Page 1

LIQ-MAN-MCL, Rev E

Rosemount™ MCL-220

Monochloramine System with Rosemount 1056 Transmitter

Manual

July 2017

Page 2

Essential instructions

Read this page before proceeding!

Your purchase from Rosemount has resulted in one of the finest instruments available for your particular application. These

instruments have been designed and tested to meet many national and international standards. Experience indicates that the

instrument's performance is directly related to the quality of the installation and knowledge of the user in operating and

maintaining the instrument. To ensure continued operation the the design specifications, read this manual thoroughly before

proceeding with installation, commissioning, operation, and maintenance of this instrument. If this equipment is used in a manner

not specified by the manufacturer, the protection provided by it against hazards may be impaired.

• Failure to follow the proper instructions may cause any one of the following situations to occur: loss of life, personal injury,

property damage, damage to this instrument, and warranty invalidation.

• Ensure that you have received the correct model and options from your purchase order. Verify that this manual covers your

model and options. If not, call 1 800 999 9307 to request the correct manual.

• For clarification of instructions, contact your Rosemount representative.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Use only qualified personnel to install, operate, update, program, and maintain the product.

• Install your equipment as specified in the installation instructions of this manual. Follow appropriate local and national

codes. Only connect the product to the electrical and pressure sources specified in this manual.

• Use only factory documented components for repair. Tampering or unauthorized substitution of parts and procedures can

affect the performance and cause unsafe operation of your process.

• All equipment doors must be closed and protective covers much be in place unless qualified personnel are performing

maintenance.

• If this equipment is used in a manner not specified by the manufacturer, the protection provided by it against hazards may

be impaired.

WARNING!

RISK OF ELECTRICAL SHOCK

Equipment protected throughout by double insulation.

• Installation of cable connections and servicing of this product may require access to shock and high voltage levels.

• Main power and relay contacts wired to separate power sources must be disconnected before servicing.

• Do not operate or energize instrument with the case open!

• Signal wiring connected in this box must be rated at least 240 V.

• Non-metallic cable strain reliefs do not provide grounding between conduit connections! Use grounding type bushings and

jumper wires.

• Unused cable conduit entries must be securely sealed by non-flammable closures to provide enclosure integrity in

compliance with personal safety and environmental protection requirements. Unused conduit openings must be sealed with

NEMA 4X or IP65 conduit plugs to maintain the ingress protection rating (NEMA 4X).

• Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70) and/or any other applicable

national or local codes.

• Operate only with front and rear panels fastened and in place over terminal area.

• Safety and performance require that this instrument be connected and properly grounded through a three-wire power

source.

• Proper relay use and configuration is the responsibility of the user.

WARNING!

This product is not intended for use in the light industrial, residential, or commercial environments per the instrument's certification

to EN50081-2.

CAUTION!

This product generates, uses, and can radiate radio frequency energy and thus can cause radio communication interference.

Improper installation or operation may increase such interference. As temporarily permitted by regulation, this unit has not been

tested for compliance within the limits of Class A computing devices, pursuant to Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection against such interference. Operation of this equipment in a residential area may cause

interference, in which case the user at his own expenace, will be required to take whatever measures may be required to correct the

interference.

Page 3

About this document

This manual contains instructions for installation and operation of the Rosemount

MCL-220 monochloramine system.

The following list provides notes concerning all revisions of this document.

Rev level Date Notes

A 09/08 This is the initial release of the product manual. This manual has been reformatted to

reflect the Emerson documentation style and updated to reflect any change in the product offering.

B 08/09 Updated ISO/DNV approval.

C 09/11 Updated Chapter 2, Table 8-2, and Figure 8-2. Updated Troubleshooting sections

Section 9.5.5, Section 9.5.6, Section 9.6, and Section 9.7.

D 03/12 Updated addresses - mail and web.

E 07/17 Changed instances of analyzer to transmitter. Updated formatting to align with new

branding guidelines. Updated addresses on back page.

Page 4

Page 5

Contents

Contents

Chapter 1 Quick Start guide ............................................................................................................. 1

Chapter 2 Description and Specifications ..........................................................................................5

2.1 Features ......................................................................................................................................... 5

2.2 Specifications .................................................................................................................................6

2.3 Ordering information ..................................................................................................................... 7

Chapter 3 Installation .......................................................................................................................9

3.1 Unpacking and inspection .............................................................................................................. 9

3.1.1 Rosemount MCL-220 ....................................................................................................... 9

3.2 Installation ..................................................................................................................................... 9

3.2.1 General information ........................................................................................................ 9

3.2.2 Sample requirements .................................................................................................... 10

3.2.3 Mounting, inlet, and drain connections ......................................................................... 10

3.2.4 Electrical connections .................................................................................................... 11

3.2.5 Installing the sensor .......................................................................................................11

Chapter 4 Wiring ........................................................................................................................... 13

4.1 Power, alarm, and output wiring .................................................................................................. 13

4.1.1 Power ............................................................................................................................ 13

4.1.2 Analog output wiring ..................................................................................................... 13

4.1.3 Alarm wiring .................................................................................................................. 14

4.2 Sensor wiring ............................................................................................................................... 15

Chapter 5 Display and operation .................................................................................................... 17

5.1 Display ......................................................................................................................................... 17

5.2 Keypad .........................................................................................................................................18

5.3 Programming the transmitter - tutorial ........................................................................................ 20

5.4 Security ........................................................................................................................................22

5.4.1 How the security code works ......................................................................................... 22

5.4.2 Assigning security codes ................................................................................................22

5.4.3 Bypassing security codes ............................................................................................... 22

5.5 Using hold ....................................................................................................................................23

5.5.1 Purpose ......................................................................................................................... 23

5.5.2 Using the hold function ................................................................................................. 23

5.6 Configuring the main display ........................................................................................................24

Chapter 6 Programming the transmitter ........................................................................................ 27

6.1 General ........................................................................................................................................ 27

6.2 Default settings ............................................................................................................................27

6.3 Configuring, ranging, and simulating outputs .............................................................................. 29

6.3.1 Purpose ......................................................................................................................... 29

6.3.2 Definitions ..................................................................................................................... 29

6.3.3 Procedure - configure outputs ....................................................................................... 30

6.3.4 Procedure - ranging outputs .......................................................................................... 31

6.3.5 Procedure - simulating outputs ......................................................................................32

6.4 Configuring alarms and assigning setpoints ................................................................................. 34

6.4.1 Purpose ......................................................................................................................... 34

6.4.2 Definitions ..................................................................................................................... 34

Instruction Manual i

Page 6

Contents

6.4.3 Procedure - configuring alarms and assigning setpoints ................................................ 36

6.4.4 Procedure - simulating alarms ....................................................................................... 37

6.4.5 Procedure - synchronizing timers ...................................................................................39

6.5 Configuring the measurement ..................................................................................................... 40

6.5.1 Purpose ......................................................................................................................... 40

6.5.2 Definitions - chlorine ..................................................................................................... 40

6.5.3 Procedure - configuring the measurement .................................................................... 40

6.6 Configuring temperature related settings .................................................................................... 41

6.6.1 Purpose ......................................................................................................................... 41

6.6.2 Definitions ..................................................................................................................... 41

6.6.3 Procedure - configuring temperature related settings ................................................... 42

6.7 Configuring security settings ........................................................................................................43

6.7.1 Purpose ......................................................................................................................... 43

6.7.2 Procedure - configuring security settings ....................................................................... 43

6.8 Resetting the transmitter ............................................................................................................. 44

6.8.1 Purpose ......................................................................................................................... 44

6.8.2 Procedure - resetting the transmitter ............................................................................ 44

