Page 1

Instruction Manual

748441-D

May 2004

Model CAT 100

Continuous Analyzer Transmitter

http://www.processanalytic.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them

normal specifications. The following instructions MUST be adhered to

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

to ensure they continue to operate within their

and integrated into your

• Read all instructions

prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

•

Follow all warnings, cautions, and instructions

•

Inform and educate your personnel in the proper installation, operation, and mainte-

marked on and supplied with the product.

nance of the product.

•

Install your equipment as specified in the Installation Instructions of the appropriate Instruction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

•

To ensure proper performance, use qualified personnel

to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY

.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

•

Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Teflon® and Viton® are registered trademarks of E. I. duPont de Nemours and Co., Inc.

SNOOP® is a registered trademark of NUPRO Co.

st

1

Edition 04/2002 2nd Edition: 05/2004

Emerson Process Management

Manufacturing GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

T +49(6055) 884-0

F +49(6055) 884-209

http://www.emersonprocess.com

Page 3

Model CAT 100

PREFACE...................................................... .............................................. .......................................P-1

Definitions............................................................................. ..............................................................P-1

Intended Use Statement.....................................................................................................................P-2

Safety Summary.................................................................................................................................P-2

General Precautions For Handling And Storing High Pressure Gas Cylinders .................................P-5

Documentation....................................................................................................................................P-6

Compliances.......................................................................................................................................P-6

1.0 DESCRIPTION AND SPECIFICATIONS..............................................................................1-1

1-1 Overview................................................................................................................................1-1

1-2 Typical Applications...............................................................................................................1-1

1-3 Detector Methodologies.........................................................................................................1-2

a. Non-Dispersive Infrared (NDIR)......................................................................... .... .... ... ..1-2

b. Paramagnetic Oxygen Method...................................................................... .... .... ....... ..1-6

c. Electrochemical Oxygen Method................................................................ ... .... .... ....... ..1-7

d. Thermal Conductivity Method.........................................................................................1-9

1-4 Specifications.........................................................................................................................1-11

a. General ...........................................................................................................................1-11

b. CAT 100 Detector...........................................................................................................1-12

Instruction Manual

748441-D

April 2002

TABLE OF CONTENTS

2.0 INSTALLATION ....................................................................................................................2-1

2-1 Process and Calibration Gas Connection........................................................................ ... ..2-1

a. Gas Conditioning.............................................................................................................2-5

2-2 Installation..............................................................................................................................2-6

a. Location...........................................................................................................................2-6

b. Limitations.......................................................................................................................2-6

c. Gas Lines........................................................................................................................2-6

d. Services ..........................................................................................................................2-6

e. Mounting Options............................................................................................................2-6

f. Vent Lines.......................................................................................................................2-6

g. Electrical Connections ....................................................................................................2-7

2-3 Analytical Leak Check...........................................................................................................2-11

a. Flow Indicator Method.....................................................................................................2-11

b. Manometer Method.........................................................................................................2-12

3.0 OPERATION .........................................................................................................................3-1

3-1 Startup Procedure .................................................................................................................3-1

3-2 Touchpad...............................................................................................................................3-1

a. Overview.........................................................................................................................3-1

b. Elements.........................................................................................................................3-1

c. Actuator Tool...................................................................................................................3-2

d. Operation ........................................................................................................................3-2

e. Functions.........................................................................................................................3-3

f. FUNCTION Touchpad ....................................................................................................3-4

g. ENTER Touchpad...........................................................................................................3-5

h. INPUT-CONTROL Touchpads........................................................................................3-5

Rosemount Analytical Inc. A Division of Emerson Process Management Contents i

Page 4

Instruction Manual

748441-D

April 2002

3-3 Entry of System Parameters..................................................................................................3-7

A. Pressure Correction........................................................................................................3-7

b. Cross Compensation ......................................................................................................3-7

c. Cross Compensation Calibration....................................................................................3-7

d. Hold.................................................................................................................................3-8

e. Automatic Calibration......................................................................................................3-8

f. Tolerance Check.............................................................................................................3-8

g. Display Off.......................................................................................................................3-9

h. Analog Signal Outputs...................................... .... .... ... .... .... .... ... .... .... .... ... .... .... .... .... .... .3-9

i. Flushing Period...............................................................................................................3-9

j. User Code..................................................................................................................... ..3-9

k. Response Time...............................................................................................................3-10

l. Offset Value....................................................................................................................3-10

m. Range Value ...................................................................................................................3-10

n. Reset...............................................................................................................................3-10

o. Program Version.............................................................................................................3-11

p. Serial Number.................................................................................................................3-11

q. Pump...............................................................................................................................3-11

3-4 Calibration..............................................................................................................................3-12

a. Zeroing............................................................................................................................3-12

b. Spanning.........................................................................................................................3-12

3-5 Manual Calibration.................................................................................................................3-13

a. Zeroing............................................................................................................................3-13

b. Spanning.........................................................................................................................3-13

3-6 Automatic Calibration (Option) ..............................................................................................3-15

a. Zeroing............................................................................................................................3-15

b. Combined Zeroing and Spanning...................................................................................3-15

3-7 Concentration Limits..............................................................................................................3-16

3-8 Measurement.........................................................................................................................3-17

3-9 Shut Down.............................................................................................................................3-18

3-10 Temperature Stabilization (option)........................................................................................3-19

a. Changing Temperature Settings.....................................................................................3-19

b. Controller Settings...........................................................................................................3-20

Model CAT 100

4.0 SERIAL INTERFACE OPTION.............................................................................................4-1

4-1 Overview................................................................................................................................4-1

4-2 Protocols........................................................................................................................... .....4-2

a. RS 232............................................................................................................................4-2

b. RS 485............................................................................................................................4-2

4-3 Setting I nterface Parameters.................................................................................................4-3

a. ON/OFF Status ...............................................................................................................4-3

b. Communication Parameters ...........................................................................................4-3

4-4 String Syntax .........................................................................................................................4-4

a. Status Strings..................................................................................................................4-5

b. Numerical Representations.............................................................................................4-6

c. Block Parity Check..........................................................................................................4-6

4-5 Instruction (Receive) Syntax.......... ............................................. ...........................................4-7

a. Instruction Listing............................................................................................................4-7

b. Response String Syntax .................................................................................................4-8

ii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 5

Model CAT 100

5.0 MAINTENANCE AND SERVICE..........................................................................................5-1

5-1 Overview................................................................................................................................5-1

a. Operating Factors ...........................................................................................................5-1

b. Analyzer Replacement....................................................................................................5-1

c. Analyzer Repair...............................................................................................................5-1

5-2 Component Removal.............................................................................................................5-2

a. Analyzer Removal...........................................................................................................5-3

b. Analyzer Replacement....................................................................................................5-3

c. Power Supply Assembly Removal......................................................................... .........5-3

5-3 Analyzer Configuration and Adjustment................................................................................5-4

a. Component Layout..........................................................................................................5-4

b. Photometer Assembly.....................................................................................................5-9

c. Analyzer Rear Panel.......................................................................................................5-12

d. Thermal Conductivity Response Time............................................................................5-14

5-4 Maintenance..........................................................................................................................5-16

a. Routine and Preventive...................................................................................................5-16

b. Checking and Cleaning of the Analyzer..........................................................................5-16

c. Cleaning and Replacement of Photometric Components...............................................5-17

d. Light Source Replacement............................................................................. .................5-18

e. Removal of Analysis Cells ..............................................................................................5-19

f. Cleaning of Analysis Cells and Windows........................................................................5-20

g. Reinstalling Analysis Cells..............................................................................................5-20

h. Reinstalling Photometer Assembly.................................................................................5-20

i. Physical Zeroing..............................................................................................................5-20

j. Replacement of Electrochemical Oxygen Sensor ..........................................................5-21

k. Check of the Sensor........................................................................................................5-22

l. Removal of the Sensor ...................................................................................................5-23

m. Basic Calibration for the Oxygen Sensor........................................................................5-27

n. Sample Pump Maintenance............................................................................................5-27

o. Replacing the EPROM....................................................................................................5-28

5-5 Analyzer Service....................................................................................................................5-29

a. Test Points for BKS PC Board........................................................................................5-29

b. Test Points for OXS PC Board........................................................................................5-35

c. Power Supply..................................................................................................................5-37

Instruction Manual

748441-D

April 2002

6.0 TROUBLESHOOTING..........................................................................................................6-1

6-1 Error Messages ................................................................................................................... ..6-1

6-2 Troubleshooting Leaks..........................................................................................................6-6

7.0 RETURN OF MATERIAL................................................................................... .................7-1

7-1 Return Of Material.................................................................................................................7-1

7-2 Customer Service..................................................................................................................7-1

7-3 Training..................................................................................................................................7-1

8.0 INDEX....................................................................................................................................8-1

Rosemount Analytical Inc. A Division of Emerson Process Management Contents iii

Page 6

Instruction Manual

748441-D

April 2002

Figure 1-1. Absorption Bands of Sample Gas and Transmittance of Interference Filters ...... 1-3

Figure 1-2. Opto-Pneumatic Gas Detector...............................................................................1-4

