then

de-grease both surfaces with a solvent.

Clean the inside of the valve using an air line.

Ensure that there are no solid objects such as

pieces of wood, plastic or packing materials

within the valve or on the valve seat.

3 Inspect the seal ring to ensure that it

was not damaged during handling. This

is especially important in case of valves

shipped with the disc in the open position

and with “fail-open” actuators.

4 Confirm that the materials of construction

listed on the valve nameplate are

appropriate for the service intended and are

as specified.

5 Ensure that the packing gland adjusting

nuts against the packing gland flange

cannot be rotated by hand.

2.2 Valve installation

Vanessa recommends that the optimum valve

installation is with the shaft in the horizontal

plane, after which it is preferable to have the

shaft at an angle so as to minimize any problem

associated with solid particles present in the

fluid that otherwise could deposit in the lower

bearing area.

NOTE

The Vanessa valve is designed to withstand design

differential pressure in both directions.

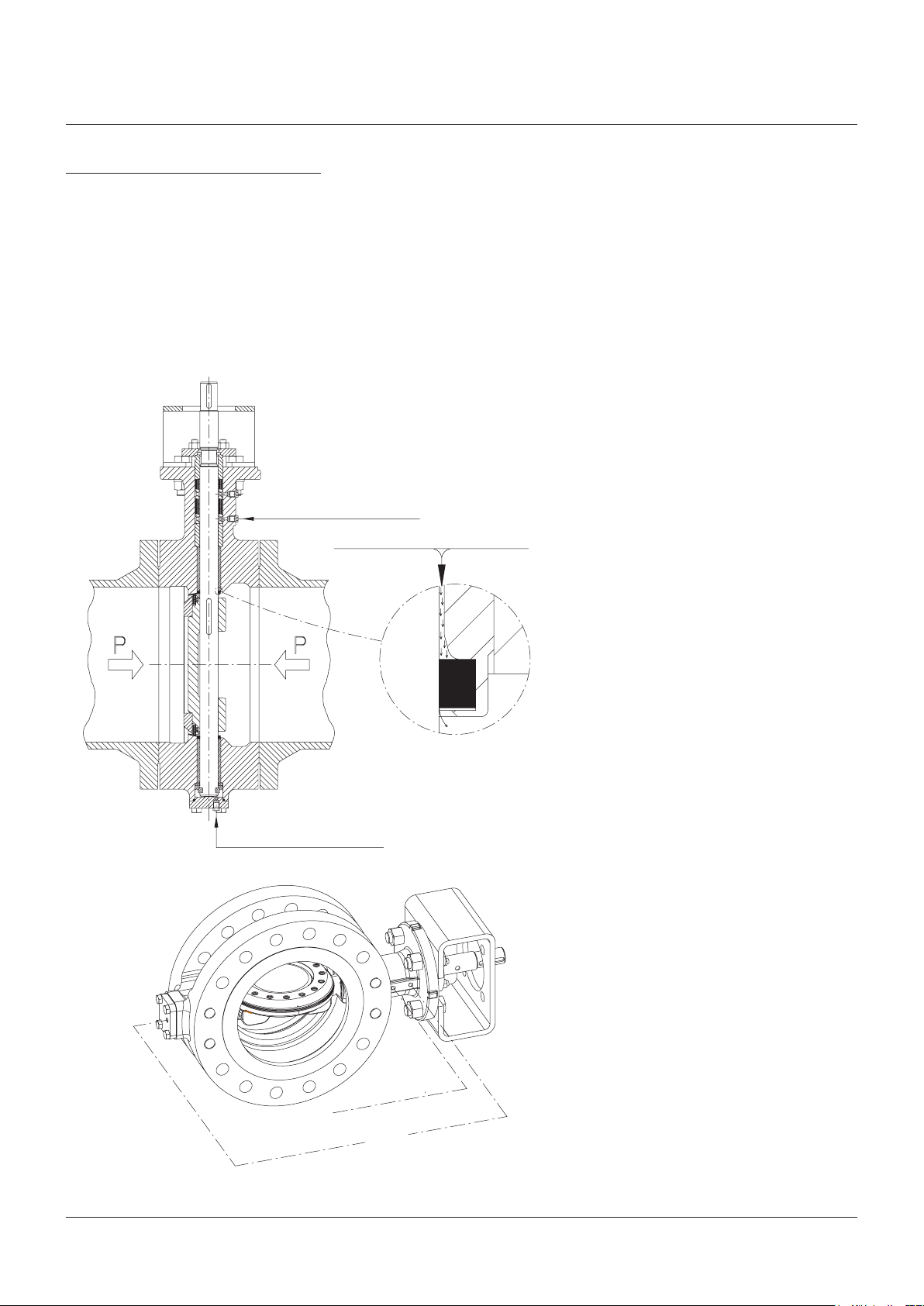

Isolating applications

The valve operating torque affects the sealing

performances. Vanessa attached the indication plate

P (figure 2) on the upstream flange as a reference for

the direction of the installation.

The best sealing performance, also for bi-directional

service, will be maintained when pressure acts on the

shaft side of the valve, which is recommended when

the service tightness requirements are more stringent

in one specific direction.

Control applications (uni-directional, where perfect

sealing is not required)

The plate could be fixed on either flange indicating

the preferred direction. Please respect the direction

of installation indicated on the relevant flange. The

selection of the actuator has been made for that

specific direction of installation.

Unless otherwise recommended by Vanessa,

the valve should be installed with the disc in

the closed position to ensure that the seal ring

in the disc is not damaged during installation.

Particular care should be taken with those

valves equipped with ‘fail-open’ actuators.

For operating temperatures above 200°C

(392°F) thermal insulation of the valve body is

recommended.

If the valve has threaded tapped holes in

the hub areas, Vanessa recommends to use

hexagonal head bolts or shorter studs to

connect the valve in this zone. The depth of the

tapped holes in the bodies of all Series 30,000

valves is specified in the technical literature.

Failure to use correct bolts/studs may result in

damage to the valve.

If the valve has welded ends, perfectly clean

and degrease the ends to be welded (of both

valve and pipe), using a cloth with acetone

or similar product. Insert correctly the valve

