Liebert FS™ DC Energy Storage System

User Manual - 190kW/10 Seconds, 540VDC

AC Power

For Business-Critical Continuity™

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 GENERAL SYSTEM INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.1 Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.2 Requesting Assistance from Liebert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.3 Applicable Standards and Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 SITE PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.1 System Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Flooring Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Floor Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Floor-Space Occupation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.3 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.1 DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.2 Status/Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.3 Grounding Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.4 AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.5 Remote Monitoring Connections—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.0 UNLOADING AND UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.1 Inspection Before Removal From the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Positioning the Liebert FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Moving the Liebert FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Storing the Liebert FS for Delayed Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.1 Cabinet Floor Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.1 Concrete, Masonry or Stone Floor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.2 Wood Floor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.3 Raised Floor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 General Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.3 Status/Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4 Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.5 AC Auxiliary Control Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.6 Remote Monitoring Connections—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Startup Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

i

5.0 SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1 Detailed System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1.1 System Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.2 Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.3 System Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.4 User interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1.5 UPS Interconnection Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1.6 Power Conversion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.1.7 Magnetic Levitation Module (MLM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.8 Flywheel Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1.9 Rotor/Flywheel—Rotating Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.10 Motor Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.11 Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.12 Flywheel Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1.13 System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.14 Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.15 Ventilation and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 List of System User-Configurable Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.1 OFF Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.3.2 STANDBY Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.3.3 STARTUP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.3.4 CHARGE Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.5 READY Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3.6 DISCHARGE Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3.7 SHUTDOWN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3.8 COAST Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.9 FAULT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.4 Maintenance and Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.1 Operator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.1 Main screen function descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2.2 System MODE Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2.3 System STATUS Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2.4 Other Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3 Security Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3.1 Security Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3.2 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3.3 EPROM (System) Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ii

6.4 Menu Tree and Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.4.1 Screen Tree Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.4.2 Navigation and Operation of Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4.3 System Setup and Parameter Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4.4 View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.4.5 Time/Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.4.6 Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4.7 Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4.8 History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4.9 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4.10 Network—Requires DCM Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.4.11 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4.12 Vitals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4.13 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4.14 About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.4.15 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.5 System Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.5.1 Initial System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.5.2 Inspection before Initial System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.5.3 Control Parameters Setup at Initial System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.5.4 Initial System Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.5.5 Regular Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5.6 Inspection Before Regular Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5.7 Starting up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.6 Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.2 Liebert Global Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.4 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.5 Record Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.6 Optional Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.7 Torque Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.8 Detecting Trouble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.9 Reporting a Problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.10 Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.11 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.12 Limited Life Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.2 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.3 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

iii

APPENDIX A.0 UPS INTERCONNECTION KITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Appendix A.1 Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix A.1.1 General Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix A.1.2 DC Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Appendix A.2 Installing the Liebert FS With a Liebert Series 610, Liebert Series 600T

or Liebert Series 600. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Appendix A.2.1 Description - Liebert Series 610/600T/600 UPS Interconnection Kit . . . . . . . . . . . . . . 87

Appendix A.2.2 Status/Control Connections - Liebert Series 610/600T/600 UPS

Interconnection Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Appendix A.2.3 UPS Configuration - Liebert FS and Liebert Series 610, 600T or 600 . . . . . . . . . . . . . 88

Appendix A.2.4 Liebert FS Configuration - Single Liebert FS on Liebert

Series 610/600T/600 DC Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix A.2.5 Liebert FS Configuration - Multiple Liebert FS Units on Liebert

Series 610/600T/600 DC Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix A.3 Installing the Liebert FS With a Liebert Npower UPS . . . . . . . . . . . . . . . . . . . . 90

Appendix A.3.1 Description - Liebert Npower UPS Interconnection Kit . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix A.3.2 Status/Control Connections - Liebert Npower UPS Interconnection Kit . . . . . . . . . . . 91

Appendix A.3.3 UPS Configuration - Liebert FS and Liebert Npower . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix A.3.4 Liebert FS Configuration - Single Liebert FS Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix A.3.5 Liebert FS Configuration - Multiple Liebert FS Units on Liebert

Npower DC Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix A.4 Installing the Liebert FS With a Liebert Series 300 UPS . . . . . . . . . . . . . . . . . . 93

Appendix A.4.1 Description - Liebert Series 300 UPS Interconnection Kit . . . . . . . . . . . . . . . . . . . . . . 93

Appendix A.4.2 Status/Control Connections - Liebert Series 300 UPS Interconnection Kit . . . . . . . . . 94

Appendix A.4.3 UPS Configuration - Liebert FS and Liebert Series 300 . . . . . . . . . . . . . . . . . . . . . . . . 94

Appendix A.4.4 Liebert FS Configuration - Single Liebert FS on Series 300 DC Bus . . . . . . . . . . . . . . 95

Appendix A.4.5 Liebert FS Configuration - Multiple Liebert FS Units on Liebert

Series 300 DC Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Appendix A.5 Installing the Liebert FS With a Liebert HiPulse UPS . . . . . . . . . . . . . . . . . . . . 96

Appendix A.5.1 Description—HiPulse UPS Interconnection Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix A.5.2 Status/Control Connections—Liebert HiPulse UPS Interconnection Kit . . . . . . . . . . . 96

Appendix A.5.3 IKIT-A05 DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix A.5.4 UPS Configuration—Liebert FS and Liebert HiPulse . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix A.5.5 Single Liebert FS on UPS DC Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Appendix A.5.6 Single Liebert FS in Parallel with Battery Pack on UPS DC Bus . . . . . . . . . . . . . . . . 98

