Page 1

S M M C - 3 M A N U A L

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION...........................................................................................................3

Pre-Programmed Configuration ............................................................................................................................ 3

WARNINGS....................................................................................................................................4

INSTALLATION..............................................................................................................................4

Pre-Programmed Connections.............................................................................................................................. 5

SYSTEM CHECK...........................................................................................................................6

OPERATION...................................................................................................................................7

Mode 1 – Independent ........................................................................................................................................... 7

Mode 2 – Priority .................................................................................................................................................... 7

Zone Assignment ................................................................................................................................................... 8

Manual Operation................................................................................................................................................... 8

Programming Instructions...................................................................................................................................... 9

TROUBLESHOOTING GUIDE ...................................................................................................12

SMMC-3 Control panel (access cover removed) ............................................................................................... 13

SPECIFICATIONS .......................................................................................................................14

Sensor Extension Wire Specifications ................................................................................................................ 14

LIMITED WARRANTY AND LIABILITY.....................................................................................15

Page 3

GE NER AL INFOR M ATION

Manual Override

The SMMC-3 Control Panel manages snow and ice melting equipment for sidewalks, driveways, gutters, downspouts,

etc. Suitable for controlling all types of heating cable systems, the SMMC-3 can monitor snow and ice accumulation in

three separate zones. The SMMC-3 programming allows each zone to be controlled independently or on a priority mode

basis. In the priority mode, one zone can be given priority and the other zones cannot be energized until the melting/deicing in that zone is complete. This can reduce the loading on the system by ensuring that multiple zones are not

energized simultaneously. The SMMC-3’s program allows customization of the key elements necessary for intelligent

and efficient snow melting control.

The SMMC-3 can access information from three different types of moisture sensors – surface (SMPS-1), aerial (SMAS-

1) and gutter (SMGS-1) and one temperature sensor (SMTS-1). The surface, aerial and gutter sensors detect moisture

from snow, ice, sleet, etc. and send appropriate signals to the SMMC-3. Similarly, the temperature sensor sends

temperature data back to the SMMC-3. Independent temperature and moisture information is processed by the SMMC-3

to ensure that heating equipment will only be energized when precipitation occurs during freezing conditions. For each of

the SMMC-3 control zones, up to two individual moisture sensors can be connected. However, for each zone only one of

these may be a surface sensor. Each SMMC-3 must have a temperature sensor, SMTS-1, in order to function. A SMTS1 is included with each SMMC-3.

The SMMC-3 is housed in an enclosure suitable for commercial/industrial applications (NEMA 12) and features an LCD

display, programming and associated indicator lights for operation of each zone.

The SMMC-3 is powered by 120VAC; control relays provide a 120VAC output to operate external contactors.

