Page 1

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C Magnetic Flowmeter

Transmitter with F

OUNDATION

™

Fieldbus and

8700 Series Magnetic Flowmeter Flowtube

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Rosemount 8742C Magnetic

Flowmeter Transmitter with

F

OUNDATION

™

Fieldbus and 8700

Series Magnetic Flowmeter

Flowtube

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of the United States, contact your local Rosemount representative.

www.rosemount.com

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

Rosemount, the Rosemount logotype, Fisher-Rosemount, Managing the Process Better,

PlantWeb, and SMART FAMILY are registered trademarks of Rosemount Inc.

DeltaV is a trademark of the Fisher-Rosemount group of companies.

HART is a registered trademark of the HART Communication Foundation.

Tefzel and Teflon are registered trademarks of E.I. du Pont de Nemours & Co.

Ryton is a registered trademark of the Phillips Petroleum Co.

Fluoraz is a registered trademark of Greens, Tweed & Co., Inc.

Hastelloy C and Hastelloy C-22 are registered trademarks of Haynes International,

OUNDATION is a trademark of the Fieldbus Foundation.

F

Cover photo: 8742h0002

Page 4

Page 5

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Transmitter Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Pre-Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Identify Options and Configurations . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hardware Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Simulate Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Changing Hardware

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Rotate Transmitter Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Conduit Ports and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Conduit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Conduit Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Transmitter Coil Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Installation Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transmitter Communication Input . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Field Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transmitter Wiring Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Transmitter to

Flowtube Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Flowtube to Remote Mount Transmitter Connections . . . . . . . . . . 2-9

Flowtube to Integral Mount Transmitter Connections. . . . . . . . . . 2-10

www.rosemount.com

Page 6

Rosemount 8742C

Reference Manual

00809-0100-40793, Rev CA

August 2004

SECTION 3

Flowtube Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Flowtube Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Flowtube Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Upstream/Downstream

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Flowtube Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Flow Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installation (Flanged Flowtube) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Flange Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Installation

(Wafer Flowtube) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Flange Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Installation

(Sanitary Flowtube) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Alignment and Bolting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Process Leak Protection (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Standard Housing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Relief Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Process Leak Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

SECTION 4

Configuration

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Quick Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Flowtube Calibration Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Assigning Device Tag and Node Address . . . . . . . . . . . . . . . . . . . . . . 4-2

AI Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Arithmetic Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Integrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PID Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Configuring Links and Scheduling Block Execution. . . . . . . . . . . . . . . 4-5

Advanced Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cascade Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

FEATURES and FEATURES_SEL . . . . . . . . . . . . . . . . . . . . . . . . 4-8

MAX_NOTIFY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

PlantWeb

™

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

TOC-2

Page 7

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

SECTION 5

Operation and

Maintenance

SECTION 6

Troubleshooting

APPENDIX A

Reference Data

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Software Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Local Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Electronics Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Auto Zero Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Configuring the Advanced Diagnostics and Empty Pipe . . . . . . . . 5-4

Learning Empty Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Diagnostic Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Hardware Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Replacing the F

Replacing the F

Replacing the F

Step 1: Function Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Step 2: Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Step 3: Wiring Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Step 4: Process Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Step 5: Installed Flowtube Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Step 6: Uninstalled Flowtube Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Rosemount 8742C Transmitter Specifications . . . . . . . . . . . . . . . . . .A-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Foundation Fieldbus Specifications . . . . . . . . . . . . . . . . . . . . . . . . A-3

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Rosemount 8705 and 8707 Flowtubes Specifications. . . . . . . . . . . . . A-5

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Rosemount 8711 Wafer Flowtube Specifications . . . . . . . . . . . . . . . A-11

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Rosemount 8714D Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

Rosemount 8742C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

Rosemount 8705 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Rosemount 8707 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-28

Rosemount 8711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Rosemount 8714 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

OUNDATION

OUNDATION

OUNDATION

™

Fieldbus Electronics Housing. . . . . . 5-9

™

Fieldbus Terminal Block in the Housing5-10

™

Fieldbus Electronics Boards. . . . . . 5-10

TOC-3

Page 8

Rosemount 8742C

Reference Manual

00809-0100-40793, Rev CA

August 2004

APPENDIX B

Product Certifications

APPENDIX C

Resource Block

APPENDIX D

Transducer Block

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ATEX Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Pressure Equipment Directive (PED) (97/23/EC) . . . . . B-1

Electro Magnetic Compatibility (EMC) (89/336/EEC) . . . . . . . . . . .B-2

Low Voltage Directive (93/68/EEC) . . . . . . . . . . . . . . . . . . . . . . . .B-2

Other important guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Hazardous Location Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Transmitter Approval Information . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Flowtube Approval Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Resource Block Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

VCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Flow-Specific Block Configuration Values . . . . . . . . . . . . . . . . . . . . . .D-3

Transducer Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Transducer Block Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

APPENDIX E

Field-Removable

Electrodes

TOC-4

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Remove the Electrode Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Replace the Electrode Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Page 9

Reference Manual

00809-0100-4793, Rev CA

August 2004

Section 1 Introduction

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Rosemount 8742C

SYSTEM DESCRIPTION The Rosemount

separate flowtube and transmitter units, and measures volumetric flow rate by

detecting the velocity of a conductive liquid that passes through a magnetic

field. Magnetic Flowmeter Systems consist of a flowtube and a transmitter.

There are three Rosemount magnetic flowmeter flowtubes:

• Flanged Rosemount 8705

• Flanged High-Signal Rosemount 8707

• Wafer-Style Rosemount 8711

• Sanitary 8721

There are three Rosemount magnetic flowmeter transmitters:

• Rosemount 8712D/H

• Rosemount 8732C

• Rosemount 8742C

The flowtube is installed in-line with process piping — either vertically or

horizontally. Coils located on opposite sides of the flowtube create a magnetic

field. A conductive liquid moving through the magnetic field generates a

voltage at the two electrodes that is proportional to the flow velocity.

The transmitter drives the coils to generate a magnetic field and electronically

conditions the voltage detected by the electrodes. The transmitter then

amplifies and conditions the electrode signal to provide a flow signal. The

transmitter can be integrally mounted or remotely mounted from the flowtube.

®

8700 Series Magnetic Flowmeter System combines

www.rosemount.com

This manual is designed to assist in the installation and operation of

Rosemount 8742C Magnetic Flowmeter Transmitter with F

fieldbus and 8700 Series Magnetic Flowmeter Flowtubes.

Attempting to install and operate the Rosemount 8705, 8707 High-Signal,

or 8711 Magnetic Flowmeter Flowtubes with the Rosemount 8712D/H,

8732, or 8742 Magnetic Flowmeter Transmitter without reviewing the instructions

contained in this manual could result in personal injury or equipment damage.

OUNDATION

™

Page 10

Rosemount 8742C

00809-0100-4793, Rev CA

Section 2: Installation

• Transmitter Commissioning

• Wiring Flowmeter to a Flowtube

Section 3: Flowtube Installation

• Handling

• Mounting

• Installation of a Flanged, Wafer, and Sanitary Flowtube

Section 4: Configuration

• Assigning Device Tag

• Configuring Blocks

• Configuring Links and Scheduling Block Execution

Section 5: Operation and Maintenance

• Software Operation

• Hardware Maintenance

• Replacing the F

OUNDATION

™

fieldbus Electronics Housing

Reference Manual

August 2004

Section 6: Troubleshooting

• Troubleshooting Procedures

• Electrical Circuit Diagrams

Appendix A: Reference Data

• Specifications for Rosemount 8742 Transmitter

and 8700 Series Flowtubes

• Ordering Tables

• Dimensional Drawings

Appendix B: Product Certifications

• Transmitter Approval Information

• Flowtube Approval Information

Appendix C: Resource Block

• Parameters and Descriptions

• Modes

Appendix D: Transducer Block

• Parameters and Descriptions

• Modes

Appendix E: Field-Removable Electrodes

• Electrode Assembly

1-2

Page 11

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Refer to the

safety messages listed at the beginning of each section before performing

any operations.

