Page 1

Fisher® Types SR5 & SR8 Sanitary Regulators

The Clean, Clear Choice For Sanitary Process Control

• Exclusively Designed for Clean / Sterile Environments

• Suitable for Clean-In-Place (CIP) and Sanitize-In-Place (SIP)

systems

• Self-Draining Design

Engineered For Precise Pressure Control Increase Process Control Integrity

Fisher Type SR5 Sanitary Pressure Reducing Regulators and

Type SR8 Sanitary Backpressure Regulators are designed for

applications such as the pharmaceutical, biotechnology, food

and beverage, consumer products, cosmetics, chemical, and

other industries — where sanitary process control is required

for steam, gases and liquids.

Fisher Sanitary Regulators Features:

• FDA and USP Class VI approved elastomers

• Exclusively designed for clean / sterile environments

• Suitable for clean-in-place (CIP) and sanitize-in-place (SIP)

systems

• Suitable for water-for-injection (WFI) systems

• Self-draining design

• Tri-Clamp® end connections (various DIN and ISO

connections upon request)

• Polyetheretherketone (PEEK) soft seat option for ANSI Class

VI shutoff at temperatures up to 400°F / 204°C

www.fi sherregulators.com

Each Fisher Sanitary Regulator has a 316L stainless steel

body, wetted metal parts, and a 316 stainless steel spring

case. All wetted surfaces are mechanically polished to a 20

Ra Microinch finish (standard) and then electropolished.

Diaphragms are available in 316L stainless steel, Fluorocarbon

(FKM) with a Polytetrafluoroethylene (PTFE) coating, or

Ethylenepropylene (EPDM). Metal or soft seats are available.

The traditional quality and robust construction of Fisher

products help enhance the purity of plant products and

environment by extending the useful life of equipment and

increase the integrity of process control systems.

Designed to meet 3A®, ASME BPE,

and European Hygienic Equipment Design Group Criteria.