Figure 1-3. Overall NDIR Method............................................................................................. 1-5

Figure 1-4. Paramagnetic Oxygen Analysis............................................................... ... .... .... ...1-6

Figure 1-5. Electrochemical Oxygen Sensor............................................................................ 1-7

Figure 1-6. Reaction of Galvanic Cell ....................................................................... .... .... .... ...1-8

Figure 1-7. Thermal Conductivity Sensor................................................................................. 1-9

Figure 1-8. Response Time vs Flow Rate Dependence........................................................1-10

Figure 2-1. Gas Connections........................................... .... .... ... .... .... .... ... .... .... .... ... .... .... .... ...2-2

Figure 2-2. Piping Diagram (Two channel series).................................................. .... ... .... .... ...2-3

Figure 2-3. CAT 100 Outline and Mounting Di mensions......................................................... 2-4

Figure 2-4. Increased Safety Junct ion Box Terminals............................ .... ... .... .... .... ... .... .... .2-10

Figure 2-5. Leak check - Flow Indicator Method....................................................................2-11

Figure 2-6. Leak Check - Manometer Method....................................................................... 2-12

Figure 3-1. CAT 100 Touchpad........................................ .... ... .... .... .... .... .... ... .... .... .... ... .... .... ...3-1

Figure 3-2. Touchpad Actuator Tool PN 42715575................................................................. 3-2

Figure 3-3. Storing The Actuator Tool......................................................................................3-2

Figure 3-4. Touchpad Operation..............................................................................................3-3

Figure 3-5. CAT 100 Analyzer Touchpad Function Identification............................................3-3

Figure 3-6. CAT 100 Touchpad Functions.......................................... .... ... .... .... .... .... ... .... .... ...3-4

Figure 3-7. Analyzer Operating Function Matrix..................................................................... 3-6

Figure 3-8. Temperature Controller............................................................... ........................3-19

Figure 5-1. CAT 100 Enclosure Assembly............................................................................ ...5-2

Figure 5-2. Analyzer Component Layout (Infrared Channel / Oxygen Measurement,

Combined) .............................................................................................................5-5

Figure 5-3. Analyzer Component Layout (1 Channel Oxygen Measurement,

Electrochemical)....................................................................................................5-6

Figure 5-4. Analyzer Component Layout (Paramagnetic Oxygen Measurement / Thermal

Conductivity, Combined)........................................................................................5-7

Figure 5-5. Analyzer Component Layout (Infrared Channel / Thermal Conductivity,

Combined) .............................................................................................................5-8

Figure 5-6. Photometer Assembly with Pyroelectrical Detector.............................................5-10

Figure 5-7. Photometer Assembly with Gas Detector............................................................ 5-11

Figure 5-8. Analyzer Rear Panel Layout................................................................................ 5-12

Figure 5-9. Pin Assignments (View Looking At Rear Panel)..................................................5-13

Figure 5-10. TC Sensor Short Response Time Setting (Standard).........................................5-15

Figure 5-11. TC Sensor Long Response Time Setting............................................................5-15

Figure 5-12. Analyzer Photometer Assembly ( 2 Channel Infrared Analyzer, Viewed From

Front Panel Side).......................................................... .......................................5-17

Figure 5-13. Photometer Assembly..........................................................................................5-19

Figure 5-14. OXS PCB Measuring Points................................................... ............................5-22

Figure 5-15. Oxygen Sensor without Infrared Channel...........................................................5-23

Figure 5-16. OXS PCB Connector P2.....................................................................................5-24

Figure 5-17. Oxygen Sensor Support (Oxygen Measurement Without Infrared Channel)..... 5-24

Figure 5-18. Oxygen Sensor with Infrared Channel................................................................5-25

Figure 5-19. OXS PCB Location of Measuring Points and Voltage Adjustment..................... 5-27

Figure 5-20. BKS PCB Location of EPROM and Battery Buffer Jumper (J7)......................... 5-28

Figure 5-21. BKS PCB Test Points........................................................................................5-29

Figure 5-22. BKS PCB Plug Locations....................................................................................5-33

Figure 5-23. BKS PCB Jumper Locations.............................................................................. .5-34

Figure 5-24. OXS PCB Test Points.........................................................................................5-35

Figure 5-25. OXS PCB Plug Locations................................................................................... 5-36

Figure 5-26. Power Supply Connections.................................................................................5-37

Model CAT 100

LIST OF ILLUSTRATIONS

iv Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 7

Model CAT 100

Table 2-1. Analog Output Terminal Assignments..................................... .... .... ....... .... .... .... ...2-7

Table 2-2. Digital Output Terminal Assignments.................................................................... 2-8

Table 2-3. Optional Status Signals Terminal Assignments.....................................................2-8

Table 2-4. Optional Cross Compensation Analog Inputs................... .....................................2-8

Table 2-5. Optional RS232/485 Terminal Assignments.......................................................... 2-9

Table 2-6. Power Connections Terminal Assignments...........................................................2-9

LIST OF DRAWINGS

659921 Assembly Drawing, CAT 100

660198 Wiring Diagram, CAT 100

660210 Installation Drawing, CAT 100

660371 Diagram, Power Input and Ground Circuits

LIST OF TABLES

(Located In Rear Of Manual)

Instruction Manual

748441-D

April 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Contents v

Page 8

Instruction Manual

748441-D

April 2002

Model CAT 100

vi Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 9

Instruction Manual

Model CAT 100

PREFACE

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of the CAT 100 .

Some sections may describe equipment not used in your configuration. The user should become

thoroughly familiar with the operation of this module before operating it. Read this instruction

manual completely.

DEFINITIONS

The following definitions apply to DANGERS, WARNINGS, CAUTIONS and NOTES found throughout

this publication.

DANGER .

Highlights the presence of a hazard which will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

748441-D

April 2002

WARNING .

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure,

condition or statement.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-1

Page 10

Instruction Manual

748441-D

April 2002

Model CAT 100

INTENDED USE STATEMENT

The Rosemount Analytical is intended for use as an industrial process measurement device only. It

is not intended for use in medical, diagnostic, or life support applications, and no independent

agency certifications or approvals are to be implied as covering such applications.

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be

impaired.

AUTHORIZED PERSONNEL

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site property,

do not operate or service this instrument before reading and understanding this instruction manual

and receiving appropriate training. Save these instructions.

DANGER.

ELECTRICAL SHOCK HAZARD

Do not open while energized. Installation requires access to live parts which can cause death or

serious injury.

For safety and proper performance this instrument must be connected to a properly grounded

three-wire source of p ower.

DANGER.

POSSIBLE EXPLOSION HAZARD

Do not operate without dome and covers secure. Ensure that all gas connections are made as labeled and are leak free. Improper gas connections could result in explosion and death.

P-2 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 11

Instruction Manual

Model CAT 100

DANGER.

TOXIC GAS

This device may contain explosive, toxic or unhealthy gas components. Before cleaning or changing parts in the gas paths, purge the gas lines with ambient air or nitrogen.

This unit’s exhaust may contain hydrocarbons and other toxic gases such as carbon monoxide.

Carbon monoxide is highly toxic and can cause headache, nausea, loss of consciousness, and

death.

WARNING: TOXIC GAS

Avoid inhalation of the exhaust gases at the exhaust fitting.

Connect exhaust outlet to a safe vent using stainless steel or Teflon line. Check vent line and con-

nections for leakage.

Keep all tube fittings tight to avoid leaks. See Sections 2-3 (page 2-11) and 6-2 (page 5-6) for leak

check information.

WARNING.

748441-D

April 2002

HAZARDOUS AREA CERTIFICATION(S)

Any addition, substitution, or replacement of components installed on or in this device, must be

certified to meet the hazardous area classification that the device was certified to prior to any such

component addition, substitution, or replacement. In addition, the installation of such device or

devices must meet the requirements specified and defined by the hazardous area classification of

the unmodified device. Any modifications to the device not meeting these requirements, will void

the product certification(s).

WARNING.

PARTS INTEGRITY AND UPGRADES

Tampering with or unauthorized substitution of components may adversely affect the safety of this

instrument. Use only factory approved components for repair.

Because of the danger of introducing additional hazards, do not perform any unauthorized modification to this instrument.

Return the instrument to a Rosemount Analytical Service office for service or repair to ensure that

safety features are maintained.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-3

Page 12

Instruction Manual

748441-D

April 2002

CAUTION.

PRESSURIZED GAS

This unit requires periodic calibration with a known standard gas. It also may utilizes a pressurized carrier gas, such as helium, hydrogen, or nitrogen. See General Precautions for Handling and

Storing High Pressure Gas Cylinders, page P-5.

CAUTION.

HEAVY WEIGHT

Use two persons or a suitable lifting device to move or carry the instrument.

Model CAT 100

P-4 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 13

Instruction Manual

748441-D

Model CAT 100

April 2002

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed

Gases" published in 1981

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of

weather and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the

shade when located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secure d against a wall or

bench, or placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a

suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suck back can occur when an empty cylinder is

attached to a pressurized system.

7. No part of cylinder should be su bjec ted to a temperat ure hig her than 125

never be permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding,

precautions must be taken to prevent striking an arc against the cylinder.

