Emerson Rosemount 702DX22, Rosemount 702 Series, Rosemount 702DX61, Rosemount 702DX42, Rosemount 702DX32 Reference Manual

Page 1

Reference Manual

00809-0200-4702, Rev CA

February 2013

Rosemount 702 Wireless Discrete Transmitter

Page 2

Page 3

Reference Manual

00809-0200-4702, Rev CA

Rosemount 702 Wireless

Discrete Transmitter

Title Page

February 2013

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number.

Customer Central

1 800 999 9307 (7:00 a.m. to 7:00 p.m. CST)

National Response Center

1 800 654 7768 (24 hours a day)

Equipment service needs

International

1 952 906 8888

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson Process

Management Sales Representative.

i

Page 4

Title Page

February 2013

Reference Manual

00809-0200-4702, Rev CA

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with

the appropriate local, national, and international standards, codes, and practices. Please

review the approvals section of the 702 Reference Manual for any restrictions associated

with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, ensure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices

Process leaks may cause harm or result in death:

Install and tighten process connectors before applying pressure

Electrical shock can result in death or serious injury:

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock

The 702 transmitter and all other wireless devices should be installed only after the Smart

Wireless Gateway has been installed and is functioning properly. Wireless devices should

also be powered up in order of proximity from the Smart Wireless Gateway, beginning with

the closest. This will result in a simpler and faster network installation.

Shipping considerations for wireless products:

The unit was shipped to you without the power module installed. Please remove the power

module prior to shipping.

Each power module contains two “C” size primary lithium batteries. Primary lithium

batteries are regulated in transportation by the U. S. Department of Transportation, and are

also covered by IATA (International Air Transport Association), ICAO (International Civil

Aviation Organization), and ARD (European Ground Transportation of Dangerous Goods). It

is the responsibility of the shipper to ensure compliance with these or any other local

requirements. Please consult current regulations and requirements before shipping.

The power module with the wireless unit contains two “C” size primary lithium/thionyl chloride

batteries. Each battery contains approximately 2.5 grams of lithium, for a total of 5 grams in

each pack. Under normal conditions, the battery materials are self-contained and are not

reactive as long as the batteries and the pack integrity are maintained. Care should be taken to

prevent thermal, electrical, or mechanical damage. Contacts should be protected to prevent

premature discharge.

Battery hazards remain when cells are discharged.

Power modules should be stored in a clean and dry area. For maximum battery life, storage

temperature should not exceed 30 °C.

The power module has surface resistivity greater than one gigaohm and must be properly

installed in the wireless device enclosure. Care must be taken during transportation to and from

the point of installation to prevent electrostatic charge build-up.

ii

Page 5

Reference Manual

00809-0200-4702, Rev CA

Contents

1Section 1: Introduction

Table of Contents

February 2013

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Using this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Models covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 Rosemount 702DX22 Wireless Discrete Transmitter . . . . . . . . . . . . . . . . . .3

1.3.2 Rosemount 702DX61 Wireless Discrete Transmitter for liquid hydrocarbon

leak detection3

1.3.3 Rosemount 702DX32 Wireless Discrete Transmitter . . . . . . . . . . . . . . . . . .3

1.3.4 Rosemount 702DX42 Wireless Discrete Transmitter . . . . . . . . . . . . . . . . . .3

1.4 Transmitter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Functions of the transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.2 Wireless Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.3 Choosing an Installation Location and Position. . . . . . . . . . . . . . . . . . . . . . . .5

1.4.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4.5 Verifying Operating Atmosphere. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2Section 2: Configuration: Models 702DX22 and 702DX61

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.2 Connecting the switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2 Configuring the Device Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 Configuring on the bench with a Field Communicator . . . . . . . . . . . . . . . . . . . . . .10

2.4 Configuring the Device Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4.1 Configuring Transmitter with Dry Contact Inputs, Measurement Option Code

22 (702DX22)11

2.4.2 Configuring Transmitter with Liquid Hydrocarbon Detection, Measurement

Option Code 61(702DX61)12

2.5 HART menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.5.1 Dry contact inputs, measurement option code 22 (702DX22) . . . . . . . . .13

