Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert Dual Unit Control for InteleCool® and InteleCool2

User Manual

®

Page 2

TABLE OF CONTENTS

1.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Connecting the Dual Unit Controller to an Electronic Thermostat . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Connecting the Dual Unit Controller to an InteleCool2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Connecting the Dual Unit Controller to the InteleCool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 CONTROL STARTUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Start the Dual Unit Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Check for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Lead Unit Schedule & Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.1 Designating the Lead InteleCool2 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.2 Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 DISPOSAL OF DUAL UNIT CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FIGURES

Figure 1 Dual Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TABLES

Table 1 Switch/jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2 Jumper settings for servicing InteleCool2 unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

i

Page 3

1.0 INSTALLATION

The optional Dual Unit Control is designed to control two InteleCool or two InteleCool2® units in a

lead/lag fashion. The control contains an electronic timer for switching the operating sequence of two

units at intervals of one, two, four or eight days.

It also contains a two-stage heat/two-stage cool electronic thermostat with individual heat and cool

setpoints. Light emitting diodes (LEDs) indicate Lead Unit 1 or 2 and power to Unit 1 or Unit 2. If

required for service, thelead/lag unit may be selected manually with the P2 jumper on the Dual Unit

Control board.

1.1 Connecting the Dual Unit Controller to an Electronic Thermostat

The instructions below refer to Liebert’s original InteleCool and newer InteleCool2.

1.1.1 Connecting the Dual Unit Controller to an InteleCool2

1. Install and level the Dual Unit Control. Leveling is not critical because the electronic thermostat

does not contain mercury-filled limit switches.

2. Wire the InteleCool2 Units to the Dual Unit Control using industry standard thermostat cable.

Each IntlelCool2 will need at least 4 conductor, 20 gauge copper, Class 2 wire for distances up to

50 feet (15.2m). Use 18 gauge copper, Class 2 wire for distances between 50 and 75 feet

(15.2 - 22.9m).

3. Wire the Dual Unit Control per the diagram on the inside cover of the Dual Unit Control. The

InteleCool2 to Dual Unit Control low voltage control wiring connections are:

Installation

InteleCool2 Terminals Dual Unit Control Terminals

R - 24 VAC R

1 - 24 VAC RTN 1/2

W - Heating W

G - Evaporator Fan See Step 4 below

Y - Cooling Y

4. Each InteleCool2 MUST have a jumper wire installed between terminals "G" and "Y". This

ensures that the fan will energize on a call for cooling.

For continuous operation of InteleCool2 unit evaporator fans, the “G” and “R” terminals may be

connected. In this mode the jumper between the “G” and “Y” terminals should be removed, and

the lead/lag function will control only the condenser fans, compressors, and heaters.

5. Tighten and check all connections for correct installation.

6. Refer to the thermostat user manual for setup and operation of the electronic thermostat.

1

Page 4

1.1.2 Connecting the Dual Unit Controller to the InteleCool

1. Install and level the Dual Unit Control.Leveling is not critical because the electronic thermostat

does not contain mercury-filled limit switches.

2. Wire the InteleCool units to the Dual Unit Control using industry-standard thermostat cable.

Each InteleCool will need at least 4 conductor, 20 gauge, Class 2 copper wire for distances up to

50 feet (15.2m). Use 18 gauge, Class 2 copper wire for distances between 50 and 75 feet (15.2 -

22.9m).

3. Wire the Dual Unit Control per the diagram on the inside cover of the Dual Unit Control. The

InteleCool to Dual Unit Control low voltage control wiring connections are as follows:

InteleCool Terminals Dual Unit Control Terminals

R & 1 - 24 VAC R

2 - 24 VAC RTN 1/2

W - Heating W

G - Evaporator Fan See Step 4 Below

Y - Cooling Y

4. Each InteleCool MUST have a jumper wire installed between terminals "G" and "Y". This assures

that the fan will energize on a call for cooling.

5. For continuous operation of InteleCool unit evaporator fans, the "G" and "R" terminals may be

connected. In this mode the jumper between the "G" and "Y" terminals should be removed, and

the lead/lag function will control only the condenser fans, compressors, and heaters.

6. Tighten and check all connections for correct installation.

7. Refer to the thermostat user manual for setup and operation of the electronic thermostat.

Installation

NOTE

The electronic thermostat does not contain mercury, but it is not for use with older versions of

the DUC printed wiring assembly. The electronic thermostat requires a connection to the

24VAC RTN terminal (Connector P1, Terminal 7) on the newer versions of the DUC printed

wiring assembly. This connection is not available on the older version of the DUC.

