User Guide

SI-I/O

Part Number: 0478-0047-03

Issue: 3

www.controltechniques.com

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or adjustment of the optional

operating parameters of the equipment or from mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development and

improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of this guide, without

notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Drive software version

The SI-I/O can only be used with drive software version 01.02.00.xx onwards.

Contents

1 How to use this guide ...........................4

1.1 Intended personnel ...............................................4

1.2 Information ............................................................4

2 Safety information .................................5

2.1 Warnings, Cautions and Notes .............................5

2.2 Electrical safety - general warning ........................5

2.3 System design and safety of personnel ................5

2.4 Environmental limits ..............................................5

2.5 Access ..................................................................5

2.6 Compliance with regulations .................................5

2.7 Adjusting parameters ............................................5

2.8 Stored charge .......................................................6

3 Introduction ...........................................7

3.1 Features ................................................................7

3.2 Option module identification ..................................7

3.3 Conventions used in this guide .............................7

3.4 Digital I/O ..............................................................8

3.5 Analog I/O .............................................................8

3.6 Relays ...................................................................8

3.7 24 V internal power supply ....................................8

4 Mechanical installation .........................9

4.1 General installation ...............................................9

10 Technical Data .....................................36

10.1 Digital inputs/outputs (Terminals 2-5) .................36

10.2 Digital Inputs (Terminals 7-9) ..............................36

10.3 Differential Analog Input (Terminals 7 and 8) ......36

10.4 Single-ended Analog Inputs (Terminals 7-9)

in Voltage input mode .........................................37

10.5 Single-ended Analog Input (Terminal 9) in

Current input mode .............................................37

10.6 Analog Output (Terminal 11) in Voltage

output mode ........................................................37

10.7 Analog Output (Terminal 11) in Current

output mode ........................................................38

10.8 Relays (Terminals 21-23) ....................................38

5 Electrical installation ..........................10

5.1 Terminal descriptions ..........................................10

5.2 Wiring, shield connections ..................................10

6 Single line descriptions ...................... 11

6.1 Single line descriptions .......................................11

6.2 Menu 9 - Resources ............................................14

7 Parameters ...........................................15

7.1 Menu 0 - Module Set-up .....................................15

7.2 Menu 1 - I/O Set-up ............................................18

7.3 Menu 2 - Digital I/O .............................................23

7.4 Menu 3 - Analog I/O ............................................24

7.5 Menu 9 - Resources ............................................27

8 Block diagrams ...................................28

8.1 Functional block diagrams ..................................28

9 Diagnostics ..........................................34

9.1 Overview .............................................................34

SI-I/O User Guide 3

Issue Number: 3

How to use

this guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

1 How to use this guide

1.1 Intended personnel

This guide is intended for personnel who have the necessary training and experience in system design, installation, commissioning and maintenance.

1.2 Information

This guide contains information covering the identification of the option module, terminal layout for installation, fitting of the option module to the drive,

parameter details, diagnostic information and the specifications of the option module.

4 SI-I/O User Guide

Issue Number: 3

How to use this

WARNING

CAUTION

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

2 Safety information

2.1 Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of the product.

2.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this User Guide.

2.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy, and is used to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid hazards either in normal operation or in the event of equipment

malfunction. System design, installation, commissioning/start-up and maintenance must be carried out by personnel who have the necessary training

and experience. They must read this safety information and this User Guide carefully.

The STOP and SAFE TORQUE OFF functions of the drive do not isolate dangerous voltages from the output of the drive or from any external option

unit. The supply must be disconnected by an approved electrical isolation device before gaining to the electrical connections.

With the sole exception of the SAFE TORQUE OFF function, none of the drive functions must be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a hazard, either through their intended behavior or through

incorrect operation due to a fault. In any application where a malfunction of the drive or its control system could lead to or allow damage, loss or injury,

a risk analysis must be carried out, and where necessary, further measures taken to reduce the risk - for example, an over-speed protection device in

case of failure of the speed control, or a fail-safe mechanical brake in case of loss of motor braking.

The system designer is responsible for ensuring that the complete system is safe and designed correctly according to the relevant safety

standards.

2.4 Environmental limits

Instructions regarding transport, storage, installation and use of the drive must be complied with, including the specified environmental limits. These

instructions can be found in the relevant drive documentation. Drives must not be subjected to excessive physical force.

2.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the place of use must be complied with.

2.6 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective ground (earth) connections.

Instructions for achieving compliance with specific EMC standards may be found in the relevant drive documentation.

Within the European Union, all machinery in which this product is used must comply with the following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

2.7 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered without careful consideration of the impact on the

controlled system. Measures must be taken to prevent unwanted changes due to error or tampering.

SI-I/O User Guide 5

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

2.8 Stored charge

The drive contains capacitors which remain charged to a potentially lethal voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated for at least ten minutes before work may continue.

6 SI-I/O User Guide

Issue Number: 3

How to use this

1

2

SI-I/O

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

3 Introduction

3.1 Features

All connections from the Option module to the drive are made via the drive connector. Connections from external equipment to the SI-I/O are made

via a 3-way plugable/removable screw connector for the two relays, and an 11-way plugable/removable screw connector for the digital and analog

I/O.

Figure 3-1 SI-I/O

All parameters associated with the SI-I/O can be found in section 7 Parameters on page 15.

3.2 Option module identification

SI-I/O can be identified by:

1. The label located on the top of the Option module.

2. The color coding across the front of the SI-I/O (Orange).

Figure 3-2 SI-I/O labels

1 Topside module label

2 Underside module label

3.2.1 Date code format

The date code is split into two sections: a letter followed by a number. The letter indicates the year, and the number indicates the week number (within

the year) in which the Option module was built.The letters go in alphabetical order, starting with A in 1990 (B in 1991, C in 1992 etc).

Example:

A date code of V35 would correspond to week 35 of year 2012.

3.3 Conventions used in this guide

The configuration of the host drive and Option module is done using menus and parameters. A menu is a logical collection of parameters that have

similar functionality. In the case of an Options module, the parameters will appear in menu 15, 16 or 17 depending on which slot the module is

installed to. The menu is determined by the number before the decimal point.

The method used to determine the menu or parameter is as follows:

•Pr S.mm.ppp - Where S signifies the Option module slot number and mm.ppp signifies the menu and parameter number of the Option module's

internal menus and parameters.

•Pr MM.ppp - Where MM signifies the menu allocated to the Option module set-up menu and ppp signifies the parameter number.

Pr mm.000 - Signifies parameter number 000 in any drive menu.

All the inputs/outputs in the SI-I/O are user programmable for function and signal processing.

SI-I/O User Guide 7

Issue Number: 3

How to use this

NOTE

NOTE

NOTE

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

3.4 Digital I/O

By default, the digital inputs/outputs on the Option module are configured to operate in positive logic.

Configuration of the maximum of eight digital inputs for positive/negative logic is carried out by setting Pr S.01.008.

By default, the SI-I/O Module is set up for four programmable digital inputs/outputs. By configuring the analog I/O as digital inputs, it is possible for the

SI-I/O module to have four programmable inputs/outputs and also four digital inputs.

The functionality of these terminals is as follows:

• The logic sense selected can be positive or negative

• The logic state of each input is monitored by a read-only parameter

• The logic state can be inverted

• The digital input can be programmed to any suitable destination bit parameter

• The digital output can be sourced from any suitable bit parameter

• The output can operate either as a push-pull or an open collector output

3.5 Analog I/O

By default, the SI-I/O is set up for three single-ended analog inputs and one analog output or one high resolution differential analog input, one singleended analog input and one analog output.

Analog inputs 1 and 2 can only be configured as ±10 Vdc voltage inputs or digital inputs. When both are configured as analog voltage inputs, they can

be used as a single high resolution differential analog input.