RETURN OF MATERIALS To expedite the return process outside the United States, contact the nearest

Rosemount representative.

Within the United States and Canada, call the North American Response

Center using the 800-654-RSMT (7768) toll-free number. The Response

Center, available 24 hours a day, will assist you with any needed information

or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

name of the process material to which the product was last exposed.

Mishandling products exposed to a hazardous substance may result in death

or serious injury. If the product being returned was exposed to a hazardous

substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with

the returned goods.

The North American Response Center will detail the additional information

and procedures necessary to return goods exposed to hazardous

substances.

See “Safety Information” on page 4-1 for complete warning information.

1-3

Page 12

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

1-4

Page 13

Reference Manual

00809-0100-4793, Rev CA

August 2004

Section 2 Installation

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Transmitter Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

This section covers the steps required to physically install the magnetic

flowmeter. Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the operations.

Please refer to the following safety messages before performing any

operation in this section.

Rosemount 8742C

SAFETY INFORMATION

Failure to follow these installation guidelines could result in death or serious injury:

Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified. Verify that the operating environment of the flowtube and transmitter is

consistent with the appropriate FM or CSA approval.

Do not connect a Rosemount 8742C to a non-Rosemount flowtube that is located in an

explosive atmosphere.

The flowtube liner is vulnerable to handling damage. Never place anything through the

flowtube for the purpose of lifting or gaining leverage. Liner damage can render the

flowtube useless.

To avoid possible damage to the flowtube liner ends, do not use metallic or

spiral-wound gaskets. If frequent removal is anticipated, take precautions to protect the

liner ends. Short spool pieces attached to the flowtube ends are often used for

protection.

Correct flange bolt tightening is crucial for proper flowtube operation and life. All bolts

must be tightened in the proper sequence to the specified torque limits. Failure to

observe these instructions could result in severe damage to the flowtube lining and

possible flowtube replacement.

www.rosemount.com

Page 14

Rosemount 8742C

Reference Manual

00809-0100-4793, Rev CA

August 2004

TRANSMITTER

SYMBOLS

Caution Symbol — Check product documentation for details.

Protective conductor (grounding) terminal.

PRE-INSTALLATION Before installing the Rosemount 8742C Magnetic Flowmeter Transmitter,

there are several pre-installation steps that should be completed to make the

installation process easier. They include identifying the options and

configurations that apply to your application, setting the hardware switches if

necessary, and consideration of physical requirements.

The mounting site for the 8742C should provide enough room for secure

mounting, easy access to the conduit ports, and full opening of the transmitter

covers.

To ensure maximum transmitter life, avoid excessive heat and vibration.

Typical problem areas include high-vibration lines with integrally mounted

transmitters, warm-climate installations in direct sunlight, and outdoor

installations in cold climates. To avoid potential problems, remotely mounted

transmitters may be installed in the control room. This protects the electronics

from the harsh environment and provides easy access for configuration or

service.

The Rosemount 8742C transmitter requires external power regardless of

whether it is mounted remotely or integrally to the flowtube. Access to a

suitable power source must be ensured.

Identify Options and

Configurations

The standard application of the Rosemount 8742C includes a FOUNDATION

fieldbus output. Be sure to identify options and configurations that apply to

your situation, and keep a list of them nearby for consideration during the

installation and configuration procedures.

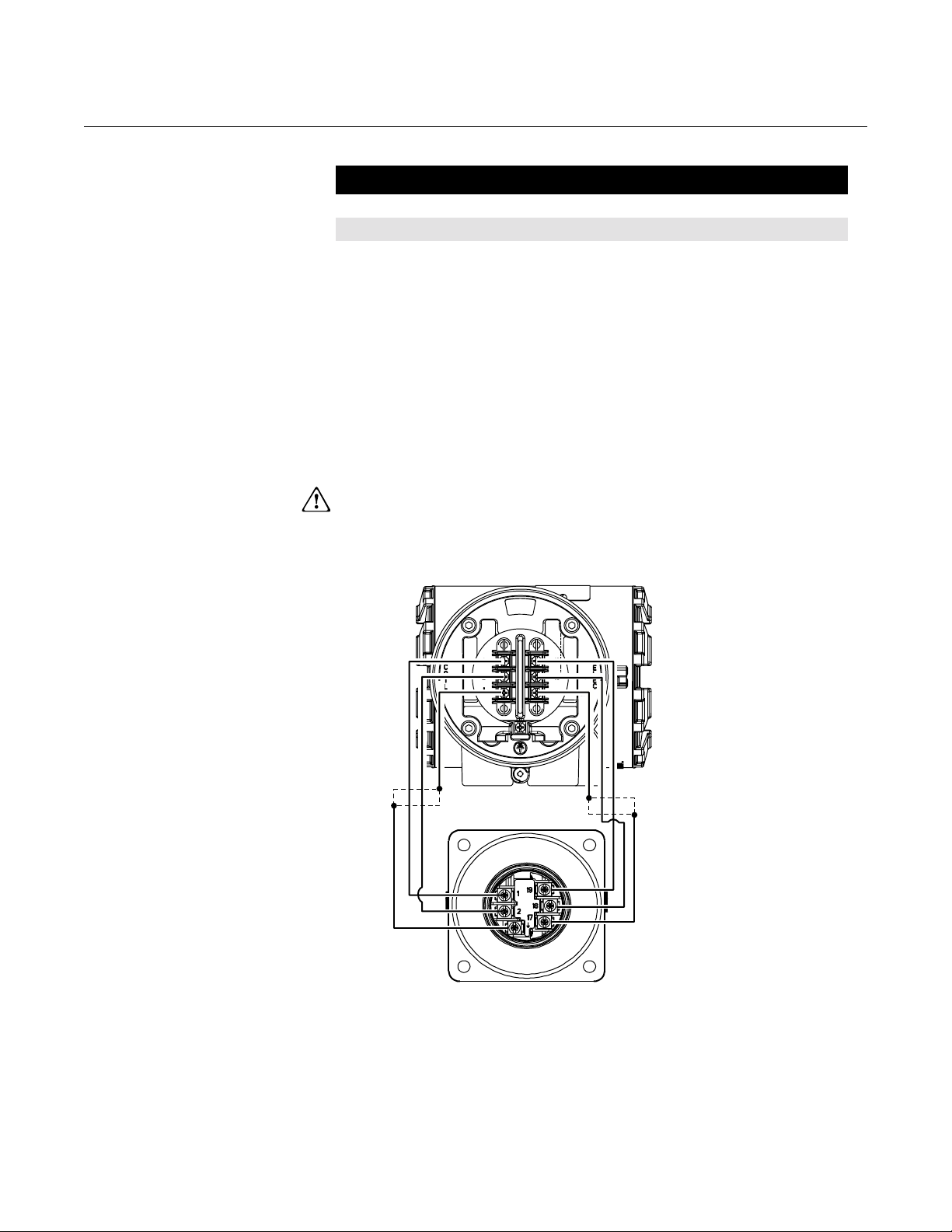

Hardware Switches The Rosemount 8742C electronics board is equipped with two

user-selectable hardware switches. These switches set Simulate Enable and

Transmitter Security. The standard configurations for these switches when

shipped from the factory are as follows:

Simulate Enable: Off

Transmitter Security: Off

Definitions of these switches and their functions are provided below. The

switches are located on the outerboard of the electronics transmitter stack.

See Figure 2-1 on page 2-3.

Simulate Enable The simulate enable switch is used in conjunction with the Analog Input (AI)

function block. The switch is used to enable flow measurement simulation.