between the edges of the pipe to be welded,

taking care of the plate that indicates the

preferential side for sealing. Carry out an initial

accurate spot welding verifying the perfect

alignment of the edge and axis of the valve.

Carry out the welding of the edge proceeding

in alternate way on both sides to reduce

the tensions introduced by the welding. It is

important to respect the interpass temperature

which must not go above 150°C (302°F).

Handling and lifting of the valves during

installation MUST be performed following the

same criteria and instructions described in

previous points “1.2 Handling requirements”

and “1.3 Storage and preservation before

Installation”.

IMPORTANT

The valve trim is designed to withstand and to seal

against the design differential pressure marked

on the valve nameplate which data are supplied

together with the present document.

Since it is impossible to maintain complete

control on the external input forces to the trim

coming from gear/actuator, the valve trim shall

not be used as a final protective mean against

the hazard caused by the closed valve upstream

pressure.

IMPORTANT

It is recommended to perform piping flushing

before installation of valve.

If this is not possible, the valves must be set with

the disc in full open position before starting with

flushing.

CAUTIONS

When the pipe is lined, be careful that the disc

does not come into contact with the lining during

its stroke, especially in lug and wafer body styles.

This verification is very important to avoid any

damage to the valve.

FIGURE 2

3

Page 4

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

2.3 Valve verification

1 Tighten the packing just enough to prevent

stem leakage. Over-tightening will decrease

packing life and increase operating torque.

2 Check the operation of the valve by stroking

it to “full open” and “full close”. To verify the

valve orientation, the disc position indicator

mark on the shaft (during the normal open

to close cycle) should rotate clockwise from

a position in line with the pipe (see figure3a)

to a position parallel to the pipe flanges

(seefigure 3b).

IMPORTANT

If piping system is pressurized with water for

testing, and in case the piping system has been

shut down after testing for a long time, the

following recommendations should be adopted:

a. Use corrosion inhibitor with water to

pressurize the piping system.

b. After testing, the piping system should be

depressurized and the test water completely

drained.

c. After testing, valves must be maneuvered

through a complete opening/closing cycle and

disc left in half-open position. Apply a film of

protective oil in the packing area by means of a

paintbrush. The protective oil must fill the area

between shaft and packing bushing.