Appendix A.5.7 Liebert FS Configuration – Multiple Liebert FS Units . . . . . . . . . . . . . . . . . . . . . . . . . 99

APPENDIX B.0 DATA COLLECTION MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Appendix B.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B.1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B.2 DCM Installation and Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B.2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Appendix B.2.2 DCM Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Appendix B.2.3 Accessing the DCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix B.2.4 Configuring DCM System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

iv

Appendix B.3 DCM Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix B.3.1 Logging into the DCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix B.3.2 Status and Detailed Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix B.3.3 Datafiles Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix B.4 DCM Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Appendix B.4.1 DCM Troubleshooting Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Appendix B.4.2 Resetting the DCM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

APPENDIX C.0 VERSATILE INTERFACE BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix C.1 General Information—Versatile Interface Board . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix C.1.1 Versatile Interface Board Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix C.1.2 VIB Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Appendix C.2 VIB Installation and Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix C.2.1 VIB Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix C.2.2 VIB Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix C.2.3 VIB Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix C.2.4 VIB Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix C.2.5 VIB Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix C.3 VIB Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix C.3.1 VIB Operational States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix C.4 Troubleshooting the VIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix C.4.1 UIB State Not Displayed on the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix C.4.2 VIB in “Disabled” or “Not Available” State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix C.4.3 Inputs Not Recognized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix C.4.4 Outputs Not Asserted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

APPENDIX D.0 INSTALLATION DRAWINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Appendix D.1 Liebert FS Flywheel Submittal Document Matrix . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix D.2 Other Liebert FS Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

APPENDIX E.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Appendix E.1 Ground Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

APPENDIX F.0 AUXILIARY BACKUP AC POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Appendix F.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Appendix F.2 Backup AC Power Supply Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Appendix F.3 Recommended Backup Power Supply Configuration . . . . . . . . . . . . . . . . . . . . . 150

Appendix F.3.1 Operating the Liebert FS+DC in Parallel With Batteries. . . . . . . . . . . . . . . . . . . . . . 151

Appendix F.3.2 Operating the Liebert FS Without Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Appendix F.4 Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

v

FIGURES

Figure 1 Liebert FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2 Single Liebert FS unit or multiple Liebert FS units integrated into a UPS system. . . . . . . . . . . . 5

Figure 3 Liebert FS unit(s) integrated into UPS system for ride-through to backup generator. . . . . . . . . . 5

Figure 4 One or more Liebert FS units in parallel with one or more battery strings, battery

cabinets or batteries in racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

