Rosemount™ 770XA Natural Gas

Chromatograph

Product Data Sheet

00813-0200-3770, Rev AA

September 2020

Rosemount 770XA Gas Chromatographs provide the most accurate analysis of natural gas available in a field mounted gas

chromatograph (GC). This GC features a design that increases analytical capability, maximizes ease of use, and widens the range of

analysis options in a GC with an ambient temperature rating of -4 to 140 °F (-20 to 60 °C). These advanced features make this GC

ideal for natural gas custody transfer and applications requiring advanced analyis, such as C9+ (with hydrocarbon dew point and

cricondentherm calculations), total sulfur, and C6+ with hydrogen sulfide (H2S).

Rosemount 770XA September 2020

Features and benefits

Easy to use

■

Single bolt analytical valve design for easy overhaul in the field

■

Large column canister for both micro-packed and capillary columns of long lengths

■

Internal stream selection and valve actuation soleniods that can be replaced easily in under five minutes

■

Easy to use MON2020™ software for diagnostics

■

Four conduit entry points in the electronics housing for easy wiring access

■

One package for fiscal metering or gas quality

■

Custody transfer analysis from C6+ to C9+

■

Contaminant monitoring - trace hydrogen sulfide, carbon dioxide, oxygen, etc.

■

Combine measurements and reduce analysis cost

— C9+ with hydrocarbon dew point

— C6+ with H2S (3 to 30 ppm H2S)

— C6+ with oxygen

— C6+ with helium and hydrogen

— C9+ with methanol and water

— Total sulfur

— C6+ with total sulfur

— C9+ with total sulfur

Reduced installation costs

■

Flexible power with both 120/240 Vac and 24 Vdc options

■

Integrated controller electronics

■

Pipe-mount, wall-mount, or floor-mount

Contents

Features and benefits........................................................................................................................................................................ 2

Applications...................................................................................................................................................................................... 3

Superior performance....................................................................................................................................................................... 6

Controller electronics and communications...................................................................................................................................... 8

Data archiving and reports.................................................................................................................................................................9

MON2020™........................................................................................................................................................................................9

Integration with third-party networks..............................................................................................................................................11

Analytical systems and integration services..................................................................................................................................... 12

Specifications.................................................................................................................................................................................. 13

Recommended installation..............................................................................................................................................................17

2 Emerson.com/Rosemount

September 2020

Rosemount 770XA

Lower operational costs

■

No shelter or instrument air required

■

Low carrier and power consumption

■

Longest gas chromatograph valve and column warranties available

Applications

Standard natural gas applications

Emerson has made popular end-user energy and gas quality applications standard on all Rosemount gas chromatographs.

Applications may vary by components of interest, analysis time, reduced hardware, or improved precision. For non-standard

natural gas applications, Emerson can custom-engineer the Rosemount 770XA Gas Chromatograph to fit most requirements.

Energy measurement (to C6+, C7+, and C9+)

The Rosemount 770XA Gas Chromatograph standard applications for energy measurement include C6+ (three minutes), C7+ (ten

minutes), and C9+ (five minutes). The latest GPA 2145/2172, AGA-8, and ISO 6976 calculations are available and can be configured

to be calculated together.

