Page 1

Smart Wireless THUM™ Adapter

Reference Manual

00809-0100-4075, Rev CA

March 2014

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4075, Rev CA

Smart Wireless THUM™ Adapter

Smart Wireless THUM™ Adapter Hardware Revision 1

HART

Field Communicator Field Device Revision Dev v2.5 DD v4

®

Device Revision 1

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number.

Customer Central

1 800 999 9307 (7:00 a.m. to 7:00 p.m. CST)

National Response Center

1 800 654 7768 (24 hours a day)

Equipment service needs

International

1 952 906 8888

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson Process

Management Sales Representative.

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the Product Certifications section for any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, ensure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Electrical shock can result in death or serious injury:

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions. This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

iii

Page 4

Reference Manual

NOTICE

NOTICE

00809-0100-4075, Rev CA

The THUM and all other wireless devices should be installed only after the Smart Wireless

Gateway has been installed and is functioning properly. Wireless devices should also be

powered up in order of proximity from the Smart Wireless Gateway, beginning with the

closest. This will result in a simpler and faster network installation.

During normal operation, or in fault condition, the THUM will cause a 2.5 V drop in the

connected loop. It is important to ensure that the power supply can provide at least 2.5 V

more than the lift off voltage of the wired device to make sure it works properly with the

THUM installed. To determine the lift off voltage for the wired device, review the wired

device operation and installation manual.

iv

Page 5

Reference Manual

00809-0100-4075, Rev CA

Content

1Section 1: Introduction

Table of Contents

March 2014

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.3 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.5 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.6 Wireless considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2Section 2: Configuration

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Device sensor configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5 Device network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.1 Join device to network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.2 Configure update rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.3 Configure THUM long tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5.4 Wired device tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6 HART tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table of Contents

v

Page 6

Table of Contents

March 2014

Reference Manual

00809-0100-4075, Rev CA

3Section 3: Mounting

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2.1 Direct mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2.2 Remote mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2.4 Load resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2.5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3 Loop current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4Section 4: Commissioning

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2 Device network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.2.1 Network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.2.2 Verify operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5Section 5: Operation and Maintenance

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.2 Startup sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.3 Advanced setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5.3.1 Configure advanced update rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5.3.2 4-20 mA current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5.3.3 Voltage drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5.3.4 Discovery mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5.3.5 Configure HART polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.6 Configure router only mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.7 HART address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.8 HART master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6Section 6: Troubleshooting

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

vi

Table of Contents

Page 7

Reference Manual

00809-0100-4075, Rev CA

AAppendix A: Reference Data

BAppendix B: Product Certifications

Table of Contents

March 2014

A.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

A.2 Physical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

A.3 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

A.4 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

A.5 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

A.6 Accessories and spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

B.1 Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

B.2 European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

B.3 Telecommunication Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

B.4 FCC and IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

B.5 Ordinary Location Certification for FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

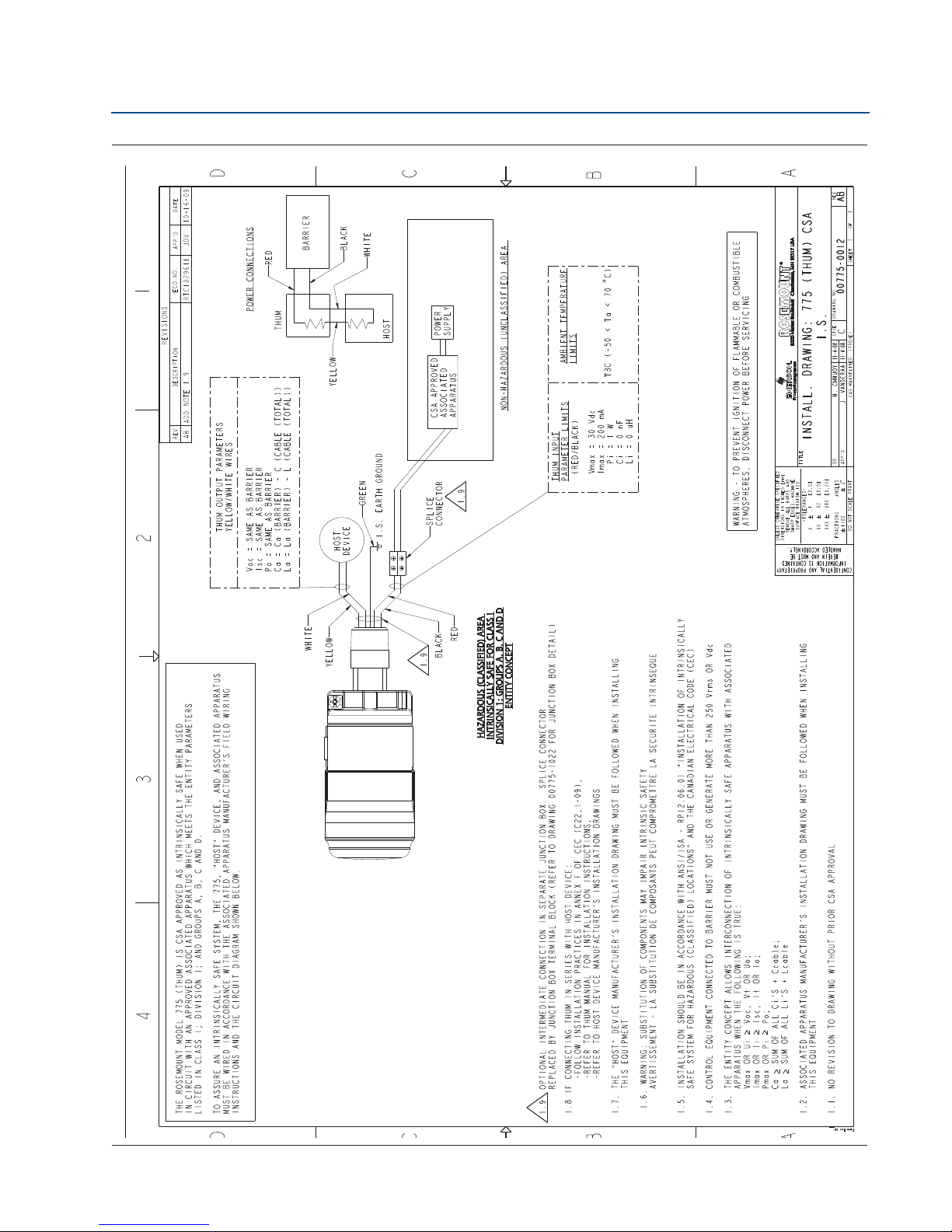

B.6 Hazardous Locations Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table of Contents

vii

Page 8

Page 9

Reference Manual

00809-0100-4075, Rev CA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

1.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

Section 1: Introduction

March 2014

1.1.1 Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Introduction

1

Page 10

Section 1: Introduction

March 2014

1.2 Overview

1.2.1 Manual

This manual is designed to assist in the installation, operation, and maintenance of the Smart

Wireless THUM™ Adapter.