Analog input 3 can operate in voltage mode (±10 Vdc), current mode (0 to 20 mA) or as a digital input.

Analog output 1 can operate in voltage mode (±10 Vdc), current mode (0 to 20 mA) or as a digital input.

The high precision differential analog input and analog output is only supported on Unidrive M600 - M800.

3.6 Relays

The two relays can be used to convey the logic state of any suitable parameter to external equipment. The logic state is processed as follows:

• A suitable source parameter is assigned to each relay

• The logic state can be inverted

• The state of the relay is monitored by a parameter

3.7 24 V internal power supply

If the user load exceeds 400 mA at 24 V, (24 V internal power supply), then an external

24 V power supply will be required which should be connected to the drive’s control terminals 1 and 2.

The user load comprises of:

• The drive’s digital outputs plus the SI-I/O digital outputs

Or

• The drive’s main encoder supply

The maximum output current from the drive’s digital output terminals 22, 24, 25 and 26 is 240 mA at 24 V, exceeding this will result in an ‘Output

overload’ digital output overload trip.

The SI-I/O has a maximum output current of 250 mA at 24 V across all four digital outputs.

If the maximum current of the drive and Option modules is exceeded a ‘PSU 24V' 24 V internal power supply overload trip will result.

8 SI-I/O User Guide

Issue Number: 3

How to use this

1

2

3

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

4 Mechanical installation

4.1 General installation

The installation of an Option module is illustrated in Figure 4-1.

Figure 4-1 Installing an Option module

1 2

4.1.1 Installing the first Option module

• Option module slots must be used in the following order: slot 3, slot 2 and slot 1. Orientate the Option module above the drive as shown in (1).

Align and insert the Option module tab into the slot (2). Press down on the Option module until it clicks into place.

Adding Option modules: Populate slot 3 first, then slot 2 and finally slot 1

SI-I/O User Guide 9

Issue Number: 3

How to use this

123456789

PL1

10 11 21 22 23

PL2

+

0V

+

0V

+

0V

+

0V

+

Analog Input 1

Analog Input 2

Analog Input 3

Analog Output 1

0V Common

0V Common

0V Common

0V Common

-

0V

0V Common

Differential Anal

ogInput

+

Differential Anal

ogInput

-

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

5 Electrical installation

5.1 Terminal descriptions

Table 5.1 SI-IO terminal descriptions

Table 5.2 11 way user connector and relay pin numbering

PL1 Function PL2 Function

T1 0 V common T21 Relay 1

T2 Digital input/output 1 T22 Relay common

T3 Digital input/output 2 T23 Relay 2

T4 Digital input/output 3 3 way 5.08 mm plugable screw connector

T5 Digital input/output 4

T6 0 V common

T7 Analog input 1/digital input 5

T8 Analog input 2/digital input 6

T9 Analog input 3/digital input 7

T10 0 V common

T11 Analog output 1/digital input 8

11 way 3.81 mm plugable screw connector

5.2 Wiring, shield connections

To prevent noise being induced onto any of the analog inputs or outputs, it is advisable to use twisted pair cable shielded with an overall outer shield.

The shield connections should be terminated at one of the zero volt terminals on the Option module, and to the zero volt connection of the signal

source. The termination of the shield should be kept as short as possible to prevent and noise being induced in this area.

Figure 5-1 Shield connections

10 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

6 Single line descriptions

6.1 Single line descriptions

6.1.1 Menu 0 - Setup

Parameter Range (Ú) Default (Ö)Type

MM.001 Module ID 0 to 999

MM.002 Software Version 00.00.00.00 to 99.99.99.99

MM.003 Hardware Version 00.00 to 99.99

MM.004 Serial Number LS 0 to 99999999

MM.005 Serial Number MS 0 to 99999999

MM.006 Module status Initializing (0), OK (1), Config (2), Error (3)

MM.007 Module reset Off (0) or On (1)

MM.008 Module default Off (0) or On (1)

MM.030 Slot Indicator 0 to 8

MM.031 Slot Menu Number 0 to 255

6.1.2 Menu 1 - I/O Setup

Parameter Range (Ú) Default (Ö)Type

S.01.001 Reset I/O Interface Off (0) or On (1) Off (0) RW Bit NC

S.01.002 Default I/O Interface Off (0) or On (1) Off (0) RW Bit NC

S.01.004 Option Module Status Initializing (0), OK (1), Config (2), Error (3)

S.01.005

I/O Output Enable

Register

S.01.006 I/O Input Register 00000000 to 11111111

S.01.007 I/O Output Register 0000000000 to 1111111111 0000000000 RW Bin US

S.01.008 Digital I/O Logic Polarity Negative Logic (0) or Positive Logic (1) Positive Logic (1) RW Txt US

S.01.009 Open Collector Output Push-Pull (0) or Open Collector (1) Push-Pull (0) RW Txt US

S.01.010 I/O Read Word 0000000000 to 1111111111 0000000000 RO Bin

S.01.011 T2 Digital I/O 1 Mode Digital Input (0) or Digital Output (1) Digital Input (0) RW Txt US

S.01.012 T3 Digital I/O 2 Mode Digital Input (0) or Digital Output (1) Digital Input (0) RW Txt US

S.01.013 T4 Digital I/O 3 Mode Digital Input (0) or Digital Output (1) Digital Input (0) RW Txt US

S.01.014 T5 Digital I/O 4 Mode Digital Input (0) or Digital Output (1) Digital Input (0) RW Txt US

S.01.015

S.01.016

T7 Digital Input 5 /

Analog Input 1 Mode

T8 Digital Input 6 /

Analog Input 2 Mode

Digital Input (0), Volt IN (1), 4-20mA Low (2), 20-

S.01.017

S.01.018

T9 Digital Input 7 /

Analog Input 3 Mode

T11 Digital Input 8 /

Analog Output 1 Mode

4mA Low (3), 4-20mA Hold (4), 20-4mA Hold (5),

0-20mA (6), 20-0mA (7), 4-20mA Trip (8), 20-

Digital Input (0), Volt Out (1), 4-20mA (2), 20-

0000000000 to 1111111111 0000000000 RW Bin US

Digital Input (0) or Volt IN (1) Volt IN (1) RW Txt US

Digital Input (0) or Volt IN (1) Volt IN (1) RW Txt US

4mA Trip (9), 4-20mA (10), 4-20mA (11)

4mA (3), 0-20mA (4), 20-0mA (5),

209

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

Off (0)

Off (0)