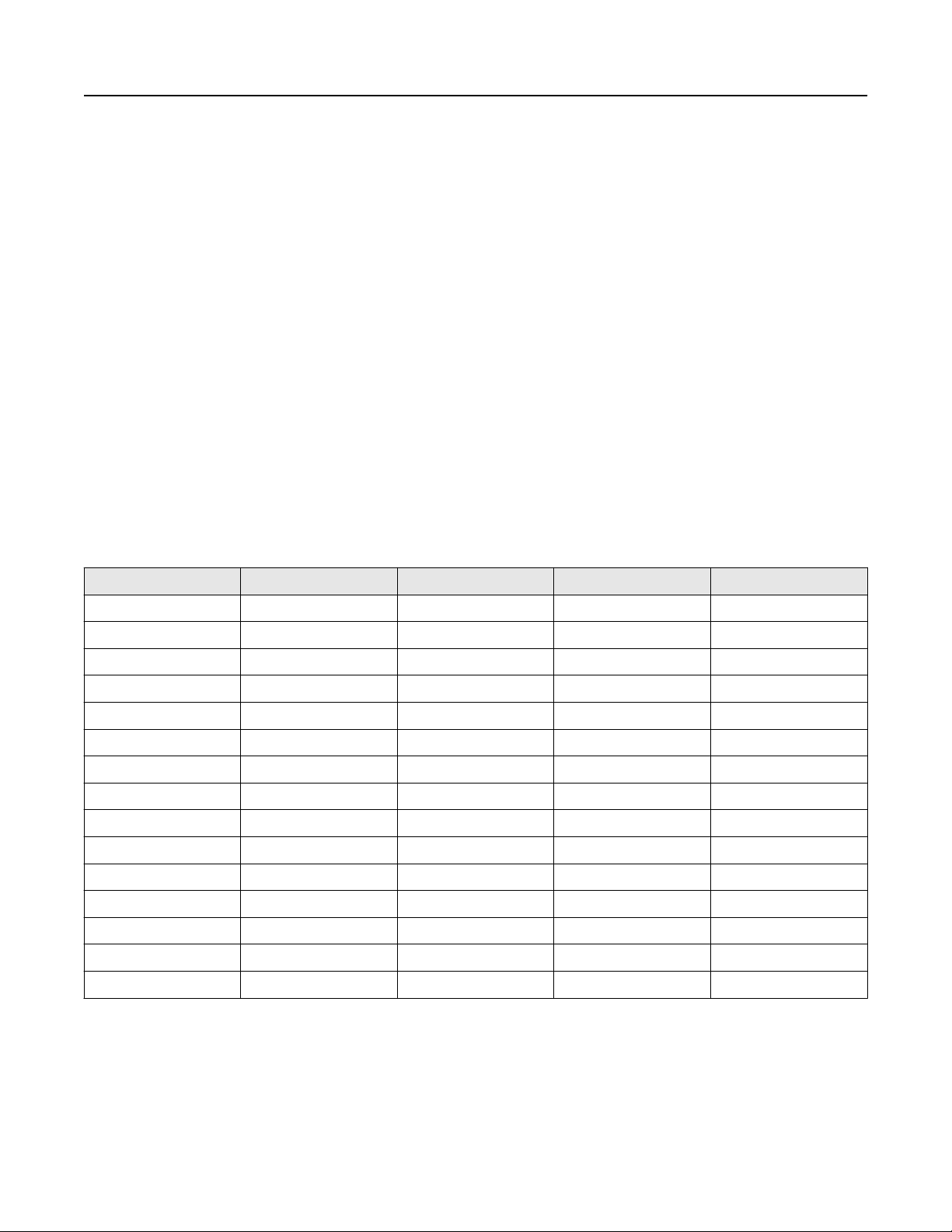

Table 1: Standard Measurement Ranges

Gas component Range C6+ C7+ C9+

Methane 65 to 100 mole % Yes Yes Yes

Ethane 0 to 20 mole % Yes Yes Yes

Propane 0 to 10 mole % Yes Yes Yes

n-Butane 0 to 5 mole % Yes Yes Yes

Iso-Butane 0 to 5 mole % Yes Yes Yes

n-Pentane 0 to 1 mole % Yes Yes Yes

Iso-Pentane 0 to 1 mole % Yes Yes Yes

Neo-Pentane 0 to 1 mole % Yes Yes Yes

Heptane

Nitrogen 0 to 20 mole % Yes Yes Yes

Carbon dioxide 0 to 20 mole % Yes Yes Yes

Hexanes

Heptanes

Octanes

Nonane

(1)

(2)

(3)

(1)

(2)

(2)

(3)

(3)

C7+ analysis results

C7+ and C9+ analysis results

C9+ analysis results

0 to 1 mole % Yes Yes Yes

0 to 1 mole % Yes Yes Yes

0 to 1 mole % No Yes Yes

0 to 0.5 mole % No No Yes

0 to 0.5 mole % No No Yes

Rosemount 770XA 3

Rosemount 770XA September 2020

Gas quality analysis

Natural gas contaminants, such as hydrogen sulfide and oxygen, reduce pipeline integrity over time. The Rosemount 770XA Gas

Chromatograph (GC) can easily measure most contaminants for online quality assurance.

The GC can combine contaminant monitoring with energy measurements for complete custody transfer analysis. To the extent

possible, these combined applications use independent gas chromatograph valves, detectors, and columns for each primary

measurement. This technique offers greater reliability, increased speed, and easier troubleshooting. This application approach also

simplifies field upgrades and re-applications in the analyzer by minimizing internal piping changes.

Hydrocarbon dew point monitoring

The Rosemount 770XA Gas Chromatograph offers accurate and reliable hydrocarbon dew point calculations from the extended

C9+ analysis by combining two detectors and a controller within a single housing, reducing complexity, minimizing maintenance

and spare parts requirements, simplifying the scope of analyzers at the pipeline, and reducing the overall cost of the analytical

solution.

This GC integrates hydrocarbon dew point software into the gas chromatograph to provide dew point temperatures for up to four

user-entered pressures and the cricondentherm using the Peng-Robinson or the Redlich-Kwong-Suave equations of state. Use

analog or Modbus® inputs from another device for the calculation pressures to get real-time dew point results.

