Emerson Rosemount 8750WA Quick Installation Manual

Quick Installation Guide

Start

Step 1: Pre-Installation

Step 2: Handling

Step 3: Mounting

Step 4: Installation

(Flanged Sensors)

(Wafer Sensors)

Step 5: Grounding

Step 6: Wiring

Step 7: Basic Configuration

Product Certifications

End

00825-0100-4750, Rev BB

January 2013

Rosemount 8750WA

Rosemount 8750WA Magnetic Flowmeter

System (Transmitter and Sensor)

www.rosemount.com

¢00825-0100-4725.¤

Quick Installation Guide

IMPORTANT NOTICE

WARNING

WARNING

Emerson Process Management

Rosemount Flow

7070 Winchester Circle,

Boulder, CO 80301

Tel (USA) 800 522 6277

Tel (International) +1 (303) 527 5200

Fax +1 (303) 530 8459

00825-0100-4750, Rev BB

Rosemount 8750WA

© 2013 Rosemount Inc. All rights reserved. All marks property of owner.

This installation guide provides basic guidelines for the Rosemount® 8750WA. It does not

provide instructions for detailed configuration, diagnostics, maintenance, service,

troubleshooting, explosion-proof, flame-proof, or intrinsically safe (I.S.) installations.

Refer to the Rosemount 8750WA reference manual (document number

00809-0100-4750) for more instructions. The manual and this QIG are also available

electronically on www.rosemount.com.

January 2013

Failure to follow these installation guidelines could result in death or serious

injury:

Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified. Verify that the operating environment of the sensor and transmitter is consistent

with the appropriate FM or CSA approval.

The sensor liner is vulnerable to handling damage. Never place anything through the

sensor for the purpose of lifting or gaining leverage. Liner damage can render the sensor

useless.

To avoid possible damage to the sensor liner ends, do not use metallic or spiral-wound

gaskets. If frequent removal is anticipated, take precautions to protect the liner ends.

Short spool pieces attached to the sensor ends are often used for protection.

Correct flange bolt tightening is crucial for proper sensor operation and life. All bolts must

be tightened in the proper sequence to the specified torque limits. Failure to observe

these instructions could result in severe damage to the sensor lining and possible sensor

replacement.