2.5.2 Liquid Hydrocarbon Detection, Measurement Option Code 61(702DX61)14

Tab le of Con tents

2.5.3 Fast Key Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.6 Remove Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

iii

Page 6

Table of Contents

February 2013

Reference Manual

00809-0200-4702, Rev CA

3Section 3: Mounting, Wiring Switches, and Sensors: Models

702DX22 and 702DX61

3.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.2 Installing the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2.1 Installing the Transmitter in a Direct Mount Configuration . . . . . . . . . . . .19

3.2.2 Installing the Transmitter in a Remote Mount. . . . . . . . . . . Configuration21

3.3 Wiring Switches and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.1 Wireless Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.2 Wiring Switches and Sensors with Liquid Hydrocarbon Detection, Measure-

ment Option Code 61(702DX61)24

3.4 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.5 Grounding the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4Section 4: Commissioning: Models 702DX22 and 702DX61

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2 Configuring the transmitter to communicate with the wireless network. . . . . .30

4.3 Using AMS Wireless Configurator to configure the transmitter . . . . . . . . . . . . . .30

4.4 Using a field communicator to change the network ID and join key . . . . . . . . . .30

4.5 Verifying operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.5.1 AMS Wireless Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5Section 5: Operation and Maintenance: Models 702DX22 and

702DX61

5.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.2 Discrete Input from Switches and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5.2.1 Dry Contact Inputs, Measurement Option Code 22 (702DX22) . . . . . . . .36

5.2.2 Wireless output specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5.2.3 Liquid Hydrocarbon Detection, Measurement Option Code 61 (702DX61)39

5.3 Interpreting LCD Screen Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.1 Startup Screen Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.2 Diagnostic Button Screen Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.3.3 Network Connection Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.3.4 Device Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.4 Replacing the power module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

iv

Table of Contents

Page 7

Reference Manual

00809-0200-4702, Rev CA

6Section 6: Configuration: Models 702DX32 and 702DX42

Table of Contents

February 2013

6.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.1.2 Ensuring proper switch connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

6.2 Discrete channel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

6.3 Device network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

6.3.1 Configuring the Transmitter with Dry Contact Inputs, Measurement Option

Code 32, 42 (702DX32, 702DX42)58

6.4 HART Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6.4.1 Measurement Option Code 32, 42 (702DX32, 702DX42) . . . . . . . . . . . . .59

6.4.2 Measurement Option Code 32, 42 (702DX32, 702DX42) . . . . . . . . . . . . .60

6.4.3 Measurement Option Code 32, 42 (702DX32, 702DX42) . . . . . . . . . . . . .61

6.4.4 Fast Key Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

6.5 Removing the power module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

7Section 7: Mounting, Wiring Switches, and Output Circuits:

Models 702DX32 and 702DX42

7.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7.2 Installing the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

7.2.1 Installing the Rosemount 702 Transmitter in a direct mount . . . . . . . . . .64

7.2.2 Installing the 702 Transmitter in a Remote Mount. . . . . . . . . . . . . . . . . . . .66

7.3 Wiring switches and sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.3.1 Dry Contact Inputs, Measurement Option Code 32, 42 (702DX32, 702DX42)

67

7.3.2 Dry contact switch inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.3.3 Output Circuits, measurement option code 42 (702DX42) . . . . . . . . . . . .69

7.3.4 Safety shower and eye wash monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

7.4 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

7.5 Grounding the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

8Section 8: Commissioning: Models 702DX32 and 702DX42

8.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.2 Configuring the transmitter to communicate with the wireless network. . . . . .78

Tab le of Con tents

8.3 Using a field communicator to change the network ID and join key . . . . . . . . . .78

8.4 Verifying operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

8.4.1 AMS Wireless Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

v

Page 8

Table of Contents

February 2013

Reference Manual

00809-0200-4702, Rev CA

9Section 9: Operation and Maintenance: Models 702DX32 and

702DX42

9.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

9.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

9.2 Discrete Input from Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

9.2.1 Dry Contact Inputs, Measurement Option Code 32, 42 (702DX32, 702DX42)

84

9.2.2 Wireless Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

9.2.3 Momentary Discrete Inputs, measurement option code 32 and 42 (702DX32,

702DX42)87

9.3 Discrete output circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

9.4 Modbus and OPC mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

9.5 Interpreting the LCD screen messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

9.5.1 Startup screen sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

9.5.2 Diagnostic button screen sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

9.5.3 Network connection status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.5.4 Device diagnostic screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.6 Replacing the power module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

AAppendix A: Specifications and Reference Data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

