Emerson SP3201, SP2203, SP2202, SP3202, SP4202 Installation Manual

...

Installation Guide

U

Regen

200V, 400V, 575V, 690V

Part Number: 0471-0029-02

Issue: 2

www.controltechniques.com

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy

of continuous development and improvement, the manufacturer reserves the right to change the specification of the

product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is supplied with the latest version of software. If this product is to be used in a new or existing system with

other drives, there may be some differences between their software and the software in this product. These differences

may cause this product to function differently. This may also apply to drives returned from a Control Techniques Service

Centre.

The software version of the drive can be checked by looking at Pr 11.29 (or Pr 0.50) and Pr 11.34. The software version

takes the form of zz.yy.xx, where Pr 11.29 displays zz.yy and Pr 11.34 displays xx, i.e. for software version 01.01.00,

Pr 11.29 would display 1.01 and Pr 11.34 would display 0.

If there is any doubt, contact a Control Techniques Drive Centre.

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is

certified to the International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save energy and

(through increased machine/process efficiency) reduce raw material consumption and scrap throughout their long

working lifetime. In typical applications, these positive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they can very easily be dismantled into their

major component parts for efficient recycling. Many parts snap together and can be separated without the use of tools,

while other parts are secured with conventional screws. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller

products come in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these

containers can be recycled. Polythene, used on the protective film and bags for wrapping product, can be recycled in the

same way. Control Techniques' packaging strategy favours easily-recyclable materials of low environmental impact, and

regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

Copyright © February 2007 Control Techniques Drives Limited

Issue Number: 2

Software: 01.07.01 onwards

How to use this guide

System design

Programming

and

commissioning

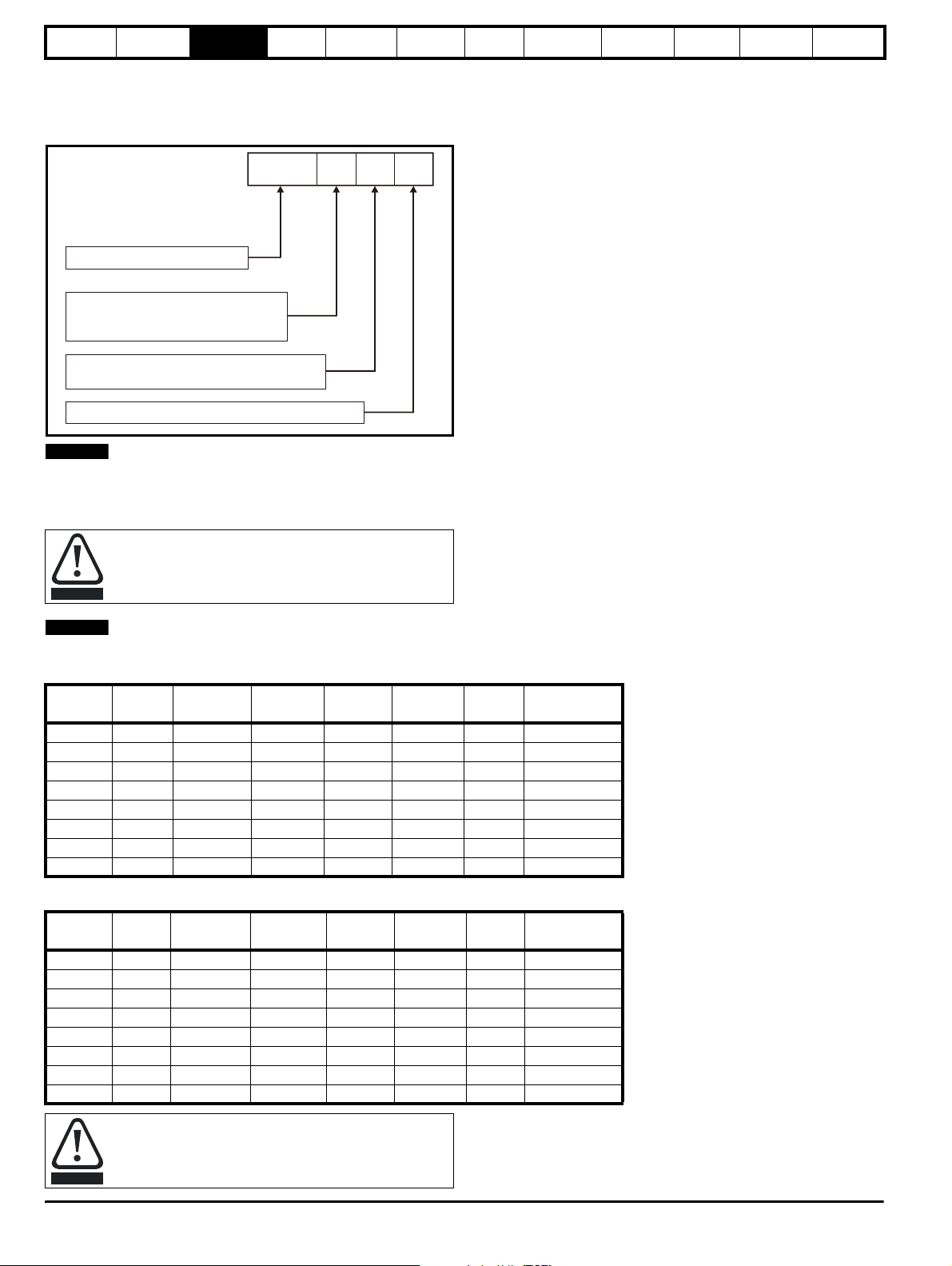

This user guide provides complete information for installing and operating a Unidrive SP from start to finish.

The information is in logical order, taking the reader from receiving the drive through to fine tuning the performance.

NOTE

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

Information contains general safety information. It is essential that the warnings are observed and the information

considered when working with or designing a system using the drive.

This guide should be read in-line with the relevant User Guide also, which contains additional information which may be

required whilst designing and commissioning a regen system.

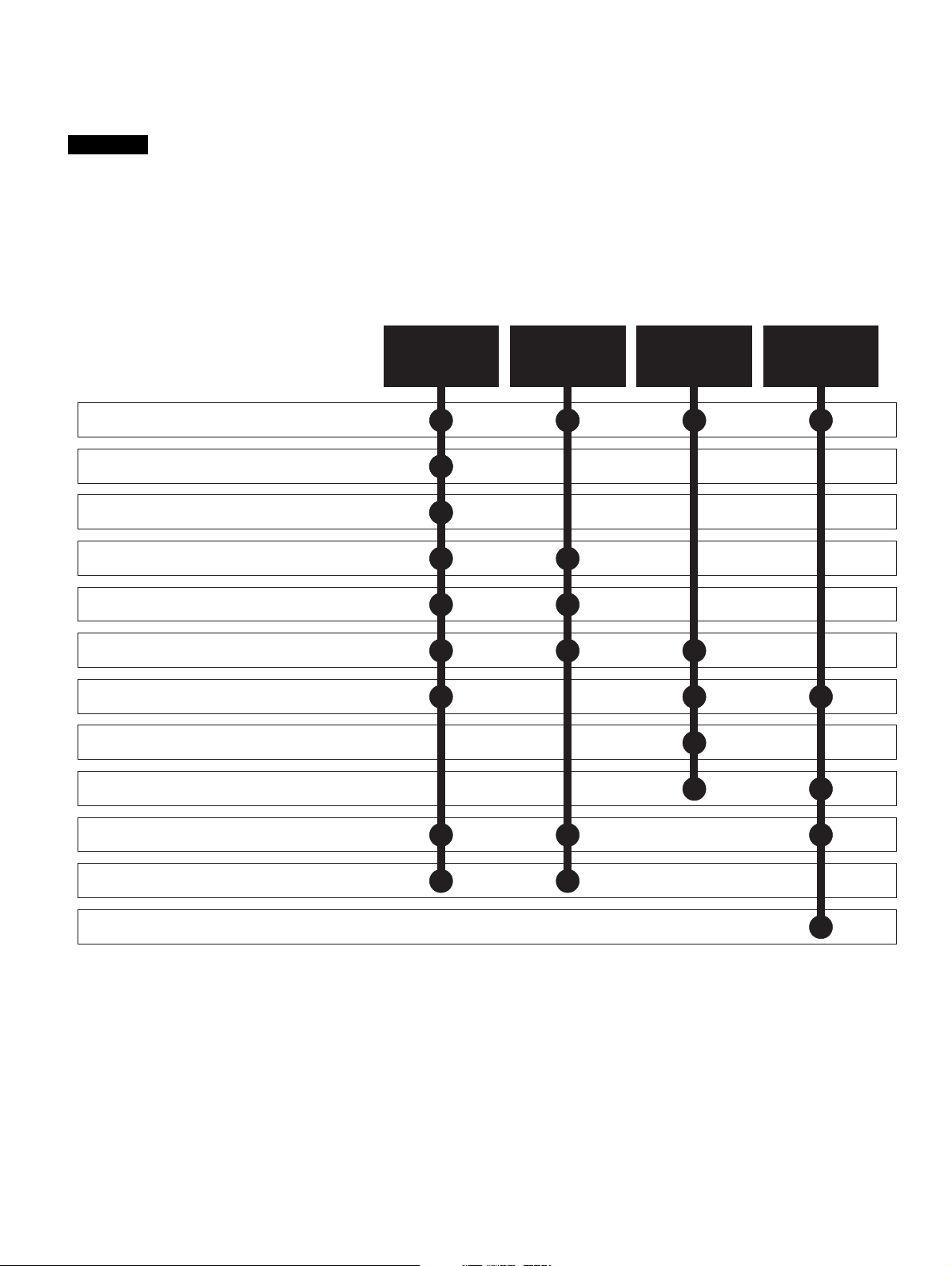

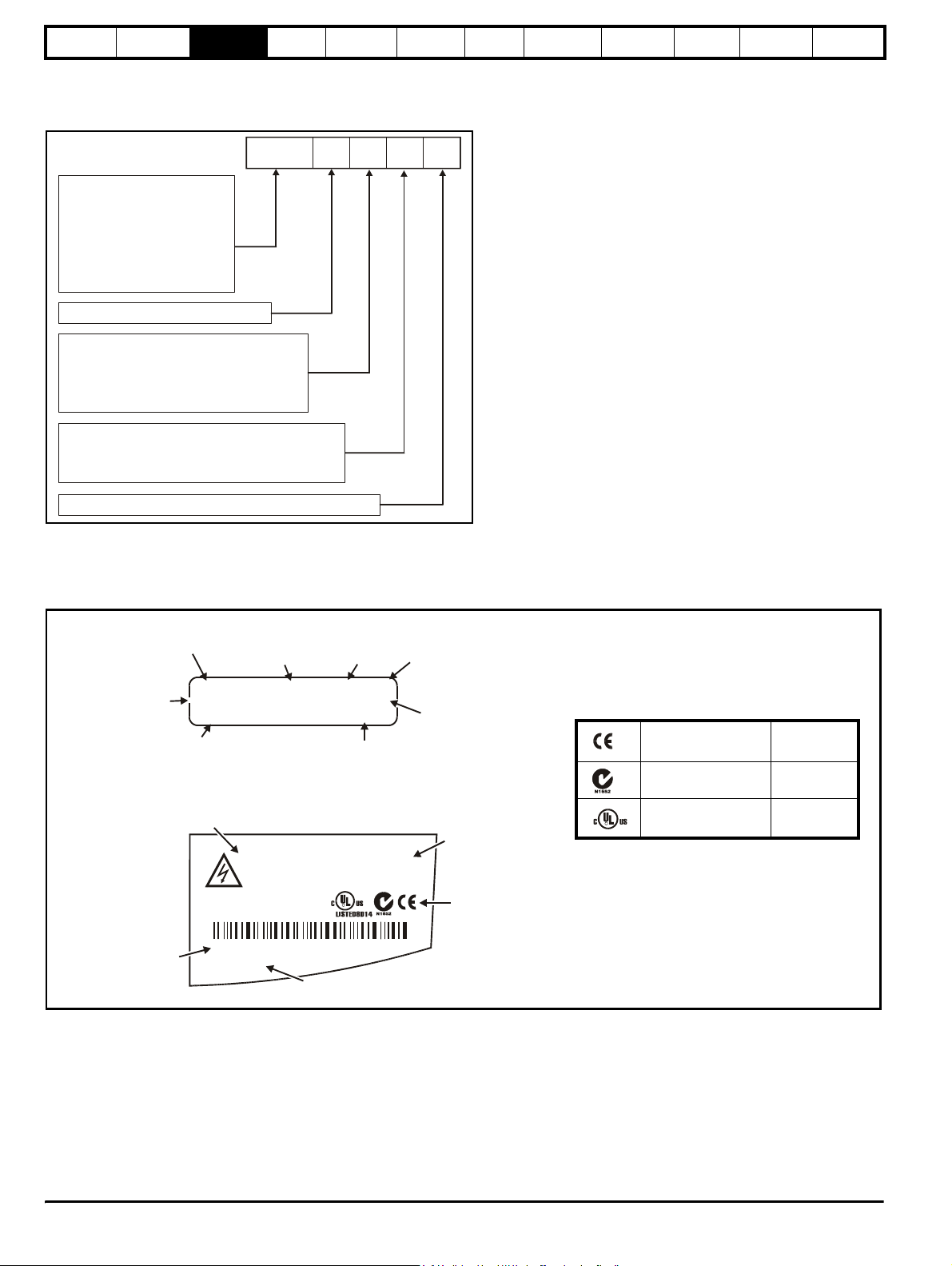

This map of the user guide helps to find the right sections for the task you wish to complete:

1 Safety information

2 Introduction

3 Product information

4 System design

5 Mechanical Installation

6 Electrical installation

7 Getting started

8 Optimisation

9 Parameters

Familiarisation System design

commissioning

Programming

and

Troubleshooting

10 Technical data

11 Component sizing calculations

12 Diagnostics

Contents

1 Safety Information .................................6

1.1 Warnings, Cautions and Notes .............................6

1.2 Electrical safety - general warning ........................6

1.3 System design and safety of personnel ................6

1.4 Environmental limits ..............................................6

1.5 Compliance with regulations .................................6

1.6 Special note on SECURE DISABLE/ENABLE

function in regen operation ....................................6

1.7 Adjusting parameters ............................................6

2 Introduction ............................................7

2.1 Regen operation ....................................................7

2.2 Advantages of Unidrive SP operating in regen

mode .....................................................................7

2.3 Principles of operation ...........................................7

2.4 Power flow .............................................................8

2.5 Synchronisation .....................................................8

2.6 Current trimming ...................................................8

2.7 Regen system configurations ................................8

2.8 Regen drive system types .....................................9

3 Product Information ............................12

3.1 Model number .....................................................12

3.2 Nameplate description ........................................12

3.3 Ratings ................................................................13

3.4 Drive features ......................................................17

3.5 Unidrive SPMC half controlled thyristor rectifier ..19

3.6 Unidrive SPMC/U technical data .........................20

3.7 Output Sharing Chokes (for motoring drives

only) ....................................................................22

3.8 Options ................................................................23

3.9 Items supplied with the drive ...............................25

3.10 Regen components .............................................25

4 System design .....................................30

4.1 Introduction .........................................................30

4.2 Power connections ..............................................30

4.3 Non standard applications ...................................40

4.4 Cable length restrictions ......................................40

4.5 Cable types and lengths ......................................42

4.6 Exceeding maximum cable length ......................42

5 Mechanical Installation .......................45

5.1 Safety information ...............................................45

5.2 Planning the installation ......................................45

5.3 Regen component dimensions ............................46

5.4 External EMC filter .............................................55

5.5 Enclosure ............................................................62

5.6 Cubicle design and drive ambient temperature ...64

6 Electrical Installation .......................... 65

6.1 Power connections ............................................. 66

6.2 AC supplies ........................................................ 74

6.3 Cable and fuse ratings ....................................... 75

6.4 EMC (Electromagnetic compatibility) ................. 77

6.5 External EMC filter ............................................. 78

6.6 Control connections ........................................... 83

7 Getting started .................................... 86

7.1 Regen parameter settings .................................. 86

7.2 Regen drive sequencing .................................... 86

7.3 Regen drive commissioning ............................... 87

7.4 Motoring drive commissioning ............................ 88

8 Optimisation ........................................ 89

8.1 Power feed-forward compensation (Pr 3.10) ..... 89

8.2 Current loop gains .............................................. 89

8.3 Voltage controller gain (Pr 3.06) ........................ 90

8.4 Power factor correction (Pr 4.08) ....................... 91

8.5 Current trimming ................................................ 91

9 Parameters .......................................... 92

9.1 Parameter ranges and variable maximums: ...... 92

9.2 Menu 0: Basic parameters ................................. 93

9.3 Menu 3: Regen sequencer ................................. 94

9.4 Menu 4: Current control ................................... 100

9.5 Menu 5: Regen control ..................................... 107

9.6 Menu 6: Clock .................................................. 111

9.7 Menu 7: Analogue I/O ...................................... 119

9.8 Menu 8: Digital I/O ........................................... 132

9.9 Menu 9: Programmable logic, motorised pot

and binary sum ................................................. 138

9.10 Menu 10: Status and trips ................................ 146

9.11 Menu 11: General drive set-up ......................... 154

9.12 Menu 12: Threshold detectors and variable

selectors ........................................................... 165

9.13 Menu 14: User PID controller ........................... 172

9.14 Menus 15, 16 and 17: Solutions Module set-up 178

9.15 Menu 18: Application menu 1 ........................... 179

9.16 Menu 19: Application menu 2 ........................... 180

9.17 Menu 20: Application menu 3 ........................... 181

9.18 Menu 22: Additional menu 0 set-up ................. 182

10 Technical data ................................... 183

10.1 Drive ................................................................. 183

10.2 Supply requirements ........................................ 191

10.3 Protection ......................................................... 192

10.4 Component data ............................................... 196

10.5 Optional external EMC filters ........................... 199

11 Component sizing ............................. 203

11.1 Sizing of MCB for switching frequency filter ..... 203

11.2 Resistor sizing for multiple drive systems ........ 204

11.3 Thermal / magnetic overload protection for soft

start circuit ........................................................ 204

4 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

12 Diagnostics ........................................206

12.1 Trip indications ..................................................206

12.2 Alarm indications ...............................................215

12.3 Status indications ..............................................215

12.4 Displaying the trip history ..................................215

Unid rive SP Regen Insta llation G uide 5

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

1 Safety Information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

WARNING

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

CAUTION

NOTE

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this guide.