2

Quick Installation Guide

STEP 1: PRE-INSTALLATION

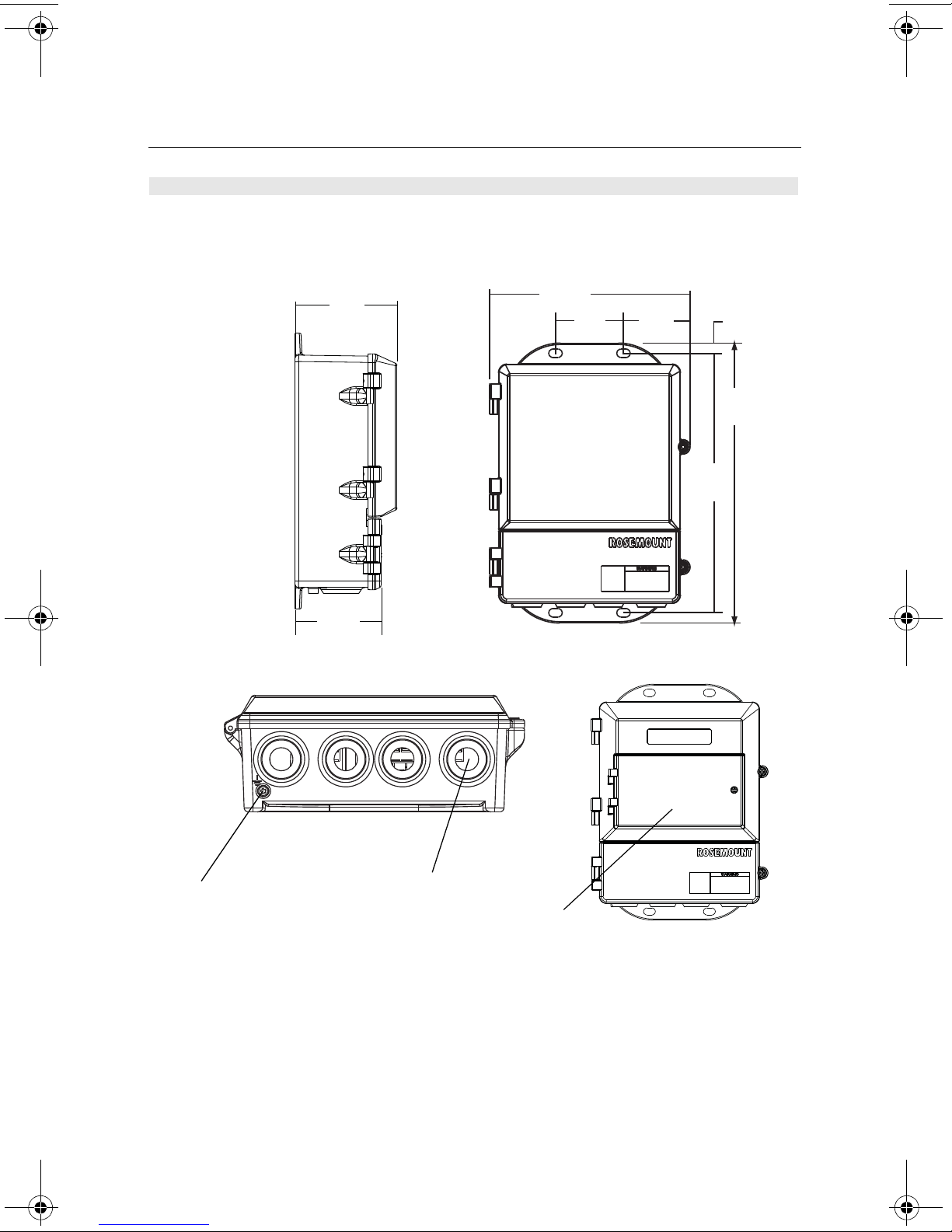

5.82

(148)

6.48 (165)

7.49 (190)

LOI Cover

4.97

(126)

8.81

(224)

3.00

(76)

3.07

(78)

4.97

(126)

1

/2”-14 NPT* (3 places)

1

/2”-14 NPT, (2 places)*

00825-0100-4750, Rev BB

January 2013

Rosemount 8750WA

Before installing the Rosemount 8750WA Magnetic Flowmeter Transmitter, there are

several pre-installation steps that should be completed to make the installation process

easier:

• Identify the options and configurations that apply to your application

• Set the hardware switches if necessary

• Consider mechanical, electrical, and environmental requirements

Mechanical Considerations

The mounting site for the Rosemount 8750WA transmitter should provide enough room for

secure mounting, easy access to conduit ports, full opening of the transmitter covers, and

easy readability of the LOI screen (see Figure 1 and Figure 2).

If the Rosemount 8750WA transmitter is mounted separately from the sensor, it is not

subject to limitations that might apply to the sensor.

Figure 1. Rosemount 8750WA32E Dimensional Drawing

NOTE:

*M20 and PG 13.5 connections are available with the use of threaded conduit adapters.

3

Rosemount 8750WA

4.31

(109)

LOI Keypad

Cover

9.01

(229)

11.15

(283)

2.81

(71)

3.11

(79)

12.02

(305)

0.44

(11)

Ground Lug

1

/2–14 NPT

Conduit

Connection

(4 Places)

WITH STANDARD COVER

NOTE

Dimensions are in inches (millimeters)

2.96

(75)

WITH LOI COVER

Figure 2. 8750WA12E Dimensional Drawing

Quick Installation Guide

00825-0100-4750, Rev BB

January 2013

4

Quick Installation Guide

STEP 1 CONTINUED...

00825-0100-4750, Rev BB

January 2013

Rosemount 8750WA

Environmental Considerations

To ensure maximum transmitter life, avoid excessive heat and vibration. Typical problem

areas:

• high-vibration lines with integrally mounted transmitters

• warm-climate installations in direct sunlight

• outdoor installations in cold climates.

Remote-mounted transmitters may be installed in the control room to protect the electronics

from the harsh environment and provide easy access for configuration or service.

Both remotely and integrally mounted Rosemount 8750WA transmitters require external

power so there must be access to a suitable power source.

Installation Procedures

Rosemount 8750WA installation includes both detailed mechanical and electrical installation

procedures.

Mount the Transmitter

At a remote site the transmitter may be mounted on a pipe up to two inches in diameter or

against a flat surface.