A.1.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

A.1.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

A.1.3 Performance specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A.2 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

A.3.1 Wireless Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

A.3.2 Other Options (Include with selected model number) . . . . . . . . . . . . . . 113

BAppendix B: Product Certifications

B.0.1 Approved manufacturing locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.0.2 European Union Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.0.3 Telecommunication compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.0.4 FCC and IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.0.5 Ordinary Location Certification for FM Approvals. . . . . . . . . . . . . . . . . . . 115

B.0.6 Hazardous Locations Certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

vi

Table of Contents

Page 9

Reference Manual

00809-0200-4702, Rev CA

CAppendix C: High Gain Remote Antenna Option

C.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

C.2 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

C.3 Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

C.4 Transient / Lightning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

C.5 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

C.6 Installing the High Gain Remote Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

DAppendix D: Installation Instructions and Drawings for Safety

Shower Monitoring

Table of Contents

February 2013

C.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Tab le of Con tents

vii

Page 10

Table of Contents

February 2013

Reference Manual

00809-0200-4702, Rev CA

viii

Table of Contents

Page 11

Reference Manual

00809-0200-4702, Rev CA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Models covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Transmitter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

1.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

Section 1: Introduction

February 2013

1.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Process leaks could result in death or serious injury.

Do not remove the switch while in operation

Install and tighten switches before applying pressure

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

1.2 Using this manual

Introduction

The sections in this manual provide information on installing, operating, and maintaining the

Rosemount 702 Wireless Discrete Transmitter. Section 2 through Section 5 are for the

Rosemount 702DX22 and Rosemount 702DX61 models. The Rosemount 702DX22 is the legacy

702 transmitter that has discrete input function only. The Rosemount 702DX61 is a special

version for liquid hydrocarbon leak detection with Tyco

Section 9 are for the Rosemount 702DX32 and Rosemount 702DX42 models. The Rosemount

702DX32 has all of the functionality of the 702DX22, with the addition of momentary discrete

input sensing and counting. The 702DX42 adds the capability of discrete output switching.