RW Bit NC

RW Bit NC

RO Num ND NC PT

RO Num ND NC PT

RO Txt ND NC PT

RO Bin US

Volt IN (1) RW Txt US

Volt Out (1) RW Txt US

SI-I/O User Guide 11

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

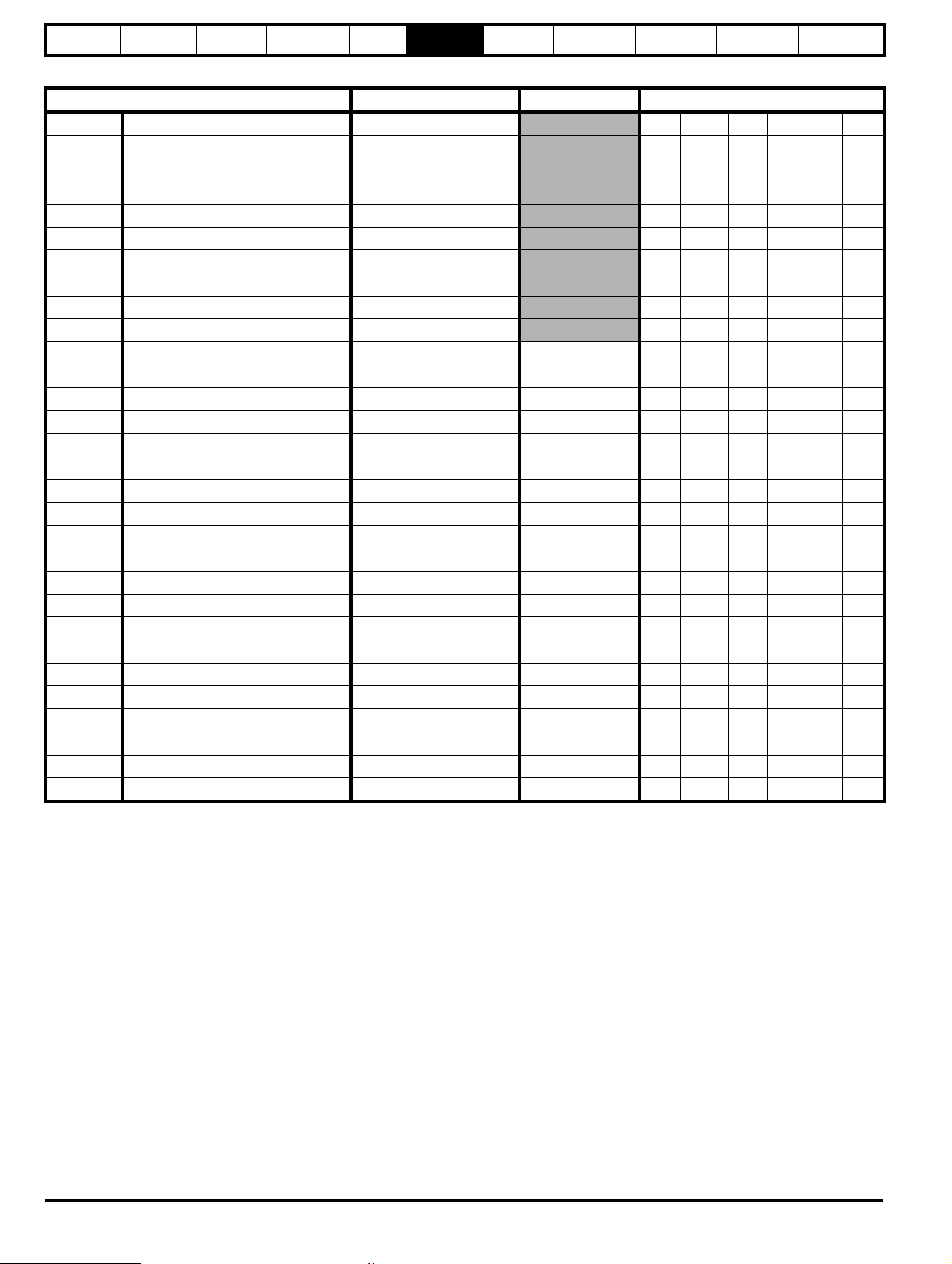

6.1.3 Menu 2 - Digital I/O

Parameter Range (Ú) Default (Ö)Type

S.02.001 Digital I/O 1 State Off (0) or On (1)

S.02.002 Digital I/O 2 State Off (0) or On (1)

S.02.003 Digital I/O 3 State Off (0) or On (1)

S.02.004 Digital I/O 4 State Off (0) or On (1)

S.02.005 Digital Input 5 State Off (0) or On (1)

S.02.006 Digital Input 6 State Off (0) or On (1)

S.02.007 Digital Input 7 State Off (0) or On (1)

S.02.008 Digital Input 8 State Off (0) or On (1)

S.02.009 Relay 1 State Off (0) or On (1)

S.02.010 Relay 2 State Off (0) or On (1)

S.02.011 Digital I/O 1 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.012 Digital I/O 2 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.013 Digital I/O 3 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.014 Digital I/O 4 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.015 Digital Input 5 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.016 Digital Input 6 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.017 Digital Input 7 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.018 Digital Input 8 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.019 Relay 1 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.020 Relay 2 Invert Off (0) or On (1) Off (0) RW Bit US

S.02.021 Digital I/O 1 Source / Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.022 Digital I/O 2 Source / Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.023 Digital I/O 3 Source / Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.024 Digital I/O 4 Source / Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.025 Digital Input 5 Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.026 Digital Input 6 Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.027 Digital Input 7 Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.028 Digital Input 8 Destination 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.029 Relay 1 Source 0.00.000 to 4.99.999 0.00.000 RW Num PT US

S.02.030 Relay 2 Source 0.00.000 to 4.99.999 0.00.000 RW Num PT US

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

RO Bit ND NC PT

12 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

6.1.4 Menu 3 - Analog I/O

Parameter Range (Ú) Default (Ö)Type

S.03.001 Analog Input 1 -100.00 to 100.00%

S.03.002 Analog Input 2 -100.00 to 100.00%

S.03.003 Analog Input 3 -100.00 to 100.00%

S.03.004 Differential Analog Input -100.0000 to 100.0000%

S.03.005 Analog Output 1 -100.00 to 100.00%

S.03.006 Analog Output 1 Source 0.00.000 to 4.99.999 0.00.000 RW Num US

S.03.007 Analog Output 1 Scaling 0.000 to 40.000 1.000 RW Num US

S.03.011 Analog Input 1 Offset -100.00 to 100.00% 0.00% RW Num US

S.03.012 Analog Input 1 Scaling 0.000 to 40.000 1.000 RW Num US

S.03.013 Analog Input 1 Invert Off (0) or On (1) Off (0) RW Bit US

S.03.014 Analog Input 1 Minimum -100.00 to 100.00% -100.00% RW Num US

S.03.015 Analog Input 1 Maximum -100.00 to 100.00% 100.00% RW Num US

S.03.016 Analog Input 1 Destination 0.00.000 to 4.99.999 0.00.000 RW Num DE US

S.03.021 Analog Input 2 Offset -100.00 to 100.00% 0.00% RW Num US

S.03.022 Analog Input 2 Scaling 0.000 to 40.000 1.000 RW Num US

S.03.023 Analog Input 2 Invert Off (0) or On (1) Off (0) RW Bit US

S.03.024 Analog Input 2 Minimum -100.00 to 100.00% -100.00% RW Num US

S.03.025 Analog Input 2 Maximum -100.00 to 100.00% 100.00% RW Num US

S.03.026 Analog Input 2 Destination 0.00.000 to 4.99.999 0.00.000 RW Num DE US

S.03.031 Analog Input 3 Offset -100.00 to 100.00% 0.00% RW Num US

S.03.032 Analog Input 3 Scaling 0.000 to 40.000 1.000 RW Num US

S.03.033 Analog Input 3 Invert Off (0) or On (1) Off (0) RW Bit US

S.03.034 Analog Input 3 Minimum -100.00 to 100.00% -100.00% RW Num US

S.03.035 Analog Input 3 Maximum -100.00 to 100.00% 100.00% RW Num US

S.03.036 Analog Input 3 Destination 0.00.000 to 4.99.999 0.00.000 RW Num DE US

S.03.037 Analog Input 3 Current Loop Loss Off (0) or On (1)

S.03.041 Differential Analog Input Offset -100.00 to 100.00% 0.00% RW Num US

S.03.042 Differential Analog Input Scaling 0.000 to 40.000 1.000 RW Num US

S.03.043 Differential Analog Input Invert Off (0) or On (1) Off (0) RW Bit US

S.03.044 Differential Analog Input Minimum -100.00 to 100.00% -100.00% RW Num US

S.03.045 Differential Analog Input Maximum -100.00 to 100.00% 100.00% RW Num US

S.03.046 Differential Analog Input Destination 0.00.000 to 4.99.999 0.00.000 RW Num DE US

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

RO Num ND NC PT

SI-I/O User Guide 13

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

6.2 Menu 9 - Resources

Parameter Range (Ú) Default (Ö)Type

S.09.030 PCB temperature -128 to 127°C

S.09.031 CPU Core Temperature -128 to 127°C

Parameters Block diagrams Diagnostics Technical Data Index

RO Num ND NC PT

RO Num ND NC PT

14 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

7 Parameters

7.1 Menu 0 - Module Set-up

All parameters in S.00.ppp (i.e. menu 0 within the option module menus) are also present in menus 15, 16 or 17 depending on the slot that the

module is installed to e.g. Pr 3.00.007 is also present as 17.007.