Chapter 7 Calibration ..................................................................................................................... 47

7.1 Introduction .................................................................................................................................47

7.2 Calibrating temperature ...............................................................................................................47

7.2.1 Purpose ......................................................................................................................... 47

7.2.2 Procedure ...................................................................................................................... 47

7.3 Calibration - monochloramine ......................................................................................................49

7.3.1 Purpose ......................................................................................................................... 49

7.3.2 Procedure - zeroing the sensor ...................................................................................... 50

7.3.3 Procedure - calibrating the sensor ..................................................................................52

7.4 Calibration - analog outputs ......................................................................................................... 54

7.4.1 Purpose ......................................................................................................................... 54

7.4.2 Procedure ...................................................................................................................... 54

Chapter 8 Maintenance .................................................................................................................. 57

8.1 Transmitter .................................................................................................................................. 57

8.2 Monochloramine sensor ...............................................................................................................57

8.2.1 General ..........................................................................................................................57

8.2.2 Cleaning the membrane ................................................................................................ 58

8.2.3 Replacing the electrolyte solution and membrane ......................................................... 58

8.3 Constant head flow controller ...................................................................................................... 60

8.3.1 General ..........................................................................................................................60

8.3.2 Cleaning the flow controller ...........................................................................................60

8.3.3 Other maintenance ....................................................................................................... 60

Chapter 9 Troubleshooting ............................................................................................................ 63

9.1 Overview ......................................................................................................................................63

9.2 Using the diagnostic feature .........................................................................................................63

9.3 Troubleshooting when a Fault message is showing ...................................................................... 64

9.3.1 Main Board CPU, Main Board Factory Data, and Main Board User Data errors ................. 65

9.3.2 Hardware Error .............................................................................................................. 65

9.3.3 Sensor Board Unknown, Sensor Board HW (Hardware) or SW (Software) Mismatch, or

Sensor Board Not Communicating

9.3.4 Sensor Incompatible ...................................................................................................... 65

9.3.5 Sensor CPU Error ............................................................................................................66

9.3.6 Sensor RTD Open ...........................................................................................................66

.................................................................................65

ii Rosemount MCL

Page 7

Contents

9.3.7 Sensor 1 Not Detected ...................................................................................................66

9.3.8 Sensor Factory Data, Sensor Board User Data, and Sensor EEPROM Write errors ............ 67

9.3.9 Sensor ADC error ........................................................................................................... 67

9.3.10 Sensor RTD Out of Range ...............................................................................................67

9.4 Troubleshooting when a Warning message is showing .................................................................68

9.4.1 Sensor Need Factory Cal ................................................................................................ 68

9.4.2 Sensor Negative Reading ............................................................................................... 68

9.4.3 Sensor RTD Sense Open ................................................................................................. 68

9.4.4 Sensor Temperature High or Low ...................................................................................69

9.5 Troubleshooting when no error message is showing .................................................................... 69

9.5.1 Zero current is too high. ................................................................................................ 69

9.5.2 Zero current is unstable. ................................................................................................ 70

9.5.3 Sensor can be calibrated, but the current is too low. ...................................................... 70

9.5.4 Process readings are erratic. .......................................................................................... 71

9.5.5 Readings drift. ............................................................................................................... 71

9.5.6 Sensor does not respond to changes in monochloramine level. ..................................... 72

9.5.7 Readings are too low. .................................................................................................... 72

9.6 Troubleshooting when no error message is showing - general ......................................................73

9.6.1 Difference between transmitter and standard thermometer is greater than 3 °C. .......... 73

9.6.2 Current output too low .................................................................................................. 74

9.6.3 Alarm relays don't work. ................................................................................................ 74

9.6.4 Bubbles trapped against membrane. ............................................................................. 74

9.7 Simulating inputs ......................................................................................................................... 74

9.8 Simulating temperature ...............................................................................................................75

9.8.1 General ..........................................................................................................................75

9.8.2 Simulating temperature ................................................................................................ 75

Instruction Manual iii

Page 8

Contents

iv Rosemount MCL

Page 9

1 Quick Start guide

For Rosemount MCL-220 Monochloramine System

Prerequisites

Refer to Chapter 3 for installation instructions and Chapter 4 for wiring instructions.

Procedure

1. Once connections are secured and verified, apply power to the transmitter.

When the transmitter is powered up for the first time, Quick Start screens appear..

Using Quick Start is easy.

a. A backlit field shows the position of the cursor.

b. To move the cursor left or right, use the keys to the left or right of the ENTER key.

To scroll up or down or to increase or decrease the value of a digit, use the keys

above and below the ENTER key. Use the left and right keys to move the decimal

point.

c. Precc ENTER to store a setting. Press EXIT to leave without storing changes.

Pressing EXIT also returns the display to the initial Quick Start screen.

d. A vertical black bar with a downward pointing arrow on the right side of the

screen means there are more items to display. Continue scrolling down to

display all the items. When you reach the bottom of the list, the arrow points up.

Quick Start guide

2. Choose the desired language. Scroll down to display more choices.

3. The next step is to configure sensor 1. Sensor 1 is the total chlorine sensor. The

screen has two control boxes.

For measurement, choose Total chlorine.

a.

b. Choose the desired units, mg/L or ppm.

4. Choose Monochloramine for sensor 1 (S1).

Instruction Manual 1

Page 10

Quick Start guide

5. Choose the desired units for chlorine.

6. Choose the desired temperature units.

The main display appears. The outputs and alarms (if an alarm board is present) are

assigned to default values.

7.

To change outputs, alarms, and other settings, go to the main menu and choose

Program. Follow the prompts.

A menu tree is on the following page. To calibrate the sensor, refer to Section.

2 Rosemount MCL

Page 11

Quick Start guide

Instruction Manual 3

Page 12

Quick Start guide

4 Rosemount MCL

Page 13

Description and Specifications

2 Description and Specifications

2.1 Features

The Rosemount MCL monochloramine system is intended for measuring monochloramine

in fresh water.

This system uses a membrane-covered amperometric sensor. A polarizing voltage applied

to a gold mesh cathode behind the membrane destroys the monochloramine diffusing

through the membrane and keeps the concentration of monochloramine in the sensor

equal to zero. The current generated by the cathode reaction is proportional to the rate of

diffusion of monochloramine through the membrane. Because the concentration of

monochloramine in the sensor is zero, the diffusion rate and the current are proportional

to the concentration of monochloramine in the sample.

Diffusion rate also depends on membrane permeability, which is a function of

temperature. An RTD in the sensor continuously measures the temperature of the sample,

and the transmitter automatically corrects the raw sensor current for temperature

changes.

Maintenance is fast and easy. Replacing a membrane requires no special tools or fixtures. A

screw cap holds the pre-tensioned membrane in place. Replacing the electrolyte solution

takes only minutes.

The Rosemount MCL-220 system includes an easy-to-use Rosemount 1056 transmitter

that features two fully programmable 4-20 mA outputs and four fully programmable

relays. The large back-lit display allows you to read monochloramine concentration at a

glance.

A constant head overflow sampler ensures correct sample flow to each sensor.

Stable monochloramine standards do not exist. The monochloramine sensor must be

calibrated using the results of a laboratory test run on a grab sample.