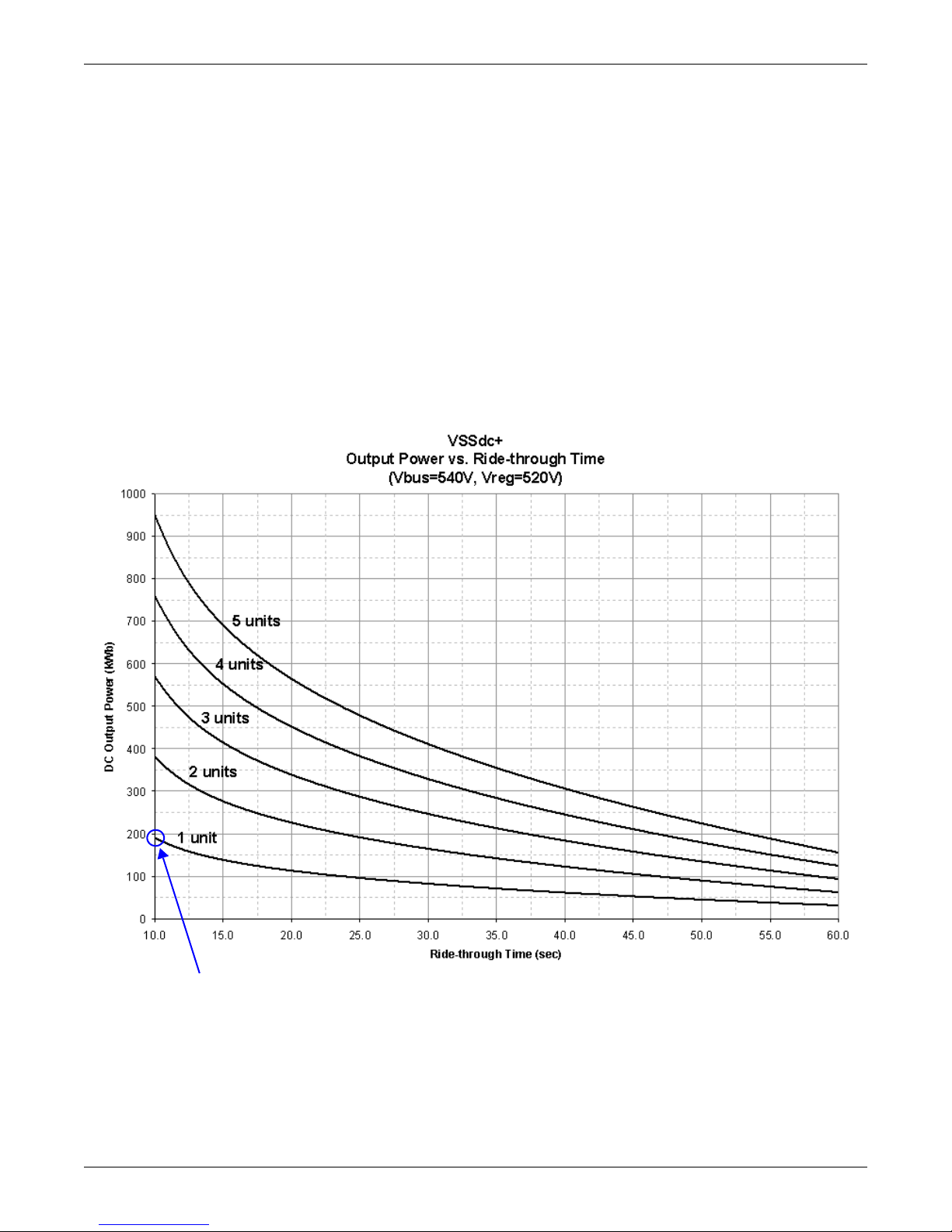

Figure 5 Liebert FS DC power duration for one or multiple units in parallel . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 Integrating a single Liebert FS unit into a UPS system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7 Integrating multiple Liebert FS units into a UPS system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8 Liebert FS shipping package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9 Removing lag bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10 Lifting the Liebert FS cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11 Removing the metal support plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12 Location of serial and model number plate (cabinet side panel removed and open door) . . . . . . 16

Figure 13 Liebert FS cabinet caster location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

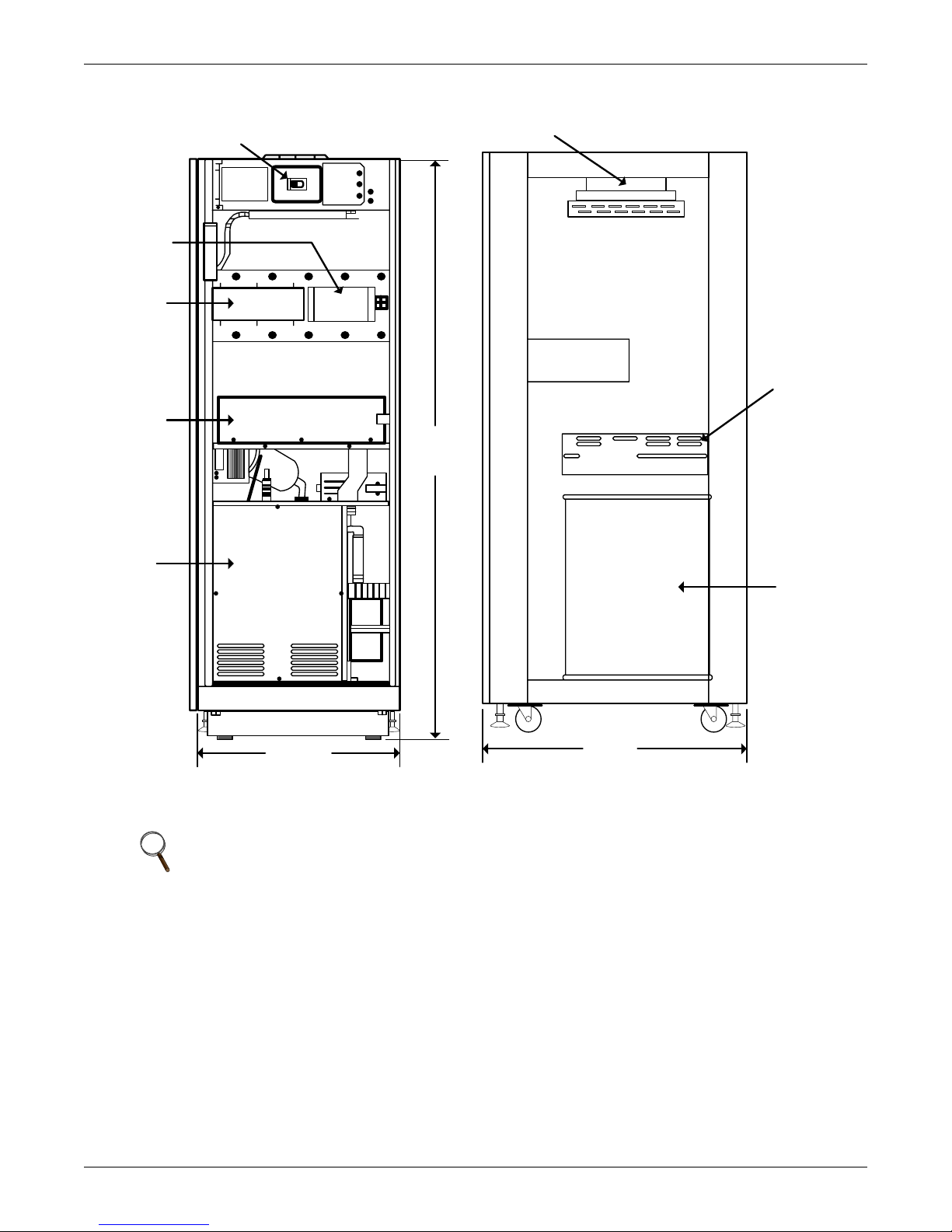

Figure 14 Dimensions, general layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15 Internal layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16 Floor mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 17 Floor mounting template layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 18 Checking hole depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 19 Inserting anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 20 Expanding anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21 Securing mounting brackets to the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 22 Mounting rear bolts—rear side of cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 23 Mounting front bolts—front side of cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 24 Bubble level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 25 Raised floor mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 26 Liebert FS cabinet with UPS interconnection kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 27 Liebert FS with circuit breaker mounting plate and access panels for DC and control

wiring connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 28 Typical circuit breaker wiring for DC connections (view from rear of circuit breaker) . . . . . . . . 27