The switch is also used as a lock-out feature for the AI function block. To

enable the simulate enable feature, the switch must transition form OFF to

ON after power is applied to the transmitter, preventing the transmitter from

being accidentally left in simulate mode.

Transmitter Security After you configure the transmitter, you may want to protect the configuration

data from unwarranted changes. Each transmitter is equipped with a security

switch that can be positioned ON to prevent the accidental or deliberate

change of configuration data.

2-2

Page 15

Reference Manual

00809-0100-4793, Rev CA

August 2004

Figure 2-1. Hardware Switches

Rosemount 8742C

Instructions for changing the hardware switches are provided in “Changing

Hardware Switch Settings” on page 2-3.

Simulate

Enable

Transmitter

Security

8742-1002H01A

Changing Hardware

Switch Settings

Rotate Transmitter

Housing

In most cases, it is not necessary to change the setting of the hardware

switches. If you need to change the switch settings, complete the steps

outlined below:

NOTE

The hardware switches are located on the electronics board and changing

their settings requires opening of the electronics housing. If possible, carry out

these procedures away from the plant environment in order to protect the

electronics.

1. Disconnect power to the transmitter.

2. Unscrew and remove the electronics cover.

3. Identify the location of the switch.

4. Change the setting of the desired switches with a small screwdriver.

Refer to Figure 2-1.

5. Screw and tighten the electronics cover.

The electronics housing can be rotated on the flowtube in 90° increments by

loosening the four mounting bolts on the bottom of the housing, rotating the

housing, and reinstalling the bolts. Refer to Figure 2-2 on page 2-4. When the

housing is returned to its original position, be sure the surface is clean and

there is no gap between the housing and the flowtube.

See “Safety Information” on page 2-1 for complete warning information.

2-3

Page 16

Rosemount 8742C

Figure 2-2. Rosemount 8742C

Transmitter Dimensional

Drawing

5.10

(130)

10.5

(267)

3.00

(76)

1.94

(49)

7.49 (190)

6.48 (165)

LOI Cover

8.81

(224)

3.07

(78)

Reference Manual

00809-0100-4793, Rev CA

August 2004

3

/4”-14 NPT Electrical

Conduit Connections

(2 places)

3.43

(87)

3

/4”-14 NPT

Flowtube Conduit

Connections

(2 places)

11.02

(280)

WIRING Correct cable preparation is important for a successful installation. The

conduit connections needed for installation depend on transmitter location. A

conduit run between the flowtube and transmitter is not required if the

transmitter is integrally mounted on the flowtube.

Conduit Ports

and Connections

Both the flowtube and transmitter junction boxes have ports for ¾-inch NPT

conduit connections. These connections should be made in accordance with

local or plant electrical codes. Unused ports should be sealed with metal

plugs. Housing damage will result if metal plugs

are overtightened.

Proper electrical installation is necessary to prevent errors due to electrical

noise and interference. Before making any electrical connections to the

Rosemount 8742C, consider the following standards and be sure to have

proper power supply, conduit, and other accessories. Shielded cable must be

used for best results in electrically noisy environments.

Conduit Connections The transmitter has ports for ¾–inch NPT conduit connections. If the port is

not being used, conduit seals should to be installed. In some cases, conduits

may also require drainage if moisture could build up in the line.

2-4

Page 17

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Conduit Cables Run the appropriate size cable through the conduit connections in your

magnetic flowmeter system. Run the power cable from the power source to

the transmitter. Run the coil drive and electrode cables between the flowmeter

and transmitter.

Prepare the ends of the coil drive and electrode cables as shown in Figure

2-3. Limit the unshielded wire length to 1-inch on both the electrode and coil

drive cables.

NOTE

Excessive lead length or failure to connect cable shields can create electrical

noise resulting in unstable meter readings.

Figure 2-3. Cable Preparation

Detail

1.00

(26)

NOTE

Dimensions are in

Cable Shield

inches (millimeters).

8705-0041B

Transmitter Coil Input The Rosemount 8742C Magnetic Flowmeter Transmitter is a four-wire device.

This wiring section covers supplying power to the flowtube coils through the

transmitter. The transmitter coil input power sends a pulsed DC frequency to

the flowtube.

Wire the transmitter according to local electrical requirements. Ground the

transmitter cage via the threaded conduit connection. For ac power

applications, connect ac Neutral to terminal N and connect ac Line to terminal

L1. For dc power applications, properly connect the positive and negative

terminals. Units powered by 15-50 V dc power supply may draw up to 1 amp

of current. In addition, follow the supply wire and disconnect requirements

below:

1.0

0.75

0.5

0.25

0

15

20

Supply Current (Amps)

I = 10/V

I = Supply current requirement (Amps)

V = Power supply voltage (Volts)

Power Supply (Volts)

30

40

50

2-5

Page 18

Reference Manual

00809-0100-4793, Rev CA

Rosemount 8742C

August 2004

Supply Wire Requirements

Use 12 to 18 AWG wire rated for the proper temperature application. For

connections in ambient temperatures above 140 °F (60 °C), use a wire

rated for 176 °F (80 °C). For ambients greater than 176 °F (80 °C), use a

wire rated for 230 °F (110 °C).

Disconnects

Connect the device through an external disconnect or circuit breaker.

Clearly label the disconnect or circuit breaker and locate it near

the transmitter and per local electrical control.

Installation Category The installation category for the Rosemount 8742C is

(Overvoltage) Category II.

Overcurrent Protection The Rosemount 8742C Flowmeter Transmitter requires overcurrent

protection of the supply lines. Maximum ratings of overcurrent devices are as

follows:

Power System Fuse Rating Manufacturer

110 V ac 250 V; 1 Amp, Quick Acting Bussman AGCI or Equivalent

220 V ac 250 V; 0.5 Amp, Quick Acting Bussman AGCI or Equivalent

Transmitter

Communication Input

The FOUNDATION fieldbus communication requires a minimum of

9 V dc and a maximum of 32 V dc at the transmitter communication terminals.

NOTES

• Do not exceed 32 V dc at the transmitter communication terminals.

• Do not apply ac line voltage to the transmitter

communication terminals.

Improper supply voltage can damage the transmitter.

Power Conditioning Each fieldbus power supply requires a power conditioner to decouple the

power supply output from the fieldbus wiring segment.

Field Wiring Power independent of the coil power supply must be supplied for FOUNDATION

fieldbus communications. Use shielded, twisted pair for best results. For new

installations or to get maximum performance, twisted pair cable designed

especially for fieldbus should be used. Table 2-1 details cable characteristics

and ideal specifications.

Table 2-1.

Ideal Cable Specifications

for Fieldbus Wiring

Characteristic Ideal Specification

Impedance 100 Ohms ± 20% at 31.25 kHz

Wire Size 18 AWG (0,8 mm2)

Shield Coverage 90%

Attenuation 3 db/km

Capacitive Unbalance 2 nF/km

2-6

See “Safety Messages” on page 2-1 for complete warning information.

Page 19

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

NOTE

The number of devices on a fieldbus segment is limited by the power supply

voltage, the resistance of the cable, and the amount of current drawn by

each device.

Transmitter Wiring

Connection

Figure 2-4. Rosemount 8742C

Transmitter Field Wiring

To make the transmitter communication wiring connection, remove the end

cover on the electronics housing. Connect the power leads to the positive (+)

and negative (–) fieldbus communication terminals. The communication

terminals are polarity insensitive: the polarity of the dc power leads does not

matter when connecting to the power terminals.

When wiring to screw terminals, crimped lugs are recommended. Tighten the

terminals to ensure adequate contact.