The functionality and properties of the parameters are identical between the two menus.

S.00.001 Module ID

Minimum 0 Maximum 65535

Default 209 Units

Type 16 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

Pr S.00.001 displays the ID number for the Option Module. For SI-I/O, this is 209.

S.00.002 Firmware version

Minimum

0 (Display

00.00.00.00)

Maximum

Default Units

Type 32 Bit Volatile Update Rate Power-up write

Display Format Version Number Decimal Places 0

Coding RO, ND, NC, PT

The firmware version of the option module is in the format of ww.xx.yy.zz

99999999 (Display

99.99.99.99)

S.00.003 Hardware version

Minimum 00.00 Maximum 99.99

Default Units

Type 16 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 2

Coding RO, ND, NC, PT

The firmware version of the option module is in the format of ww.xx.yy.zz

S.00.004 Serial Number LS

S.00.005 Serial Number MS

Minimum 0 Maximum 99999999

Default Units

Type 32 Bit Volatile Update Rate Power-up write

Display Format None Decimal Places 0

Coding RO, ND, NC, PT

The module serial number is available as a pair of 32-bit values where Serial Number LS (Pr S.00.004) provide the least significant 8 decimal digits,

and Serial Number MS (Pr S.00.005) provides the most significant 8 decimal digits. The reconstructed serial number is ((S.00.005 x 100000000) +

S.00.004). For example serial number "0001234567898765" would be stored as S.00.005 = 123456 and S.00.004 = 67898765.

SI-I/O User Guide 15

Issue Number: 3

How to use this

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.00.006 Module Status

Minimum 0 Maximum 101

Default Units

Type 8 Bit Volatile Update Rate Background read

Display Format None Decimal Places 0

Coding RO, TE, ND, NC, PT

This parameter displays the current status of the module. All possible values are shown in the table below.

Value Text Description

0 Initializing Module is currently initializing.

1 Ok Module has initialized and has found no errors.

2 Config

3Error

A configuration error has been detected in one of the

communications protocols or user program

An error has occurred preventing the firmware or user program

from running correctly.

100 Bootloader The bootloader is currently running.

101 Updating

The bootloader is currently performing a firmware update. The

power must not be turned off in this state.

S.00.007 Reset Module

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

Changes to the module's configuration will not take effect until the module has been reset.

• To reset the module:

•Set Pr S.00.007 to On (1).

• When the sequence has been completed, Pr S.00.007 will be reset to Off (0).

The module will reset using the updated configuration.

This sequence does NOT store the module's configuration parameters in the drive or the module's flash memory. This parameter will change back to

Off immediately, and as such the change may not be visible in the display.

S.00.008 Default Module

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

If the host drive is defaulted (see the drive user guide for details), it will also clear the current configuration for the slot the module is installed to.

This can be performed as follows:

•Set Pr S.00.008 to On.

• Reset the module by setting Pr S.00.007 to On.

• Default parameter values for the module will be loaded.

The module will reset using the default values.

S.00.030 Slot Indicator

Minimum 0 Maximum 8

Default Units

Type 8 Bit Volatile Update Rate Written on power-up

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the slot number that the module is installed in.

16 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.00.031 Slot Menu Number

Minimum 0 Maximum 255

Default Units

Type 8 Bit Volatile Update Rate Written on power-up

Display Format None Decimal Places 0

Coding RO, ND, NC, PT, BU

This parameter shows the drive menu number associated with the slot that the module is installed in.

For example:

• If the module is installed in slot 1, this parameter will show 15.

• If the module is installed in slot 2, this parameter will show 16.

• If the module is installed in slot 3, this parameter will show 17.

SI-I/O User Guide 17

Issue Number: 3

How to use this

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

7.2 Menu 1 - I/O Set-up

Menu 1 contains all the parameters relating to the setup of the I/O interface on the SI-I/O module.

S.01.001 Reset I/O Interface

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

Changes to the module's configuration will not take effect until the module has been reset.

To reset the module:

•Set Pr S.01.001 to On (1).

• When the sequence has been completed, Pr S.01.001 will be reset to Off (0).

• The module will reset using the updated configuration.

This sequence does NOT store the module's configuration parameters in the drive or the module's flash memory. This parameter will change back to

Off immediately, and as such the change may not be visible in the display.

S.01.002 Default I/O Interface

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate Read every 200 ms

Display Format None Decimal Places 0

Coding RW, NC

If the host drive is defaulted (see the drive user guide for details), it will also clear the current configuration for the slot the module is installed to.

This can be performed as follows:

•Set Pr S.01.002 to On.

• Reset the module by setting Pr S.01.001 to On.

• Default parameter values for the module will be loaded.

The module will reset using the default values.

S.01.004 Option Module Status

Minimum 0 Maximum 2

Default Units

Type 8 Bit Volatile Update Rate Background read

Display Format None Decimal Places 0

Coding RO, TE, ND, NC, PT

This parameter displays the current status of the module. All possible values are shown in the table below.

Value Text Description

0 Running OK The module is healthy.

1 Initializing Indicates that the module is initializing.

Indicates that there is an error in the mapping parameters.

2 Mapping Error

For example, the destination should not be non-existent or

read-only.

3 Error

An error has occurred preventing the firmware or user

program from running correctly.

100 Bootloader The bootloader is currently running.

101 Updating

The bootloader is currently performing a firmware update.

The power must not be turned off in this state.

18 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.01.005 I/O Output Enable Register

Minimum

0 (Display

0000000000)

Maximum

1023 (Display

1111111111)

Default 0 Units

Type 16 Bit User Save Update Rate Background read

Display Format Binary Decimal Places 0

Coding RW

Parameter S.01.005 is used to disable or enable relevant bits in the Output Register (Pr S.01.007).

If the bit is set to zero, the relevant bit in the Output Register (Pr S.01.007) is disabled. If the bit is set to 1 then the relevant bit in the Output Register

can be used to directly control the digital output but the conditions below will need to be fulfilled:

• The corresponding bit in the I/O Output Enable Register (Pr S.01.005) is set to 1.

• The I/O must be a digital I/O and configured as an output or is a Relay Output.

• The corresponding I/O Source/Destination parameter must be set to 00.000.

If the above conditions are not met, then the digital output is controlled by the normal logic.

The table below shows how the bits correspond to each function.

Bit 98765432 1 0

Te rm i n al

Te rm i n al

description

T23 T21 T11 T9 T8 T7 T5 T4 T3 T2

Digital

Digital

Relay 2Relay 1Digital

Input

8

Digital

Input

7

Digital

Input

6

Digital

Input

5

I/O 4

I/O 3

Digital

I/O 2

Digital

I/O 1

S.01.006 I/O Input Register

Minimum

0 (Display

00000000)

Maximum

255 (Display

11111111)

Default 0 Units

Type 16 Bit Volatile Update Rate 1 ms write

Display Format Binary Decimal Places 0

Coding RO

The Digital I/O Input Register (Pr S.01.006) is always active and displays the state of all the digital I/O which are configured as inputs.

This register is updated every 1 ms.

The table below shows how the bits correspond to each function.