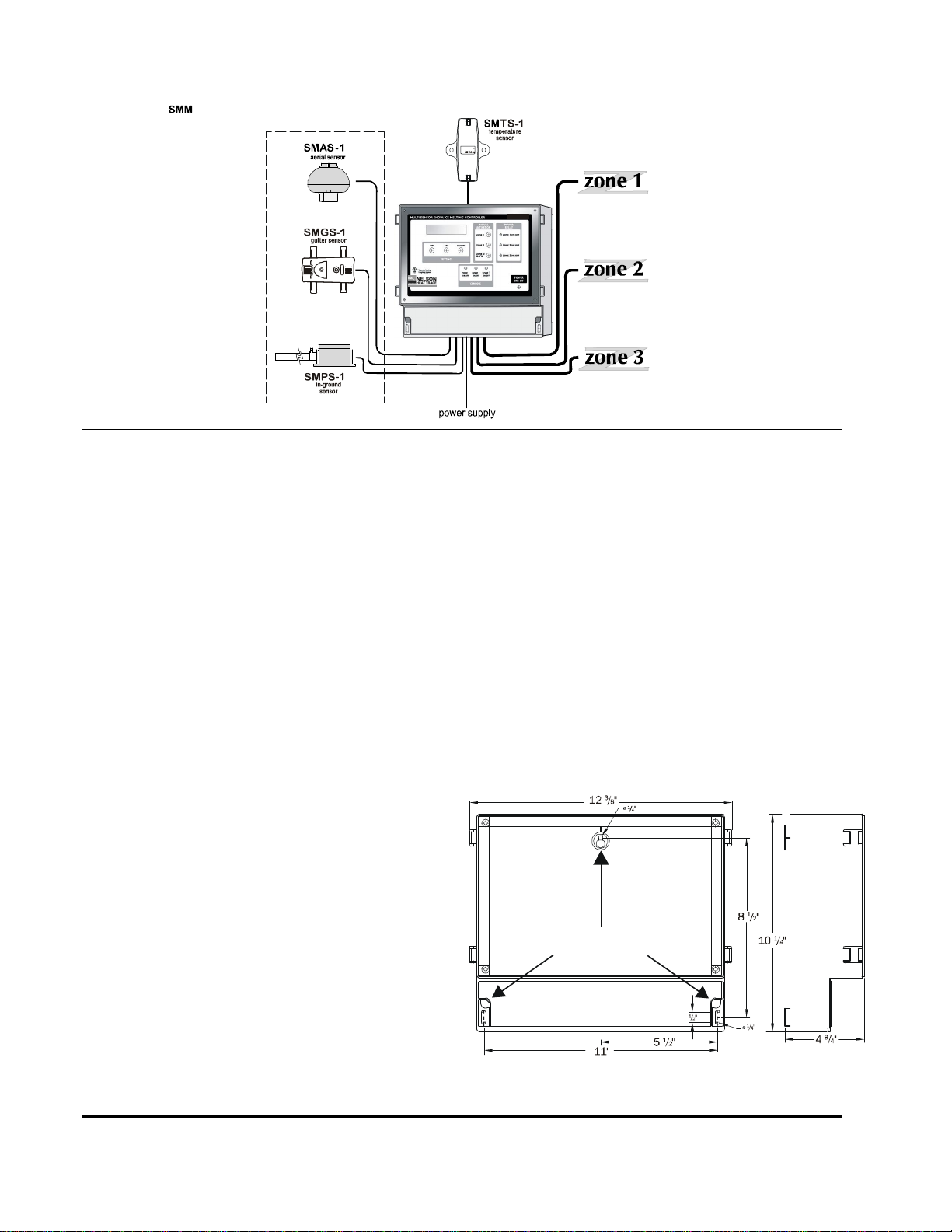

See Fig. 1 & 2.

PRE-PROGRAMMED CONFIGURATION

The SMMC-3 Control Panel is delivered preprogrammed for a single zone system, for use with either an aerial (SMAS-1)

or gutter (SMGS-1) sensor. (Note that the SMMC-3 does not distinguish between the gutter and aerial sensors). The deenergize temperature (the SMMC-3 will not energize the heating equipment when the ambient temperature is warmer

than this) is pre-set to 37°F (3°C), and relay hold time (the length of time that the heating equipment will stay energized

after it no longer senses the presence of ice/snow in the zone) is 3.0 hours. If the snow/ice melting system has been

designed to operate in this manner, then no programming is required: simply wire as per the following instructions.

Output Relay

Status Lights

(on when ZONE

heating is energized)

Fig.1

Control PanelSMMC-3

Buttons

SMMC-3

LCD

Programming

Buttons

Sensor Status

Lights

(on when ZONE

sensor is energized)

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

ON/OFF

Access Cover

Switch

GA-2318, R1

Sheet 3 of 15

May 2008

Page 4

Installation & Operat ing Instructions

120 VAC, to contactor coils

power contactors(s)

C

-3

Fig.3

Mou n ting: m ou nts to wall via thr ee #10 screw s

mounting screw

Fi g.2

Sa mple Application Il lustrati on

snow/ice

sensor

options

maximum 2 sensors

per zone

WARN ING S

1. A qualified electrician must install the SMMC-3.

2. If after carefully reading these instructions you still

have questions regarding installation operation or

maintenance of this product, call the numbers listed

for assistance.

3. Prior to installation, check the SMMC-3 Control

Panel for possible shipping damage. Do not install a

damaged SMMC-3 Control Panel.

4. All heating equipment, controls & associated

systems must be installed in compliance with the

latest editions of all applicable electrical codes and

ordinances.

5. The SMMC-3 has been designed to accept only

Nelson moisture and temperature sensor inputs.

The risk of fire or electric shock exists if the SMMC3 is connected to any device other than a Nelson

sensor.

INSTA LL ATION

1. Mount the SMMC-3 securely to the wall with three

#10 screws, mount in an upright position in an indoor

location, in an area that is dry and not subject to

temperature extremes. See Fig. 3 for mounting

details.

2. Four ½” connectors have been installed on the

SMMC-3 Control Panel box to facilitate connection of

electrical conduit for input power supply wiring, and

contactor output wiring.

3. Remove the lower front access cover to begin

connecting wiring. On the back of the access cover is

a wiring guide label.

4. Connection to the SMMC-3 is done through terminal

blocks. Fish the wire being connected through the

adjacent knock-out, and pull out approximately 12” of

wire. The top half of the terminal block is removable

for easy wiring; gently pull up on the top half to

remove. After connecting the wire to the top half

gently set it back into the base while carefully pulling

back excess wire through the knock-out.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 4 of 15

May 2008

*

*maximum 1 SMPS-1 sensor per zone

SMMC-3

power contactors(s)

power contactors(s)

120 VAC, 450 VA

6. Do not connect heating equipment directly to the

SMMC-3 Control Panel. The SMMC-3 control relays

provide an output to operate external contactors. Each

output provides a maximum current output of 1.25A.