Both transmitter covers must be fully engaged to meet explosion proof

requirements. Do not remove the transmitter covers in an explosive

atmosphere when the transmitter is powered

6234 ft (1900 m) max

(depending upon cable

Integrated

Power

Conditioner

and Filter

Segment

Power

Supply

(Trunk)

(1)

Terminators

Fieldbus

.

(The power supply,

filter, first terminator,

and configuration tool

are typically located

in the control room.)

*Intrinsically safe installations may

allow fewer devices per I.S. barrier.

(1) Pending final approval.

OUNDATION

F

Fieldbus

Configuration

Too l

(Spur)

Devices 1 through 11*

(Spur)

8742-8742_01A

2-7

Page 20

Rosemount 8742C

Figure 2-5. Power Connections

Input Power 90–250 V ac

Reference Manual

00809-0100-4793, Rev CA

August 2004

Grounding

Lugs

Fieldbus Outputs

8742-1002F01A

Transmitter to

Flowtube Wiring

Figure 2-6. Conduit Preparation

Wrong Correct

Power

Outputs

Power

Outputs

Flanged and wafer flowtubes have two conduit ports as shown in Figures

3-13, 3-14, 3-15, and 3-16. Either one may be used for both the coil drive and

electrode cables. Use the stainless steel plug that is provided to seal the

unused conduit port.

A single dedicated conduit run for the coil drive and electrode cables is

needed between a flowtube and a remote transmitter. Bundled cables in a

single conduit are likely to create interference and noise problems in your

system. Use one set of cables per conduit run. See Figure 2-6 for proper

conduit installation diagram and Table 2-2 for recommended cable. For

integral and remote wiring diagrams refer to Figure 2-7 and Figure 2-8.

Coil Drive

and

Electrode

Cables

Power

Outputs

Power

Outputs

Coil Drive and

Electrode

Cables

2-8

Page 21

Reference Manual

00809-0100-4793, Rev CA

August 2004

Table 2-2. Cable Requirements

Rosemount 8742C

Description Part Number

Signal Cable (20 AWG) Belden 8762, Alpha 2411 equivalent 08712-0061-0001

Coil Drive Cable (14 AWG) Belden 8720, Alpha 2442 equivalent 08712-0060-0001

Combination Signal and Coil Drive Cable (18 AWG)

Belden 9368 equivalent

(1) Combination signal and coil drive cable is not recommended for

high-signal magmeter system. For remote mount installations, combination signal and coil drive

cable should be limited to less than 100 ft. (30 m).

(1)

Remote transmitter installations require equal lengths of signal and coil drive

cables. Integrally mounted transmitters are factory wired and do not require

interconnecting cables.

Lengths from 5 to 1,000 feet (1.5 to 300 meters) may be specified, and will be

shipped with the flowtube.

08712-0750-0001

Flowtube to Remote

Mount Transmitter

Connections

Figure 2-7. Wiring Diagram

Connect coil drive and electrode cables as shown in Figure 2-7.

Do not connect ac power to the flowtube or to terminals 1 and 2 of the

transmitter, or replacement of the electronics board will be necessary.

8742b_07a

2-9

Page 22

Rosemount 8742C

Table 2-3. Flowtube to Remote

Mount Transmitter

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8712D/H Transmitters Rosemount 8705/8707/8711 Flowtubes

11

2 2

17 17

18 18

19 19

Flowtube to Integral

Mount

Transmitter Connections

Figure 2-8. Wiring Diagram to

Rosemount 8732C/8742C

Transmitter

Connect coil drive and electrode cables as shown in Figure 2-8.

Do not connect ac power to the flowtube or to terminals 1 and 2 of the

transmitter, or replacement of the electronics board will be necessary.

Electronics

Board

Table 2-4. Flowtube to Integral

Mount Transmitter

2-10

8732-8732B01A

Rosemount 8732C/8742C Rosemount 8705/8711 Flowtubes

11

2 2

17 17

18 18

19 19

Page 23

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Section 3 Flowtube Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Flowtube Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3

Flowtube Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Installation (Flanged Flowtube) . . . . . . . . . . . . . . . . . . . . . page 3-7

Installation (Wafer Flowtube) . . . . . . . . . . . . . . . . . . . . . . . page 3-10

Installation (Sanitary Flowtube) . . . . . . . . . . . . . . . . . . . . . page 3-12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-12

Process Leak Protection (Optional) . . . . . . . . . . . . . . . . . page 3-15

This section covers the steps required to physically install the magnetic

flowtube. For electrical connections and cabling see Section 2: Installation.

Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Please refer to

the following safety messages before performing any operation in this section.

SAFETY MESSAGES This symbol is used throughout this manual to indicate that special attention

to warning information is required.

Failure to follow these installation guidelines could result in death or serious injury:

Installation and servicing instructions are for use by qualified personnel only. Do not perform

any servicing other than that contained in the operating instructions, unless qualified. Verify

that the operating environment of the flowtube and transmitter is consistent with the

appropriate hazardous area approval.

Do not connect a Rosemount 8742C to a non-Rosemount flowtube that is located in an

explosive atmosphere.

www.rosemount.com

Page 24

Rosemount 8742C

Reference Manual

00809-0100-4793, Rev CA

August 2004

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please review

the approvals section of the 8742C reference manual for any restrictions associated with a

safe installation.

Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Electrical shock can result in death or serious injury

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

The flowtube liner is vulnerable to handling damage. Never place anything through the

flowtube for the purpose of lifting or gaining leverage. Liner damage can render the flowtube

useless.

To avoid possible damage to the flowtube liner ends, do not use metallic or spiral-wound

gaskets. If frequent removal is anticipated, take precautions to protect the liner ends. Short

spool pieces attached to the flowtube ends are often used for protection.

Correct flange bolt tightening is crucial for proper flowtube operation and life. All bolts must

be tightened in the proper sequence to the specified torque limits. Failure to observe these

instructions could result in severe damage to the flowtube lining and possible flowtube

replacement.

3-2

Page 25

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

FLOWTUBE HANDLING Handle all parts carefully to prevent damage. Whenever possible, transport

the system to the installation site in the original shipping containers.

®

Te fl on

mechanical damage and normal unrestrained distortion. Remove the end

covers just before installation.

Flanged 6- through 36-inch flowtubes come with a lifting lug on each flange.

The lifting lugs make the flowtube easier to handle when it is transported and

lowered into place at the installation site.

Flanged ½- to 4-inch flowtubes do not have lugs. They must be supported

with a lifting sling on each side of the housing.

Figure 3-1 shows flowtubes correctly supported for handling and installation.

Notice the plywood end pieces are still in place to protect the flowtube liner

during transportation.

Figure 3-1. Rosemount 8705

Flowtube Support for Handling

-lined flowtubes are shipped with end covers that protect it from both

½- through 4-Inch

Flowtubes

See ”Safety Messages” on pages 3-1 and 3-2 for complete warning information.

8732-0281B02AB, C02AB

6-Inch and Larger

Flowtubes

3-3

Page 26

Reference Manual

00809-0100-4793, Rev CA

Rosemount 8742C

August 2004

FLOWTUBE MOUNTING Physical mounting of a flowtube is similar to installing a typical section of pipe.

Conventional tools, equipment, and accessories (bolts, gaskets, and

grounding hardware) are required.