Figure 29 Ground connection on the Liebert FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 30 Service panel location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 31 Auxiliary backup power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

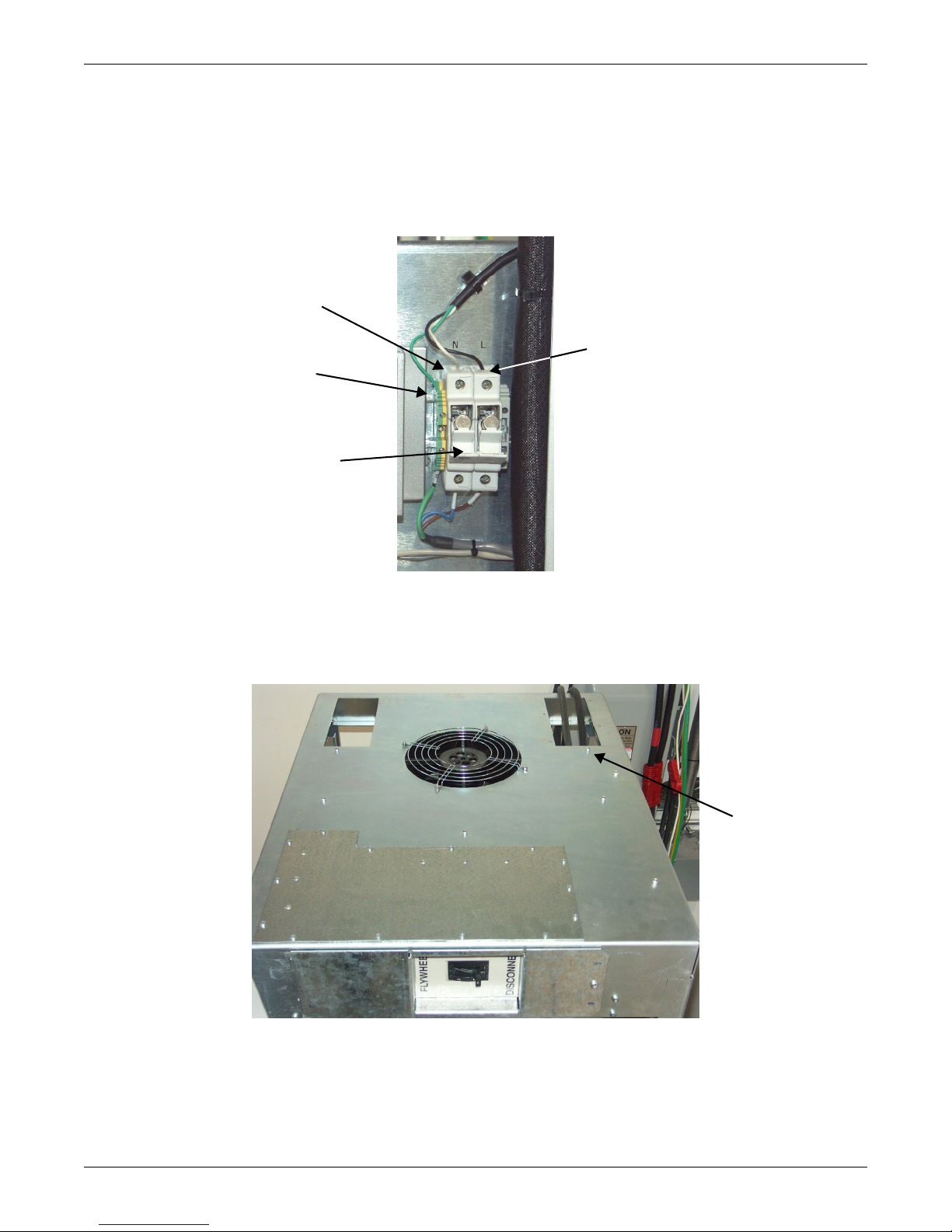

Figure 32 Auxiliary power fused disconnect with connection points for AC wire . . . . . . . . . . . . . . . . . . . . . 30

Figure 33 Top access panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 34 Remote monitoring (DCM) connections (inside cabinet front door) . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 35 Liebert FS front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 36 Electrical system schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 37 Schematic of the levitation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 38 Liebert FS flywheel module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 39 Rotating group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 40 Cross-section of the synchronous reluctance motor rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 41 Vacuum system operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 42 Schematic for the speed and temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 43 Cutaway flywheel module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 44 Voltage and Inductance curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 45 Vreg delta help screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 46 STANDBY mode diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 47 Startup mode diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 48 CHARGE mode diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 49 READY mode diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 50 DISCHARGE mode diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 51 SHUTDOWN mode diagram - shutdown after full discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 52 SHUTDOWN mode diagram - user-initiated shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 53 Typical operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

vi

Figure 54 Control panel view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 55 Main screen functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 56 Fault screen functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 57 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 58 User level main menu screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 59 READ ONLY level parameter view screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 60 USER level or above parameter edit screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 61 HELP screen for User Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 62 Graphical HELP screen for VREG DELTA1, VREG TSOC, and VREG DELTA2