The risk of fire or electric shock exists if the heating

equipment is directly connected to the SMMC-3 Control

Panel.

7. These instructions must be saved and made available

to owners or users of this product and/or transferred to

future owners.

8. Secure the SMMC-3 in an accessible location. The

SMMC-3 Control Panel is not suitable for installation

environments subject to condensing moisture or those

exposed to temperature extremes.

9. Avoid shock or vibration.

locations

Page 5

5. The SMMC-3 terminal blocks serve 5 distinct connection sectors (see Fig 4), they are:

1. SMTS-1 – temperature sensor.

2. SMAS-1 aerial sensors / SMGS-1 gutter sensors (one each per zone).

3. SMPS-1 in-ground sensors (one each per zone).

4. Output to power contactors (one each per zone).

5. Control power input.

Connection to each sensor is described below:

6. The SMTS-1 is connected to the left-most terminal block, identified as TEMP. SENSOR. The SMMC-3 will not

function if the SMTS-1 wire color codes are not properly matched at the terminal block. See Fig. 4

7. The SMAS-1 or the SMGS-1 may be connected to any one of the 3 terminal blocks, identified as A/G. SENS. The

Zone number at the terminal block correlates to a snow-melting zone, ensure that the sensor is connected to the

proper zone terminal. The SMMC-3 will not function properly if the SMAS-1 / SMGS-1 wire color codes are not

properly matched at the terminal block. See Fig. 4

8. The SMPS-1 may be connected to any one of the 3 terminal blocks identified as PAV. SENS. The zone number at

the terminal block correlates to a snow-melting zone; ensure that the sensor is connected to the proper zone

terminal. The SMMC-3 will not function properly if the SMPS-1 wire color codes are not properly matched at the

terminal block. See Fig. 4

9. The outputs to the power contactors may be connected to any one of the 3 terminal blocks in the – OUTPUT TO

POWER CONTACTORS – segment, ZONE #1, 2 OR 3.

The Zone number at the terminal block correlates to a snow-melting zone; ensure that the output being connected

matches the sensor inputs connected. The output wire must be connected with the polarity as noted, ensure voltage

and amperages are suitable for the contactor being used. The SMMC-3 will not function properly if the output

connections are improperly made. See Fig. 4

10. The power supply is connected to the right-most terminal block, identified as POWER SUPPLY. The power supply

wires must be connected with the polarity as noted, ensure supply voltage is correct and noted ampacity is

available. The SMMC-3 will not function if the power supply connections are improperly made. See Fig. 4

11. At this point a quick check on the power supply wiring can be made. Energize the supply circuit for the SMMC-3

Control Panel, and turn on the SMMC-3 via the toggle switch, the LCD should illuminate at this point. Reattach the

front access cover; connection of the SMMC-3 is complete.

12. Each of the SMAS-1, SMGS-1 or SMPS-1 sensors connected to the SMMC-3 must be activated by programming

the SMMC-3; to do so, follow the steps in the programming section of this instruction.

PRE-PROGRAMMED CONNECTIONS

1. Remove lower access panel on the SMMC-3.

2. Connect the temperature sensor lead to the temperature sensor terminal block.

3. Connect the aerial or gutter sensor lead to the Zone 1 sensor terminal block.

4. Connect the control wire from the contactor coil to the Zone 1 output terminal block, 120VAC only. DO NOT

CONNECT OUTPUT DIRECTLY TO THE LOAD. THIS WILL DAMAGE THE SMMC-3 AND CAN RESULT IN

RISK OF INJURY OR FIRE.

5. Connect 120VAC to the power supply terminal block, verify polarity.

6. Turn on the power to the SMMC-3 using the toggle switch on the front panel.

7. System is now operational.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 5 of 15

May 2008

Page 6

Fig. 4 SMMC-3 Control Panel (Typical Connections)

L2

Sup

Connection Box

SMTS-1 SMAS-1/SMGS-1 SMPS-1 Contactor Output

SMAS-1 or SMGS-1

Sensor Wire

To Heater

Cables

SYSTEM CHEC K

Before you energize the controller, confirm :

· All the sensors, relay coils and the power supply

are connected to the proper terminal blocks.

· Only approved cable was used to extend the

sensors.

· The polarity of the 120 VAC power supply is

appropriate.

· You have connected the output terminals to a

relay or contactor coil, NOT DIRECTLY TO THE

HEATER LOAD.

After energizing the controller, you should see:

· The display lit and reading the temperature in

the area of the SMTS-1.

· The Small green LED’s next to the connected

terminal blocks are lit (no LED for the SMTS-1

block).

Control

Wiring

SMMC-3

Power

Input

L1

Heater Power

Contactor/

To cycle system and check sensor operation:

1. Submerge the SMTS-1 in a quart (litre) of water

and crushed ice.

2. After 20 minutes, confirm the display reads 32°F

(0°C).