1.3 System design and safety of

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

design to avoid hazards either in normal operation or in the event of

equipment malfunction. System design, installation, commissioning and

maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this

guide carefully.

The STOP and SECURE DISABLE functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit. The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical connections.

None of the drive functions must be used to ensure safety of

personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended behaviour or

through incorrect operation due to a fault. In any application where a

malfunction of the drive or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

personnel

Getting

started

of fuses or other protection, and protective earth (ground) connections.

This guide contains instruction for achieving compliance with specific

EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

Optimisation Parameters

98/37/EC: Safety of machinery.

89/336/EEC: Electromagnetic Compatibility.

Technical

data

Component

sizing

Diagnostics

1.6 Special note on SECURE DISABLE/

ENABLE function in regen operation

In regen operation the enable input of the Regen drive stage has no

safety functions. It only enables the active rectifier operation. It does not

disable any operation of the motoring drive(s) and it does not prevent the

regen stage from producing DC power.

The enable input of the motoring drive stage can be used for safety

functions if required. Consult the Unidrive SP User Guide for information

on SECURE DISABLE.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

1.4 Environmental limits

Instructions in this guide regarding transport, storage, installation and

use of the drive must be complied with, including the specified

environmental limits. Drives must not be subjected to excessive physical

force.

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

6 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

2 Introduction

The following installation guide should be read in conjunction with the

Unidrive SP User Guide.

Any Unidrive SP drive can be configured as an AC Regenerative Unit

(hereafter referred to as a Regen drive).

This guide covers the following:

• Principles and advantages of operation in regen mode

• Safety information

• EMC information

• Detailed information on additional components required

• System design

• Special considerations

• Installation

• Commissioning and optimisation of the completed system

At least two Unidrive SP drives are required to form a complete

regenerative system - one connected to the supply and the second one

connected to the motor. A Unidrive SP in regen mode converts the AC

mains supply to a controlled DC voltage, which is then fed into another

drive(s) to control a motor(s).

NOTE

The motoring drive(s) in a regen configuration could be another drive

other than a Unidrive SP, e.g. Unidrive classic or Commander SK etc.

NOTE

The following regen components are also required in addition to the

Unidrive SP drives.

1. Regen inductor

2. Switching frequency filter inductor

3. Switching frequency filter capacitor

4. Softstart resistor

5. Varistors

6. MCBs

7. Overload relays

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

• Transient operation is possible between 40 and 72Hz down to the

above supply voltage levels for approximately 1 second.

• The Regen and motoring drives are identical (when using Unidrive

SP).

• Power feed-forward term available, using analogue I/O set-up

• A fast transient response is possible using the power feed forward

term.

2.3 Principles of operation

The input stage of a non-regenerative AC drive is usually an

uncontrolled diode rectifier, therefore power cannot be fed back onto the

AC mains supply. By replacing the diode input rectifier with a voltage

source PWM input converter (Unidrive SP), AC supply power flow can

be bi-directional with full control over the input current waveform and

power factor. Currents can now be controlled to give near unity power

factor and a low level of line frequency harmonics.

In the case of a Unidrive SP operating in regenerative mode, the IGBT

stage is used as a sinusoidal rectifier converting the AC supply to a

controlled DC voltage.

Furthermore, by maintaining the DC bus voltage above the peak supply

voltage the load motor can be operated at a higher speed without field

weakening. Alternatively, the higher output voltage available can be

exploited by using a motor with a rated voltage higher than the AC mains

supply, thus reducing the current for a given power.

Regen inductors must be used to ensure a minimum source impedance,

these being selected and specified later in the guide.

The difference between the PWM line voltage and the supply voltage

occurs across the regen inductors at the Regen drive. This voltage has a

high frequency component, which is blocked by the regen inductor, and

a sinusoidal component at line frequency. As a result currents flowing in

these inductors are sinusoidal with a small high frequency ripple

component.

2.1 Regen operation

For use as a regenerative front end for four quadrant operation.

Regen operation allows bi-directional power flow to and from the AC

supply. This provides far greater efficiency levels in applications which

would otherwise dissipate large amounts of energy in the form of heat in

a braking resistor.

The harmonic content of the input current is negligible due to the

sinusoidal nature of the waveform when compared to a conventional

bridge rectifier or thyristor front end.

2.2 Advantages of Unidrive SP operating in regen mode

The main advantages of an AC Regen system are:

• Energy saving

• The input current waveform is sinusoidal

• The input current has a near unity power factor

• Power factor correction can be implemented using Pr 4.08

• The output voltage for the motor can be higher than the available AC

mains supply.

• The Regen drive will synchronise to any frequency between 30 and

100Hz, provided the supply voltage is within the supply requirements

(operating frequency range of 48Hz to 65Hz)

• Under conditions of AC mains instability, a Unidrive SP Regen

system can continue to operate down to approximately 75Vac (200V

product) 150Vac (400V product) 225Vac (575V and 690V product)

supply voltage without any effect on the DC bus voltage and hence

on the operation of the motoring drives (increased current will be

taken from the AC supply during this condition to compensate up to

the current limit of the Regen drive)

Unid rive SP Regen Insta llation G uide 7

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

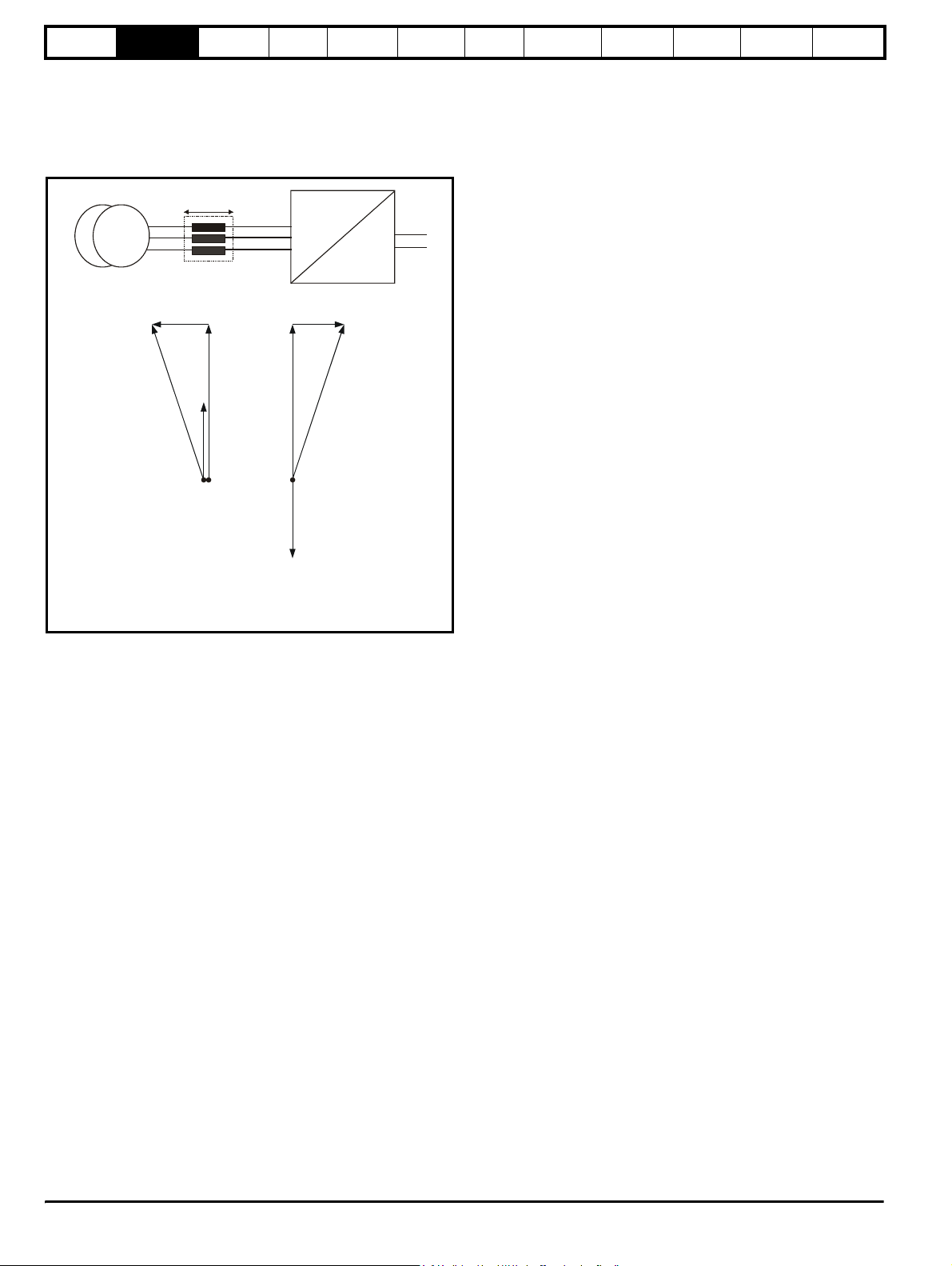

2.4 Power flow

The following phasor diagram illustrates the relationship between the

supply voltage and the Regen drive voltage. The angle between the two

voltage vectors is approximately 5° at full load, this results in a near unity

power factor of 0.996.

Figure 2-1

AC

U

V

W

+DC

-DC

DC

VAC

JLIrω

V

s

V

r

I

r

Supply

jLIrω

V

V

s

r

I

r

Power flow

from supply

V

Supply voltage

s

V Voltage at line terminals of Regen drive

r

j LI Voltage across Regen inductor

ω

r

I Current at line terminals of Regen drive

r

jLIrω

V

r

Power flow

back to supply

I

r

V

s

The direction of the power flow can be changed relative to the supply

voltage, by making small changes to the Regen drives output voltage

and phase.

2.5 Synchronisation

The synchronisation of the Regen drive to the supply does not require

additional hardware. The space vector modulator within the Regen drive

represents the angle and magnitude of the AC supply at all times. This

however is not the case when the AC supply is first connected or when

the Regen drive is disabled.

Unless some form of synchronisation is carried out the current

controllers will start with values of zero resulting in zero volts being

applied to the inverter output terminals. The phase locked loop (PLL)

would also start with zero and so would not lock onto the supply.

To overcome these problems the following information must be obtained

before the Regen drive attempts to start:

1. The mains supply voltage vector magnitude

2. The angle of the supply voltage vector

3. The frequency of the supply

These values are obtained by carrying out a synchronisation on enable

• The first stage of the pre-start tests is to measure the initial DC Bus

voltage, which is assumed to be equal to the peak line-to-line

voltage of the supply.

• The second stage of the pre-start test is to apply two short pulses of

zero volts at the converter input. These pulses must be short enough

so that the peak current is less than the over current trip level of the

converter. The time between the pulses must also be long enough

so that the current built up in the input inductors during the first pulse

has decayed to a low level before the second pulse is applied.

These are used to calculate the instantaneous angle of the supply

voltage vector during the first test pulse. The second test pulse is

Getting

started

Optimisation Parameters

Te ch n ic al

data

Component

sizing

Diagnostics

then applied at time Td later to allow the supply frequency to be

calculated.

At this stage the supply inductance is also calculated

• Once the synchronization is complete the phase locked loop (PLL) is

set-up. At this point the whole control system could be started and

should operate without any large transients.

• To improve the robustness of the start-up phase a further short test

pulse voltage vector, with the same magnitude and phase as the

estimated supply voltage vector is applied. This is to detect

measurement errors that could have occurred because of supply

distortion present during the pre-start tests.

2.6 Current trimming

A current feedback trimming routine runs before the drive is enabled to

minimise offsets in the current feedback. This feature can be user

configured, for more details refer to section 8.5 Current trimming on

page 91.

2.7 Regen system configurations

The Regen drive has been designed to provide a regulated DC supply to

other motoring drives. The Regen drive gives bi-directional power flow

with sinusoidal currents and a near unity power factor.

Following are the possible configurations for Unidrive SP Regen:

• Single Regen, single or multiple motoring (Figure 4-1 on page 32)

• Single Regen, multiple motoring using a Unidrive SPMC (Figure 42 on page 34)

• Single Regen, multiple motoring using an external charging resistor

(Figure 4-3 on page 36)

• Multiple Regen, multiple motoring using a Unidrive SPMC (Figure 44 on page 38)

Refer to Table 3-2 on page 14, for the Regen drive ratings.

The sizing of a regen system must take into account the following

factors:

• Line voltage

• Motor rated current, rated voltage and power factor

• Maximum load power and overload conditions

In general, when designing a regen system, equal Regen and motoring

drive rated currents will work correctly. However, care must be taken to

ensure that under worst case supply conditions the Regen drive is able

to supply or absorb all the required power. In multi-drive configurations,

the Regen drive must be of a sufficient size to supply the net peak power

demanded by the combined load of all the motoring drives and total

system losses.

If the Regen drive is unable to supply the full power required by the

motoring drive, the DC bus voltage will drop and in severe cases may

lose synchronisation with the mains and trip. If the Regen drive is unable

to regenerate the full power from the motoring drive on the DC bus, then

the Regen and motoring drive(s) will trip on over-voltage.

8 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

2.8 Regen drive system types

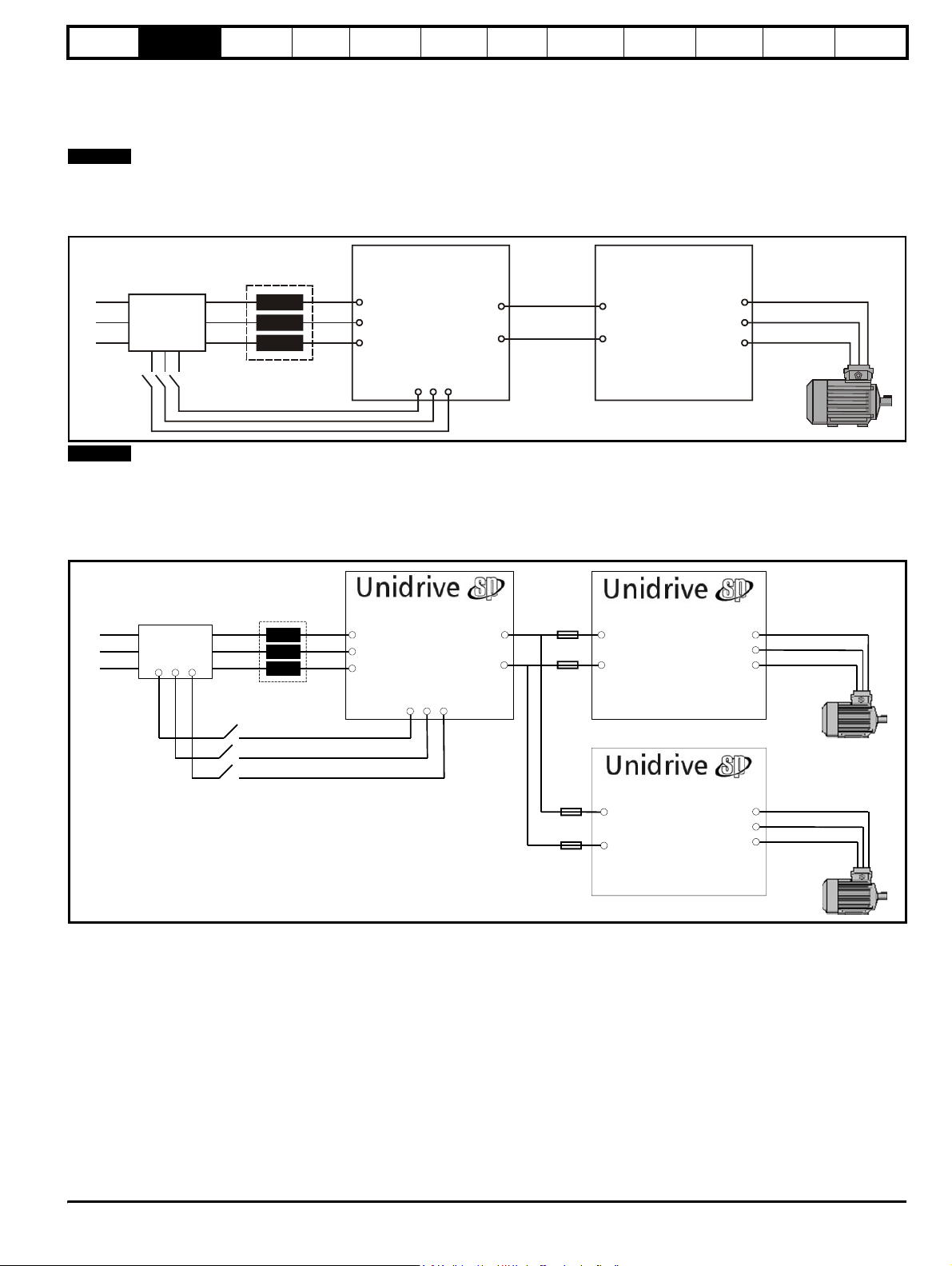

2.8.1 Single Regen, single motoring system

Figure 2-2 shows a typical layout for a standard regen system consisting of a single Regen drive and single motoring drive. In this configuration the

Regen drive is supplying the motoring drive and passing the regenerative energy back to the mains supply.