The measured C6/C7/C8 and C9+ components allow for an accurate determination of the hydrocarbon dew point for pipelinequality natural gas using reliable and low-maintenance thermal conductivity detectors (TCDs), avoiding standalone dew point

analyzers or flame ionization detectors (FIDs), which require additional utility gas requirements. For heavier gas applications where

significant amounts of components above C10 are expected, an FID can be combined with a TCD to provide further extended

analysis.

4 Emerson.com/Rosemount

September 2020

Rosemount 770XA

Custom applications

If the standard applications do not fit your needs, Emerson can customize the Rosemount 770XA Gas Chromatograph to meet

many measurement requirements. Submit a completed application data sheet with your request or ask our application engineers

for assistance.

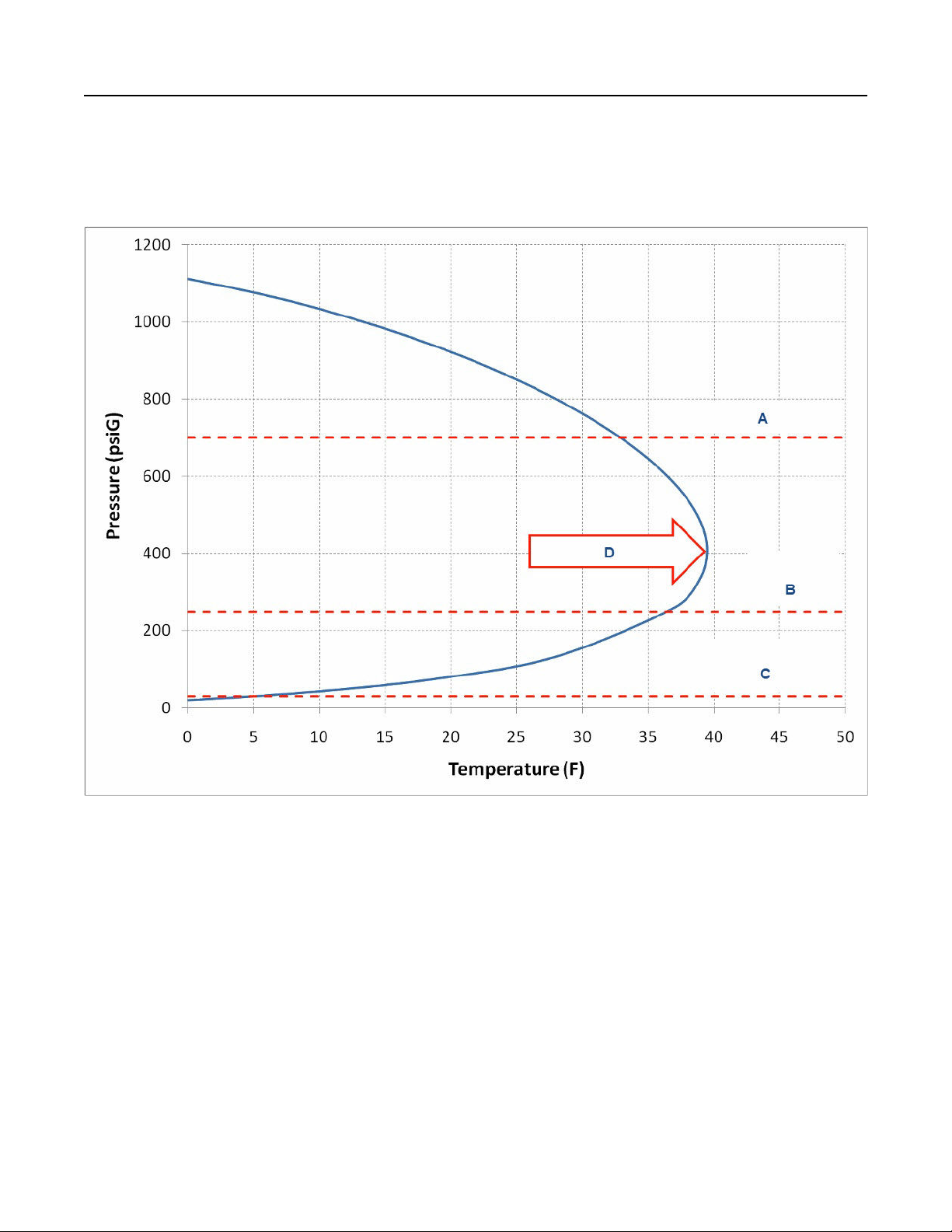

A typical phase curve showing the cricondentherm and the hydrocarbon dew point calculated at three pressures for practical

operational use.

