User Guide

SI-Universal

Encoder

Part Number: 0478-0214-02

Issue: 2

Original Instructions

General information

For the purposes of compliance with the EU Machinery Directive 2006/42/EC.

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or

incorrect installation or adjustment of the optional operating parameters of the equipment or from

mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment

to a policy of continuous development and improvement, the manufacturer reserves the right to change the

specification of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means,

electrical or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

Firmware version

This product is supplied with the latest firmware version. If this product is to be connected to an existing

system or machine, all firmware versions should be verified to confirm the same functionality as products of

the same model already present. This may also apply to products returned from an Emerson Industrial

Automation Service Centre or Repair Centre. If there is any doubt please contact the supplier of the product.

The firmware version can be checked by looking at Pr xx.002.

Environmental statement

Emerson Industrial Automation is committed to minimising the environmental impacts of its manufacturing

operations and of its products throughout their life cycle. To this end, we operate an Environmental Management

System (EMS) which is certified to the International Standard ISO 14001. Further information on the EMS, our

Environmental Policy and other relevant information is available on request, or can be found at:

http://www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/Pages/environment.aspx.

The electronic variable-speed drives manufactured by Emerson Industrial Automation have the potential to save

energy and (through increased machine/process efficiency) reduce raw material consumption and scrap

throughout their long working lifetime. In typical applications, these positive environmental effects far outweigh the

negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should

instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to

dismantle into their major component parts for efficient recycling. Many parts snap together and can be separated

without the use of tools, while other parts are secured with conventional fasteners. Virtually all parts of the product

are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while

smaller products come in strong cardboard cartons which themselves have a high recycled fibre content. If not reused, these containers can be recycled. Polythene, used on the protective film and bags for wrapping product, can

be recycled in the same way. Emerson Industrial Automation’s packaging strategy prefers easily-recyclable

materials of low environmental impact, and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best

practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH)

requires the supplier of an article to inform the recipient if it contains more than a specified proportion of any

substance which is considered by the European Chemicals Agency (ECHA) to be a Substance of Very High

Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

For current information on how this requirement applies in relation to specific Emerson Industrial Automation’s

products, please approach your usual contact in the first instance. Emerson Industrial Automation’s position

statement can be viewed at:

www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/reachregulation/Pages/

reachregulation.aspx.

Copyright © June 2016 Emerson Industrial Automation.

The information contained in this guide is for guidance only and does not form part of any contract. The accuracy

cannot be guaranteed as Emerson have an ongoing process of development and reserve the right to change the

specification of their products without notice.

Control Techniques Limited. Registered Office: The Gro, Newtown, Powys SY16 3BE. Registered in England and

Wales. Company Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France.

Share Capital: 65 800 512 €, RCS Angoulême 338 567 258.

Issue Number: 2

Firmware: 01.00.04.02 onwards

For patent and intellectual property related information please go to: www.ctpatents.info

Contents

1 How to use this guide ................................................... 5

1.1 Intended personnel .................................................................................5

1.2 Information .............................................................................................. 5

2 Safety information ......................................................... 6

2.1 Warnings, Cautions and Notes ...............................................................6

2.2 Electrical safety - general warning .......................................................... 6

2.3 System design and safety of personnel .................................................. 6

2.4 Environmental limits ................................................................................ 7

2.5 Access ..................................................................................................... 7

2.6 Compliance with regulations ................................................................... 7

2.7 Adjusting parameters .............................................................................. 7

2.8 Stored charge .......................................................................................... 7

3 Introduction .................................................................... 8

3.1 Features .................................................................................................. 8

3.2 Option module identification .................................................................... 8

3.3 Set-up parameters ..................................................................................8

3.4 Compatibility with encoder types ............................................................. 9

3.5 Encoder feedback selection .................................................................. 17

3.6 Considerations ...................................................................................... 21

4 Mechanical Installation ............................................... 23

4.1 General installation ...............................................................................23

5 Electrical installation ................................................... 24

5.1 Basic Functions ..................................................................................... 24

5.2 Wiring, Shield connections .................................................................... 28

6 Getting started ............................................................. 33

6.1 Installation ............................................................................................. 33

6.2 Setting up a feedback device ................................................................ 33

6.3 Encoder Simulation Output Set-up ........................................................ 41

6.4 Freeze System ...................................................................................... 45

6.5 Thermistor input .................................................................................... 45

7 Parameters ................................................................... 46

7.1 Introduction ........................................................................................... 46

7.2 Menu 1x parameter for P1 Interface .....................................................47

7.3 Menu 2x parameters for P2 interface .................................................. 101

8 Advanced operation .................................................. 123

8.1 Encoder communications .................................................................... 123

9 Diagnostics ................................................................ 126

9.1 Overview ............................................................................................. 126

SI-Universal Encoder User Guide 3

Issue: 2

10 Terminal data ............................................................. 129

10.1 15 Way D-type connectors ..................................................................129

10.2 10-Way pluggable connections ...........................................................133

4 SI-Univers al Encoder User Guide

Issue: 2

1 How to use this guide

this guide

How to use

1.1 Intended personnel

This guide is intended for personnel who have the necessary training and experience in system

design, installation, commissioning and maintenance.

1.2 Information

This guide contains information covering the identification of the option module, terminal layout for

installation, installation of the option module to the drive, parameter details and diagnosis

information. Additional to the aforementioned are the specifications of the option module.

information

Introduction

Installation

installation

Getting started Parameters

Safety

Mechanical

Electrical

SI-Universal Encoder User Guide 5

Issue: 2

Advanced

operation

Diagnostics Terminal data Index

2 Safety information

WARNING

CAUT ION

NOTE

2.1 Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information which helps to ensure correct operation of the product.

2.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive.

Specific warnings are given at the relevant places in this User Guide.

2.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a

system. If installed incorrectly, the drive may present a safety hazard. The drive uses high voltages

and currents, carries a high level of stored electrical energy, and is used to control equipment which

can cause injury. Close attention is required to the electrical installation and the system design to

avoid hazards either in normal operation or in the event of equipment malfunction. System design,

installation, Commissioning/start-up and maintenance must be carried out by personnel who have

the necessary training and experience. They must read this safety information and this User Guide

carefully.

No function of the drive isolates dangerous voltages from the output of the drive or from any

external option unit (This includes the STOP and Safe Torque Off functions). The supply must be

disconnected by an approved electrical isolation device before gaining access to the electrical

connections.

With the sole exception of the Safe Torque Off function, none of the drive functions must be

used to ensure safety of personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a hazard,

either through their intended behavior or through incorrect operation due to a fault. In any

application where a malfunction of the drive or its control system could lead to or allow damage,

loss or injury, a risk analysis must be carried out, and where necessary, further measures taken to

reduce the risk - for example, an over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of motor braking.

The system designer is responsible for ensuring that the complete system is safe and

designed correctly according to the relevant safety standards.

6 SI-Univers al Encoder User Guide

Issue: 2

2.4 Environmental limits

Instructions in the Power Installation Guide regarding transport, storage, installation and use of the

drive must be complied with, including the specified environmental limits. Drives must not be

subjected to excessive physical force.

2.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the

place of use must be complied with.

this guide

information

How to use

Safety

2.6 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring

regulations, accident prevention regulations and electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective earth (ground) connections.

The Power Installation Guide contains instructions for achieving compliance with specific EMC

standards.

Within the European Union, all machinery in which this product is used must comply with the

following directives:

• Safety of Machinery 2006/42/EC.

• Electromagnetic Compatibility (EMC) Directive 2014/30/EU.

2.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

2.8 Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply

has been disconnected. If the drive has been energized, all supplies including DC supplies must be

isolated at least ten minutes before work may continue.