NOTE

The power up connections to L1, L2, L3 of the Regen drive are only made during power-up. Once both drives are powered up, this is switched out

and the main regen supply switched in. The auxiliary on the charging circuit to the Regen drive’s L1, L2, L3 connections for power up must be closed

(charging supply removed) before the Regen drive can be enabled.

Figure 2-2 Single Regen, single motoring system

Regen

inductor

L1

L2

Additional

circuitry

L3

U

Regen drive

U

AC supply

V

connection

W

L1

+DC

-DC

L2 L3

Common

DC bus

connections

U

Motoring drive

+DC

-DC

Motor

Connection

U

V

W

Power up only

NOTE

For the above single Regen, single motoring configuration; the Regen drive must be of the same frame size or larger.

2.8.2 Single Regen, multiple motoring system

Figure 2-4 shows the layout for a regen system consisting of a single Regen drive with multiple motoring drives. In this configuration the Regen drive

is sized to the total power of all motoring drives.

Figure 2-3 Single Regen, multiple motoring system

Regen

Inductor

L1

L2

L3

Additional

Circuitry

Regen Drive

U

AC Supply

V

Connection

W

L1

+DC

-DC

L2 L3

DC Bus

Connections

Motoring Drive

+DC

-DC

Connection

Motor

U

V

W

Power up only

Motoring Drive

+DC

Connection

-DC

Motor

U

V

W

It is also possible to have a single Regen drive powering multiple motoring drives as shown with the power up connections also being provided via the

Regen drives L1, L2, L3 inputs and using the Regen drives own internal softstart.

In this arrangement the total capacitance of the motoring drives must not exceed the capacitance of the Regen drive, in cases where this does please

contact Technical Support.

Unid rive SP Regen Insta llation G uide 9

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

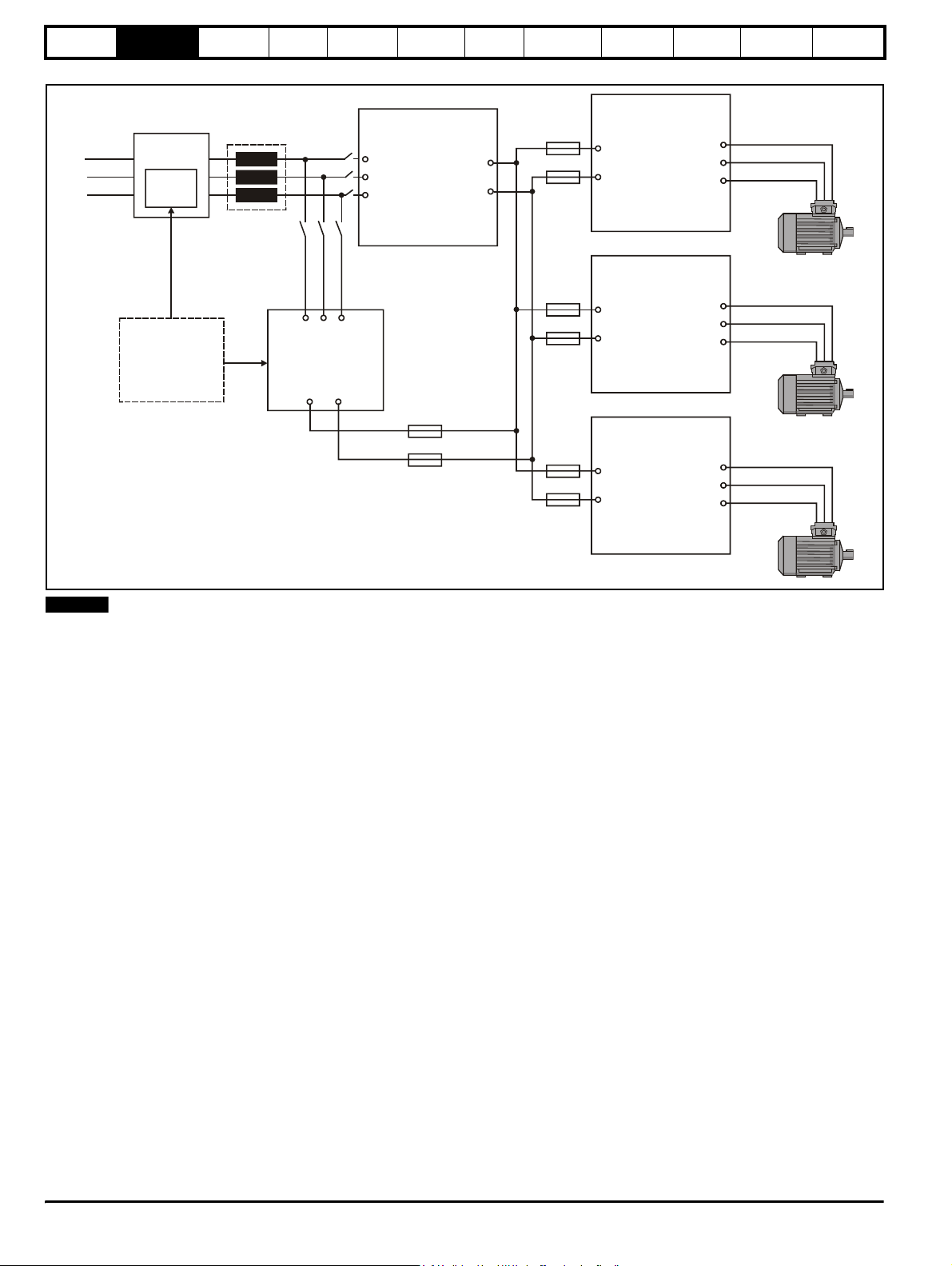

Figure 2-4 Single Regen, multiple motoring system

Electrical

installation

Getting

started

Optimisation Parameters

Te ch n ic al

data

Component

sizing

Diagnostics

Regen

Additional

L1

L2

L3

circuitry

External

charging

circuit

inductor

U

Regen drive

U

AC supply

V

connection

W

+DC

-DC

U

Motoring drive 1

+DC

-DC

connection

Motor

U

V

W

U

Motoring drive 2

Charging circuit can

consist of either

Unidrive SPMC

solution or external

charging circuit as

detailed in Chapter 4

System Design

L1 L2 L3

Unidrive

SPMC

+DC -DC

Common DC Bus

+DC

connection

-DC

connections

Motor

U

V

W

U

Motoring drive 3

+DC

connection

-DC

Motor

U

V

W

NOTE

For a single Regen and multiple motoring drive arrangement optional charging circuits can be used for the increased inrush current generated by the

additional capacitance of the multiple motoring drives. The charging circuit can consist of either a Unidrive SPMC rectifier module or an external

charging resistor as detailed in Chapter 4 System design

10 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

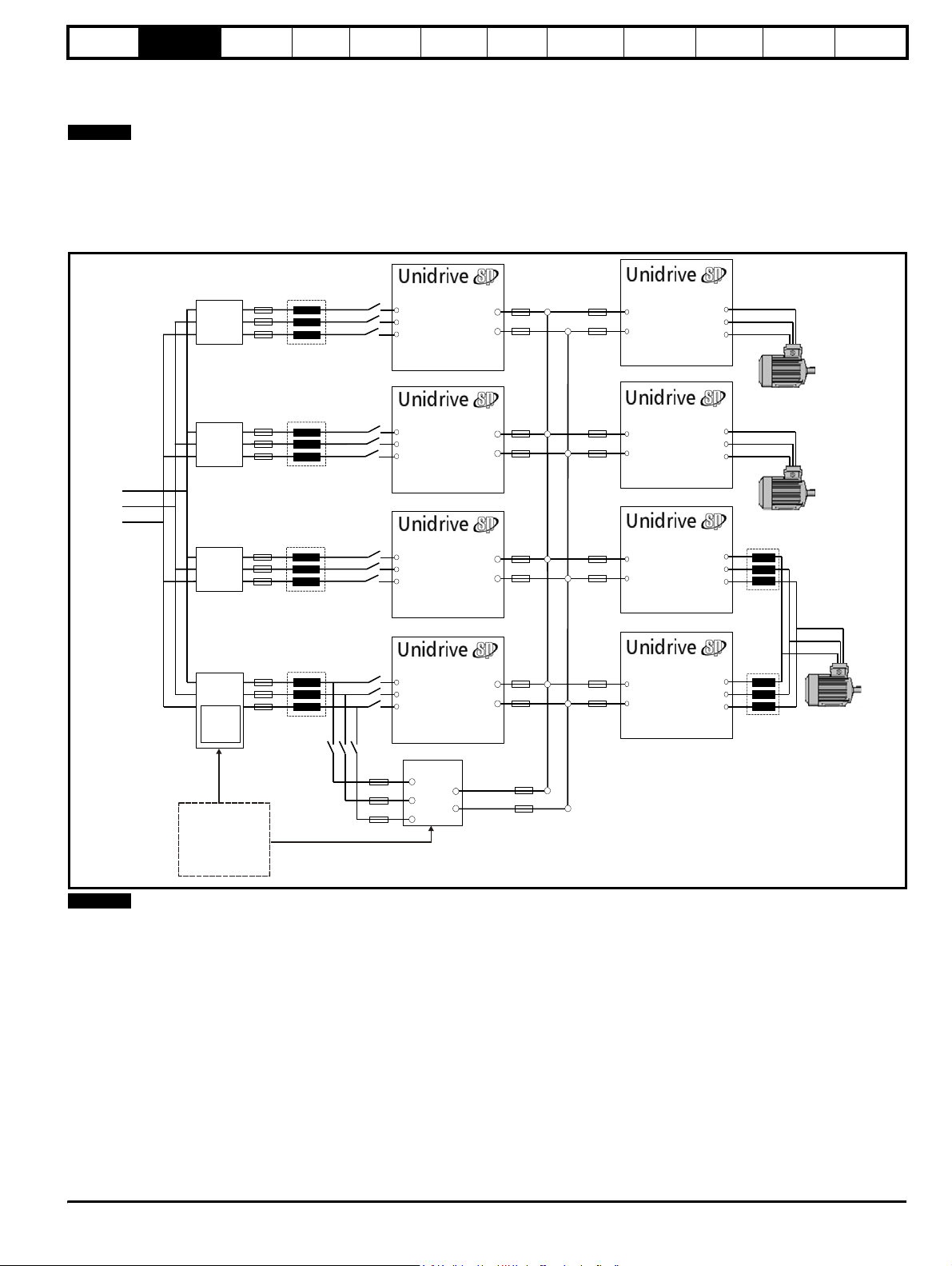

2.8.3 Multiple Regen, multiple motoring system

Figure 2-5 shows a multiple regen drive system with multiple motoring drives. For this configuration the regen drives are sized to the total power

requirement of all motoring drives.

NOTE

For the multiple regen and multiple motoring drives arrangement there are two possible options for the required start-up circuit. This can either consist

of a Unidrive SPMC rectifier module (for example an SPMC 1402 is capable of charging a maximum DC Bus capacitance of 66mF) or an external

charging resistor as detailed in Chapter 4 System design on page 30.

Special care should be taken when designing a multiple regen and multiple motoring drive system ensuring that all the required fusing is in place on

both the common DC Bus connections and the AC supply to all regen drives.

Figure 2-5 Multiple Regen, multiple motoring system

DC Bus

Additional

Circuitry

Regen Drive

U

V

W

+DC

-DC

Connections

Motoring Drive

Motor

Connection

U

V

W

+DC

-DC

Regen Drive

Additional

Circuitry

L1

L2

L3

Additional

Circuitry

Additional

Circuitry

External

charging

circuit

Charging circuit can

consist of either

Unidrive SPMC

solution or external

charging circuit

(Unidrive SPMC

recommended)

U

V

W

Regen Drive

U

V

W

Regen Drive

U

V

W

SPMC

L1

L2

L3

+DC

-DC

+DC

-DC

+DC

-DC

+DC

-DC

Motoring DriveMotoring Drive

+DC

-DC

Motor

Connection

U

V

W

Motoring DriveMotoring DriveMotoring DriveMotoring Drive

Motor

Connection

U

V

W

+DC

-DC

Motoring Drive

Motor

Connection

U

V

W

+DC

-DC

NOTE

All drives paralleled must be of the same frame size, and a derating also

applies as specified in Chapter 3 Product Information on page 12

Unidr ive SP Re gen Inst allatio n Guide 11

Issue Number: 2 www.controltechniques.com

Safety

/

date code

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

3 Product Information

3.1 Model number

The way in which the model numbers for the Unidrive SP range are formed is illustrated below.

Technical

data

Component

sizing

Diagnostics

Unidrive SP product line

SP:

Solutions platform

complete inverter drive

Power module power stages

SPMA:

for custom drive systems AC input

SPMD:

Power module power stages

for custom drive systems DC input

SP frame size

Voltage rating

0:

Voltage independent

2:

200V to 240V

4:

380V to 480V

5:

500V to 575V

6:

500V to 690V

Configuration

Wall mount

0:

Wall mount, no dynamic brake control

2:

Stand alone, no dynamic brake control

3:

Current rating step

SPX

1 4 0 1

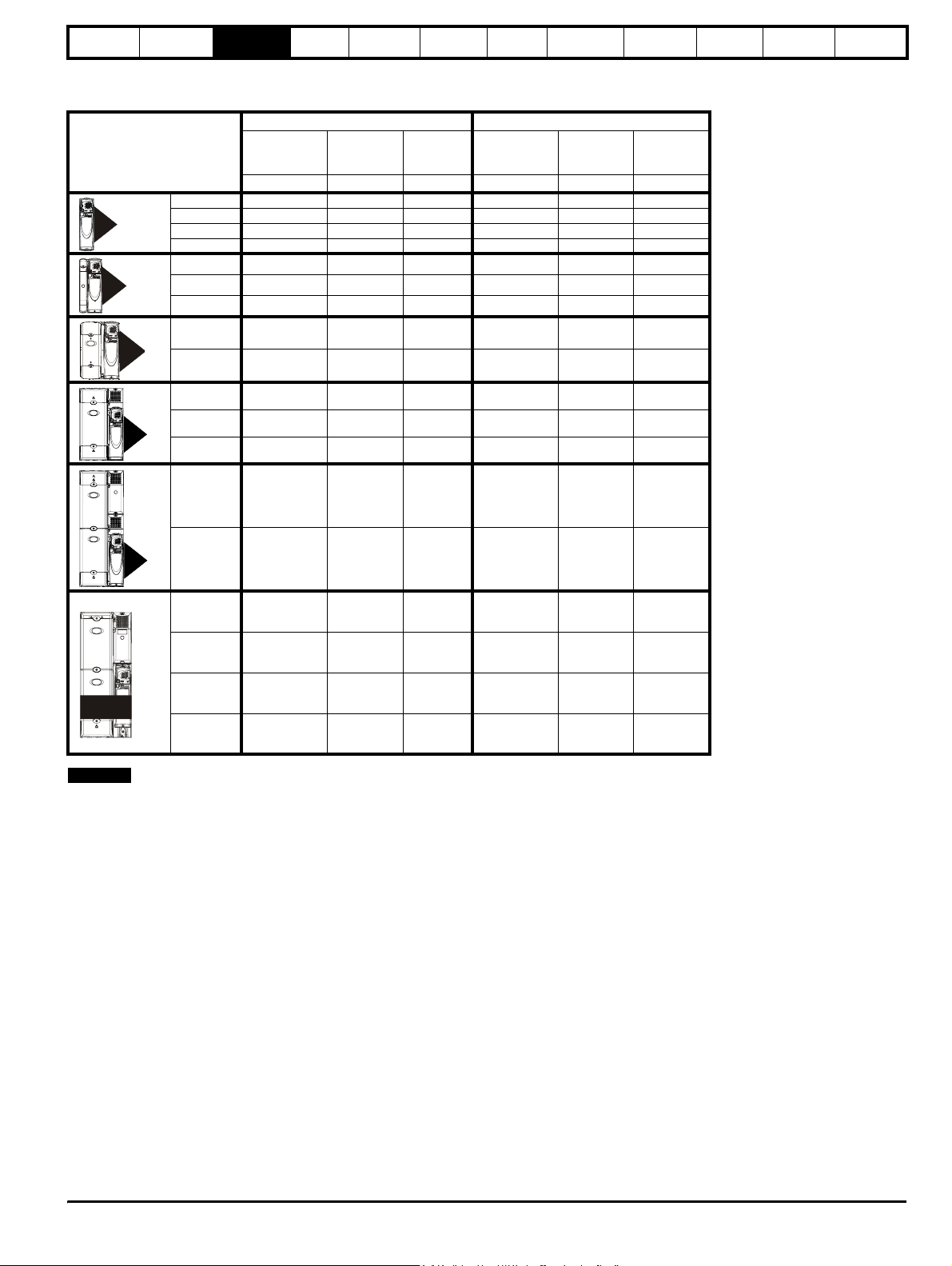

3.2 Nameplate description

See Figure 3-2 on page 17 for location of rating labels.