®

TraceTek® sensors. Section 6 through

1

Page 12

Section 1: Introduction

February 2013

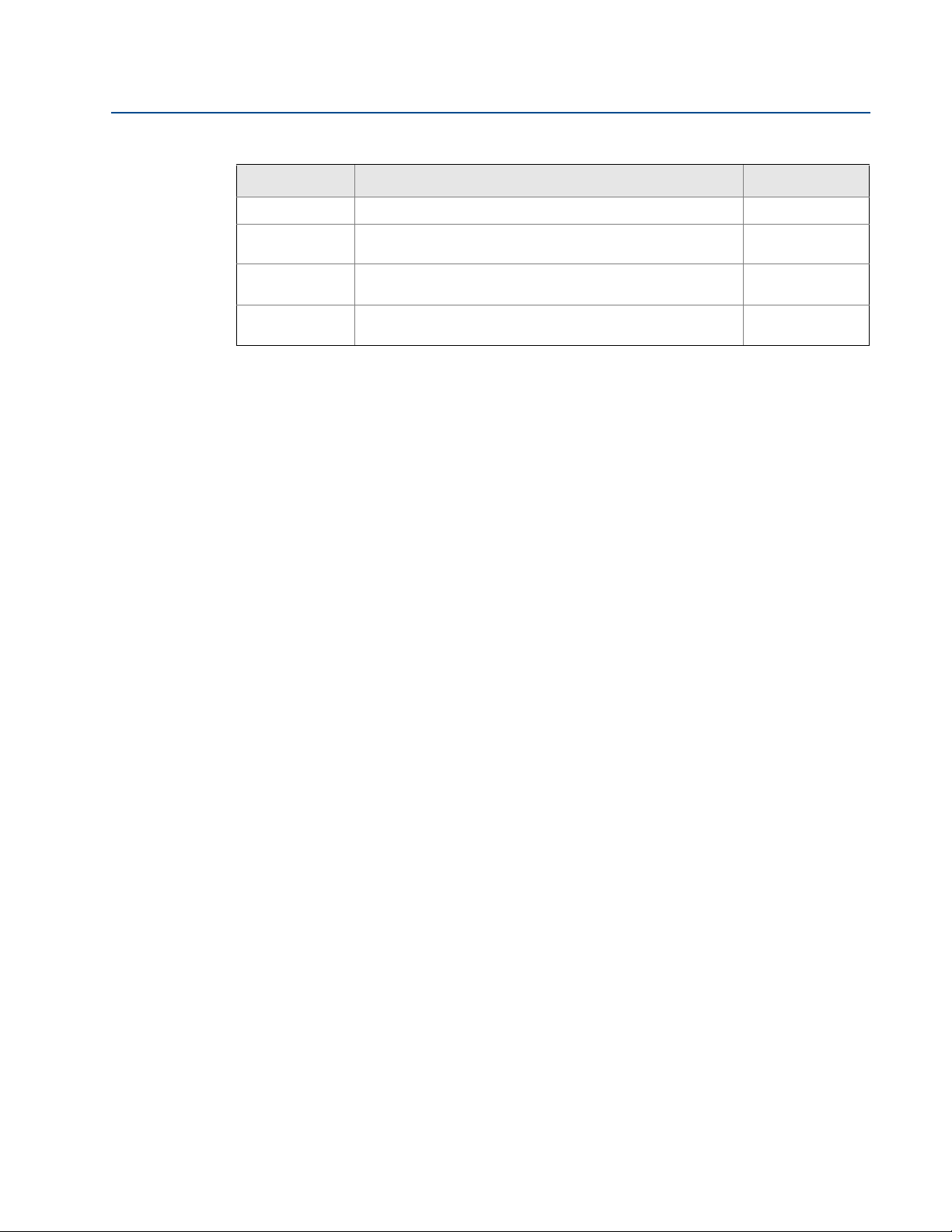

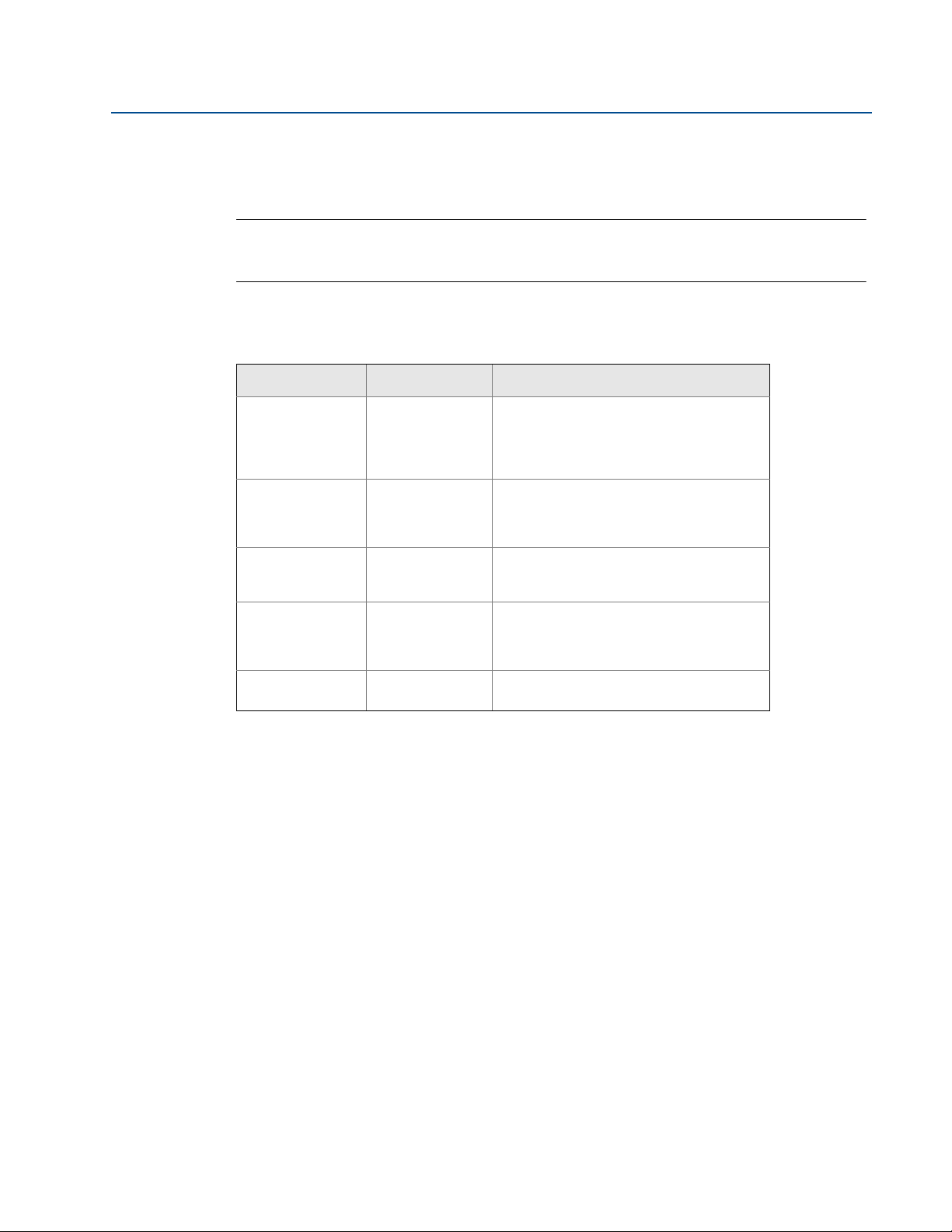

Model Number Functionality Manual Sections

702DX22 Two channel discrete input 1, 2, 3, 4, 5

Reference Manual

00809-0200-4702, Rev CA

702DX61 One channel for Tyco TraceTek liquid hydrocarbon leak

detection

702DX32 Two channel discrete input with momentary input detection

and counting

702DX42 Two channel discrete input or discrete output, with

momentary input detection and counting

1, 2, 3, 4, 5

1, 6, 7, 8, 9

1, 6, 7, 8, 9

The manual sections are organized as follows:

Section 2: Configuration: Models 702DX22 and 702DX61 contains information on the

configuration of the Rosemount 702 transmitter so that it can be added to the wireless network.

This configuration can be done using the AMS Suite™ Wireless Configurator or a Field

Communicator. Field Communicator menu trees are here.

Section 3: Mounting, Wiring Switches, and Sensors: Models 702DX22 and 702DX61 contains

information on the mounting of the transmitter and wiring of switches and sensor to the

transmitter.

Section 4: Commissioning: Models 702DX22 and 702DX61 contains information for the

commissioning of the transmitter onto the wireless network, and how to verify that the

transmitter has successfully joined.

Section 5: Operation and Maintenance: Models 702DX22 and 702DX61 provides detailed

information on operation of the Rosemount 702 transmitter with various switch and sensor configurations. LCD display messages are shown. Power module replacement is described.