Bit 76543210

Te rm i n al

Te rm i n al

description

T11T9T8T7T5T4T3T2

Digital

Input 8

Digital

Input 7

Digital

Input 6

Digital

Input 5

Digital

I/O 4

Digital

I/O 3

Digital

I/O 2

Digital

I/O 1

S.01.007 I/O Output Register

Minimum

0 (Display

0000000000)

Maximum

1023 (Display

1111111111)

Default 0 Units

Type 16 Bit User Save Update Rate 2 ms read

Display Format Binary Decimal Places 0

Coding RW

Bits in the I/O Output Register (Pr S.01.007) can be used to control the digital I/O directly. The bits control the output directly and are not modified by

the corresponding Digital I/O Invert function. The bits in the I/O Output Register (Pr S.01.007) only control the corresponding digital output if all the

conditions below are met:

• The corresponding bit in the I/O Output Enable Register (Pr S.01.005) is set to 1.

• The I/O must be a digital I/O and configured as an output or is a Relay Output.

• The corresponding I/O Source/Destination parameter must be set to 00.000.

If the above conditions are not met, then the digital output is controlled by the normal logic.

The table below shows how the bits correspond to each function.

Bit 9876543210

Te rm i n al

Te rm i n al

description

T23 T21 T11 T9 T8 T7 T5 T4 T3 T2

Digital

Digital

Relay 2Relay 1Digital

Input

8

Digital

Input

7

Digital

Input

6

Digital

Input

5

I/O 4

I/O 3

Digital

I/O 2

Digital

I/O 1

SI-I/O User Guide 19

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.01.008 Digital I/O Logic Polarity

Minimum 0 Maximum 1

Default 1 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

This parameter controls the logic for all the digital inputs on the module.

Value Text Description

0 Negative Logic Negative Logic

1 Positive Logic Positive Logic

S.01.009 Open Collector Output

Minimum 0 Maximum 1

Default 0 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

Value Text Description

0 Push-pull Push-pull output

1 Open Collector Open Collector output

S.01.010 I/O Read Word

Minimum

0 (Display

00000000)

Maximum

255 (Display

11111111)

Default 0 Units

Type 16 Bit Volatile Update Rate Background read

Display Format None Decimal Places 0

Coding RO

The I/O Read Word (Pr S.01.010) reflects the state of digital I/O 1 - 8. Each bit matches the value of the state parameter for the respective digital input

or output so the bit value for the digital inputs will be the state of the actual input before any inversion selection is applied. The bit value for the digital

output will include the state inversion if selected in the invert parameter for the output.

The table below shows how the bits correspond to each function.

Bit 76543210

TerminalT11T9T8T7T5T4T3 T2

Te rm i n al

description

Digital

Input 8

Digital

Input 7

Digital

Input 6

Digital

Input 5

Digital

I/O 4

Digital

I/O 3

Digital

I/O 2

Digital

I/O 1

S.01.011 T2 Digital I/O 1 Mode

S.01.012 T3 Digital I/O 2 Mode

S.01.013 T4 Digital I/O 3 Mode

S.01.014 T5 Digital I/O 4 Mode

Minimum 0 Maximum 1

Default 0 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

Digital I/O 1-4 are the standard I/O that are compatible with IEC61131-2 logic levels. When the channel mode is set to zero, the I/O is configured as a

digital input. When the channel mode is set to one, the I/O is configured as a digital output.

Value Text Description

0 Digital Input Digital Input

1 Digital Output Digital Output

20 SI-I/O User Guide

Issue Number: 3

How to use this

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.01.015 T7 Digital Input 5, Analog Input 1 Mode

S.01.016 T8 Digital Input 6, Analog Input 2 Mode

Minimum 0 Maximum 1

Default 1 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

Terminals 7 and 8 can be configured as digital inputs, analog voltage inputs or a single differential analog input.

Value Text Description Function of T7 Function of T8

0 Digital Input Digital Input Digital Input 5 Digital Input 6

1 Volt IN Analog Voltage Input Analog Input 1 Analog Input 2

2 Differential

Differential Analog

Voltage Input

Positive Differential

Analog Input

Negative Differential

Analog Input

When Pr S.01.015 or Pr S.01.016 are set to Digital Input (0), terminals T7 or T8 will be configured as digital inputs.

When Pr S.01.015 or Pr S.01.016 are set to Volt IN (1), terminals T7 or T8 will be configured as independent single ended analog voltage inputs.

When either Pr S.01.015 or Pr S.01.016 are set to Differential (2), the terminals T7 and T8 are combined so that they can be used as a high precision

differential analog voltage input with T7 as the positive input and T8 as the negative input. This will disable the single ended analog voltage input

parameters and they will not update.

A combination of setting these parameters to either Digital Input (0) or Volt IN (1) is permitted between the two terminals so that one terminal can be

used as digital input and the other can be configured as a single ended analog voltage input.

Setting either of these parameters to Differential (2) will override any other value in the other mode parameter to configure both inputs as a single

differential analog input.

The value of Differential (2), is only available with SI-I/O firmware V01.00.01.xx and later. To use the differential analog input in previous firmware,

Pr S.01.015 and Pr S.01.016 must both be set to Volt IN (1).

S.01.017 T9 Digital Input 7, Analog Input 3 Mode

Minimum 0 Maximum 11

Default 1 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

Terminal 9 can be configured as a digital input, an analog voltage input or an analog current input.

The table below shows all possible values of Pr S.01.017.

Value Text Description

0

Digital Input Digital Input 7

1

Volt IN ±10 V Analog voltage Input

2

4-20 mA Low 4-20 mA switching to equivalent of 4 mA input current on loss

3

20-4 mA Low 20-4 mA switching to equivalent of 20 mA input current on loss

4

4-20 mA Hold 4-20 mA hold at level before loss on loss

5

20-4 mA Hold 20-4 mA hold at level before loss on loss

6

0-20 mA 0-20 mA

7

20-0 mA 20-0 mA

8

4-20 mA Trip 4-20 mA trip on loss

9

20-4 mA Trip 20-4 mA trip on loss

10

4-20 mA 4-20 mA no action on loss

11

20-4 mA 20-4 mA no action on loss

S.01.018 T9 Digital Input 8, Analog Output 1 Mode

Minimum 0 Maximum 5

Default 1 Units

Type 8 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW, TE

Terminal 11 can be configured as a digital input, an analog voltage output or an analog current output.

SI-I/O User Guide 21

Issue Number: 3

How to use this

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

The table below shows all possible values of Pr S.01.018.

Value Text Description

0 Digital Input Digital Input 7

1 Volt Out ±10 V Analog voltage Output

2 4-20 mA 4-20 mA output current

3 20-4 mA 20-4 mA output current

4 0-20 mA 0-20 mA output current

5 20-0 mA 20-0 mA output current

The analog output is only supported on Unidrive M600 - M800.

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

22 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

7.3 Menu 2 - Digital I/O

Menu 2 on the module controls and displays all parameters associated with the Digital I/O.

S.02.001 Digital I/O 1 State

S.02.002 Digital I/O 2 State

S.02.003 Digital I/O 3 State

S.02.004 Digital I/O 4 State

S.02.005 Digital Input 5 State

S.02.006 Digital Input 6 State

S.02.007 Digital Input 7 State

S.02.008 Digital Input 8 State

S.02.009 Relay 1 State

S.02.010 Relay 2 State

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit Volatile Update Rate

Display Format None Decimal Places 0

Coding RO, ND, ND, PT

Digital I/O X State shows the state of the digital I/O in question. All I/O use IEC61131-2 logic levels. As default the inputs use positive logic, and so the

state parameter is 0 if the digital I/O is low or 1 if the digital I/O is high. Digital I/O Logic Polarity (Pr S.01.008) can be set to Negative Logic (0) to

change the logic for Digital I/O 1-8, so that the state parameter is 0 if the digital I/O is high and 1 if the digital I/O is low.