Figure 3-1 Typical drive rating labels

Rating label

Input voltage

rating

Model

Output voltage

range

Approvals label

I/P 200-240V 50-60Hz 3ph 6.6A

SP1201

O/P 0-240V 4.3 / 5.2A

Model

Please read manual before connecting.

Input

frequency

S.No:

3000005001

SP 1,5 TL

Heavy Duty / Normal Duty

rating output current

SP1201 0.75 / 1.1kW

Electric Shock Risk: Wait 10 min between

disconnecting supply & removing covers

SP 1,5 TL

IND.

CONT.

EQ.

No. of

phases

R

Typical input

current for

Normal Duty

rating

Serial

number

Heavy Duty

Normal Duty

power rating

Approvals

Key to approvals

CE approval Europe

C Tick approval Australia

UL / cUL approval

R

USA &

Canada

Serial

number

3000005001

STDL25

Made In U.K

Ser No:

Customer and

12 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

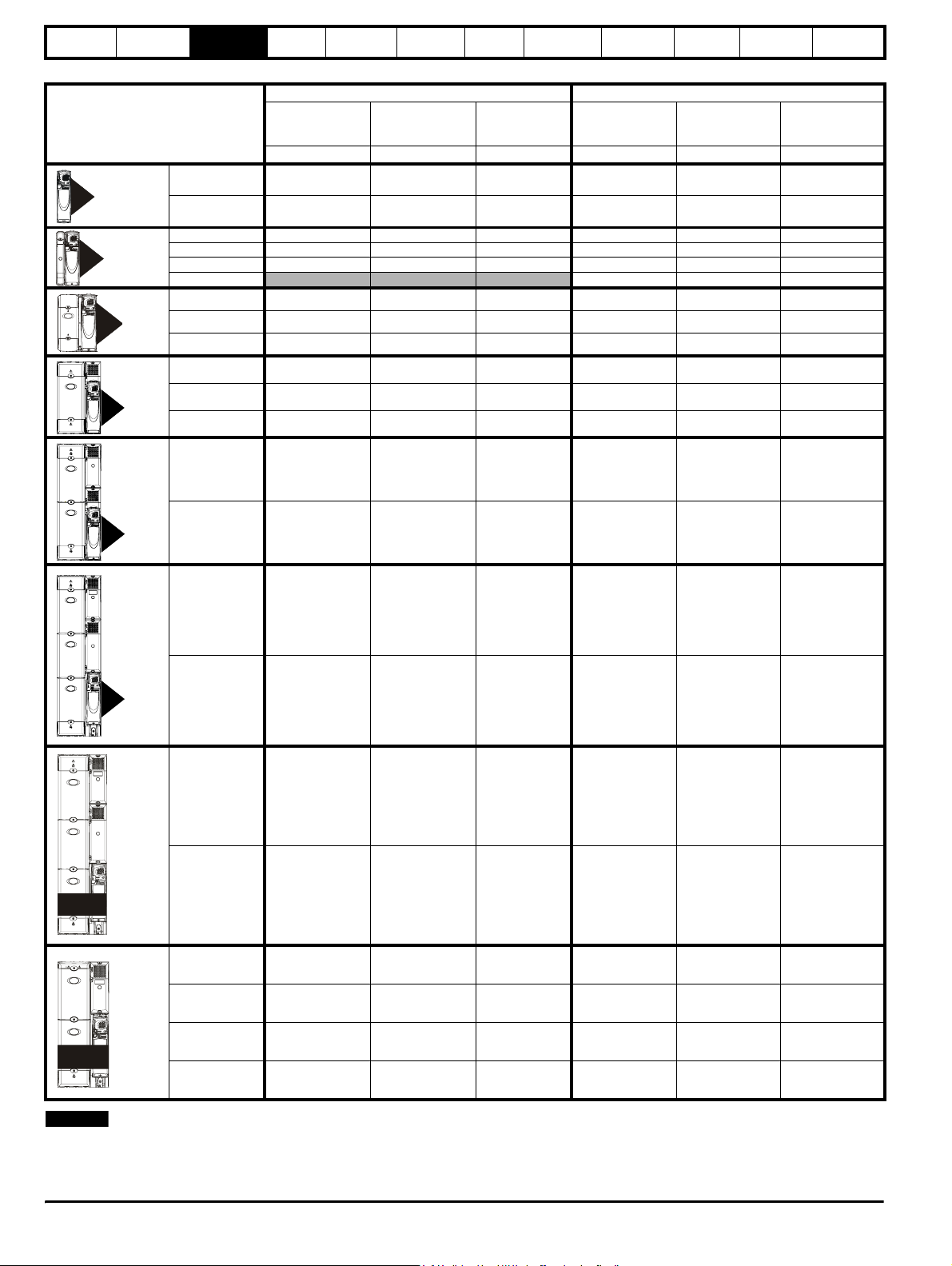

3.3 Ratings

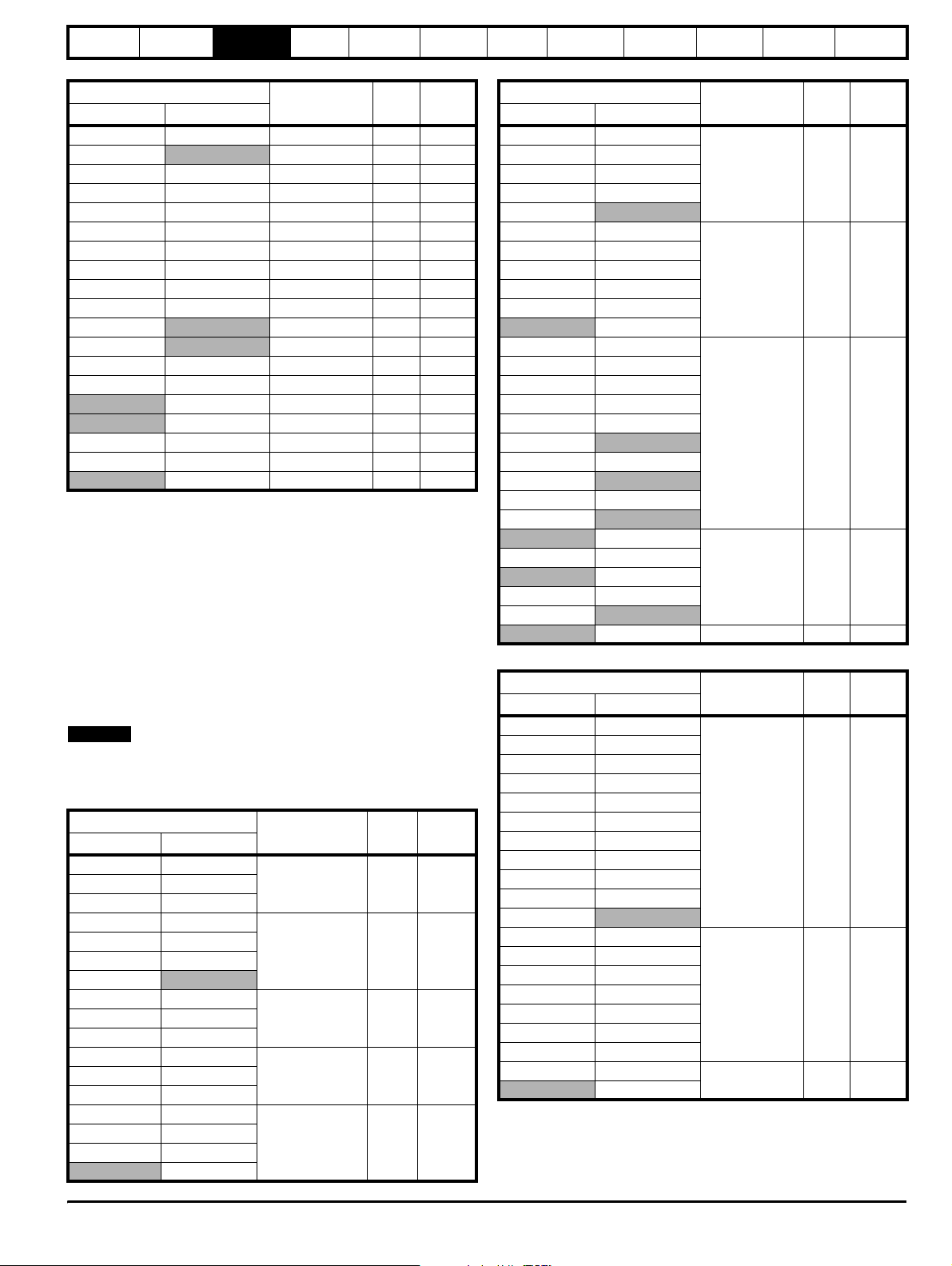

Table 3-1 200V Drive ratings (200V to 240V ±10%)

Normal Duty Heavy Duty

Model

1201 5.2 1.1 1.5 4.3 0.75 1.0

1

2

3

4

1202 6.8 1.5 2.0 5.8 1.1 1.5

1203 9.6 2.2 3.0 7.5 1.5 2.0

1204 11 3.0 3.0 10.6 2.2 3.0

2201 15.5 4.0 5.0 12.6 3.0 3.0

2202 22 5.5 7.5 17 4.0 5.0

2203 28 7.5 10 25 5.5 7.5

3201 42 11 15 31 7.5 10

3202 54 15 20 42 11 15

4201 68 18.5 25 56 15 20

4202 80 22 30 68 18.5 25

4203 104 30 40 80 22 30

5201 130 37 50 105 30 40

Maximum

continuous

output current

AkWhpAkWhp

Nominal

power

at 220V

Electrical

installation

Motor

power

at 230V

Getting

started

Maximum

continuous

output current

Optimisation Parameters

Nominal

power

at 220V

Motor

power

at 230V

Technical

data

Component

sizing

Diagnostics

55

5202 154 45 60 130 37 50

1201 192 55 175 156 45 60

1202 248 75 100 192 55 75

1203 312 90 125 250 75 100

SPMD

1204 350 110 150 290 90 125

NOTE

The above current ratings are given for max 40°C (104°F), and 3.0 kHz

switching. Derating is required for higher switching frequencies, ambient

temperature >40°C (104°F) and high altitude. For further information,

refer to both the Unidrive SP and SPM User Guides.

Unidr ive SP Re gen Inst allatio n Guide 13

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

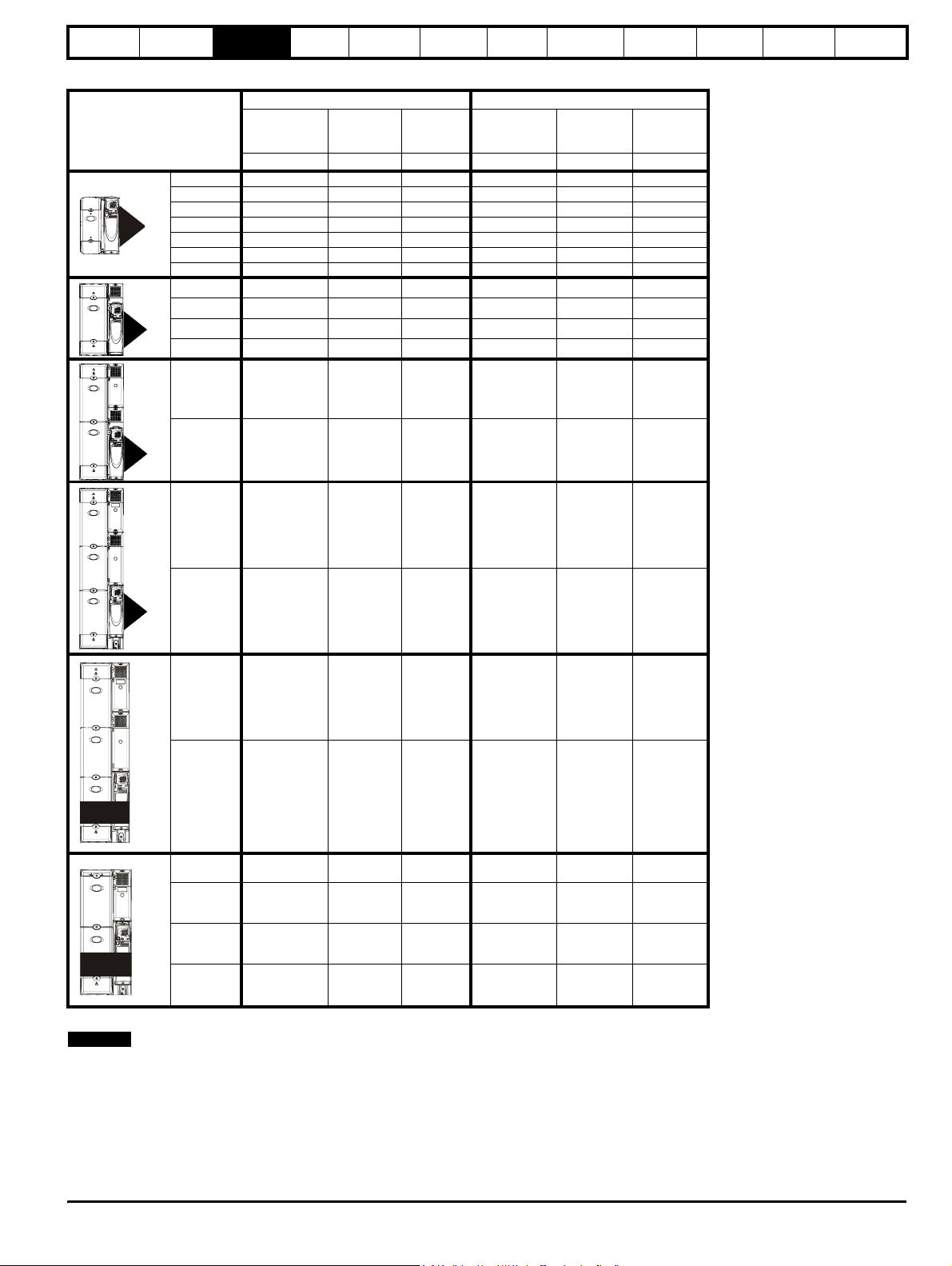

Table 3-2 400V drive ratings (380V to 480V ±10%)

Model

1405 8.8 4.0 5.0 7.6 3.0 5.0

1

2

3

1406 11 5.5 7.5 9.5 4.0 5.0

2401 15.3 7.5 10 13 5.5 10

2402 21 11 15 16.5 7.5 10

2403 29 15 20 25 11 20

2404

3401 35 18.5 25 32 15 25

3402 43 22 30 40 18.5 30

3403 56 30 40 46 22 30

4401 68 37 50 60 30 50

Maximum

continuous

input current

AkWhpAkWhp

Electrical

installation

Normal Duty Heavy Duty

Typical motor

power

at 400V

Getting

started

Typ i cal m o to r

power

at 460V

Optimisation Parameters

Maximum

continuous

input current

29 15 20

Technical

data

Typical motor

power

at 400V

Component

sizing

Diagnostics

Typical motor

power

at 460V

4

55

56

4402 83 45 60 74 37 60

4403 104 55 75 96 45 75

5401 138 75 100 124 55 100

5402 168 90 125 156 75 125

6401 202 110 150 180 90 150

6402 236 132 200 210 110 150

1401 205 110 150 180 90 150

SPMA

1402 236 132 200 210 110 150

1401 205 110 150 180 90 150

1402 246 132 200 210 110 150

1403 290 160 250 246 132 200

SPMD

1404 350 200 300 290 160 250

NOTE

The SPMD1404 can deliver 350A continuously only if the ambient is 35°C or lower and it is docked to the SPMC. Under all other circumstances the current rating is 335A.

The above current ratings are given for max 40°C (104°F), and 3.0 kHz switching. Derating is required for higher switching frequencies, ambient

temperature >40°C (104°F) and high altitude. For further information, refer to both the Unidrive SP and SPM User Guides.