3. Put a drop of water on each sensor surface*, the

Power Relay light(s) on the front panel will light

up and the associated output relay will energize.

4. Dry off the sensor surface; the relay output will

de-energize and the relay light will turn off after

the pre-set hold time.

* To confirm SMPS-1 operation, the slab

temperature must be below 59°F (15°C).

ply

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 6 of 15

May 2008

Page 7

OP ERAT IO N

The SMMC-3 is a programmable controller, capable of controlling three separate snow/ice melting zones. A control relay

for each zone is included in the SMMC-3 to operate a contactor for each zone to energize the snow/ice melting

equipment. There are two operating mode selections possible with the SMMC-3:

MODE 1 – INDEPENDENT

In this mode each snow/ice melting zone is controlled independently. Mode 1 allows all 3 zones to be energized

simultaneously. This mode is best used where circuit loading is not a concern (e.g. adequate circuit ampacity is

available to operate the entire snow/ice melting load simultaneously).

MODE 2 – PRIORITY

In this mode each zone is controlled on a priority basis, with the most critical zone (always Zone 1) being melted first,

followed then by the less critical zones. Mode 2 allows only 1 of the zones to be energized at a time. This mode is best

used where circuit loading is a concern. A slight delay is provided when switching power between zones to ensure

circuits are not overloaded. Set-up in Mode 2 must be done either with Zones 1 & 2, (with Zone 3 not being used), or

Zones 1, 2 & 3. Operation is sequential, beginning with Zone 1. When Zone 1 is melted, the SMMC-3 de-energizes it

and then energizes Zone 2. However if snow/ice is detected on Zone 1, Zone 2 is de-energized and Zone 1 re-energized.

Similar logic applies for Zone 2 & 3; i.e. the lower numbered zone always takes priority.

The Priority mode available in the SMMC-3 can reduce circuit loading by splitting up a large snow melting area into

separate, smaller zones. For example, if a large area would require 90 Amps of current, this could be split into two

separate zones of, say, 50 Amps in one zone and 40 Amps in the other. Then, by programming the SMMC-3 in the

Priority Mode, only one zone will be enabled at any on time, resulting in a maximum circuit loading of 50 Amps.

Similarly, the area could be split into three zones of, say 25, 35 and 30 Amps; in this case circuit loading would be 35

Amps maximum. It should be further noted that when in Priority mode, the SMMC-3 always gives priority to Zone 1;

when Zone 1 is completely melted, then Zone 2 is enabled until melted, and then, finally Zone 3; i.e. Zone 1 always has

higher priority over Zone 2, which has higher priority over Zone 3. Further, if snow/ice is detected in a zone with higher

priority, then operation reverts to the zone with higher priority. For example, if melting has been completed in Zone 1,

and Zone 2 has been enabled, then if snow/ice is detected in Zone 1, operation in Zone 2 will be suspended, and Zone 1

will be re-enabled until melting is again complete, at which time melting in Zone 2 will recommence.

It is also important to give consideration to the assignment of zones; usually, high traffic areas will be given a high

priority, with lower traffic areas given lower priority. Zones can be easily reassigned at the terminals of the SMMC-3.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 7 of 15

May 2008

Page 8

ZONE ASSIGNMENT

M. Time Delay Zone 1

min.0 <2.0H> Max.10

(only sensors acti vated will sho w)

M1= Mo de 1 Ind epe nd ent

LCD Explanation

A1-A2-A3-P1-P2-P3-M1

The SMMC-3 uses the concept of a zone system to most

efficiently control snow/ice melting equipment. The term

“zone” means an area (either surface area or roof/gutter

area, or some combination of both) heated by a specific

set of snow/ice melting equipment that is controlled in a

common manner. The SMMC-3 allows for up to three

zones, and each zone can have multiple moisture sensors

for, say, roof/gutter, aerial and/or surface snow/ice

detection. If any one of the sensors detects moisture, the

heating equipment may be energized. The moisture

sensor in the zone should be generally, surrounded by the

heating equipment to ensure that the heating equipment is

only energized when there is snow/ice present in the zone.

Zones can be used to represent different areas; for

example a parking ramp area could be one zone while

roof/gutter de-icing on the same building could be another

zone. Similarly, two sidewalks on different sides of the

same building (possibly one on the north side and one on

the south side) could represent two separate zones. The

perimeter of a football stadium could be split into three

separate zones to reflect different weather conditions on

different sides of the building.

MANUAL OPERATION

The power to any one of the snow-melting zones may be

activated manually by pressing and holding the ZONE X

button until the information below appears on the LCD

screen. Manual activation will only work a long as the

ambient temperature is below the SMMC-3 shut-off

temperature. The duration of the time the zone will remain

energized (Time Delay) is pre-set to 2.0 hours; this can be

adjusted by following the programming instructions below.