°

F (52 °C). A flame should

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-5

Page 14

Instruction Manual

9

6

C

US

748441-D

April 2002

Model CAT 100

DOCUMENTATION

The following CAT 100 instruction m ateria ls are av ailab le . Contact Customer Service Center or the local

representative to order.

748441 Instruction Manual (this document)

COMPLIANCES

This product may carry approvals from several certifying agencies. The certification marks appear on the

product name-rating plate.

Area Classifications:

USA

Class I Zone 1

AEx d e m IIB + H

Canada

Ex d e m IIB + H

European Union

ATEX, Category 2, Zone 1, IIB + H

T4

2

T4

2

T4

2

USA/Canada

Certified by Canadian Standards Association, an OSHA Nationally Recognized Testing Laboratory (NRTL) for USA and Canada.

European Union

Conforms with the provisions of the EMC Directive 89/336/EEC, Low Voltage Directive 73/23/EEC, Potentially Explosive Atmospheres Directive

94/9/EC, including amendments by the CE marking Directive 93/68/EEC.

EC type Examination Certificate, LCIE 00 ATEX 6009 X.

Rosemount Analytical has satisfied all obligations from the European Leg-

islation to harmonize the product requirements in Europe.

Australia/New Zealand

Conforms with Electromagnetic Compatibility – Generic Emission standard

and AS/NZS 4251.1 – 1994 Pa rt 1 – Residential, commercial, and light industrial.

Complies with the NAMUR RECOMMENDATION, Electromagnetic Compatibility (EMC) issue 1998.

®

0081

EEx d e m II B (+H2) T4

LCIE 00 ATEX 6009 X

II 2 G

N

NAMUR

P-6 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 15

Model CAT 100

DESCRIPTION AND SPECIFICATIONS

Instruction Manual

748441-D

April 2002

SECTION 1

1-1 OVERVIEW

This manual describes the CAT 100 Continuous Analyzer Transmitter.

The CAT 100 is a 1 or 2 channel Continuous

Gas Analyzer with FOUNDATION Fieldbus

communications. Its Class I, Zone I (IIB) + H

approved enclosure makes it suitable for installation in hazardous environments. The

field mountable housing design allows the

CAT 100 to be mounted close to the process

instead of in a remote shelter. This feature

greatly reduces installation and utility costs

while improving process efficien cy.

The CAT 100 can continuously measure 1 or

Carbon Monoxide (CO) Carbon Dioxide (CO

Hexane (CH equiv.) (C

Hydrogen (H

Ethylene (C

) Helium (He) Argon (Ar)

2

) Propane (C3H8) Butane (C4H10)

2H4

6H14

Some standard industry applications include:

Petrochemical Refinery

•

Light Naphtha Isomerization

H

, CO and CO2 in make-up Hydrogen

2

Gas to Combined Feed

H

in Scrubber Off Gas to Refinery Fuel

2

Gas Header

•

Catalytic Reforming

in Recycle Gas from Product Separa-

H

2

tor

H

in Net Gas from Net Gas Knockout

2

Drum

H

in CCR Nitrogen Header

2

H

in Surge Hopper Vent

2

•

Fluidized Catalytic Cracking

CO and O

Monitoring of Fluidized Cata-

2

lytic Cracking Regenerator Gas

•

Sulfur Recovery Units

2 components in a single analyzer using a

combination of Non Dispersive Infrared

(NDIR), Paramagnetic Oxygen, Thermal Conductivity, and Electrochemical sensors. The

CAT 100 also features an optional customized

sample-handling module.

2

1-2 TYPICAL APPLICATIONS

The CAT 100 Continuous Analyzer Transmitter supports a variety of industry applications,

drawing on more than 40 years of development and process expertise in sensors, digital

signal processing and software technologies.

The CAT 100 can satisfy the most demanding

single or multi-component analysis requirements. More than 60 gas components can be

measured including:

) Methane (CH4)

2

) Water Vapor (H2O) Oxygen (O2)

Propylene in Feed to Sulfur Recovery

Plant

Petrochemical Complex

Ethylene in Primary and Secondary DeMethanizer Overhead

CO

in Ethane-Ethylene Splitter

2

Propylene in Splitter Bottoms

Ammonia and Urea

, CO and CO2 in Synthesis Gas

H

2

Utilities

in Cooling Gas in Turbine Generators

H

2

Continuous Emission Monitoring Systems

(CEMS)

Metals

in Endothermic Furnace

H

2

All Applications

Continuous Emission Monitoring Systems

(CEMS)

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Page 16

Instruction Manual

748441-D

April 2002

Model CAT 100

1-3 DETECTOR METHODOLOGIES

The CAT 100 can employ up to two of four different measuring methods depending on the

configuration chosen. The methods are:

NDIR, Paramagnetic O

, Electrochemical O2,

2

and Thermal Conductivity.

a. Non-Dispersive Infrared (NDIR)

The non-dispersive infrared method is

based on the principle of absorption of infrared radiation by the sample gas being

measured. The gas-specific wavelengths

of the absorption bands characterize the

type of gas while the strength of the absorption gives a measure of the concentration of the gas component being

measured.

An optical bench is employed comprising

an infrared light source, two analysis cells

(reference and measurement), a chopper

wheel to alternate the radiation intensity

between the reference and measurement

side, and a photometer detector. The detector signal thus alternates between concentration dependent and conce nt rat ion

independent values. The difference between the two is a reliable measure of the

concentration of the absorbing gas component.

Depending on the gas being measured

and its concentration, one of two different

measuring methods may be used as follows:

Interference Filter Correlation (IFC)

With the IFC method the analysis cell is

alternately illuminated with filtered infrared

concentrated in one of two spectrally

separated wavelength ranges. One of

these two wavelength bands is chosen to

coincide with an absorption band of the

sample gas and the other is chosen such

that none of the gas constituents expected to be encountered in practice absorbs anywhere within the band.

The spectral transmittance curves of the

interference filters used in the CAT 100

analyzer and the spectral absorption of

the gases CO and CO

are shown in

2

Figure 1-1 (page 1-3). It can be seen that

the absorption bands of these gases each

coincide with the pas s bands of one of the

interference filters. The forth interference

filter, used for generating a reference signal, has its pass band in a spectral region

where none of these gases absorb. Most

of the other gases of interest also do not

absorb within the pass band of this reference filter.

The signal generation is accomplished

with a pyroelectrical (solid-state) detector.

The detector records the incoming infrared radiation. This radiation is reduced by

the absorption of the gas at the corresponding wavelengths. By comparing the

measurement and reference wavelength,

an alternating voltage signal is produced.

This signal results from the cooling and

heating of the pyroelectric detector material.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 17

Model CAT 100

A

Figure 1-1. Absorption Bands of Sample Gas and Transmittance of Interference Filters

Transmittance (%)

CO2 CO

bsorption Band

Transmittance (%)

0 15 30 54 60 75 90

HC CO

0 18 36 54 72 90

3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600

CO

2

Reference

Wave Length (nm)