Transition setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 63 USER or higher level parameter selection for view/edit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 64 VIEW menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 65 TIME/DATE set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 66 Temperature view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 67 Figure 5-14. Voltages view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 68 History view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 69 Charge history. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 70 Discharge history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 71 Discharge History, Event list screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 72 Warning history, Event list screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 73 Fault history, Event list screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 74 Vitals history view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 75 Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 76 Counters - screen 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 77 Options view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 78 Networks view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 79 Networks view, Edit DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 80 Networks view, Edit Settings (Service level). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 81 Electrical view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 82 Vitals view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 83 Password screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 84 Change password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 85 Change password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 86 ABOUT screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 87 Serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 88 Tools for USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 89 USER level menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 90 VIEW menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 91 Warning history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 92 Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 93 Warning screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 94 Fault screen descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 95 Top view of Liebert FS Cabinet with UPS interconnection kit . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 96 Circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 97 Liebert Series 610 225kVA UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 98 Liebert Series 610/600T/600 status/control terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 99 Liebert FS integrated into a Liebert Npower UPS system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 100 Liebert Series 300 UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 101 Liebert Series 300 status/control terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 102 Liebert HiPulse status/control terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 103 Circuit-breaker (open door and cabinet faceplate removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 104 Data Collection Module location, features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 105 DCM LAN connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 106 Options view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 107 Enable or disable DCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 108 Networks view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

vii

Figure 109 Networks view, turn off DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 110 Networks view, edit settings (service level). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 111 DCM screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 112 DCM setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 113 DCM status screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 114 Datafiles screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 115 Data Collection Module reset button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 116 VIB components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 117 I/O Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 118 Versatile Interface Board mounted in the Liebert FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 119 VIB screw terminal connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 120 No UVR, circuit breaker to terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 121 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 122 Electrical system block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 123 24 UVR, circuit breaker to terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 124 48 UVR, circuit breaker to terminal block wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 125 Outline drawing, Liebert FS cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 126 Control wiring, external interconnect diagram—Liebert FS cabinet to Liebert Npower

UPS module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 127 Control wiring external interconnect—Liebert FS to Liebert Series 300 . . . . . . . . . . . . . . . . . . 119

Figure 128 Control wiring—external interconnect diagram, Liebert FS cabinet to Liebert

Series 610 UPS module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 129 Control wiring—external interconnect diagram, Liebert FS cabinet to Liebert

Series 610 UPS module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 130 Elevation drawing, Liebert FS cabinet with shipping package . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 131 Elevation drawing—Liebert FS cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 132 Control wiring diagram, Liebert FS power rack system in parallel for capacity . . . . . . . . . . . . 124

Figure 133 Liebert FS cabinet with optional power terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 134 Liebert FS cabinet mechanical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 135 Elevation drawing—Liebert FS cabinet with integrated circuit breaker . . . . . . . . . . . . . . . . . . 127

Figure 136 One-line drawing, three Liebert FS systems in parallel configuration . . . . . . . . . . . . . . . . . . . . 128

Figure 137 Control wiring diagram—Liebert FS cabinet - manually operated circuit breaker . . . . . . . . . . 129

Figure 138 One-line diagram—Liebert FS systems with factory-integrated circuit breakers

with Liebert UPS module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 139 One-line diagram—single Liebert FS system with factory-integrated circuit breaker

supplying Liebert UPS module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 140 Control wiring diagram—Liebert FS - optional electrically operated circuit breaker

Liebert Npower units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 141 Two-eight paralleled Liebert FS units with factory-integrated circuit breaker in parallel

with a Liebert UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 142 One-line diagram, single Liebert FS and battery with factory-integrated circuit breaker

supplying Liebert UPS—UPS DC terminal point of common connection . . . . . . . . . . . . . . . . . . 134

Figure 143 One-line diagram, single Liebert FS and battery with factory-integrated circuit

breaker supplying Liebert UPS—UPS battery point of common connection . . . . . . . . . . . . . . . 135

Figure 144 Status/control wiring, multiple units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 145 Wiring specifications, Liebert FS and Liebert Series 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 146 Wiring specifications, Liebert FS and Liebert Npower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 147 Wiring specifications, Liebert FS and Liebert Series 610 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 148 Wiring specifications, Liebert FS and Liebert HiPulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 149 Floor mounting template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 150 System mounting kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 151 Liebert FS block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 152 Power line diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 153 UPS cable entry—bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 154 UPS cable entry—top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 155 Raised floor mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 156 A single Liebert FS+DC unit operating with a UPS in conjunction with batteries . . . . . . . . . . 151

viii

Figure 157 Multiple Liebert FS+DC units operating with a UPS in conjunction with batteries . . . . . . . . . 151

Figure 158 A single Liebert FS unit operating with a UPS and without batteries attached

to the DC bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 159 Multiple Liebert FS units operating with a UPS and without batteries attached

to the DC bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 160 Liebert FS connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

TABLES

Table 1 System information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2 General system specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3 Tightening torque for ground connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 4 Control panel keyboard layout (refer to Figure 54) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 5 Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 6 System status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 7 EEPROM parameter number ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 8 PCMC parameters, read-only and user (Liebert FS software) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 9 Control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 10 Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 11 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 12 Torque specifications (unless otherwise labeled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 13 Recommended test equipment and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 14 Projected component life, replacement schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 15 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 16 Faults—causes and responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 17 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 18 Key to UPS model interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 19 Liebert Series 610/600T/600 model ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 20 Liebert FS Software Control Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 21 Liebert FS Software Control Parameters varying with UPS size . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 22 Liebert Npower model ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 23 Liebert FS Software Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 24 Liebert FS Software Control Parameters varying with UPS size . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 25 List of Liebert Series 300 models ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 26 Liebert FS Software Control Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 27 Liebert FS Software Control Parameters varying with UPS size . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 28 Liebert HiPulse model ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 29 Liebert FS Software Control Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 30 Liebert FS Software Control Parameters varying with UPS size . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 31 Liebert FS Software Control Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 32 Liebert FS Software Control Parameters varying with UPS size . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 33 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 34 VIB I/O functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 35 Submittal documents accompanying Liebert FS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 36 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

ix

x

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation and maintenance of your Liebert FS.