14 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

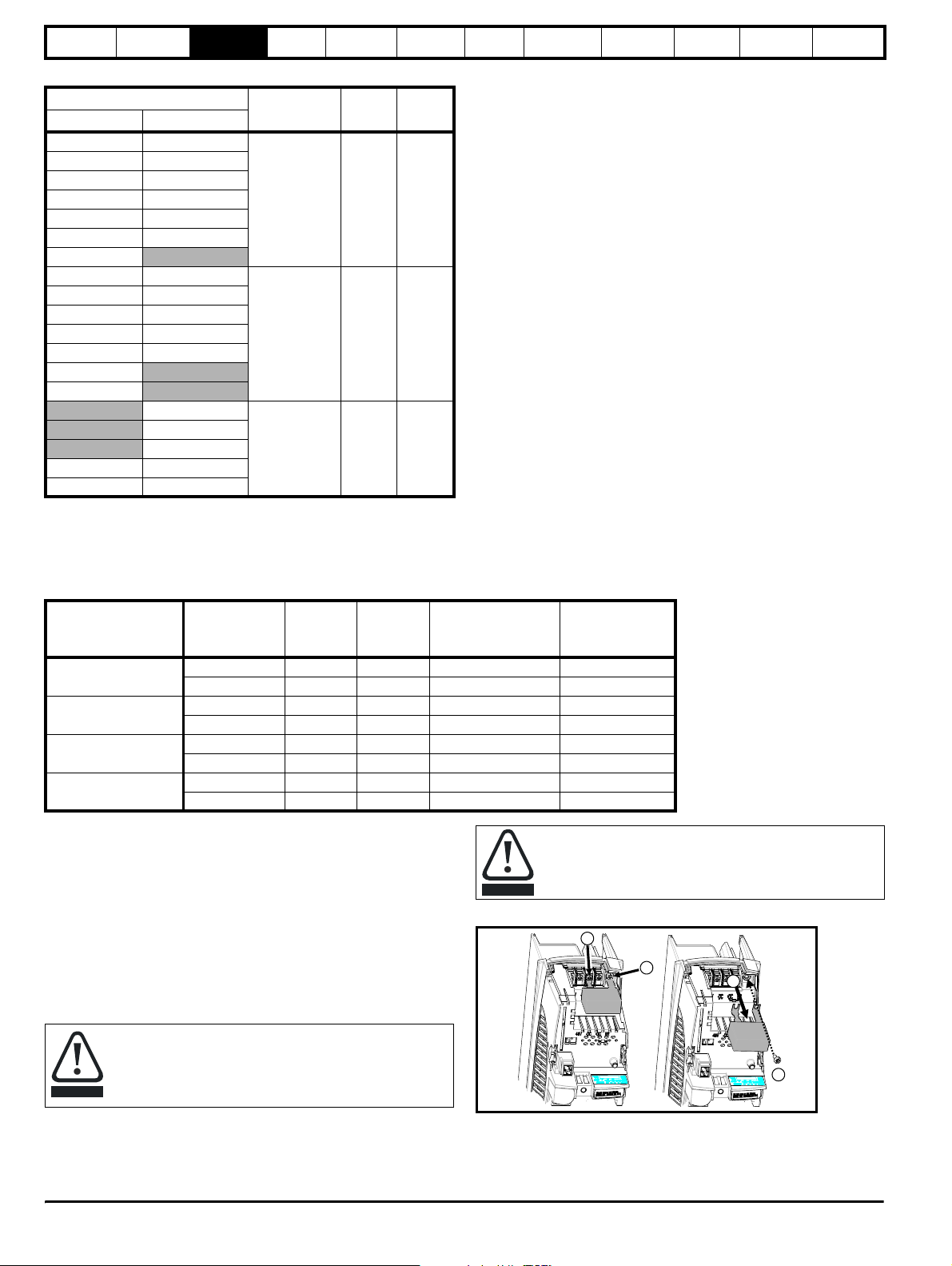

Table 3-3 575V Drive ratings (500V to 575V ±10%)

Normal Duty Heavy Duty

3

4

Model

Maximum

continuous

output current

AkWhpAkWhp

3501 5.4 3.0 3.0 4.1 2.2 2.0

3502 6.1 4.0 5.0 5.4 3.0 3.0

3503 8.4 5.5 7.5 6.1 4.0 5.0

3504 11 7.5 10 9.5 5.5 7.5

3505 16 11 15 12 7.5 10

3506 22 15 20 18 11 15

3507 27 18.5 25 22 15 20

4603 36 22 30 27 18.5 25

4604 43 30 40 36 22 30

4605 52 37 50 43 30 40

4606 62 45 60 52 37 50

5601 84 55 75 63 45 60

Nominal

power

at 575V

Electrical

installation

Motor

power

at 575V

Getting

started

Maximum

continuous

output current

Optimisation Parameters

Nominal

power

at 575V

Motor

power

at 575V

Technical

data

Component

sizing

Diagnostics

SPMA

55

56

5602 99 75 100 85 55 75

6601 125 90 125 100 75 100

6602 144 110 150 125 90 125

1601 125 90 125 100 75 100

1602 144 110 150 125 90 125

1601 125 110 150 100 90 125

1602 144 132 175 125 110 150

1603 168 160 200 144 132 175

SPMD

1604 192 185 250 168 160 200

The power ratings above for model size 4 and larger are for the 690V drives when used on a 500V to 575V supply.

NOTE

The above current ratings are given for max 40°C (104°F), and 3.0 kHz switching. Derating is required for higher switching frequencies, ambient

temperature >40°C (104°F) and high altitude. For further information, refer to both the Unidrive SP and SPM User Guides.

Unidr ive SP Re gen Inst allatio n Guide 15

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Table 3-4 690V Drive ratings (690V ±10%)

Maximum

continuous

output current

AkWhpAkWhp

4

Model

4601 22 18.5 25 19 15 20

4602 27 22 30 22 18.5 25

4603 36 30 40 27 22 30

4604 43 37 50 36 30 40

4605 52 45 60 43 37 50

4606 62 55 75 52 45 60

5601 84 75 100 63 55 75

Mechanical

installation

Normal Duty Heavy Duty

Nominal

power

at 690V

Electrical

installation

Motor

power

at 690V

Getting

started

Maximum

continuous

output current

Optimisation Parameters

Nominal

power

at 690V

Motor

power

at 690V

Technical

data

Component

sizing

Diagnostics

SPMA

55

56

5602 99 90 125 85 75 100

6601 125 110 150 100 90 125

6602 144 132 175 125 110 150

1601 125 110 150 100 90 125

1602 144 132 175 125 110 150

1601 125 110 150 100 90 125

1602 144 132 175 125 110 150

1603 168 160 200 144 132 175

SPMD

1604 192 185 250 168 160 200

NOTE

The above current ratings are given for max 40°C (104°F), and 3.0 kHz switching. Derating is required for higher switching frequencies, ambient

temperature >40°C (104°F) and high altitude. For further information, refer to both the Unidrive SP and SPM User Guides.

16 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

A

±

r

A

Information

Introduction

Product

information

System

design

3.4 Drive features

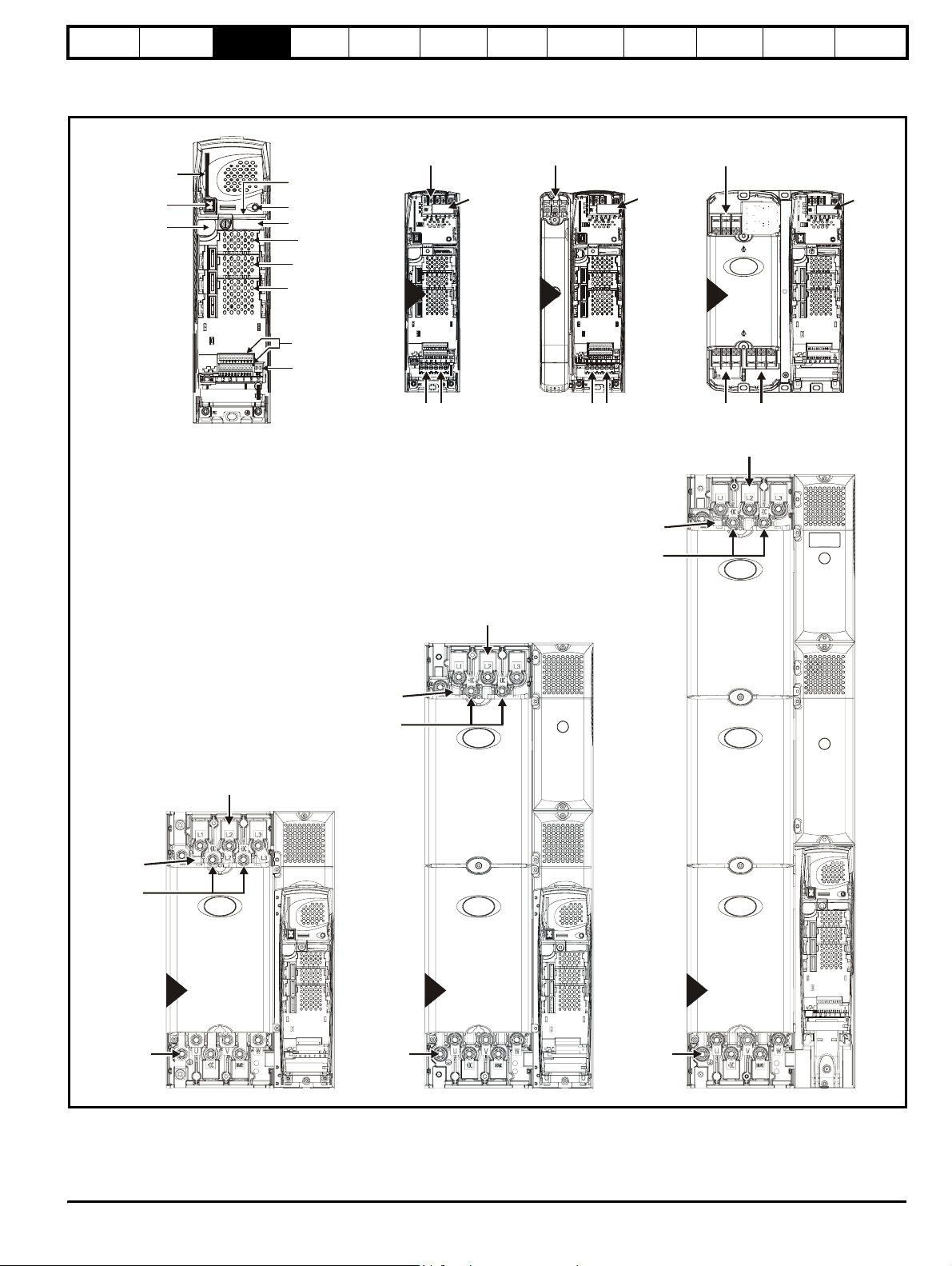

Figure 3-2 Features of the drive sizes 1 to 6

SMARTCARD

slot

Keypad

connection

Serial port

connector

Approvals label

Status LED

Rating label

Solutions Module

slot 1

Solutions Module

slot 2

Solutions Module

slot 3

Mechanical

installation

±

Electrical

installation

DC Bus output

(High current)

1

EMC

capacitor

must be

removed

Getting

started

Optimisation Parameters

DC Bus output

(High current)

2

EMC

capacitor

must be

removed

Technical

data

±

DC Bus output

(High current)

3

3

Component

sizing

Diagnostics

EMC

capacito

must be

removed

Charging input

(L1, L2, L3)

Control terminals

Relay terminals

EMC capacitor

±

DC Bus output

(High current)

Charging input

(L1, L2, L3)

must be

removed

AC supply

(U, V, W)

Charging input

(L1, L2, L3)

Charging input

(L1, L2, L3)

AC supply

(U, V, W)

EMC capacitor

must be

removed

±

DC Bus output

(High current)

Charging input

(L1, L2, L3)

(U, V, W)

Charging input

(L1, L2, L3)

C supply

EMC capacitor

must be

removed

±

DC Bus output

(High current)

AC supply

(U, V, W)

4

AC supply

(U, V, W)

5

C supply

(U, V, W)

6

Unidr ive SP Re gen Inst allatio n Guide 17

Issue Number: 2 www.controltechniques.com

Safety

y

Information

Introduction

Product

information

System

design

Mechanical

installation

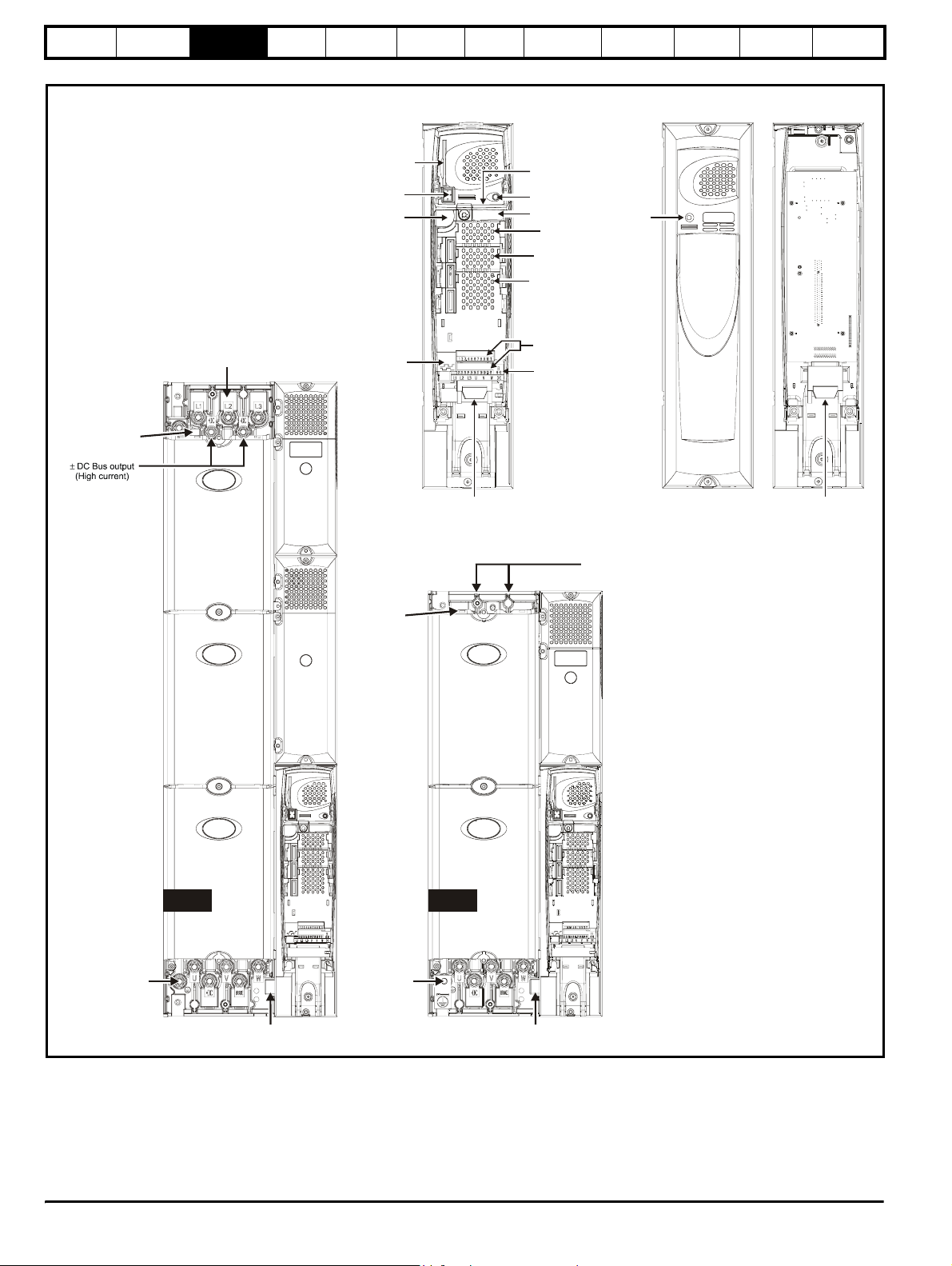

Figure 3-3 Features of the drive sizes SPMA and SPMD

SMARTCARD

slot

Keypad

connection

Serial port

connector

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Master interface Slave interface

Cover Base

Approvals label B

Status LED

Rating label

Solutions Module

slot 1

Solutions Module

slot 2

Solutions Module

slot 3

Stat us

LED

Component

sizing

Diagnostics

EMC capacitor

must be removed

Charging input

(L1, L2, L3)

Encoder

connection

EMC capacitor

must be removed

Output connections

to slave

Control terminals

Relay terminals

±

(high current)

DC Bus output

Input from Master /

Output to slave

SPMA SPMD

AC supply

(U, V, W)

Heatsink fan

supply connections

AC supply

(U, V, W)

Heatsink fan

suppl

connections

18 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

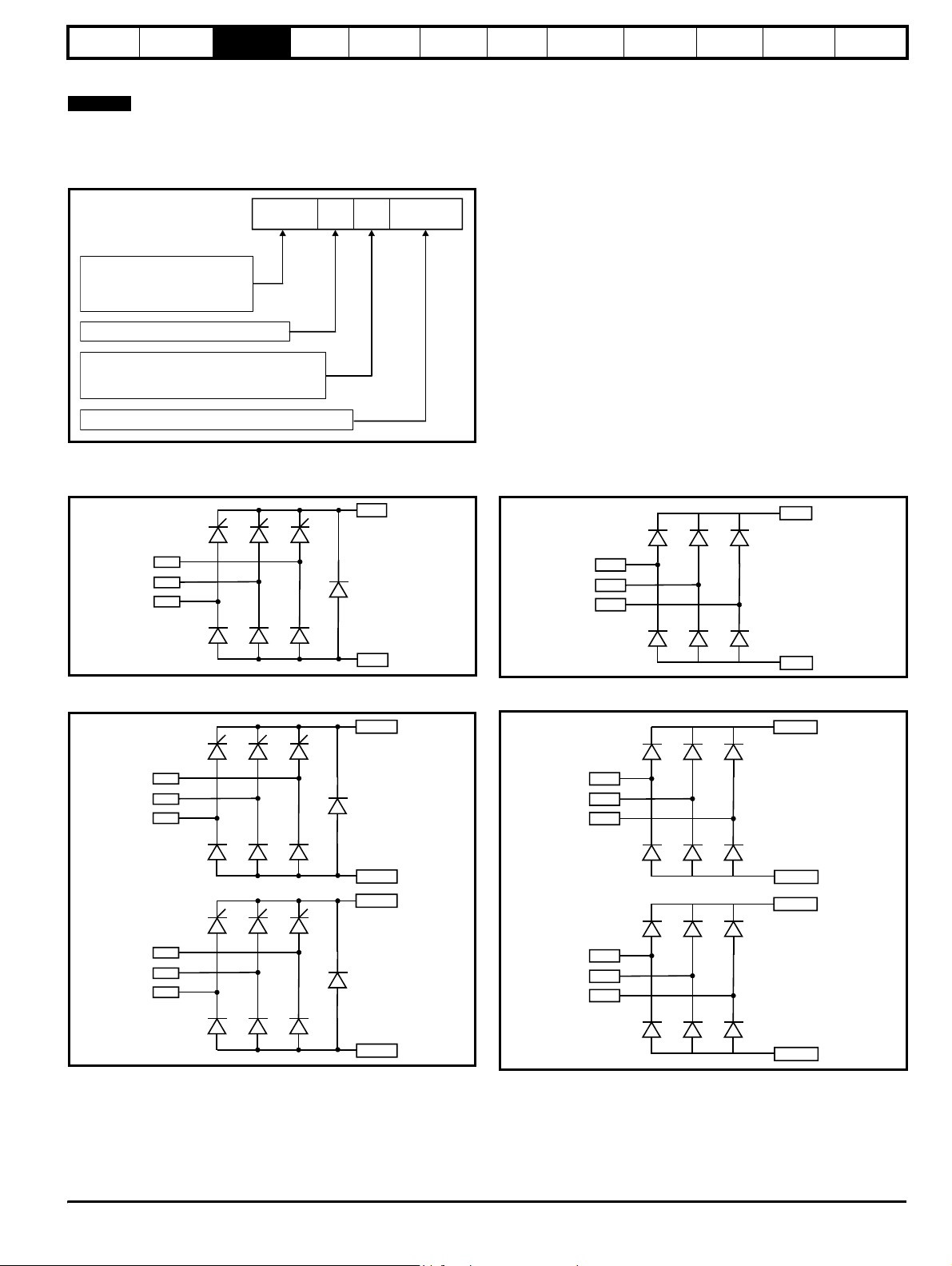

3.5 Unidrive SPMC half controlled thyristor rectifier

NOTE

For the 200V modules where an external charging circuit is required the

SPMU1401, SPMU1402 and SPMU2402 can be used as detailed

following:

Figure 3-4 Rectifier (SPMC and SPMU)

SPMC 1 402

Unidrive SPM product line

Controlled rectifier

SPMC:

SPMU:

Uncontrolled rectifier

Number of rectifier stages

Vol tag e rat i ng

4: 380V to 480V

6: 500V to 690V

Current rating step

The Unidrive SPMC is a controlled thyristor rectifier and the SPMU is an uncontrolled rectifier.