Section 1: Introduction

Manual and Transmitter Overview

Considerations

Return of Materials

Section 2: Configuration

Device Sensor Configuration

Device Network Configuration

Section 3: Mounting

Reference Manual

00809-0100-4075, Rev CA

Mount the Sensor

Sensor Assembly/Leads

Grounding

Section 4: Commissioning

Network Status

Verify Operation

Section 5: Operation and Maintenance

Startup Sequence

Advanced Setup

Appendix A: Reference Data

Specifications

Dimensional Drawings

Ordering Information

Appendix B: Product Certifications

Product Certifications

Installation Drawings

2

Introduction

Page 11

Reference Manual

00809-0100-4075, Rev CA

1.2.2 Features

An installation-ready solution that provides rich wireless HART

Works with any 2- or 4-wire HART devices

Flexibility to meet your most demanding applications

Wireless output with >99% data reliability delivers rich HART data, protected by

industry leading security

Gain access to additional HART information, such as diagnostics or multi-variable data

Add wireless to almost any measurement point without affecting the approval of the

sub-device

IEC 62591 (WirelessHART™) capabilities extend the full benefits of PlantWeb

previously inaccessible locations

1.3 Considerations

1.3.1 General

Section 1: Introduction

March 2014

®

data

®

to

The Smart Wireless THUM Adapter is connected to a HART sub-device. With simple HART

configuration, the THUM transmits the HART information from the sub-device into the Wireless

network.

1.3.2 Commissioning

The THUM can be commissioned before or after installation. It may be useful to bench

commission the THUM before installation to ensure proper operation and to become familiar

with the functionality. The instruments should be installed in accordance with intrinsically safe

or non-incendive field wiring practices, when required. The THUM Adapter is powered when

connected to a powered loop.

1.3.3 Mechanical

When choosing an installation location and position for the transmitter, take into account

access to the device. For best performance, the antenna should be vertical and have some space

between objects in a parallel metal plane such as a pipe or metal framework, as the pipes or

framework may adversely affect the performance of the antenna.

1.3.4 Electrical

The THUM Adapter is connected into a powered 4–20 mA loop, powering itself by scavenging

power. The THUM Adapter causes a voltage drop across the loop. The drop is linear from 2.25

volts at 3.5 mA to 1.2 volts at 25 mA, but does not effect the 4–20 mA signal on the loop. Under

fault conditions, the maximum voltage drop is 2.5 volts.

1.3.5 Environmental

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations certifications.

Introduction

3

Page 12

Section 1: Introduction

March 2014

Temperature limits

Operating Limit Storage Limit

–40 to 185 °F –40 to 185 °F

–40 to 85 °C –40 to 85 °C

1.3.6 Wireless considerations

Power up sequence

Power should not be applied to any wireless device until the Smart Wireless Gateway

(“Gateway”) is installed and functioning properly. Wireless devices should also be powered up

in order of proximity from the Gateway, beginning with the closest. This will result in a simpler

and faster network installation. Enable Active Advertising on the Gateway to ensure that new

devices join the network faster. For more information see the Smart Wireless Gateway Manual

(Doc. No. 00809-0200-4420).

Reference Manual

00809-0100-4075, Rev CA

THUM adapter position

If possible, the THUM Adapter should be positioned vertically, either straight up or straight

down, and it should be approximately 3 ft. (1 m) from any large structure, building, or

conductive surface to allow for clear communication to other devices. If the THUM Adapter is

mounted horizontally, wireless communication range may be decreased.

Figure 1-1. THUM adapter position

Conduit entry

When installing the THUM Adapter into the conduit entry of a wired device, use an approved

thread sealant. Thread sealant provides a water tight seal. The thread sealant also provides a

lubrication to ensure easy removal of the THUM Adapter.

M20 conduit adapter

When using the M20 Conduit Adapter on the THUM Adapter, use an approved thread sealant

and tighten wrench tight to the THUM Adapter. When installing the M20 conduit adapter into a

conduit tighten to 32.5 Nm/25 ft-lb. to ensure water tight seal.

4

Introduction

Page 13

Reference Manual

00809-0100-4075, Rev CA

Field communicator connections

In order for the Field Communicator to interface with the THUM Adapter, the wired device must

be powered. The Field Communicator must be put into poll mode and should use the THUM

Adapter address of 63.

Power supply

Minimum loop load of 250 Ohms.

The THUM Adapter communicates and derives power from a standard 4-20 mA/HART loop. The

THUM Adapter causes a small voltage drop on the loop which is linear from 2.25 V at 3.5 mA to

1.2 V at 25 mA. Under fault conditions, the maximum voltage drop is 2.5 V. The THUM Adapter

will not affect the 4-20 mA signal under normal or fault conditions as long as the loop has at

least a 2.5 V margin at the maximum loop current (25 mA for a typical 4-20 mA/HART device).

Limit the power supply to 0.5 Amps maximum, and voltage to 55 Vdc.

Section 1: Introduction

March 2014

Loop Current THUM Adapter voltage drop

3.5 mA 2.25 V

25 mA 1.2 V

Load resistor

If required, add a load resistor as shown in Figure 3-20, Figure 3-22, and Figure 3-24. The resistor

should be adequately rated for the application (1W minimum) and be compatible with the

supplied splice connector which accepts wire sizes from 14 to 22 AWG.

When adding a load resistor, ensure that uninsulated conductors do not contact the enclosure

and/or other exposed metal parts.

Introduction

5

Page 14

Section 1: Introduction

March 2014

1.4 Service support

To expedite the return process outside of North America, contact your Emerson Process

Management representative.

Within the United States, call the Emerson Process Management Response Center toll-free

number 1 800 654 7768. The center, which is available 24 hours a day, will assist you with any

needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to

a hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

Reference Manual

00809-0100-4075, Rev CA

1.5 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

6

Introduction

Page 15

Reference Manual

00809-0100-4075, Rev CA

Section 2 Configuration

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Device sensor configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Device network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

HART tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

Section 2: Configuration

March 2014

2.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

2.2 Connections

Section 2 details wiring the THUM Adapter to the different types of compatible sub-devices.

Configuration

7

Page 16

Section 2: Configuration

March 2014

2.3 Device sensor configuration

Reference Manual

00809-0100-4075, Rev CA

The THUM Adapter, attached to a powered sub-device, receives HART® communication from a

handheld Field Communicator or AMS

®

Field communicator

In order to communicate with the THUM Adapter, polling must be activated on the Field

Communicator. The default address for the THUM Adapter is 63. Also, note that any

configuration changes must be sent to the transmitter using the Send key (F2).

AMS wireless configurator

AMS is capable of connecting devices directly using a HART modem or the Gateway. For

configuring through AMS Wireless Configurator, double click the device icon and choose the

Configure/Setup tab. AMS configuration changes are implemented when the Apply button is

selected.