Instruction Manual

748441-D

April 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Page 18

Instruction Manual

A

748441-D

April 2002

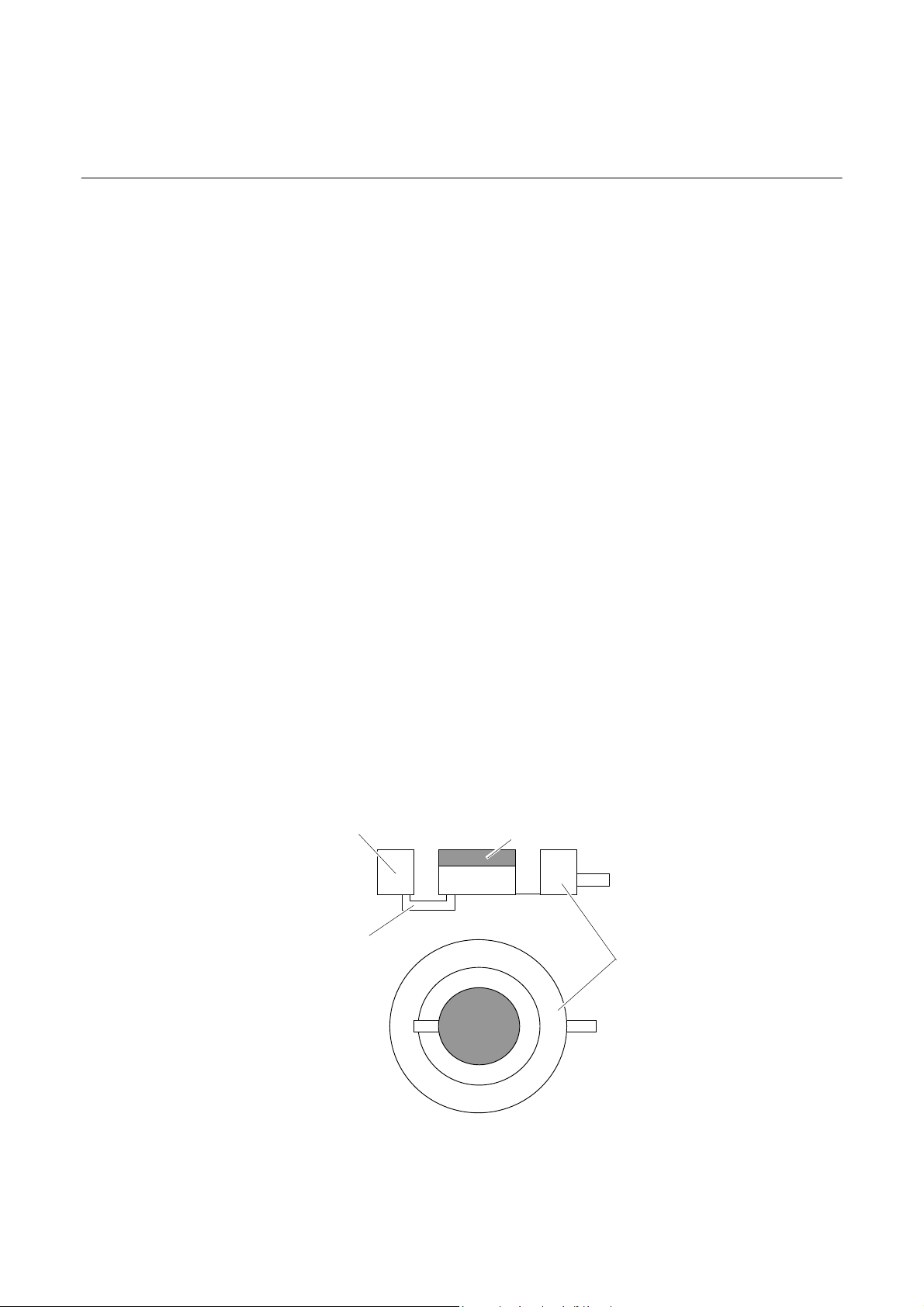

Opto-Pneumatic Method

In the opto-pneumatic method, a thermal

radiator generates the infrared radiation

which passes through the chopper wheel.

This radiation alternately passes through

the filter cell and reaches the measuring

and reference side of the analysis cell

with equal intensity. After passing another

filter cell, the radiation reaches the pneumatic detector.

The pneumatic detector compares and

evaluates the radiation from the measuring and reference sides of the analysis

cell and converts them into voltage signals proportional to their respective intensity.

The pneumatic detector consists of a gasfilled absorption chamber and a compen sation chamber which are connected by a

flow channel in which a Microflow filament

sensor is mounted. This is shown Figure

1-2.

In principle the detector is filled with the

infrared active gas to be measured and is

only sensitive to this distinct gas with its

characteristic absorption spectrum. The

absorption chamber is sealed with a window which is transparent for infrared radiation. The window is usually Calcium

Fluoride (CaF

).

2

bsorption chamber

Flow channel with

Microflow sensor

When the infrared radiation passes

through the reference side of the analysis

cell into the detector, no pre-absorption

occurs. Thus, the gas inside the absorption chamber is heated, expands and

some of it passes through the flow channel into the compensation chamber.

When the infrared radiation passes

through the open measurement side of

the analysis cell into the detector, a part

of it is absorbed depending on the gas

concentration. The gas in the absorption

chamber is, therefore, heated less than in

the case of radiation coming from the reference side. Absorption chamber gas becomes cooler, gas pressure in the

absorption chamber is reduced and some

gas from the compensation chamber

passes through the flow channel into the

absorption chamber.

The flow channel geometry is designed in

such a way that it hardly impedes the gas

flow by restriction. Due to the radiation of

the chopper wheel, the different radiation

intensities lead to periodically repeated

flow pulses within the detector.

The Microflow sensor evaluates these

flow pulses and converts them into electrical pulses which are processed into the

corresponding analyzer output.

Window

CaF

2

Figure 1-2. Opto-Pneumatic Gas Detect or

Model CAT 100

Compensation chamber

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 19

Model CAT 100

A

r

r

A

Instruction Manual

748441-D

April 2002

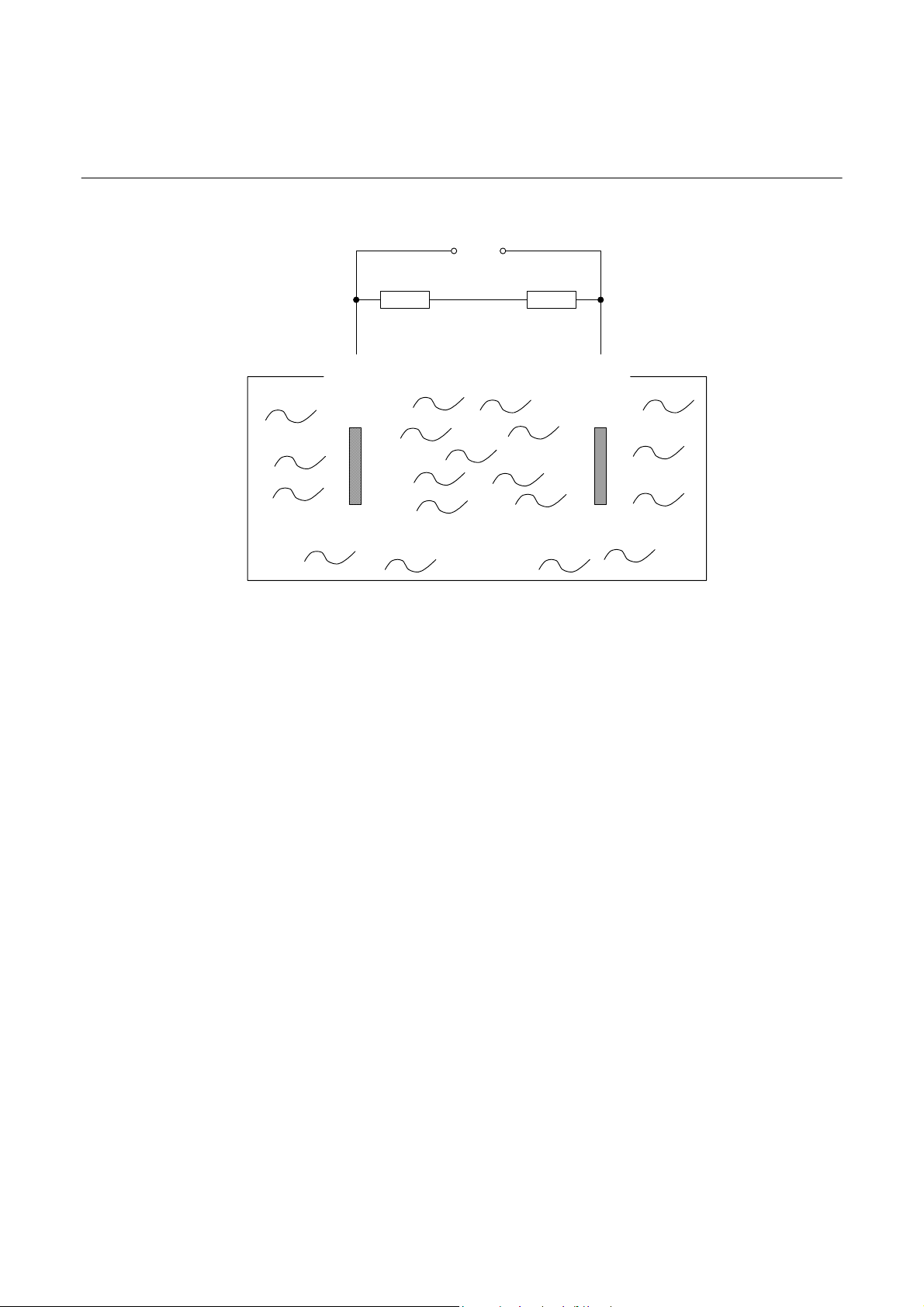

Overall NDIR Method

In the case of dual-channel analyzers, the

broadband emission from two infrared

sources pass through the chopper wheel.

In the case of the Interference Filter Correlation (IFC) method, the infrared radiation then passes through combinations of

interference filters. In the case of the

opto-pneumatic method, the infrared radiation passes through an optical filter

depending on the application and ne ed for

reduction of influences. Then the infrared

radiation enters the analysis cells from

which it is focused by filter cells onto the

corresponding detector. The preamplifier

detector output signal is then converted

into the analytical results expressed directly in the appropriate physical concentration units such as percent v olume,

ppm, mg/Nm

3

, etc. This is shown in

Figure 1-3 (page 1-5).

MOTOR

Light Source

Chopper Blade

Duplex Filter Disc

Analysis Cell

(measuring side)

Analysis Cell

(reference side)

dapter Cell

(high measuring range)

nalysis Cell

(undivided)

Filter Cell

Preamplifier

Filter Cell

Pyroelectric Detector

(solid-state detector)

Gas Detecto

Preamplifie

Chopper Blade

Figure 1-3. Overall NDIR Method

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Page 20

Instruction Manual

r

A

748441-D

April 2002

Model CAT100

b. Paramagnetic Oxygen Method

The paramagnetic principle refers to the

induction of a weak magnetic field, parallel and proportional to the intensity of a

stronger magnetizing field.