Installation

installation

operation

Introduction

Mechanical

Electrical

Getting started Parameters

Advanced

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 7

Issue: 2

3 Introduction

Topside label

Underside label

3.1 Features

The SI-Universal Encoder module allows for various types of feedback device to be connected to

the drive and to be configured for either reference or main motor control feedback. The module also

has a simulated encoder output which can be programmed to operate in either AB, FD, FR or SSI

mode (software simulation), or alternatively use a hardware simulated encoder output from either

the modules encoder input or the drives main encoder input (provided the encoder type is suitable).

3.2 Option module identification

The SI-Universal Encoder can be identified by:

1. The label located on the topside of the option module.

2. The color coding across the front of the option module: Dark brown.

Figure 3-1 SI-Universal Encoder label

3.2.1 Date code format

The date code is split into two sections: a letter followed by a number.

The letter indicates the year, and the number indicates the week number (within the year) in which

the option module was built.

The letters go in alphabetical order, starting with A in 1991 (B in 1992, C in 1993 etc.).

Example:

A date code of W35 would correspond to week 35 of year 2013.

3.3 Set-up parameters

The SI-Universal Encoder option module provides two position feedback interfaces, two freeze

systems, encoder simulation output and a temperature sensor input. The setup menus for these

functions depend on which slot the option module is fitted in as shown in Table 3-1.

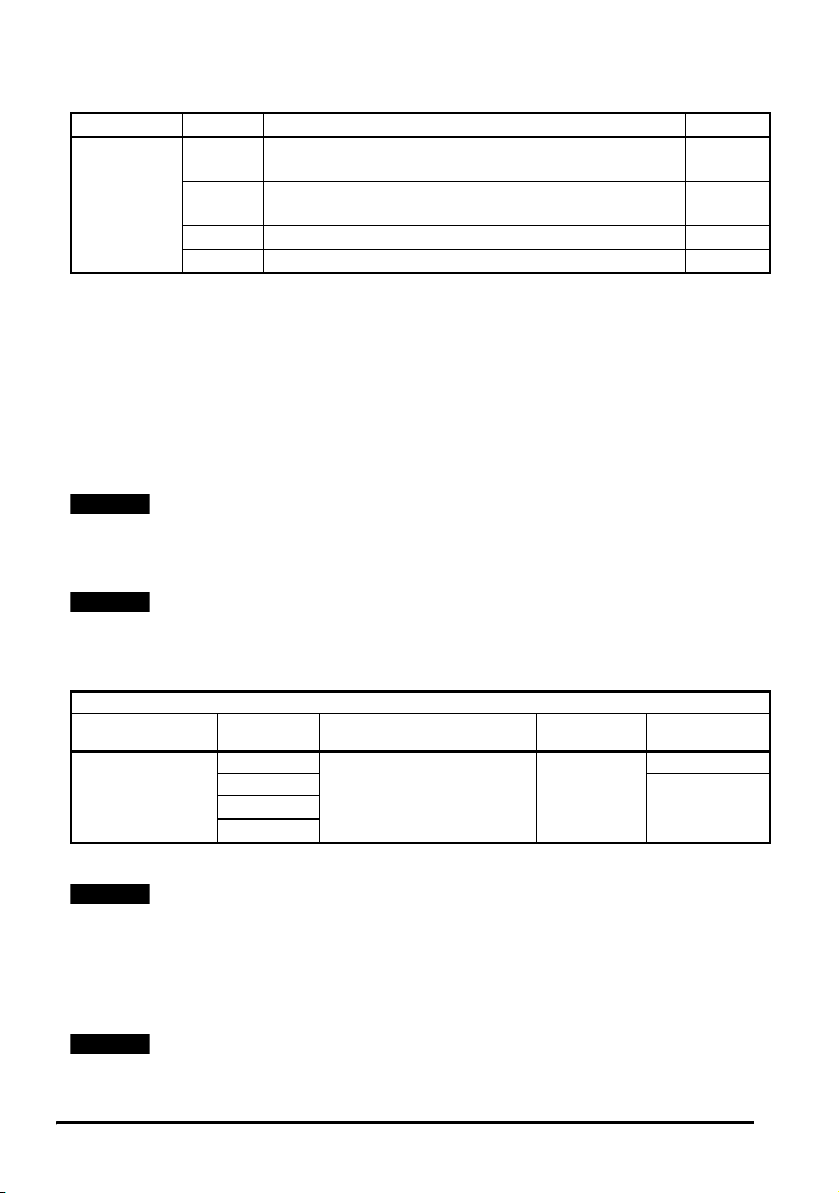

Table 3-1 Set-up parameters

Functions Slot 1 Slot 2 Slot 3

P1 position interface, freeze system, encoder simulation

output and temperature sensor input

P2 position interface Menu 25 Menu 26 Menu 27

The method used to determine the menu or parameter is as follows:

•Pr 1x.ppp - Where 1x signifies the menu allocated to the option module P1 setup menu (Menu

15, Menu16 or Menu 17) and ppp signifies the parameter number within the set-up menu for

the P1 position interface.

•Pr 2x.ppp - Where 2x signifies the menu allocated to the option module P2 setup menu (Menu

25, Menu 26 or Menu 27) and ppp signifies the parameter number within the set-up menu for

the P2 position interface.

8 SI-Univers al Encoder User Guide

Menu 15 Menu 16 Menu 17

Issue: 2

3.4 Compatibility with encoder types

NOTE

NOTE

NOTE

The SI-Universal Encoder module is compatible with the following encoder types.

3.4.1 Incremental encoders AB, FD, FR and SC

These types of encoders give incremental position and are intended to be used for control in

RFC-A mode. They can be used for operation in RFC-S mode but a phasing test is required at

every power-up.

Type Encoder Description Pr1x.038 Pr2x.038

Incremental

AB

FD

FR

Quadrature incremental encoder.

With or without marker pulse.

Incremental encoder with frequency and

direction outputs. With or without marker pulse

pulse.

Incremental encoder with forward and reverse

outputs. With or without marker pulse.

01

12

23

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

SC

SinCos encoder with no serial communications

No optional marker pulse.

6

Quadrature detection logic determines rotation from the phase relationship of the two channels.

These encoders can be used for RFC-A and RFC-S mode of operation and are available with a

marker pulse, which identifies each individual rotation of the encoder, and is also used to reset the

drive position parameter. The marker pulse is not required for correct operation.

With this type of feedback, the drive must carry out a phasing test to find the phase offset angle on

power up for operation in RFC-S mode.

SC

When a SinCos encoder is used additional position resolution is obtained by measuring the

magnitude of the signals.

Refer to section 3.4.2 for information regarding SinCos encoder feedback signals.

Limitations

Type Encoder Max Input Frequency Max no. of Lines

AB

500 kHz*

100,000

Incremental

FD

FR

SC

See Table 3-2 Interpolated information

based on frequency and voltage level on

page 11.

* Max input frequency = LPR x max rpm / 60

The maximum speed in rpm which an encoder connected to The SI-Universal Encoder module can

reach can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

(60 x 500 x 10

3

) / 4096 = 7324 rpm

installation

Electrical

Getting started Parameters

Advanced

operation

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 9

Issue: 2

The absolute maximum input frequency for any SC, SinCos encoder used with the SI-Universal

NOTE

2.5Vdc

.

0.5 Vdc

0.5 Vdc

SIN

COS

REFSIN,

REFCOS

Encoder option module is 500 kHz.

3.4.2 SinCos encoder feedback signals

For the SinCos encoder to be compatible with the SI-Universal Encoder option module, the output

signals from the encoder must be a 1 V peak to peak differential voltage (across sinref to sin and

cosref to cos).