WARNING

!

The installation of the Liebert FS must comply with applicable national, federal, state and

local codes.

ONLY qualified service personnel should perform maintenance on the Liebert FS

system. When performing maintenance with any part of the equipment, service personnel

and test equipment should be standing on rubber mats. The service personnel should wear

insulating shoes for isolation from direct contact with the floor (earth ground).

Never work alone, even if all power is removed from the equipment. A second person should

be standing by to assist and summon help in case an accident should occur.

Under typical operation and with all UPS doors closed, only normal safety precautions are

necessary. The area around the Liebert FS system should be kept free of puddles of water,

excess moisture and debris.

Special safety precautions are required for procedures involving handling, installation and

maintenance of the UPS system. Observe all safety precautions in this manual before

handling, installing or operating the UPS system.

This equipment contains circuits that are energized with high voltage. Only test

equipment designed for troubleshooting and for use with those voltages should be used.

Always check with an AC and DC voltmeter to ensure safety before making contact or using

tools. Even when the power is turned Off, dangerously high electric charges may exist within

the UPS.

WARNING

!

Exercise extreme care when handling Liebert FS cabinets to avoid equipment damage or

injury to personnel. Refer to Section 3.0 and Section 4.0 for equipment handling

information and installation procedures.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or

others approved for use in fighting electrical fires.

WARNING

!

Extreme caution is required when performing maintenance.

Be constantly aware that the Liebert FS contains high DC as well as AC voltages. With input

power off and the battery disconnected, high voltage at filter capacitors and power circuits

should be discharged within 30 seconds. However, if a power circuit failure has occurred, you

should assume that high voltage may still exist after shutdown. Check with a voltmeter

before making contact.

Check for voltage with both AC and DC voltmeters prior to making contact.

WARNING

!

When the Liebert FS is under power, both the operator and any test equipment must be

isolated from direct contact with earth ground and the Liebert FS chassis frame by using

rubber mats.

Some components within the cabinets are not connected to chassis ground. Any contact

between floating circuits and the chassis is a lethal shock hazard. Exercise caution that the

test instrument exterior does not make contact either physically or electrically with earth

ground.

1

CAUTION

!

Do not loosen or tamper with vacuum components and fittings.

CAUTION

!

This unit contains components sensitive to electrostatic discharge.

CAUTION

!

Do not remove plug-in printed circuit cards during operation. Improper removal of a card can

cause severe damage to the unit.

CAUTION

!

The 110/230VAC must remain connected at all times to ensure reliable backup power to

Liebert FS auxiliaries.

CAUTION

!

Do not use this unit for other than its intended use.

CAUTION

!

A qualified electrician must perform all electrical connections.

All wiring size and installation must comply with all applicable local, regional and national

regulations (e.g., National Electric Code for USA).

Safety Precautions

Read this manual thoroughly, paying special attention to the sections that apply to you, before working with the Liebert FS.

Under typical operation and with all cabinet doors closed, only normal safety precautions are necessary. The area around the Liebert FS should be kept free from puddles of water, excess moisture or

debris.

Special safety precautions are required for procedures involving handling, installation and maintenance of the Liebert FS. Observe precautions in 7.0 - Maintenance before as well as during performance of any maintenance procedure on the Liebert FS.

This equipment contains circuitry that is energized with high voltage. Only test equipment designated for troubleshooting should be used. This is particularly true for oscilloscopes. Always check

with an AC and DC voltmeter to ensure safety before making contact or using tools. Even when the

power is turned Off, dangerously high voltage may exist at the capacitor banks.

ONLY qualified service personnel should perform maintenance on the Liebert FS. When performing

maintenance with any part of the equipment under power, service personnel and test equipment

should be standing on rubber mats. The service personnel should wear insulating shoes for isolation

from direct contact with the floor (earth ground).

One person should never work alone. A second person should be standing by to assist and summon

help in case an accident should occur.

2

1.0 GENERAL SYSTEM INFORMATION

1.1 General Information

1.1.1 Safety Considerations

Read and follow the instructions in this manual before interacting with the system. This document

contains important information and instructions for your Liebert FS. All procedures defined in the

manual related to unpacking, installing and operating the unit must be followed.

Refer to this manual before contacting Liebert Global Services for technical assistance.

WARNING

!

Failure to recognize electrical hazards could prove fatal. Failure to abide by instructions

provided herein may void your warranty.

1.1.2 Requesting Assistance from Liebert

If you require assistance for any reason, contact Liebert Global Services at 1-800-LIEBERT

(1-800-543-2378). Have the following information available:

Table 1 System information

Date Purchased

Date Installed

Location

System Model Number

System Serial Number

Interconnected UPS Manufacturer

Interconnected UPS Model

Software Version; Primary *

Software Version; Secondary *

Software Version; Bootloader *

General System Information

3

1.2 General System Description

The Liebert FS is a flywheel energy storage system, a mechanical battery that stores energy in the

form of a rotating mass. This energy is immediately convertible to useful electric power.

The Liebert FS is available with a wide performance range up to 190 kW as a single unit configuration.

Figure 1 Liebert FS

General System Information

The Liebert FS is configured as a two-terminal plus ground DC flywheel power system and is used as

a functional replacement for or an availability supplement to a bank of chemical batteries for an

Uninterruptible Power System. Like a chemical battery bank, Liebert FS receives charge and float

power from the two terminal UPS DC bus and returns power to the same DC bus whenever the bus

voltage droops below a programmable threshold level.