Clockwise to close

Disc in open position

FIGURE NO. 3A

Disc in closed position

Disc position

indicator mark

Disc - shaft key and position indicator mark plane

Shaft key

Disc position indicator mark

Clockwise to close

Shaft key

FIGURE NO. 3B

Disc - shaft key and position indicator mark plane

4

Page 5

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

2.4 TROUBLESHOOTING GUIDE

Symptom Possible cause Resolution

Valve won’t rotate 1. Packing is too tight 1. Loosen gland nuts

2. Actuator has failed 2. Replace or repair

3. Valve packed with debris 3. Flush or clean valve to remove debris

4. Stem key has sheared 4. Determine cause of shearing and correctly replace stem key

5. Fluid solidification between bearings and shaft 5. Flush bearings by flushing holes (if present)

Stem packing leaking 1. Gland flange nuts too loose 1. Tighten gland flange nuts

2. Packing damaged 2. Replace packing - see Paragraph 3.1

Bottom flange gasket leaking 1. Bottom flange bolting loose 1. Tighten bottom flange bolting

2. Spiral wound gasket damage 2. Replace gasket - see Paragraph 3.3

Valve leaking 1. Valve not fully closed 1. Close valve

2. Debris trapped in valve 2. Cycle and flush (with valve open) to remove debris

3. Actuator mechanical stops improperly set 3 Remove the stop for closure and reset properly

4. Seal ring damaged 4. Replace seal ring - see Paragraph 3.2

Jerky operation 1. Packing is too tight 1. Loosen gland nuts, cycle valve, retighten

2. Air supply inadequate 2. Increase air supply pressure and/or volume

3. Actuator/stem adapter misaligned 3. Remove actuator mounting and realign

5

Page 6

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

SECTION 3 - MAINTENANCE

The Vanessa Series 30,000 has been designed

to require a minimum of maintenance.

WARNING

Depressurize the line before starting any

maintenance. Failure to do so may cause serious

personal injury and/or equipment damage.

3.1 Packing maintenance

If shaft leakage is observed through the

packing, tighten the gland nuts slowly and

evenly until the leakage stops.

CAUTION

Do not over-tighten packing gland nuts. Overtightening will increase the torque required to

operate the valve.

When tightening the gland nut, use half-turn

increments until leakage has stopped.

Please refer to the figure no. 4.

To replace the packing proceed as follows:

1 Remove the gear/actuator and relevant

connecting keys (4f). Please note the

actuator position relative to the valve

position for reassembly of gear/actuator

later.

2 Remove gland nuts (5d). If present, remove

bellevilIe springs (5n), taking care of noting

their assembly configuration to reassemble

them correctly (point 7).

3 Remove packing gland flange (5f), anti blow-

out ring if present (5g), and gland bushing

(5c).

4 Remove packing (5a). If valve is with packing

flush option, remove lantern ring also (5h).

5 Carefully clean packing cavity and shaft (4a).

6 Apply a thin film of lubricant on each new

packing ring (5a) surfaces (lubricant should

be in accordance with Table IV). Insert new

packing rings, paying attention to insert the

two braided rings at the bottom and top of

the entire packing. If valve is with packing

flush option, insert the lantern ring (5h) in

the same sequence as previously removed

(or as indicated in figure 4). If the packing

rings are of the split variety, install with

splits staggered at 180° from each other.

7 Reassemble gland bushing (5c), anti blow-

out ring if present (5g), and gland flange

(5f). If present, assemble the belleville

springs (5n), following the assembly

configuration noted in the previous point 2,

then assemble by hand the gland nuts (5d)

without tightening (after applying a thin film

of lubricant on the threads of the stud bolts,

in accordance with Table IV).

8

Reassemble keys (4f) on the upper stem end.

9 Reassemble gear/actuator and close the

valve.

CAUTION

Do not force actuator on the stem! This should be

a free moving fit.

10 Tighten gland nuts (5d) in accordance to

Table I (Torque values for gland nuts).

