Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Smart Wireless Gateway

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Emerson Process Management has

two toll-free assistance numbers:

Global Service Center

Software and Integration Support

1-800-833-8314 (United States)

+63-2-702-1111 (International)

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of the United States, contact your local Emerson Process Management

representative.

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

PlantWeb is a registered trademark of one of the Emerson Process Management group of

companies.

Modbus is a registered trademark of Schneider Automation, Inc.

All other marks are the property of their respective owners.

www.emersonprocess.com

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Table of Contents

SECTION 1

Overview

SECTION 2

Initial Connection

SECTION 3

Mounting and

Connection

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Prepare PC/Laptop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connections and Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Configure the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

System Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Pipe Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Bracket Mount (alternate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Remote Antenna (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Connecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Terminating Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

SECTION 4

Software Setup

SECTION 5

Host Integration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Security Setup Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

AMS Wireless Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Licensing and Credits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Network Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Internal Firewall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Communication Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Register Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

TOC-1

Smart Wireless Gateway

SECTION 6

Troubleshooting

SECTION 7

Glossary

Reference Manual

00809-0200-4420, Rev EA

November 2011

APPENDIX A

Product Specifications

APPENDIX B

Product Certifications

APPENDIX C

Delta V Ready

APPENDIX D

Redundancy

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Communication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Self-Organizing Network Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

System Security Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Telecommunication Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

FCC and IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Ordinary Location Certification for FM . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Union Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Mounting and Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Mounting and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Gateway Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

TOC-2

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 1 Overview

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . .page 1-3

SAFETY MESSAGES Instructions and procedures in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to these safety messages before performing an operation preceded by

this symbol.

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the device is consistent with the

appropriate hazardous locations certifications.

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

INTRODUCTION The Smart Wireless Gateway connects WirelessHART™ self-organizing

networks with host systems and data applications. Modbus communications

over RS-485 or Ethernet provide universal integration and system

interoperability. The optional OPC functionality from the Gateway offers a

means to connect to newer systems and applications while providing a richer

set of data.

The Smart Wireless Gateway provides industry leading security, scalability,

and data reliability. Layered security ensures that the network stays protected.

Additional devices can be added at anytime. There is no need to configure

communication paths because the Gateway manages the network

automatically. This feature also ensures that WirelessHART field devices

have the most reliable path to send data.

Smart Wireless Gateway

What is Included?

The box containing the Smart Wireless Gateway will contain several items

essential to the complete installation and operation of the Gateway.

• Smart Wireless Gateway

• Quick Installation Guide

• Software pack, 2 disk set

• Crossover cable, Ethernet

• Mounting hardware

• Conduit plugs, 4

• Conduit adapters (optional)

If an optional remote antenna has been ordered, it will be in a separate box

containing:

• Remote mount antenna

• Mounting hardware

• Lightning arrestor

• Cable (1 or 2 pieces that total 50 ft, [15,2 m] in length)

• Coaxial Sealant

Reference Manual

00809-0200-4420, Rev EA

November 2011

MANUAL This manual will help to install, configure, operate, and maintain the Gateway.

Section 1 – Overview

This section introduces the product and describes what components may be

found in the box. It also includes details for services and support as well as

return and disposal of the product.

Section 2 – Initial Connection

This section describes how to connect to the Gateway for the first time and

what settings should be configured before placing it on a live control network.

It is important to note that some Gateways are used in stand-alone

applications and do not reside on a network. In these cases, it is still important

to configure the items outlined in this section.

Section 3 – Mounting and Connection

This section describes how to properly mount the Gateway and make

electrical connections, including electrical wiring, grounding, and host system

connections. This section also describes how to mount the optional remote

antenna.

Section 4 – Software Setup

This section describes the installation and setup of the optional software

included with the Smart Wireless Gateway. This software will aid in secure

host integration as well as wireless field device configuration.

Section 5 – Host Integration

This section describes how to connect the Gateway to a host system and

integrate data gathered from the field device network. It covers network

architectures, security, and data mapping.

1-2

Section 6 – Trouble shooting

This section provides troubleshooting tips as well as information to contact

technical support over the phone or through email.

Section 7 – Glossary

The glossary defines terms used throughout this manual or that appear in the

web interface of the Smart Wireless Gateway.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Appendices

The appendices provide additional and more specific information on a variety

of subjects including Product Specifications and Product Certifications.

Smart Wireless Gateway

SERVICE SUPPORT Global Service Center

Software and Integration Support

United States 1 800 833 8314

International 63 2 702 1111

Customer Central

Technical Support, quoting, and order related questions

United States 1 800 999 9307 (7:00 a.m. to 7:00 p.m. CST)

Asia Pacific 65 6777 8211

Europe/

Middle East/ Africa 49 8153 9390

RETURN OF MATERIALS To expedite the return process outside of North America, contact your

Emerson Process Management representative.

PRODUCT

RECYCLING/DISPOSAL

Within the United States, call the Emerson Process Management Response

Center toll-free number 1 800 654 7768. The center, which is available 24

hours a day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

process material to which the product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

Recycling of equipment and packaging should be taken into consideration

and disposed of in accordance with local and national legislation/regulations.

1-3

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

1-4

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 2 Initial Connection

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Failure to follow these installation guidelines could result in death or serious injury:

• Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions: This device may not cause harmful interference. This device must

accept any interference received, including interference that may cause undesired

operation.

This device must be installed to ensure a minimum antenna separation distance of 20

cm from all persons.

OVERVIEW This section describes how to connect to the Gateway for the first time and

what settings should be configured before placing it on a live control network.

It is important to note that some Gateways are used in stand-alone

applications and do not reside on a network. In these cases, it is still important

to configure the items outlined in this section.

Before the Gateway can be permanently mounted and connected to a live

control network, it needs to be configured with an IP address. This is done by

forming a private network between the gateway and a PC/Laptop. The

following items are needed to complete this section:

• Gateway

• PC/Laptop

• Crossover Cable (supplied with the Gateway)

• 24 VDC (nominal) power supply

NOTE

If the Gateway was ordered with the DeltaV™ Ready option, it has been

configured to operate on a DeltaV control network, and the Initial

Configuration Section does not need to be completed. Only setting the

password is required.

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

SYSTEM

REQUIREMENTS

The following requirements apply to the PC/Laptop used to configure the

Gateway. Additional requirements may apply if using the optional Security

Setup Utility or AMS

on page 4-1 for more information.

Web Browser Applications

• Mozilla

• Microsoft Internet Explorer

Ethernet

• 10/100base-TX Ethernet communication protocol

®

Wireless Configurator. See Section 4: Software Setup

®

Firefox® 1.5 or higher

®

6.0 or higher

INITIAL SETUP

Prepare PC/Laptop The PC/Laptop will need to be configured to form a private network before

communicating to the Gateway. The network settings can be found in the

control panel of the PC/Laptop. To configure these settings:

1. Find and open the Control Panel. (It is generally found from the Start

Menu.)

2. Open Network Connections.

3. Select Local Area Connection.

4. Right click the mouse and select Properties from the list.

5. Select Internet Protocol (TCP/IP), and choose the Properties

button.