Mercury thermostats may be used with the newer version of the DUC, but the P1 Terminal 7

connection noted above is not required for the mercury-style thermostat.

2

Page 5

2.0 CONTROL STARTUP

2.1 Start the Dual Unit Control

1. Turn the thermostat Off.

2. Turn on power to both InteleCool2 units.

3. Turn on circuit breakers in each InteleCool2. Both green “POWER ON” LED’s and 1 of the green

“LEAD UNIT” LED’s of the Dual Unit Control will be lit if the unit has been properly connected.

4. Turn the thermostat switch to the “Auto” setting.

One or both of the InteleCool2 units should start if the thermostat is in a call for heating or cool-

ing.

2.2 Check for Operation

1. Raise the thermostat setpoint to force a call for heating.

2. Then lower the thermostat setpoint to force a call for cooling.

The InteleCool2 unit’s fans should run when there is a call for either heating or cooling.

2.3 Lead Unit Schedule & Selection

After verifying the connections and startup, the lead unit may be selected and the lead/lag schedule

may be set.

Control Startup

2.3.1 Designating the Lead InteleCool2 Unit

The position of the P4 jumper on the Dual Unit Control board determines which InteleCool2 unit is

the lead unit: the P4 jumper will be on pins 3 and 4, or “NORMAL.”

Designation as the lead unit may be determined externally by checking a unit’s LEAD UNIT LEDs on

the front panel of the DUC. The InteleCool2 unit whose LEAD UNIT LED is lit is the lead unit. If the

designation is satisfactory, no changes are necessary.

To change which InteleCool2 unit is the lead unit, place the P4 jumper on pins 1 and 2 or “REVERSE”

on the Dual Unit Control in the InteleCool2 unit chosen to serve as the lead unit.