11 Cycle the valve.

12 Pressurize again the line.

13

If a leakage is detected, tighten the gland nuts

slowly and evenly until the leakage stops.

FIGURE NO. 4

6

Page 7

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

3.2 Sealing elements maintenance

To replace the sealing elements proceed as

follows (please refer to figure no. 5):

WARNING

Depressurize the line before starting any

maintenance. Failure to do so may cause

seriouspersonal injury and/or damage to the valve.

1 Remove the valve with the disc in the closed

position from line. Clean the valve according

to proper cleaning procedure as outlined by

the plant or according to a recommended

procedure.

2 Open the valve a few degrees.

3 Loosen the seal retainer ring screws (2c).

4 Open valve to full open position.

NOTE

In small size valves it may be easier to unbolt the

actuator and rotate the disc beyond the full-open

position to provide more space to work with components.

5 Carefully remove the retainer ring screws

(2c) with security washers (2d), then remove

the seal retaining ring (2b).

6 Remove seal ring (3a) and spiral wound

gasket (3b).

7 Inspect the body seat. Clean it, if necessary,

with fine abrasive cloth (No. 600 or finer),

after having cleaned it perfectly with solvent.

8 Inspect and clean the disc seal ring area

and spiral wound gasket groove. No foreign

particles must be present before spiral

wound gasket and seal ring assembly.

9 Apply a thin film of lubricant on the surface

area of the disc (2a) where seal ring (3a)

and spiral wound gasket (3b) will be located

(lubricant should be in accordance with

Table IV).

CAUTION

Apply only a thin film of lubricant where indicated.

Failure to do so will hinder the assembly and may

cause damage to the valve.

10 Assemble the new spiral wound gasket

(3b) in the disc groove, without forcing and

taking care not to damage it.

11

Replace seal ring (3a) on the disc through the

shaft side of the body. To properly locate the

seal ring, there are two different solutions:

• solution 1 - ref. to figure no. 6a: align the

internal slot of the seal ring (3a) to the

reference pin (F).

• solution 2 - ref. to figure no. 6b: align the

reference mark (C) on the seal ring (3a)

with the relevant reference mark (D) on

the disc.

12 Assemble the seal retainer ring (2b). There

are two different solutions as per previous

point 11:

• solution 1 - ref. to figure no. 6a: make

sure that the slot on the edge of the seal

retainer ring(B) is in correspondence with

reference pin (F).

• solution 2 - ref. to figure no. 6b: ensure to

locate the hole (E) of the seal retainer ring

with the relevant marks on the disc (D)

and seal ring (C).

13 Hand tighten all the fastening screws

(2c), with relevant lock washers (2d) after

applying Loctite

®

270 or equivalent on the

bottom side of the threads (they have to

be perfectly cleaned with solvent before

applying Loctite

®

). Then, verify that the seal

ring can be moved freely by hand without

rotating it.

14 Apply a thin film of lubricant to the body seat

and to the external edge (sealing conical

surface) of the seal ring (3a). Lubricant

should be in accordance with Table IV.

15 Seat and unseat the valve twice.

16 Keep the valve in the closed position without

applying torque. Tighten at least two

retaining screws (2c) to avoid the seal ring

moving from the position found.

FIGURE NO. 5

7

Page 8

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

17 Open the disc a few degrees and tighten,

using a torque wrench, all screws (2c).

Use a torque value from Table III for valves

according to solution 1 (ref. to figure no. 6a).

Use instead a torque value from Table II for

valves according to solution 2 (ref. to figure

no. 6b).

It is recommended to use the crossover

method to tighten all retaining screws.

IMPORTANT

• Solution 1 - ref. to figure no. 6a:

The seal ring is supplied with an index marking (A).

After the complete assembling, verify that the

index marking (A) can be seen in the slot (B) of the

seal retainer flange.

Slot (B) and marking (A) have to be perfectly

aligned.

If not visible or not aligned, loosen the retaining

screws, re-align the index marking and start

again the procedure from point 12.

• Solution 2 - ref. to figure no. 6b:

The seal ring and the disc are completed with two

reference markings, (C) and (D).