A. Pipeline pressure

B. Regulated pressure

C. Sample handling pressure

D. Cricondentherm

Rosemount 770XA 5

Rosemount 770XA

September 2020

Superior performance

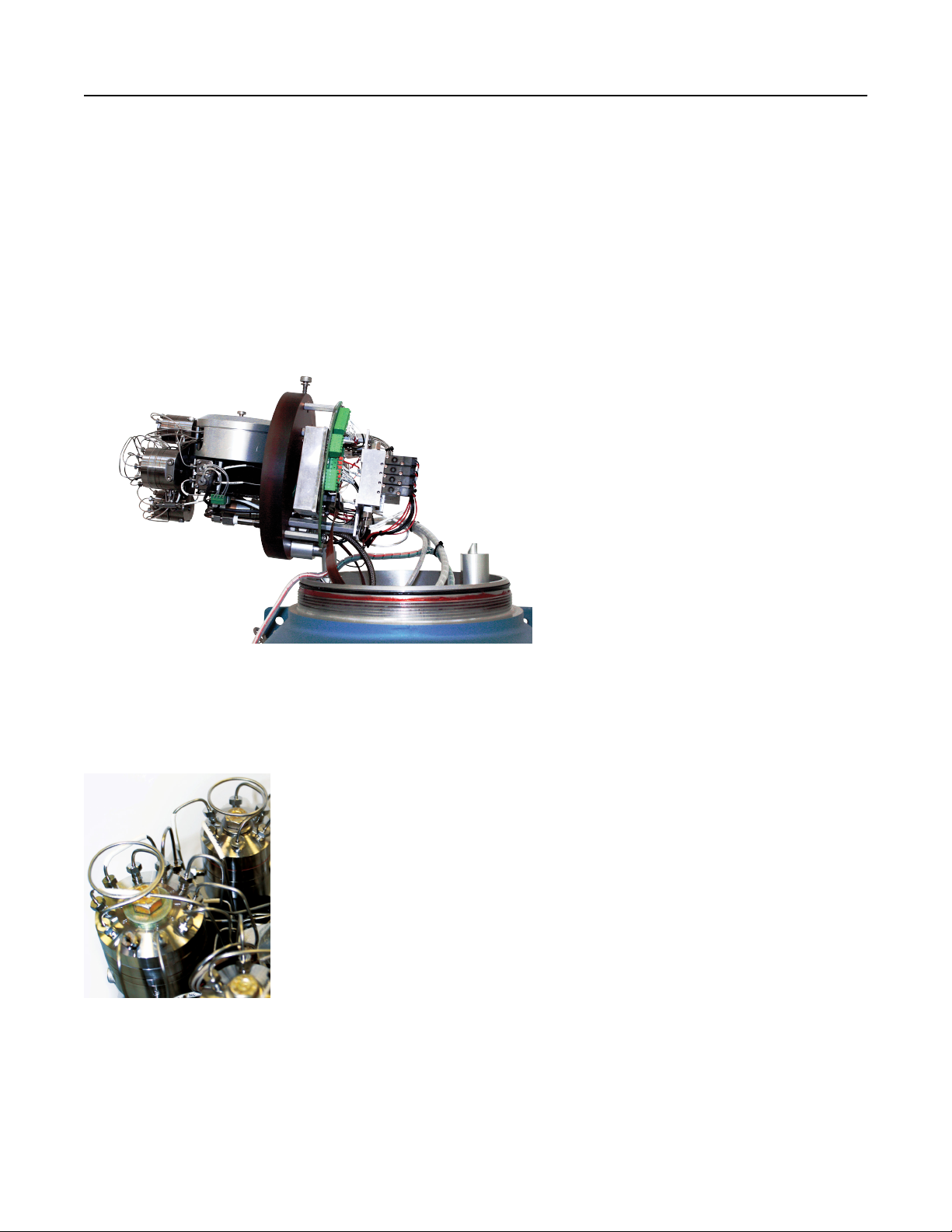

Modular analytical oven

Building off of the proven valves, columns, and detectors of the Rosemount 500 and Rosemount 700 gas chromatographs (GCs),

the Rosemount 770XA gas chromatograph analytical oven has been designed for maximum serviceability and expandability. It

features a clean architecture with few cables, making the analyzer simple to maintain. In addition, the oven features a unique,

pivot-top base that provides maximum accessibility to all of the components below.

Multiple temperature control zones and up to four 6-port or 10-port valves and two independent detectors provide extreme

application flexibility and range. All components in the oven are completely accessible and serviceable in the field to reduce the

total cost of ownership over the life of the analyzer.

Unique analytical assembly design pivots to allow instant access to all components.

Gas chromatograph valves

The GC has the capacity to support up to six 6-port or 10-port diaphragm/piston gas chromatograph valves. These pneumatic

valves are guaranteed for the life of the gas chromatograph and are specified to operate over five million cycles. The unique,

double-diaphragm design removes the need for springs, O-rings, and lubrication. To service the valve, the operator just needs to

replace a cost-effective diaphragm set, which can normally be done in less than ten minutes.