Instruction Manual 5

Page 14

Description and Specifications

2.2 Specifications

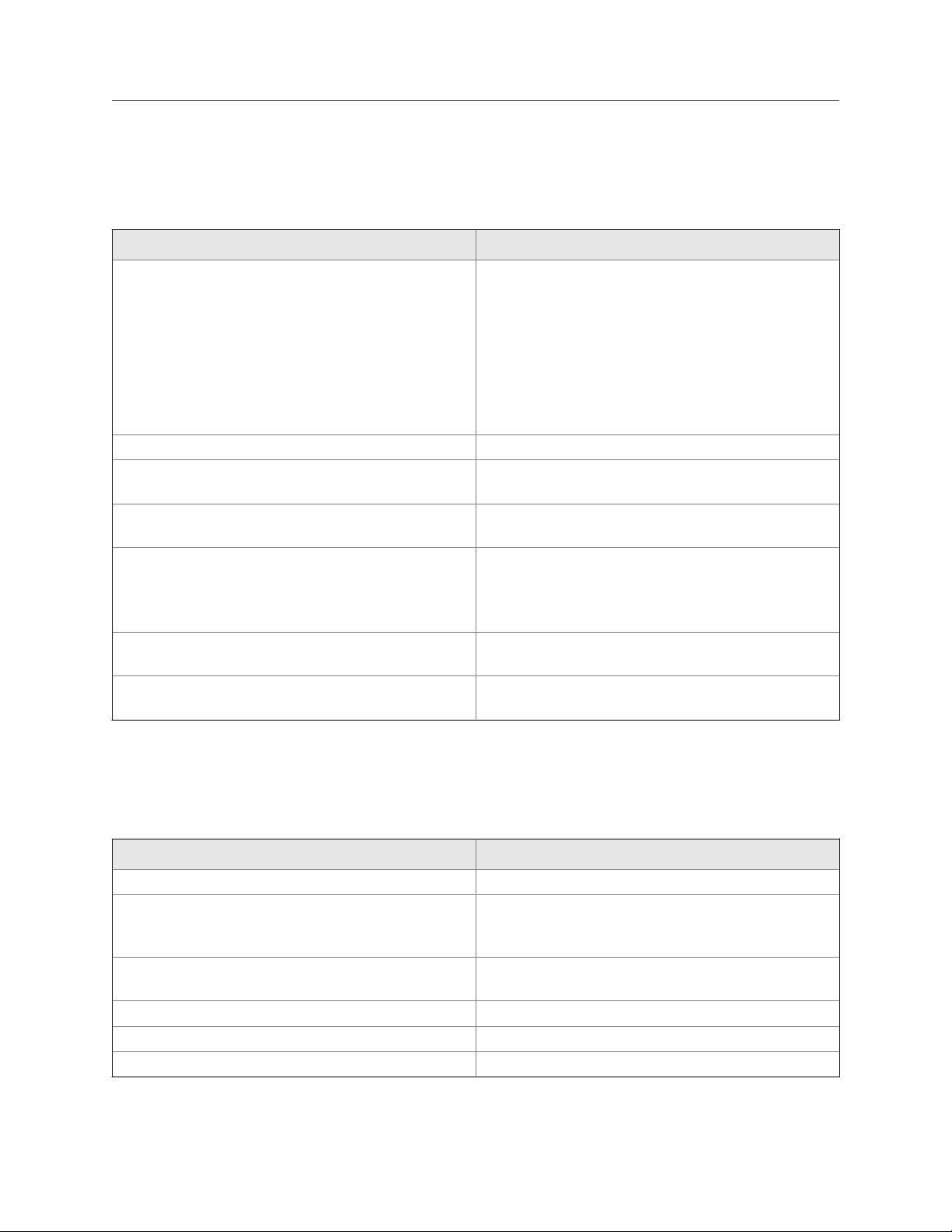

General SpecificationsTable 2-1:

Physical characteristics Specifications

Sample requirements • Pressure: 3 to 65 psig (122 to 549 kPa abs). A check

valve in the inlet prevents the sensor flow cells from

going dry if sample flow is lost. The check valve opens

at 3 psig (122 kPa abs). If the check valve is removed,

minimum pressure is 1 psig (108 kPa abs).

• Temperature: 0 to 50 °C (32 to 122 °F)

• Minimum flow: 3 gal/hr (11 L/hr)

• Maximum flow: 80 gal/hr (303 L/hr); high flow causes

the overflow tube to back up.

Sample conductivity > 10 µS/cm at 25 °C (77 °F)

Process connection 1/4 in. OD tubing compression fitting (can be removed and

replaced with barbed fitting for soft tubing).

Drain connection 3/4 in. barbed fitting. Sample must drain to open atmos-

phere.

Wetted parts Overflow sampler: acrylic, nylon, polycarbonate, polyester,

silicone

Monochloramine sensor: Noryl

(3)

tex

. PFTE gold mesh cathode (not normally wetted)

Response time to step change in monochloramine concentration

Weight/shipping weight 10 lb/13 lb (4.5 kg/6.0 kg) (rounded to the nearest 1 lb

(1) Noryl is a registered trademark of General Electric.

(2) Viton is a registered trademark of E.I. duPont de Nemours & Co.

(3) Zitex is a registered trademark of Performance Plastic Corp.

<60 sec to 95% of final reading for inlet sample flow of 17

gph (64 L/hr)

[0.5 kg])

(1)

, Viton

(2)

, silicone, and Zi-

Sensor SpecificationsTable 2-2:

Physical characteristics Specifications

Range 0 to 6 ppm as Cl2. For higher ranges, consult the factory.

pH range Response is practically independent of pH between pH 7.0

and 10.0. Sensor current at pH 10.0 is within 5% of sensor

current at pH 7.0.

Accuracy Accuracy depends on the accuracy of the chemical test

used to calibrate the sensor.

Linearity 2% (typ.)

Electrolyte volume 25 mL (approx.)

Electrolyte life 2 months (approx.)

6 Rosemount MCL

Page 15

Description and Specifications

Rosemount 1056 Transmitter SpecificationsTable 2-3:

Physical characteristics Specifications

Case Polycarbonate NEMA 4X/CSA 4 IP65)

Conduit openings Accepts PG13.5 or 1/2 in. conduit fittings

Languages English, French, German, Italian, Spanish, Portuguese, and

Chinese

Ambient temperature and humidity 0 to 55 °C (321 to 131 °F); relative humidity 5 to 95% (non-

condensing)

Storage temperature -20 to 60 °C (-4 to 140 °F)

Power 84 to 265 Vac, 47.5 to 65.0 Hz, switching, 15 W.

Equipment protected by double insulation.

RFI/EMI

LVD

Outputs Two 4-20 mA or 0-20 mA isolated outputs. Continuously

Alarms Four alarm relays. Any relay can be configured as a fault

Relays Form C, SPDT, epoxy sealed

Relay contact ratings

Terminal connections rating Power connector (3 leads): 18-12 AWG wire size. Current

Hazardous location approvals For more information, refer to the Rosemount 1056 prod-

EN-61326

EN-61010-1

adjustable. Linear or logarithmic. Maximum load 550 Ω.

Output dampening is user-adjustable.

alarm instead of a process alarm. Each relay can be configured independently, and each can be programmed with interval timer settings.

5A at 28 Vdc or 300 Vac (resistive)

1/8 HP at 120/240 Vac

output connectors (2 leads): 24-16 AWG wire size. Alarm

relay terminal blocks: 18-16 AWG wire size.

uct data sheet. Approvals apply to the transmitter only.

The MCL is not suitable for use in hazardous areas.

2.3 Ordering information

The Rosemount MCL-220 is a complete system for the determination of monochloramine

in water. It consists of a monochloramine sensor, Rosemount 1056 transmitter, Variopol

cable, and constant head overflow cup to control sample flow. All components are

mounted on a backplate, and the cable is pre-wired to the transmitter. Three replacement

membranes and a 4-oz bottle of electrolyte solution are shipped with the sensor.