Figure 3-2 Stegmann SinCos encoder feedback signals

Stegmann

Stegmann encoders typically have a 2.5 Vdc offset. The sinref and cosref are a flat DC level at 2.5

Vdc and the cos and sin signals have a 1 V peak to peak waveform biased at 2.5 Vdc.

The result is a 1 V peak to peak differential voltage as show in Figure 3-2.

Heidenhain

The Heidenhain Sin and Cos signals with respect to zero volts are offset at 2.5 Vdc as shown in

Figure 3-3.

The feedback signals which are seen by The SI-Universal Encoder module are the differential

signals Sin - Sin\ and Cos - Cos\ as in Figure 3-3, these being 90° phase shifted and at 1 Vdc peak

to peak.

10 SI-Univ er sal Encoder User Guide

Issue: 2

Figure 3-3 Heidenhain SinCos encoder feedback signals

COS

2.5Vdc

SIN

0.25Vdc

SIN, COS signals

with respect to 0V

(offset at 2.5Vdc)

COS

SIN

0.5Vdc

0.5Vdc

Differential signals

received by

SI-Universal Encoder

0Vdc

COS ref SIN ref

0.25Vdc

NOTE

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

installation

Electrical

Getting started Parameters

Encoders are available which have a 1 V peak to peak voltage on sinref, sin, cos and cosref. This

results in a 2 V peak to peak voltage seen at the module’s terminals. The drive will still function with

this type of encoder, however with reduced position resolution equivalent to four times the line rate.

(line rate = no. of lines per revolution x revolutions per second.) It is recommended that encoders of

this type are not used with a drive, and that the encoder feedback signals should meet the above

parameters (1 V peak to peak).

Sincos encoder resolution

The sine wave frequency can be up to 500 kHz but the resolution is reduced at high frequency.

Table 3-2 shows the number of bits of interpolated information at different frequencies and with

different voltage levels at the encoder port. The total resolution in bits per revolution is the ELPR

plus the number of bits of interpolated information. Although it is possible to obtain 11 bits of

interpolation information, the nominal design value is 10 bits.

Table 3-2 Interpolated information based on frequency and voltage level

Volt/Freq 1 kHz 5 kHz 50 kHz 100 kHz 200 kHz 500 kHz

1.2 11 11 10 10 9 8

1.0 11 11 10 9 9 7

0.8 10 10 10 9 8 7

0.6 10 10 9 9 8 7

0.4999876

SI-Universal Encoder User Guide 11

Issue: 2

Advanced

operation

Diagnostics Terminal data Index

3.4.3 Incremental plus commutation (absolute encoders) AB Servo, FD Servo,

NOTE

NOTE

FR Servo and SC Servo

Type Encoder Description Pr 1x.038

Quadrature incremental encoder with

AB Servo

Incremental plus

commutation

FD Servo

(absolute encoders)

FR Servo

SC Servo

The incremental part of an incremental encoder with commutation works in exactly the same way

as an incremental encoder. The additional channels (U, V and W) give the absolute electrical

position to electrical 60°.

When operating the drive in RFC-S mode, the absolute position (to 60° electrical or better) of the

machine shaft is required to enable the drive to apply torque in the correct direction. The marker

signal is not effective until the shaft passes a particular position, so this cannot be used to

determine the absolute position. Therefore in RFC-S mode an encoder with additional commutation

is required.

The U, V and W commutation signals should have a period that is one electrical revolution

as shown in Figure 3-4.

Therefore with a 6 pole machine the U, V and W commutation signals will repeat three times per

mechanical revolution, or with an 8 pole machine four times per mechanical revolution etc.

The U, V and W commutation signals are used when the drive is enabled to locate the position of

the machine shaft within 60° electrical so that the current vector can be applied within 30° electrical

either side of the correct position for maximum torque production. The torque capability of the drive

during this period can be reduced to as low as 0.866 of the nominal level.

Once the shaft has moved through a maximum of 60° electrical, one of the U, V or W signals will

have changed state. The location of the waveform edge is used to locate the machine position

exactly. This information is then stored by the option module and used until power-down to place

the current vector in the correct position for maximum torque. To ensure that this process is carried

out correctly the control algorithm waits for two changes of the state of the U, V and W waveforms,

after this point maximum torque is available.

Using this type of encoder does not result in any movement when the drive is first enabled after

power-up, only a small reduction in torque described above for the first 60° to 120° electrical of

movement.

commutation outputs.

With or without marker pulse.

Incremental encoder with frequency, direction

and commutation outputs.

With or without marker pulse.

Incremental encoder with forward, reverse and

commutation outputs.

With or without marker pulse.

Absolute SinCos encoder plus commutation

signals with or without marker pulse.

3

4

5

12

In AB Servo, FD Servo or FR Servo modes only, the value in Pr 1x.070 provides information on the

commutation signal inputs (UVW). Pr 1x.070 permits the user to determine the current segment and

status of the commutation signal inputs. For further details refer to Pr 1x.068.

12 SI-Univ er sal Encoder User Guide

Issue: 2

Figure 3-4 Example of encoder feedback signals (6 pole commutation signals)

Incremental

signals

360 electrical degrees (encoder)°

90 separation of A and B°

Index

alignment

reference

1

/

3

1

/

2

2

/

3

1

Mechanical revolution / pole pairs

A

/A

B

/B

Z

/Z

U

V

W

Marker

signals

Commutation

signals

min

max

NOTE

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

installation

Electrical

Getting started Parameters

Limitations

Type Encoder Max Input Frequency

Incremental plus

commutation

AB Servo

FD Servo

FR Servo

SC Servo

500 kHz*

See Table 3-2 Interpolated information

based on frequency and voltage

Max no. of Lines

(LPR)

100,000

level on page 11

* Max input frequency = LPR x max rpm / 60

The maximum speed in rpm which an encoder connected to the SI-Universal Encoder option module

can reach, can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

(60 x 500 x 10

SI-Universal Encoder User Guide 13

Issue: 2

3

) / 4096 = 7324 rpm

Advanced

operation

Diagnostics Terminal data Index

3.4.4 Incremental plus comms (absolute encoders) SC Hiperface, SC EnDat

NOTE

NOTE

NOTE

NOTE

and SC SSI

Type Encoder Description Pr 1x.038

Incremental

plus

comms

(absolute

encoders)

SC

Hiperface

SC

EnDat

SC SSI Absolute SinCos encoder using SSI comms protocol. 11

SC BiSS Absolute SinCos encoder using BiSS comms protocol 17

The SC Hiperface and SC EnDat encoders can be considered as a mixture of an incremental

encoder (analog SinCos feedback signals) and an absolute encoder (serial link used for absolute

position). The only difference between the encoders being the serial link protocol.

The RS 485 serial link allows the drive at power up to interrogate the SinCos encoder in comms

channel order to determine the initial absolute position of the encoder shaft. When the interrogation

is complete and the initial absolute position is known the position is incremented from the absolute

value using the analog sine/cosine interface.

The comms channels can then be used for either error checking, Pr 1x.040 or data transfer,

Pr 1x.068 to Pr 1x.069. The incremental SinCos plus communications encoder can be used when

operating in either RFC-A or RFC-S modes.

A flux alignment test is required during set up to determine the phase offset angle for operation in

servo mode. The results of the alignment test are stored in EEPROM and do not need to be done

after every power up.

The position retrieved during the initalization is compared to the partial position calculated from the

measurements of the Sine and Cosine signals. If they do not agree within a certain tolerance a trip

is generated.

Type Encoder Max Input Frequency *

Incremental plus

communications

* Max input frequency = LPR x max rpm / 60

Absolute SinCos encoder using Stegmann RS485

comms protocol (HiperFace).