6. From the General tab, select Use the following IP address button.

7. Set the IP Address to 192.168.1.12 and press the Tab button.

8. A Subnet mask of 255.255.255.0 should fill in automatically.

9. Click OK to close the Internet Protocol (TCP/IP) window.

10. Click Close on the Local Area Connection window.

2-2

Internet proxies will need to be disabled through the PC/Laptop’s default

internet browser.

1. Find and open the default internet browser (typically Microsoft

Internet Explorer).

2. Find the Tools menu and select Internet Options.

3. From the Connections tab, click the LAN Settings button.

4. Under Proxy Server the boxes for Automatically Detect Settings

and Use a proxy server for your LAN should be unchecked.

5. Click OK to close the Local Area Network (LAN) Settings window.

6. Click OK to close the Internet Options window.

The PC/Laptop is now set up to form a private network and to communicate

with the Gateway.

NOTE:

Connecting to the Gateway's secondary Ethernet port will require different

network settings. Please see Table 2-1 for additional network settings.

Reference Manual

+++

S

S

S

S

Not Used

Not Used

d

Not Used

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Table 2-1. Default IP Addresses

Gateway PC/Laptop

Ethernet 1 192.168.1.10 192.168.1.12

Ethernet 2 192.168.2.10 192.168.2.12

Ethernet 1 (DeltaV Ready) 10.5.255.254 10.5.255.200

Ethernet 2 (DeltaV Ready) 10.9.255.254 10.9.255.200

Connections and Power Physically connect the PC/Laptop to the Gateway with the supplied crossover

cable by connecting one end to the Ethernet port on the back of the

PC/Laptop. Connect the other end to the Ethernet 1 port on the Gateway.

Figure 2-1 shows the standard terminal block diagram. Once the Gateway

and PC/Laptop are connected, wire a 24 VDC (nominal) power supply with a

capacity of at least 250 mA to the Gateway power input terminals.

Figure 2-1. Standard Terminal

Block.

24 VDC

(nominal)

Power Input

+

Case

Ethernet 2

with Power

(Covered)

When making physical connections to the Gateway it is important to use the electrical

conduit entries located on the bottom of the housing. Connecting through the open terminal

block cover (the lower cover) may stress the connections and damage the Gateway.

S

-

Ethernet 2

(Secondary) (Primary)

Serial

Modbus

AB

Ethernet 1

-

Not Use

2-3

Reference Manual

00809-0200-4420, Rev EA

Smart Wireless Gateway

November 2011

Configure the Gateway It is now possible to log into the Gateway for the first time and begin

configuration for placement on a live control network. The following items

need to be configured:

• Security Passwords

• Time Settings

• TCP/IP Network Settings

Use the following procedure to log in to the Gateway:

1. Open a standard web browser (typically Microsoft Internet Explorer).

2. Enter 192.168.1.10 in the address bar

3. Acknowledge the security to proceed.

4. Enter admin for User Name.

5. Enter default for the Password.

The web browser will now be directed to the Gateway’s default home page.

There is a navigation menu located on the left hand side with four main areas.

• Diagnostics: View status of communications, client server parameters,

and more

• Monitor: Screens created by the user to view data from field devices

• Explorer: Basic view of values from field devices

• Setup: Configure the Gateway for operations, security, and host system

integration

Table 2-2. Role Based Access

User Accounts

Security Passwords

There are four role based user accounts for the gateway with varying levels of

access. The table below describes this access.

Role User Name Web Interface Access

Executive exec Read-only access

Operator oper Read-only access

Maintenance maint Configure HART® device settings

Configure Modbus communications

Configure Modbus register mapping

Configure OPC browse tree

Configure custom trends

Administrator admin Includes all maintenance privileges

Configure Ethernet network settings

Configure WirelessHART network settings

Set passwords

Set time settings

Set home page options

Configure custom point pages

Restart applications

Each of the initial passwords for the user accounts is default. It is

recommended, for security purposes, that these passwords are changed. The

administrator password should be appropriately noted when changed. If it is

lost, please contact Emerson Process Management for technical support.

2-4

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 2-2. User Accounts

Smart Wireless Gateway

To change the User Accounts Passwords:

1. Navigate to Setup>Security>User accounts.

2. Set the new password for each role based user account, and confirm.

3. Click Submit.

Time Settings

The Gateway is the timekeeper for the WirelessHART network, so it is

imperative that the Gateway’s time is accurate for timestamp data to be

meaningful. Time settings can be found by navigating to Setup>Time.

There are three ways to set the Gateway time:

1. Network Time Protocol (recommended).

This option uses a Network Time Protocol (NTP) server to slowly

adjust the Gateway’s time in order to match the time of the control

network. Enter the IP address for the NTP server and select the

packet version (1, 2, 3, or 4).

2. Set with PC Time.

This option will match the Gateway’s time to that of the PC/Laptop.

3. Manual Entry.

This option allows the user to enter a specific date (MM:DD:YY) and

time (HH:MM:SS).

NOTE

Network Time Protocol (NTP) is recommended for the best network

performance because it always adjusts time to match the network time server.

2-5

Smart Wireless Gateway

Figure 2-3. Time Settings

TCP/IP Network Settings

Reference Manual

00809-0200-4420, Rev EA

November 2011

Use caution when making changes to the TCP/IP network settings. If they are lost or

improperly configured, it may be impossible to log into the Gateway. Contact the network

administrator for information on the proper TCP/IP network settings to apply.

Prior to the gateway being installed and connected to a live control network, it

should be configured with an IP address, as well as other TCP/IP network

settings.

Request the following configuration items from the network administrator:

• Specify an IP address, or use a DHCP server

• Hostname

• Domain Name

• IP address

•Netmask

• Gateway

Obtaining an IP address from a DHCP server is not recommended, since the

Gateway operation will be dependant on the availability of the DHCP server.

For maximum gateway availability it is best practice to specify an IP address.

2-6

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

To change the TCP/IP Network Settings:

1. Navigate to Setup>Ethernet protocol.

2. Select Specify an IP address (recommended).

3. Enter the following:

• Hostname

• Domain Name

• IP Address

•Netmask

• Gateway

4. Click Submit.

5. When prompted, click Restart apps.

6. Click Yes to confirm restart.

7. Close the web browser.

NOTE

Once the IP Address of the Gateway has been changed, communications to

the web interface will be lost. Restart the web browser, then log back into the

Gateway using the new IP address and other TCP/IP network settings. The

PC/Laptop TCP/IP network settings may need to be changed.

Figure 2-4. Ethernet Settings

2-7

Reference Manual

00809-0200-4420, Rev EA

Smart Wireless Gateway

November 2011

System Backup The Gateway has a System Backup and Restore feature that saves all

user-configured data. It is best practice that a System Backup be performed

periodically throughout the installation and configuration process.

1. Navigate to Setup>System Backup>Save.

2. Click Save Configuration.

3. The Gateway collects the configuration date and when the file

download pop up appears, click Save.

4. Enter a save location and file name.

5. Enter Save.

6. Click Return to form.

NOTE

System backup contains user passwords and keys used for encrypting

communication. Store downloaded system backups in a secure location.