2.3.2 Schedule

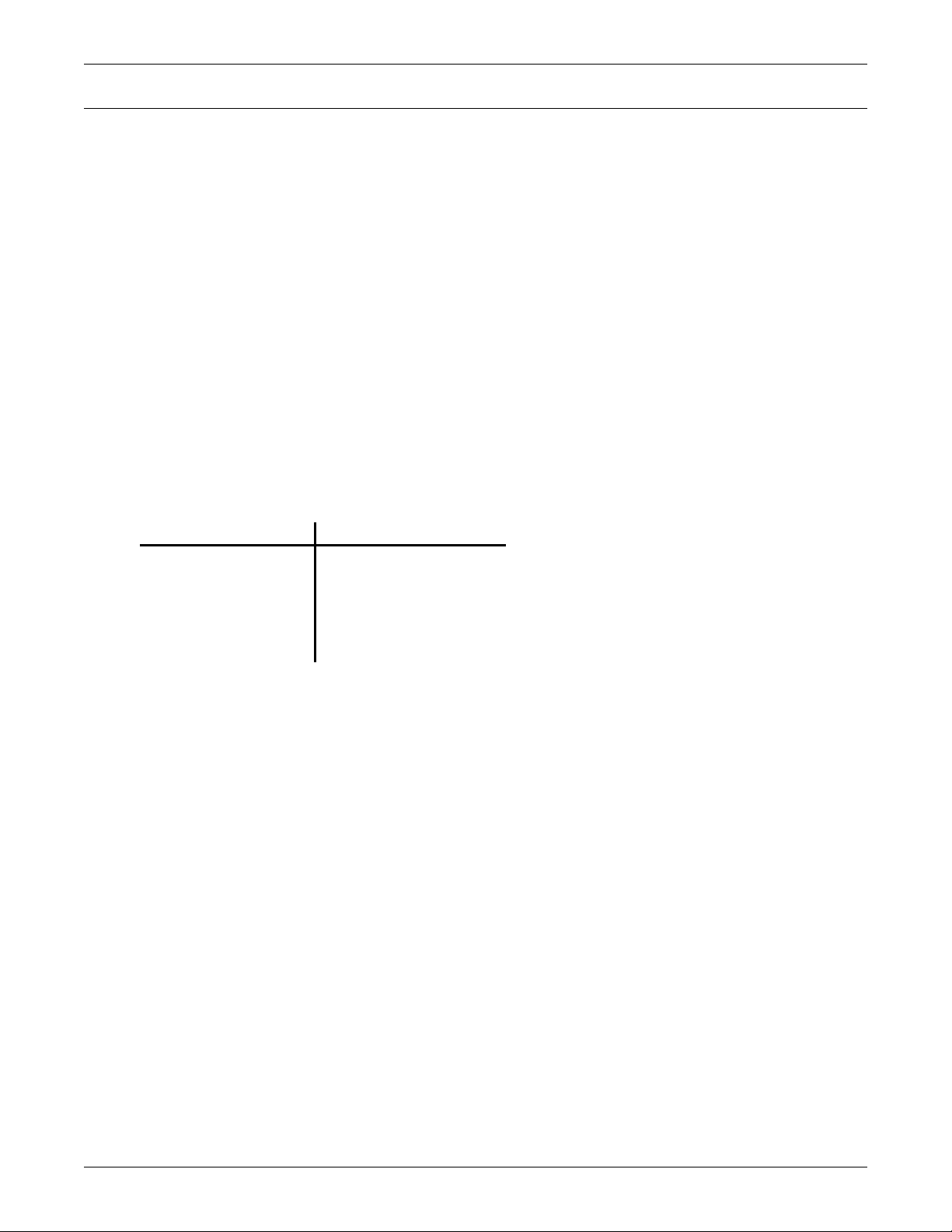

The Dual Unit Control lead/lag schedule may be set with jumpers on the printed circuit board. By

using the P2 and P3 jumpers and Table 1, the jumpers may be placed for the desired number of days

between switchover. The P2 jumper is on the lower right hand corner of the board (see Figure 1). The

P3 jumper is on the lower mid section of the board (see Figure 1).

Table 1 Switch/jumper settings

# Days for Lead/ Lag

Switchover Cycle P2 P3

8 Pins 8/4DAY Pins 1 & 2 (SLOW)

4 Pins 4/2DAY Pins 1 & 2 (SLOW)

2 Pins 4/2DAY Pins 3 & 4 (FAST)

1 Pins 2/1 DAY Pins 3 & 4 (FAST)

NOTE

If the lead/lag schedule is changed while the unit is running, the schedule change may not

take effect until the original schedule is completed. Also, the unit will retain the lead/lag order

of the units, even if power is removed, for two to five days, depending on the setting of the P2

and P3 jumpers.

3

Page 6

Figure 1 Dual Unit Control Board

RYWR YW

1/2

DRAWING IS

NOT TO SCALE

1/2

Unit 1Unit 2

P4

Slow

Fast

12

Reverse

Normal

34

1

2

P3

34

P1

Control Startup

P5

P5

to LED

Panel

1

2

3

4

5

6

7

P1 to

Thermostat

TB1

P2

WARNING

!

InteleCool and InteleCool2 units contain potentially lethal voltage.

Shut off power before performing any service work.

During service, the P2 jumper should be placed on the pins that identify the unit NOT being

serviced. Refer to Table 2 for required jumper pin connections. The P2 setting will override

the lead unit setting until the jumper is returned to the proper number-of-days location.

Table 2 Jumper settings for servicing InteleCool2 unit

To service desired unit Jumper Settings P2 Jumper Setting P4

Unit 1 Lead 2 Pins 3 & 4 (normal)

Unit 2 Lead 1 Pins 3 & 4 (normal)

8/4Day

4/2Day

2/1Day

Lead1

Lead2

S

e

r

v

i

c

e

4

Page 7

3.0 DISPOSAL OF DUAL UNIT CONTROL

Some thermostats used on this control may contain mercury in a sealed tube. Do

not place the control in the trash at the end of its useful life. If this control is

replacing a control that contains mercury in a sealed tube, do not place the old control in the trash.

Contact your local waste management authority for instructions regarding recycling and the proper disposal of this control or of an old control containing mercury

in a sealed tube. If you have questions, call the thermostat manufacturer at

1-800-468-1502.

Disposal of Dual Unit Control

5

Page 8

Ensuring The High Availability

0f Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2007 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks

or registered trademarks of their respective owners.

Technical Support / Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@emersonnetworkpower.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@emersonnetworkpower.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@emersonnetworkpower.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

SL-19534 _REV0_04-07

Emerson Network Power.

The global leader in enabling Business-Critical Continuity.

AC Power

Connectivity

DC Power

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2007 Emerson Electric Co.

Embedded Computing

Embedded Power Power Switching & Controls

Monitoring

Outside Plant

Precision Cooling

EmersonNetworkPower.com

Racks & Integrated Cabinets

Services

Surge Protection

Loading...

Loading...