After the complete assembling, verify that both

markings can be seen through the hole (E) of the

seal retainer flange. The two markings have to be

perfectly aligned.

If not visible or not aligned, loose the retaining

screws, re-align the index markings and start

again the procedure from point 12.

3.3. Bottom flange gasket maintenance

If necessary to replace the bottom spiral wound

gasket, proceed as follows (see fig. no. 7):

1 Remove the bottom flange (6a).

2 Remove the spiral wound gasket (6c).

3 Inspect and clean the groove of the spiral

wound gasket in the body and in the bottom

flange.

4 Apply a thin film of lubricant on the bottom

spiral wound gasket (6c), then insert it

on the bottom flange (6a), centering and

positioning all on the body bore (lubricant

should be in accordance with Table IV).

Rotate the bottom flange to accommodate

the correct position and center the holes

with the threaded holes on the body.

5 Apply a thin film of lubricant on the threads

of the screws (6b), then introduce and

tighten them using a torque value from

Table III (lubricant should be in accordance

with Table IV).

FIGURE NO. 6A

FIGURE NO. 7

FIGURE NO. 6B

8

Page 9

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

SECTION 4 - STANDARD OPTIONS

This section (4) is referred only to Vanessa

products configured with the following options:

- bearing and packing flushing,

- live loaded packing.

Upper flushing inlet

Disc

side

Shaft

side

4.1 Bearing and packing flushing

4.1.1 Bearing flushing

The bearing flushing option is obtained by

adding two tapped holes, one in the bottom

flange and one in the neck of the valve

(seefig.9). This option includes the introduction

of a lantern ring at the bottom of the valve

packing. Bearing flushing is recommended

when the valve is installed in a service where

the particles present in the fluid or the line

fluid itself can migrate into the shaft/bearing

area causing problems. A typical example is

sulphur recovery services, where the sulphur

in a liquid or gaseous state may enter this area

and crystallise as a consequence of the plant

shutdown.

Flush pressure = P + 5%

This crystallisation may result in an increase

in the torque requirement of the valve. Another

example may be a fluid that contains particles

(e.g. catalyst) that may cause similar problems

to those highlighted above.

In these types of situations the bearing

flushing may be used to introduce an inert fluid

compatible with the process via the bearing

flush taps (see fig. 8) so as to create a pressure

barrier which prevents the introduction of the

unwanted products from the line into the shaft/

bearing area. The pressure of the flushing fluid

must be slightly higher than the line pressure

(i.e.P1+ approx5%). This both acts as a safety

measure and is a positive step in increasing

the lifetime of the valve, as well as maintaining

the constant torque requirement and hence

operability of the valve.

The bearings may be continuously flushed,

this is recommended by Vanessa for critical

services such as described above. Periodic

flushing may be used for less critical services

in order to clean the bearing/shaft interface or

in order to prepare the valve for a shutdown of

the process.

The bearing flush taps may also be used to

introduce a lubricant compatible with the

process to the bearing areas for high cycle or

dry gas service. The presence of the bearing

protector drastically reduces the consumption

of the flushing or lubricant by reducing the

amount of fluid required to give efficient service

(see fig. 8).

Further information is available from Vanessa

on request.

FIGURE NO. 8

FIGURE NO. 9

Lower flushing inlet

Upper bearing flushing connection

Lower bearing flushing

connection

The bearing protector

minimizes the consumption

of the clean fluid

Packing flushing

connection

9

Page 10

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

4.1.2 Packing flushing

The packing flushing option is obtained

by the introduction of a tapped hole that

communicates directly to the packing set in the

neck of the valve via a lantern ring. This option

can be used to monitor the rate of emission

of the line fluid toward the atmosphere (it is

important to point out that the packing of the

Vanessa valve fully complies with TA Luft and

EPA requirements). This flush tap may also be

used to capture and evacuate line fluid so as to

prevent any atmospheric loss, with the lantern

ring and split packing configuration acting as a

double block and bleed unit.

A suitable fluid may also be introduced via the

packing flush tap into the packing area so as

to eliminate any possible fugitive emissions

(seefig. 9). By keeping the fluid pressurized at a

pressure that is higher with respect to the line

pressure, the passage of any line fluid towards

the atmosphere can be effectively blocked

giving the valve excellent fugitive emissions

control. However, the fluid used must be

compatible with the line fluid as it may have the

possibility of finding its way into the line as well

as toward the atmosphere.