Instruction Manual 7

Page 16

Description and Specifications

Transmitter model Description

1056-03-24-38-AN Rosemount 1056 transmitter, single input (monochlora-

Sensor model Description

499ACL-03-54-VP Monochloramine sensor with Variopol connector

Sensor cable Description

23747-04 Interconnecting cable, Variopol for Rosemount 499ACL

Part number Description

9240048-00 Tag, stainless steel (specify marking)

Component PartsTable 2-4:

mine), alarm relays, analog output, 115/230 Vac

sensor, 4 ft

AccessoriesTable 2-5:

8 Rosemount MCL

Page 17

3 Installation

3.1 Unpacking and inspection

Complete the following steps when you unpack your instrument.

1. Inspect the shipping container. If there is damage, contact the shipper immediately

for instructions.

2. Save the box.

3. If there is no apparent damage, unpack the container.

4. Ensure that all items shown on the packing list are present. If items are missing,

notify Rosemount immediately.

3.1.1 Rosemount MCL-220

The Rosemount MCL-220 consists of the following items mounted on a back plate.

1. The Rosemount 1056-03-24-38-AN with sensor cable attached.

2. Constant head overflow sampler with flow cell for monochloramine sensor.

3. The monochloramine sensor (Rosemount 499ACL-03-54-VP), three membrane

assemblies, and a bottle of electrolyte solution are in a separate package.

Installation

3.2 Installation

3.2.1 General information

1. Although the system is suitable for outdoor use, do not install it in direct sunlight or

in areas of extreme temperature.

CAUTION!

HAZARDOUS AREAS

The Rosemount MCL is not suitable for use in hazardous areas.

2. To keep the transmitter enclosure watertight, install plugs (provided) in the unused

conduit openings.

3. Install the system in an area where vibrations and electromagnetic and radio

frequency interference are minimized or absent.

4. Keep the transmittter and sensor wiring at least one foot from high voltage

conductors. Be sure there is easy access to the transmitter and sample conditioning

system.

5. Be sure there is easy access to the transmitter and sensor.

Instruction Manual 9

Page 18

Installation

3.2.2 Sample requirements

Be sure the sample meets the following requirements:

1. Temperature: 0 to 50 °C (32 to 122 °F)

2. Pressure: 3 to 65 psig (122 to 549 kPa abs)

3. Minimum flow: 3 gal/hr (11 L/hr)

3.2.3 Mounting, inlet, and drain connections

The Rosemount MCL-220 is intended for wall mounting only. Refer to Figure 3-1 for details.

The sensor screws into the flow cell adapter.

Rosemount MCL-220 Monochloramine SystemFigure 3-1:

A 1/4 in. OD tubing compression fitting is provided for the sample inlet. If desired, the

compression fitting can be removed and replaced with a barb fitting. The inlet fitting

screws into a 1/4 in. FNPT check valve. The check valve prevents the sensor flow cell from

going dry if sample flow is lost.

The sample drains through a 3/4 in. barbed fitting.

Attach a piece of soft tubing to the fitting and allow the waste to drain to open

1.

atmosphere. Do not restrict the drain line.

10 Rosemount MCL

Page 19

2. Remove the foam packing insert between the outer tube and the inner overflow

tube.

3. Adjust the sample flow until the water level is even with the central overflow tube

and excess water is flowing down the tube.

3.2.4 Electrical connections

Refer to Section 4.1 for details.

3.2.5 Installing the sensor

The Rosemount MCL is provided with the sensor cable pre-wired to the transmitter. The

terminal end of the sensor is keyed to ensure proper mating with the cable receptacle.

1. Once the key has slid into the mating slot, tighten the connection by turning the

knurled ring clockwise.

2. Screw the sensor into a plastic fitting, which is held in the flow cell by a union nut.

Do not remove the protective cap on the sensor until ready to put the sensor in

service.

Installation

Instruction Manual 11

Page 20

Installation

12 Rosemount MCL

Page 21

4 Wiring

4.1 Power, alarm, and output wiring

WARNING!

RISK OF ELECTRICAL SHOCK

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70)

and/or any other applicable national or local codes.

4.1.1 Power

Wire AC mains power supply to the power supply board, which is mounted vertically on

the left hand side of the transmitter enclosure.

The power connector is at the top of the board.

Procedure

Wiring

1. Unplug the connector from the board and wire the power cable to it.

Lead connections are marked on the connector. (L is live or hot; N is neutral; the

ground connection has the standard symbol.)

2. Provide a switch or breaker to disconnect the transmitter from the main power

supply.

3. Install the switch or breaker near the transmitter and label it as the disconnecting

device for the transmitter.

4.1.2 Analog output wiring

Two analog current outputs are located on the main circuit board, which is attached to the

inside of the enclosure door.

Figure 4-1 shows the location of the terminals. The connectors can be detached for wiring.

TB-1 is output 1. TB-2 is output 2. Polarity is marked on the circuit board.

Instruction Manual 13

Page 22

Wiring

Analog output connectionsFigure 4-1:

The analog outputs are on the main board near the hinged end of the enclosure door.

For best EMI/RFI protection, use shielded output signal cable enclosed in earth-grounded

metal conduit.

Keep output signal wiring separate from power wiring. Do not run signal and power or

relay wiring in the same conduit or close together in a cable tray.

4.1.3 Alarm wiring

The alarm relay terminal strip is located just below the power connector on the power

supply board.

See Figure 4-2.

14 Rosemount MCL

Page 23

Wiring

Alarm relay connectionsFigure 4-2:

Keep alarm relay wiring separate from signal wiring. Do not run signal and power or relay

wiring in the same conduit or close together in a cable tray.

4.2 Sensor wiring

The Rosemount MCL is provided with sensor cables pre-wired to the transmitter. If it is

necessary to replace the sensor cable, refer to the instructions below.

1.

Shut off power to the transmitter.

2. Loosen the four screws holding the front panel in place and let it drop down.

3. Locate the signal board.

Slot 1 (left) Slot 2 (center)

communication input 1 (chlorine)

4. Loosen the gland fitting and carefully push the sensor cable up through the fitting as

you pull the board forward to gain access to the wires and terminal screws.

5.

Disconnect the wires and remove the cable.

Instruction Manual 15

Page 24

Wiring

6. Insert the new cable through the gland and pull the cable through the cable slot.

7. Wire the sensor to the signal board.

See Figure 4-3.

Figure 4-3:

Rosemount 499ACL-03-54-60 Sensor Wiring to Rosemount 1056

Transmitter

8. Once the cable has been connected to the board, slide the board fully into the

enclosure while taking up the excess cable through the cable gland.

9. Tighten the gland nut to secure the cable and ensure a sealed enclosure.

16 Rosemount MCL

Page 25

5 Display and operation

5.1 Display

The transmitter has a four line display.

See Figure 5-1. The display can be customized to meet your requirements. Refer to

Section 5.6.

Main DisplayFigure 5-1:

Display and operation

When the transmitter is being programmed or calibrated, the display changes to a screen

similar to the one shown in Figure 5-2. The live readings appear in small font at the top of

the screen. The rest of the display shows programming and calibration information.

Programming items appear in lists. The screen can only show four items at a time, and the

arrow bar at the right of the screen indicates whether there are additional items in the list.

See Figure 5-3 for an explanation of the arrow bar.

Programming Screen Showing Item ListFigure 5-2:

The position of the cursor is shown in reverse video. See Section 5.2 and Section 5.3 for more information.

Instruction Manual 17

Page 26

Display and operation

Arrow BarFigure 5-3:

The arrow bar shows whether additional items in a list are available.

5.2 Keypad

Local communication with the transmitter is through the membrane keypad.

Figure 5-4 and Figure 5-5 explain the operation of the keys.