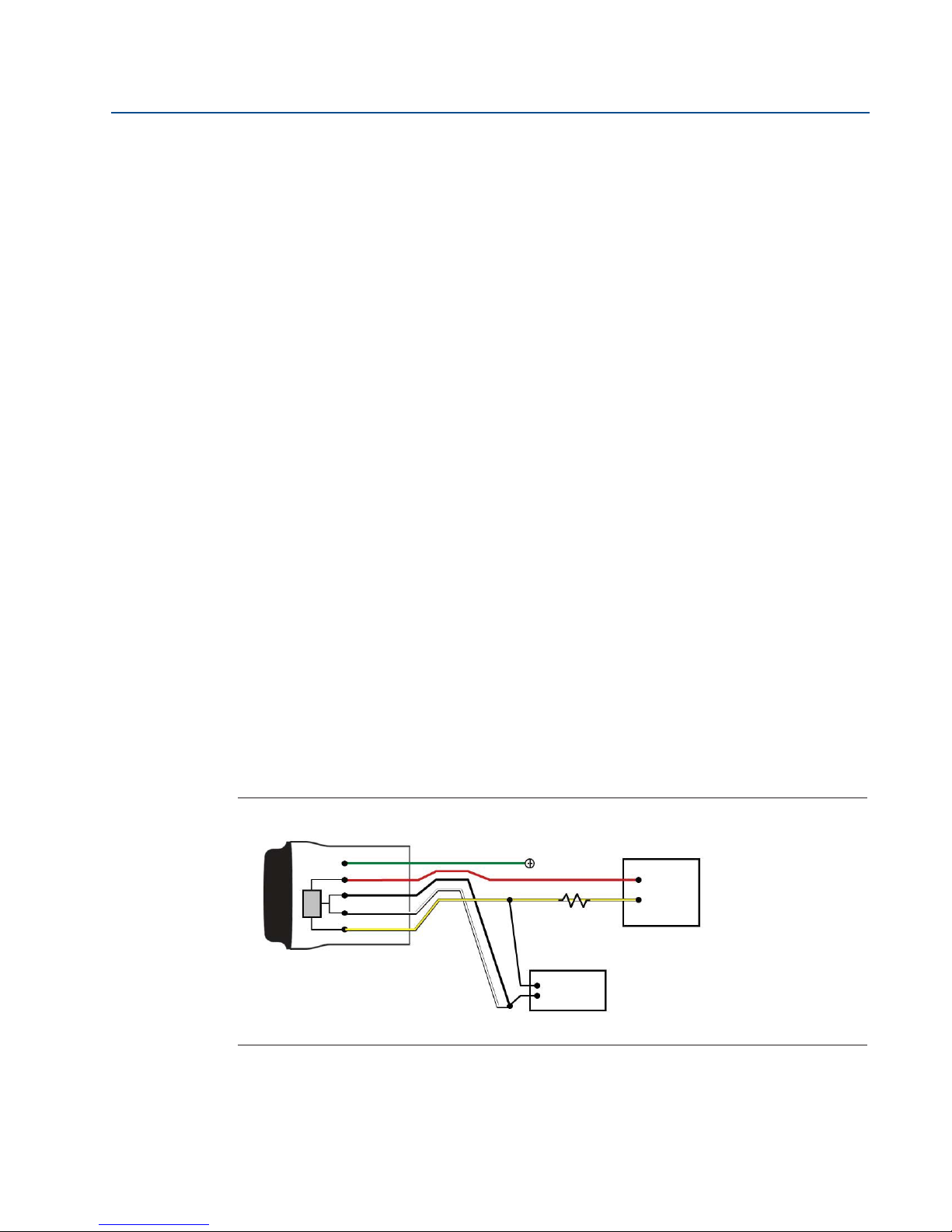

2.4 Connection diagrams

Bench hook-up

Connect the bench equipment as shown in either Figure 2-1 or Figure 2-2, and turn on the Field

Communicator by pressing the ON/OFF key or log into AMS. The Field Communicator or AMS

will search for a HART-compatible device and indicate when the connection is made. If the Field

Communicator or AMS fail to connect, it indicates that no device was found. If this occurs, refer

to Section 4: Commissioning.

.

Field hook-up

Section 2: Configuration details the field hook-up requirements in Figure 2-1 and Figure 2-2.

Figure 2-1. THUM adapter only, powered by a current source

THUM Adapter

Green

Red

Black

White

Yell ow

8

Ground

250 Ohm Resistor not

required, but may be

used to verify current

HART

Modem

+

-

20 mA

Current

Source

Configuration

Page 17

Reference Manual

00809-0100-4075, Rev CA

Figure 2-2. THUM adapter only, powered by a 24 V power supply with 1200 Ohm resistor

The 1200 Ohm resistor should be adequately rated for the application (3W minimum).

to limit current to 20 mA

THUM Adapter

Green

Red

Black

White

Yel low

Ground

HART MODEM

1200

Ohm

Resistor

Section 2: Configuration

+

24V

Power

Supply

-

March 2014

2.5 Device network configuration

2.5.1 Join device to network

Fast Keys

In order to communicate with the Smart Wireless Gateway, and ultimately the Host System, the

THUM must be configured to communicate over the wireless network. This step is the wireless

equivalent of connecting wires from a transmitter to the host system.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 1: Join Device to Network.

Using a Field Communicator or AMS, enter the Network ID and Join Key so that they match the

Network ID and Join Key of the Smart Wireless Gateway and other devices in the network. If the

Network ID and Join Key are not identical to those set in the Gateway, the THUM will not

communicate with the network. The Network ID and Join Key may be obtained from the Smart

Wireless Gateway on the Setup>Network>Settings page on the web server.

2.5.2 Configure update rate

Fast Keys

2, 1, 1

2, 1, 2

The Update Rate is the frequency at which a new measurement is taken and transmitted over

the wireless network. This by default is 1 minute. This may be changed at commissioning, or at

any time via AMS Wireless Configurator. The Update Rate is user selectable from 8 seconds to 60

minutes.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 2: Configure Update Rate.

Configuration

9

Page 18

Section 2: Configuration

March 2014

2.5.3 Configure THUM long tag

Reference Manual

00809-0100-4075, Rev CA

Fast Keys

The Long Tag is how the THUM Adapter will show up in the Smart Wireless Gateway web

interface. By setting this parameter to a unique value it will be easier to determine which THUM

Adapter you are communicating with. One way to do this is to use the tag number of the wired

device that the THUM adapter is connected to followed by THUM (HARTTAG-THUM).

1. From the Home screen, select 2: Configure.

2. Select 1: Manual Setup.

3. Select 2: Device Information tab.

4. Enter the Long Tag.

2, 2, 4, 2

2.5.4 Wired device tag

For HART 5 devices the THUM Adapter uses the message field when reporting the HART tag to

the Smart Wireless Gateway. To ensure that you can identify the wired device in the Gateway

make sure to write the tag information into the message field for all HART 5 devices. For HART 6

or newer devices the THUM reports the long tag as the HART tag to the Gateway.

