Page 1

Choice for Sanitary

Fisher Types

NOW AVAILABLE

• Polyetheretherketone (PEEK) soft seat option

for ANSI Class VI shutoff at temperatures up

to 400°F / 204°C

• Expanded spring ranges on smaller sizes of

Type SR8 models NPS 1/2 to 1-1/2 / DN 15 to

40 allowing setpoints up to125 psi / 8,6 bar

SR5

SR8

Other Options

• Pressure loaded spring case design permits

varying setpoints from a remote location

• Barstock machined version of the 316 Stainless

steel spring case for aesthetics

• 10 Ra fi nish (optional) on wetted surfaces

• Vacuum protection option including a

lower diaphragm support to protect against

vacuum conditions

• Gauge port in body

• T-Handle adjusting screw

• Various DIN and ISO end connections

Emerson Process Management

Regulator Technologies, Inc.

Americas

Worldwide Headquarters

310 East University Drive

McKinney, Texas 75069-1872 USA

T: +1 800 558 5853

T: +1 972 548 3574

F: +1 972 542 6433

TESCOM Corporation

12616 Industrial Boulevard

Elk River, Minnesota 55330-2445 USA

T: +1 800 447 1250

T: +1 763 241 3238

F: +1 763 241 3224

For further information visit www.emersonprocess.com/regulators

Emerson Process Management

Regulator Technologies, Inc.

Europe

Natural Gas : T: +39 051 4190611

Industrial: T: +39 051 4190606

LP-Gas: T: +420 2 710 35 607

TESCOM: T: +49 (0) 38823 31 0

Emerson Process Management

Regulator Technologies, Inc.

Asia Pacific

T: +65 6770 8337

Middle East

T: +971 4811 8100

NPS 1/2 and 3/4 /

DN 15 and 20

Six Body Sizes

NPS 1 and 1-1/2 /

DN 25 and 40

Available

The Clean, Clear

Process Control

D350923X012 © 2011 Emerson Process Management Regulator Technologies, Inc. All rights reserved. Printed in the U.S.A. 10/11.

Fisher, Emerson Process Management, and the Emerson Process Management design are marks of one of the Emerson Process

Management group of companies. All other marks are the property of their respective owners.

NPS 2 and 3 /

DN 50 and 80

EMERSON. CONSIDER IT SOLVED.

Page 2

Engineered for precise pressure

Fisher Types

control in a sanitary environment.