18 Rosemount MCL

Page 27

Display and operation

Analyzer KeypadFigure 5-4:

Four navigation keys move the cursor around the screen. The position of the cursor is shown in reverse

video. The navigation keys are used to increase or decrease the value of a numeral. Press ENTER to select

an item and store numbers and settings. Press EXIT to return to the previous screen without storing

changes. Pressing MENU always causes the main menu to appear.

Navigation KeysFigure 5-5:

The operation of the navigation keys is shown. To move a decimal point, highlight it and then press Up or

Down.

Instruction Manual 19

Page 28

Display and operation

5.3 Programming the transmitter - tutorial

Setting up and calibrating the transmitter is easy. The following tutorial describes how to

move around in the programming menus. For practice, the tutorial also describes how to

assign ppm monochloramine values to the 4 and 20 mA analog outputs.

1. Press MENU.

The main menu screen appears. There are four items in the main menu. Calibrate is in

reverse video, meaning that the cursor is on Calibrate.

2. To assign values to the analog outputs, the Program sub-menu must be open. Use

Down to move the cursor to Program. Press ENTER.

The Program menu appears. There are six items in the Program menu. The screen

displays four items at a time. The downward pointing arrow on the right of the sreen

shows there are more items available in the menu.

3. To view the other items, use Down to scroll to the last item shown and continue

scrolling down. When you have reached the bottom, the arrow will point up. Move

the cursor back to Outputs and press ENTER.

The Outputs screen appears. The cursor is on Range. Output range is used to assign

values to the low and high current outputs.

20 Rosemount MCL

Page 29

Display and operation

4. Press ENTER.

The Output Range screen appears. The screen shows the present values assigned to

output 1 (O1) and output 2 (O2). The screen also shows which sensors the outputs

are assigned to. S1 is sensor 1. The assignments shown are the defaults for the

MCL-220. Outputs are freely assignable under the Configure menu.

5. For practice, change the 20 mA settings for output 1 to 8.5 ppm.

a.

Move the cursor to the O1 S1 20 mA: 10.00 line and press ENTER.

The screen below appears.

b. Use the navigation keys to change 10.00 to 8.5 ppm. Use Left and Right to

move from digit to digit. Use Up and Down to increase or decrease the numeral.

To move the decimal point, press Left or Right until the decimal point is

c.

highlighted. Press Up to move the decimal point to the right. Press Down to

move to the left.

d. Press ENTER to store the setting.

The display returns to the summary screen. Note that the 20 mA setting for output 1

has changed to 8.50 ppm.

Instruction Manual 21

Page 30

Display and operation

6. To return to the main menu, press MENU. To return to the main display, press MENU

and then EXIT.

5.4 Security

5.4.1 How the security code works

Security codes prevent accidental or unwanted changes to program settings or

calibrations. There are three levels of security.

1. A user can view the default display and diagnostic screens only.

2. A user has access to the calibration and hold menus only.

3. A user has access to all menus.

1. If a security code has been programmed, pressing MENU causes the security screen

to appear.

Enter the three-digit security code.

2.

3. If the entry is correct, the main menu screen appears. The user has access to the submenus the code entitles him to.

4. If the entry is wrong, the Invalid code screen appears.

5.4.2 Assigning security codes

See Section 6.7.

5.4.3 Bypassing security codes

Call the factory.

22 Rosemount MCL

Page 31

5.5 Using hold

5.5.1 Purpose

To prevent unwanted alarms and improper operation of control systems or dosing pumps,

place the alarms and outputs assigned to the sensor in hold before removing it for

maintenance.

Hold is also useful if calibration will cause an out of limits condition. During hold, outputs

assigned to the sensor remain at the last value, and alarms assigned to the sensor remain

in their present state.

Once in hold, the sensor remains in hold until hold is turned off. However, if power is loss

than restored, hold is automatically turned off.

5.5.2 Using the hold function

To put the sensor in hold, complete the following steps.

1. Press MENU.

Display and operation

The main Menu screen appears.

2. Choose Hold.

The screen shows the current hold status for each sensor.

Instruction Manual 23

Page 32

Display and operation

3. Select the sensor to be put in hold. Press ENTER.

4. To put the sensor in hold, choose Yes. To take the sensor out of hold, choose No.

5.6 Configuring the main display

The main display can be configured to meet your requirements.

1.

Press MENU.

The main menu screen appears.

2. Move the cursor to Display and press ENTER.

The screen shows the present configuration. There are four items: Main Format,

Language, Warning, and Contrast.

3. To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

Press ENTER to store the setting.

4.

5. Main Format lets you configure the second line in the main display as well as the four

smaller items at the bottom of the display. Move the cursor to the desired place in

the screen and press ENTER.

24 Rosemount MCL

Page 33

Display and operation

6. Scroll through the list of items and select the parameter you wish to be displayed.

Once you are done making changes, press EXIT twice to return to the display menu.

7.

8. Press MENU and then EXIT to return to the main display.

The following abbreviations are used in the quadrant display.

O output

T temperature (live)

Tm temperature (manual)

M measurement

9. Choose Language to change the language used in the display.

Choose Warning to disable or enable warning messages.

10.

11. Choose Contrast to change the display contrast.

12. To change the contrast, choose either lighter or darker and press ENTER.

Every time you press ENTER, the display becomes lighter or darker.

Instruction Manual 25

Page 34

Display and operation

26 Rosemount MCL

Page 35

Programming the transmitter

6 Programming the transmitter

6.1 General

This section describes how to make the following program settings using the local keypad.

1. Configure and assign values to the analog current outputs.

2. Configure and assign values to the alarm relays.

3. Choose the type of chlorine measurement being made. This step is necessary

because the transmitter used with the MCL can measure forms of chlorine other

than monochloramine.

4. Choose temperature units or manual temperature correction for chlorine and pH (if

a pH sensor is installed).

5. Set two levels of security codes.

6. Reset the analyzer to factory default settings.

6.2 Default settings

The transmitter leaves the factory with the default settings shown in Table 6-1. You can

change the settings to any value shown in the column labeled Choices.

Default SettingsTable 6-1:

Item Choices Default

Sensor assignment

Sensor 1 monochloramine monochloramine

Outputs

1. Assignments

a. output 1 monochloramine monochloramine

b. output 2 temperature temperature

2. Range 0-20 or 4-20 mA 4-20 mA

3. 0 or 4 mA setting

a. chlorine -9999 to +9999 0

b. temperature -999.9 to +999.9 0

4. 20 mA setting

a. chlorine -9999 to +9999 10

b. temperature -999.9 to +999.9 0

5. Fault current (fixed) 0.00 to 22.0 mA 12.00 mA

6. Dampening 0 to 999 sec 0 sec

Instruction Manual 27

Page 36

Programming the transmitter

Default Settings (continued)Table 6-1:

Item Choices Default

7. Simulate 0.00 to 22.00 mA 12.00 mA

Alarms

1. Logic high or low AL1 low, AL2, 3, 4, high

2. Assignments

a. AL1 and AL2 monochloramine, temperature, fault,

interval timer

b. AL3 and AL4 monochloramine, temperature, fault,

interval timer

3. Deadband 0 to 9999 0

4. Interval timer settings

a. interval time 0.0 to 999.9 hr 24.0 hr

b. on time 0 to 999 sec 10 sec

c. recovery time 0 to 999 sec 60 sec

monochloramine (sensor 1)

temperature (sensor 1)

Measurement

1. Monochloramine (sensor 1)

a. units ppm or mg/L ppm

b. resolution 0.01 or 0.001 0.001

c. input filter 0 to 999 sec 5 sec

Temperature related settings

1. Units °C or °F °C

2. Temperature compensation automatic or manual automatic

Security code

1. Calibrate/Hold 000 to 999 000

2. Program/Display 000 to 999 000

Calibration - Analog Outputs

1. 4mA 0.000 to 22.000 mA 4.000 mA

2. 20 mA 0.000 to 22.000 mA 20.000 mA

28 Rosemount MCL

Page 37

Programming the transmitter

6.3 Configuring, ranging, and simulating outputs

6.3.1 Purpose

This section describes how to configure, range, and simulate the two analog current

outputs.