Upstream/Downstream

Piping

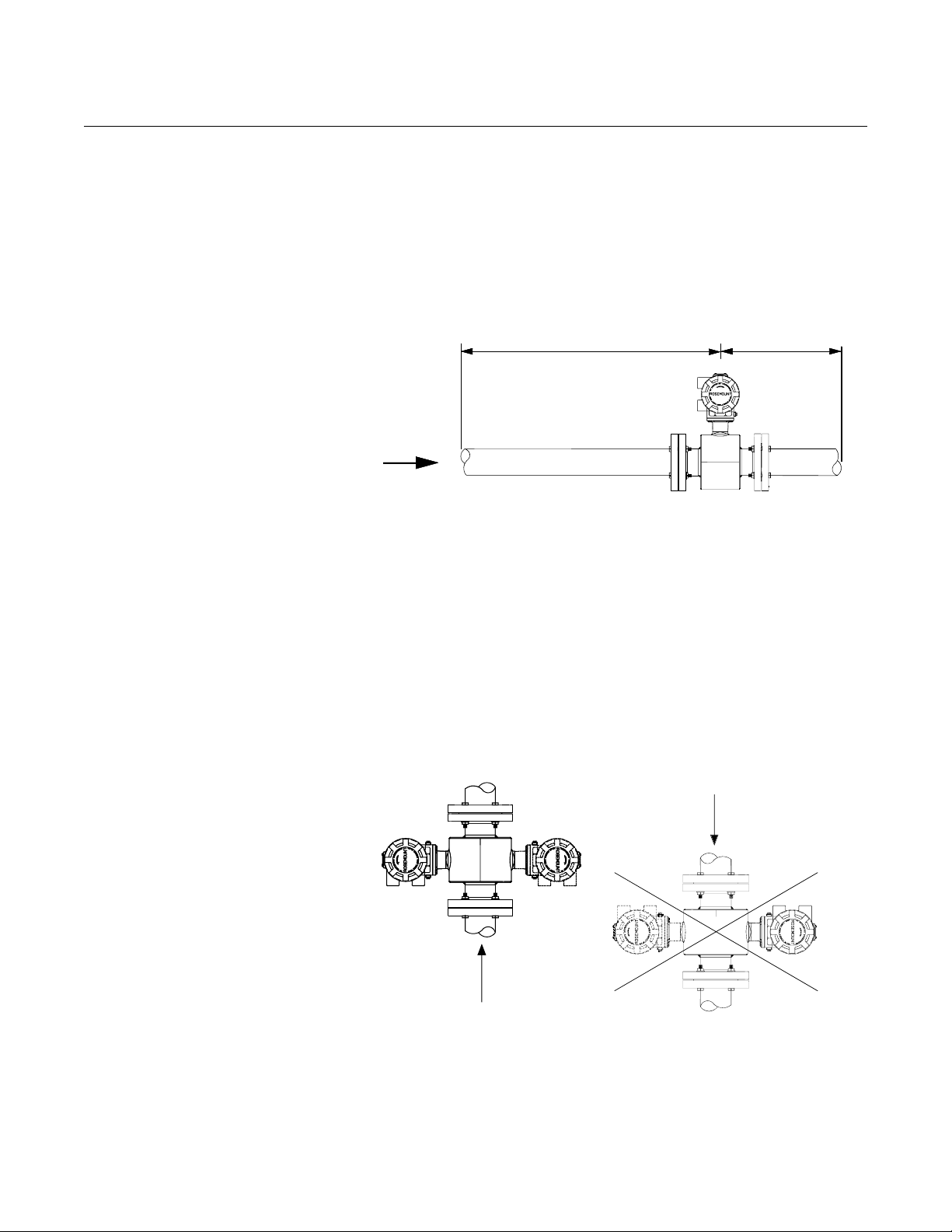

To ensure specification accuracy over widely varying process conditions,

install the flowtube a minimum of five straight pipe diameters upstream and

two pipe diameters downstream from the electrode plane (see Figure 3-2).

Figure 3-2. Upstream and

Downstream

Straight Pipe Diameters

5 Pipe Diameters

FLOW

2 Pipe Diameters

Flowtube Orientation The flowtube should be installed in a position that ensures the flowtube

remains full during operation. Figures 3-3, 3-4, and 3-5 show the proper

flowtube orientation for the most common installations. The following

orientations ensure that the electrodes are in the optimum plane to minimize

the effects of entrapped gas.

Vertical installation allows upward process fluid flow and is generally

preferred. Upward flow keeps the cross-sectional area full, regardless

of flow rate. Orientation of the electrode plane is unimportant in vertical

installations. As illustrated in Figures 3-3 and 3-4, avoid downward flows

where back pressure does not ensure that the flowtube remains full at all

times.

8732-0281G02A

Figure 3-3. Vertical Flowtube

Orientation

3-4

A

FLOW

B

FLOW

8735-0005A01AB, 0005A01BB

Page 27

Reference Manual

00809-0100-4793, Rev CA

August 2004

Figure 3-4. Incline or Decline

Orientation

Rosemount 8742C

A

B

FLOW

Figure 3-5. Horizontal Flowtube

Orientation

FLOW

Horizontal installation should be restricted to low piping sections that are

normally full. Orient the electrode plane to within 45 degrees of horizontal in

horizontal installations. A deviation of more than 45 degrees of horizontal

would place an electrode at or near the top of the flowtube thereby making it

more susceptible to insulation by air or entrapped gas at the top of the

flowtube.

FLOW

The electrodes in the Rosemount 8711 are properly oriented when the top

of the flowtube is either vertical or horizontal, as shown in Figure 3-6. Avoid

any mounting orientation that positions the top of the flowtube

at 45° from the vertical or horizontal position.

8732-0005A01EB, 0005A01FB

8732-0005A01C

3-5

Page 28

Rosemount 8742C

Figure 3-6. Rosemount 8711

Mounting Position

Reference Manual

00809-0100-4793, Rev CA

August 2004

45° Electrode Plane

45° Electrode Plane

Flow Direction The flowtube should be mounted so that the FORWARD end of the flow

arrow, shown on the flowtube identification tag, points in the direction of flow

through the tube (see Figure 3-7).

Figure 3-7. Flow Direction

FLOW

8711-8711-E01AB, 8711-8711-F01A

8712-0281H02FD

3-6

Page 29

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

INSTALLATION

(FLANGED FLOWTUBE)

The following section should be used as a guide in the installation of the

flange-type Rosemount 8705 and Rosemount 8707 High-Signal Flowtubes.

Refer to page 3-10 for installation of the wafer-type Rosemount 8711

Flowtube.

Gaskets The flowtube requires a gasket at each of its connections to adjacent devices or

piping. The gasket material selected must be compatible with the process fluid and

operating conditions. Metallic or spiral-wound gaskets can damage the

liner. If the gaskets will be removed frequently, protect the liner ends. All other

applications (including flowtubes with lining protectors or a grounding

electrode) require only one gasket on each end connection, as shown in

Figure 3-8. If grounding rings are used, gaskets are required on each side of

the grounding ring, as shown in Figure 3-9.

Figure 3-8. Gasket Placement

Gasket (Supplied by user)

Figure 3-9. Gasket Placement

with Non-attached Grounding

Rings

Gasket (Supplied by user)

Grounding Ring

Gasket (Supplied by user)

Flange Bolts Suggested torque values by flowtube line size and liner type are listed in

Table 3-1 on page 3-8 for ASME B16.5 (ANSI) flanges and Table 3-2 and

Table 3-3 for DIN flanges. Consult the factory for other flange ratings. Tighten

flange bolts in the incremental sequence as shown in Figure 3-10. See

Table 3-1 and Table 3-2 for bolt sizes and hole diameters.

8705-0040E

8705-0038D

See ”Safety Messages” on pages 3-1 and 3-2 for complete warning information.

3-7

Page 30

Rosemount 8742C

Reference Manual

00809-0100-4793, Rev CA

August 2004

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten left and then snug and tighten right. Failure to do so

will result in liner damage.

Always check for leaks at the flanges after tightening the flange bolts. Failure

to use the correct flange bolt tightening methods can result in severe damage.

All flowtubes require a second torquing twenty-four hours after initial flange

bolt tightening.