Pipe Mounting

To mount the transmitter on a pipe:

1. Attach the mounting bracket to the pipe using the mounting hardware.

2. Attach the Rosemount 8750WA transmitter to the mounting bracket using the mounting

screws.

Identify Options and Configurations

The standard application of the 8750WA includes a 4–20 mA output and control of the

sensor coils and electrodes. Other applications may require one or more of the following

configurations or options:

• Multidrop Communications

• Digital Output

• Digital Input

• Pulse Output

Additional options may apply . Be sure to identify those options and configurations that apply

to your situation and keep a list of them nearby for consideration during the installation and

configuration procedures.

5

Quick Installation Guide

STEP 1 CONTINUED...

00825-0100-4750, Rev BB

Rosemount 8750WA

January 2013

Hardware Jumpers/Switches

The 8750WA electronics board is equipped with three or four user-selectable hardware

switches depending on the transmitter model ordered. These switches set the Failure Alarm

Mode, Internal/External Analog Power, Internal/External Pulse Power (8750WA32), and

Transmitter Security. The standard configuration for these switches when shipped from the

factory is as follows:

Failure Alarm Mode: HIGH

Internal/External Analog Power: INTERNAL

Internal/External Pulse Power: EXTERNAL (8750WA32 only)

Transmitter Security: OFF

Changing Hardware Switch Settings

In most cases, it is not necessary to change the setting of the hardware switches. If you

need to change the switch settings, complete the steps outlined in the manual.

Electrical Considerations

Before making any electrical connections to the Rosemount 8750WA, consider the local and

plant electrical standards and be sure to have the proper power supply, conduit, and other

accessories.

Rotate Transmitter Housing

The integral electronics housing can be rotated on the sensor in 90° increments by

loosening the four mounting bolts on the bottom of the housing, and reinstalling the bolts.

When reinstalling the housing, be sure the surface is clean and there is no gap between the

housing and the sensor.

6

Quick Installation Guide

STEP 2: HANDLING

½- through 4-Inch Sensors

6-Inch and Larger Sensors

00825-0100-4750, Rev BB

January 2013

Handle all parts carefully to prevent damage. Whenever possible, transport the system to

the installation site in the original shipping containers. PTFE-lined sensors are shipped with

end covers that protect it from both mechanical damage and normal unrestrained distortion.

Remove the end covers just before installation.