The state parameter represents the digital I/O state whether it is configured as an input or as an output. If the digital I/O is configured as an output to

be controlled using the Digital I/O Register (Pr S.01.007), then the state parameter will still show the state of the output even though the source is

zero.

For Relay 1 and 2, the state parameter is 0 if the relay contact is open, the state parameter is 1 if the relay contact is closed.

S.02.011 Digital I/O 1 Invert

S.02.012 Digital I/O 2 Invert

S.02.013 Digital I/O 3 Invert

S.02.014 Digital I/O 4 Invert

S.02.015 Digital Input 5 Invert

S.02.016 Digital Input 6 Invert

S.02.017 Digital Input 7 Invert

S.02.018 Digital Input 8 Invert

S.02.019 Relay 1 Invert

S.02.020 Relay 2 Invert

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places 0

Coding RW

A value of Off (0) or On (1) in Digital I/O X Invert allows the I/O state to be non-inverted or inverted as required.

2 ms read/write - Unidrive M600 - M800

8 ms read/write - Unidrive M200 - M400

S.02.021 Digital I/O 1 Source / Destination

S.02.022 Digital I/O 2 Source / Destination

S.02.023 Digital I/O 3 Source / Destination

S.02.024 Digital I/O 4 Source / Destination

S.02.025 Digital Input 5 Destination

S.02.026 Digital Input 6 Destination

S.02.027 Digital Input 7 Destination

S.02.028 Digital Input 8 Destination

S.02.029 Relay 1 Source

S.02.030 Relay 2 Source

Minimum 0.00.000 Maximum 4.99.999

Default 0.00.000 Units

Type 32 Bit User Save Update Rate Drive Reset read

Display Format Slot Menu Parameter Decimal Places 0

Coding RW, PT, BU

The Digital I/O X Source / Destination parameters provide the routing for the source and/or destination for the digital I/O.Relay X Source provides the

routing for the source of the two relays.

SI-I/O User Guide 23

Issue Number: 3

How to use this

NOTE

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

7.4 Menu 3 - Analog I/O

Menu 3 on the module controls and displays all parameters associated with the Analog I/O.

S.03.001 Analog Input 1

S.03.002 Analog Input 2

S.03.003 Analog Input 3

Minimum -100.00 Maximum 100.00

Default Units %

Type 16 Bit Volatile Update Rate 250 µs write

Display Format None Decimal Places 2

Coding RO, FI, ND, NC, PT

Analog inputs 1, 2 and 3 have a resolution of 12 bits. The input can operate in different modes as defined the mode selected in Pr S.01.015 to Pr

S.01.017 including current modes.

The "Input Level" is defined for the different modes as shown in the table below.

Mode Input Level

Volt IN (Input Voltage / 10 V) x 100.00 %

0-20mA (Input Current / 20 mA) x 100.00 %

20-0mA ((20 mA – Input Current) / 20 mA) x 100.00 %

4-20mA ((Input Current – 4 mA) / 16 mA) x 100.00 %

20-4mA ((20 mA – Input Current) / 16 mA) x 100.00 %

Analog Inputs 1-3 (Pr S.03.001 to Pr S.03.003) are derived as follows (Analog Input 1 is used for this example):

is the value after the minimum and maximum limits are applied.

A

1

If Analog Input 1 Minimum (Pr S.03.014) ≥ Analog Input 1 Maximum (Pr S.03.015) then: A

If Analog Input 1 Minimum (Pr S.03.014) < 0.00% and Analog Input 1 Maximum (Pr S.03.015) > 0.00 % then:

Input Level is limited between - Analog Input 1 Minimum (Pr S.03.014) and + Analog Input 1 Maximum (Pr S.03.015).

= Input Level x (100.00 % / Analog Input 1 Maximum (Pr S.03.015)

A

1

Otherwise:

Input Level is limited between Analog Input 1 Minimum (Pr S.03.014) and Analog Input 1 Maximum (Pr S.03.015).

= [(Input Level - Analog Input 1 Minimum (Pr S.03.014)) x 100.00 %] / [Analog Input 1 Maximum (Pr S.03.015) - Analog Input 1 Minimum (Pr

A

1

S.03.014)].

= 0.00 % whatever the input level is.

1

S.03.004 Differential Analog Input

Minimum -100.0000 Maximum 100.0000

Default Units %

Type 32 Bit Volatile Update Rate 4 ms write

Display Format None Decimal Places 4

Coding RO, ND, NC, PT

The Differential Analog Input has a resolution of 16 bits. The minimum resolution of Pr S.03.004 is 0.0030518 % (100 / 215 %).

The level of Differential Analog Input (Pr S.03.004) is calculated in the same way as Analog Inputs 1-3 (Pr S.03.001 - Pr S.03.003).

The differential analog input is only available on Unidrive M600 - M800.

S.03.005 Analog Output 1

Minimum -100.00 Maximum 100.00

Default 0.00 Units %

Type 16 Bit Volatile Update Rate Background read

Display Format None Decimal Places 2

Coding RO, PT

Analog Output 1 (Pr S.03.005) has a resolution of 12 bits plus sign. Analog Output 1 (Pr S.03.005) shows the value passed by Analog Output 1

Source (Pr S.03.006) which is then scaled by Analog Output 1 Scaling (Pr S.03.007) and clamped between -100.00 and 100.00%.

The analog output is only available on Unidrive M600 - M800.

24 SI-I/O User Guide

Issue Number: 3

How to use this

NOTE

NOTE

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.03.006 Analog Output 1 Source

Minimum 0.00.000 Maximum 4.99.999

Default 0.00.000 Units

Type 32 Bit User Save Update Rate Background read

Display Format

Slot Menu

Parameter

Decimal Places

Coding RW, BU

Analog Output 1 Source (Pr S.03.006) defines the source parameter for T11 analog output 1.

The analog output is only available on Unidrive M600 - M800.

S.03.007 Analog Output 1 Scaling

Minimum 0.000 Maximum 40.000

Default 1.000 Units

Type 16 Bit User Save Update Rate Background read

Display Format None Decimal Places 3

Coding RW, BU

Analog Output 1 Scaling (Pr S.03.007) defines the scaling that is applied to T11 analog output 1.

The analog output is only available on Unidrive M600 - M800.

S.03.011 Analog Input 1 Offset

S.03.021 Analog Input 2 Offset

S.03.031 Analog Input 3 Offset

S.03.041 Differential Analog Input Offset

Minimum -100.00 Maximum 100.00

Default 0.00 Units %

Type 16 Bit User Save Update Rate Background read

Display Format None Decimal Places 2

Coding RW

S.03.012 Analog Input 1 Scaling

S.03.022 Analog Input 2 Scaling

S.03.032 Analog Input 3 Scaling

S.03.042 Differential Analog Input Scaling

Minimum 0.000 Maximum 40.000

Default 1.000 Units

Type 16 Bit User Save Update Rate Background read

Display Format None Decimal Places 3

Coding RW, BU

SI-I/O User Guide 25

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.03.013 Analog Input 1 Invert

S.03.023 Analog Input 2 Invert

S.03.033 Analog Input 3 Invert

S.03.043 Differential Analog Input Invert

Minimum 0 Maximum 1

Default 0 Units

Type 1 Bit User Save Update Rate Background read

Display Format None Decimal Places

Coding RW

All of the Analog Inputs will operate in the same way as shown below but only Analog Input 1 is used for reference.