The minimum and maximum settings possible are noted on

the LCD, adjustable in 0.5 hour increments.

Pressing UP increases the delay time.

Pressing DOWN decreases the delay time.

Press the SET button to accept the chosen delay time.

Once the delay time is set, the SMMC-3 returns to normal

control function, and energizes the heating equipment for

the selected zone.

To de-energize the manually activated heating

equipment, use the toggle switch on the front panel.

When operating in Mode 2 – Priority, the manual

override works as described if no snow melting zones

are energized. If any snow-melting zone is energized

the manual override only works to energize the higher

priority zone, thereby de-energizing the lower priority

zone.

It is important to note that manual operation is not

possible if the SMMC-3 has already energized the zone,

and that manual control will be overridden if the zone

moisture sensor detects precipitation.

Temperat ure

at SM TS -1 lo cation

Temperatu re

Valu e & U ni ts

°C o r ° F

Outside T=-3°C

(only sens ors act ivat ed will sho w)

A1= SMAS -1 o r S MGS-1 ZONE 1

A2= SMAS -1 o r S MGS-1 ZONE 2

A3= SMAS -1 o r S MGS-1 ZONE 3

P1= SMPS-1 ZON E 1

P2= SMPS-1 ZON E 2

P3= SMPS-1 ZON E 3

M2= Mo de 2 Pri ority

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 8 of 15

May 2008

Page 9

PROGRAMMING INSTRUCTIONS

Level 2. Operating Mode Selection

2.Mode: 1 or 2

2. Mode No.2

<2zones> <3zones>

Level 3. Sensor Activation/De-activati on

3.Sensor Activation

1. Degree: °C or °F

<°C > <°F >

3.Sensor Activation

Yes <P.Zone3> No

2.Mode: 1 or 2

<No.1 > <No.2 >

Level 1. Temperature Unit Selection

The SMMC-3 program has been structured into 6 levels; within

each of these levels are further degrees of selection. Each

programming step is clearly described on the LCD, and easily

adjusted by the “UP”, “DOWN”, and “SET” buttons.

During programming:

· All regular operating functions of the SMMC-3 are

· If a button is not pressed for approximately 90

· Pressing the BACK button results in an exit from

Resetting to Factory Conditions

When the SMMC-3 is first energized, and during the time the initial

LCD display (SMMC Ver. X.X) screen shows push the UP and

DOWN buttons simultaneously to access the option to revert to

factory set conditions. Use the UP or DOWN button to select “yes”

or “no”; the program accepts the selection and returns to normal

operation.

To begin programming the SMMC-3 hold the SET button down for

5 seconds. The display will start in program level 1. To move to

other levels use the UP or DOWN buttons.

PROGRAM MODE

1. Degree: °C or °F

The default temperature units setting is °F.

To move to the next level use the UP or DOWN buttons.

Press the SET button to select the temperature display units.

Pressing UP selects Degrees C.

Pressing DOWN selects Degrees F.

After pressing the UP or DOWN button, the program automatically

accepts the selection and advances to the next program level.

suspended.

seconds, the program will return to normal

operation, saving programming changes made up to

the point exited.

the programming sequence, with the changes made

up to that point saved.

Pressing UP selects Mode 1 (Independent).

Pressing DOWN selects Mode 2 (Priority).

After pressing the UP button for Mode 1, the program

automatically accepts the selection and advances to the next

program level.

After pressing the DOWN button for Mode 2, the program

automatically accepts the selection and then moves to

another input screen, as shown below.

Pressing UP selects a 2 Zone system (Zone 1 & 2).

Pressing DOWN selects a 3 Zone system (Zone 1, 2 & 3).

After pressing the UP or DOWN button, the program

automatically accepts the selection and advances to the next

program level.

PROGRAM MODE

The default sensor activation setting is for an aerial (SMAS-

1), or gutter (SMGS-1) sensor, zone 1.

To move to the next level use the UP or DOWN buttons.

Press the SET button to begin the process to activate or

deactivate sensors. Each of the 3 control zones may have up

to 2 individual sensors, for a total of 6 sensors. <A/G.ZoneX>

refers to either an SMAS-1 or SMGS-1 sensor, <P.ZoneX>,

refers to an SMPS-1 in-ground sensor. The

activation/deactivation operation for all 6 sensors must be

stepped through before this operation is complete.

Yes <A/G.Zone1> No

3.Sensor Activation

Yes <A/G.Zone2> No

3.Sensor Activation

Yes <A/G.Zone3> No

PROGRAM MODE

The default mode setting is Mode 1.

To move to the next level use the UP or DOWN buttons.

Press the SET button to select the operating mode.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

Yes <P.Zone1> No

3.Sensor Activation

Yes <P.Zone2> No

3.Sensor Activation

3.Sensor Activation

GA-2318, R1

Sheet 9 of 15

May 2008

Page 10

Pressing UP activates the selected sensor.