Integrated into a UPS, the Liebert FS is used as the alternate source of power to supply DC power to

the UPS inverter if the AC supply voltage (UPS input) is outside the acceptable range. The Liebert FS

supplies power to the UPS inverter until the utility power is restored, until an alternate power source

is available, or until the Liebert FS’ energy is exhausted.

One or more Liebert FS units may be integrated into UPS and can be put in parallel as shown in

Figures 2 and 3, to achieve higher power output or higher ride-through duration.

4

General System Information

Figure 2 Single Liebert FS unit or multiple Liebert FS units integrated into a UPS system

UPS Block Diagram

UPS

Utility

Power

EMER SO

Network Power

N

Liebert FS Unit 1

AC

DC Bus

DC

Liebert

EMER SO

Network Power

N

Liebert FS Unit 2 Liebert FS Unit N

DC

Loads

AC

Liebert

EMER SO

Network Power

N

Liebert

Figure 3 Liebert FS unit(s) integrated into UPS system for ride-through to backup generator

UPS Block Diagram

Utility

Power

ATS

Backup

Generator

AC

DC Bus

DC

Loads

UPS

EMERSO

Network Power

N

DC

Liebert

EMER SO

Network Power

N

Liebert

AC

EMER SO

Network Power

N

Liebert

Liebert FS Unit 1 Liebert FS Unit 2 Liebert FS Unit N

5

General System Information

Figure 4 One or more Liebert FS units in parallel with one or more battery strings, battery cabinets or

batteries in racks

UPS Block Diagram

UPS

Utility

Power

AC

DC Bus

DC

DC

Loads

AC

EMERSON

Network Power

Liebert

FS Unit 1

Lieber t

EMERSON

Network Power

Lieber t

Liebert

FS Unit 2

1.2.1 General Specifications

Table 2 summarizes the technical specifications of the Liebert FS.

Table 2 General system specifications

Rated Power Delivery

Input Voltage (DC) 360 through 600 VDC; > 520 VDC required for 190kW

Output Voltage (DC) 350 through 590 VDC; > 510 VDC required for 190kW

Input Voltage Aux. (AC) 85 VAC – 265 VAC (47-63Hz)

Operating Temperature -20°C to 50°C (-4°F to 122°F)

Non-Operating Temperature -20°C to 80°C (-4°F to 176°F)

Dimensions (W x D x H) 63 x 83 x 180 cm (25 x 33 x 71 in)

Total Weight 590 kg (1,300 lb)

EMERSON

Network Power

Liebert

Lieber t

Battery 1

FS Unit N

Dependent upon the duration required;

refer to Figure 5

Battery 2 Battery N

For more-detailed technical specifications, refer to Technical specifications on page 148.

6

1.2.2 Features and Benefits

The Liebert FS provides clean constant DC output to the DC bus, at the user-selected, regulated voltage, until the stored energy is depleted. See Figure 5 for a graphic representation of the performance

power and duration curves of single and paralleled unit combinations.

Key Technological Features

• Active magnetic bearings

• Internal, integrated vacuum system

• Synchronous reluctance motor-generator

• Fiber composite flywheel

• Unique patented safety system

Key Customer Benefits

• High reliability

• Significantly increased power supply reliability

• Low total cost of ownership

• Operational flexibility

• Environmentally friendly

• Easy to install and easy to operate.

• Low standby losses

• Small footprint

• Lightweight

• Reliable, cost effective power systems for UPS ride-through needs

General System Information

1.2.3 Applicable Standards and Certification

For distribution in North America, the Liebert FS is listed to the following Underwriter’s Laboratory

(UL) applicable requirements:

• UL 508, Standard for Safety for Electrical Industrial Control Equipment;

• UL 1004, Standard for Safety for Electric Motors;

• UL 1248, Standard for Safety for Engine-Generator Assemblies;

The Liebert FS is designed in accordance with the applicable sections of the requirements published by:

• National Fire Protection Association (NFPA)/National Electric Code (NEC)

• National Electrical Manufacturer's Association (NEMA)

• Occupational Safety & Health Administration (OSHA)

The Liebert FS is also listed to the following Canadian Standards as determined by UL (cUL):

• CSA-C22.2 No. 100-04, “Motors and Generators,”

• CSA-C22.2 No. 14-95, “Industrial Control Equipment,”

The "Uniform Building Code (UBC) Zone 4" certification requirements.

7

For distribution in Europe, the Liebert FS is CE-marked and meets the applicable requirements of

the following European directives:

“Low Voltage Directive” 73/23/EEC and its amendments by the directive 93/68/EEC;

“Machinery Directive” 98/037/EEC and its amendments by the directive 98/79/EEC;

• IEC/EN 60439-1:1999—”Low-voltage switchgear and control gear assemblies Part 1: Typetested and partially type-tested assemblies”

• IEC/EN 60204-1:1997—”Safety of machinery - Electrical equipment of machines Part 1: General requirements”

• EN 1127-1:1997—”Explosive atmospheres: Explosion prevention and protection Part 1: Basic

concepts and methodology”

• Machinery Directive Annex 1—”Essential Health and Safety Requirements Relating to the

Design and Construction of Machinery and Safety Components”

“Electromagnetic Compatibility (EMC) Directive” 89/336/EEC and its amendments by the directives 92/31/EEC and 93/68/EEC.