SPMC1402 and 1601

Figure 3-5 Single half controlled thyristor

+DC

SPMU1401, 1402 and 1601

Figure 3-7 Single diode rectifier

Technical

data

Component

sizing

+DC

Diagnostics

L1

L2

L3

SPMC2402 and 2601

Figure 3-6 Dual half controlled thyristor

L1A

L2A

L3A

L1B

L2B

L3B

-DC

+DC (A)

-DC (A)

+DC (B)

L1

L2

L3

-DC

SPMU2402 and 2601

Figure 3-8 Dual diode rectifier

+DC (A)

L1A

L2A

L3A

-DC (A)

+DC (B)

L1B

L2B

L3B

-DC(B)

-DC (B)

The Unidrive SPMC is a half controlled thyristor bridge is used as a front end to the SPMD inverter module or as a stand alone rectifier for several

smaller drives. Soft-start is built in.

The Unidrive SPMU is used as a front end to the SPMD inverter module or as a stand alone rectifier for several smaller drives. Softstart must be

supplied externally using a resistor and contactor or SPMC.

An external 24V, 3A power supply is required in addition to the AC supply to allow the rectifier to operate. Control wiring is required between the

rectifier and motoring drive(s) so that if the rectifier indicates a fault the motoring drive(s) will be disabled.

Unidr ive SP Re gen Inst allatio n Guide 19

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

The 24V supply must be protected using a 4A slow-blow fuse, one for each supply pole.

Control connections to the Unidrive SPMC/U should be made with 0.5mm2 cable.

The status relay contacts are rated for switching non-inductive loads at 250Vac 6A non-inductive, up to 4Adc if the voltage is limited to 40V or up to

400mA dc if the voltage is limited to 250Vdc. Protection from overcurrent must be provided.

Figure 3-9 SPMC/U rating label

Input voltage, frequency,

no. of phases and current

Approvals

Serial

number

STDN39

Customer and

date code

Status1 Status0

Status

LEDs

I/P 380-480V 50-60Hz 3ph 204A

O/P 513-648V 552A

Output voltage

and current

Model:

SPMC = Controlled

SPMU = Uncontrolled

SPMC1402

Number of

rectifier

stages

Ser No: 3000005001

Voltage

rating:

4 - 400V

6 - 690V

Indicates

sub-rating

within frame

size

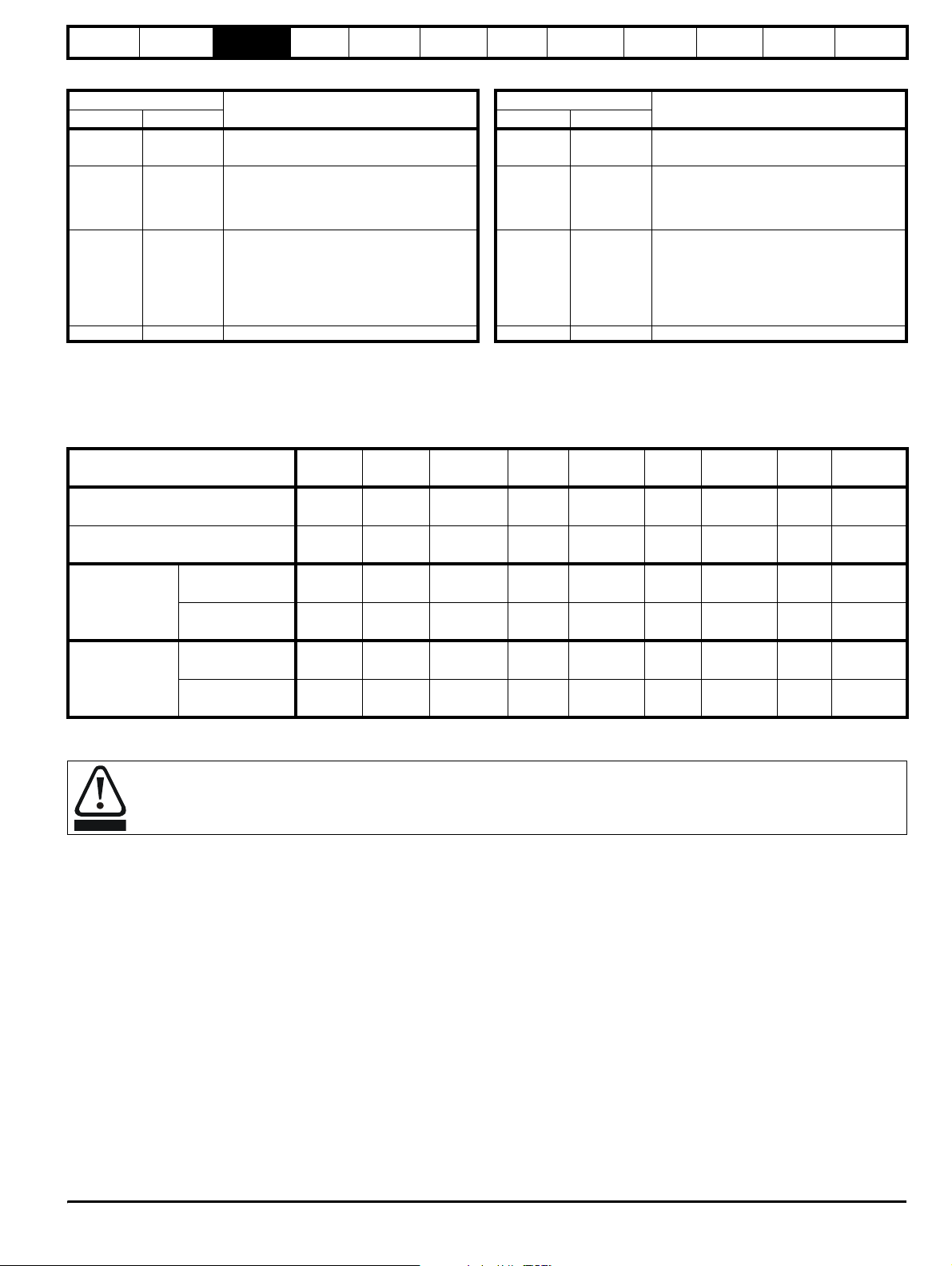

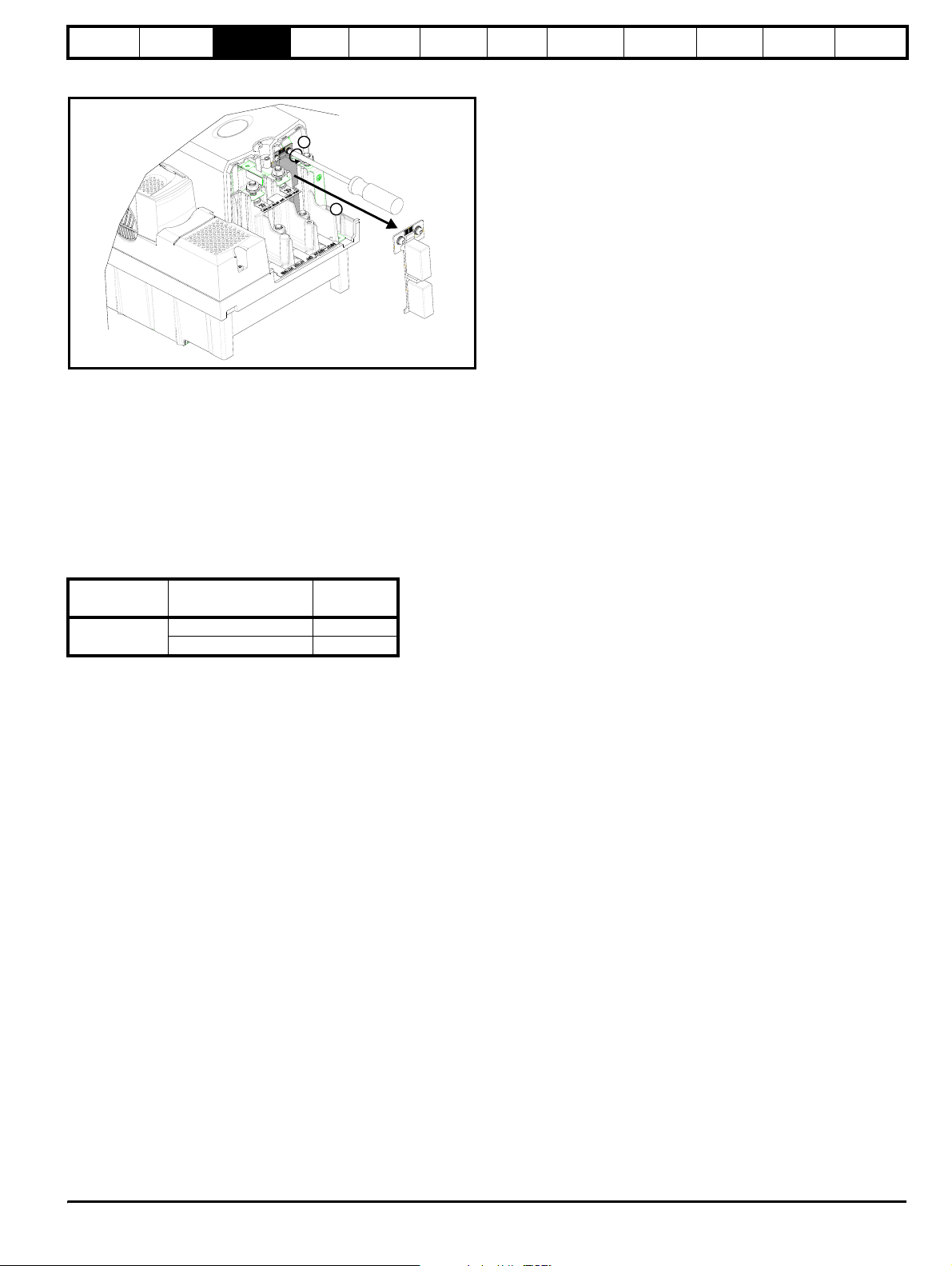

3.6 Unidrive SPMC/U technical data

Table 3-5 Unidrive SPMC / U input current, fuse and cable ratings

Semi-conductor fuse

in series with HRC fuse

HRC IEC

class gG UL

class J

Semi-

conductor

IEC class aR

mm

Model

Typical input

current

A

Maximum

input current

A

Typical DC

current

Adc

SPMC1402 339 344 379 540 400 2 x 120 2 x 4/0 2 x 120 2 x 4/0

SPMC2402 2 x 308 2 x 312 2 x 345 450 400 2 x 120 2 x 4/0 2 x 120 2 x 4/0

SPMU1401 207 210 222 250 315 2 x 70 2 x 2/0 2 x 70 2 x 2/0

SPMU1402 339 344 379 540 400 2 x 120 2 x 4/0 2 x 120 2 x 4/0

SPMU2402 2 x 339 609 2 x 379 450 400 2 x 120 2 x 4/0 2 x 120 2 x 4/0

SPMC1601 192 195 209 250 250 2 x 70 2 x 2/0 2 x 120 2 x 4/0

SPMC2601 2 x 170 2 x 173 2 x 185 250 250 2 x 70 2 x 2/0 2 x 120 2 x 4/0

SPMU1601 192 195 209 250 250 2 x 70 2 x 2/0 2 x 120 2 x 4/0

SPMU2601 2 x 170 2 x 173 2 x 185 250 250 2 x 70 2 x 2/0 2 x 120 2 x 4/0

Cable sizes

AC input DC output

2

AWG

mm

2

AWG

The user must provide a means of preventing live parts from

being touched. A cover around the electrical connections at

the top of the inverter and the bottom of the rectifier where the

WARNING

cables enter is required.

Input fuses as specified must be provided.

WARNING

The Unidrive SPMC/U depends on the drive for protection.

Status outputs must be linked to the drive enable regen

drive(s) and circuit to ensure that when the rectifier indicates

WARNING

a fault the motoring drive(s) are disabled.

20 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

Table 3-6 Key to Unidrive SPMC (rectifier) LEDs Table 3-7 Key to Unidrive SPMU (rectifier) LEDs

Status Output

1: Left LED

OFF OFF

0: Right LED

Definition

Mains loss or 24V supply to the rectifier has

been lost

Status Output

1: Left LED

0: Right LED

Definition

OFF OFF 24V supply to the rectifier has been lost

Any of the following:

OFF ON Phase loss OFF ON

• Internal fault

• Check that rectifier is an SPMU. This

could indicate that unit is an SPMC

Any of the following:

Any of the following:

• Rectifier heatsink over temperature

• Rectifier PCB over temperature

• Status input wire break

ON OFF

• Snubber overheating due to excessive

cable charging current or supply notching

• Rectifier heatsink over temperature

• Rectifier PCB over temperature

ON OFF

• Status input wire break

ON ON System healthy ON ON System healthy

The half controlled thyristor rectifier can be used as an external charging module for a regen system consisting of multiple drives. The required

softstart function is built into the SPMC module as standard. An external 24V, 3A power supply is required in addition to the AC supply for the SPMC

to allow the rectifier to operate. Control wiring is required between the rectifier and drive(s) so that if the rectifier indicates a fault all drive(s) will be

disabled.

Table 3-8 SPM rectifier charging data

Model

AC line current

(100% Normal Duty Motor Current)

DC link current

(100% Normal Duty Motor Current)

Maximum

DC bus

capacitance on

a supply <25kA

Maximum

DC bus

capacitance on

a supply <25kA

Max capacitance

(mF)

When used with

line reactor

Max capacitance

(mF)

When used with

line reactor

SPMU

1401

207 339 677 339 677 192 385 192 385

222 379 758 379 758 209 418 209 418

44 66 132 66 132 29.3 59 29.3 59

INL401 INL402 2 x INL402 INL402 2 x INL402 INL602 2 x INL602 INL602 2 x INL602

44 66 66 66 66 29.3 29.3 29.3 29.3

INL401 INL402 INL412 INL402 INL412 INL602 INL612 INL602 INL612

SPMU

1402

SPMU

2402

SPMC

1402

SPMC

2402

SPMU

1601

SPMU

2601

SPMC

1601

SPMC

2601

Also refer to the Unidrive SPM User Guide for further detailed information on the Unidrive SPMC mechanical and electrical installation.

• The user must provide a means of preventing live parts from being touched. A cover around the electrical connections at the top of

the inverter and the bottom of the rectifier where the cables enter is required.

WARNING

• Fusing as specified must be provided.

Unidr ive SP Re gen Inst allatio n Guide 21

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

3.7 Output Sharing Chokes (for motoring drives only)

The following section covers the output sharing chokes which are currently available for Unidrive SP. These being used for the motoring drives in a

regen system only (between drive and motor).