Absolute SinCos encoder using EnDat comms protocol. 9

Limitations

Max no. of

Lines (LPR)

SC Hiperface

SC EnDat

SC SSI

SC BiSS

Table 3-2

information based on

frequency and voltage

level

Interpolated

100,000

on page 11

7

Max Baud

Rate (bits/s)

9600 (fixed)

4M

The maximum speed in rpm which an encoder connected to the SI-Universal Encoder can achieve

can be calculated from:

Max rpm = (60 x Max input frequency) / Encoder LPR

e.g. For a 4096 line encoder the maximum rpm would be:

(60 x 500 x 10

The absolute maximum input frequency for any SC, SinCos encoder used with the SI-Universal

3

) / 4096 = 7324 rpm

Encoder Module is 500 kHz.

14 SI-Univ er sal Encoder User Guide

Issue: 2

3.4.5 Comms only, (absolute encoders) SSI and EnDat

NOTE

NOTE

NOTE

Type Encoder Description Pr 1x.038 Pr 2x.038

EnDat

Comms

(absolute)

SSI

BiSS*

The SSI (Synchronous Serial Interface), EnDat (Encoder Data) and BiSS (Bi-directional

Synchronous Serial) encoders have a serial link between the encoder and drive which passes all

positional information.

Absolute EnDat only encoder

Additional communications with the

encoder is not possible.

Absolute SSI only encoder.

Additional communications with the

encoder is not possible.

Absolute BiSS C mode only encoder

Additional communications with the

encoder is not possible

8 4

10 5

13 6

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

It should be noted that EnDat, BiSS and SSI encoders must be initialized before their position data

can be used. The encoder is automatically initialized at power-up after trips 100 - 135 are reset, or

when the initialization parameter (Pr 1x.075) is set to 1.

SSI, EnDat, BiSS*

The interfaces transmit data synchronised with a CLOCK signal provided from the drive. This

makes it possible to transmit position values quickly and reliably with only four signal lines.

The main difference between the SSI and the EnDat/BiSS being that the standard SSI encoder is

Uni-directional whereas the EnDat and BiSS are Bi-directional. The data transfer for both the SSI,

BiSS and the EnDat use the 485 standard for data and clock signals.

Limitations

Type Encoder

Max Baud

Rate (bits/sec)

Max Speed

rpm

EnDat

Comms Only

4 Mbits/sec 50,000 rpmSSI

BiSS*

The SSI input at default is configured to operate in Gray code, this can be changed to binary format

by setting Pr 1x.048= 1.

A flux alignment test is required during set up to determine the phase offset angle for operation in

RFC-S mode.

* BiSS is not currently supported.

installation

Electrical

Getting started Parameters

Advanced

operation

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 15

Issue: 2

3.4.6 Linear Encoders

NOTE

Type Encoder Description Pr 1x.038 Pr 2x.038

AB Linear quadrature encoder 0 1

SC Linear SinCos encoder 6

Digital hall effect + Linear quadrature

incremental encoder

Digital hall effect + Linear SinCos

incremental encoder

Linear absolute SinCos encoder

Linear

encoder

AB Servo

SC Servo

SC

Hiperface

SC EnDat 9

SC SSI 11

SC BiSS* 17

EnDat

SSI 10 5

Linear absolute encoder

BiSS* 13 6

Linear Quadrature / SinCos Encoder

These types of encoder are purely incremental and have no information for commutation. With this

type of feedback the drive must carry out a phasing test to find the phase offset angle on every

power up for operation in RFC-S mode.

Digital Hall Effect + Linear Quadrature / SinCos Incremental encoder

These types of encoder have digital hall effect signals U, V, W plus complements that supply the

necessary signals for deriving the position at power-up. The quadrature signals, incremental or

SinCos are used for speed feedback. A flux alignment test is required during set-up to determine

the phase offset angle for operation in RFC-S mode.

Linear Absolute SinCos encoder

These types of encoder derive the absolute position at power-up via the comms protocol,

Hiperface, EnDat or SSI with the incremental signals, SinCos, being used for incremental position

and speed feedback. A flux alignment test is required during set-up to determine the phase offset

angle for operation in RFC-S mode.

Linear Absolute encoder

These types of feedback are comms only encoders, which derive the position at power- up via

either the EnDat or SSI comms protocols. The position feedback is also passed via comms during

operation. The comms only encoders operate with the drive being the master and passing the

required clock signal. A flux alignment test is required during set-up to determine the phase offset

angle for operation in RFC-S mode.

3

12

7

84

Refer to section 3.4.2 SinCos encoder feedback signals on page 10 for further information on the

SinCos encoder feedback signals.

* BiSS is not currently supported.

16 SI-Univ er sal Encoder User Guide

Issue: 2

Limitations

NOTE

Type Encoder Max input frequency Max no. of lines Max baud rate

AB

AB Servo

SC

SC Servo

Linear

encoder

In some applications using RFC-A control, the maximum speed of the system is above the speed at

SC Hiperface 9600 bits/sec

SC EnDat

SC SSI

SC BiSS*

EnDat

SSI

BiSS*

See Table 3-2 Interpolated

information based on

frequency and voltage

level

500 kHz

100,000

on page 11

4 Mbits/sec

which the encoder feedback frequency is too high to be used by the drive. For these types of

applications Pr 03.024 RFC Feedback should be set to 2 (Feedback NoMax) for low speed

operation and 3 (Sensorless NoMax) for high-speed operation. It should be noted that the drive no

longer checks that the maximum encoder frequency cannot be exceeded, and therefore the user

must ensure that Pr 03.024 is set to 3 before the encoder frequency limit is reached.

3.4.7 Drive firmware compatibility

The SI-Universal Encoder module is compatible with the Unidrive M600 to M702 range of drives.

The recommended drive firmware version is V01.09.00.00 or later.

3.5 Encoder feedback selection

3.5.1 Encoder selection

The SI-Universal Encoder module supports a total of 15 encoder types. These range from

Quadrature relative encoders to Quadrature plus Commutation, SinCos plus Comms and Comms

only absolute encoders.

When selecting an encoder there are essentially two groups these being absolute and relative.

Absolute encoders providing the absolute position at power-up to the drive and only requiring a

phasing test during the initial set-up when used for RFC-S operation. Relative encoders requiring a

phasing test at every power up when used for RFC-S operation.

Either absolute or relative encoders can be used for RFC-A operation.

Absolute encoders

The absolute encoders which are compatible with drive are as follows:

• AB Servo, FD Servo, FR Servo, SC Servo

• SC Hiperface, SC EnDat, SC SSI, SC BiSS*

• EnDat, SSI, BiSS*

Non absolute encoders

At power up the encoder counters will start to increment from the incremental position as the

encoder rotates, the position is reset to zero on detection of the first marker.

Compatible relative encoders being:

AB, FD, FR, SC

* BiSS is not currently supported.

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

installation

Electrical

Getting started Parameters

Advanced

operation

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 17

Issue: 2

3.5.2 Standard feedback

NOTE

Basic encoder (AB, FD, FR)

• 6 wire (+ 2 for marker if required)

• Up to 100,000 ppr

• AB - quadrature signals (best noise immunity)

• FD - frequency and direction

• FR - forward and reverse

• Marker input (only connect if needed, low noise immunity)

• Freeze based directly on the encoder counter

• Termination control (P1 Interface Only)

• Wirebreak detection (P1 Interface Only)

A quadrature encoder will provide sufficient performance for most applications once tuned.

Servo encoders (AB Servo, FD Servo, FR Servo, SC Servo)

• 12 wire (+ 2 for marker if required)

• Reduced maximum torque until two valid changes

• AB, FD, FR and SC signals used for motor control and speed feedback.