10

Configuration

Page 19

Reference Manual

00809-0100-4075, Rev CA

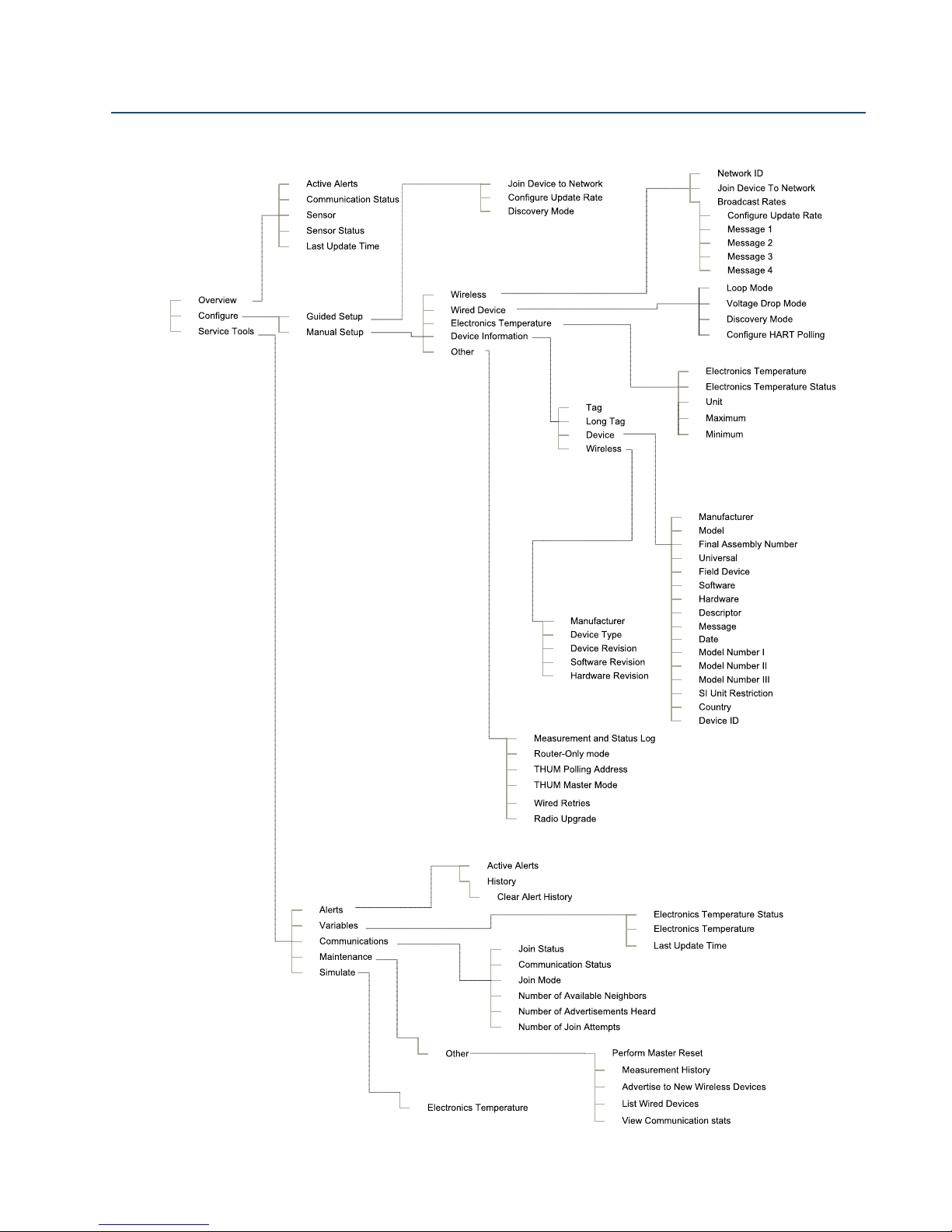

2.6 HART tree

Section 2: Configuration

March 2014

Configuration

11

Page 20

Section 2: Configuration

March 2014

Reference Manual

00809-0100-4075, Rev CA

12

Configuration

Page 21

Reference Manual

00809-0100-4075, Rev CA

Section 3 Mounting

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Loop current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

3.1.1 Warnings

Section 3: Mounting

March 2014

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

Mounting

13

Page 22

Section 3: Mounting

March 2014

3.2 Mounting

The THUM can be installed in one of two configurations:

Direct Mount: The THUM Adapter is connected directly to the conduit entry of the wired device.

Figure 3-1. Direct Mount

3.2.1 Direct mount

Reference Manual

00809-0100-4075, Rev CA

1. Install the HART® device according to standard installation practices, being sure to use

an approved thread sealant on all connections.

2. Attach the THUM Adapter to the wired device as shown in Figure 3-1. When installing

the THUM Adapter into the conduit entry of a wired device, use an approved thread

sealant.

3. Connect the THUM Adapter to the HART wired device using the wiring diagrams below.

See Figure 3-19 through Figure 3-26 on the following pages.

4. Close the housing cover on the HART wired device, so that metal touches metal, but do

not over tighten to prevent damaging the unit.

NOTE

Two splice connectors are included with the THUM Adapter. The first is a two connection splice.

The second is a three connection splice for use with a resistor, if there is not enough resistance in

the loop. Both of these splice connectors can accept 14 to 22 gauge wire. See wired device

reference manual for information on the required loop resistance.

Remote Mount: The THUM Adapter is mounted separate from the wired device housing and

then connected to the wired device using conduit.

Figure 3-2. Remote mount

14

Mounting

Page 23

Reference Manual

00809-0100-4075, Rev CA

3.2.2 Remote mount

1. Install the HART device according to standard installation practices, being sure to use

an approved thread sealant on all connections.

2. The THUM Adapter should be mounted as shown in Figure 3-2 on page 14.

3. Connect the THUM Adapter to the wired device using standard practices. Wire running

from the THUM Adapter to the wired device must be shielded or in conduit.

4. Ground the Remote Mount Kit per local practices.

5. Connect the THUM Adapter to the HART wired device using the wiring diagrams below.

See Figure 3-19 through Figure 3-26 on the following pages.

6. Close the housing cover on the HART wired device, so that metal touches metal, but do

not over tighten to prevent damaging the unit.

NOTE

Two splice connectors are included with the THUM Adapter. The first is a two connection splice.

The second is a three connection splice for use with a resistor, if there is not enough resistance in

the loop. Both of these splice connectors can accept 14 to 22 gauge wire. See wired device

reference manual for information on the required loop resistance.

Section 3: Mounting

March 2014

3.2.3 Power supply

Minimum loop load of 250 Ohms.

The THUM Adapter communicates and derives power from a standard 4-20 mA/HART loop. The

THUM Adapter causes a small voltage drop on the loop which is linear from 2.25 V at 3.5 mA to

1.2 V at 25 mA. Under fault conditions, the maximum voltage drop is 2.5 V. The THUM Adapter

will not affect the 4-20 mA signal under normal or fault conditions as long as the loop has at

least a 2.5 V margin at the maximum loop current (25 mA for a typical 4-20 mA/HART device).

Limit the power supply to 0.5 Amps maximum, and voltage to 55 Vdc.

Loop Current THUM Adapter voltage drop

3.5 mA 2.25 V

25 mA 1.2 V

3.2.4 Load resistor

If required, add a load resistor as shown in Figure 3-20, Figure 3-22, and Figure 3-24. The

resistor should be adequately rated for the application (1W minimum) and be compatible with

the supplied splice connector which accepts wire sizes from 14 to 22 AWG.

Mounting

15

Page 24

Section 3: Mounting

March 2014

3.2.5 Wiring

Note:

In order for the THUM Adapter to function properly there must be at least 250 Ohms resistance

in the loop. If the 4–20 mA loop does not have the required resistance, wire a resistor as shown

in Figure 3-20, Figure 3-22, or Figure 3-24 as applicable.

When adding a load resistor ensure that uninsulated conductors do not contact the enclosure

and/or other exposed metal parts.

Figure 3-3. Direct mount wiring diagram for 2-wire device

Reference Manual

00809-0100-4075, Rev CA

THUM Adapter

Green

Red

Black

White

Yellow

Wired Device

Ground

- PWR / COMM

+ PWR / COMM

4-20 mA Loop +

4-20 mA Loop -

Splice Connector

Power +

Supply-

Load Resistor t250 :

NOTE:

In order for the THUM Adapter to function properly there must be at least 250 Ohms resistance

in the loop. If the 4–20 mA loop does not have the required resistance, wire a resistor as shown

in Figure 3-6, Figure 3-10, or Figure 3-13 as applicable.