Important

Configure the outputs first.

1. Configuring an output means

a. Assigning a sensor and measurement (monochloramine or temperature) to an

output.

b. Selecting a 4-20 mA or 0-20 mA output.

c. Choosing a linear or logarithmic output.

d. Set the amount of dampening on the analog outputs.

e. Selecting the value the output current goes to if the transmitter detects a fault.

2. Ranging the output means assigning values to the low (0 or 4 mA) and high (20 mA)

outputs.

3. Simulating an output means making the transmitter generate an output equal to

the value you entered.

6.3.2 Definitions

Analog current

output

Assigning an

output

Linear output

Logarithmic

output

Dampening

Fault

The analyzer provides either a continuous 4-20 mA or 0-20 mA output

signal proportional to monochloramine or temperature.

The outputs are freely assignable. Outputs can be assigned to either

monochloramine or temperature.

Linear output means the current is directly proportional to the

common logarithm of the variable assigned to the output

(monochloramine or tempreature).

Logarithmic output means the current is directly proportional to the

common logarithm of the variable assigned to the output

(monochloramine or temperature).

Output dampening smoothes out noisy readings. It also increases

response time. The time selected for output dampening is the time to

reach 63% of the final reading following a step change. Output

dampening does not affect the response time of the display.

The transmitter continuously monitors itself and the sensor for faults.

If the transmitter detects a fault, a fault message appears in the main

display. At the same time, the output current goes to the value

programmed in this section. There are two output fault modes: fixed

Instruction Manual 29

Page 38

Programming the transmitter

and live. Fixed means the selected output goes to the previously

programmed value (between 0.00 and 22.00 mA) when a fault occurs.

Live means the selected output is unaffected when the fault occurs.

Ranging an

output

The outputs are fully rangeable, including negative numbers. If the

output is logarithmic, assigned values must be positive.

6.3.3 Procedure - configure outputs

Complete the following steps to configure the analog current outputs.

1.

Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

The cursor is on Outputs.

3. Press ENTER.

4. Choose Configure.

30 Rosemount MCL

Page 39

Programming the transmitter

5. Choose Output 1 or Output 2.

The screen shows the present configuration. There are six items: Assign (S1 is sensor

1), Range, Scale, Dampening, Fault Mode, and Fault Value. To display the fifth and sixth

items, scroll to the bottom of the screen and continue scrolling.

6. To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

7. Press ENTER to store the setting.

For an explanation of terms, see Section 6.3.1 and Section 6.3.2.

8. To return to the main display, press MENU and then EXIT.

6.3.4 Procedure - ranging outputs

Complete the following steps to range the outputs by assigning values to the low and high

outputs.

1. Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

The cursor is on Outputs.

3. Press ENTER.

Instruction Manual 31

Page 40

Programming the transmitter

4. Choose Range.

5. Choose Output 1 or Output 2.

The screen shows the present settings for the outputs. O1 is output 1, O2 is output 2,

and S1 is sensor 1.

6. To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

7.

Press ENTER to store the setting.

For an explanation of terms, see Section 6.3.1 and Section 6.3.2.

8. To return to the main display, press MENU and then EXIT.

6.3.5 Procedure - simulating outputs

Complete the following steps to simulate an output by making the transmitter generate

an output current equal to the value you enter.

1. Press MENU.

32 Rosemount MCL

Page 41

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

The cursor is on Outputs.

3. Press ENTER.

Programming the transmitter

4. Choose Simulate.

5. Choose Output 1 or Output 2.

6. Enter the desired simulated output current.

Instruction Manual 33

Page 42

Programming the transmitter

7. To end the simulated current, press MENU or EXIT.

6.4 Configuring alarms and assigning setpoints

6.4.1 Purpose

The Rosemount MCL-220 transmitter has an optional alarm relay board. This section

describes how to configure and assign setpoints to the alarm relays, simulate alarm action,

and synchronize interval timers.

Important

Configure the alarms first.

1. Configuring an alarm means

a. Assigning a sensor and measurement (monochloramine or temperature) to an

alarm. An alarm relay can also be used as a timer.

b. Selecting high or low logic.

c. Choosing the deadband.

d. Setting the interval timer parameters.

2. Simulating an alarm means making the transmitter energize or de-energize an alarm

relay.

6.4.2 Definitions

Assigning

alarms

Fault alarm

Alarm logic,

setpoints, and

deadbands

There are four alarm relays. The relays are freely assignable to either

monochloramine or temperature. Alarm relays can also be assigned to

operate as interval timers or as fault alarms. A fault alarm activates

when the transmitter detects a fault in either itself of the sensor.

A fault condition exists when the transmitter detects a problem with

the sensor or with the transmitter itself that is likely to cause seriously

erroneous readings. If an alarm was programmed as a fault alarm, the

alarm activates. At the same time, a fault message appears in the main

display.

See Figure 6-1 and Figure 6-2.

34 Rosemount MCL

Page 43

Programming the transmitter

High Alarm LogicFigure 6-1:

The alarm activates when the chlorine concentration exceeds the high setpoint. The

alarm remains activated until the reading drops below the value determined by the

deadband.

Low Alarm LogicFigure 6-2:

The alarm activates when the chlorine concentration drops below the low setpoint.

The alarm remains activated until the reading increases above the value determined

by the deadband.

Interval timer

Any alarm relay can be used as an interval timer. Figure 6-3 shows how

the timer operates. While the interval timer is operating, the main

display, analog outputs, and assigned alarms for the sensor can be put

on hold. During hold, the main display remains at the last value.

Instruction Manual 35

Page 44

Programming the transmitter

Operation of the Interval TimerFigure 6-3:

The numbers in parentheses are the allowed values for each timer parameter.

Synchronize

timer

If two or more relays are being used as interval timers, choosing

synchronize timers will cause each timer to start one minute later than

the preceding timer.

6.4.3 Procedure - configuring alarms and assigning setpoints

Complete the following steps to configure the alarms and assign setpoints.

Press MENU.

1.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

3. Choose Alarms.

36 Rosemount MCL

Page 45

4. Choose Configure/Setpoint.

Programming the transmitter

5. Choose Alarm 1, Alarm 2, Alarm 3, or Alarm 4.

The screens summarizes the present configuration and setpoints. There are nine

items: Setpoint, Assign (S1 is sensor 1), Logic, Deadband, Interval time, On time, Recover time,

and Hold while active. The last four items describe the operation of the timer. Only four

items are shown at a time. To view the remaining items, scroll to the bottom of the

screen and continue scrolling.

6.

To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

7. Press ENTER to store the setting.

For an explanation of terms, see Section 6.4.1 and Section 6.4.2.

8. To return to the main display, press MENU and then EXIT.

6.4.4 Procedure - simulating alarms

Complete the following steps to make the analyzer energize or de-energize an alarm relay.

Instruction Manual 37

Page 46

Programming the transmitter

1. Press MENU.

2. Move the cursor to Program and press ENTER.

3. Choose Alarms.

The main Menu screen appears.

4. Choose Simulate.

5. Choose Alarm 1, Alarm 2, Alarm 3, or Alarm 4.

38 Rosemount MCL

Page 47

6. Choose Don't simulate, De-energize, or Energize.

7. Press MENU or EXIT to end simulation.

6.4.5 Procedure - synchronizing timers

Synch Timers is available only if two or more alarm relays have been configured as interval

timers.