Thermal conductivity detectors (TCDs)

The TCD is the detector of choice for most applications due to its universal response to components of interest in natural gas and

light refinery and hydrocarbon processing gas analysis. The TCD in the Rosemount 770XA GC is able to measure well beyond the

normal ranges seen in other designs by performing many applications with low parts-per-million measurement requirements. This

greatly simplifies the GC design and lowers the cost to the end user when a simple and rugged TCD can be used.

6 Emerson.com/Rosemount

September 2020

Rosemount 770XA

Micro flame photometric detector (µFPD)

The µFPD photo multiplier tube (PMT) module enables the measurements of trace sulfur compounds when integrated with

Rosemount 770XA GCs.

A. µFPD PMT Module

A. µFPD burner

The µFPD is installed in the analyzer oven. The associated electronics are mounted underneath. The design eliminates the need for

instrument air, greatly reducing installation cost of the GC. The µFPD module comes fully integrated with the GC.

Micro-packed columns

The GC offers micro-packed columns with a superior combination of features found in both capillary and conventional packed

columns: speed, sharp peak resolution, and low carrier gas consumption. In addition, the unique design provides for greatly

extended column life and the longest warranty available on the market. You can also use standard capillary columns in GC

applications if required.

Stream switching module

The internal sample stream switching module is available in four-stream or eight-stream versions. This saves end users the

additional hardware and assembly costs associated with externally mounted stream selection assemblies. The module uses inert

gas for solenoid actuation, with easy access for tubing changes and maintenance. For applications with varying stream

composition, a double-block-and-bleed configuration is optionally available.

Rosemount 770XA 7

Rosemount 770XA

September 2020

Controller electronics and communications

Modular electronics

The controller electronics, option cards, and field termination boards are all packaged conveniently in the lower section of the gas

chromatograph (GC). Customer-terminated power and output connections are also made in this lower section of the GC.

Touch key local operator interface (optional)

The local operator interface (LOI) permits maintenance and operation of a GC without a laptop or personal computer (PC). The LOI

is a high-resolution color display that is touch key infrared activated and supports all core GC operations.

Features include:

■

Color LCD display with full VGA (640 x 840 pixels) resolution

■

User-adjustable auto-backlighting for easy viewing

■

Eight infrared-activated touch keys and screen saver

In addition, the LOI:

■

Eliminates external magnetic pen requirements and tactile buttons.

■

Maintains the Rosemount 770XA's hazardous area classifications.

■

Includes complete GC status, control, and diagnostics, including full chromatogram display and alarm messages.

Local indication and operation panel

You can view analyzer health and valve status through the GC's front cover. The panel displays green (healthy), yellow (warning),

and red (failure) light emitting diodes (LEDs), along with LEDs indicating gas chromatograph valve on/off actuations, power, and

central processing unit (CPU) health. Each valve can be actuated manually for simplified troubleshooting and fast system purging

after maintenance.

Flexible inputs and outputs (I/O)

The GC is built with enough I/O to handle most applications, including:

■

Five discrete digital outputs

■

Five discrete digital inputs

■

Two analog inputs

■

Six analog outputs

■

Three Modbus® serial ports (RS-232/RS-485/RS-422)

■

Two Modbus-enabled Ethernet ports (one with DHCP server for local access)

If you need more I/O, the GC includes two expansion slots that use the I/O cards from the ROC-800 family of flow computers.

8 Emerson.com/Rosemount

September 2020

Rosemount 770XA

Data archiving and reports

The gas chromatograph (GC) includes expanded reports and data archiving that conforms to the latest API 21.1 requirements for

metering audit purposes and backup of the primary systems, such as flow computers or SCADA systems. Every analysis is time and

date stamped and archived for retrieval via the MON2020™ software.

Security

Event logs

Alarm logs

Maintenance log

Archiving

Chromatograms

Drawings and

documents

Four levels of password-protected security, configurable to read/write or read-only for third party

access.

A continuous record of all operator changes, with time, date, and user identification name records.

A continuous record of all historical alarms, time and date stamped with alarm state and description.

A scratch pad for tracking maintenace or testing performed on the GC system.

Over 31,700 analysis records (which is over 65 days for a C6+ three-minute application), 370 final

calibration records, and 370 validation records are archived automatically with time and date stamps.

Over 1,700 worth of analysis chromatograms and 370 chromatograms and user-selected protected

chromatograms that are permanently stored, including the factory testing chromatograms.

User manuals and drawings in several file formats are stored in the controller memory for convenient

retrieval using the MON2020 software, eliminating the risk of manuals and drawings being misplaced.