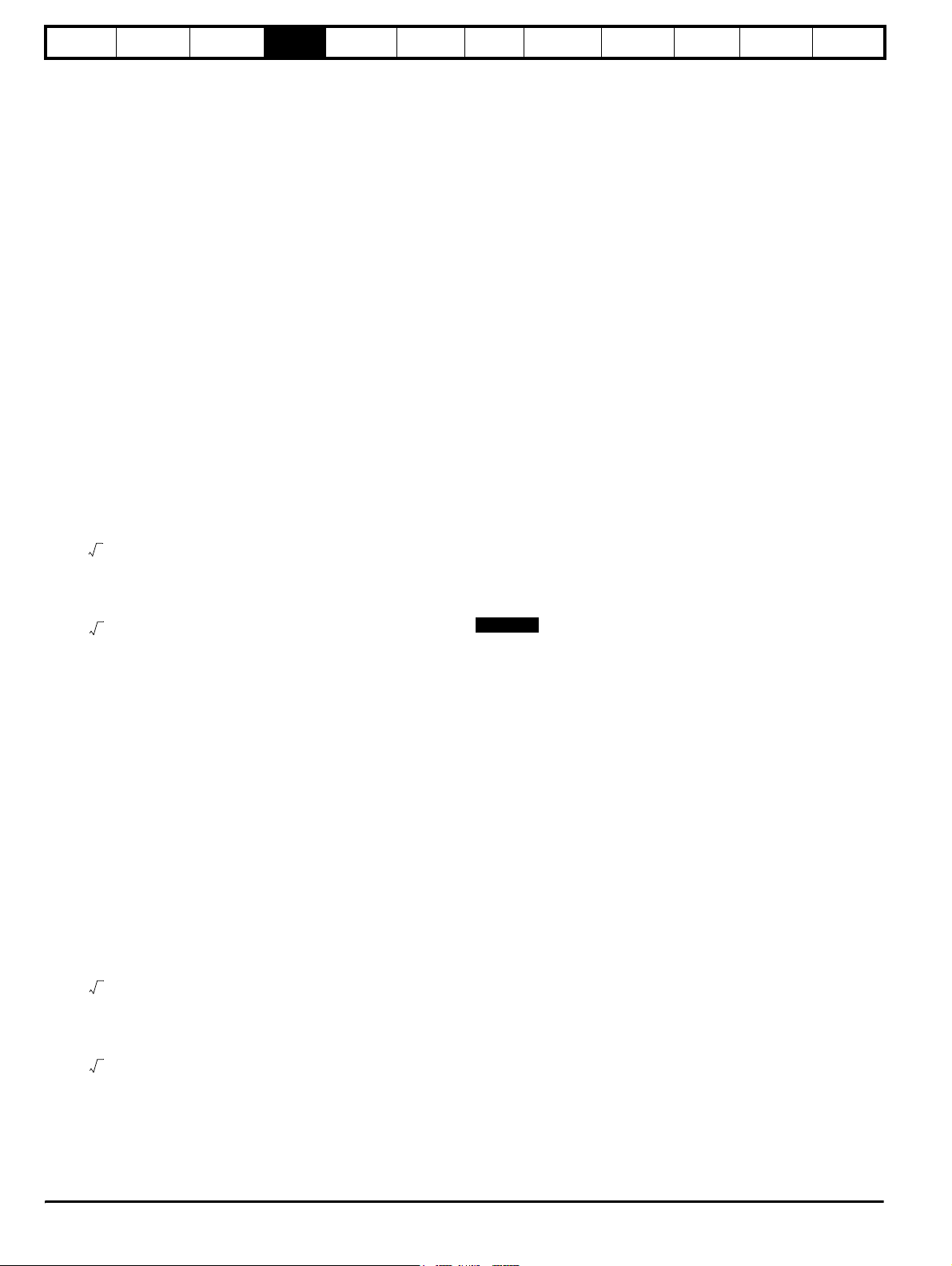

Figure 3-10 Output sharing choke identification

OTL:

Output sharing choke

Voltage rating

4: 380V to 480V

6: 500V to 690V

0: Single

1: Dual

Current rating step

NOTE

OTL

4 0 1

For the 200V SPMx modules used in parallel configurations and where output sharing chokes are required the 400V OTL output sharing chokes

should be used.

The following tables detail the output chokes required for the various configurations of paralleled SPMA and SPMD power modules.

When connecting either SPMA or SPMD drives in parallel

they must be de-rated by 5%

CAUTION

NOTE

In order to achieve the best possible current sharing between paralleled Unidrive SPM modules, sharing chokes must be fitted.

Table 3-9 400 / 600V output sharing choke ratings

Model

CurrentAInductanceµHWidth (W)mmDepth (D)mmHeight (H)mmWeight

kg

Part No.

OTL401 221 40.1 240 220 210 20 4401-0197-00

OTL402 267 34 242 220 205 20 4401-0198-00

OTL403 313 28.5 242 220 205 25 4401-0199-00

OTL404 378 23.9 242 220 205 25 4401-0200-00

OTL601 135 103.9 242 170 203 20 4401-0201-00

OTL602 156 81.8 242 170 203 20 4401-0202-00

OTL603 181 70.1 242 200 203 20 4401-0203-00

OTL604 207 59.2 242 200 203 20 4401-0204-00

Table 3-10 400 / 600V centre tapped output sharing choke ratings

Model

CurrentAInductanceµHWidth (W)mmDepth (D)mmHeight (H)mmWeight

kg

Part No.

OTL411 389.5 42.8 300 150 160 8 4401-0188-00

OTL412 470.3 36.7 300 150 160 8 4401-0189-00

OTL413 551 31.1 300 150 160 8 4401-0192-00

OTL414 665 26.6 300 150 160 9 4401-0186-00

OTL611 237.5 110.4 300 150 160 8 4401-0193-00

OTL612 273.6 88.4 300 150 160 8 4401-0194-00

OTL613 319.2 76.7 300 150 160 8 4401-0195-00

OTL614 364.8 65.7 300 150 160 8 4401-0196-00

The OTLX1X centre tapped output sharing chokes can only

be used when two Unidrive SPM drives are paralleled

together. For all other combinations the OTLX0X output

CAUTION

sharing choke must be used.

22 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

3.8 Options

Figure 3-11 Options available for Unidrive SP Regen

SMARTCARD*

Electrical

installation

Getting

started

Keypad

Optimisation Parameters

Technical

Automation Fieldbus

data

Component

sizing

Diagnostics

External

footprint /

bookcase

CT Comms

cable

EMC filter

* A SMARTCARD is provided with the Unidrive SP as standard. Only one SMARTCARD can be fitted at any one time.

NOTE

Position feedback modules will still function with a drive configured in regen mode, however, this would only be required where the Regen drive is to

be used to provide additional Solutions Module slots for the motoring drive.

Unidr ive SP Re gen Inst allatio n Guide 23

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

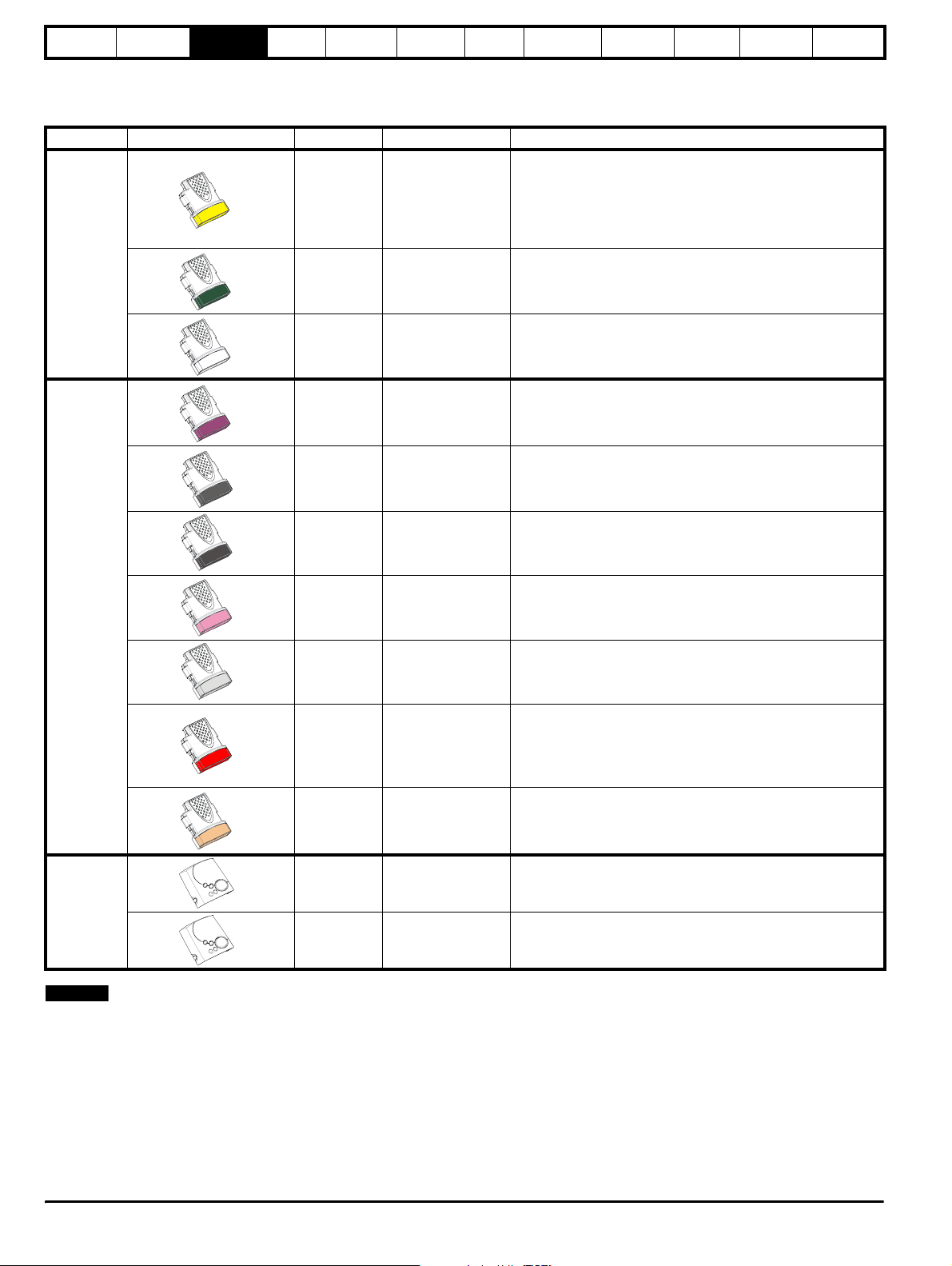

All Unidrive SP Solutions Modules are colour-coded in order to make identification easy. The following table shows the colour-code key and gives

further details on their function.

Table 3-11 Solutions Module identification

Type Solutions Module Colour Name Further Details

Extended I/O interface

Increases the I/O capability by adding the following to the

Yellow SM-I/O Plus

existing I/O in the drive:

• digital inputs x 3

• analogue output (voltage) x 1

• digital I/O x 3 • relay x 2

• analogue inputs (voltage) x 2

Automation

Fieldbus

Dark Green SM-Applications

White SM-Applications Lite

Purple SM-PROFIBUS-DP

Medium Grey SM-DeviceNet

Dark Grey SM-INTERBUS

Pink SM-CAN

Light Grey SM-CANopen

Red SM-SERCOS

Beige SM-Ethernet

Applications Processor (with CTNet)

nd

2

processor for running pre-defined and /or customer created

application software with CTNet support

Applications Processor

nd

2

processor for running pre-defined and /or customer created

application software

Profibus option

PROFIBUS DP adapter for communications with the Unidrive

SP.

DeviceNet option

Devicenet adapter for communications with the Unidrive SP

Interbus option

Interbus adapter for communications with the Unidrive SP

CAN option

CAN adapter for communications with the Unidrive SP

CANopen option

CANopen adapter for communications with the Unidrive SP

SERCOS option

Class B compliant. Torque velocity and position control modes

supported with data rates (bit/sec): 2MB, 4MB, 8MB and 16MB.

Minimum 250µsec network cycle time. Two digital high speed

probe inputs 1µsec for position capture

Ethernet option

10 base-T / 100 base-T; Supports web pages, SMTP mail and

multiple protocols: DHCP IP addressing; Standard RJ45

connection

N/A SM-Keypad

LED keypad option

Keypad with a LED display

Keypad

N/A SM-Keypad Plus

NOTE

Position feedback modules will still function with a drive configured in

LCD keypad option

Keypad with an alpha-numeric LCD display with Help function

regen mode, however, this would only be required where the Regen

drive is to be used to provide additional Solutions Module slots for the

motoring drive.

24 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

3.9 Items supplied with the drive

The drive is supplied with a copy of the Unidrive SP Short Form Guide, a

SMARTCARD, the safety booklet, the certificate of quality, an accessory

kit box (see the Unidrive SP User Guide for details) and a CD ROM

containing the following user guides:

• Unidrive SP User Guide (English, French, German, Italian, Spanish)

• Unidrive SP Advanced User Guide

• Unidrive SP Regen Installation Guide

• Solutions Module User Guides

• Unidrive SPM User Guide

3.10 Regen components

3.10.1 Regen inductor

The following regen inductors are special parts being

designed for very high levels of harmonic voltage and having

a high saturation current with good linearity below saturation.

CAUTION

The regen inductor supports the difference between the PWM voltage

from the Unidrive SP Regen drive and sinusoidal voltage from the

supply.

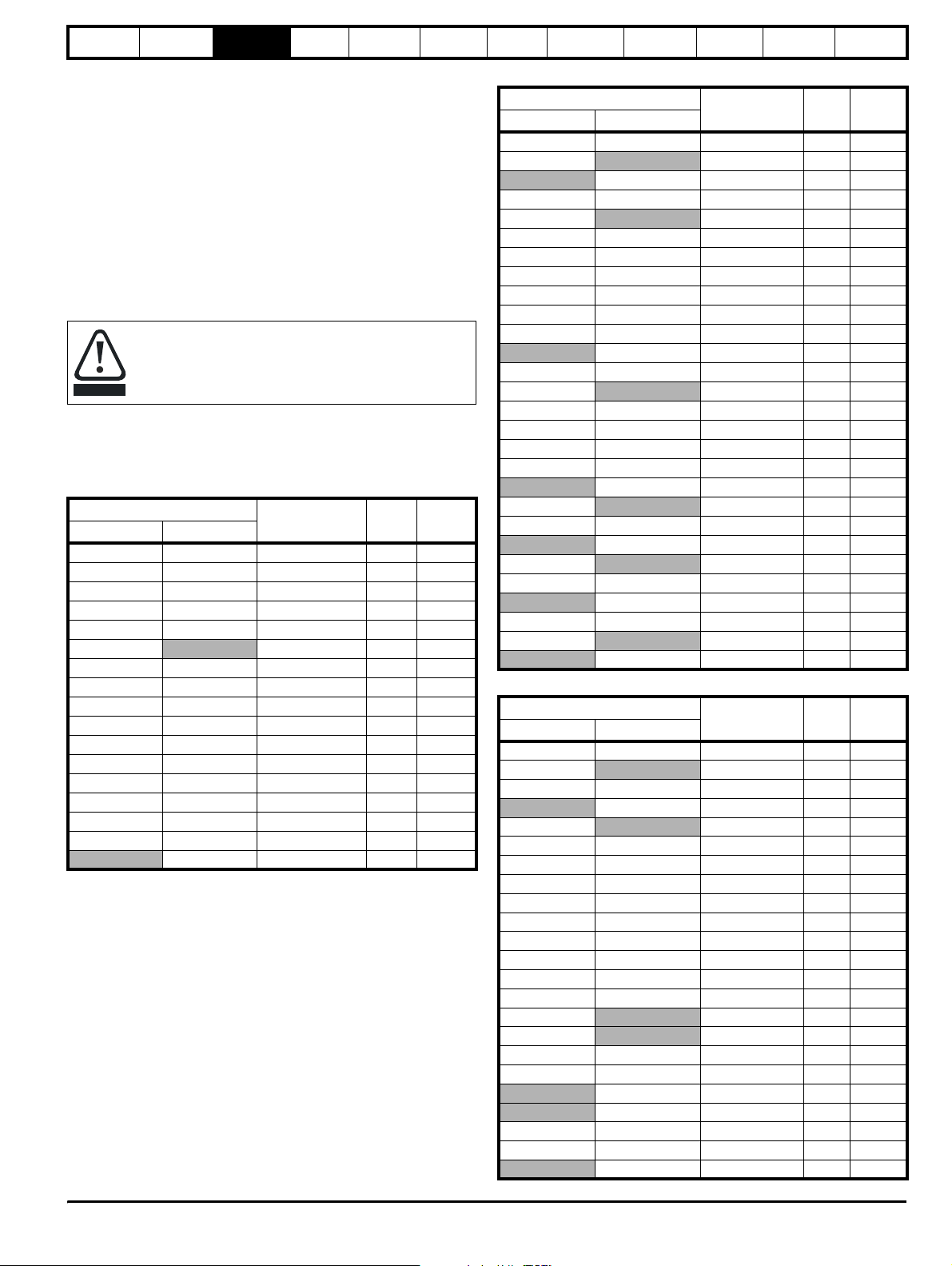

Table 3-12 200V (200V to 240V ± 10%) Regen Inductors

Heavy Duty Normal Duty

SPMD1201 SP5202 4401-0321 0.22 156.0

SPMD1202 SPMD1201 4401-0322 0.18 192.0

SPMD1203 SPMD1202 4401-0323 0.14 250.0

SPMD1204 SPMD1203 4401-0324 0.11 312.0

Under no circumstances must a part be used other than

those listed.