• Marker input (optional)

• Freeze based directly on the encoder counter

• Termination control (not for commutation signals)

• Wirebreak detection

• Phase error detection based on commutation signals

• P1 interface only

Non-absolute SINCOS encoder (SC)

•6 wire

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits of

interpolation information

• High resolution speed feedback, generally for induction motors but also servo motors

• Marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Initialization required to align the analog signals with the encoder counter

• P1 interface only

3.5.3 High resolution feedback

Stegmann Hiperface SINCOS encoders (SC Hiperface)

•8 wire

• 8 - 12 V supply

• Absolute position determined via asynchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits of

interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Auto-configuration is possible

• Encoder phase error detection using comms

• Comms includes message XOR checksum

• Initialization required to obtain the absolute position via comms and to align the analog signals

with the encoder counter

• P1 interface only

18 SI-Univ er sal Encoder User Guide

Issue: 2

An SC Hiperface encoder will provide high performance and is recommended for precision

NOTE

NOTE

applications.

this guide

How to use

Heidenhain EnDat SINCOS encoders (SC EnDat)

• 10 wire

• 5 V supply

• Absolute position determined via synchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits of

interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Encoder phase error detection using comms

• Comms includes CRC check

• Auto-configuration is possible

• Initialization required to obtain the absolute position via comms and to align the analog signals

with the encoder counter

• Encoder cable length compensation allowing high baud rates with long encoder cables.

• P1 interface only

An SC EnDat encoder will provide high performance and is recommended for precision

applications.

SSI SINCOS encoders (SC SSI)

• 10 wire

• Absolute position determined via synchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits of

interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Auto-configuration is not possible

• Encoder phase error detection using comms

• The comms protocol does not include any error checking

• Initialization required to take the absolute position via comms and to align the analog signals

with the encoder counter

• Gray code or binary format encoders

• Power supply fail bit monitoring

• P1 interface only

SSI only encoder (SSI)

•6 wire

• Position obtained via synchronous comms

• Not auto configurable, no error checking, too slow for use as motor feedback

• Feedback resolution defined by comms resolution

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection by comms error

• Gray code or binary format encoders

• Power supply fail bit monitoring

information

Safety

Introduction

Mechanical

Installation

installation

Electrical

Getting started Parameters

Advanced

operation

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 19

Issue: 2

SSI only encoders are not recommended for use as motor feedback, but can be used for either

NOTE

NOTE

NOTE

NOTE

positioning or reference.

EnDat only encoders (EnDat)

•6 wire

• Position obtained via synchronous comms

• Feedback resolution defined by comms resolution

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection by comms error

• Comms includes CRC check

• Auto-configuration is possible

• Compatible with EnDat 2.1 and EnDat 2.2

• Encoder cable length compensation allowing high baud rates with long encoder cables.

An EnDat encoder will provide high performance and is recommended for precision applications.

BiSS SINCOS encoders (SC BiSS)*

• 10 wire

• 5 V to 15 V supply

• Absolute position determined via synchronous comms

• Nominally the feedback resolution is sine waves per revolution plus 9 additional bits of

interpolation information

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection

• Encoder phase error detection using comms

• Comms includes CRC check

• Partial auto-configuration is possible

• Initialization required to obtain the absolute position via comms and to align the analog signals

with the encoder counter

• Encoder cable length compensation allowing high baud rates with long encoder cables.

A SC BiSS encoder will provide high performance and is recommended for precision applications

BiSS only encoders (BiSS)*

•6 wire

• 5 V to 15 V supply

• Position obtained via synchronous comms

• Feedback resolution defined by comms resolution

• No marker input

• Freeze is based on the time of the freeze event and interpolation between samples

• Wirebreak detection by comms error

• Comms includes CRC check

• Partial auto-configuration is possible

• Compatible with BiSS C Mode.

• Encoder cable length compensation allowing high baud rates with long encoder cables.

A BiSS encoder will provide high performance and is recommended for precision applications

* BiSS is not currently supported.

20 SI-Univ er sal Encoder User Guide

Issue: 2

3.6 Considerations

When selecting an encoder, there are a number of considerations, these being application, drive

operation, and encoder specification dependant.

3.6.1 Application dependant

1. Operating mode

2. Is the application a positioning application where high resolution is required?

3. Is absolute position required at every power up, for example for operation in servo mode where

a phasing test is not possible at every power-up?

4. What resolution is required (e.g. AB 1024 encoder = 10bit resolution, SC Hiperface 1024 = 19

bit resolution)?

5. What environment is the encoder to be installed in?

6. What cable lengths are to be used?

7. Encoder supply voltage should be selected dependant upon the cable lengths due to voltage

drop

8. Are motor objects to be saved to the encoder?

3.6.2 Drive operation dependant

1. When operating in RFC-S mode the drive requires the absolute position at power-up, be this

from an absolute encoder or through a phasing test at every power-up

2. When operating in RFC-A either an absolute or non-absolute encoder can be used

3. Encoder power supply and loading when operating with long cable lengths

3.6.3 Encoder specification dependant

1. Encoder voltage levels, are these compatible with the drive?

2. Incremental encoder signals are these compatible (SC, AB, FR, FD)?

3. Incremental signals do not exceed maximum input frequency for option module

4. Comms encoder protocol is compatible (Hiperface, EnDat, SSI, BiSS*)

5. Comms encoder baud rate is compatible with drive

6. Application cable lengths do not exceed incremental signals cable length

7. Application cable lengths do not exceed the recommended cable length for comms operation,

this being baud rate specific

8. Encoder loading does not exceed encoder power supply from module (external power supply

should be used if this is the case)

3.6.4 Drive resolution / Feedback accuracy

The following values calculated are not a direct representation of performance at the motor shaft,

with the motors inductance and load inertia smoothing out the shaft value to a much lower level.

The value calculated is the instantaneous change in the internal speed feedback value seen by the

drive between sample periods, and when the number of counts per revolution changes by 1 count.

This change is due to at any given speed it is unlikely that the number of counts per sample period

will always be a whole number e.g. 1 in 10 sample periods may have an extra pulse to ensure the

average speed is as demanded.

How to use

this guide

information

Safety

Introduction

Mechanical

Installation

installation

Electrical

Getting started Parameters

Advanced

operation

Diagnostics Terminal data Index

* BiSS is not currently supported.

SI-Universal Encoder User Guide 21

Issue: 2

3.6.5 Available resolution

NOTE

The following Quadrature and SinCos type incremental encoders are available with various lines

per revolution with the drive being compatible with encoders ranging from 1 PPR (4 CPR) to

100,000 PPR (400,000CPR).

The comms only encoders which include both EnDat, BiSS* and SSI are also available with various

comms resolutions with drive being compatible up to 32 bits

AB Quadrature Incremental Encoder

• A 4096 LPR encoder has 4096 pulses per channel, and 16,384 edges. Available resolution =

16,384 counts / turn.

SC Incremental Encoder

• An SCS50 SinCos encoder has 1024 sine waves per revolution with the drive interpolating

each sine wave to 9 bits worth of resolution giving a total resolution of 2 x 1024 x 2

9

=

1,048,576 counts per revolution

EnDat Comms Only Encoder

• An EnDat comms only encoder has 25 bits giving a total resolution of = 33554432 counts per

revolution

Comparing a 4096 PPR incremental encoder to a SCS50 SinCos encoder, the SCS50 SinCos

encoder will have a factor of 128 less ripple than the 4096 PPR encoder.

Therefore the encoder selected can influence the digital torque ripple significantly and should be

considered on high resolution / accuracy applications.