Level 4. Ambient Off Temperature Setting

4.Ambient Off Temp.

min.34 <37°F> Max.50

Level 5. Slab Off Temperature Setting

5.Slab Off Temp.

min.41 <50°F> Max.68

Level 6. Setting the Relay Hold Time

6.Relay Hold Time Z1

min.0 <3.0H> Max.10

Outside T = 10°F

Pressing DOWN de-activates the selected sensor.

After pressing the UP or DOWN button for <P.Zone3>, the

program automatically accepts the selections and advances to the

next program level.

PROGRAM MODE

4.Ambient Off Temp.

The default ambient off temperature is 37°F (3°C).

To move to the next level use the UP or DOWN buttons.

Press the SET button to adjust the ambient off temperature, the

temperature above which the SMMC-3 will no longer energize the

heating equipment. The minimum and maximum settings possible

are noted on the LCD.

Pressing UP increases the degree setting.

Pressing DOWN decreases the degree setting.

Press the SET button to accept the chosen ambient off

temperature and advances to the next program level.

PROGRAM MODE

5.Slab Off Temp.

The default slab off temperature is 50°F (10°C).

To move to the next level use the UP or DOWN buttons.

Press the SET button to adjust the slab off temperature, the

temperature above which the SMMC-3 will de-energize the inground heating equipment. The minimum and maximum settings

possible are noted on the LCD.

Press the SET button to adjust the relay hold time for the

snow melting zones. The relay hold time is the amount of time

the snow melting zone remains energized after the moisture

sensor is dry. Each of the 3 zones is set independently, in 0.5

hour increments. The minimum and maximum settings

possible are noted on the LCD. The relay hold times for all 3

sensors must be stepped through before this operation is

complete.

min.0 <3.0H> Max.10

6.Relay Hold Time Z2

min.0 <3.0H> Max.10

6.Relay Hold Time Z3

Pressing UP increases the relay hold time.

Pressing DOWN decreases the relay hold time.

Press the SET button to accept the chosen relay hold time

and advance to the timing for the next zone.

After the hold time for Zone 3 has been set the program

automatically returns to programming Level #1 “Temperature

Unit Selection”. To exit the programming sequence and return

to normal control operation press the BACK button.

Temperature Stand-by

Whenever the ambient air temperature exceeds the ambient

off temp, the SMMC-3 goes into a “temperature stand-by”

mode, at which time all moisture sensors are de-activated. As

soon as the ambient air temperature drops below the ambient

off temp, the sensors are reactivated and operation begins as

normal.

Temperature Stand-by

Pressing UP increases the degree setting.

Pressing DOWN decreases the degree setting.

Press the SET button to accept the chosen slab off temperature

and advances to the next program level.

PROGRAM MODE

6.Relay Hold Time

The default relay hold time is 3.0 hours for all zones.

To move to the next level use the UP or DOWN buttons.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 10 of 15

May 2008

Page 11

Error M essages

SMTS-1 Error

The SMMC-3 will display an error message whenever a problem is

detected with the connection to the SMTS-1 or any of the SMPS1’s. Note that the connection status to a gutter (SMGS-1) or aerial

(SMAS-1) sensor is not monitored by the SMMC-3.

Manual only <M1>

Error!- SMTS-1 <cancel>

SMPS-1 Error

Error!- SMPS-1

<cancel>

The error screen will flash intermittently with the standard

operating screen. To cancel the error message press the

DOWN button when the error screen is showing.

If there is a SMTS-1 error all automatic operation of the

SMMC-3 ceases, however manual operation of each zone is

still possible.

If there is an SMPS-1 error, automatic control of the

associated zone is suspended, again manual operation is still

possible. Once the sensor problem has been fixed turn off the

power to the SMMC-3 Control Panel at the toggle switch,

reconnect the sensor wiring to the terminal block, then after a

minimum 10 seconds turn back on the power. The SMMC-3

program will recognize the sensor and begin normal

operation.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 11 of 15

May 2008

Page 12

TROU BLE SHOOTING GU ID E

SYMPTOMS PROBABLE CAUSE CORRECTION

System is not operating and system

light is not lit.

Display is not lit and power switch

is on.

System is not operating,

Temperature Standby on display.

Error! – SMTS-1 on display and

system not operating.

Error! – SMTS-1 on display after

corrections made.

Error! – SMPS-1 on display and

system not operating.

The aerial or gutter sensors are wet

(covered in snow), the LED above

the corresponding terminal block is

lit and the system is not heating.

The in-ground sensor is wet

(covered in snow), the sensor

surface is warm and system is not

heating.

No Power to SMMC-3 Turn on power using switch on front

panel.

Supply not energized or power

input fuse burned out.

Check power supply. If LED above

power input terminal connection is

not lit, replace fuse (4A spare fuse )

supplied with SMMC-3.