Table 3-1. Flange Bolt Torque Specifications for

Rosemount 8705 and 8707 High-Signal Flowtubes

Teflon/Tefzel liner Polyurethane liner

Size Code Line Size

005

010 1 inch (25 mm) 8 12 — —

015 1

020 2 inch (50 mm) 19 17 14 11

030 3 inch (80 mm) 34 35 23 23

040 4 inch (100 mm) 26 50 17 32

060 6 inch (150mm) 45 50 30 37

080 8 inch (200 mm) 60 82 42 55

100 10 inch (250 mm) 55 80 40 70

120 12 inch (300 mm) 65 125 55 105

140 14 inch (350 mm) 85 110 70 95

160 16 inch (400 mm) 85 160 65 140

180 18 inch (450 mm) 120 170 95 150

200 20 inch (500 mm) 110 175 90 150

240 24 inch (600 mm) 165 280 140 250

300 30 inch (750 mm) 195 415 165 375

360 36 inch (900 mm) 280 575 245 525

1

/2-inch (15 mm) 8 8 — —

1

/2 inch (40 mm) 13 25 7 18

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 150

(pound-feet)

Class 300

(pound-feet)

See ”Safety Messages” on pages 3-1 and 3-2 for complete warning information.

3-8

Page 31

Reference Manual

00809-0100-4793, Rev CA

August 2004

Table 3-2. Flange Bolt Torque and Bolt Load Specifications for Rosemount 8705

Tef lon/ Tefz e l li n er

Size

Code

005

010 1 inch (25 mm) 13 6983 13 6983 13 6983 13 8816

015 1

020 2 inch (50 mm) 25 10420 25 10420 25 10420 25 14457

030 3 inch (80 mm) 14 5935 14 5935 18 7612 18 12264

040 4 inch (100 mm) 17 7038 17 7038 30 9944 30 16021

060 6 inch (150mm) 23 7522 32 10587 60 16571 60 26698

080 8 inch (200 mm) 35 11516 35 11694 66 18304 66 36263

100 10 inch (250 mm) 31 10406 59 16506 105 25835 105 48041

120 12 inch (300 mm) 43 14439 82 22903 109 26886 109 51614

140 14 inch (350 mm) 42 13927 80 22091 156 34578 156 73825

160 16 inch (400 mm) 65 18189 117 28851 224 45158 224 99501

180 18 inch (450 mm) 56 15431 99 24477 — — — 67953

200 20 inch (500 mm) 66 18342 131 29094 225 45538 225 73367

240 24 inch (600 mm) 104 25754 202 40850 345 63940 345 103014

Line Size (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton)

1

/2-inch (15 mm) 7 3209 7 3809 7 3809 7 4173

1

/2 inch (40 mm) 24 9983 24 9983 24 9983 24 13010

PN10 PN 16 PN 25 PN 40

Rosemount 8742C

Figure 3-10. Flange Bolt

Torquing Sequence

4-Bolt

8-Bolt

20-Bolt

Torque the flange bolts

in increments according to

the above numerical sequence.

12-Bolt

14-Bolt

8701-0870G02A

3-9

Page 32

Reference Manual

00809-0100-4793, Rev CA

Rosemount 8742C

Table 3-3. Flange Bolt Torque and Bolt Load Specifications for Rosemount 8705

Polyurethane Liner

Size

Code

005

010 1 inch (25 mm) 2 119 1 3 1890 5 2958 10 5555

015 1

020 2 inch (50 mm) 6 2535 10 4021 15 6294 26 10831

030 3 inch (80 mm) 5 2246 9 3563 13 5577 24 19998

040 4 inch (100 mm) 7 3033 12 4812 23 7531 35 11665

060 6 inch (150mm) 16 5311 25 8425 47 13186 75 20829

080 8 inch (200 mm) 27 8971 28 9487 53 14849 100 24687

100 10 inch (250 mm) 26 8637 49 13700 87 21443 155 34547

120 12 inch (300 mm) 36 12117 69 19220 91 22563 165 36660

140 14 inch (350 mm) 35 11693 67 18547 131 29030 235 47466

160 16 inch (400 mm) 55 15393 99 24417 189 38218 335 62026

200 20 inch (500 mm) 58 15989 114 25361 197 39696 375 64091

240 24 inch (600 mm) 92 22699 178 36006 304 56357 615 91094

Line Size

1

/2-inch (15 mm) 1 521 1 826 2 1293 6 3333

1

/2 inch (40 mm) 5 1960 7 3109 12 4867 20 8332

(Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton) (Newton-meter) (Newton)

PN 10 PN 16 PN 25 PN 40

August 2004

INSTALLATION

(WAFER FLOWTUBE)

The following section should be used as a guide in the installation of the

Rosemount 8711 Flowtube. Refer to page 3-7 for installation of the

flange-type Rosemount 8705 and 8707 High-Signal flowtube.

Gaskets The flowtube requires a gasket at each of its connections to adjacent devices

or piping. The gasket material selected must be compatible with the process

fluid and operating conditions. Metallic or spiral-wound gaskets can

damage the liner. If the gaskets will be removed frequently, protect the

liner ends. If grounding rings are used, a gasket is required on each side of

the grounding ring.

Alignment and Bolting

1. On 11/2 - through 8-inch (40 through 200 mm) line sizes, place

centering rings over each end of the flowtube. The smaller line sizes,

0.15- through 1-inch (4 through 25 mm), do not require centering

rings.

2. Insert studs for the bottom side of the flowtube between the pipe

flanges. Stud specifications are listed in Table 3-4. Using carbon

steel bolts on smaller line sizes, 0.15- through 1-inch

(4 through 25 mm), rather than the required stainless steel bolts,

will degrade performance.

3-10

Page 33

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Table 3-4. Stud Specifications

Nominal Flowtube Size Stud Specifications

0.15 – 1 inch (4 – 25 mm) 316 SST ASTM A193, Grade B8M

Class 1 threaded mounted studs

11/2 – 8 inch (40 – 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

3. Place the flowtube between the flanges. Make sure that the centering

rings are properly placed in the studs. The studs should be aligned

with the markings on the rings that correspond to the flange you are

using.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 3-5. Do not

overtighten the bolts or the liner may be damaged.

NOTE

On the 4- and 6-inch PN 10–16, insert the flowtube with rings first and then

insert the studs. The slots on this ring scenario are located on the inside of the

ring.

Figure 3-11. Gasket Placement

with Centering Rings

Centering Rings

Installation, Studs

Nuts and Washers

Customer-supplied

Gasket

FLOW

Flange Bolts Flowtube sizes and torque values for both Class 150 and Class 300 flanges

are listed in Table 3-5. Tighten flange bolts in the incremental sequence,

shown in Figure 3-10.

Always check for leaks at the flanges after tightening the flange

bolts. All flowtubes require a second torquing 24 hours after initial flange bolt

tightening.

8732-0002A1A

3-11

Page 34

Rosemount 8742C

INSTALLATION

(SANITARY FLOWTUBE)

Reference Manual

00809-0100-4793, Rev CA

August 2004

Table 3-5. Flange bolt Torque Specifications of Rosemount 8711 Flowtubes

Size Code Line Size Pound-feet Newton-meter

15F 0.15 inch (4 mm) 5 6.8

30F 0.30 inch (8 mm) 5 6.8

005

010 1 inch (25 mm) 10 13.6

015 1

020 2 inch (50 mm) 25 34.1

030 3 inch (80 mm) 40 54.6

040 4 inch (100 mm) 30 40.1

060 6 inch (150 mm) 50 68.2

080 8 inch (200 mm) 70 81.9

1

/2-inch (15 mm) 5 6.8

1

/2 inch (40 mm) 15 20.5

Gaskets

The flowtube requires a gasket at each of its connections to adjacent devices

or piping. The gasket material selected must be compatible with the process

fluid and operating conditions. Gaskets are supplied with all Rosemount 8721

Sanitary flowtubes except when the process connection is an IDF sanitary

screw type.