3.6.6 Internal digital torque ripple calculation

Following is an example of the internal digital torque ripple calculation

AB Quadrature Encoder

1024 line encoder running at 1500 rpm and drive speed loop sample time = 250 µs

• 1500 rpm / 60 s = 25 rev/s

• 25 rev / s x 1024 ppr = 25600 pulses/s

• 25600 pulses / s x 4 edges = 102400 edges/s

• 102400 edges / s x 250 x 10

Therefore due to the digitisation of the encoder feedback the average number of edges seen will be

25.6, but this must be due to the relevant number of 25 and 26 edges over an infinite length of time.

As such:

25 edges / 250 x 10

100,000 / 4 = 25,000 pulses

25,000 / 1024 = 24.4 rev/s

24.4 x 60 = 1464.8 rpm

26 edges / 250 x 10

104,000 / 4 = 26,000 pulses

26,000 / 1024 = 25.4 rev/s

25.4 x 60 = 1523.4 rpm

1523 - 1464 = 59 rpm

The difference of 1 pulse gives an instantaneous speed change of 59 rpm.

* BiSS is not currently supported.

-6

= 25.6 edges per sample period

-6

= 100,000 edges/sec.

-6

= 104,000 edges/sec.

22 SI-Univ er sal Encoder User Guide

Issue: 2

4 Mechanical Installation

WARNING

2

this guide

How to use

Before installing or removing an option module from any drive, ensure the AC supply

has been disconnected for at least 10 minutes and refer to section 2 Safety

information on page 6. If using a DC bus supply ensure this is fully discharged before

working on any drive or option module.

4.1 General installation

Installation of an option module is illustrated in Figure 4-1.

Figure 4-1 Installing an option module on Unidrive M600 to M702

information

Introduction

Installation

installation

Getting started Parameters

operation

Safety

Mechanical

Electrical

Advanced

Diagnostics Terminal data Index

Option module slots must be used in the following order: (Slot 3), (Slot 2) then (Slot 1).

• Move the option module in the direction shown (1/2).

• Align and insert the option module tab into the slot provided. This is highlighted in the detailed

view (A).

• Press down on the option module until it clicks into place.

SI-Universal Encoder User Guide 23

Issue: 2

5 Electrical installation

5.1 Basic Functions

The following functions are provided via the 15-way high density D-type connector and a 10-way

pluggable connector on the drive:

• Two position feedback interfaces (P1 and P2).

• One encoder simulation output.

• Two freeze trigger inputs (marker inputs).

• One thermistor input.

The P1 position interface is always available but the availability of the P2 position interface and the

encoder simulation output depends on the position feedback device used on the P1 position

interface.

5.1.1 Compatible position feedback devices

Table 5-1 Supported feedback devices on the P1 position interface

Encoder type

Quadrature incremental encoders with or without marker pulse AB (0)

Quadrature incremental encoders with UVW commutation signals for absolute

position for permanent magnet motors with or without marker pulse

Forward / reverse incremental encoders with or without marker pulse FR (2)

Forward / reverse incremental encoders with UVW commutation signals for

absolute position for permanent magnet motors with or without marker pulse

Frequency and direction incremental encoders with or without marker pulse FD (1)

Frequency and direction incremental encoders with UVW commutation signals

for absolute position for permanent magnet motors with or without marker pulse

Sincos incremental encoders with or without marker pulse SC (6)

Sincos incremental with commutation signals with or without marker pulse SC Servo (12)

Heidenhain sincos encoders with EnDat comms for absolute position SC EnDat (9)

Stegmann sincos encoders with Hiperface comms for absolute position SC Hiperface (7)

Sincos encoders with SSI comms for absolute position SC SSI (11)

Sincos encoders with BiSS comms for absolute position (not currently

supported)

SSI encoders (Gray code or binary) SSI (10)

EnDat communication only encoders EnDat (8)

BiSS communication only encoders (not currently supported) BiSS (13)*

* BiSS is not currently supported.

Pr 1x.038

setting

AB Servo (3)

FR Servo (5)

FD Servo (4)

SC BiSS (17)*

24 S I-Universal Encoder User Guide

Issue: 2

Table 5-2 Supported feedback devices on the P2 position interface

Encoder type Pr 2x.038 setting

Quadrature incremental encoders with or without marker pulse AB (1)

Frequency and direction incremental encoders with or without marker pulse FD (2)

Forward / reverse incremental encoders with or without marker pulse FR (3)

EnDat communication only encoders EnDat (4)

SSI encoders (Gray code or binary) SSI (5)

BiSS communication only encoders (not currently supported) BiSS (6)*

Table 5-3 shows the possible combinations of position feedback device types connected to the P1

and P2 position interfaces and the availability of the encoder simulation output.

Table 5-3 Availability of the P2 position feedback interface and the encoder simulation

output

Functions

P1 Position feedback

interface

P2 Position feedback interface Encoder Simulation Output

AB Servo

FD Servo

FR Servo

SC Servo

AB

FD

AB, FD, FR

EnDat, BiSS, SSI

FR

SC

Full

SC Hiperface

SC EnDat

SC SSI

SC BiSS*

EnDat

BiSS*

SSI

AB, FD, FR

(No Z marker pulse input)

EnDat, BiSS*, SSI (with freeze input)

No Z marker pulse output

AB, FD, FR

EnDat, BiSS*, SSI

Full

EnDat, BiSS*, SSI No Z marker pulse output

The priority of the position feedback interfaces and the encoder simulation output on the 15-way Dtype is assigned in the following order from the highest priority to the lowest.

• P1 position interface (highest)

• Encoder simulation output

• P2 position interface (lowest)

this guide

information

Introduction

Installation

installation

Getting started Parameters

operation

Diagnostics Terminal data Index

How to use

Safety

Mechanical

Electrical

Advanced

* BiSS is not currently supported.

SI-Universal Encoder User Guide 25

Issue: 2

For example, if an AB Servo type position feedback device is selected for use on the P1 position

NOTE

interface, then both the encoder simulation output and the P2 position interface will not be available

as this device uses all connections of the 15-way D-type connector. Also, if an AB type position feedback device is selected for use on the P1 position

interface and Pr 1x.085 is set to a valid source for the encoder simulation output, then the P2 position

interface will not be available.

Depending on the device type used on the P1 position interface, the encoder simulation output may

not be able support a marker pulse output (e.g. SC EnDat or SC SSI device types). Pr 1x.086 shows

the status of the encoder simulation output indicating whether the output is disabled, no marker pulse

is available or full encoder simulation is available.

When using the P1 and P2 position interfaces and the encoder simulation output together, the P2

position interface uses alternative connections on the 15-way D-type

connector. Pr 2x.072 shows the status of the P2 position interface and indicates if alternative

connections are being used for the P2 position interface.

26 S I-Universal Encoder User Guide

Issue: 2

5.1.2 Terminal descriptions

12345

6 78910

12345

678910

1112131415

10-way pluggable connector

15-way female D-type connector

Table 5-4 Terminal information

this guide

information

How to use

Safety

Table 5-5 P1 Interface connection details

Terminal Encoder

15 way

D-type

connector

10 way

pluggable

connector

1 AF A F F

2

3 BD B D R

4 B\ D\ B\ D\ R\

5 ZDATA

6 Z\ DATA\

73

84

95

10 6

11 8

12 9

13 10 +V (Power Supply Output)

14 2, 7 0V

15 Thermistor

AB FD FR

A\ F\ A\ F\ F\

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

1 + 24 V Freeze Input

AB

FD

Servo

FR

Servo

Servo

U P2 / Enc. Sim. Out U

U\ P2 / Enc. Sim. Out U\

V P2 / Enc. Sim. Out V

V\ P2 / Enc. Sim. Out V\

W P2 / Enc. Sim. Out CLK

W\ P2 / Enc. Sim. Out CLK\

SC

SC

A

(Cos)

A\

(Cos\)

B

(Sin)

B\

(Sin\)

Hiperface

EnDat

Cos DATA A DATA A (Cos) DATA

CosRef DATA\ A\ DATA\ A\ (Cos\) DATA\

Sin CLK B CLK B (Sin) CLK

SinRef CLK\ B\ CLK\ B\ (Sin\) CLK\

Freeze

1

Freeze

1\

* BiSS is not currently supported.