Figure 3. Rosemount 8750WA Flanged Sensor Support for Handling

Rosemount 8750WA

7

Quick Installation Guide

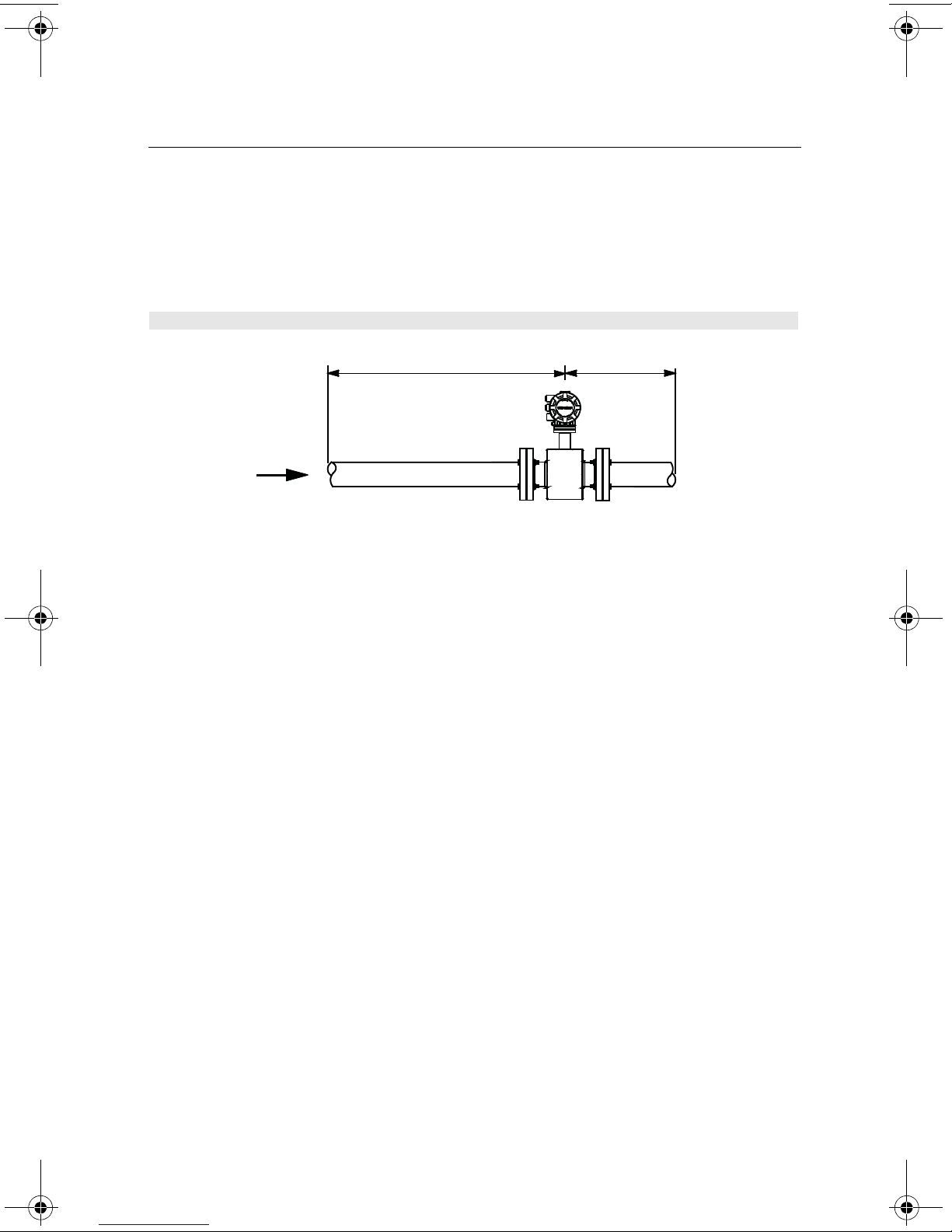

STEP 3: MOUNTING

5 Pipe Diameters

2 Pipe Diameters

Flow

00825-0100-4750, Rev BB

Rosemount 8750WA

January 2013

Upstream/Downstream Piping

To ensure specification accuracy over widely varying process conditions, install the sensor a

minimum of five straight pipe diameters upstream and two pipe diameters downstream from

the electrode plane (see Figure 4).

Figure 4. Upstream and Downstream Straight Pipe Diameters

The 8750WA sensor may be installed with as few as zero pipe diameters upstream. Consult

the factory for performance in applications with less than ideal straight runs.

Flow Direction

The sensor should be mounted so the FORWARD end of the flow arrow, shown on the

sensor identification tag, points in the direction of flow through the sensor.

Sensor Orientation

The sensor should be installed in a position that ensures the sensor remains full during

operation. Vertical installation allows upward process fluid flow and keeps the

cross-sectional area full, regardless of flow rate. Horizontal installation should be restricted

to low piping sections that are normally full. In these cases, orient the electrode plane to

within 45 degrees of horizontal.

8

Quick Installation Guide

STEP 3 CONTINUED...

FLOW

FLOW

45° Electrode Plane

45° Electrode Plane

00825-0100-4750, Rev BB

January 2013

Figure 5. Sensor Orientation

Rosemount 8750WA

The electrodes in the Rosemount 8750WA flanged sensor are properly orientated when the

two measurement electrodes are in the 3 and 9 o’clock positions, as shown on the right of

Figure 5.

The electrodes in the Rosemount 8750WA wafer sensor are properly orientated when the

top of the sensor is either vertical or horizontal, as shown in Figure 6. Avoid any mounting

orientation that positions the top of the sensor at 45° from the vertical or horizontal position.

Figure 6. Rosemount 8750WA Wafer Sensor Mounting Position

9

Quick Installation Guide

STEP 4: INSTALLATION

00825-0100-4750, Rev BB

Rosemount 8750WA

January 2013

Flanged Sensors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The gasket

material selected must be compatible with the process fluid and operating conditions. Metallic or

spiral-wound gaskets can damage the liner. Gaskets are required on each side of a

grounding ring. All other applications (including sensors with lining protectors or a grounding

electrode) require only one gasket on each end connection.