Figure 3-4. Remote mount wiring diagram for 2-wire device

THUM Adapter

Green

Ground

Yellow

16

Black

White

Red

Remote Mount Housing

+ COMM

- COMM

Shield Wire

To Wired Device

4-20 mA Loop +

4-20 mA Loop -

+

- Supply

Load Resistor t250 :

Power

Mounting

Page 25

Reference Manual

Remote Mount Housing

4-20 mA Loop -

4-20 mA Loop +

Ground

+ COMM

- COMM

THUM Adapter

Green

Red

Black

White

Yellow

To Wired Device

Shield Wire

Load Resistor t250

00809-0100-4075, Rev CA

Figure 3-5. Direct mount wiring diagram for 2-wire device with resistor

Figure 3-6. Remote mount wiring diagram for 2-wire device with resistor

THUM Adapter

Green

Red

Black

White

Yellow

Wired Device

Ground

- PWR / COMM

+ PWR / COMM

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250 :

Splice Connector

Section 3: Mounting

Power +

Supply-

March 2014

Figure 3-7. Direct mount wiring diagram for 4-wire passive device

THUM Adapter

Green

Red

Black

White

Yell ow

Wired Device

Ground

Power+

COMM-

COMM+

:

+ Power

- Supply

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Power-

Power +

Supply-

Load Resistor t250 :

Mounting

17

Page 26

Section 3: Mounting

Remote Mount Housing

4-20 mA Loop -

4-20 mA Loop +

Ground

+ COMM

- COMM

THUM Adapter

Green

Red

Black

White

Yel low

To Wired Device

Shield Wire

Load Resistor t250

March 2014

NOTE:

A passive loop exists when the wired device is not supplying power to the 4–20 mA loop. It is

important to verify if the wired device is operating in active or passive mode.

Figure 3-8. Remote mount wiring diagram for 4-wire passive device

Reference Manual

00809-0100-4075, Rev CA

+ Power

- Supply

:

Figure 3-9. Direct mount wiring diagram for 4-wire passive device with resistor

THUM Adapter

Green

Red

Black

White

Yellow

Wired Device

Ground

COMM-

Power+

COMM+

Power-

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250 :

Power +

Supply-

18

Mounting

Page 27

Reference Manual

00809-0100-4075, Rev CA

Figure 3-10. Remote mount wiring diagram for 4-wire passive device with resistor

Section 3: Mounting

March 2014

THUM Adapter

Remote Mount Housing

Green

Ground

Red

Black

White

Yellow

+ COMM

- COMM

Load Resistor t250 :

Shield Wire

To W ire d De vic e

4-20 mA Loop +

4-20 mA Loop -

+ Power

- Supply

Figure 3-11. Direct mount wiring diagram for 4-wire active device

THUM Adapter

Green

Yel low

White

Black

Red

Wired Device

Ground

Power+

COMM-

COMM+

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250 :

Power-

Input

Card

NOTE:

An active loop exists when the wired device is supplying the power to the 4-20 mA loop. It is

important to verify if the wired device is operating in active or passive mode.

Mounting

19

Page 28

Section 3: Mounting

March 2014

Figure 3-12. Remote mount wiring diagram for 4-wire active device

Green

Ground

Black

White

Yellow

THUM Adapter

Red

Remote Mount Housing

Shield Wire

+ COMM

- COMM

Reference Manual

00809-0100-4075, Rev CA

To W ire d De vic e

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250 :

Input

Card

Figure 3-13. Direct mount wiring diagram for 4-wire active device with resistor

THUM Adapter

Green

Yell ow

White

Black

Red

Wired Device

Ground

Power+

COMM-

COMM+

Power-

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250

Input

Card

:

20

Mounting

Page 29

Reference Manual

00809-0100-4075, Rev CA

Figure 3-14. Remote mount wiring diagram for 4-wire active device with resistor

Section 3: Mounting

March 2014

THUM Adapter

Remote Mount Housing

Green

Ground

Red

Black

White

Yellow

4-20 mA Loop +

4-20 mA Loop -

Load Resistor t250 :

Shield Wire

Load Resistor t250 :

+ COMM

- COMM

Input

Card

To Wired Device

Figure 3-15. Direct mount wiring diagram for 4-wire active device with no 4-20 mA loop

THUM Adapter

Green

Yel low

White

Black

Red

Wired Device

Ground

Splice Connector

Load Resistor t250 :

Mounting

COMM+

COMM-

Power-

Power+

21

Page 30

Section 3: Mounting

March 2014

Figure 3-16. Remote mount wiring diagram for 4-wire active device with no 4-20 mA loop

Reference Manual

00809-0100-4075, Rev CA

THUM Adapter

Remote Mount Housing

Green

Ground

Red

Black

White

Yellow

+ COMM

- COMM

Load Resistor t250

To Wired Device

:

Figure 3-17. THUM adapter only, powered by a 24 V power supply with 1200 Ohm resistor

to limit current to 20 mA

THUM Adapter

Green

Red

Black

White

Yel low

Ground

Junction Box

250

Ohm

Resistor

1200

Ohm

Resistor

Require d

+

-

24 V

Power

Supply

22

Mounting

Page 31

Reference Manual

00809-0100-4075, Rev CA

Figure 3-18. THUM adapter only, powered by a 24 V power supply with 1200 Ohm resistor

Figure 3-19. Wiring diagram for 2-wire device

Green

Ground

to limit current to 20 mA

THUM Adapter

Remote M ount

Red

Black

White

Yellow

THUM Adapter

Green

Red

Black

White

Yell ow

Housing

250 Ohm

Resistor

Wired Device

Ground

- PWR / COMM

+ PWR / COMM

1200 Ohm

Resistor

Required

4-20 mA Loop +

4-20 mA Loop -

Splice Connector

+

-

24 V

Power

Supply

Section 3: Mounting

March 2014

Mounting

Figure 3-20. Wiring diagram for 2-wire device with resistor

THUM Adapter

Green

Red

Black

White

Yell ow

Wired Device

Ground

- PWR / COMM

+ PWR / COMM

4-20 mA Loop +

4-20 mA Loop -

Resistor

Splice Connector

NOTE

A passive loop exists when the wired device is not supplying power to the 4-20 loop. It is

important to verify if the wired device is operating in active or passive mode.

23

Page 32

Section 3: Mounting

March 2014

Figure 3-21. Wiring diagram for 4-wire passive device

Reference Manual

00809-0100-4075, Rev CA

THUM Adapter

Green

Red

Black

White

Yellow

4-20 mA/HART +

4-20 mA/HART -

Wired Device

Ground

Power+

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Power +

Power -

Power-

Figure 3-22. Wiring diagram for 4-wire passived device with resistor

THUM Adapter

Green

Red

Black

White

Yel low

4-20 mA/HART +

4-20 mA/HART -

Wired Device

Ground

Power+

Power-

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Resistor

Power +

Power -

24

NOTE

An active loop exists when the wired device is supplying power to the 4-20 mA loop. It is

important to verify if the wired device is operating in an active or passive mode.