Drive

Part number mH Arms

SP1203 SP1203 4401-0310 3.50 9.6

SP1204 SP1204 4401-0311 2.70 11.0

SP2201 SP2201 4401-0312 2.20 15.5

SP2202 SP2202 4401-0313 1.60 22.0

SP2203 SP2203 4401-0314 1.10 31.0

SP3201

4401-0314 1.10 31.0

SP3202 SP3201 4401-0315 0.81 42.0

SP4201 SP3202 4401-0316 0.60 56.0

SP4202 SP4201 4401-0317 0.50 68.0

SP4203 SP4202 4401-0318 0.40 80.0

SP5201 SP4203 4401-0319 0.32 105.0

SP5202 SP5201 4401-0320 0.26 130.0

SPMD1204 4401-0325 0.10 350.0

Table 3-13 400V (380V to 480V ± 10%) Regen Inductor

Drive

Heavy Duty Normal Duty

Part number mH Arms

SP1405 SP1405 4401-0001 6.30 9.5

SP1406

4401-0001 6.30 9.5

SP1406 4401-0002 5.00 12.0

SP2401 SP2401 4401-0003 3.75 16.0

SP2402

4401-0003 3.75 16.0

SP2403 SP2402 4401-0004 2.40 25.0

SP2404 SP2403 4401-0005 1.76 34.0

SP3401 SP2404 4401-0005 1.76 34.0

SP3402 SP3401 4401-0006 1.50 40.0

SP3403 SP3402 4401-0007 1.30 46.0

SP4401 SP3403 4401-0008 1.00 60.0

SP4401 4401-0009 0.78 70.0

SP4402 SP4402 4401-0010 0.63 96.0

SP4403

4401-0010 0.63 96.0

SP5401 SP4403 4401-0011 0.48 124.0

SP5402 SP5401 4401-0012 0.38 156.0

SP6401 SP5402 4401-0013 0.33 180.0

SP6402 SP6401 4401-0014 0.30 200.0

SP6402 4401-0015 0.20 300.0

SPMA1401

4401-0013 0.33 180.0

SPMA1402 SPMA1401 4401-0014 0.30 200.0

SPMA1402 4401-0015 0.20 300.0

SPMD1401

4401-0013 0.33 180.0

SPMD1402 SPMD1401 4401-0014 0.30 200.0

SPMD1402 4401-0015 0.20 300.0

SPMD1403 SPMD1403 4401-0015 0.20 300.0

SPMD1404

4401-0015 0.20 300.0

SPMD1404 4401-0205-00 0.16 350.0

Table 3-14 575V (500V to 575V ± 10%) Regen Inductor

Drive

Heavy Duty Normal Duty

Part number mH Arms

SP3505 SP3505 4401-0210 5.30 19.0

SP3506

4401-0211 4.60 22.0

SP3507 SP3506 4401-0212 3.80 27.0

SP3507 4401-0212 3.80 27.0

SP4601

4401-0211 4.60 22.0

SP4602 SP4601 4401-0212 3.80 27.0

SP4603 SP4602 4401-0212 3.80 27.0

SP4604 SP4603 4401-0213 2.80 36.0

SP4605 SP4604 4401-0214 2.40 43.0

SP4606 SP4605 4401-0215 1.90 52.0

SP5601 SP4606 4401-0216 1.60 63.0

SP5602 SP5601 4401-0217 1.20 85.0

SP6601 SP5602 4401-0218 1.00 100.0

SP6602 SP6601 4401-0219 0.80 125.0

SPMA1601

SPMD1601

4401-0218 1.00 100.0

4401-0218 1.00 100.0

SPMA1602 SPMA1601 4401-0219 0.80 125.0

SPMD1602 SPMD1601 4401-0219 0.80 125.0

SPMA1602 4401-0220 0.70 144.0

SPMD1602 4401-0220 0.70 144.0

SPMD1603 SP6602 4401-0220 0.70 144.0

SPMD1604 SPMD1603 4401-0221 0.60 168.0

SPMD1604 4401-0222 0.53 192.0

Unidr ive SP Re gen Inst allatio n Guide 25

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

Table 3-15 690V (690V ± 10%) Regen Inductor

Drive

Heavy Duty Normal Duty

SP4601

Part number mH Arms

4401-0210 5.30 19.0

SP4602 SP4601 4401-0211 4.60 22.0

SP4603 SP4602 4401-0212 3.80 27.0

SP4604 SP4603 4401-0213 2.80 36.0

SP4605 SP4604 4401-0214 2.40 43.0

SP4606 SP4605 4401-0215 1.90 52.0

SP5601 SP4606 4401-0216 1.60 63.0

SP5602 SP5601 4401-0217 1.20 85.0

SP6601 SP5602 4401-0218 1.00 100.0

SP6602 SP6601 4401-0219 0.80 125.0

SPMA1601

SPMD1601

4401-0218 1.00 100.0

4401-0218 1.00 100.0

SPMA1602 SPMA1601 4401-0219 0.80 125.0

SPMD1602 SPMD1601 4401-0219 0.80 125.0

SPMA1602 4401-0220 0.70 144.0

SPMD1602 4401-0220 0.70 144.0

SPMD1603 SP6602 4401-0220 0.70 144.0

SPMD1604 SPMD1603 4401-0221 0.60 168.0

SPMD1604 4401-0222 0.53 192.0

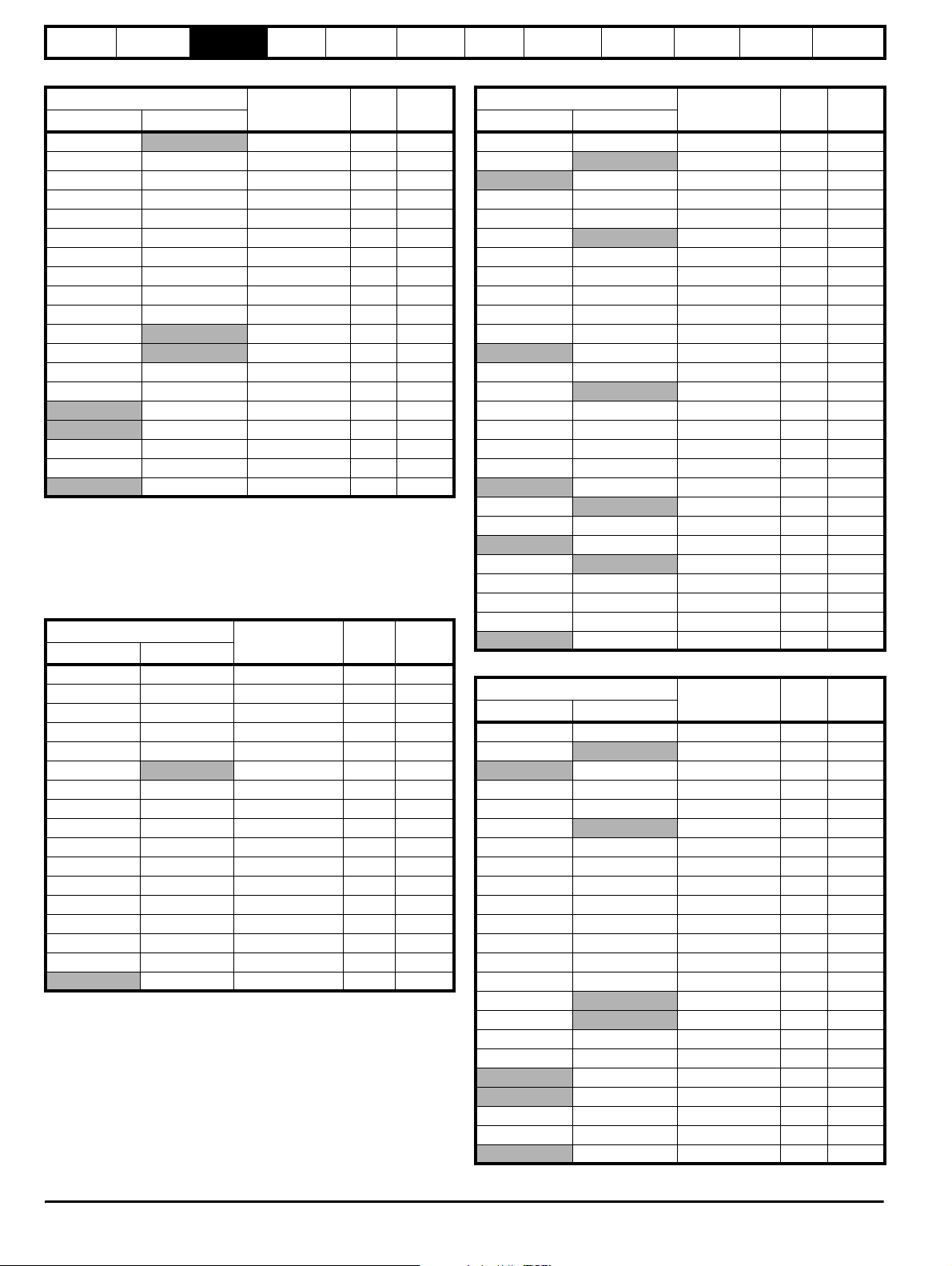

3.10.2 Switching frequency filter

These components are used to form the filter, preventing switching

frequency harmonic currents getting back onto the supply. If the filter is

not fitted, the presence of currents in the kHz region could cause supply

problems or disturbance to other equipment.

Table 3-16 200V (200V to 240V ± 10%) SFF Inductors

Drive

Heavy Duty Normal Duty

SP1203 SP1203 4401-1310 0.88 9.6

SP1204 SP1204 4401-1311 1.50 11.0

SP2201 SP2201 4401-1312 1.10 15.5

SP2202 SP2202 4401-1313 0.70 22.0

SP2203 SP2203 4401-1314 0.50 31.0

SP3201

SP3202 SP3201 4401-1315 0.40 42.0

SP4201 SP3202 4401-1316 0.30 56.0

SP4202 SP4201 4401-1317 0.25 68.0

SP4203 SP4202 4401-1318 0.20 80.0

SP5201 SP4203 4401-1319 0.16 105.0

SP5202 SP5201 4401-1320 0.13 130.0

SPMD1201 SP5202 4401-1321 0.11 156.0

SPMD1202 SPMD1201 4401-1322 0.088 192.0

SPMD1203 SPMD1202 4401-1323 0.068 250.0

SPMD1204 SPMD1203 4401-1324 0.055 312.0

SPMD1204 4401-1325 0.048 350.0

Part number mH Arms

4401-1314 0.50 31.0

Table 3-17 400V (380V to 480V ± 10%) SFF Inductor

Drive

Heavy Duty Normal Duty

Part number mH Arms

SP1405 SP1405 4401-0162 3.16 9.5

SP1406

4401-0162 3.16 9.5

SP1406 4401-0163 2.50 12.0

SP2401 SP2401 4401-0164 1.875 16.0

SP2402 SP2402 4401-0165 1.20 25.0

SP2403

4401-0165 1.20 25.0

SP2404 SP2403 4401-0166 0.88 34.0

SP3401 SP2404 4401-0166 0.88 34.0

SP3402 SP3401 4401-0167 0.75 40.0

SP3403 SP3402 4401-0168 0.65 46.0

SP4401 SP3403 4401-0169 0.50 60.0

SP4401 4401-0170 0.39 70.0

SP4402 SP4402 4401-0171 0.315 96.0

SP4403

4401-0171 0.315 96.0

SP5401 SP4403 4401-0172 0.24 124.0

SP5402 SP5401 4401-0173 0.19 156.0

SP6401 SP5402 4401-0174 0.165 180.0

SP6402 SP6401 4401-0175 0.135 220.0

SP6402 4401-0176 0.10 300.0

SPMA1401

4401-0174 0.165 180.0

SPMA1402 SPMA1401 4401-0175 0.135 220.0

SPMA1402 4401-0176 0.10 300.0

SPMD1401

4401-0174 0.165 180.0

SPMD1402 SPMD1401 4401-0175 0.135 220.0

SPMD1403 SPMD1402 4401-0176 0.10 300.0

SPMD1404 SPMD1403 4401-0176 0.10 300.0

SPMD1404 4401-1205 0.08 350.0

Table 3-18 575V (500V to 575V ± 10%) SFF Inductor

Drive

Heavy Duty Normal Duty

Part number mH Arms

SP3505 SP3505 4401-1211 1.40 22.0

SP3506

4401-1211 1.40 22.0

SP3506 4401-1213 1.40 36.0

SP3507 SP3507 4401-1213 1.40 36.0

SP4601 SP4601 4401-1211 1.40 22.0

SP4602

4401-1211 1.40 22.0

SP4603 SP4602 4401-1213 1.40 36.0

SP4604 SP4603 4401-1214 1.20 43.0

SP4605 SP4604 4401-1215 1.00 52.0

SP4606 SP4605 4401-1216 0.80 63.0

SP5601 SP4606 4401-1217 0.60 85.0

SP5602 SP5601 4401-1218 0.50 100.0

SP6601 SP5602 4401-1219 0.40 125.0

SP6602 SP6601 4401-1220 0.35 144.0

SPMA1601

SPMD1601

4401-1219 0.40 125.0

4401-1219 0.40 125.0

SPMA1602 SPMA1601 4401-1220 0.35 144.0

SPMD1602 SPMD1601 4401-1220 0.35 144.0

SPMA1602 4401-1221 0.30 168.0

SPMD1602 4401-1221 0.30 168.0

SPMD1603 SP6602 4401-1221 0.30 168.0

SPMD1604 SPMD1603 4401-1222 0.26 192.0

SPMD1604 4401-1223 0.21 192.0

26 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Table 3-19 690V (690V ± 10%) SFF Inductor

Drive

Heavy Duty Normal Duty

Part number mH Arms

SP4601 SP4601 4401-1211 1.40 22.0

SP4602

4401-1211 1.40 22.0

SP4603 SP4602 4401-1213 1.40 36.0

SP4604 SP4603 4401-1213 1.40 36.0

SP4605 SP4604 4401-1214 1.20 43.0

SP4606 SP4605 4401-1215 1.00 52.0

SP5601 SP4606 4401-1216 0.80 63.0

SP5602 SP5601 4401-1217 0.60 85.0

SP6601 SP5602 4401-1218 0.50 100.0

SP6602 SP6601 4401-1219 0.40 125.0

SPMA1601

SPMD1601

4401-1218 0.50 100.0

4401-1218 0.50 100.0

SPMA1602 SPMA1601 4401-1219 0.40 125.0

SPMD1602 SPMD1601 4401-1219 0.40 125.0

SPMA1602 4401-1220 0.35 144.0

SPMD1602 4401-1220 0.35 144.0

SPMD1603 SP6602 4401-1220 0.35 144.0

SPMD1604 SPMD1603 4401-1221 0.30 168.0

SPMD1604 4401-1222 0.26 192.0

The inductors are standard three phase inductors (rated at Unidrive SP

Regen drive rated current). They carry only 50/60Hz current with a

negligible amount of high frequency current. The above switching

frequency filter inductors are calculated at 4% of the regen drives rating

using the following formula. A tolerance can be applied to the calculated

value in the range of, -10% to +30%.

L switching frequency filter mH = VLL / √3 x 1 / Irated x 0.04 x 1 / (2 x pi

x f).

Where:

VLL = Supply voltage line-to-line

f = Supply frequency

Irated = Drive rated current

NOTE

This calculation also gives the correct inductance value for a 480V, 60Hz

supply.

Table 3-20 200V (200V to 240V ± 10%) SFF Capacitors

Drive

Heavy Duty Normal Duty

Part number uF Arms

SP1203 SP1203

1664-1074 7 1.7SP1204 SP1204

SP2201 SP2201

SP2202 SP2202

SP2203 SP2203

SP3201 SP3201

1664-2174 16.6 4.3

SP3202

SP4201 SP3202

1665-8324 32 11SP4202 SP4201

SP4203 SP4202

SP5201 SP4203

1664-2644 64 17SP5202 SP5201

SPMD1201 SP5202

SPMD1202 SPMD1201

SPMD1203 SPMD1202

SPMD1204 SPMD1203

2 x 1664-2644 2 x 64 2 x 17

SPMD1204

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Table 3-21 400V (380V to 480V ± 10%) SFF Capacitors

Drive

Heavy Duty Normal Duty

Part number uF Arms

SP1405 SP1405

SP1406 SP1406

SP2401 SP2401

1610-7804 8 4.3

SP2402 SP2402

SP2403

SP2404 SP2403

SP3401 SP2404

SP3402 SP3401

SP3403 SP3402

1665-8324 32 11

SP4401 SP3403

SP4401

SP4402 SP4402

SP4403 SP4403

SP5401 SP5401

SP5402 SP5402

SP6401 SP6401

SP6402

1665-8484 48 17

SPMA1401 SPMA1401

SPMA1402

SPMD1401 SPMD1401

SPMD1402

SP6402

SPMA1402 SPMA1402

SPMD1402

1665-8774 77 26

SPMD1403 SPMD1403

SPMD1404

SPMD1404 2 x 1665-8394 2 x 39 2 x 13

Table 3-22 575V (500V to 575V ± 10%) SFF Capacitors

Drive

Heavy Duty Normal Duty

Part number uF Arms

SP3505 SP3505

SP3506 SP3506

SP3507 SP3507

SP4601 SP4601

SP4602 SP4602

SP4603 SP4603

1666-8113 11.2 5

SP4604 SP4604

SP4605 SP4605

SP4606 SP4606

SP5601 SP5601

SP5602

SP6601 SP5602

SP6602 SP6601

SPMA1601 SP6602

SPMA1602 SPMA1601

1666-8223 22.5 10

SPMD1601 SPMA1602

SPMD1602 SPMD1601

SPMD1603 SPMD1602

SPMD1604 SPMD1603

SPMD1604

2 x 1666-8233

2 x

22.5

Diagnostics

2 x 10

Unidr ive SP Re gen Inst allatio n Guide 27

Issue Number: 2 www.controltechniques.com

Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation Parameters

Technical

data

Component

sizing

Diagnostics

Table 3-23 690V (690V ± 10%) SFF Capacitors

Drive

Heavy Duty Normal Duty

Part number uF Arms

SP4601 SP4601

SP4602 SP4602

SP4603 SP4603

SP4604 SP4604

1668-7833 8.3 4.3

SP4605 SP4605

SP4606 SP4606

SP5601

SP5602 SP5601

SP6601 SP5602

SP6602 SP6601

SPMA1601 SPMA1601