The paramagnetic method of determination of oxygen concentration utilizes nitrogen filled quartz spheres arranged at

opposite ends of a bar, the center of

which is suspended by and free to rotate

on a thin platinum wire ribbon in a cell. Nitrogen (N

) is used because it is diamag-

2

netic or repelled by a magnet.

A small mirror that reflects a light beam

coming from a light source to a photo detector, is mounted on the platinum ribbon.

A strong permanent magnet specifically

shaped to produce a strong, highly inhomogeneous magnetic field inside the

analysis cell, is mounted outside the wall

of the cell.

When oxygen molecules enter the cell,

their paramagnetism will cause them to

be drawn towards the region of greatest

Light

Source

Photo detecto

Display

magnetic field strength. The oxygen

molecules thus exert different forces on

the two suspended nitrogen filled quartz

spheres, producing a torque which

causes the mirror to rotate away from its

equilibrium position.

The rotated mirror deflects the incident

light onto the photo detector creating an

electrical signal which is amplified and fed

back to a coil attached to the bar holding

the quartz spheres, forcing the suspended

spheres back to the equilibrium position.

The current required to generate the restoring torque to return the quartz bar to

its equilibrium position is a direct measure

of the O

2

The complete paramagnetic analysis cell

consists of an analysis chamber, permanent magnet, processing electronics, and

a temperature sensor. The temperature

sensor is used to control a heat exchanger to warm the measu ring gas to

about 55 °C. Refer to Figure 1-4 (page 1-

6).

Permanent Magnet

Platinum Wire

Mirror

mplifier

Quartz Sphere(s)

Wire Loop

Figure 1-4. Paramagnetic Oxygen Analysis

concentration in the sample gas.

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 21

Model CAT100

A

Instruction Manual

748441-D

April 2002

c. Electrochemical Oxygen Method

The electrochemical method of det ermining oxygen concentration is based on the

galvanic cell principle shown in Figure 1-6

(page 1-8).

The electrochemical oxygen sensor

(Figure 1-5, page 1-7) incorporates a lead

and gold galvanic process with a lead anode and a gold cathode, using an acid

electrolyte.

Oxygen molecules diffuse through a nonporous Teflon membrane into the electrochemical cell and are reduced at the gold

cathode. Water is the byproduct of this

reaction.

On the anode, lead oxide is formed which

is transferred into the electrolyte. The lead

anode is continuously regenerated and,

therefore, the electrode potential remains

unchanged for a long time. The rate of diffusion and corresponding response time

(t

) of the sensor is dependent on the

90

thickness of the Teflon membrane.

The electric current between the electrodes is proportional to the O

concentra-

2

tion in the sample gas being measured.

The resultant signal is measured as a

voltage across the resistor and thermistor,

the latter of which is use d for temperature

compensation. A change in the output

voltage (mV) represents oxygen concentration.

NOTE

The electrochemical O

cell requires a

2

minimum internal consumption of

oxygen. Sample gases with an oxygen

concentration of less than 0.1 % could

result in a reversible detuning of sensitivity and the output will become unstable. The recommended practice is

to purge the cell with conditioned ambient air between periods of measurement. If the oxygen concentration is

below 0.1 % for several hours or days,

the cell must be regenerated for about

one day with ambient air. Temporary

flushing with nitrogen (N

) for less than

2

one hour (analyzer zeroing) will have

no effect on the sensitivity or stability.

Lead Wire (Anode)

Lead Wire (Cathode)

Anode (Lead)

O-Ring

Black

Red

Resistor

Plastic Disc

Plastic Disk

Thermistor

cid Electrolyte

Sponge Disc

Cathode (Gold Film)

Teflon Membrane

Figure 1-5. Electrochemical Oxygen Sensor

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Page 22

Instruction Manual

(

)

(

)

)

)

748441-D

April 2002

Red

Thermistor (5

(-) (+)

Gold Lead

Cathode (2) Anode (1)

O2 + 4 H + 4 e → 2 H2O2 Pb + 2 H

Summary reaction O

V out

Electrolyte (3)

(ph 6)

+ 2 Pb → 2 PbO

2

Black

Resistor (6

O → 2PbO + 4 H + 4 e

2

Figure 1-6. Reaction of Galvanic Cell

Model CAT100

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 23

Model CAT 100

d. Thermal Conductivity Method

Instruction Manual

748441-D

May 2004

To measure gases like Hydrogen (H

Helium (He), the measurement method of thermal

conductivity (TC) will be used.

Sensor Design

The sensor consists of four small PT

100 resistors arranged in a Wheatstone Bridge which is mounted into

a block made of either aluminum,

stainless steel or Hastelloy, depending on the application (e.g. stainless

steel / Hastelloy for corrosive

gases). The block is thermostat controlled to suppress influence of external temperature change.

Analysis Cell

Both the volume of the block and the mass of

the resistors have been minimized on order

to obtain short response time.

The block contains two gas paths for sample

and reference gas, whereat the reference

gas path is closed for standard applications.

Always two sensors are located in the sample and the reference gas path. The resistors

are full glass packaged to withstand aggressive gases.

Figure 1-7. Thermal Conductivity Sensor

), Argon (Ar) or

2

The material in contact with the gases are

glass, Gold, Aluminum, stainless steel and

Hastelloy, so a high resistance against corrosion by aggressive gases is provided by

this cell.

Measurement Method

The entire measurement cell is thermostat controlled

to a temperature of up to 75 °C. The four sensors

are electrically heated to a high er temperature and

the signal of the Wheatstone Bridge is monitored.

Depending on the thermal conductivity of the gases

that pass the cell, the temperature of the sensors in

contact with the gas changes and thus their electrical resistance. This changes the output signal of the

Wheatstone Bridge and electronic circuitry processes this signal to obtain standardized signal amplitudes, and transmits these to both an indicator

instrument and to the signal output connector.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-9

Page 24

Instruction Manual

748441-D

May 2004

Model CAT 100

1-10 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 25

Model CAT100

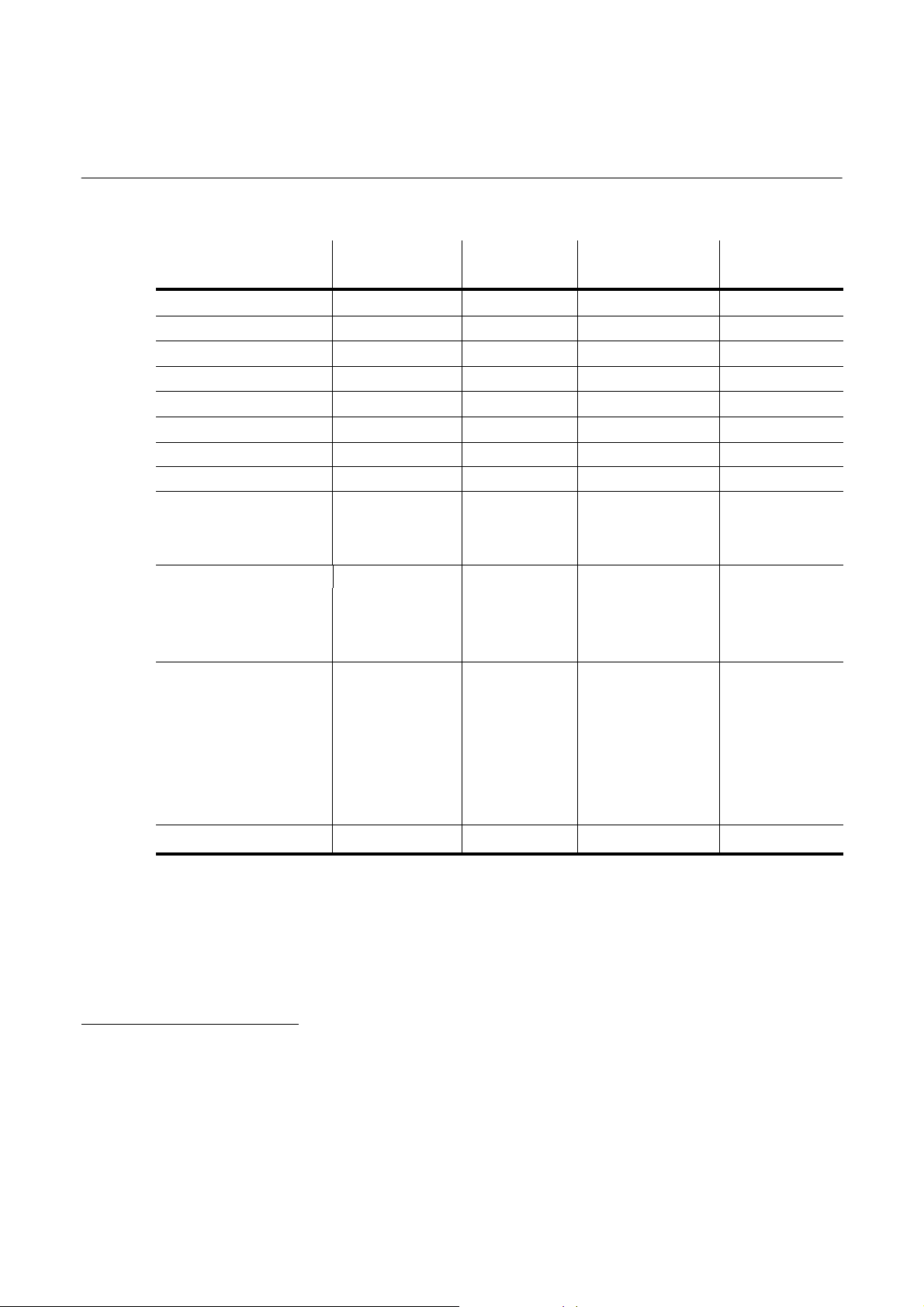

1-4 SPECIFICATIONS

a. General

Power ............................................Universal Power Supply 90-264 VAC, 50-60 Hz, ±10% 180 Watts