2-8

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 3 Mounting and Connection

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Remote Antenna (optional) . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-6

Explosions could result in death or serious injury:

• Verify that the operating atmosphere of the device is consistent with the

appropriate hazardous locations certifications.

Electrostatic discharge can damage electronics:

• Use proper personal grounding before handling electronics or making contact with

leads and terminals

Electrical shock could cause death or serious injury. If the device is installed in a

high-voltage environment and a fault condition or installation error occurs, high voltage may

be present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference, this device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

OVERVIEW This section describes how to properly mount the Gateway and make

electrical connections, including electrical wiring, grounding, and host system

connections. This section also describes how to mount the optional remote

antenna.

General Considerations The Smart Wireless Gateway may be mounted in any General Purpose

location. Be sure the covers are secured tightly to prevent exposure of any

electronics to moisture and contamination.

The Gateway should be mounted in a location that allows convenient access

to the host system network (process control network) as well as the wireless

field device network.

3-1

Reference Manual

Gateway

Ground

Control

Room

Infrastructure

Mast or

Pipe

15-25 ft.

(4,6-7,6 m)

6 ft. (2 m)

00809-0200-4420, Rev EA

Smart Wireless Gateway

November 2011

Physical Description For dimensional drawing information refer to Appendix A: Product

Specifications. The cast aluminum housing encloses the electronics circuitry

of the Gateway. The front of the enclosure has an upper cover and a junction

box cover. The upper cover provides access to the electronics and radio. The

junction box cover provides access to the terminal block.

To open either cover, use a ¼-in. bladed screwdriver to remove the

appropriate screw on the unhinged side of the enclosure.

MOUNTING Find a location where the Gateway has optimal wireless performance. Ideally

this will be 15-25 ft. (4,6 - 7,6 m) above the ground or 6 ft. (2 m) above

obstructions or major infrastructure. Figure 3-1 show an example gateway

installation.

Figure 3-1. Gateway Installation

Pipe Mount The following hardware and tools are needed to mount the Gateway to a 2-in.

pipe:

5

/16-in. u-bolts (supplied with Gateway)

the Gateway enclosure, and through the washer plate.

3-2

•Two

• 2-in. mounting pipe

• ½-in. socket-head wrench

Mount the Gateway using the following procedure:

1. Insert one u-bolt around the pipe, through the top mounting holes of

2. Use a ½-in. socket-head wrench to fasten the nuts to the u-bolt.

3. Repeat for the second u-bolt and the lower mounting holes.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 3-2. Pipe Mount

Smart Wireless Gateway

Bracket Mount (alternate) The following hardware and tools are needed to mount the Gateway to a

support bracket:

•Four

• Mounting support bracket

•

•

Mount the Gateway using the following procedure:

1. Drill four

2. Using a

15

/16-in. bolts

3

/8-in. drill

1

/2 -in. socket-head wrench

3

/8-in. (9,525 mm) holes spaced 3.06-in. (77 mm) apart

horizontally and 11.15-in. (283 mm) apart vertically in the support

bracket, corresponding with the holes on the Gateway enclosure.

1

/2-in. socket-head wrench, attach the Gateway to the support

bracket with four

15

/16-in. bolts.

3-3

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

REMOTE ANTENNA

(OPTIONAL)

The remote antenna options provide flexibility for mounting the Gateway

based on wireless connectivity, lightning protection, and current work

practices.

When installing remote mount antennas for the Smart Wireless Gateway, always use

established safety procedures to avoid falling or contact with high-power electrical lines.

Install remote antenna components for the Smart Wireless Gateway in compliance with

local and national electrical codes and use best practices for lightning protection.

Before installing consult with the local area electrical inspector, electrical officer, and work

area supervisor.

The Smart Wireless Gateway remote antenna option is specifically engineered to provide

installation flexibility while optimizing wireless performance and local spectrum approvals.

To maintain wireless performance and avoid non-compliance with spectrum regulations, do

not change the length of cable or the antenna type.

If the supplied remote mount antenna kit is not installed per these instructions, Emerson

Process Management is not responsible for wireless performance or non-compliance with

spectrum regulations.

The remote mount antenna kit includes coaxial sealant for the cable

connections for the lightning arrestor and antenna.

Find a location where the remote antenna has optimal wireless performance.

Ideally this will be 15-25 ft (4,6 - 7,6 m) above the ground or 6 ft (2 m) above

obstructions or major infrastructure. To install the remote antenna use one of

the following procedures:

Installation of WL2/WN2 Option (outdoor applications):

1. Mount the antenna on a 1.5-2 inch pipe mast using the supplied

mounting equipment.

2. Connect the lightning arrestor directly to the top of the Gateway.

3. Install the grounding lug, lock washer, and nut on top of the lightning

arrestor.

4. Connect the antenna to the lightning arrestor using the supplied

coaxial cable ensuring the drip loop is not closer than 1 foot (0,3m)

from the lightning arrestor.

5. Use the coaxial sealant to seal each connection between the wireless

field device, lightning arrestor, cable, and antenna.

6. Ensure that the mounting mast, lightning arrestor, and Gateway are

grounded according to local/national electrical code.

Any spare lengths of coaxial cable should be placed in 12 inch (0,3 m) coils.

3-4

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 3-3. Installation of

WL2/WN2 Option

Smart Wireless Gateway

Installation of WL3/WL4 Option (indoor to outdoor applications):

1. Mount the antenna on a 1.5-2 inch pipe mast using the supplied

mounting equipment.

2. Mount the lightning arrestor near the building egress.

3. Install the grounding lug, lock washer, and nut on top of lightning

arrestor.

4. Connect the antenna to the lightning arrestor using the supplied

coaxial cable ensuring the drip loop is not closer than 1 foot (0,3m)

from the lightning arrestor.

5. Connect the lightning arrestor to the Gateway using the supplied

coaxial cable.

6. Use the coaxial sealant to seal each connection between the

Gateway, lightning arrestor, cable, and antenna.

7. Ensure that the mounting mast, lightning arrestor, and Gateway are

grounded according to local/national electrical code.

Figure 3-4. Installation of

WL3/WL4 Option

Any spare lengths of coaxial cable should be placed in 12 inch (0,3 m) coils.

3-5

Smart Wireless Gateway

NOTE: WEATHER PROOFING IS REQUIRED!

The remote mount antenna kit includes coaxial sealant for the cable

connections for the lightning arrestor, antenna, and Gateway. The coaxial

sealant must be applied to guarantee performance of the wireless field

network. Please see Figure 3-5 for details on how to apply weather proofing.