Figure 3-23. Wiring diagram for 4-wire active device

THUM Adapter

Green

Yel low

White

Black

Red

4-20 mA/HART +

4-20 mA/HART -

Wired Device

Ground

Power+

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Power +

Power -

Power-

Mounting

Page 33

Reference Manual

00809-0100-4075, Rev CA

Figure 3-24. Wiring diagram for 4-wire active device with resistor

Section 3: Mounting

March 2014

THUM Adapter

Green

Yellow

White

Black

Red

4-20 mA/HART +

4-20 mA/HART -

Wired Device

Ground

Splice Connector

4-20 mA Loop +

4-20 mA Loop -

Resisto r

Power-

Power+

Power +

Power -

Figure 3-25. Wiring diagram for 4-wire active device with no 4-20 mA loop

THUM Adapter

Green

Yellow

White

Black

Red

4-20 mA/HART +

4-20 mA/HART -

Wired Device

Ground

Power+

Splice Connector

Resistor

Power +

Power -

Power-

Figure 3-26. Wiring diagram for THUM adapter as router, no wired device

THUM Adapter

Green

Red

Black

White

Yel low

Junction Box

Ground

250

Ohm

1200

Ohm

Resistor

24V

Power

The 1200 Ohm resistor should be adequately rated for the application (3W minimum).

Mounting

25

Page 34

Section 3: Mounting

March 2014

3.3 Loop current test

To verify that the THUM Adapter will work under all conditions, a loop current test should be

performed. This test will exercise the loop under the highest possible voltage drop conditions.

1. Place loop in manual control.

2. Drive loop to high alarm level. For details see wired device instruction manual.

When the THUM Adapter is connected to a valve, this will need to be done at the

current source and not from the valve.

When the THUM Adapter is connected to a transmitter, this will need to be performed

at the transmitter.

3. Place the THUM Adapter into fixed voltage drop mode.

AMS

Right click on the THUM Adapter and select Configure. When the menu opens, select Manual

Setup from the window on the left and select the Wired Device tab on the top. Make sure that

the Time drop down menu at the bottom of the page has Current selected. Under the Volta ge

Drop drop down menu in the Smart Power Options box, select Fixed Voltage Drop. Hit the Apply

button to make any changes. See Figure 3-27 on page 27.

Reference Manual

00809-0100-4075, Rev CA

Field communicator

When communicating to the THUM Adapter select: Configure - Manual setup - Wired Device

- Voltage Drop Mode. In the method choose Fixed Voltage Drop.

Function Key Sequence Menu Items

Voltage Drop 2,2,2,2 Voltage Drop

4. Verify that the current on the loop reaches the high alarm levels.

5. Place the THUM Adapter into variable voltage drop mode.

AMS

Right click on the THUM Adapter and select Configure. When the menu opens, select Manual

Setup from the window on the left and select the Wired Device tab on the top. Make sure that

the Time drop down menu at the bottom of the page has Current selected. Under the Volta ge

Drop drop down menu in the Smart Power Options box, select Variable Voltage Drop. Hit the

Apply button to make any changes. See Figure 3-27.

Field communicator

When communicating to the THUM Adapter select: Configure - Manual setup - Wired Device

- Voltage Drop Mode. In the method choose Variable Voltage Drop.

Function Key Sequence Menu Items

Voltage Drop 2,2,2,2 Voltage Drop

26

Mounting

Page 35

Reference Manual

00809-0100-4075, Rev CA

6. Remove loop from high alarm value.

Figure 3-27. AMS configure screen

Section 3: Mounting

March 2014

Mounting

27

Page 36

Section 3: Mounting

March 2014

Reference Manual

00809-0100-4075, Rev CA

28

Mounting

Page 37

Reference Manual

00809-0100-4075, Rev CA

Section 4 Commissioning

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Device network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

4.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

4.1.1 Warnings

Section 4: Commissioning

March 2014

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

Commissioning

29

Page 38

Section 4: Commissioning

March 2014

4.2 Device network configuration

In order to communicate with the Smart Wireless Gateway, and ultimately the Information

System, the transmitter must be configured to communicate with the wireless network. This

step is the wireless equivalent of connecting wires from a transmitter to the information system.

Using a Field Communicator or AMS, enter the Network ID and Join Key so that they match the

Network ID and Join Key of the gateway and other devices in the network. If the Network ID

and Join Key are not identical, the THUM Adapter will not communicate with the network. The

Network ID and Join Key may be obtained from the Smart Wireless Gateway on the Setup>Net-

work>Settings page on the web server, shown in Figure 4-1.

Figure 4-1. Gateway network setting

Reference Manual

00809-0100-4075, Rev CA

AMS

Right click on the THUM Adapter and select Configure. When the menu opens, select Join

Device to Network and follow the method to enter the Network ID and Join Key.

Field communicator

The Network ID and Join Key may be changed in the wireless device by using the following Fast

Key sequence. Set both Network ID and Join Key.

Operation can be verified in three locations: by using the Field Communicator, at the Gateway

via the Smart Wireless Gateway’s integrated web server, or via AMS

Function Key Sequence Menu Items

Wireless Setup 1,4 Smart Power, Network ID, Set Join Key, Radio State

30

™

Wireless Configurator.

Commissioning

Page 39

Reference Manual

00809-0100-4075, Rev CA

4.2.1 Network status

If the THUM Adapter was configured with the Network ID and Join Key and sufficient time for

network polling has passed, the transmitter should be connected to the network. To verify

connectivity, open the Smart Wireless Gateway’s integral web interface and navigate to the

Explorer page.

This page will display the THUM Adapter's HART tag, PV, SV, TV, QV, and Update Rate. A green

status indicator means that the device is working properly. A red indicator means that there is a

problem with either the device or its communication path. For more detail on a specific device,

click on the tag name.

Section 4: Commissioning

March 2014

4.2.2 Verify operation

Operation can be verified in three locations: by using the 375 Field Communicator, at the

Gateway via the Smart Wireless Gateway’s integrated web server, or via AMS™ Wireless

Configurator.

Field communicator

In order for the THUM adapter to communicate with a Field Communicator, a THUM adapter DD

is required. The Field Communicator must be put into a polling mode using the THUM adapter

address of 63. Connect the Field Communicator to the wired device. The Field Communicator

should find both the THUM adapter and the wired device.

Table 4-1. Field Communicator connections

Function Key Sequence Menu Items

Communications 3, 3 Join Status, Wireless Mode, Join Mode, Number of Available

Smart Wireless Gateway

If the THUM Adapter was configured with the Network ID and Join Key, and sufficient time has

passed for network polling, the transmitter will be connected to the network. To verify device

operation and connection to the network with the Smart Wireless Gateway’s integrated web

server, open the Smart Wireless Gateway’s integral web interface and navigate to the Explorer

page.

Neighbors, Number of Advertisements Heard, Number of Join

Attempts

NOTE:

It may take several minutes for the device to join the network.

Commissioning

31

Page 40

Section 4: Commissioning

March 2014

AMS Wireless Configurator

When the device has joined the network, it will appear in the Wireless Configurator as illustrated

below.

Troubleshooting

Reference Manual

00809-0100-4075, Rev CA

If the device is not operating properly, refer to the troubleshooting section of the manual. The

most common cause of incorrect operation is the Network ID and Join Key. The Network ID and

Join Key in the device must match that of the Smart Wireless Gateway.

The Network ID and Join Key may be obtained from the Smart Wireless Gateway on the

Setup>Network>Settings page on the web server. The Network ID and Join Key may be

changed in the wireless device by using the following Fast Key sequence.

Reference information

Function Key Sequence Menu Items

Wireless Setup 1, 4 Smart Power, Network ID, Set Join Key, Radio State

NOTE

In order to communicate with a Field Communicator, the wired device must be powered.