Channels (Detectors)/Number....... NDIR, PMD (PO

Mounting........................................ 4” or 6” Pipe, Rack, or Wall Mount

Area Classification......................... See Compliances page P-6

Corrosion Protection Option.......... Instrument grade air is required. Consult factory for requirements

Ambient Range.............................. Temperature (Standard): +5 °C to +45 °C (+41° to 113 °F)

Temperature (Optional): -30 °C to +50 °C (-34° to 122 °F)

Relative Humidity: 5 % to 95 %

Inputs/Outputs...............................Digital: RS 232/ RS 485 serial data or

Analog Current Outputs: Up to 2 isolated 4-20 mA, common

Analog Digital Outputs: Up to 8, 5-30 VDC, max current 30 mA

Analog Current/Voltage Input: Up to 3 (Option for TC electronic

Relay Outputs: Up to 3 “non-voltage carrying contacts”, max 30 V,

Instrument Weight......................... 120 to 150 lbs. (55-70 kg)

Instruction Manual

748441-D

April 2002

Maximum at Start Up. Up to 380 Watts with optional case heater.

), E02, TC. Up to two in one analyzer.

2

FOUNDATION Fieldbus

ground, burden: R

cross compensation) 0(2) - 10 V, 0(4) - 20 mA, 0(0.2) - 1 V

1 A, 30 W

< 500 ohms

B

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-11

Page 26

Instruction Manual

748441-D

April 2002

b. CAT 100 Detector

Model CAT100

Detection Limit

2,3

2,3

2,3

2,3

Linearity

Zero Drift

Span Drift

Repeatability

Response Time

2,3

NDIR

≤1% ≤1% ≤1% ≤2%

O

2

Paramagnetic

1

O

2

Electrochemical

≤1% ≤1% ≤1% ≤1%

≤

2%/week

≤

2%/week

≤

2%/week

≤1%/week ≤1%/week ≤1%/week ≤2%/week

≤1% ≤1% ≤1% ≤1%

5 s ≤ t90 ≤7 s

4

<5-6 s 12s

Thermal

Conductivity 1

≤

2%/week

3s ≤ t90 ≤ 20s 4

Sample Flow Rate .2-1.5 l/min .2-1.0 l/min .2-1.5 l/min .2-1.5 l/min

Sample Pressure

≤

1,500 hPa abs

Atm

≤

1,500 hPa abs

≤

1,500 hPa abs

Influence of Pressure

Standard 5

Pres. Comp. Opt.

≤

0.1%/hPa

5

≤0.01%/hPa

≤

0.1%/hPa

≤0.01%/hPa

≤

0.1%/hPa

≤0.01%/hPa

≤

0.1%/hPa

≤0.01%/hPa

Influence of Temperature

On Zero

On Span

On Span

2

2,6

Sensor Materials in Contact with Sample

Warm-up Time

≤

1%

7

≤5%

≤

1%

Anodized Alum,

Stainless Steel

(gold coated),

BaF

, CaF2

2

15 to 50 Min

≤

1%

≤1%

≤

1%

Stainless Steel,

Platinum, Glass,

PTFE, PVDF,

FPM, Epoxy

resin (Solvent

resistant: no

FPM, no epoxy

but Nickel, Kal-

rez)

4

50 Min 15 to 50 Min 50 Min

≤

1%

≤2%

≤

1%

Aluminum,

Stainless Steel,

FPM, Gold &

ABS,

Teflon

Stainless Steel/

Hastelloy/Glass

≤

1%

≤5%

≤

2%

Glass;

Glass;

7

1

Thermostatically controlled cell 55 °C.

2

Related to full scale, per 10 K.

3

At constant pressure and temperature.

4

Dependent on sensor.

5

Related to measuring valu e.

6

With optional temperature stabilization.

7

Starting from 20° C to +5 °C or +40 °C.

1-12 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 27

Model CAT 100

Instruction Manual

748441-D

May 2004

SECTION 2

INSTALLATION

DANGER.

POSSIBLE EXPLOSION HAZARD

Do not open while energized. Do not operate without dome and covers secure. Installation of this device must be made in

accordance with all applicable national

and/or local codes. See specific references

on installation drawing located in the rear

of this manual.

DANGER.

ELECTRICAL SHOCK HAZARD

Installation and servicing of this device requires access to components that may

present electrical shock and/or mechanical

hazards. Refer installation and servicing to

qualified service personnel.

CAUTION.

HIGH PRESSURE GAS CYLINDERS

This unit requires periodic calibration with

a known standard gas. It also may utilizes

a pressurized carrier gas, such as helium,

hydrogen, or nitrogen. See General Precautions for Handling and Storing High

Pressure Gas Cylinders page P-5.

2-1 PROCESS AND CALIBRATION GAS CON-

NECTION

Besides sample gas, the CAT 100 requires

other gases for operation. In most cases, one

or more Calibration Standards mus t be provided. These should be cylinders of gas which

closely resemble the expected sample, both in

species and concentrations. These calibration

gases are normally introduced into the system

as an input to the Sample Conditioning Plate

Option or sample conditioning may be provided by others.

Each gas cylinder should be equipped with a

clean, hydrocarbon free two-stage pressure

regulator with indicating gauges of approximately 0 to 3000 psig (0 to 207 bar) for cylinder pressure and 0 to 100 psig (0 to 6.7 bar)

for delivery pressure. Pressure regulators

should have a metallic as opposed to elastomeric diaphragm, and provide for ¼ inch

compression fitting outlet and should be LOX

clean.

NOTE

All connections specified in the Installation Drawing, in conjunction with the Application Data Sheet, should be made.

For single channel and dual channel CAT 100

analyzers being plumbed in series, connection

1 is the gas inlet and connection 2 is the g as

outlet for both channels. Dual channel analyzers with parallel tubing use gas inlets and

outlets noted in Figure 2-1

When ONE optional auto calibration solenoid

valve block is installed, the sample gas is introduced to connection 9 instead of connection 1. In this case, the outlet at connection 5

is used.

When parallel tubing and TWO auto calibration valve blocks are supplied, gas inlet 3 and

gas outlet 4 are used for the second channel.

Zero gas 1 and span gas 1 are used for channel 1 (valve block 1) while zero gas 2 and

span gas 2 are used for channel 2 (valve

block 2) (see Figure 2-1

(page 2-2).

).

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 2-1

Page 28

Instruction Manual

748441-D

May 2004

Model CAT 100

An external flow meter may be used (if no internal is available) to adjust the flow rate. In

nel series analyzer is show in Figure 2-2

(page 2-3).

hazardous areas this must be done in accordance with the legislation. The flow must be

adjusted so that calibration gases and sample

gas have the same rate. The auto calibration

solenoid valve option is only available with a

two-channel analyzer with series connection.

Sample pump and solenoid value options are

available with parallel channels depending on

space only. For parallel channels, an external

optional sample handling plate as shown in

Figure 2-3 (page 2-4) may be required to pro-

vide pumping, valving and throttling capabiliAn example of a typical gas connection ar-

ties as necessitated by the application.