Figure 7. Flanged gasket placement

Flange Bolts

Suggested torque values by sensor line size and liner type are listed in Table 1 on page 11.

Consult the factory if the flange rating of the sensor is not listed. Tighten flange bolts on the

upstream side of the sensor in the incremental sequence shown in Figure 8 on page 11 to

20% of the suggested torque values. Repeat the process on the downstream side of the

sensor. For sensors with more or less flange bolts, tighten the bolts in a similar crosswise

sequence. Repeat this entire tightening sequence at 40%, 60%, 80%, and 100% of the

suggested torque values or until the leak between the process and sensor flanges stop.

If leakage has not stopped at the suggested torque values, the bolts can be tightened in

additional 10% increments until the joint stops leaking, or until the measured torque value

reaches the maximum torque value of the bolts. Practical consideration for the integrity of

the liner often leads the user to distinct torque values to stop leakage due to the unique

combinations of flanges, bolts, gaskets, and sensor liner material.

Check for leaks at the flanges after tightening the bolts. Failure to use the correct tightening

methods can result in severe damage. Sensors require a second tightening 24 hours after

the initial installation. Over time, sensor liner materials may deform under pressure.

10

Quick Installation Guide

00825-0100-4750, Rev BB

January 2013

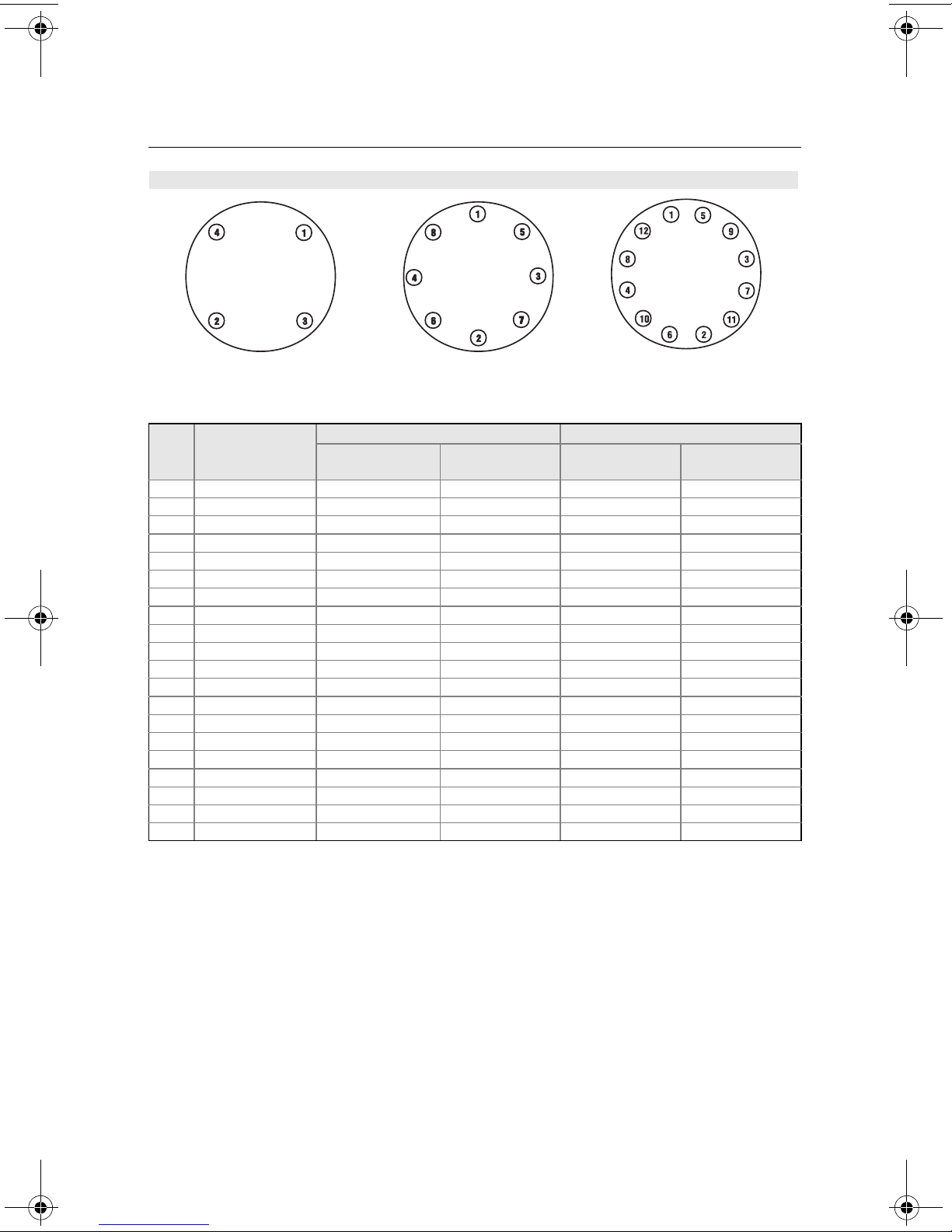

Figure 8. Flange Bolt Torquing Sequence

Table 1. Suggested Flange Bolt Torque Values for ASME B16.5 (ANSI) Flanged Sensors

PTFE Liner Polyurethane/Neoprene liner

Size

Code

Line Size

005 0.5 inch (15 mm) 8 8 - 010 1 inch (25 mm) 8 12 - 015 1.5 inch (40 mm) 13 25 7 18

020 2 inch (50 mm) 19 17 14 11

030 3 inch (80 mm) 34 35 23 23

040 4 inch (100 mm) 26 50 17 32

060 6 inch (150mm) 45 50 30 37

080 8 inch (200 mm) 60 82 42 55

100 10 inch (250 mm) 55 80 40 70

120 12 inch (300 mm) 65 125 55 105

140 14 inch (350 mm) 85 110 70 95

160 16 inch (400 mm) 85 160 65 140

180 18 inch (450 mm) 120 170 95 150

200 20 inch (500 mm) 110 175 90 150

240 24 inch (600 mm) 165 280 140 250

300 30 inch (750 mm) 195

360 36 inch (900 mm) 280

400 40 inch (1000 mm) - - 420 42 inch (1050 mm) - - 480 48 inch (1200 mm) - - -