1.

Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

Programming the transmitter

3. Choose Alarms.

The summary display shows the current Synch Timers setting (Yes or No).

4.

To make a change, choose Synch Timers and press ENTER.

A screen appears in which the present setting can be edited.

5. Press ENTER to store the setting.

For an explanation of terms, see Section 6.4.1 and Section 6.4.2.

6. To return to the main display, press MENU and then EXIT.

Instruction Manual 39

Page 48

Programming the transmitter

6.5 Configuring the measurement

6.5.1 Purpose

This section describes the following:

1. Program the transmitter to measure monochloramine using the 499ACL-03 sensor.

This step is necessary, because the transmitter can be used with other sensors to

measure other chlorine oxidants.

2. Set the level of electronic filtering of the sensor current.

6.5.2 Definitions - chlorine

Chlorine

oxidants

Filter

Resolution

Although the MCL is used to measure monochloramine only, the

transmitter used in the MCL can be used to measure other chlorine

oxidants, for example, free and total chlorine.

The transmitter applies a software filter to the raw sensor current. The

filter reduces noisy readings and increases the response time. Only the

filter time can be changed. The filter threshold cannot be changed.

If the chlorine concentration is less than 1.00 ppm (mg/L), the display

resolution can be set to 0.XX or 0.XXX.

6.5.3 Procedure - configuring the measurement

Complete the following steps to configure the transmitter to measure monochloramine.

1.

Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

3. Choose Measurement.

The screen summarizes the present configuration for sensor 1 (monochloramine).

There are four items: Measure, Units, Filter, and Resolution.

40 Rosemount MCL

Page 49

Programming the transmitter

4. To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

To store the setting, press ENTER.

5.

a. For Measurement, choose Chloramine.

b. Leave Filter at the default value unless readings are noisy.

6. To return to the main display, press MENU and then EXIT.

6.6 Configuring temperature related settings

6.6.1 Purpose

This section describes how to do the following:

1.

Choose temperature units.

2. Choose automatic or manual temperature correction for membrane permeability.

3. Enter a temperature for manual temperature compensation.

6.6.2 Definitions

Automatic

temperature

correction

Manual

temperature

correction

The monochloramine sensor is a membrane-covered amperometric

sensor. It produces a current directly proportional to the rate of

diffusion of monochloramine through the membrane. The diffusion

rate, in turn, depends on the concentration of monochloramine in the

sample and membrane permeability. Membrane permeability is a

function of temperature. As temperature increases, permeability

increases. Thus, an increase in temperature will cause the sensor

current and the transmitter reading to increase even though the

concentration of monochloramine remained constant. In automatic

temperature correction, the transmitter uses the temperature

measured by the sensor to continuously correct for changes in

membrane permeability.

In manual temperature correction, the transmitter uses the

temperature you enter for correction. It does not use the actual process

temperature. Do not use manual temperature correction unless the

Instruction Manual 41

Page 50

Programming the transmitter

measurement and calibration temperatures differ by no more than

about 2 °C. Manual temperature correction is useful if the sensor

temperature element has failed and a replacement sensor is not

available.

6.6.3 Procedure - configuring temperature related settings

Complete the following steps to set the temperature units and to select automatic or

manual temperature correction.

1. Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

3. Choose Temperature.

The screen summarizes the present sensor configuration. There are between two

and three items. Units and S1 Temp Comp always appear. If manual temperature

compensation was selected, the manual temperature value entered for the sensor

(S1 Manual) also appears.

4. To make a change, move the cursor to the desired line and press ENTER.

A screen appears in which the present setting can be edited.

5. To store a setting, press ENTER.

For an explanation of terms, see Section 6.6.2.

6. To return to the main display, press MENU and then EXIT.

42 Rosemount MCL

Page 51

Programming the transmitter

6.7 Configuring security settings

6.7.1 Purpose

This section describes how to set security codes. There are three levels of security.

1. A user can view the default display and diagnostic screens only.

2. A user has access to the calibration and hold menus only.

3. A user has access to all menus.

The security code is a three digit number. The table shows what happens when different

security codes (XXX and YYY) are assigned to Calibration/Hold and All. 000 means no security.

Calibration/Hold All What happens

000 XXX User enters XXX and has access to all

menus.

XXX YYY User enters XXX and has access to Cal-

ibration and Hold menus only. User

enters YYY and has access to all menus.

XXX 000 User needs no security code to have

access to all menus.

000 000 User needs no security code to have

access to all menus.

6.7.2 Procedure - configuring security settings

Follow the steps below to set security codes.

1.

Press MENU.

The main Menu screen appears.

2. Move the cursor to Program and press ENTER.

3. Scroll to the bottom of the screen and continue scrolling until Security is highlighted.

Press ENTER.

Instruction Manual 43

Page 52

Programming the transmitter

4. To make a change, move the cursor to the desired line and press ENTER.

5.

6. To return to the main display, press MENU and then EXIT.

The screen shows the existing security codes.

A screen appears in which the present setting can be edited.

Press ENTER to store a change.

The security code takes effect two minutes after pressing ENTER.

6.8 Resetting the transmitter

6.8.1 Purpose

This section describes how to clear user-entered values and restore default settings. There

are three resets:

1. Resetting to factory default clears ALL user-entered settings, including sensor and

analog output calibration, and returns ALL settings and calibration values to the

factory defaults.

2. Resetting a sensor calibration to the default value clears user-entered calibration

data for the selected sensor but leaves all other user-entered data unaffected.

3. Resetting the analog output calibration clears only the user-entered analog output

calibration. It leaves all other user-entered settings unchanged.

6.8.2 Procedure - resetting the transmitter

Complete the following steps to reset the transmitter.

1. Press MENU.

The main Menu screen appears.

2. Move to Program and press ENTER.

44 Rosemount MCL

Page 53

Programming the transmitter

3. Scroll to the bottom of the screen and continue scrolling until Reset Analyzer is

highlighted. Press ENTER.

4. Choose whether to reset all user-entered values (Factory Defaults), sensor calibration

(Sensor Cal Only), or output calibration (Output Cal Only).

If you choose Sensor Cal Only or Output Cal Only, a second screen appears in which you

can select which sensor or output calibration to reset.

5.

To return to the main display, press MENU and then EXIT.

Instruction Manual 45

Page 54

Programming the transmitter

46 Rosemount MCL

Page 55

7 Calibration

7.1 Introduction

The Calibrate menu allows you to do the following:

1. Calibrate the temperature sensing element in the monochloramine sensor.

2. Calibrate the monochloramine sensor.

3. Calibrate the analog outputs.

7.2 Calibrating temperature

7.2.1 Purpose

The monochloramine sensor is a membrane-covered amperometric sensor. As the sensor

operates, monochloramine diffuses through the membrane and is consumed at an

electrode immediately behind the membrane. The reaction produces a current that

depends on the rate at which the monochloramine diffuses through the membrane. The

diffusion rate, in turn, depends on the concentration of monochloramine and how easily it

passes through the membrane (membrane permeability). Because membrane

permeability is a function of temperature, the sensor current changes if the temperature

changes. To account for changes in sensor current caused by temperature alone, the

transmitter automatically applies a membrane permeability correction. The membrane

permeability changes about 3%/° C at 25 °C (77 °F), so a 1 °C error in temperature produces

about a 3% error in the reading.

Calibration

Without calibration, the accuracy of the temperature measurement is about ±0.4 °C.

Calibrate the sensor/transmitter unit if:

1. ±0.4 °C accuracy is not acceptable.