Figure 3-5. Applying coaxial

sealant to cable connections

Table 3-1. Remote Antenna Kit Options

Kit

Option

WL2

WL3

WL4

WN2

Reference Manual

00809-0200-4420, Rev EA

November 2011

Antenna Cable 1 Cable 2 Lightning Arrestor

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+8 dB Gain

50 ft. (15,2 m)

LMR-400

30 ft. (9,1 m)

LMR-400

40 ft. (12,2 m)

LMR-400

25 ft. (7,6 m)

LMR-400

N/A Head mount, jack to plug

Gas discharge tube

0.5 dB insertion loss

20 ft. (6,1 m)

LMR-400

10 ft. (3,0 m)

LMR-400

N/A Head mount, jack to plug

In-line, jack to jack

Gas discharge tube

0.5 dB insertion loss

In-line, jack to jack

Gas discharge tube

0.5 dB insertion loss

Gas discharge tube

0.5 dB insertion loss

CONNECTING All connections to the Gateway can be made at the terminal block, which is

located in the lower junction box section of the enclosure. The terminal block

label is located on the inside of the lower cover. See Figure 3-6 for the

standard terminal block label and Figure 3-8 for the fiber optic terminal block

label.

The junction box portion of the enclosure has four conduit entries for power

and communications wiring. Do not run communication wiring in conduit or

open trays with power wiring, or near heavy electrical equipment.

Install the included conduit plugs in any unused conduit openings. For NEMA

4X and IP65 requirements, use thread seal (PTFE) tape or paste on male

threads to provide a watertight seal.

Grounding The Gateway enclosure case should always be grounded in accordance with

national and local electrical codes. The most effective grounding method is a

direct connection to earth ground with minimal impedance. Ground the

Gateway by connecting the external grounding lug to earth ground. The

connection should be 1 Ω or less. The external ground lug is located below

the Gateway enclosure and is identified by the following symbol:

3-6

Reference Manual

+

+

+

+

-

AB

S

S

S

S

24 VDC

(nominal)

Power Input

Serial

Modbus

Not Used

Not Used

d

Not Used

Case

(Covered)

S

Ethernet 2

with Power

Ethernet 2

Ethernet 1

(Secondary) (Primary)

T

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Ethernet The Gateway is equipped with two 10/100 Based-TX Ethernet

communications ports (see Figure 3-6). These connections can be used to

access the Gateway’s web interface and to communicate Modbus TCP and

OPC protocols.

The primary Ethernet port (Ethernet 1) is used to connect to the host system

or other application systems. The secondary Ethernet port (Ethernet 2) can be

used as a back up connection or a maintenance port for local access to the

Gateway.

Figure 3-6. Terminal Block

Diagram

Not Use

-

Ethernet connections should use Cat5E shielded cable to connect to an

Ethernet hub, switch, or router. The maximum cable length should not exceed

328 ft. (100 m).

NOTE

Unless dual Ethernet ports were specified at the time of order, the secondary

Ethernet port (Ethernet 2) will not be active.

RS-485 The Gateway may be ordered with an optional RS-485 (serial) connection

(Figure 3-6). It is referenced by the A and B Serial Modbus terminals. This

connection is used to communicate Modbus RTU on an RS-485 data bus.

Use 18 AWG single twisted shielded pair wiring to connect the Gateway to the

RS-485 data bus. The total bus length should not exceed 4000 ft. (1220 m).

Connect the Tx + (positive, transmit) wire to terminal A and the Rx - (negative,

receive) wire to terminal B. The wiring shield should be trimmed close and

insulated from touching the Gateway enclosure or other terminations.

If the existing data bus uses a 4 wire Full Duplex configuration, see Figure 3-7

to convert to a 2-wire Half Duplex configuration.

Figure 3-7. Convert from Full to

Half Duplex

Tx +

Tx + = (A)

Rx +

x -

Rx - = (B)

Rx -

3-7

Reference Manual

ON

K40

1

2

3

470Ω Pull-down Resistor

120Ω Terminating Resistor

470Ω Pull-up Resistor

Electronics

Radio

DIP Switches

Main Circuit Board

Up to 4000 ft. (1220 m)

Device 1

Device 2

A

B

Terminators required

only for high data rates

and long cable runs

Device N

(up to 32

possible)

00809-0200-4420, Rev EA

Smart Wireless Gateway

November 2011

Terminating Resistors Three DIP switches are provided to enable various terminating resistors to the

RS-485 data bus. The switches are found inside the electronics housing near

the top center of the main circuit board (Figure 3-8).

Figure 3-8. RS-485 Resistor DIP

Switches

Figure 3-9. Typical Half Duplex

(2-wire) Network

Switches 1 and 3 are connected to pull-up and pull down resistors. Switch 1 is

for the Tx + (A) line and Switch 3 is for the Rx – (B) line. These 470 Ω

resistors are used to prevent noise from being interpreted as valid

communications during periods when no actual communications are

occurring. Only one set of pull-up and pull-down resistors should be active on

the RS-485 data bus at time.

Switch 2 is connected to a 120 Ω terminating resistor. This resistor is used to

dampen signal reflections on long cable runs. RS-485 specifications indicate

that the data bus should be terminated at both ends (Figure 3-9). However

termination should only be used with high data rates (above 115 kbps) and

long cable runs.

3-8

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Power The Gateway is designed to be powered by 24 VDC (nominal) and requires

250 mA of current. The positive and negative connections are found on the

left side of the terminal block (Figure 3-6). An additional case ground is found

on the left side of the junction box enclosure.

Connect supply power to the positive + and negative – power terminals found

on the left side of the terminal block (Figure 3-6). An additional internal case

ground can be found on the left side of the enclosure. The wiring should

include an external power shut-off switch or circuit breaker that is located near

the Gateway.

NOTE

Using an uninterruptible power supply (UPS) is recommended to ensure

availability should there be a loss of power.

3-9

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

3-10

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 4 Software Setup

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Security Setup Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

AMS Wireless Configurator . . . . . . . . . . . . . . . . . . . . . . . . page 4-4

Licensing and Credits . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4-6

OVERVIEW This section discusses the installation and setup of the optional software

included with the Smart Wireless Gateway. This software is not required for

the wireless field network to operate; however, it will aid in secure host

integration as well as wireless field device configuration. The following table

describes what items are installed and on which disk they can be found.

Table 4-1. Software

Applications

SYSTEM

REQUIREMENTS

Table 4-2. PC Hardware

Name Description Location

Security Setup Utility This utility allows the setup of SSL enable

AMS Wireless

Configurator

Network Configuration This application configures AMS Wireless

communications between the Gateway and host

system.

This application allows complete configuration of

wireless field devices and provides added

security through drag and drop provisioning.

Configurator to interface to a Wireless Network

or a HART Modem.

Disk 1

Disk 2

Disk 2

Additional system components may be installed depending on the current

configuration of the system.

Minimum Requirements Recommended Requirements

Intel Core 2 Duo, 2.0 GHz Intel Core 2 Quad, 2.0 GHz or greater

1 GB Memory 3 GB Memory or Greater

1.5 GB free hard disk space 2 GB or more of free hard disk space

Note: Additional hard disk space is required for SNAP-ON applications.

The minimum monitor requirements are 1024 x 768 resolution and 16-bit color.

4-1

Smart Wireless Gateway

Table 4-3. Supported Operating

Systems

Operating System Version

Windows XP Professional, Service Pack 3

Windows Server 2003 Standard, Service Pack 2

Windows Server 2003 R2 Standard, Service Pack 2

Windows Server 2008 Standard, Service Pack 2

Windows Server 2008 R2 Standard, Service Pack 1

Windows 7 Professional, Service Pack 1

Windows 7 Enterprise, Service Pack 1

Note: Only 32-bit versions of the operating systems are supported for AMS Wireless Configurator.