The SMMC-3 is in a standby mode,

NORMAL OPERATION

the ambient temperature outside is

above the programmed

temperature required to melt snow.

There is a communication problem

with the temperature sensor

Make sure the temperature sensor

lead wires are connected to the

terminal properly. If the sensor wire

has been extended, use 3

Conductor Instrumentation Cable,

#18AWG, unshielded, common

conductors such as twisted pair

communications wire, telephone

wire, electrical building wire and

doorbell wire is not acceptable.

Manufacturer: Belden #5301UE or

equal.

Need to clear SMTS-1 error from

SMMC-3 program.

Turn off system using the front

panel switch, wait 10 seconds and

turn on again. The SMMC-3 should

now recognize the sensor.

There is a communication problem

with the in-ground sensor.

Make sure the in-ground sensor

lead wires are connected to the

terminal properly. If the sensor wire

has been extended, use 4

Conductor Instrumentation Cable,

#18AWG, shielded, common

conductors such as twisted pair

communications wire, telephone

wire, electrical building wire and

doorbell wire is not acceptable.

Manufacturer: Belden #9418 or

equal.

Possible communication problem

with the aerial or gutter sensor. No

error message will show on the

display when this occurs.

Make sure the in-ground sensor

lead wires are connected to the

terminal properly. If the sensor wire

has been extended, use 3

Conductor Instrumentation Cable,

#18-20AWG, shielded or

unshielded, common conductors

such as twisted pair

communications wire, telephone

wire, electrical building wire and

doorbell wire is not acceptable.

Manufacturer: Belden #8770 or

equal.

The surface of the in-ground sensor

may be dirty, possibly covered with

sealant.

Clean the sensor surface to get rid

of any contaminant, use mild

detergent and carefully scrub with

steel wool.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 12 of 15

May 2008

Page 13

doors to sense air

SMMC-3 CONTROL PANEL (ACCESS COVER REMOVED)

SMTS-1

Zone 1 Sensor

Input SMAS-1 or

SMGS-1 (Default)

Zone 2 Sensor

Input SMAS-1 or

SMGS-1

Zone 3 Sensor

Input SMAS-1

or SMGS-1

Zone 1 Sensor

Input SMPS-1

(must be programmed

To activate)

Zone 2 Input

for SMPS-1

Zone 3 Input

for SMPS-1

Zone 1 Output

Terminal Block

Connector to

Contactor Coil

(Default)

Zone 2

Output

Fuse

“Fuse OK” LED

Zone 3

Output

120VAC Power Connection

Temperature

Sensor, SM TS-1:

this is included with

the SMMC-3 and

must be installed

out

temperature.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

Aerial Snow

Sensor, SM AS-1:

Mast mounted to

sense falling snow

(may be used as the

preprogrammed

sensor).

Gutter Sensor,

SMGS-1: secured in

the gutter to detect

moisture conditions

(may be used as the

preprogrammed

sensor).

In-Ground Sensor , SM PS-1:

installed in-ground to detect

moisture and slab temperature

(the SMMC-3 must be

programmed to recognize this

sensor, refer to the instruction

manual for details).

Wiring guide on

back of terminal

block cover

GA-2318, R1

Sheet 13 of 15

May 2008

Page 14

SP ECIFICATION S

Electrical

Power Requirements

120 VAC, 50/60 hz, 480VA

Control Relays – Outputs

120 VAC, Pilot Duty, 120VA

Power Supply – Sensors

24 VAC, Class 3, 12VA

Temperature Sensor Supply

5 VDC, Class 2, 0.5VA

SENSOR EXTENSION WIRE SPECIFICATIONS

Aerial Sensor SMAS-1

3 Conductor Instrumentation Cable, #18-20AWG, shielded or unshielded,

common conductors such as twisted pair communications wire, telephone wire,

electrical building wire and doorbell wire is not acceptable.

Manufacturer: Belden #8770 or equal

Gutter Sensor SMGS-1

3 Conductor Instrumentation Cable, #18-20AWG, shielded or unshielded,

common conductors such as twisted pair communications wire, telephone wire,

electrical building wire and doorbell wire is not acceptable.

Manufacturer: Belden #8770 or equal

Temperature Sensor SMTS-1

3 Conductor Instrumentation Cable, #18AWG, unshielded, common conductors

such as twisted pair communications wire, telephone wire, electrical building

wire and doorbell wire is not acceptable.

Manufacturer: Belden #5301UE or equal

Pavement Sensor SMPS-1

4 Conductor Instrumentation Cable, #18AWG, shielded, common conductors

such as twisted pair communications wire, telephone wire, electrical building

wire and doorbell wire is not acceptable.