You can also upload user-generated documents (such as maintenance checksheets or installation

drawings) to the controller for later retrieval.

Standard reports include

Average reports

Analysis reports

Raw data report

Calibration report

Final calibration report

Molecular weight vs. response

factor graph

Hourly, 24-hour, weekly, monthly, and variable averages

Physical property calculations for component and group analysis and alarms

Retention times, peak areas, detector number, method, integration start/stop, and peak width

for analysis

Raw component data, new response factors, retention times, and deviation from last

calibration

Results from the calibration response factors and retention time adjustments

The response factors plotted on a log/log graph as outlined in the GPA2198-03 Appendix B to

confirm the fidelity of the detector response across components

MON2020

™

Emerson has designed the Rosemount 770XA gas chromatograph (GC) to operate unattended. If adjustments are needed,

Emerson's proprietary gas chromatograph software, called MON2020, allows complete control of the GC either locally or remotely.

From MON2020, you can:

■

Start or stop analysis, calibration, or validation cycles

■

Configure, ignite, and check the status of the micro flame photometric detector (µFPD) or the flame ionization detector (FID)

flames

■

Generate and save current and historical analysis and calibration reports

■

Review and modify analytical settings

■

Upload and display multiple chromatograms for comparison

■

Upload and trend any of the measured results

■

Export data to text, HTML, or Microsoft® Excel™ for use in third party applications

Rosemount 770XA 9

Rosemount 770XA

■

Check on original calibration against the last calibration

■

Perform GC operation checks and modifications simultaneously

■

Upload and view manuals and drawings stored in the gas chromatograph

MON2020 is a Windows® based software program that makes analyzer configuration, maintenance, and data collection easy. With

intuitive drop-down menus and fill-in-the-blank tables, even new users can quickly navigate through the software.

Figure 1: MON2020 Interface

September 2020

A. Simple drop-down menus

B. Connect to any GC with a mouse click

C. Full featured chromatogram display

D. Response Factor Fidelity chart

E. Fully detailed Timed Events table

F. Automatic listing of measured components

G. Quickly add chromatograms to overlay

H. Save chromatograms to hard drive

With its abilities to communicate with your enterprise network and export to numerous file types, MON2020 is a powerful tool that

ensures operators, engineers, maintenance personnel, and management have access to critical data, such as current and archived

chromatograms, alarm history, event logs, and maintenance logs.

MON2020's chromatogram viewer allows you to view and compare both live and archived chromatograms simultaneously. Despite

its small size, the chromatogram file includes analysis and calculation results, integration and valve time settings, retention time

settings, and raw peak data.

MON2020's trend viewer makes it easy to trend multiple variables on a single chart. To help diagnose process or analysis issues, you

can select single or multiple points on the trend viewer; the chromatograms associated with these points will open in the

chromatogram viewer. You can save the trend files or export them as text, CSV, or Microsoft Excel files.

10 Emerson.com/Rosemount

September 2020

MON2020 can connect to a Rosemount GC via Ethernet directly or over your local or wide area network. The software is equipped

with multi-level username and password security settings to limit and control access to the GC and provide levels of access

authority ranging from read-only access to full control of the GC and its data.

Rosemount 770XA

Integration with third-party networks

Whether you want to network gas chromatographs (GCs) throughout your network or simply link a single GC to a flow computer,

you can configure the Rosemount 770XA to handle almost any scenario.

■

Choice of Ethernet, Modbus® Serial, or 4–20 mA analog outputs

■

Use MON2020™ for diagnostics, configuration, and data retrieval over Ethernet, serial, or modem connections

■

Use multi-dropped serial or Ethernet networks to connect multiple XA series gas chromatographs

■

Able to connect to multiple personal computer (PC) workstations using MON2020

The GC supports three types of communication interfaces:

■

10/100 Mbps Ethernet connectivity

■

RS-232, RS-422, and RS-485 serial communication links

■

4–20 mA analog outputs

Ethernet connectivity

Two Ethernet interfaces are available on the GC. You can configure each interface with a static Internet protocol (IP) address,

subnet mask, and gateway.

You can configure the RJ45 connector Ethernet port to operate as a DHCP host to simplify local PC access.

The Ethernet interfaces on the GC serve MON2020 connections and Modbus TCP requests. The dual Ethernet interfaces can be

used in many ways. Examples:

■

Connect to a plant network for GC maintenance personnel and the other to a control network using Modbus TCP.

■

Connect to a broadband cellular wireless gateway for remote GC access, for data collection and maintenance, and the other for

a local connection.

OPC

With the optional GC-OPC server, the GC can connect via OPC with fully configurable definition files sand remote operation control

capabilities.