Table 4-2. THUM adapter HART fast key sequence

Func tion Key Sequence Menu Items

Device Info 2, 2, 4, 3 Manufacturer, Model, Final Assembly Number, Universal,

Guided Setup 2, 1 Configure, Guided Setup, Join Device to Network, Configure

Manual Setup 2, 2 Configure, Manual Setup, Wireless, Pressure, Device

Field Device, Software, Hardware, Descriptor, Message,

Date, Model Number I, II, III, SI Unit Restriction, Country

Update Rate, Zero Trim, Configure Device Display, Configure

Process Alarms

Temperatures, Device Information, Display, Other

Wireless 2, 2, 1 Network ID, Join Device to Network, Configure Update Rate,

32

Configure Broadcast Power Level, Power Mode, Power

Source

Commissioning

Page 41

Reference Manual

00809-0100-4075, Rev CA

Section 5: Operation and Maintenance

Section 5 Operation and Maintenance

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

Startup sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

Advanced setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

5.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

5.1.1 Warnings

March 2014

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

5.2 Startup sequence

Because the THUM is a power scavenging device, different capabilities are available at different

times after startup. Configuration is available immediately after startup and includes Update

Rate and Discovery method. All network settings including Network ID, Join Key can not be set

until the radio is completely initialized. This may take up to three (3) minutes after startup.

After this amount of time has passed, the THUM adapter will start to join the network. Time to

join the network depends on network size and number of devices and if active advertising is

turned on in the Gateway. After sufficient time to join has passed go to the Explorer page on the

Smart Wireless Gateway to see if the THUM has joined.

Operation and Maintenance

33

Page 42

Section 5: Operation and Maintenance

March 2014

5.3 Advanced setup

5.3.1 Configure advanced update rate

Reference Manual

00809-0100-4075, Rev CA

Fast Keys

The “Configure Update Rate” method sets all three update rates based on one user input. The

“configure Advanced Update Rate” method allows for each update rate to be set independently

of the other two. Values for all update rates are between 8 seconds and 60 minutes. Only one

update rate can be set to 8 seconds.

In AMS Select Manual Setup and then the Wireless tab.

2, 2, 1,3

5.3.2 4-20 mA current

Fast Keys

This optimizes the THUM Adapter to the available loop current.

There are two options “Variable Current Mode” and “Fixed Current Mode”. Variable current

mode is the default mode and is used when the current on the loop is changing between 3.5 mA

to 25 mA.

Fixed Current mode is user selectable. This mode is for when the current on the loop is fixed and

will not drop below 15 mA. If the current drops below 15 mA when the THUM Adapter is in fixed

current mode, there may be issues with network traffic, and the THUM Adapter may drop off of

the wireless network. The HART loop will not be affected.

In AMS Select Manual Setup and then the Wired Device tab.

2, 2, 2,1

5.3.3 Voltage drop

Fast Keys

This optimizes the THUM Adapter to the available voltage on the loop. There are two options:

Variable and Fixed. Variable is the default mode. In Variable mode the THUM drops between

2.25 V at 3.5 mA and 1.2 V at 25 mA. In Fixed mode the THUM will always drop 2.25 volts. Fixed

mode is used for verifying that there is enough voltage on the loop in the loop check procedure.

In AMS Select Manual Setup and then the Wired Device tab.

2, 2, 2,2

5.3.4 Discovery mode

Fast Keys

The discovery mode is how the THUM Adapter determines which wired device it will update for.

There are 3 modes “First Device Found”, “Fixed Polling Address”, and “Fixed Mapping”. The

default mode is First Device Found. In First Device Found Mode, the THUM Adapter will update

for the first wired device that it finds on the wired bus. This mode is best used when there is only

one device on the wired bus. If more than one wired device is found, the THUM Adapter will go

into alert.

34

2, 2, 2,3

Operation and Maintenance

Page 43

Reference Manual

00809-0100-4075, Rev CA

In Fixed Polling Address mode, the THUM will only update for a wired device at specific HART

polling address. Any address can be entered. If no device is found at this address, the THUM

Adapter will go into an alarm state.

In Fixed Mapping mode, the user selects the long tag from a list of devices that are currently on

the wired bus. If the selected device goes off line, the THUM will not start updating new device,

and will go into an alarm state.

In AMS Select Manual Setup and then the Wired Device tab.

5.3.5 Configure HART polling

Section 5: Operation and Maintenance

March 2014

Fast Keys

The Configure HART Polling method allows the user to select which commands the THUM

Adapter will update for the wired device. The user can select from pre setup information or

select custom and enter the HART command that they would like to have the THUM Adapter

update for the wired device.

In AMS Select Manual Setup and then the Wired Device.

2, 2, 2,4

5.3.6 Configure router only mode

Fast Keys

This mode will set the THUM Adapter up as a router only device. The THUM Adapter will no

longer look for wired devices or update for any wired device that is on the HART loop. The THUM

Adapter will continue to send updates for itself and will also act as a wireless node in the wireless

network.

In AMS Select Manual Setup and then the Other tab.

2, 2, 5,2

5.3.7 HART address

Fast Keys

This is the HART Polling address of the THUM adapter. This can be changed from 0 to 63. This is

used when using wired HART communication to talk with the THUM. The THUM Adapter default

HART polling address is 63.

2, 2, 5,3

In AMS Select Manual Setup and then the Other tab.

5.3.8 HART master

Fast Keys

Here is where the user can set the THUM Adapter to either a primary or secondary HART master.

The THUM is set to primary as default, if another primary master is on the HART loop it may be

necessary to change the THUM Adapter to a secondary master. This will not affect the

functionality of the THUM Adapter. The number of retries can be set to between 2 and 5.

In AMS Select Manual Setup and then the Other tab.

Operation and Maintenance

2, 2, 5,4

35

Page 44

Section 5: Operation and Maintenance

March 2014

Reference Manual

00809-0100-4075, Rev CA

36

Operation and Maintenance

Page 45

Reference Manual

00809-0100-4075, Rev CA

Section 6 Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

Troubleshooting recommended actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

6.1 Overview

Table 6-1 on page 38 provides summarized maintenance and troubleshooting suggestions for

the most common operating problems.

If you suspect malfunction despite the absence of any diagnostic messages on the Field

Communicator display, follow the procedures described here to verify that transmitter

hardware and process connections are in good working order. Always deal with the most likely

checkpoints first.

Section 6: Troubleshooting

March 2014

6.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

Tro u bl esh o oti ng

37

Page 46

Section 6: Troubleshooting

March 2014

Table 6-1. Troubleshooting recommended actions

Symptom Recommended Action

Wired Troubleshooting

Reference Manual

00809-0100-4075, Rev CA

Wired device does not turn on

when THUM Adapter is added to

loop

Wired Device does not function

properly through loop check

Can not communicate with

wired device or THUM Adapter

Can not communicate with

THUM Adapter

Configuration Troubleshooting

Can not configure THUM

Adapter with 375 or AMS

THUM Adapter does not

communicate with wired device

Duplicate HART Master

Detected

Check the wiring and connections between THUM Adapter and wired device

Verify that enough voltage is being supplied to power both the THUM Adapter and wired

device

Determine total voltage drop of system assume 2.5 volts for THUM Adapter

Verify that enough voltage is on the loop

Verify that wiring is correct

Verify that enough voltage is being supplied to power both THUM Adapter and wired device

Verify that between 250 and 1100 Ohms resistance is present

Verify that wiring is correct

Verify that enough voltage is being supplied to power both THUM Adapter and wired device

Verify that between 250 and 1100 Ohms resistance is present

Verify that Field communicator or AMS is set to poll for THUM Adapter address

Power Cycle device to try again

Make sure that the correct DD is loaded into the 375 or AMS

Run the “Configure Discovery Mode” method to connect the THUM Adapter to wired device

Check the wiring and connections between THUM Adapter and wired device

Verify that between 250 and 1100 Ohms resistance is present for HART communications

Verify that the wired device is functioning properly

Power Cycle device to try again

Verify that two primary masters are on the loop

Then set the THUM Adapter into secondary master mode

Power Cycle device to try again

If THUM Adapter is in secondary master mode and 375 or AMS is connected to loop this error

will occur

The error will disappear after the 375 or AMS is removed from the loop.