2. The temperature measurement is suspected of being in error. Calibrate

temperature by making the transmitter reading match the temperature measured

with a standard thermometer.

7.2.2 Procedure

Complete the following steps to calibrate the temperature in the transmitter.

1. Remove the sensor from the flow cell. Place it in an insulated container of water

along with a calibrated thermometer. Submerge at least the bottom two inches of

the sensor.

2. Allow the sensor to reach thermal equilibrium.

The time constant for the sensor is about five minutes, so it may take as long as

thirty minutes for equilibration.

Instruction Manual 47

Page 56

Calibration

3. Press MENU.

The main Menu screen appears. The cursor is on Calibrate.

4. Press ENTER.

5. Choose the sensor you wish to calibrate.

Sensor 1 is the monochloramine sensor.

6. Choose Temperature.

7. Change the display to match the temperature read from the calibrated

thermometer. Press ENTER.

If the present temperature is more than 5 °C different from the value entered, an

error message appears.

8.

To force the transmitter to accept the calibration, choose Yes. To repeat the

calibration, choose No.

For troubleshooting assistance, see Section 9.5.

9. To return to the main display, press MENU and then EXIT.

48 Rosemount MCL

Page 57

7.3 Calibration - monochloramine

7.3.1 Purpose

As Figure 7-1 shows, a monochloramine sensor generates a current directly proportional to

the concentration of monochloramine in the sample. Calibrating the sensor requires

exposing it to a solution containing no monochloramine (zero standard) and to a solution

containing a known amount of monochloramine (full-scale standard).

Sensor Current as a Function of Monochloramine ConcentrationFigure 7-1:

Calibration

The zero standard is necessary, because monochloramine sensors, even when no

monochloramine is in the sample, generate a small current called the residual current or

zero current. The transmitter compensates for the residual current by subtracting it from

the measured current before converting the result to a monochloramine value. New

sensors require zeroing before being placed in service, and sensors should be zeroed

whenever the fill solutions is replaced. Deionized water makes a good zero standard.

The purpose of the full-scale standard is to establish the slope of the calibration curve.

Because stable monochloramine standards do not exist, the sensor must be calibrated

against a test run on a grab sample of the process liquid. Several manufacturers offer

portable test kits for this purpose. Observe the following standards when taking and

testing the grab sample.

• Take the grab sample from a point as close to the MCL as possible. Be sure that

taking the sample does not alter the flow of the sample to the unit. It is best to

install the sample tap just downstream from the tap for the MCL.

• Monochloramine solutions are moderately unstable. Run the test immediately after

taking the sample. Try to calibrate the sensor when the monochloramine

concentration is at the upper end of the normal operating range.

Instruction Manual 49

Page 58

Calibration

7.3.2 Procedure - zeroing the sensor

Complete the following steps to calibrate the sensor with the zero standard.

1. Remove the sensor from the flow cell and place it in the zero standard (deionized

water). Be sure no air bubbles are trapped against the membrane.

The sensor current drops rapidly at first and then gradually reaches a stable zero

value.

2. To monitor the sensor current, press DIAG.

3. Choose Sensor 1 (monochloramine).

The input current is the first line in the display. Note the units: nA is nanoamps; uA is

microamps. Typical zero current for the new sensor is between -10 and 15 nA. A new

sensor or a sensor in which the electrolyte solution has been replaced may require

several hours (occasionally as long as overnight) to reach a minimum zero current.

Important

Do not start the zero routine until the sensor has been in the zero solution for at least two

hours.

4. Press MENU.

The main Menu screen appears. The cursor is on Calibrate.

Press ENTER.

5.

6. Choose Sensor 1.

7. Choose Monochloramine.

50 Rosemount MCL

Page 59

8. Choose Zero Cal.

The transmitter automatically starts the zero calibration.

If the zero calibration was successful, the following screen appears.

Calibration

If the zero current is moderately larger than expected, an error message appears.

9. To force the transmitter to accept the zero current, choose Yes. To repeat the

calibration, choose No.

For troubleshooting information, see Section 9.5.

If the zero current is much larger than expected, the zero calibration failure screen

appears.

Instruction Manual 51

Page 60

Calibration

The transmitter will not update the zero current. For troubleshooting assistance, see

Section 9.5.

10. To return to the main display, press MENU and then EXIT.

7.3.3 Procedure - calibrating the sensor

Complete the following steps to calibrate the monochloramine sensor with the full scale

standard solution.

1. Place the monochloramine sensor in the flow cell. Adjust the sample flow until water

overflows the inside tube in the constant head flow controller.

2. Adjust the monochloramine concentration until it is near the upper end of the

operating range. Wait until the analyzer reading is stable before starting calibration.

3. Press MENU.

The main Menu screen appears. The cursor is on Calibrate.

4. Press ENTER.

5. Choose Sensor 1.

6. Choose Monochloramine.

52 Rosemount MCL

Page 61

Calibration

7. Choose In Process Cal.

8.

Follow the screen points. Once the reading is stable, press ENTER. Take the sample

and press ENTER.

At this point, the transmitter stores the present sensor current and temperature and

uses those values in calibration.

9. Determine the free chlorine concentration in the sample and enter the value in the

screen below.

See Section 7.3.1 for sampling and testing precautions.

If the calibration was successful, the live reading changes to the value entered in

step 9, and the display returns to the screen in step 6. If the sensitivity is too far

outside the range of expected values the following screen appears.

The transmitter doesn't update the calibration. For troubleshooting assistance, see

Section 9.5.

10. To return to the main display, press MENU and then EXIT.

Instruction Manual 53

Page 62

Calibration

7.4 Calibration - analog outputs

7.4.1 Purpose

Although the transmitter analog outputs are calibrated at the factory, they can be

trimmed in the field to match the reading from a standard milliameter. Both the low (0 or

4 mA) and high (20 mA) outputs can be trimmed.

7.4.2 Procedure

Complete the following steps to calibrate the transmitter's analog outputs.

1. Connect a calibrated milliameter across the output you wish to calibrate. If a load is

already connected to the output, disconnect the load.

Do not put the milliameter in parallel with the load.

2. Press MENU.

The main Menu screen appears. The cursor is on Calibrate.

3. Press ENTER.

4. Choose the output you wish to calibrate.

The transmitter simulates the low output current.

5. Change the value in the display to match the reading from the milliameter.

The transmitter simulates the 20 mA output current.

54 Rosemount MCL

Page 63

6. Change the value in the display to match the reading from the milliameter.

If the calibration was successful, the screen below appears.

Calibration

If the user enterd value is more than ±1 mA different from the nominal value, a

possible error screen appears.

7.

To force the transmitter to accept the calibration, choose Yes.

8. To return to the main display, press MENU and then EXIT.

Instruction Manual 55

Page 64

Calibration

56 Rosemount MCL

Page 65

8 Maintenance

8.1 Transmitter

The transmitter used with the Rosemount MCL requires little maintenance.

Clean the transmitter case and front panel by wiping with a clean soft cloth dampened

with water only. Do not use solvents, like alcohol, that might cause a buildup of static

charge.

The sensor circuit board (PN 24203-01) is replaceable.

To replace the board:

WARNING!

RISK OF ELECTRICAL SHOCK

Disconnect main power and relay contacts wired to separate power source before servicing.

Maintenance

Procedure

1. Turn off power to the transmitter.

2. Loosen the four screws holding the front panel in place and let the front panel drop

down.

3. Loosen the gland fitting and carefully push the sensor cable up through the fitting as

you pull out the circuit board.

4. Once you have access to the terminal strip, disconnect the sensor.

5. Unplug the sensor board from the main board.

See Figure 4-2.