SC

EnDat

/

SC

BiSS*

DATA

DATA\

SSI

Freeze

1

Freeze

1\

P2 /

Enc.

Sim.

Out

P2 /

Enc.

Sim.

Out

SC

SSI

Servo

DATA Z

DATA\ Z\

CLK W

CLK\ W\

SC

BiSS*

P2/

Freeze1

P2/

Freeze1\

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

P2 / Enc.

Sim. Out

Installation

installation

operation

Introduction

Mechanical

Electrical

Getting started Parameters

Advanced

Diagnostics Terminal data Index

SI-Universal Encoder User Guide 27

Issue: 2

Table 5-6 P2 Interface and simulated encoder output connection details

Terminal P2

10

D-

15 way

type

connector

7 3 A F F DATA Asim Fsim Fsim DATAsim

8 4 A\ F\ F\ DATA\ Asim\ Fsim\ Fsim\ DATAsim\

9 5 B D R CLK Bsim Dsim Rsim CLKsim

10 6 B\ D\ R\ CLK\ Bsim\ Dsim\ Rsim\ CLKsim\

11 8 Z Freeze2 Zsim

12 9 Z\

way

pluggable

connector

AB FD FR

Interface

EnDat

SSI

BiSS

Freeze2

\

Encoder Simulation Output

AB FD FR SSI

Zsim\

When the EnDat, SSI or BiSS* type position feedback device is selected for use on the P1 interface

and the encoder has no freeze inputs, it is possible to use P1 and P2 position interface and the

encoder simulation output together, the P2 position interface uses alternative connections on the

15-way D-type connector. Pr 2x.072 shows the status of the P2 position interface and indicates if

alternative connections are being used for the P2 position interface.

Table 5-7 P2 Interface and simulated encoder output connection details when P1 interface

is EnDat, SSI or BiSS* with no freeze inputs.

Ter min al P2

10

15 way

type

D-

connector

5

6 DATA\

73 Asim Fsim Fsim DATAsim

84

95

10 6

11 8 CLK

12 9 CLK\

way

pluggable

connector

Interface

EnDat Alt

SSI Alt

BiSS Alt

DATA

Encoder Simulation Output

AB FD FR SSI

Asim\ Fsim\ Fsim\ DATAsim\

Bsim Dsim Rsim CLKsim

Bsim\ Dsim\ Rsim\ CLKsim\

* BiSS is not currently supported.

5.2 Wiring, Shield connections

Shielding considerations are important for PWM drive installations, due to the high voltages and

currents present in the output circuit with a wide frequency spectrum, typically from 0 to 20 MHz.

Encoder inputs are liable to be disturbed if careful attention is not given to the physical managment

of the cable shields.

Encoder mounting methods

There are three methods for mounting an encoder on the motor:

1. Galvanic isolation between encoder and motor

2. Galvanic isolation between encoder circuit and encoder body

3. No Isolation

5.2.1 Encoder with galvanic isolation from motor

When galvanically isolated the encoder device is mounted to the motor with isolation installed

between the motor housing / shaft and encoder as shown in Figure 5-1.

28 S I-Universal Encoder User Guide

Issue: 2

Figure 5-1 Galvanic Isolation

0V

+5V

0V

+5V

B

B

A

A

Motor

Shaft

Motor

Housing

Encoder

Housing

Isolation

between motor housing

and encoder housing

Encoder

Body

Isolation

between motor shaft

and encoder

Encoder

Connection

Encoder

Circuit

An example of this is the Unimotor, where isolation from the motor is achieved by inserting a plastic

mounting plate between the motor housing and encoder housing and a plastic insert fitted in the

motor shaft for encoder mounting to the motor shaft. With this preferred method of mounting, noise

currents are prevented from passing from the motor housing into the encoder housing, and hence

into the encoder cable.

The ground connection of the cable shield is optional, but this may be required in order to comply

with safety measures, or to reduce radiated radio frequency emissions from either the drive or

encoder.

5.2.2 Encoder circuit with galvanic isolation from encoder body

In this case, the encoder device is mounted directly on the motor housing with contact being made

between the motor housing/shaft and encoder. With this mounting method, the encoders internal

circuits are exposed to electrical noise from the motor housing through the stray capacitance, and

must therefore be designed to withstand this situation. However, this arrangement still prevents

large noise currents from flowing from the motor body into the encoder cable.

The ground connection of the cable shield is optional, this may be required to comply with safety

measures or to reduce radiated radio frequency emissions from either the drive or encoder.

this guide

information

Introduction

Installation

installation

Getting started Parameters

operation

How to use

Safety

Mechanical

Electrical

Advanced

SI-Universal Encoder User Guide 29

Issue: 2

Diagnostics Terminal data Index

Figure 5-2 Encoder galvanically isolated from encoder body

0V

+5V

0V

+5V

B

B

A

A

Motor

Shaft

Motor

Housing

Galvanic

Isolation

No Isolation

between motor housing

and encoder housing

No Isolation

between motor shaft

and encoder

Encoder

Encoder

body

Connection

Stray

Capacitance

Encoder

Housing

Encoder

Circuit

0V

+5V

0V

+5V

B

B

A

A

Motor

Shaft

Motor

Housing

EncoderEncoder

housing

Body

No Isolation

between motor housing

and encoder housing

No Isolation

between motor shaft

and encoder

Encoder

Connection

0V connected

to encoder

housing

Encoder

Circuit

Stray

capacitance

5.2.3 No isolation

As shown in Figure 5-3, the encoder 0V connection may be permanently connected to the housing.

This has the advantage that the encoder body can form a shield for its internal circuits. However

this permits noise current from the motor body to flow into the encoder cable shield. The use of high

quality shielded cable correctly terminated, will help protect the data against induced noise, but a

greater level of care must be taken to ensure good cable management than would be used for

example in isolated cases.

Figure 5-3 No isolation

30 S I-Universal Encoder User Guide

Issue: 2

5.2.4 Cable requirements

CAUT ION

WARNING

Twisted

pair

cable

Twisted pair shield

Cable

Cable overall shield

NOTE

All mounting methods:

• Shield connection at drive terminal to 0V

• Shield connection at encoder to 0V

• It is recommended that the shielded cable should be run in a continuous length to the terminal,

to avoid the injection of noise at intermediate pigtails and to maximise the shielding benefit.

• The shield connections ("pigtails") to the drive and encoder should be kept as short as possible

Mounting with no isolation:

• Shield connected to ground at both ends. The connection must be made by direct fixing of the

cable to the grounded metal parts, i.e. to the encoder body and the drive grounding bracket as

shown in Figure 5-5 on page 32, "Pigtails" must be avoided. The outer sheath of the cable

should be stripped back enough to allow for the ground clamp to be installed. The shield

connection should not be broken. The ground clamps should be located as close as possible to

the drive and encoder.

• It is essential that the shielded cable should be run in a continuous length to the terminal, to

avoid the injection of noise at intermediate "pigtails" and to maximise the shielding benefit.

this guide

information

Introduction

Installation

How to use

Safety

Mechanical

Under no circumstances should the cable shield connection be omitted at any end of the

cable, since the noise voltage may well be sufficient to destroy the line driver and

receiver chips in the encoder and the drive.