Wireless Network Troubleshooting

THUM Adapter not joining

network

Limited Bandwidth Error Reduce the Update Rate on THUM Adapter and wired device

38

Verify network ID and join key

Wait longer (30 min.)

Verify THUM Adapter is within range of at least one other device

Verify network is in active network advertise

Power Cycle device to try again

Verify device is configured to join. Send the “Force Join” command to the device

See troubleshooting section of Smart Wireless Gateway for more information

Increase communication paths by adding more wireless points

Check that THUM Adapter has been online for at least an hour

Check that THUM Adapter is not routing through a “limited” routing node

Create a new network with an additional Smart Wireless Gateway

Tro u bl esh o oti ng

Page 47

Reference Manual

00809-0100-4075, Rev CA

Appendix A Reference Data

Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 41

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 43

A.1 Functional specifications

Input

Any 2- or 4-wire HART powered device.

Output

IEC 62591 (WirelessHART)

Appendix A: Reference Data

March 2014

Humidity limits

0–100% relative humidity

Update rate

User selectable, 8 sec. to 60 min.

A.2 Physical specifications

Electrical connections

The THUM is connected into a powered 4–20 mA loop, powering itself by scavenging power.

The THUM causes a voltage drop across the loop. The drop is linear from 2.25 volts at 3.5 mA to

1.2 volts at 25 mA, but does not effect the 4–20 mA signal on the loop. Under fault conditions,

the maximum voltage drop is 2.5 volts.

Power supply

Minimum load on loop 250 Ohms.

To maintain normal operating functions of the sub-device, the power in the loop must have at

least a 2.5 V margin at a 250 Ohm load.

Limit power supply to 0.5 Amps maximum.

Limit power supply to 55 Vdc maximum.

Field Communicator connections

Utilize sub-device HART connections.

Materials of construction

Housing option D - Low-copper aluminum

Housing option E - 316 SST

Reference Data

39

Page 48

Appendix A: Reference Data

March 2014

Paint - Polyurethane

M20-Conduit Adapter - SST

M20-Conduit Adapter O-ring - Buna-n

Antenna

Poly butadine terephthalate (PBT) / Polycarbonate (PC) integrated omnidirectional antenna

Weight

THUM Adapter only AL - 0.65 lbs. (0.29 kg)

THUM Adapter only SST - 1.1 lbs. (0.5 kg)

AL THUM Adapter with AL remote kit - 3.2 lbs. (1.45 kg)

SST THUM Adapter with SST remote kit - 5.8 lbs. (2.65 kg)

AL THUM Adapter with M20 conduit adapter - 0.85 lbs. (.038 kg)

SST THUM Adapter with M20 conduit adapter - 1.3 lbs. (0.59 kg)

Enclosure ratings

Housing option code D is NEMA 4X, and IP66.

Mounting

The THUM Adapter may be attached directly to the conduit of any 2- or 4-wire HART device or

mounted remotely by using the remote mount kit.

Reference Manual

00809-0100-4075, Rev CA

A.3 Performance specifications

ElectroMagnetic compatibility (EMC)

All Models:

Meets all relevant requirements of EN 61326-1 (2006) when installed with shielded wiring. The

sub-device must also use shielded wiring for installation.

Vibration effect

Output unaffected when tested per the requirements of IEC60770-1 field with general

application or pipeline with low vibration level (10-60 Hz 0.15 mm displacement peak

amplitude / 60-500 Hz 2g).

When the THUM Adapter is used on wired devices that are subject to vibration levels greater

than 2g, it is recommended that the THUM Adapter be remotely mounted using the remote

mount kit.

Temperature limits

Operating Limit Storage Limit

–40 to 185 °F –40 to 185 °F

–40 to 85 °C –40 to 85 °C

Output specifications

The THUM allows Wireless communication between the HART device it is connected to and the

Smart Wireless Gateway.

40

Reference Data

Page 49

Reference Manual

00809-0100-4075, Rev CA

A.4 Dimensional drawings

THUM adapter 1/2 NPT

Appendix A: Reference Data

1.42

(36.1)

March 2014

2.0

(50.8)

Dimensions are in inches (millimeters)

5.15

(130.8)

1.91

(48.5)

Reference Data

41

Page 50

Appendix A: Reference Data

March 2014

THUM adapter with M20 conduit adapter

1.07

(27.17)

Reference Manual

00809-0100-4075, Rev CA

Adapter for

M20 Entry

2.0

(50.8)

Dimensions are in inches (millimeters)

4.20

(107)

4.85

(123.19)

6.48

(164.6)

THUM adapter with remote mount kit

Conduit

Entry

3.45

(88)

1.91

(48.5)

Dimensions are in inches (millimeters)

42

4.85

(123.19)

2.00

(50.8)

Electronic

Side

Reference Data

Page 51

Reference Manual

00809-0100-4075, Rev CA

Appendix A: Reference Data

March 2014

A.5 Ordering information

Tabl e A-1. Smart Wireless THUM adapter ordering information

★ The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The Expanded offering is subject to additional delivery lead time.

Model Product Description

775 Smart Wireless THUM Adapter

Output

X Wireless

Housing

Standard Standard

D Aluminum ★

Expanded

E SST

Mounting Connection

Standard Standard

1

2 M20-Conduit Adapter ★

PlantWeb Functionality

Standard Standard

1 HART® Data ★

Certification

Standard Standard

NA No Approval ★

I5 FM Intrinsically Safe, Non-incendive ★

I6 CSA Intrinsically Safe ★

I1 ATEX Intrinsic Safety ★

N1 AT EX Type n ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

I2 INMETRO Intrinsic Safety ★

N2 INMETRO Type n ★

I3 China Intrinsic Safety ★

IP Korea (KOSHA) Intrinsic Safety ★

IW India (CCOE) Intrinsic Safety ★

IM GOST (Russia) Intrinsically Safe ★

Wireless Update Rate, Operating Frequency, and Protocol

Standard Standard

WA3 User Configurable Update Rate, 2.4 GHz DSSS, WirelessHART ★

Omnidirectional, Wireless Antenna, and SmartPower™ Options

Standard Standard

WK9 Long range, Integral Antenna, Power Scavenging ★

Typical Model Number: 775XD11I5WA3WK9

1

/2 - 14 NPT ★

Reference Data

43

Page 52

Appendix A: Reference Data

March 2014

Reference Manual

00809-0100-4075, Rev CA

A.6 Accessories and spare parts

Tabl e A-2. Accesso ries

Item Description Part Number

Remote Mount Kit - AI 00775-9000-0001

Remote Mount Kit - SST 00775-9000-0011

M20-Conduit Adapter 00775-9001-0001

44

Reference Data

Page 53

Reference Manual

00809-0100-4075, Rev CA

Appendix B: Product Certifications

Appendix B Product Certifications

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45