(1) Sensors ordered with flange option code “A1” use MSS-SP44 Class 150 flanges.

(2) Sensors ordered with flange option code “AA” use AWWA Table D flanges

Sensors ordered with flange option code “AB” use AWWA Table E flanges

(3) Neoprene Liner only

Class 150

(pound-feet)

(1)(2)

(1)(2)

Class 300

(pound-feet)

- 165

- 245

Rosemount 8750WA

Class 150

(pound-feet)

(1)(2)

(1)(2)

(2)(3)

(2)(3)

(2)(3)

Class 300

(pound-feet)

-

-

-

-

-

11

Quick Installation Guide

00825-0100-4750, Rev BB

Rosemount 8750WA

January 2013

Wafer Sensors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The gasket

material selected must be compatible with the process fluid and operating conditions. Metallic or

spiral-wound gaskets can damage the liner. Gaskets are required on each side of a

grounding ring. See Figure 9 below.

Figure 9. Wafer gasket placement

Spacer Installation

Horizontal meters

Vertical meters

O-ring

Alignment

1. On 1.5 - through 8-inch (40 through 200 mm) line sizes. Rosemount strongly

recommends installing the alignment spacers provided to insure proper centering of the

wafer sensor between the process flanges. The smaller line sizes, 0.5 and 1 in. (15 and

25 mm), do not require alignment spacers.

2. Insert studs for the bottom side of the sensor between the pipe flanges and center the

alignment spacer in the middle of the stud. See Figure 9 for the bolt hole locations

recommended for the spacers provided. Stud specifications are listed in Table 2.

3. Place the sensor between the flanges. Make sure that the alignment spacers are

properly centered on the studs. For vertical flow installations slide the oring over the stud

to keep the spacer in place. See Figure 9. To ensure the spacers match the flange size

and class rating for the process flanges see Table 3.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 4 on page 13. Do not overtighten the

bolts or the liner may be damaged.

Table 2. Stud Specifications

Nominal Sensor Size Stud Specifications

0.5 – 1 inch (15 – 25 mm) 316 SST ASTM A193, Grade B8M Class 1 threaded mounted studs

1.5 – 8 inch (40 – 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

NOTE

Using carbon steel bolts on smaller line sizes, 0.5 and 1 in. (15 and 25 mm), rather than the

required stainless steel bolts, will degrade performance.

12

Loading...

Loading...