Section 6: Configuration: Models 702DX32 and 702DX42 contains information on the

configuration of the Rosemount 702 transmitter so that it can be added to the wireless network.

This configuration can be done using the AMS Suite Wireless Configurator or a Field

Communicator. Field Communicator menu trees are here.

Section 7: Mounting, Wiring Switches, and Output Circuits: Models 702DX32 and 702DX42

contains information on the mounting of the transmitter and wiring of switches and sensor to

the transmitter.

Section 8: Commissioning: Models 702DX32 and 702DX42 contains information for the

commissioning of the transmitter onto the wireless network, and how to verify that the

transmitter has successfully joined.

Section 9: Operation and Maintenance: Models 702DX32 and 702DX42 provides detailed

information on operation of the 702 transmitter with various switch and sensor configurations.

Also described are: Momentary discrete input detection and counting, discrete output switch

function, and variable reporting and mapping. LCD display messages are shown. Power module

replacement is described.

Appendix A: Specifications and Reference Data supplies functional, physical and performance

specifications; as well as ordering information.

Appendix B: Product Certifications contains telecommunication compliance information,

ordinary location certification, hazardous locations certificates and intrinsic safety installation

drawings.

2

Introduction

Page 13

Reference Manual

00809-0200-4702, Rev CA

Section 1: Introduction

February 2013

Appendix C: High Gain Remote Antenna Option describes the high gain remote antenna, its

specifications and installation.