Alignment and Bolting Standard plant practices should be followed when installing a magmeter with

sanitary fittings. Unique torque values and bolting techniques are not

required.

Figure 3-12. Rosemount 8721

Sanitary Installation

User supplied clamp

User supplied gasket

If ordered manufacturer

supplied clamp and gasket.

8721_A_06.EPS

GROUNDING Process grounding the flowtube is one the most important details of flowtube

installation. Proper process grounding ensures that the transmitter amplifier is

referenced to the process. This creates the lowest noise environment for the

transmitter to make a stable reading. Use Table 3-6 to determine which

grounding option to follow for proper installation.

3-12

Page 35

Reference Manual

00809-0100-4793, Rev CA

August 2004

NOTE

Consult factory for installations requiring cathodic protection or situations

where there are high currents or high potential in the process.

The flowtube case should always be earth grounded in accordance with

national and local electrical codes. Failure to do so may impair the protection

provided by the equipment. The most effective grounding method is direct

connection from the flowtube to earth ground with minimal impedance.

The Internal Ground Connection (Protective Ground Connection) located in

side the junction box is the Internal Ground Connection screw. This screw is

identified by the ground symbol:

Table 3-6. Grounding Installation

Grounding Options

Type of Pipe No Grounding Options Grounding Rings Grounding Electrodes Lining Protectors

Conductive Unlined Pipe See Figure 3-13 Not Required Not Required See Figure 3-14

Conductive Lined Pipe Insufficient Grounding See Figure 3-14 See Figure 3-13 See Figure 3-14

Non-Conductive Pipe Insufficient Grounding See Figure 3-15 See Figure 3-16 See Figure 3-15

Rosemount 8742C

Figure 3-13. No Grounding

Options or Grounding Electrode

in Lined Pipe

Earth

Ground

8705-0040C

3-13

Page 36

Rosemount 8742C

Figure 3-14. Grounding with

Grounding Rings or Lining

Protectors

Reference Manual

00809-0100-4793, Rev CA

August 2004

Earth

Ground

Figure 3-15. Grounding with

Grounding Rings or Lining

Protectors

Grounding Rings or

Lining Protectors

Earth

Ground

Grounding Rings

8705-038C

8711-0360A01B

3-14

Page 37

Reference Manual

00809-0100-4793, Rev CA

August 2004

Figure 3-16. Grounding with

Grounding Electrodes

Rosemount 8742C

Earth

Ground

8711-0360A01A

PROCESS LEAK

PROTECTION

(OPTIONAL)

The Rosemount 8705 Flowtube housing is fabricated from carbon steel to

perform two separate functions. First, it provides shielding for the flowtube

magnetics so that external disturbances cannot interfere with the magnetic

field and thus affect the flow measurement. Second, it provides the physical

protection to the coils and other internal components from contamination and

physical damage that might occur in an industrial environment. The housing is

completely welded and gasket-free.

The three housing configurations are identified by the W0, W1, or W3 in the

model number option code when ordering. Below are brief descriptions of

each housing configuration, which are followed by a more detailed overview.

• Code W0 — sealed, welded coil housing (standard configuration)

• Code W1 — sealed, welded coil housing with a relief valve capable of

venting fugitive emissions to a safe location (additional plumbing from

the flowtube to a safe area, installed by the user, is required to vent

properly)

• Code W3 — sealed, welded coil housing with separate electrode

compartments capable of venting fugitive emissions (additional

plumbing from the flowtube to a safe area, installed by the user, is

required to vent properly)

3-15

Page 38

Rosemount 8742C

Reference Manual

00809-0100-4793, Rev CA

August 2004

Standard Housing

Configuration

Figure 3-17. Standard Housing

— Configuration Sealed Welded

Housing (Option Code W0)

The standard housing configuration is identified by a code W0 in the model

number. This configuration does not provide separate electrode

compartments with external electrode access. In the event of a process leak,

these models will not protect the coils or other sensitive areas around the

flowtube from exposure to the pressure fluid (Figure 3-17).

¾–14 NPT Conduit

(no relief valve)

Connection

8705-1002A05D

Relief Valves The first optional configuration, identified by the W1 in the model number

option code, uses a completely welded coil housing. This configuration does

not provide separate electrode compartments with external electrode access.

This optional housing configuration provides a relief valve in the housing to

prevent possible overpressuring caused by damage to the lining or other

situations that might allow process pressure to enter the housing. The relief

valve will vent when the pressure inside the flowtube housing exceeds 5 psi.

Additional piping (provided by the user) may be connected to this relief valve

to drain any process leakage to safe containment (see Figure 3-18).

Figure 3-18. Coil-Housing

Configuration — Standard

Welded Housing With Relief

Valve (Option Code W1)

Optional:

Use drain port to

plumb to a safe area

(Supplied by user)

¼'' NPT – 5 psi

Pressure Relief Valve

¾–14 NPT Conduit

Connection

3-16

8705-0021A05B

Page 39

Reference Manual

00809-0100-4793, Rev CA

August 2004

Rosemount 8742C

Process Leak

Containment

Figure 3-19. Housing

Configuration — Sealed

Electrode Compartment (Option

Code W3)

The second optional configuration, identified as option code W3 in the model

number, divides the coil housing into three compartments: one for each

electrode and one for the coils. Should a damaged liner or electrode fault

allow process fluid to migrate behind the electrode seals, the fluid is contained

in the electrode compartment. The sealed electrode compartment prevents

the process fluid from entering the coil compartment where it would damage

the coils and other internal components.

The electrode compartments are designed to contain the process fluid at full

line pressure. An o-ring sealed cover provides access to each of the electrode

compartments from outside the flowtube; drainports are provided in each

cover for the removal of fluid.

NOTE

The electrode compartment could contain full line pressure and it must be

depressurized before the cover is removed.

Fused Glass Seal

O-Ring Seal

Sealed Electrode Compartment

1

/2 - 27 NPT

Optional:

Use drain port to

plumb to a safe area

Grounding Electrode Port

(Supplied by user)

If necessary, capture any process fluid leakage, connect the appropriate

piping to the drainports, and provide for proper disposal

(see Figure 3-19).

8705-0007ADGB

3-17

Page 40

Reference Manual

00809-0100-4793, Rev CA

August 2004

Section 4 Configuration

Quick Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Assigning Device Tag and Node Address . . . . . . . . . . . . page 4-2

AI Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-3

Arithmetic Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-3

Integrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-3

PID Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-4

Configuring Links and Scheduling Block Execution . . . page 4-5

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-8

This section covers basic operation, software functionality, and basic

configuration procedures for the Rosemount 8742C Magnetic Flowmeter

Transmitter with F

F

OUNDATION fieldbus technology and the function blocks used in the

OUNDATION

transmitter, refer to Appendix C: Resource Block, Appendix D: Transducer

Block, and Appendix E: Field-Removable Electrodes.

™

fieldbus. For more information about the

Rosemount 8742C

Calibration Rosemount flowtubes are wet calibrated at the factory. They do not need

further calibration during installation.

Figure 4-1 illustrates how the flow signal is channeled through the transmitter.

Figure 4-1. Functional Block Diagram for the Rosemount 8742C Flowmeter with F

Function Blocks

•AI

•PID

•Integrator

OUNDATION fieldbus

F

Compliant

Communications

Stack

• Arithmetic

Resource Blocks

• Physical Device

Information

Analog-to-Digital

Signal Conversion

OUNDATION fieldbus

Transducer Block

•Damping

• Diagnostics

• Engineering Units

Input-to-Output

Galvanic Isolation

8732-8732_01A

www.rosemount.com

Page 41

Reference Manual

00809-0100-4793, Rev CA

Rosemount 8742C

Each FOUNDATION fieldbus configuration tool or host device has a different

way of displaying and performing configurations. Some will use Device

Descriptions (DD) and DD Methods to make configuring and displaying data

consistent across host platforms. There is no requirement that a configuration

tool or host support these features. This section describes how to reconfigure

the device manually.