Analog Input 1 (Pr S.03.001) is modified by Analog Input 1 Offset (Pr S.03.011), the Analog Input 1 Scaling (Pr S.03.012) and Analog Input 1 Invert

(Pr S.03.013) before it is routed to its destination as follows:

= Analog Input 1 (Pr S.03.001) + Analog Input 1 Offset (Pr S.03.011)

A

1O

A

is the value after the offset has been applied and is limited between -100.00 and 100.00 %

1O

A

= A1O x Analog Input 1 Scaling (Pr S.03.012)

1S

A

is the value after the scaling and the offset have been applied and is limited between -100.00 and 100.00 %.

1S

If Analog Input 1 Invert (Pr S.03.013) = 0 then A

= A1S otherwise A1I = -A

1I

1S

A1I is the value after the invert, scaling and offset have been applied and is the final value that is routed to the destination defined by Analog Input 1

Destination (Pr S.03.016).

S.03.014 Analog Input 1 Minimum

S.03.024 Analog Input 2 Minimum

S.03.034 Analog Input 3 Minimum

S.03.044 Differential Analog Input Minimum

Minimum -100.00 Maximum 100.00

Default -100.00 Units %

Type 16 Bit User Save Update Rate Background read

Display Format None Decimal Places 2

Coding RW

S.03.015 Analog Input 1 Maximum

S.03.025 Analog Input 2 Maximum

S.03.035 Analog Input 3 Maximum

S.03.045 Differential Analog Input Maximum

Minimum -100.00 Maximum 100.00

Default 100.00 Units %

Type 16 Bit User Save Update Rate Background read

Display Format None Decimal Places 2

Coding RW

Pr S.03.014 and Pr S.03.015 control the minimum and maximum limits for Analog Input 1. See Analog Input 1 (Pr S.03.001) for more details.

S.03.016 Analog Input 1 Destination

S.03.026 Analog Input 2 Destination

S.03.036 Analog Input 3 Destination

S.03.046 Differential Analog Input Destination

Minimum 0.00.000 Maximum 4.99.999

Default 0.00.000 Units

Type 32 Bit User Save Update Rate Drive reset read

Display Format

Slot Menu

Parameter

Decimal Places

Coding RW, BU

These parameters set the destination for each analog input in question. See Analog Input 1 (Pr S.03.001) for more details.

26 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams Diagnostics Technical Data Index

S.03.037 Analog Input 3 Current Loop Loss

Minimum 0 Maximum 1

Default Units

Type 1 Bit Volatile Update Rate Background write

Display Format None Decimal Places

Coding RO, ND

If T9 Digital Input 7 / Analog Input 3 Mode (Pr S.01.017) is set to any of the 4-20 mA or 20-4 mA modes and the current falls below 3mA, then Analog

Input 3 Current Loop Loss (Pr S.03.037) will be set to On (1). If the current is greater than 3 mA or any other mode is selected, then Analog Input 3

Current Loop Loss (Pr S.03.037) will be set to Off (0).

7.5 Menu 9 - Resources

S.09.030 PCB Temperature

S.09.031 CPU Core Temperature

Minimum -128 Maximum 127

Default 0 Units °C

Type 8 Bit Volatile Update Rate Background write

Display Format Decimal Places

Coding RO, NC, PT

Pr S.09.030 and S.09.031 display the current temperature of the 2 internal thermistors inside the module.

SI-I/O User Guide 27

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

T2 Digital

I/O 1 state

Digital I/O

logic polarity

Open

collector

output

T2 Digital

I/O 1 mode

select

S.01.011

??.???

??.???

Any unprotected

bit parameter

??.???

??.???

x(-1)

x(-1)

T2 Digital I/O

1 invert

T2 Digital I/O

1 destination

/ source

S.02.001

Any bit

paramter

T3 Digital I/O 2

T2

S.01.008

S.01.009

S.02.011

S.02.021

T3 Digital

I/O 2 state

Digital I/O

logic polarity

Open

collector

output

T3 Digital

I/O 2 mode

select

S.01.012

??.???

??.??? Any unprotected

bit parameter

??.???

??.???

x(-1)

x(-1)

T3 Digital I/O

2 invert

T3 Digital I/O

2 destination

/ source

S.02.002

Any bit

paramter

T3

S.01.008

S.01.009

S.02.012

S.02.022

T2 Digital I/O 1

guide

Safety

information

Introduction

8 Block diagrams

8.1 Functional block diagrams

Figure 8-1 Digital I/O 1/2

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

28 SI-I/O User Guide

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

T4 Digital

I/O 3 state

Digital I/O

logic polarity

Open

collector

output

T4 Digital

I/O 1 mode

select

S.01.013

??.???

??.???

Any unprotected

bit parameter

??.???

??.???

x(-1)

x(-1)

T4 Digital I/O

3 invert

T4 Digital I/O 3

destination/source

S.02.003

Any bit

paramter

T5 Digital I/O 4

T4 S.01.008 S.01.009

S.02.013

S.02.023

T5 Digital

I/O 4 state

Digital I/O

logic polarity

Open

collector

output

T5 Digital

I/O 4 mode

select

S.01.014

??.???

??.???

Any unprotected

bit parameter

??.???

??.???

x(-1)

x(-1)

T5 Digital I/O 4

invert

T5 Digital I/O 4

destination/source

S.02.004

Any bit

paramter

T5

S.01.008 S.01.009

S.02.014

S.02.024

T4 Digital I/O 3

guide

Figure 8-2 Digital I/O 3/4

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

SI-I/O User Guide 29

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

T7 Digital

input 5 invert

T7 Digital input 5

destination/source

Digital I/O

logic polarity

Open

collector

output

T7 Digital Input 5,

Analog Input 1 Mode

S.01.015

S.02.005

S.02.015 S.02.025

T7

S.01.008 S.01.009

??.???

??.???

Any unprotected

Any bit

parameter

bit parameter

x(-1)

T7 Digital Input 5

T7 Digital

Input 5 State

T8 Digital

input 6 invert

T8 Digital input 6

destination/source

Digital I/O

logic polarity

Open

collector

output

T8 Digital Input 6,

Analog Input 2 Mode

S.01.016

S.02.006

S.02.016 S.02.026

T8

S.01.008 S.0 1.009

??.???

??.???

Any unprotected

Any bit

parameter

bit parameter

x(-1)

T8 Digital

Input 6 state

T9 Digital

Input 7 state

T11 Digital

Input 8 state

T8 Digital Input 6

T9 Digital

input 7 invert

T9 Digital input 7

destination/source

Digital I/O

logic polarity

Open

collector

output

T9 Digital Input 7,

Analog Input 3 Mode

S.01.017

S.02.007

S.02.017

S.02.027

T9 S.01.008 S.01.009

??.???

??.???

Any unprotected

Any bit

parameter

bit parameter

x(-1)

T9 Digital Input 7

T11 Digital

input 8 invert

T11 Digital input 8

destination/source

Digital I/O

logic polarity

Open

collector

output

T8 Digital Input 8,

Analog Output Mode

S.01.018

S.02.008

S.02.018

S.02.028

T11

S.01.008

S.01.009

??.???

??.???

Any unprotected

Any bit

parameter

bit parameter

x(-1)

T11 Digital Input 8

To analog

input 1

To a na log

input 2

To analog

input 3

To analog

output

guide

Safety

information

Figure 8-3 Digital input 5/6/7/8

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

30 SI-I/O User Guide

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

??.???

??.???

x(-1)

Differential Analog

input destination

Differential Analog

input invert

Differential Analog

input offset

Differential

Analog input

scaling

Differential

Analog input

Differential

Analog input

maximum

Differential

Analog input

minimum

S.03.046

S.01.015

S.03.041

S.03.043

S.03.045

S.03.044

Differential

analog input

destination

Any unprotected

variable parameter

S.01.016

S.03.004

T7 Digital input 5,

Analog input 1 mode

T8 Digital input 6,

Analog input 2 mode

+

+

+

-

2

2

T7

T8

A/D

S.03.042

??.???