As with the bearing flushing option this

may also be used to introduce a lubricant

compatible with the process.

4.3 Live loaded packing

The live loaded packing option is designed

to supplement the already excellent

characteristics of the Vanessa valve packing.

This option guarantees a constant compression

of the packing set giving a further guarantee of

the fugitive emissions control of the Vanessa

valve. The fact that the packing is subject to a

near constant force supplied by the Belleville

washers reduces the maintenance cycle

required by the packing (see fig. 10).

Care should be taken in replacing the Belleville

springs as their order (parallel or series)

should be noted.

The packing nuts should be tightened in

accordance with Table I.

At this point it is worth mentioning that the

TALuft test has shown that the Vanessa Series

30,000std. Packing is more than adequate in

passing its stringent requirements.

The live loaded packing option should be

considered in valves that are subject to severe

cycling duty or valves that are subject to severe

thermal cycles.

The drawing shows typical set ups for the live

loaded packing option.

The type of lubricant used for flushing is at

the clients’ care. Vanessa may be contacted

to supply further detailed, process specific

information.

FIGURE NO. 10

10

Page 11

VANESSA SERIES 30,000

InstallatIon and MaIntenance InstructIons

TABLE I: Torque values for gland nuts

ND Trim A Trim B Trim C Trim D Trim E

in. mm Nm ft·lb Nm ft·lb Nm ft·lb Nm ft·lb Nm ft·lb

3 80 - - 15 11 15 11 30 22 - 4 100 - - 15 11 15 11 30 22 - 6 150 - - 15 11 20 15 35 26 50 37

8 200 - - 15 11 20 15 60 44 105 78

10 250 - - 25 18 20 15 70 52 135 100

12 300 - - 25 18 25 18 75 55 240 177

14 350 - - 30 22 30 22 75 55 240 177

16 400 - - 30 22 35 26 100 74 175 129

18 450 - - 35 26 40 30 205 151 480 354

20 500 - - 35 26 45 33 320 236 195 144

24 600 - - 45 33 55 41 420 310 605 446

28 700 30 22 85 63 100 74 465 343 - 30 750 30 22 105 78 135 100 485 358 - 32 800 30 22 105 78 165 122 505 372 - 36 900 30 22 110 81 220 162 545 402 - 40 1000 30 22 110 81 225 166 - - - 42 1050 30 22 110 81 230 170 - - - 48 1200 30 22 110 81 235 173 - - - 54 1350 50 37 155 115 - - - - - 60 1500 65 48 160 118 - - - - - 64 1600 65 48 - - - - - - - 72 1800 65 48 - - - - - - - 84 2100 65 48 - - - - - - - -

Note: the torque values are those suggested for the hydraulic test of the body.

TABLE IV: Lubrication

Type Component to lubricate

Light mineral oil

®

Molykote

Molykote®spray - 321R (dry lubricant) or

equivalent

- P74 (grease) or equivalent

1. Packing rings (5a)

2. Disc surface areas (2a) for seal ring and spiral wound

gasket location

3. Spiral wound gasket (6c)

1. Stud bolts/nuts (5d)

2. Screw (6b)

1. Seal ring (3a)

2. Body seat

TABLE II: Tightening torque values for bolts

and screws

Bolt

dimensions

(mm)

8 12 9

10 24 18

12 41 30

14 66 49

16 103 76

18 142 105

20 201 148

22 274 202

24 348 257

Torque values

Torque

(Nm)

Torque

(ft·lb)

TABLE III: General torque values for bolting

Bolt

dimensions

(mm)

6 10 7

8 20 15

10 45 33

12 70 52

14 110 81

16 175 129

18 235 173

20 335 247

22 370 273

24 460 339

27 595 439

30 760 561

33 785 579

36 1010 745

39 1315 970

42 1625 1199

45 2035 1501

Torque values

Torque

(Nm)

Torque

(ft·lb)

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Vanessa is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

11

Loading...

Loading...