Manufacturer: Belden #9418 or equal

Mechanical

NEMA 12 non-metallic enclosure

System Mem ory

Non-Volatile: no data loss

with a loss of system power

Dimensions

12.375” W x 10.25” H x 4.75” D

Certification

Environm ental Specifications

Ambient Operating Temperature Range

-4°F to 160°F / -20°C to 70°C

Storage Temperature

-4°F to 185°F / -20°C to 85°C

Relative Humidity

0 to 90% RH, non condensing

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

GA-2318, R1

Sheet 14 of 15

May 2008

Page 15

LIMI TE D WARR AN TY AND LIABILITY

Nelson warrants that if there are any defects in material or workmanship in any heating cable or accessory during the first year (two

years on MI or self regulating heaters) after the date of its purchase, we will provide new products to replace any defective items, or

we will refund the purchase price paid for the accessory or cable, not including any labor or other installation costs. As an alternate,

we may elect to repair the cable or accessory at our factory with all shipping and other removal costs borne by the purchaser.

We further warrant that any services performed for the Buyer hereunder will be performed in a good and skillful manner, based on our

understanding of pertinent technical data as of the date of performance of such services. Nelson’s sole responsibility and liability in

the event of any defect, error, omission, or failure in the services rendered hereunder shall be to provide corrected services of the type

provided for herein, designed to correct such defect, error, omissions, or failure, and in no event shall the Nelson’s liability with

respect to such warranty exceed the amount received by it from the Buyer on account of such services.

Our obligation to provide corrected services, new products, refund the purchase price, or perform the repair described above is

conditioned upon (a) the installation of the accessory or cable conforming to the specifications set forth in our installation instructions

and (b) the accessory or cable not having been damaged by mechanical or electrical activities unrelated to the operation of the

accessory or cable.

A refund of your purchase price, provision of replacement products the repair of the accessory or cable or provision of

corrected services as described above shall be your sole and exclusive remedy for a breach of this warranty. THESE ARE

THE SOLE AND EXCLUSIVE WARRANTIES GIVEN BY NELSON WITH RESPECT TO THE GOODS AND SERVICES AND ARE

IN LIEU OF AND EXCLUDE ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARISING BY OPERATION OF LAW OR

OTHERWISE, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

WHETHER OR NOT THE PURPOSE OR USE HAS BEEN DISCLOSED TO NELSON IN SPECIFICATIONS, DRAWINGS OR

OTHERWISE, AND WHETHER OR NOT NELSON'S PRODUCTS ARE SPECIFICALLY DESIGNED AND/OR MANUFACTURED

BY NELSON FOR YOUR USE OR PURPOSE.

This warranty does not extend to any losses or damages due to misuse, accident, abuse, neglect, normal wear and tear, negligence

(other than Nelson's), unauthorized modification or alteration, use beyond rate capacity, or improper installation, maintenance or

application. To the extent that you or your agents has supplied specifications, information, representation of operating conditions or

other data to Nelson in the selection or design of the Goods and the preparation of Nelson’s quotation, and in the event that actual

operating conditions or other conditions differ from those represented by you, any warranties or other provisions contained herein

which are affected by such conditions shall be null and void.

If within thirty (30) days after your discovery of any warranty defects within the warranty period, you notify Nelson thereof in writing,

Nelson shall, at its option, repair, correct or replace F.O.B. point of manufacture, or refund the purchase price for, that portion of the

Goods found by Nelson to be defective. Failure by you to give such written notice within the applicable time period shall be deemed

an absolute and unconditional waiver of your claim for such defects. Goods repaired or replaced during the warranty period shall be

covered by the foregoing warranty for the remainder of the original warranty period or ninety (90) days from the date of shipment,

whichever is longer.

This limited warranty does not cover any costs relating to the repair or replacement of any accessory or cable at the

installation site. Our accessories and cables are not easily accessible. A failed accessory or cable usually cannot be easily

repaired. Replacement of a failed accessory or cable will require that the materials under which it is installed be removed to permit

replacement of the accessory or cable. We w ill not reimburse any costs relating to the repair or replacement of any accessory

or cable at the installation site.

IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL NELSON’S LIABILITY TO YOU

AND/OR YOUR CUSTOMERS EXCEED THE PRICE PAID BY YOU FOR THE SPECIFIC GOODS PROVIDED BY NELSON

GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. YOU AGREE THAT WE SHALL NOT BE LIABLE TO YOU OR YOUR

CUSTOMERS FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL OR PUNITIVE DAMAGES. No agent, employee or

representative of ours has authority to bind us to any affirmation, representation or w arranty concerning the goods sold

unless such affirmation, representation or warranty is specifically incorporated by w ritten agreement.

To obtain new products, arrange repair of existing product, or a refund under this warranty, please contact Nelson with a description

of the defect and proof of purchase at the addresses noted herein.

PO. Box 726 n TULSA, OK 74101 n TEL 918-627-5530 n FAX 918-641-7336 n www.nelsonheaters.com

ÓCopyright 2008 GA-2318, R1

Sheet 15 of 15

May 2008

Loading...

Loading...