rangement for a single channel or dual chan-

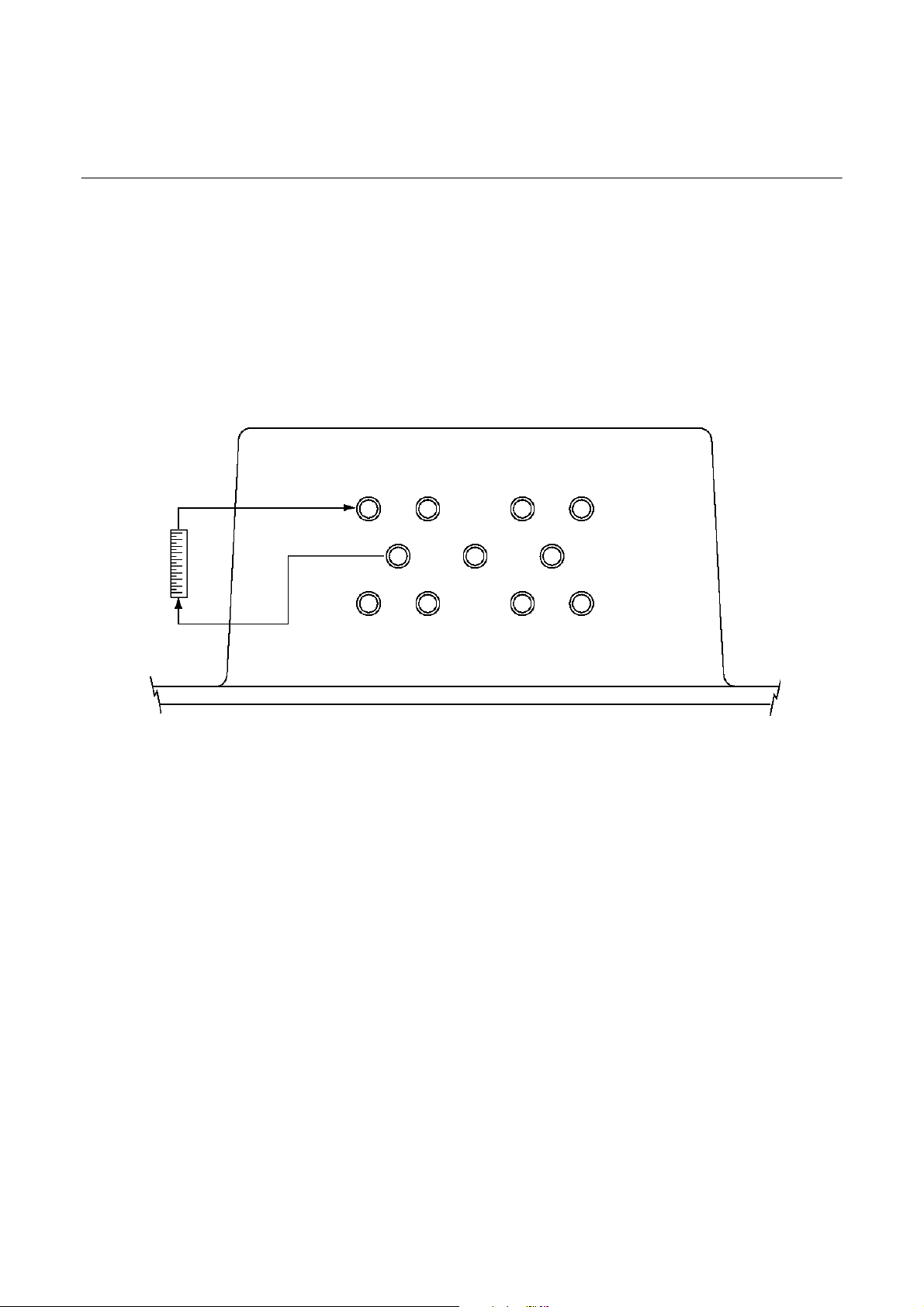

1 2 3 4

Flow Meter*

(option)

567

8 9 10 11

Bottom View

Single or dual channel (Ch) in series:

1 – Gas Inlet (Ch1) 2 – Gas Outlet (Ch1)

Dual channel in parallel:

1 – Gas Inlet (Ch1) 2 – Gas Outlet (Ch1) 3 – Gas Inlet (Ch2) 4 – Gas Outlet (Ch2)

Single or dual channel in series including one auto calibration valve block:

5 – Outlet (Span/Zero/Sample)* 6 – Span Gas 1 Inlet 7 – Span Gas 2 Inlet 8 – Zero Gas Inlet

9 – Sample Gas Inlet

Dual channel in parallel including two auto calibration valve blocks:

1 – Gas Inlet (Ch1) 2 – Gas Outlet (Ch1) 3 – Gas Inlet (Ch2) 4 – Gas Outlet (Ch2)

6 – Span Gas 1 Inlet 7 – Span Gas 2 Inlet 8 – Zero Gas 1 Inlet 10 – Zero Gas 2 Inlet

Option Purge of the CAT housing:

11 – Purge Gas Inlet

* Standard: Outlet = Gas outlet ; Valve block outlet is connected to internal BINOS gas inlet; Option: Valve block

outlet maybe used as outlet for external sample handling (special solution: consult factory)

Figure 2-1. Gas Connections

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 29

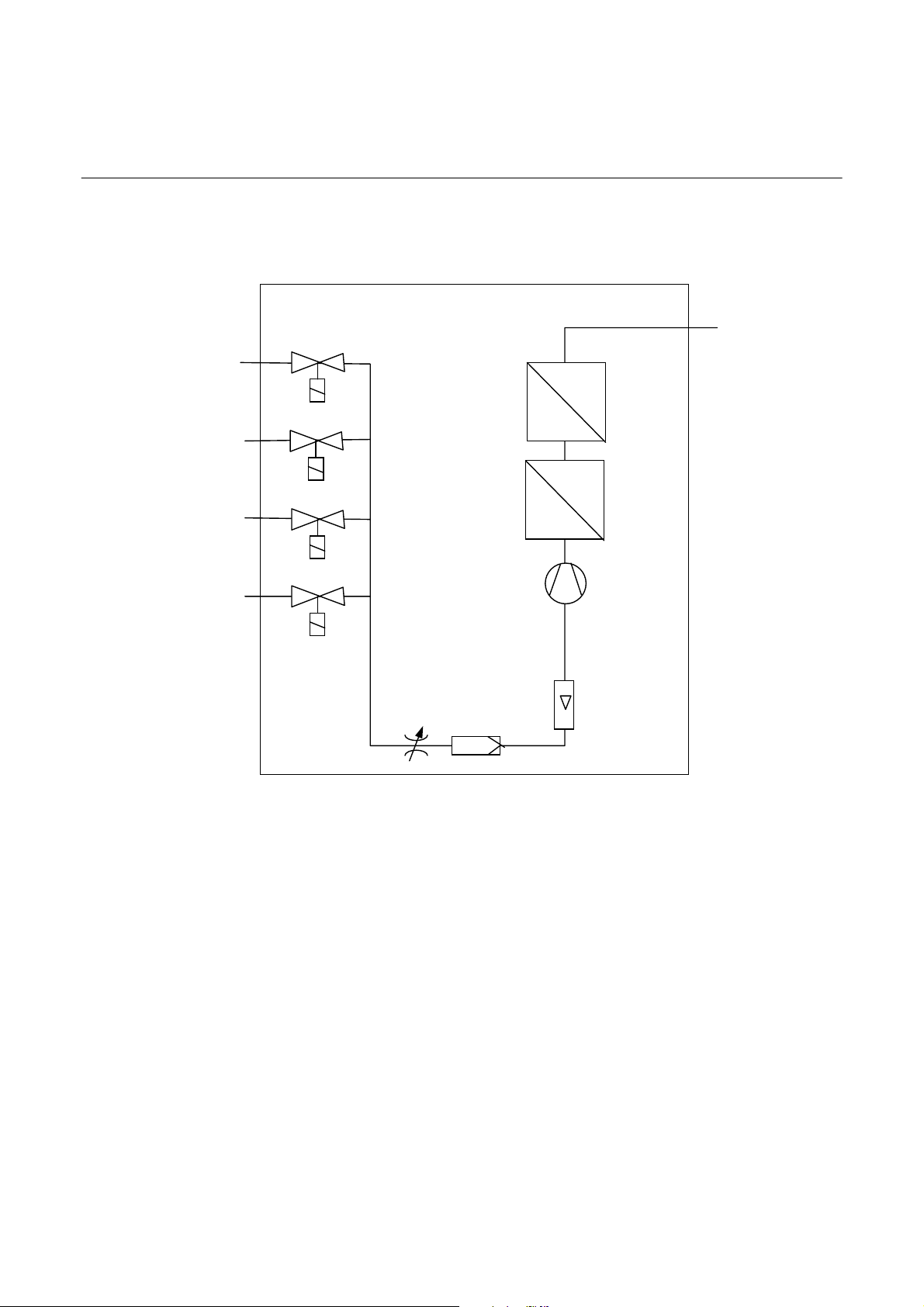

Model CAT100

Span gas 1

Span gas 2

Sample gas

Zero gas

Solenoid Valve

Block

(option)

V1

Channel 2

(option)

V2

V3

V4

Gas Sampling Pump

Throttle and Safety Filter

Channel 1

(option)

(option)

Flow Meter

(option)

Figure 2-2. Piping Diagram (Two channel series)

Instruction Manual

748441-D

April 2002

Gas Outlet

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Page 30

Instruction Manual

[

]

[

]

[

A

[

[

[

]

[

]

[

A

748441-D

April 2002

16.00

27.00

685.8]

14.25

362]

25.50

647.7]

.62

[15.7]

1.25

[31.8]

2.25

[57.2]

Figure 2-3. CAT 100 Outline and Mounting Dimensions

406.4

13.00

330.2

MOUNTING HOLE

.625 [15.88] DIA

4 PLC’S

D

C

2.00

50.8

1.00

25.4

D. SAMPLE HANDLING PLATE OPTION. SIZE AND

ARRANGEMENT SUBJECT TO APPLICATION.

C. ELEVEN GAS CONNECTION PORTS (IF REQUIRED

FOR APPLICATION, FLAME ARRESTOR(S) INSTALLED). SEE FIGURE 2-1.

B. ANALOG AND DIGITAL I/O PORTS (M16 x 1.5).

. INCREASED SAFETY JUNCTION BOX.