Fisher® Type SR5 Sanitary Pressure Reducing

Regulator and Type SR8 Sanitary Backpressure

Regulator are designed for applications in

pharmaceutical, biotechnology, food and beverage,

consumer products, cosmetics, chemical, and

other industries – where sanitary process control is

SR5

SR8

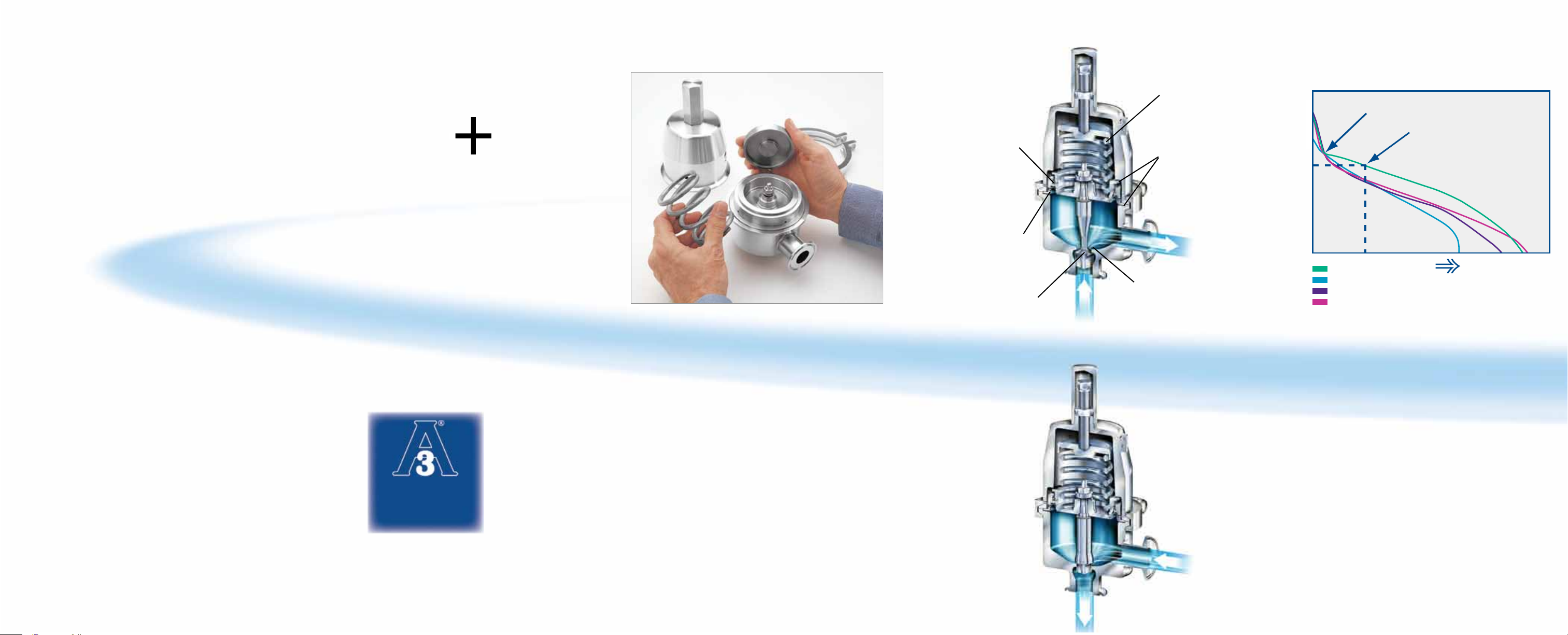

Type SR5 Pressure Reducing

Wide

control

range

Guiding to

improve

stability

Metal-to-metal

stops to protect

diaphragm

Sanitary Regulator

Performance Comparison

30.0

Setpoint

25.0

10% Offset

20.0

15.0

required for steam, gases, and liquids.

Fisher Sanitary Regulators Features:

• FDA and USP Class VI approved elastomers

• Designed exclusively for use in clean/

sterile environments

• Superior fl ow performance and accuracy

• Available in sizes NPS 1/2, 3/4, 1, 1-1/2, 2,

and 3 / DN 15, 20, 25, 40, 50, and 80

• Suitable for clean-in-place (CIP) and

sanitize-in-place (SIP) systems

• Suitable for water-for-injection (WFI) and

clean steam systems

• Self-draining design

• Tri-Clamp

®

end connections

The Clean, Clear

Choice for Sanitary

Process Control

Designed to meet 3A®,

ASME BPE, and European

Hygienic Equipment

Design Group Criteria.

Construction materials enhance purity of

plant products and environment.

Each Fisher Sanitary Regulator has a 316L Stainless

steel body, wetted metal trim parts and a

316 Stainless steel spring case. The wetted surfaces

are mechanically polished to a 20 Ra Microinch fi nish

(standard) and then electropolished. Diaphragms are

available in 316L Stainless steel, Fluorocarbon (FKM)

with a Polytetrafl uoroethylene (PTFE) coating or

Ethylenepropylene (EPDM). Metal or soft seats

Molded

diaphragm

to improve

accuracy

Hard or soft

seats available

Type SR8 Backpressure

Self-draining

The Fisher Type SR8

Sanitary Regulator

has the same superior

construction and

features as the Type SR5

but functions as a

backpressure regulator.

Outlet Pressure

10.0

psig

5.0

Fisher Type SR5

Competitor 1

Competitor 2

Competitor 3

Increasing

Flow

Superior flow performance

and accuracy.

To evaluate the performance of a regulator,

compare the stated capacities at equivalent

operating pressures and offset factors. The

Type SR5 is designed to deliver high fl ows with

minimal offset to maintain an even pressure

over the full range of fl ow. In addition, the

large turndown ratio eliminates the need for

are available.

reduced fl ow (Cv) trims.

Loading...

Loading...