Reference Manual

00809-0200-4420, Rev EA

November 2011

SOFTWARE

INSTALLATION

The software can be found on the 2 disk pack, included with the Gateway.

Depending on the PC system configuration, installation may take 30-35

minutes. Installing both disks in order is recommended. The Security Setup

Utility is located on Disk 1. To install the software:

1. Exit/close all Windows programs, including any running in the

background, such as virus scan software.

2. Insert Disk 1 into the CD/DVD drive of the PC.

3. Follow the prompts.

AMS Wireless Configurator is located on Disk 2. To install the software:

1. Exit/close all Windows programs, including any running in the

background, such as virus scan software.

2. Insert Disk 2 into the CD/DVD drive of the PC.

3. Click Install from the menu when the AMS Wireless Configurator setup

begins.

4. Follow the prompts.

5. Allow AMS Wireless Configurator to reboot PC.

6. Do not remove the disk from the CD/DVD drive.

7. Installation will resume automatically after login.

8. Follow the prompts.

NOTE:

If the autorun function is disabled on the PC, or installation does not begin

automatically, double click D:\SETUP.EXE (where D is the CD/DVD drive on

the PC) and click OK.

SECURITY SETUP

UTILITY

4-2

The Security Setup Utility enables secure communications between the

Gateway and host system, asset management software, data historians, or

other applications. This is done by encrypting the standard data protocols

(AMS, Modbus TCP, and OPC) used by the Gateway and making them

available through various proxies within the Security Setup Utility. These

proxies can function as a data server for other applications on the control

network. The Security Setup Utility can support multiple Gateways at once

and each proxy can support multiple client application connects. Figure 4-1

shows a typical system architecture using the Security Setup Utility.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 4-1. Typical Host System

Architecture Using Security

Setup

Smart Wireless Gateway

NOTE:

OPC communications requires the use of the Security Setup Utility regardless

of whether encryption is required.

Setup In the Security Setup Utility add a new proxy for each Gateway based on the

communication protocol that is being used. For example, add an OPC proxy

for each Gateway that is communicating OPC.

Use the following procedure to add a new proxy in the Security Setup Utility:

1. Open the Security Setup Utility.

2. Click EDIT>NEW, then select the type of new proxy to be added.

3. Right click on the new proxy entry and select Properties.

4. Enter the target Gateway’s Hostname and IP Address.

5. Click OK.

6. Click FILE>SAVE.

7. When prompted for authentication, enter the admin password for the

target Gateway.

8. Click OK.

9. Repeat steps 2-8 to added additional proxies.

10. Click FILE>EXIT to close the Security Setup Utility.

4-3

Smart Wireless Gateway

During this process the Gateway will exchange security certificates (digital

signatures) with the proxy.

Figure 4-2. Security Setup Utility

Reference Manual

00809-0200-4420, Rev EA

November 2011

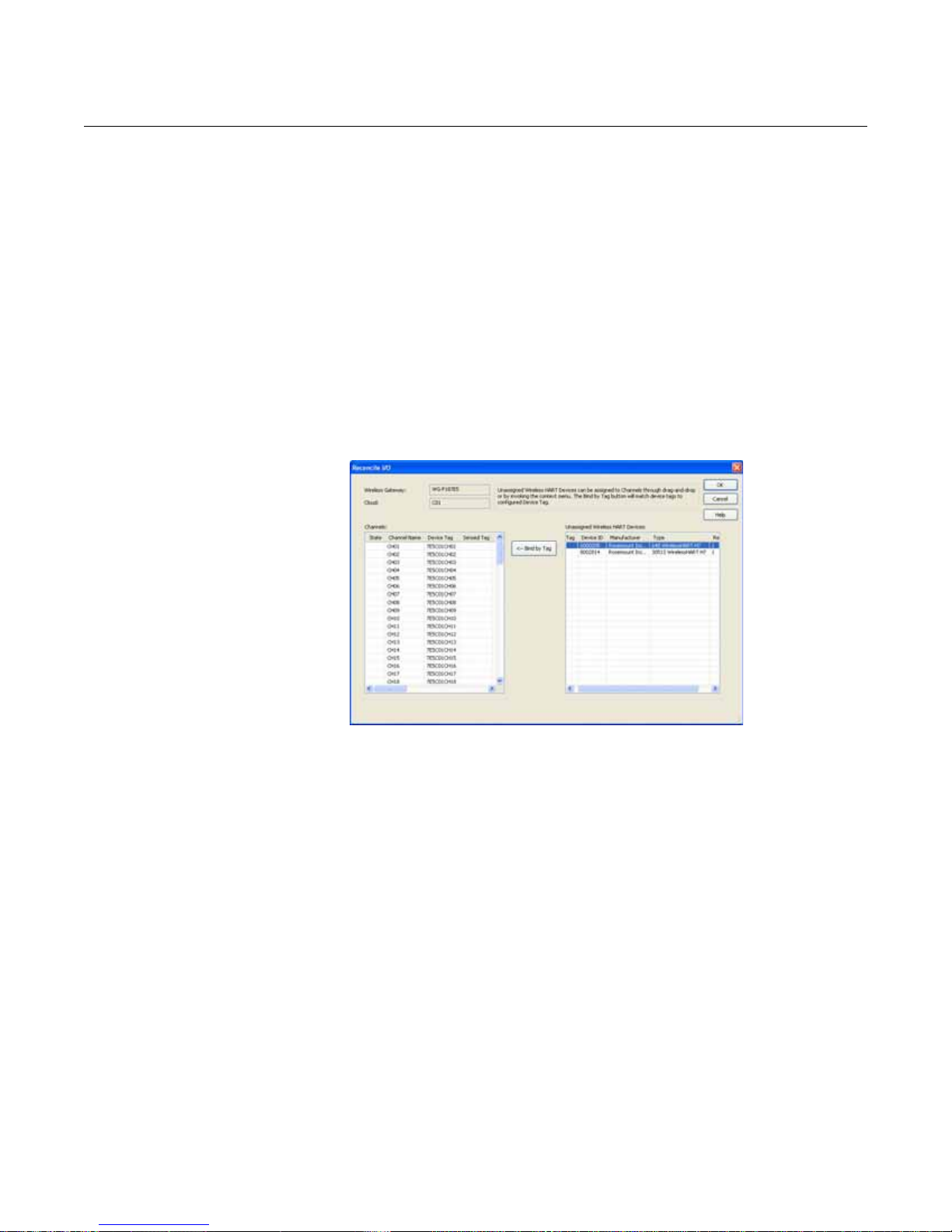

AMS WIRELESS

CONFIGURATOR

AMS Wireless Configurator helps deploy and configure wireless field devices.

It provides an integrated operating environment that leverages the full

capabilities of WirelessHART, including embedded data trending, charting,

and graphical display capabilities provided by enhanced EDDL technology.