August 2004

QUICK START-UP Once the magnetic flowmeter system is installed and communication is

established, configuration of the transmitter must be completed. The standard

transmitter configuration, without Option Code C1, Custom Configuration, is

shipped with the following parameters:

Engineering Units: ft/s

Tube Size: 3-in.

Flowtube Calibration Number: 100000501000000

Flowtube

Calibration Number

ASSIGNING DEVICE TAG

AND NODE ADDRESS

A unique flowtube calibration number, imprinted on the flowtube tag, enables

any Rosemount flowtube to be used with any Rosemount transmitter without

further calibration. Rosemount flow lab tests determine individual flowtube

output characteristics. The characteristics are identified by a 16-digit

calibration number.

The 16-digit calibration number can be programmed into the Rosemount

8712D/H or 8732C transmitter using the Local Operator

Interface (LOI) or the 375 Field Communicator. Refer to the appropriate

transmitter product manual for complete instructions. In a F

fieldbus environment, the 8742C can be configured using the DeltaV

configuration tool or another F

The calibration number is more than a correction factor, or K- factor, for the

flowtube. The first five digits represent the low frequency gain. The ninth

through thirteenth digits represent the high frequency gain. Both numbers are

normalized from an ideal number of 10000. Standard configurations use the

low frequency gain, but in noisy applications it may be worthwhile to switch to

the higher frequency. An additional transmitter procedure, called Auto Zero, is

required to perform at the higher coil drive frequency. The seventh and eighth

digits represent the zero offset at both frequencies where the nominal value

is 50. Empty pipe functionality is a transmitter feature that is controlled by a

parameter in the transducer block. To turn off this feature, see Section 4:

Operation and Maintenance, “Learning Empty Pipe” on page 4-5.

The 8742C Magnetic Flowmeter Transmitter is shipped with a blank tag and a

temporary address to allow a host to automatically assign an address and a

tag. If the tag or address need to be changed, use the features of the

configuration tool. The tools do the following:

• Change the tag to a new value.

• Change the address to a new address.

OUNDATION fieldbus configuration device.

OUNDATION

™

4-2

When the device is at a temporary address, only the tag and address can be

changed or written to. The resource, transducer, and function blocks are all

disabled.

Page 42

Reference Manual

00809-X0100-4793, Rev CA

August 2004

Rosemount 8742C

AI BLOCK The Analog Input (AI) function block provides the primary interface of the

measurement to the control and/or monitoring systems. To properly configure

the device, three parameters must be set in order to correctly interface

between the AI block and transducer block.

1. The CHANNEL parameter defines which transducer block

measurement is used by the AI block. In the 8742C Magnetic

Flowmeter Transmitter, only one channel is available: AI1.CHANNEL

= 1 (Flow).

2. The second parameter is the XD_SCALE.UNITS_INDX. The default

configuration is feet per second (ft/s). Other units are available and

listed in Appendix D: Table D-3.

3. Finally, since the flow measurement from the transducer block is in

the correct units, L_TYPE is configured as Direct. L_TYPE can be

either Direct or Indirect.

NOTE

Refer to the F

00809-0100-4783, for more details on configuring and troubleshooting the AI

Block.

OUNDATION fieldbus Block product manual, document

ARITHMETIC BLOCK The Arithmetic function block provides the ability to configure a range

extension function for a primary input and applies the nine (9) different

arithmetic types as compensation to or augmentation of the range extended

input. All operations are selected by parameter and input connection.

The nine (9) arithmetic functions are Flow Compensation Linear, Flow

Compensation Square Root, Flow Compensation Approximate, Btu Flow,

Traditional Multiply and Divide, Average, Summer, Fourth Order Polynomial,

and Simple HTG Compensate Level.

This Arithmetic function block supports mode control (Auto, Manual, and Out

of service). There is no standard alarm detection in this block.

NOTE

Refer to the F

00809-0100-4783, for more details on configuring and troubleshooting the

Arithmetic Block.

OUNDATION fieldbus Block product manual, document

INTEGRATOR The Integrator (INT) function block integrates one or two variables over time.

The block compares the integrated or accumulated value to pre-trip and trip

limits and generates discrete output signals when the limits are reached.

The Integrator function block supports mode control, demand reset, a reset

counter, and signal status calculation. There is no process alarm detection in

the block.

NOTE

Refer to the F

00809-0100-4783, for more details on configuring and troubleshooting the

Integrator Block.

OUNDATION fieldbus Block product manual, document

4-3

Page 43

Reference Manual

00809-0100-4793, Rev CA

Rosemount 8742C

August 2004

PID BLOCK The PID function block combines all of the necessary logic to perform

proportional/integral/derivative (PID) control. The block supports mode

control, signal scaling and limiting, feedforward control, override tracking,

alarm limit detection, and signal status propagation.

The block supports two forms of the PID equation: Standard and Series. You

can choose the appropriate equation using the FORM parameter. The

Standard ISA PID equation is the default selection.

s

1

-----------------

Standard Out GAIN e 1

Series Out GAIN e× 1

Where

GAIN: proportional gain value

τ

: integral action time constant (RESET parameter) in seconds

r

s: laplace operator

τ

: derivative action time constant (RATE parameter)

d

α: fixed smoothing factor of 0.1 applied to RATE

F: feedforward control contribution from the feedforward input (FF_VAL parameter)

e: error between setpoint and process variable

× F+×=

s1+

τ

r

1

×

+

-------

+ F+=

τ

s

r

τ

d

----------------------------++

ατ

s1+×

d

τ

s1+

d

----------------------------

ατ

s1+×

d

To further customize the block for use in your application, you can configure

filtering, feedforward inputs, tracking inputs, setpoint and output limiting, PID

equation structures, and block output action.

NOTE

Refer to the F

OUNDATION fieldbus Block product manual, document

00809-0100-4783, for more details on configuring and troubleshooting the

PID Block.

4-4

Page 44

Reference Manual

00809-X0100-4793, Rev CA

August 2004

Rosemount 8742C

CONFIGURING LINKS

AND SCHEDULING

BLOCK EXECUTION

Figure 4-2. Measurement

Configuration

Without configuring the links between blocks and scheduling the blocks to

execute in the proper order, the application will not work correctly. Most hosts

and/or configuration tools make this task a simple matter by using a Graphical

User Interface (GUI).

Transducer

Block

Flow

Macro Cycle

AI

AI Block

In

FBUS_48A

4-5

Page 45

Rosemount 8742C

Advanced Applications

Figure 4-3. Control

Configuration

Reference Manual

00809-0100-4793, Rev CA

August 2004

Transducer

Block

Flow

In

AI Block

AI1

Out

In

Macro Cycle

PID

PID Block

Out

Analog Output

Block (AO)

CAS_IN

BKCAL_OUT

AO

FBUS_47A

4-6

Page 46

Reference Manual

00809-X0100-4793, Rev CA

August 2004

Rosemount 8742C

Cascade Control Cascade control applications require two inputs. The configuration is to link

the output of one AI block into the PID block in the 8742C transmitter and to

link the AI block of a second 8742C transmitter into the PID block of that

transmitter. Another set of links between the second PID and the AO block,

located in the control valve, is required (see Figure 4-4).

Figure 4-4. Cascade Control

Configuration

Transducer

Block

Flow

AI

Block 1 (AI1)

IN

AI