Modbus serial

The Modbus protocol is widely used today, because it is simple and effective. You can configure the GC to use the flow computer

industry standard SIM-2251 Modbus map and make it compatible with communication links from Danalyzer legacy GC

installations. You can also configure fully customized Modbus maps using either single register per floating point (ENRON format)

or two registers per floating point format, used in DCS and PLC systems.

You can configure three hard-wired serial ports as RS-232, RS-485, or RS-422 links to communicate to host systems using the

Modbus protocol. In addition, you can configure a fourth serial port for RS-232 with a nine-pin D-type connector that you can use

for direct connection to a Daniel® ultrasonic flow meter or local MON2020 access. The ultrasonic flow meter link enables the online

calculation of the speed of sound for continuous validation of the custody measurement. If more serial links are required, you can

add up to two additional serial ports using the two expansion ports using ROC800 series in/out (I/O) cards.

4-20 mA analog outputs

The GC supports six isolated 4-20 mA analog outputs that you can expand to fourteen analog outputs with optional expansion

cards.

Rosemount 770XA 11

Rosemount 770XA

September 2020

Analytical systems and integration services

Emerson offers a comprehensive range of analytical system solutions and third party integration services. From stand-alone panels

and cabinets to three-sided shelters and environmentally controlled walk-in enclosures, our complete range of capabilities is

backed by over 60 years of analytical expertise across thousands of process installations throughout the world.

From front end engineering design (FEED) and consulting services to manufacturing, integration, and testing to commissioning

services and on-going lifecycle support, Emerson provides complete turnkey analytical solutions.

With full scope analytical systems integration centers and regional support facilities strategically located across the world, Emerson

has the global resources and analytical expertise to provide localized support.

Engineered sample systems

Any gas chromatograph (GC) is only as good as the quality of the sample it measures.

The standard sample system includes a particulate filter and liquid filter/shut-off for each sample stream. If required, Emerson can

also custom engineer the sample system for the specific requirements of the application.

Common features include:

■

Heated and open-panel designs

■

All components rated for the area classification

■

Variety of sample probes to extract a reliable and stable sample from the process

Environmental chamber testing

Every Rosemount GC that leaves an Emerson facility undergoes rigorous testing throughout assembly. Emerson puts the majority

of its systems systems into an 18-hour environmental chamber test, where the systems must operate to specification in an

environment where the temperatures cycle between 0 and 130 °F (-18 and 50 °C).

Figure 2: Environmental Testing Chamber

12 Emerson.com/Rosemount

September 2020 Rosemount 770XA

Specifications

Consult Emerson if your requirements are outside the specifications listed in this section. Improved performance, other products,

and material offerings may be available depending on the application.

Construction

Hazardous area certified for:

Environmental

temperature

Enclosure

protection rating

Dimensions

Corrosion

protection

Mounting

Approximate

weight (without

sample system)

-4 to 140 °F (-20 to 60 °C)

IP66

Wall mount: Height x width x depth = 28 x 17.5 x 19.6 in. (711 x 445 x 498 mm)

Pipe mount: Height x width x depth = 28 x 17.5 x 26.4 in. (711 x 445 x 671 mm)

Floor mount: Height x width x depth = 60.3 x 17.5 x 24.1 in. (1532 x 445 x 612 mm)

Gas chromatograph (GC) enclosure material: Copper free aluminum coated with industrial grade powder

coat suitable for high humidity and salt-laden environments

Process wetted materials: Stainless steel. Where the function of an item excludes the use of stainless steel

(e.g. glass rotameter tubes), materials that are resistant to corrosion are used.

Electronics: All electronic circuit boards are tropicalized with a clear conformal coating.

Floor-standing (standard), wall, or pipe-mount (optional)

110 lb. (50 kg)

Certifications and approvals

The Rosemount 770XA has the following certifications and approvals.

Refer to the Rosemount 770XA product page for product certificates and approvals.

Follow all safety markings on the analyzer.

Type

Environment Operating temperature

Specifications

■

Thermal conductivity detector (TCD): 0 to 130 °F (-18 to 55 °C)

■

Flame ionization detector (FID): 32 to 140 °F (0 to 60 °C)

■

Micro flame photometric detector (µFPD): 32 to 122 °F (0 to 50 °C)

■

Hazardous area certified: -4 to 140 °F (-20 to 60 °C)

■

0 to 95% relative humidity (non-condensing)

■

Indoor/outdoor

■

Pollution - degree 2 (The gas chromatograph can withstand some non conductive

environmental pollutants, e.g., humidity.)