• Display and modify device configuration

• View device diagnostics

• View process variables

• Provision a wireless device using the drag-and-drop operation so it can

join a Gateway’s self-organizing network

• Enhance AMS Wireless Configurator functionality with the AMS

Wireless SNAP-ON Application

• Restrict access to AMS Wireless Configurator functions through the

use of security permissions

See the release notes for information specific to the current release of AMS

Wireless Configurator. To display the release notes, select

START>PROGRAMS>AMS WIRELESS CONFIGURATOR>HELP.

Setup AMS Wireless Configurator supports connectivity to a Wireless Network and a

HART Modem. Both of these interfaces must be configured through the

Network Configuration application. To run this application, select

START>PROGRAMS>AMS DEVICE MANAGER>NETWORK

CONFIGURATION.

4-4

NOTE:

Do not have the Security Setup Utility running at the same time as the

Network Configuration application or else a configuration error might occur.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 4-3. Wireless Network in

the Network Configuration

Smart Wireless Gateway

Use the following procedure to configure a wireless network for AMS Wireless

Configurator:

1. Open the Network Configuration application.

2. Click Add…

3. Select Wireless Network and click Install…

4. Click Next.

5. Enter a name for the wireless network and click Next.

6. Enter the HostName or IP Address for the Gateway and click Add.

7. Repeat step 6 if multiple Gateways need to be added.

8. Check the box to Enable Secure Communications with the Smart

Wireless Gateway.

9. Click Finish to close the configuration window.

10. Click Close to exit the Network Configuration application.

Use the following procedure to configure a HART modem for AMS Wireless

Configurator:

1. Open the Network Configuration application.

2. Click Add…

3. Select HART modem and click Install…

4. Click Next.

5. Enter a name for the HART modem and click Next.

6. Select the HART master type (default is AMS will be Primary HART

master) and click Next.

7. Select the COM port for the HART modem and click Next.

8. Check the box to Check to support Multi Drop devices.

9. Check the box to Include WirelessHART Adapter.

10. Click Finish to close the configuration window.

11. Click Close to exit the Network Configuration application.

4-5

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

LICENSING AND

CREDITS

The latest licensing agreements are included on each disk of the software

pack.

“This product includes software developed by the OpenSSL Project for use in

the OpenSSL Toolkit. (http://www.openssl.org/)”

“This product includes software written by Eric Young (eay@cryptsoft.com)”

4-6

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 5 Host Integration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 5-1

Network Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-1

Internal Firewall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-3

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-4

OVERVIEW This section describes how to connect the Gateway to a host system and

integrate data gathered from the field device network. It covers network

architectures, security, and data mapping.

NETWORK

ARCHITECTURE

Figure 5-1. Ethernet

Architecture

Physical connection types are important when determining the network

architecture and what protocols can be used for integration. Ethernet is the

primary physical connection type. Fiber Optic and RS485 are available as

optional connection types. The following network architecture diagrams will

help when integrating data from the Gateway into the host system.

Ethernet

An Ethernet connection supports Modbus TCP, OPC, AMS, and HART TCP

protocols. Using this connection type, the Gateway is wired directly to a

control network (see Figure 5-1) using a network switch, router, or hub. Often

there are two networks for redundancy purposes.

5-1

Smart Wireless Gateway

Fiber Optic (Optional)

A Fiber Optic connection supports Modbus TCP, OPC, AMS, and HART TCP

protocols. Using this connection type, the Gateway is wired to a fiber optic

switch (see Figure 5-2).

NOTE:

A fiber optic connection requires a third party copper Ethernet to fiber optic

Ethernet converter.

Figure 5-2. Fiber Optic

Architecture

Reference Manual

00809-0200-4420, Rev EA

November 2011

5-2

RS485 (serial)

An RS485 connection supports Modbus RTU protocol. Using this connection

type, the Gateway is wired to an RS485 bus which typically leads to a serial

I/O card or Modbus I/O card (see Figure 5-3). Up to 31 Gateways can be

connected to a single I/O card in this manner.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Figure 5-3. RS485 Architecture

Smart Wireless Gateway

INTERNAL FIREWALL The Gateway supports an internal firewall that inspects both incoming and

outgoing data packets. TCP ports for communication protocols are user

configurable, including user specified port numbers and the ability to disable

ports.

The Gateway’s internal firewall settings can be found by navigating to

Setup>Security>Protocols.

Figure 5-4. Security Protocols

page (internal firewall)

5-3

Reference Manual

00809-0200-4420, Rev EA

Smart Wireless Gateway

November 2011

MODBUS The Gateway supports both Modbus RTU over the RS-485 serial port and

Modbus TCP over Ethernet. It functions as a sub device on the Modbus

network and must be polled by a Modbus master or client (host system).

Communication Settings It is import that the Modbus communication settings in the Gateway match the

setting in the Modbus master or client. Please refer to host system

documentation for more information on how to configure these settings. The

Modbus communication settings can be found by navigating to

Setup>Modbus>Communications.

Figure 5-5. Modbus

Communications Page

One Modbus Address: When this option is selected, this address is used by

the Gateway for Modbus RTU communications.

Multiple Modbus Addresses: When this option is selected, a new column for

address will appear on the Modbus mapping page.

Modbus TCP Port: This is the TCP/IP port the Gateway uses for Modbus

TCP (Ethernet). To change TCP/IP port settings, see the Internal Firewall

section for more details.

Baud Rate: The data rate or speed of serial communications. This setting is

only required for Modbus RTU.

Parity: This setting determines parity (none, even, or odd) to use for error

checking purposes. This setting is only required for Modbus RTU.

Stop B its: This setting determines the number (1 or 2) of stop bits to use

when ending a message. This setting is only required for Modbus RTU.

Response delay time (ms): This setting determines how long (ms) the

Gateway waits before responding to a Modbus request. This setting is only

required for Modbus RTU.

Unmapped register read response?: This is the value returned by the

Gateway if the Modbus master requests a register with no data assigned to it

(empty register). It is recommended this be set to zero fill to prevent errors.

5-4

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Floating point representation: This setting determines if the Gateway uses

floating point values or integer values. There are three options for this setting.

• Float: This option uses 32 bit floating point values.

• Round: This option rounds the data value to the nearest whole number.

• Scaled: This option uses scaled integers to offset negative values or

increase decimal point resolution. The equation for scaled integers is:

y = Ax - (B - 32768)

Where:

y = Scaled integer returned by the Gateway

A = Gain for scaled integer value

x = Measured value from wireless field device

B = Offset for scaled integer value

Use swapped floating point format?: This setting switches which register is

sent first for a floating point value. This setting is only used for floating point

values.

Incorporate value’s associated status as error?: This setting will cause the

Gateway to report a predetermined value when a communications or critical

diagnostic error is received from the wireless field device. The value is user

configurable depending on which floating point representation is chosen. See

Value reported for error below.

Value re ported for error (floating point) : This setting determines what value

is reported if the wireless field device reports a failure or stops communicating

to the Gateway. This setting is used for floating point values. The choices are

NaN (not a number), +Inf (positive infinity), -Inf (negative infinity), or Other

(user specified).