1.3 Models covered

The following Rosemount 702 Wireless Discrete Transmitters are covered by this manual:

1.3.1 Rosemount 702DX22 Wireless Discrete Transmitter

Two input channels,

Discrete input only

1.3.2 Rosemount 702DX61 Wireless Discrete Transmitter for

liquid hydrocarbon leak detection

Detects hydrocarbon leaks using Tyco TraceTek sensor

Color coded terminal block for easy wiring of Tyco sensors

Compatible with Tyco TT5000 TraceTek fuel sensing cable

Compatible with Tyco TT-FSS TraceTek Fast Fuel Sensor

1.3.3 Rosemount 702DX32 Wireless Discrete Transmitter

Two discrete input channels

Momentary input detection and counting

1.3.4 Rosemount 702DX42 Wireless Discrete Transmitter

Two channels

Each channel configurable to discrete input or discrete output

Momentary input detection and counting

Discrete output switch function

1.4 Transmitter overview

Features of the Rosemount 702 Wireless Discrete Transmitter include:

An installation-ready solution that provides a variety of mounting options, transmitter

configurations, and switches

Flexibility to meet your most demanding applications

Wireless output with >99% data reliability delivers rich HART

industry leading security

Single or dual switch input with logic for limit contact and opposing contact

applications

®

data, protected by

Introduction

The integral LCD conveniently displays the primary switch input and diagnostics of the

transmitter

Simple and easy installation practices currently being used for robust installations

3

Page 14

Section 1: Introduction

February 2013

1.4.1 Functions of the transmitter

Switches produce either an open or closed signal. By using simple HART configuration, the 702

transmitter converts the switch signal to a wireless-enabled signal.

1.4.2 Wireless Considerations

Power Up Sequence

The Smart Wireless Gateway should be installed and functioning properly before any wireless

field devices are powered. Install the Black Power Module, SmartPower

number 701PBKKF (part number 00753-9220-0001) into the 702 transmitter to power the

device. Wireless devices should also be powered up in order of proximity from the Gateway,

beginning with the closest. This will result in a simpler and faster network installation. Enable

Active Advertising on the Gateway to ensure that new devices join the network faster. For more

information see the Smart Wireless Gateway Manual (Document Number 00809-0200-4420).

Antenna Position

Reference Manual

00809-0200-4702, Rev CA

™

Solutions model

The antenna should be positioned vertically, either straight up or straight down, and it should be

approximately 3 ft. (1 m) from any large structure, building, or conductive surface to allow for

clear communication to other devices.

Figure 1-1. Antenna Position

Preparing (or sealing) the conduit entries

Upon installation, ensure that each conduit entry is either sealed with a conduit plug with

appropriate thread sealant, or has an installed conduit fitting or cable gland with appropriate

thread sealant.

4

Introduction

Page 15

Reference Manual

Conduit Entry

Conduit Entry

COMM

P/N 00753-9200-0020

1

2

3

4

00809-0200-4702, Rev CA

Figure 1-2. Locating Conduit Entries

Connecting the Field Communicator to the Power Module

Section 1: Introduction

February 2013

The Power Module needs to be connected for the Field Communicator to interface with the 702

transmitter.

Figure 1-3. Field Communicator Connections

1.4.3 Choosing an Installation Location and Position

Introduction

Choosing an Installation Location and Position

When choosing an installation location and position, take into account access to the

transmitter. For best performance, the antenna should be vertical with space between objects in

a parallel metal plane, such as a pipe or metal framework, as the pipes or framework may

adversely affect the antenna’s performance.

5

Page 16

Section 1: Introduction

Housing Temperature Rise, Above

Ambient °C (°F)

3 4 5 6 7 8 9

0

60 (108)

50 (90)

40 (72)

30 (54)

20 (36)

10 (18)

4.2

55

Extension Length (in.)

815 °C (1500 °F) Process Temperature

540 °C (1000 °F) Process Temperature

250 °C (482 °F) Process Temperature

February 2013

1.4.4 Electrical

Caring for the Power Module

The Rosemount 702 Wireless Discrete Transmitter is self-powered. The included Black Power

Module contains two “C” size primary lithium/thionyl chloride batteries. Each battery contains

approximately 2.5 grams of lithium, for a total of 5 grams in each pack. Under normal

conditions, the battery materials are self-contained and are not reactive as long as the batteries

and the power module are maintained. Care should be taken to prevent thermal, electrical, or

mechanical damage. Contacts should be protected to prevent premature discharge.

Use caution when handling the power module, it may be damaged if dropped from heights in

excess of 20 feet (6.10 m).

Making Switch Connections

Make switch connections through the cable entry in the side of the connection head. Be sure to

provide adequate clearance for cover removal.

Reference Manual

00809-0200-4702, Rev CA

1.4.5 Verifying Operating Atmosphere

Verify that the operating atmosphere of the transmitter is consistent with the appropriate

hazardous locations certifications.