Figure 5 Liebert FS DC power duration for one or multiple units in parallel

1900 kW-sec delivered

GT model, 510 VDC, with filter

General System Information

10 seconds at 190kW (max. power)

@ 510 VDC min

kWb = Refers to Kilowatts on the DC bus of the UPS system

Discharge Voltage = 510VDC

The Liebert FS is integrated into UPS systems as shown in Figures 2 through 4 and Figures 6

and 7.

8

Figure 6 Integrating a single Liebert FS unit into a UPS system

UPS Block Diagram

Bypass

Breaker

Bypass

Static

Switch

General System Information

GRID

Utility

Feeder

Breaker

UPS

Input

Breaker

UPS

Rectifier

EMERSON

Network Power

UPS

DC

Bus

Lieber t

UPS

Output

Breaker

CRITICAL

AC LOADS

Liebert FS

Several Liebert FS units can be put in parallel to achieve higher power output and higher ridethrough duration (see Figure 7). One or more Liebert FS units may also be connected in parallel with

a UPS battery plant (valve- regulated or wet cells) to provide an overall incremental reliability and

life improvement for the DC battery plant. In this situation, the Liebert FS unit would be connected

in parallel with the battery plant (through its own disconnect device) to the UPS DC Bus.

Figure 7 Integrating multiple Liebert FS units into a UPS system

Bypass

GRID

Utility

Feeder

Breaker

Bypass Breaker

UPS

Input

Breaker

EMERSON

Network Power

Liebert FS

Unit #1

Static

Switch

UPS

Rectifier

Liebert

UPS Block Diagram

UPS

DC Bus

EMERSON

Network Power

Liebert FS

Unit #2

Lieber t

UPS

Inverter

EMERSON

Liebert FS

Network Power

Unit #N

UPS

Output

Breaker

Lieber t

CRITICAL

AC LOADS

9

2.0 SITE PREPARATION

Site preparation for the Liebert FS is minimal. If a UPS system is already installed, the only requirements are to properly:

• Place the unit in relation to walls, ceiling and other equipment and

• Fasten the unit to the floor.

CAUTION

!

The following sections should be read thoroughly before proceeding with site preparation for

installing the Liebert FS.

NOTE

All drawings referred to in this section are in Appendix D.0 - Installation Drawings.

2.1 System Location

Choose a location for the Liebert FS that offers:

• Easy connection to inputs, outputs and auxiliary equipment

• Enough space to service the Liebert FS

• Air circulation sufficient to expel heat produced by Liebert FS

• Protection against moisture and excessive humidity (not to exceed 95% non-condensing)

• Protection against excessive dust and other particulate matter

• Compliance with fire prevention regulations and practices

• Operating environment temperature of -4°F to 122°F (-20°C to 50°C)

Site Preparation

2.2 Environmental Considerations

Place the system in a clean, dust-free environment. Air must be free to circulate around the cabinet(s). The system pulls air through the front of the Liebert FS and exhausts it out the top for cooling.

If the unit must be located in a dusty environment, Liebert recommends installing an optional air filter, which mounts on the lower inside of the Liebert FS door.

Adequate ventilation, including air conditioning if necessary, must be provided to limit heat accumulation. The ambient temperature for the unit must be from -4°F to 122°F (-20°C to 50°C). Avoid placing the unit in direct sunlight or near other heat sources.

There is a 32°F (0°C) minimum ambient temperature requirement for starting up the unit. Once the

unit has been running for some time, it will keep itself warm enough in ambient temperatures as low as

-4°F (-20°C).

Humidity is not to exceed 95% (non-condensing).

10

2.3 Flooring Requirements

2.3.1 Floor Loading

The Liebert FS should be mounted on a finished surface, such as concrete, block, brick or wood. The

floor must be strong enough to support the equipment load and suitable for installation of an anchoring kit with vertical floor loading properly calculated (assume 2,000 PSI or 140 kg/cm

caster wheels; this includes safety factors).

• When installing on a concrete, masonry or stone floor, use the factory-supplied masonry fasteners

(anchors). The fastener manufacturer’s allowable shear load (parallel to floor) for these fasteners

is 2,030 lb. (9 kN) when mounted in normal-weight concrete (2,000 to 3,000 PSI; 140-210 kg/cm

of at least 3 in. (7.6cm) thickness.

• If installing on a floor consisting of a material other than normal-weight concrete as described

above, the mounting should be capable of sustaining a shear load (parallel to floor) of at least

1,500 lb. (6.7 kN) for each of the four mounting points.

• If installing on a raised floor that is less than 2 in. (5cm) thick or constructed of a material not

appropriate for the masonry fasteners provided or lag screw engagement, mount using through

bolts with nuts and large diameter washers as shown in Figure 155.

Full details for mounting the cabinet are found in 4.1 - Cabinet Floor Mounting.

NOTE

The above loads (both the fastener manufacturer load and the minimum mounting load)

include the required safety factors.

Site Preparation

2

contact load at

2

)

2.3.2 Floor-Space Occupation

The Liebert FS cabinet requires a floor space of 23" wide by 33" deep (63 x 83cm), resulting in a footprint of 5.7 square feet (0.5m

2

2.3.3 Clearances

The Liebert FS installation requires a ceiling height of at least 7 ft. (214cm).

The unit occasionally vents air out of the top. Loose ceiling tiles above the unit may be moved by the

airflow. Ample clearance to access the cable connection at the top of the unit must also be provided.

All system electrical connections are to be routed through the top or side of the cabinet.

A 36" (91cm) clearance is required in the front of the unit for National Electrical Code (NEC) compliance.