Value reported for error (rounded and native integer): This setting

determines what value is reported if the wireless field device reports a failure

or stops communicating to the Gateway. This setting is used for rounded or

scaled integers. The choice is a user specified value between -32768 and

65535.

Scaled floating point maximum integer value: This determines the

maximum integer value for the purpose scaling integers. 999-65534

Use global scale gain and offse t? : This setting determines if a global gain

and offset is applied for scaled integers or if each value has a unique gain and

offset. Unique gain and offsets are found on the Modbus Mapping page.

Global scale gain: This value is multiplied to the data values for the purpose

of scaling integers. If global scaling is not selected, a gain value will be

available for each separate data value on the Modbus Mapping page.

Register Mapping Register Mapping is the process of assigning data points from wireless field

Global scale offset: This value is added to the data values for the purpose of

scaling integers. If global scaling is not selected, an offset value will be

available for each separate data value on the Modbus Mapping page.

devices to Modbus registers. These registers can then be read by a Modbus

master or client. Modbus register mapping can be found by navigating to

Setup>Modbus>Mapping.

5-5

Smart Wireless Gateway

Figure 5-6. Modbus Register

Map Page

Reference Manual

00809-0200-4420, Rev EA

November 2011

To add a new data point to the Modbus register map:

1. Click New entry.

2. Complete all of the table entries for the new data point (note that the

entry columns may vary based on the Modbus communications settings).

3. Repeat for each new data point.

4. Click Submit.

5. When changes have been accepted, click Return to form.

Address: This is the Modbus RTU address used by the Gateway for this data

point. It is possible to group data points assigning them the same address (i.e.

all data points from the same process unit can have the same address). This

column only appears if Multiple Modbus Addresses is selected on the Modbus

Communications page.

Register: This is the Modbus register number used for this data value.

Modbus registers hold two bytes (16 bits) of information; therefore 32 bit floats

and integers require two Modbus registers. Each data point needs a unique

Modbus register number, unless they are assigned different addresses.

Register numbers 0-19999 are reserved for Boolean (bit, coil, binary, etc…)

values. Register numbers 20000+ are reserved for floating point or integer

values.

Point Name: This is a two part name for the data point. The first part is the

HART Tag of the wireless field device which is producing the data. The

second part is the parameter of the wireless field device.

5-6

Point Name is entered as <HART Tag.PARAMETER>. Point Name can be

entered using the list of values (…) or manually entered. The following table

gives a list of standard device parameters which may be considered for

Modbus register mapping.

Reference Manual

00809-0200-4420, Rev EA

November 2011

Table 5-1. Device parameters

available via Modbus

Smart Wireless Gateway

Parameter Description Data Type

PV Primary Variable 32 bit float

SV Secondary Variable 32 bit float

TV Tertiary Variable 32 bit float

QV Quaternary Variable 32 bit float

RELIABILITY A measure of connectivity to the Gateway 32 bit float

ONLINE Wireless communications status Boolean

PV_HEALTHY Health status for PV Boolean

SV_HEALTHY Health status for SV Boolean

TV_HEALTHY Health status for TV Boolean

QV_HEALTHY Health status for QV Boolean

PV, SV, TV, and QV (dynamic variables) will vary by device type. Please refer

to the device’s documentation for more information on what value is

represented by each dynamic variable.

RELIABILITY and ONLINE relate to wireless communications. RELIABILITY

is the percentage of messages received from the wireless field device.

ONLINE is a true/false indication of whether the device is communicating on

the wireless network.

**_HEALTHY parameters are a true/false indication of the health of a

particular variable (** = dynamic variable – PV, SV, etc…). These parameters

incorporate critical diagnostics from the wireless field device as well as

communication status.

NOTE:

The **_HEALTHY parameters are a great indication of the health and

communications status of the data values.

State (state value): The value of a data point which drives a Modbus output

of 1. For example, if a data point is reported as either True or False, a state

value of True will report a 1 for True and 0 for False. A state of False will

report a 0 for True and a 1 for False. State is only required for register

numbers 0-19999 (Boolean, bit, coil, binary, etc…).

Invert: This check box will invert the Modbus output from a 1 to a 0 or a 0 to a

1. Invert is only used for Boolean values using register numbers 0-19999.

Gain: This value is multiplied to the data value for the purpose of scaling

integers. Gain is only required if scaled is chosen on the Modbus

communications page and globe gain and offset is not chosen.

Offset: This value is added to the data value for the purpose of scaling

integers. Offset is only required if scaled is chosen on the Modbus

communications page and globe gain and offset is not chosen.

Predefined Modbus Registers

In addition to user configurable parameters, the Gateway also supports a list

of predefined Modbus registers with diagnostics and test parameters. The

following table is a list of the predefined Modbus registers.

5-7

Smart Wireless Gateway

Table 5-2. Predefined Modbus

Registers

Description Register Data Type

Current Year (1) 49001 32 bit int

Current Month (1) 49002 32 bit int

Current Day (1) 49003 32 bit int

Current Hour (1) 49004 32 bit int

Current Minute (1) 49005 32 bit int

Current Second (1) 49006 32 bit int

Messages Received 49007 32 bit int

Corrupt Messages Received 49008 32 bit int

Messages Sent With Exception 49009 32 bit int

Messages Sent Count 49010 32 bit int

Valid Messages Ignored 49011 32 bit int

Constant Float 12345.0 49012 32 float

SYSTEM_DIAG.HART_DEVICES 49014 32 bit int

SYSTEM_DIAG.ADDITIONAL_STATUS_0 49015 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_1 49016 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_2 49017 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_3 49018 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_4 49019 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_5 49020 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_6 49021 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_7 49022 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_8 49023 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_9 49024 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_10 49025 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_11 49026 8 bit unsigned int

SYSTEM_DIAG.ADDITIONAL_STATUS_12 49027 8 bit unsigned int

SYSTEM_DIAG.UNREACHABLE 49028 32 bit int

SYSTEM_DIAG.UPTIME 49029 32 bit int

SYSTEM_DIAG.TEST_BOOLEAN 49031 Boolean

SYSTEM_DIAG.TEST_BYTE 49032 8 bit int

SYSTEM_DIAG.TEST_UNSIGNED_BYTE 49033 8 bit unsigned int

SYSTEM_DIAG.TEST_SHORT 49034 16 bit int

SYSTEM_DIAG.TEST_UNSIGNED_SHORT 49035 16 bit unsigned int

SYSTEM_DIAG.TEST_INT 49036 32 bit int

SYSTEM_DIAG.TEST_UNSIGNED_INT 49038 32 bit unsigned int

SYSTEM_DIAG.TEST_FLOAT 49040 32 bit float

Reference Manual

00809-0200-4420, Rev EA

November 2011

5-8

Reference Manual

00809-0200-4420, Rev EA

November 2011

Smart Wireless Gateway

Section 6 Troubleshooting

This section provides basic troubleshooting tips for the Smart Wireless Field

Network. To receive technical support by phone:

Global Service Center

Software and Integration support.

• United States – 1 800 833 8314

• Internat i o n al – 63 2 702 1111

Customer Central

Technical support, quoting, and order-related questions.