Page 2

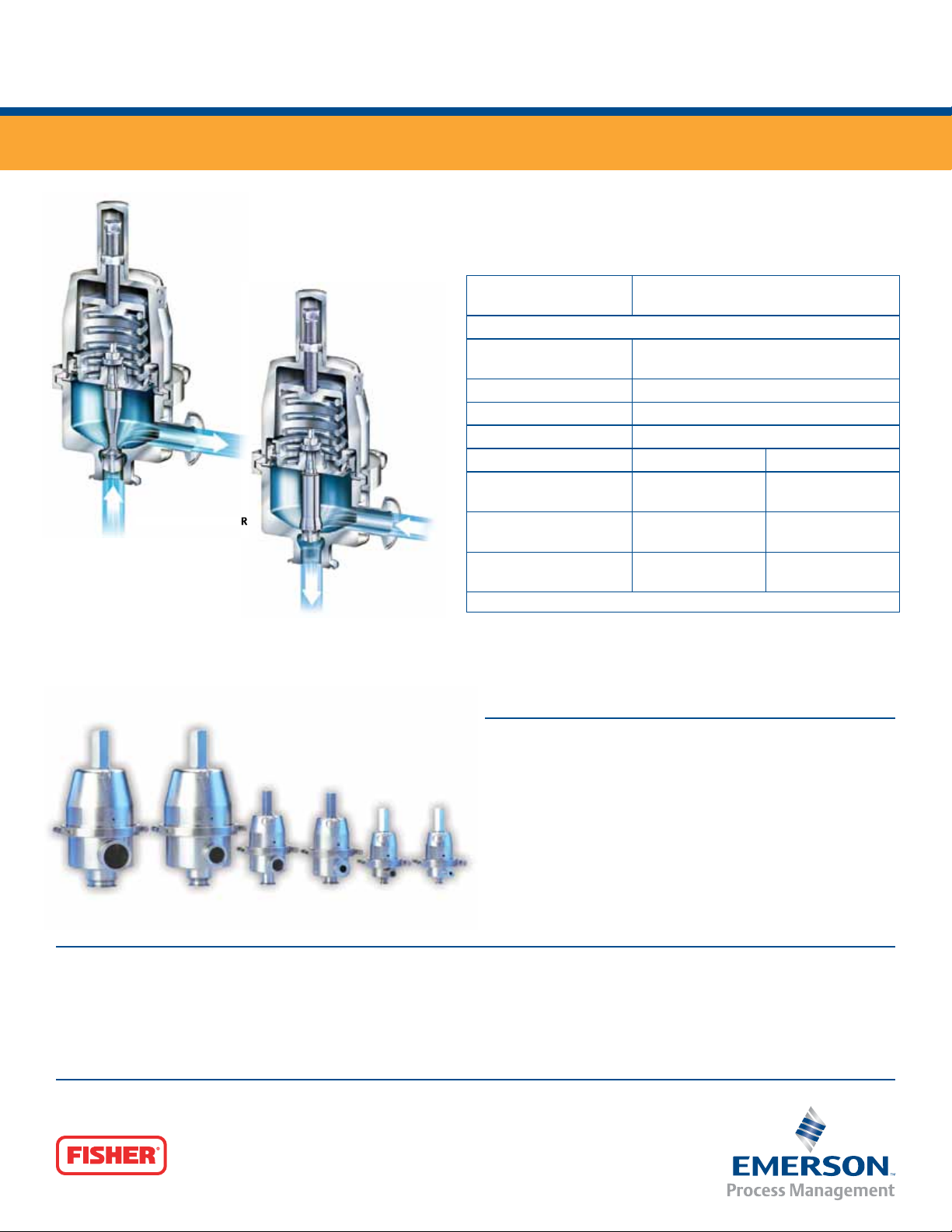

Types SR5 & SR8 Specifications

Precise Sanitary Environment Pressure Control

TYPE SR5 PRESSURE

REDUCING REGULATOR

TYPE SR8 PRESSURE

REDUCING REGULATOR

Six Port Sizes

Available

Body Sizes and End

Connection Style

Body, wetted metal parts

Spring case 316 Stainless steel

Diaphragm 316L SST, FKM/PTFE, EPDM

Seat Metal or soft seat (PTFE or PEEK)

Spring Ranges Type SR5 Type SR8

NPS 1/2 to 1 / DN 15 to 25

NPS 1-1/2 / DN 40

NPS 2 and 3 / DN 50 and 80

* Available in various DIN IS Connections upon request

Superior Service and Support

NPS 1/2, 3/4, 1, 1-1/2, 2 and 3 / DN 15,

20, 25, 40, 50, and 80 Tri-Clamp® fittings*

Materials

316L Stainless steel with 20 Ra mechanical

finish and electropolish (10 Ra optional)

2 to135 psig /

0,14 to 9,3 bar

5 to 100 psig /

0,35 to 6,9 bar

10 to 75 psig /

0,69 to 5,2 bar

2 to 125 psig /

0,14 to 8,6 bar

2 to 125 psig /

0,14 to 8,6 bar

10 to 60 psig /

0,69 to 4,1 bar

With the most complete line of regulators in the industry,

Emerson worldwide distribution network includes an

experienced sales and support team consisting of more

than 2,000 technical experts available to serve you from

nearly 200 offices throughout the world. No other supplier

can equal Emerson’s product integrity, reliability, safety,

and performance. Call your local Sales Office for additional

information.

Emerson Process Management Regulator Technologies, Inc.

Americas - Worldwide Headquarters

310 East University Drive

McKinney, Texas 75069-1872 USA

T: +1 800 558 5853

T: +1 972 548 3574

F: +1 972 542 6433

www.emersonprocess.com/regulators

D350921X012 © 2011 Emerson Process Management Regulator Technologies, Inc.; All Rights Reserved. Printed in the U.S.A. 10/11.

Fisher, Emerson Process Management, and the Emerson Process Management design are marks of one of the Emerson Process Management

group of companies. All other marks are the propert y of their respective owners.

Europe

T: +39 051 4190606

Asia Pacific

T: +65 6770 8337

Middle East

T: +971 4811 8100

Loading...

Loading...