Cable shield ground connection

For all mounting methods, grounding of the feedback cable shield has added benefits. It can protect

the drive and encoder from induced fast electrical transients, and prevent radiated radio-frequency

emission. However it is essential that it be carried out in the correct manner as explained above

and as shown in Figure 5-5.

Connecting the cable shield to ground at both ends carries the risk that an electrical fault

might cause excessive power current to flow in the cable shield and overheat the cable.

There must be an adequately rated safety ground connection between the motor/

encoder and the drive.

Recommended Cable

The recommended cable for feedback signals is a twisted pair, shielded with an overall shield as

shown below.

Figure 5-4 Feedback cable, twisted pair

installation

operation

Electrical

Getting started Parameters

Advanced

Diagnostics Terminal data Index

Using this type of cable allows for the connection of the outer shield to ground and the inner shields

to 0V at both the drive and encoder.

Ensure that feedback cables are kept as far away as possible from power cables and

avoid parallel routing.

SI-Universal Encoder User Guide 31

Issue: 2

Figure 5-5 Feedback cable connections

Cable

Cable

shield

Twi sted

pair

shield

Cable

shield

Twis ted

pair

shield

Connection

at motor

Connection

at drive

Ground clamp

on shield

Shield

connection

to 0V

Shield

connection

to 0V

32 S I-Universal Encoder User Guide

Issue: 2

6 Getting started

WARNING

6.1 Installation

The control circuits are isolated from the power circuits in the drive by basic insulation

only as specified in IEC60664-1. The installer must therefore ensure that the external

control circuits are insulated from human contact by at least one layer of insulation rated

for use at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as Safety Extra Low

Voltage (SELV) (e.g. to a personal computer) an additional isolating barrier must be

included in order to maintain the SELV classification.

Encoder connections

In order to ensure correct operation there are a number of checks which should be carried out:

• Ensure the encoder is securely mounted to the motor as spurious operation can result due to

the encoder slipping whilst the motor is rotating.

• Ensure encoder connections to both the encoder and the option module terminals are secure.

Intermittent connections can result in spurious operation or the option module not detecting the

feedback signals.

• Ensure the shielding recommendations as specified in section 5.2 Wiring, Shield

connections on page 28 are followed to prevent noise being induced in the encoder feedback

signals. Noise induced in the encoder feedback cables can result in spurious operation, and in

extreme cases can result in encoder failure and/or damage to the option modules encoder

input.

Encoder feedback is transmitted from an encoder as low voltage digital signals. Ensure that

electrical noise from the drive or motor does not adversely affect the encoder feedback. Ensure that

the drive and motor are connected in accordance with the instructions given in the appropriate

Power Installation Guide. Also verify that the encoder feedback wiring and shielding

recommendations are followed in section 5.2 Wiring, Shield connections on page 28.

this guide

information

Introduction

Installation

installation

started

Parameters

How to use

Safety

Mechanical

Electrical

Getting

6.2 Setting up a feedback device

6.2.1 P1 position interface

The parameter settings which must be made to utilize each of the compatible feedback device

types with the P1 position interface on the drive are described here. For more information regarding

these parameters refer to section 7 Parameters on page 46.

If the position feedback device connected to the P1 position interface is required to be used for

motor control feedback, then Pr 03.026 on the drive will need to be set to P1 SlotX (where X is the

slot in which the module is installed).

SI-Universal Encoder User Guide 33

Issue: 2

Advanced

operation

Diagnostics Terminal data Index

Table 6-1 Parameters required for feedback device set-up on the P1 position interface

AB, FD, FR, AB

Parameter

P1 Marker Mode

(1x.031)

P1 Rotary Turns

Bits (1x.033)

P1 Rotary Lines Per

Revolution (1x.034)

P1 Comms Bits

(1x.035)

P1 Supply Voltage

(1x.036)*

P1 Comms Baud

Rate (1x.037)

P1 Device Type

(1x.038)

P1 Autoconfiguration Select

(1x.041)

P1 SSI Binary Mode

(1x.048)

Servo, FD

Servo, FR

Servo, SC,

SC Servo

SC

Hiperface

SC

EnDat

SC

BiSS**

EnDat

9

9 9

99999999

9999

99999999

9999 9

SC

SSI BiSS**

SSI

99 9

99 9

99

9 Information to be entered by user.

Parameters can be set-up automatically by the drive using the auto-configuration parameter.

This must be set by the user if auto-configuration is disabled (i.e. Pr 1x.041 = Disabled (0)).

* 1x.036: If the output voltage from the encoder is >5V, then termination resistors must be disabled

by setting Pr 1x.039 to 0.

** BiSS is not currently supported.

Table 6-1 shows a summary of the parameters required to set-up each feedback device.

34 SI-Univ er sal Encoder User Guide

Issue: 2

6.2.2 P1 position interface: Detailed feedback device commisioning & start-up

NOTE

Standard quadrature encoder with or without commutation signals (A, B, Z or A, B, Z, U, V,

W), or Sincos encoder with or without UVW commutation signals

AB (0) for a quadrature encoder without commutation signals*

Device Type (1x.038)

Supply Voltage

(1x.036)

Rotary Line Per

Revolution (1x.034)

Termination Select

(1x.039)

(AB or AB Servo

only)

Marker Mode

(1x.031)

AB Servo (3) for a quadrature encoder with commutation signals

SC (6) for a Sincos encoder without commutation signals*

SC Servo (12) for a Sincos encoder with commutation signals

5 V (0), 8 V (1) or 15 V (2)

If the output voltage from the encoder is >5 V the termination resistors must

be disabled. Set Pr 1x.039 to 0.

Set to the number of lines or sine waves per revolution of the encoder

0 = A, B, Z termination resistors disabled

1 = A, B termination resistors enabled and Z termination resistors disabled

2 = A, B, Z termination resistors enabled

Bit

3 2 1 0

XXX1

No action is taken unless marker flag is zero before

marker event occurs

Description

XX1 XPr 1x.028 and Pr 1x.058 are set to zero

Pr 1x.028, Pr 1x.029, Pr 1x.030 and the related part of

X1XX

Pr 1x.058 are not reset. Pr 1x.058 is transferred to

Pr 1x.059 and Pr 1x.032 is set to 1

1XXX

See section 7.2.3 Menu 1x P1 Interface parameter

descriptions on page 53

this guide

information

Introduction

Installation

installation

started

Parameters

How to use

Safety

Mechanical

Electrical

Getting

Error Detection Level

(1x.040)

Bit

4 3 2 1 0

X X X X 1 Enable wire break detection

Description

X 1 X X X Disable trips Encoder PS to SSI Error P1

1 X X X X Disable the Setup changed P1 trip

* These settings should only be used in RFC-A mode. If used in RFC-S mode, a phase offset test

must be performed after every power up.

SI-Universal Encoder User Guide 35

Issue: 2

Advanced

operation

Diagnostics Terminal data Index

Incremental encoder with Frequency and Direction (F and D), or

NOTE

Forward and Reverse (CW and CCW) signals with or without commutation signals

FD (1) for frequency and direction signals without commutation signals*

Device Type (1x.038)

Supply Voltage

(1x.036)

Rotary Line Per

Revolution (1x.034)

Termination Select

(1x.039)

Marker Mode

(1x.031)

FR (2) for forward and reverse signals without commutation signals*

FD Servo (4) for frequency and direction signals with commutation signals

FR Servo (5) for forward and reverse signals with commutation signals

5 V (0), 8 V (1) or 15 V (2)

If output voltage from the encoder is >5 V, then the termination resistors

must be disabled. Set Pr 1x.039 to 0

Set to the number of pulses per revolution of the encoder divided by 2