• United States – 1 800 999 9307 (7:00 am to 7:00 pm CST)

• Asia Pacific – 65 6777 8211

• Europe / Middle East / Africa – 49 (8153) 9390

Or email the wireless specialists at:

Specialists-Wireless.EPM-RTC@EmersonProcess.com

Initial Connection

Web browser returns page not found 1. Use the supplied crossover cable to connect the Gateway and PC/Laptop

2. Verify the Gateway is properly powered, 24 VDC (nominal) and 250 mA. Open the upper

cover and verify if any indicator lights are on.

3. Verify which Ethernet port is being used on the Gateway.

4. Verify the IP address for the Gateway (default primary port is 192.168.1.10, default

secondary port is 192.168.2.10 or for DeltaV Ready Gateway’s default primary port is

10.5.255.254, default secondary port is 10.9.255.254).

5. Verify the IP address of the PC/Laptop is in the same subnet range as the Gateway (i.e. If the

Gateway IP is 155.177.0.xxx, then the PC/Lap IP address should be 155.177.0.yyy).

6. Disable internet browser proxy settings.

Can not find Gateway after changing IP

address

Can not find Gateway using Secondary

Ethernet Port

Can not log into the Gateway 1. Verify the user name and password. The administrator user name is admin and the default

1. Verify the IP address of the PC/Laptop is in the same subnet range as the Gateway (i.e. If the

Gateway IP is 155.177.0.xxx, then the PC/Lap IP address should be 155.177.0.yyy).

1. Verify which Ethernet port is being used on the Gateway.

2. Verify the IP address for the Gateway (default primary port is 192.168.1.10, default

secondary port is 192.168.2.10).

3. Verify the IP address of the PC/Laptop is in the same subnet range as the Gateway (i.e. If the

Gateway IP is 155.177.0.xxx, then the PC/Lap IP address should be 155.177.0.yyy).

password is default. See Table 2-1.

6-1

Reference Manual

00809-0200-4420, Rev EA

Smart Wireless Gateway

AMS Wireless Configurator

Gateway does not appear in AMS Wireless

Configurator

Wireless devices do not appear under the

Gateway

Wireless device appears with red HART

symbol

Device configuration items are grayed out 1. Verify whether current or historical information is being displayed. This setting is displayed at

Wireless Field Devices

Wireless device does not appear on the

network

Wireless device appears in the join failure

list

Wireless device appears with service

denied

1. Verify the Security Setup Utility is installed on the same PC as AMS Wireless Configurator.

2. Setup a wireless network interface using the Network Configuration application. See

Section 4: Software Setup.

3. Verify if the wireless network interface is configured for Secure Gateway Communications.

4. Verify secure/unsecure AMS protocol settings in the Gateway. Log on to the Gateway and

navigate to SETUP > SECURITY > PROTOCOLS.

5. Restart AMS data server. Right click on AMS server icon in the Windows system tray (lower

right corner) and select stop server.

1. Verify wireless devices are connected to the Gateway. Log on to the Gateway and navigate

to EXPLORER.

2. Right click on wireless network and select rebuild hierarchy.

1. Install latest device support files from AMS. Go to www.emersonprocess.com > BRANDS >

AMS SUITE > AMS DEVICE MANAGER > DEVICE DESCRIPTION (DDs).

the bottom of each device configuration screen. Configuration requires the Current setting.

2. For security purposes a configuration timeout is applied to sessions that have been idle for

more than 30 minutes. Log back into AMS Wireless Configurator.

1. Verify the device has power.

2. Verify the device is within effect communications range.

3. Verify the proper Network ID has been entered into the device

1. Re-enter the Network ID and Join Key into the device.

1. Verify the total number of devices on the network (100 max).

2. Go to SETUP > NETWORK > BANDWIDTH and click analyze bandwidth

(Note: any changes will require the network to reform)

3. Reduce the update rate for the device.

November 2011

Modbus Communications

Can not communicate using Modbus RTU 1. Verify the use of RS-485

2. Verify wiring connections. See Section 3: Mounting and Connection.

3. Verify if termination is required.

4. Verify that Modbus serial communications setting in the Gateway match the Modbus Host

settings. Log on to the Gateway and navigate to SETUP > MODBUS >

COMMUNICATIONS.

5. Verify the Modbus address for the Gateway

6. Verify Modbus register mapping in the Gateway. Log on to the Gateway and navigate to

SETUP > MODBUS > MAPPING.

Can not communicate using Modbus TCP 1. Verify secure / unsecure Modbus protocol settings in the Gateway. Log on to the Gateway

and navigate to SETUP > SECURITY > PROTOCOLS.

2. Verify the Modbus TCP communications settings in the Gateway. Log on to the Gateway and

navigate to SETUP > MODBUS > COMMUNICATIONS.

3. Verify Modbus register mapping in the Gateway. Log on to the Gateway and navigate to

SETUP > MODBUS > MAPPING.

Can not communicate using secure

Modbus TCP

1. Verify the Security Setup Utility has been installed.

2. Configure a Secure Modbus Proxy for the Gateway. See Section 4: Software Setup.

3. Verify secure / unsecure Modbus protocol settings in the Gateway. Log on to the Gateway

and navigate to SETUP > SECURITY > PROTOCOLS.

4. Verify the Modbus TCP communications settings in the Gateway. Log on to the Gateway and

navigate to SETUP > MODBUS > COMMUNICATIONS.

5. Verify Modbus register mapping in the Gateway. Log on to the Gateway and navigate to

SETUP > MODBUS > MAPPING.

6-2

Reference Manual

00809-0200-4420, Rev EA

November 2011

OPC Communications

OPC application can not find a Gateway

OPC server

Gateway OPC server does not show any

Gateways

Gateway OPC server does not show any

data tags

Smart Wireless Gateway

1. Verify the Security Setup Utility has been installed on the same PC as the OPC application.

2. Configure an OPC proxy for the Gateway. See Section 4: Software Setup.

1. Configure an OPC proxy for the Gateway. See Section 4: Software Setup.

1. Configure the Gateway OPC Browse Tree. Log on to the Gateway and navigate to SETUP >

OPC > OPC BROWSE TREE.

2. Verify the connection status for the OPC proxy in the Security Setup Utility.

3. Verify if the OPC proxy is configured for secure or unsecure communications.

4. Verify secure / unsecure OPC protocol settings in the Gateway. Log on to the Gateway and

navigate to SETUP > SECURITY > PROTOCOLS.

5. Verify network firewall and port settings.

6-3

Smart Wireless Gateway

Reference Manual

00809-0200-4420, Rev EA

November 2011

6-4

Reference Manual

00809-0200-4420, Rev EA

November 2011

Section 7 Glossary

This glossary defines terms used throughout this manual or that appear in the

web interface of the Smart Wireless Gateway.

Term Definition

Access Control List A list of all devices that are approved to join the network.

Active Advertising An operational state of the network manager that causes the

Baud Rate Communication speed for Modbus RTU

Burst Rate The interval in which a wireless field device transmits

Certificate A digital signature used to authenticate a client/server while

Connectivity Typically refers to a combination of communication statistics

Device ID A hexidecimal number that provides unique device