??.???

x(-1)

T7 Analog

input 1 destination

T7 Analog

input 1 invert

T7 Analog

input 1 offset

T7 Analog

input 1

scaling

T7 Analog

input 1

T7 Analog input

1 maximum

T7 Analog input

1 minimum

S.03.016

S.03.011

S.03.013

S.03.015

S.03.014

Analog input 1

destination

Any unprotected

variable parameter

S.03.001

T7 Digital input 5,

Analog input 1 mode

+

+

1

S.01.015

T7

A/D

S.03.012

??.???

??.???

x(-1)

T8 Analog input

2 destination

T8 Analog

input 2 invert

T8 Analog

input 2 offset

T8 Analog

input 2

scaling

T8 Analog

input 2

T8 Analog input

2 maximum

T8 Analog input

2 minimum

S.03.026

S.03.021

S.03.023

S.03.025

S.03.024

Analog input 2

destination

Any unprotected

variable parameter

S.03.002

T8 Digital input 6,

Analog input 2 mode

+

+

1

S.01.016

T8

A/D

S.03.022

Figure 8-4 Analog input 1/2, differential analog input

guide

information

Safety

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

SI-I/O User Guide 31

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

??.???

??.???

x(-1)

T9 Analog

input 3 destination

T9 Analog

input 3 invert

T9 Analog

input 3 offset

T9 Analog

input 3

maximum

T9 Analog

input 3

minimum

T9 digital input 7

Analog input 3 mode

T9 Analog

input 3 scaling

Analog input

3 current loop

loss

S.03.036

S.03.031 S.03.033

S.03.035

S.03.034

Analog input

3 destination

Any unprotected

variable parameter

T9 Analog

input 3

+

+

A/D

S.03.032

Volt IN

4-20 mA Low

4-20 mA Hold

20-4 mA Hold

0-20 mA

20-0 mA

4-20 mA Trip

20-4 mA Trip

4-20 mA

20-4 mA

20-4 mA Low

T9

S.01.017

11

10

9

8

7

6

5

4

3

2

1

T11 Analog

output 1

scaling

T11 Analog

output 1 source

T11 Analog

output 1

??.???

??.???

S.03.036

Any unprotected

variable parameter

A/D

T11 digital input 8

DAC output 1 mode

Volt OUT

20-4 mA

0-20 mA

20-0 mA

4-20 mA

T11

S.01.018

5

4

3

2

1

S.03.007

S.03.003

S.03.037

S.03.005

guide

Safety

information

Introduction

Mechanical

installation

Figure 8-5 Analog input 3 and analog output 1

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

32 SI-I/O User Guide

Issue Number: 3

How to use this

mm.ppp

mm.ppp

Key

Read-write

(RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

The parameters are all shown in their default settings

T22

T21

T23

Relay 1

source

Relay 1

state

Relay 1

invert

S.02.019

??.???

??.???

x(-1)

Any bit

paramter

S.02.029

Relay 2

source

Relay 2

state

Relay 2

invert

S.02.020

??.???

??.???

x(-1)

Any bit

paramter

S.02.030

S.02.009

S.02.010

guide

Safety

information

Figure 8-6 Relay output

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters

Block diagrams Diagnostics Technical Data Index

SI-I/O User Guide 33

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams

Diagnostics Technical Data Index

9 Diagnostics

9.1 Overview

This section provides basic diagnostic information intended to resolve the most common problems encountered when setting up an SI-I/O option

module.

Drive trip display codes

If the option module detects an error during operation, it will force a trip on the drive. However, the trip string displayed on the drive will only indicate

which slot initiated the trip. The exact reason for the trip will be indicated in the drive trip code parameters (Pr 10.020 and Pr 10.070).

Table 9.1 shows the possible trips that will be displayed on the drive when a problem is detected with the option module or when the option module

initiates a trip.

Table 9.1 Digital I/O - 1-4

Trip Description

SlotX HF The drive has detected that an option module is present but is unable to communicate with it due to a hardware fault.

SlotX Error User trip generated by the option module

SlotX Not

Fitted

SlotX

Different

9.1.1 Module error codes

If the option module detects an internal error during operation, it will force a trip on the drive and provide a sub-trip string for a clearer definition of the

trip. Table 9.2 shows the possible module error codes.

Table 9.2 Module error codes

Value Text Description

200 SW fault Software fault

201 BG Orun Background task overrun

202 FW invalid

203 Drv unknown Unknown drive type

204 Drv unsupported Unsupported drive type

205 Mode unknown Unknown mode

206 Mode unsupported Unsupported mode

207 FLASH corrupt Corrupted Non-volatile Flash

208 Dbase init Database initialization error

209 FS init File system initialization error

210 Memory alloc Memory allocation error

211 Filesystem File system error

212 Configuration Configuration file error

213 OHt Overheated

214 TO drv

215 eCMP eCMP comms failure

216 TO eCMP slot 1 Slot 1 eCMP timeout

217 TO eCMP slot 2 Slot 2 eCMP timeout

218 TO eCMP slot 3 Slot 3 eCMP timeout

219 TO eCMP slot 4 Slot 4 eCMP timeout

220 Output overload Digital output overload

This trip will occur if a drive slot was previously configured with an option module but on power up, no option module was detected.

This trip will occur if a drive slot was previously configured with an option module but on power up, a different option module was

detected. Replacing the option module with another one of the same ID number will not initiate this trip.

The trip will also occur if an option module is installed to a previously unused slot.

Invalid firmware for hardware

version

The drive has not responded

with the watchdog period

34 SI-I/O User Guide

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

Parameters Block diagrams

Diagnostics Technical Data Index

9.1.2 I/O error codes

If the Option module detects an I/O error during operation, it will force a trip on the drive and provide a sub-trip string for a clearer definition of the trip.

Table 9.3 shows all possible I/O error codes.

Table 9.3 I/O error codes

Value Text Description

100 DIO Overload Digital Input/Output overload

101 Cur LoopLoss Analog Input 3 has entered the Current Loop Loss condition

102 T9 OverVolt The over voltage condition has been detected on terminal 9

103 Param Occupied There is a destination conflict between two destination parameters on the module

SI-I/O User Guide 35

Issue Number: 3

How to use this

guide

Safety

information

Introduction

Mechanical

installation

Electrical

installation

Single line

descriptions

10 Technical Data

10.1 Digital inputs/outputs (Terminals 2-5)

Default function Positive logic mode

Type Positive or negative logic inputs or Negative logic push-pull or open collector outputs

Absolute maximum voltage range -18 V to +36 V

Update time 2 ms for Unidrive M600 - M800

8 ms for Unidrive M200 - M400

Operating as an input

Logic mode controlled by Pr S.01.008

Voltage range 0 V to +24 V

Impedance >2 mA @ +15 Vdc from IEC61131-2, clause 3.3.1 type 1

Input thresholds 10 V ±0.8 V

Operating as an output

Mode controlled by Pr S.01.009

Current limits 100 mA for Digital I/O 1&2

100 mA for Digital I/O 3&4

Isolation Not isolated from control circuit

Overvoltage protection Series resistor, filter capacitor and clamping diodes

Parameters Block diagrams Diagnostics

Technical Data Index

10.2 Digital Inputs (Terminals 7-9)

Default function Positive logic mode

Type Positive or negative logic inputs

Absolute maximum voltage range -18 V to +36 V

Update time 2 ms for Unidrive M600 - M800

8 ms for Unidrive M200 - M400

Operating as an input

Logic mode controlled by Pr S.01.008

Voltage range 0 V to +24 V

Impedance >2 mA @ +15 V dc from IEC61131-2, clause 3.3.1 type 1

Input thresholds 10 V ± 0.8 V

10.3 Differential Analog Input (Terminals 7 and 8)

(Unidrive M600 - M800 only)