■

Vibration: Conforms to ASTM D4169

Rosemount 770XA 13

Rosemount 770XA September 2020

Type Specifications

Hazardous area certifications (hardware

dependent)

USA and Canada

■

Class I, Zone 1, Ex/AEx db IIC, Gb T6/T4/T3

■

Class I, Division 1, Groups B, C, and D, IP66

EU ATEX and IECEx

■

Ex db IIC Gb T6/T4/T3

■

Ta = -20 °C to 60 °C

■

SIRA 08ATEX 1328X

■

IECEx SIR 08.0093X

Consult factory for additional product certifications available.

Table 2: Approval Temperature Ratings

T6 Basic system no alternative options included

T4 Liquid sample injection valve (LSIV) option included

T4 Heat trace option with a maximum 176 °F (80 ⁰C) temperature switch setpoint

T3 Heat trace option with a maximum 230 °F (110 ⁰C) temperature switch setpoint

14 Emerson.com/Rosemount

September 2020

Performance capabilities

Rosemount 770XA

Oven

Valves

Carrier gas

Sample and

calibration gas input

pressure range

Gas input pressures

(maximums)

Detectors

Streams

Gating options

Chromatograms

stored/archived

internally

Airless, maximum 248 °F (120 °C)

Six-port and ten-port diaphragm chromatograph valves. Other types of valves, such as liquid injection or

rotary valves, may be used depending on the application.

Application-dependent. Typically zero-grade helium, nitrogen, or hydrogen.

3 to 30 psig (0.2 to 2.1 bar)

15 psig (1 bar) recommended

Sample gas: 90 psig (6.2 bar)

Carrier gas: 90 psig (6.2 bar)

Actuation gas: 110 psig (7.6 bar)

Thermal conductivity detector (TCD)

Flame ionization detector (FID)

Micro flame photometric detector (µFPD)

Available in mulitple configurations

Up to 20 externally controlled streams or up to 8 internal (includes calibration stream)

Fixed-time, slope sensing gating of peaks

Stores over 80 days of analysis report data and up to 2,500 individual chromatograms

Electronics

Power

Standard

Optional

Typical power

consumption at

72 °F (22 °C)

Note

Add 15.5 Watts DC (18 Watts AC) for local operator interface (LOI).

24 Vdc at the unit (21 - 30 Vdc)

90 to 264 Vac, 47 to 63 Hz

Start-up: 105 Watts DC (125 Watts AC)

Steady state: 35 Watts DC (40 Watts AC)

Rosemount 770XA 15

Rosemount 770XA September 2020

Communications (standard)

■

Ethernet: Two available connections - one RJ-45 port and one four-wire terminal with 10/100 Mbps

■

Analog inputs: Two standard input filtered with transient protection, 4-20 mA (user scalable and assignable)

■

Analog outputs: Six self-powered isolated outputs, 4-20 mA

■

Digital inputs: Five inputs, user assignable, optically isolated, rated to 30 Vdc at 0.5 A

■

Digital outputs: Five user-assignable outputs, Form C and electro-mechanically isolated, 24 Vdc

■

Serial: Three termination blocks, configurable as RS-232, RS-422, or RS-485 and one RS-232 D-sub (9-pin) Modbus®/personal

computer (PC) connection

Communications (optional)

Two expansion slots available for additional communications.

Each slot has the capacity to add one of the following:

■

Four analog inputs (isolated) card

■

Four analog outputs (isolated) card

■

Eight digital inputs (isolated) card

■

Five digital outputs (isolated) card

■

One RS-232, RS-422, or RS-485 serial connection card

16 Emerson.com/Rosemount

September 2020 Rosemount 770XA

Recommended installation

The drawings below represent the minimum recommended installation guidelines for the Rosemount 770XA gas chromatograph.

Please consult Emerson for detailed installation recommendation of your application.

Dimensions are in inches (mm).

Floor mount details

Figure 3: Floor Mount Side and Front Views

Rosemount 770XA 17

Rosemount 770XA

Pole and wall mount details

Figure 4: Pole Mount Side View and Wall Mount Side and Front Views

September 2020

A. Pole mount option

B. Wall mounting kit

C. Mounting holes

D. Liquid sample injection valve (LSIV)

18 Emerson.com/Rosemount

September 2020 Rosemount 770XA

Rosemount 770XA 19

00813-0200-3770

Rev. AA

September 2020

AMERICAS

Emerson Automation Solutions

10241 West Little York, Suite 200

Houston, TX 77040 USA

Toll Free 866 422 3683

+1 713 396 8880 (North America)

+1 713 396 8759 (Latin America)

+1 713 466 8175

gc.csc@emerson.com

EUROPE

Emerson

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

gc.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

MIDDLE EAST AND AFRICA

Emerson

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

+971 4 811 8100

+971 4 886 5465

gc.csc@emerson.com

©

2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

ASIA-PACIFIC

Emerson

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

gc.csc@emerson.com

Loading...

Loading...