Note: The Increased Safety Junction Box must be

protected by fuse supply which has a breaking capacity adjusted to the short circuit of the equipment.

2.50

[63.5]

DIMENSIONS

INCH

MM

Model CAT100

3.00

76.2]

2.90

[73.7]

B

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 31

Model CAT100

Instruction Manual

748441-D

April 2002

a. Gas Conditioning

If the CAT 100 is not supplied with the optional Sample Handling Plate, care must

be taken to ensure that the sample gas is

properly conditioned for successful operation of the various detectors.

All gases must be supplied to the analyzer as conditioned gases! When the

system is used with corrosive gases, it

must be verified that there are no gas

components which may damage the gas

path components.

The gas conditioning must meet the following conditions:

•

Free of condensable constituents

•

Free of dust above 2 µm

•

Free of aggressive constituents

which may damage the gas

paths

When analyzing vapors, the dew point of

the sample gas must be at least 10 °C below the ambient temperature in order to

avoid the precipitation of condensate in

the gas paths.

An optional barometric pressure compensation feature can be supplied for th e

CAT 100. This requires a pressure sensor

with a range of 800 – 1,100 hPa. The

concentration values computer by the detectors will then be corrected to eliminate

erroneous measurements due to changes

in barometric pressure.

The gas flow rate must be in the range of

0.2 l/min to a maximum of 1.5 l/min. A

constant flow rate of 1 l/min is recommended.

NOTE

The maximum gas flow rate for paramagnetic oxygen detectors is 1. 0 l / mi n !

• Temperature and pressure in ac-

cordance with the specifications

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Page 32

Instruction Manual

748441-D

April 2002

Model CAT100

2-2 INSTALLATION

CAUTION.

Do not operate or service this instrument

before reading and understanding this instruction manual and receiving appropriate training.

WARNING

ELECTRICAL SHOCK HAZARD

POSSIBLE EXPLOSION HAZARD

Do not open while energized. Do not operate without dome and covers secure. Installation requires access to live parts

which can cause death or serious injury.

CAUTION.

HIGH PRESSURE GAS CYLINDERS

This unit requires periodic calibration with

a known standard gas. It also may utilizes

a pressurized carrier gas, such as helium,

hydrogen, or nitrogen. See General Precautions for Handling and Storing High

Pressure Gas Cylinders, page P-5.

Refer to the installation drawing supplied with

the application data package.

a. Location

The CAT 100 is designed to be installed

in unsheltered environmental locations. It

is recommended that the analyzer be located out of direct sunlight to the extent

possible.

The CAT 100 should be installed as near

as possible to the sample point, in order

to avoid low response time caused by

long sample gas lines.

b. Limitations

See Specification, Section 1-4 (page 1-

11).

c. Gas Lines

For external gas lines, the use of all new

tubing throughout is strongly recommended. The preferred type is new, refrigeration grade copper tubing, sealed at

the ends. Generally, stainless steel tubing

is less desirable as it contains hydrocarbon contaminants introduced through

cleaning. Pre-cleaned and rins ed st ain less steel tubing is available from various

supply houses, and is recommended if

stainless steel is desired.

d. Services

All input power, AC or DC as well as input

and output digital and analog signals connect through the Safety Junction Box located above the CAT 100 dome.

Power Cable

AC Operation: 16 gauge, minimum .

DC Operation: 12 gauge, minimum.

e. Mounting Options

The CAT 100 can be mounted to either 4½ or 6-¼ inch diameter pipe stands. Alternately, the analyzer can be wall or floor

mounted.

Although the CAT 100 is enclosed in an

explosion proof and environmentally

sealed enclosure (NEMA 4X, IP 55), it

should be protected from direct sunlight.

In areas subjected to harsh winter climates, protection should be provided from

rain and snow. A corrugated awning or

other suitable means can be provided to

meet these conditions.

See drawing 660210 located in the rear of

this manual for typical pipe mounting

method. Note that the mounting stand is

an option.

f. Vent Lines

Connect all vent lines (thes e are specified

on the Application Data Sheet) to an ap-

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 33

Model CAT100

Instruction Manual

748441-D

April 2002

propriate header. The header should have

a means of being purged when venting

dangerous gases. Insure that there is no

backpressure in the vent system as this

will cause variations in the repeatability of

through the Increased Safety Junction

Box. Cable length for these signals

should not exceed 3,000 feet (914 meters), to avoid excessive capacitance

and corresponding signal distortion.

the system.

The following connections are made

g. Electrical Connections

through the Increased Safety Junction

Box:

NOTES

•

1) The enclosure is a NEMA 4X/ IP 55.

All entry locations must be sealed.

2) North American area classification

– Class I Zone 1, Group IIB +H

T4.

2

CENELEC Category 2 – Zone 1,

Group IIB +H

T4.

2

Electrical Power

•

2 Analog Outputs

•

Optional 3 Analog Inputs (for TC

cross compensation)

• 8 Digital Outputs

3) Readily accessible main power

disconnect to be supplied by customer.

4) Electrical installation to be in ac-

• RS 232/RS 485 or Optional

FIELDBUS

•

Optional 3 Relay Outputs

cordance with National Electrical

Code. (ANSI/NFPA 70) and or other

applicable national or local codes.

Connect all required signal cables to

the Increased Safety Junction Box. The

cable entry locations are indicated on

Connections must be made as follows:

USA: ½” Rigid Metal Conduit

European Union: Certified Glands

Canada: Either

the inside cover of the junction box.

The actual electrical connections will

be specified in the Application Data

package. All connections are not necessary for every application.

The Increased Safety Junction Box

must be protected by fuse supply

which has a breaking capacity ad-

All analog/digital inputs and analog/digital/serial outputs are made

justed to the short circuit of the

equipment.

Terminal Description

Top 16 (C-wht) VDC Gnd

Top 17 (C-wht/blk) 0 (2) – 10 VDC [option 0 (0.2) – 1 VDC], Channel 1

Top 18 (C-wht/brn)

0 (4) – 20 mA, Channel 1 (R

≤ 500 Ω)

B

Top 19 (C-wht/red) 0 (2) – 10 VDC [option 0 (0.2) – 1 VDC], Channel 2

Top 20 (C-wht/org)

0 (4) – 20 mA, Channel 2 (R

≤ 500 Ω)

B

Bottom 16 (C-wht/yel) mA return (Gnd)

Bottom 17 (C-wht/grn) mA return (Gnd)

Bottom 18 (C-wht/blu) mA return (Gnd)

Bottom 19 (C-wht/vio) mA return (Gnd)

Table 2-1. Analog Output Terminal Assignments

NOTE

NOTE

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Page 34

Instruction Manual

748441-D

April 2002

Terminal Description

Bottom 1 (C-blk) High limit reached, channel 2

Bottom 2 (C-brn) Low limit reached, chan nel 2

Bottom 3 (C-red) High limit reached, channel 1

Bottom 4 (C-org) Low limit reached, chan nel 1

Bottom 5 (C-yel) Gnd

Bottom 6 (C-grn) Valve control, span gas 2

Bottom 7 (C-blu) Valve control span gas 1

Bottom 8 (C-vio) Valve control, zero gas

Bottom 9 (C-gry) Valve control, sample gas

Note: The loading of the open collector digital outputs is a maximum of 30 VDC and 30 mA.

Terminal Description

Bottom 10 (C-wht/gry) OK/Failure (open/closed)

Bottom 11 (C-blk/red) OK/Failure (closed/open)

Bottom 12 (C-blk/org) Measure/Calibration (open/closed)

Bottom 13 (C-blk/yel) Measure/Calibration (closed/open)

Bottom 14 (C-blk/grn) OK/Failure (common)

Bottom 15 (C-blk/blu) Measure/Calibration (common)

Bottom 20 (D-blk/yel) Pump Off/On (open/closed)

Bottom 21 (D-blk/blu) Pump Off/On (closed/open)

Top 21 (D-blk/grn) Pump Off/On (common)

Note: Non-voltage carrying contacts, maximum 30 V, 1 A, 30 W.

Table 2-3. Optional Relay Outputs (Status Signals) Terminal Assignments

Terminal Description

Top 1 (D-blk) Interfering gas 1

Top 2 (D-brn) Interfering gas 1

Top 3 (D-red) Interfering gas 2

Top 4 (D-org) Interfering gas 2

Top 5 (D-yel) Interfering gas 3

Top 6 (D-grn) Interfering gas 3 (Gnd)

Table 2-4. Optional Analog Inputs for TCD Cross Compensation

Model CAT100

Table 2-2. Digital Output Terminal Assignments

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 35

Model CAT100

Terminal Signal Terminal Signal

Top 7 (D-blu) Gnd Top 11 (D-wht/blk) Gnd

Top 8 (D-vio) RxD Top 12 (D-wht/brn) RxD Top 9 (D-gry) TxD Top 13 (D-wht/red) RxD +

Top 10 (D-wht) Gnd Top 14 (D-wht/org) TxD Top 15 (D-wht/yel) TxD +

Table 2-7. Foundation Fieldbus Terminal Assignments (option)

Connect AC power through a 10 A circuit

breaker that is to be located close to the

CAT 100. The circuit breaker will provide