Isolating the transmitter from sources of heat

The transmitter will operate within specifications for ambient temperatures between -40 and

185 °F (-40 and 85 °C). Heat from the process is transferred from the switch to the transmitter

housing. If the expected process temperature is near or beyond specification limits, consider

using an extension, or remote mount the transmitter to thermally isolate it from the process.

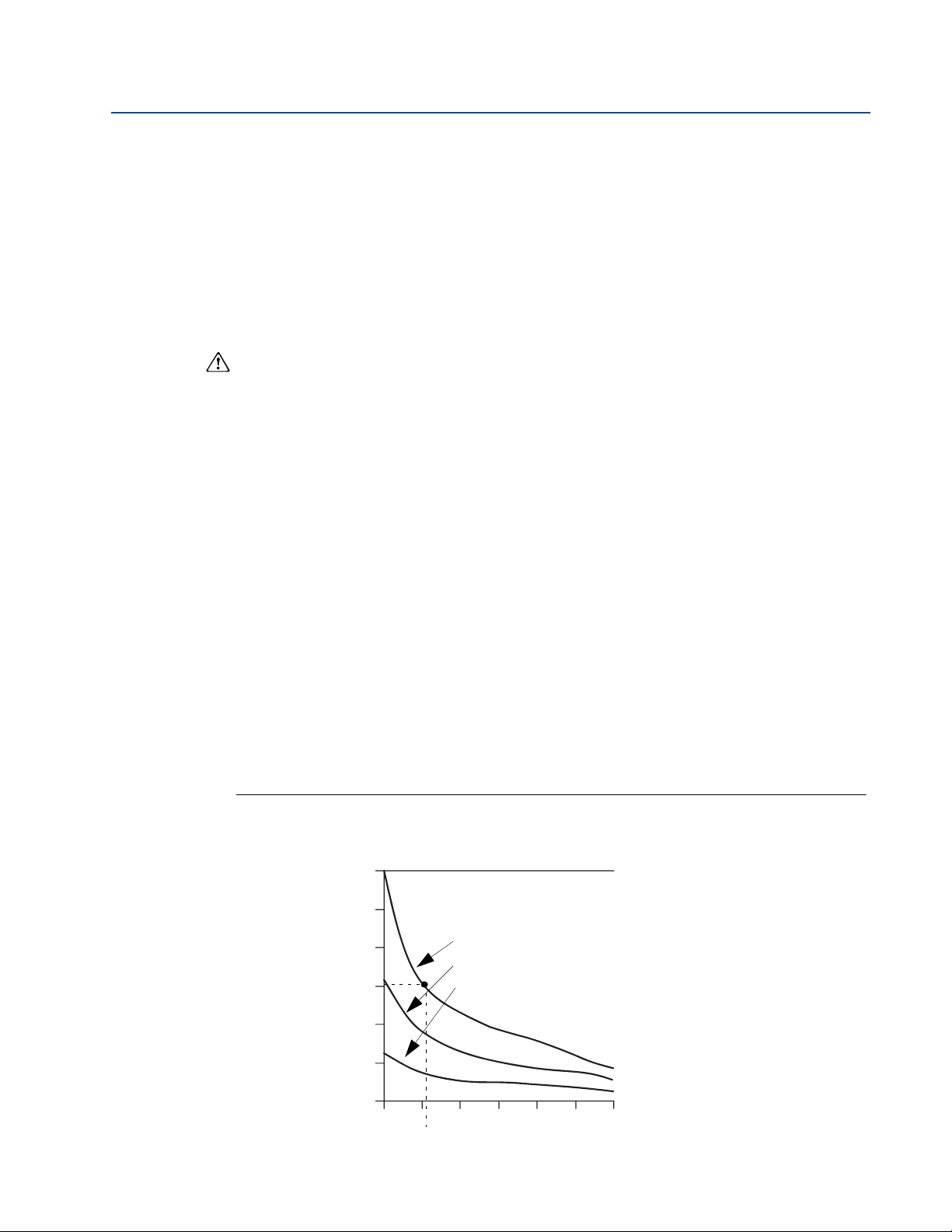

Figure 1-4 provides an example of the relationship between the transmitter housing

temperature rise and the extension length.

Figure 1-4. Rosemount 702 Transmitter Connection Head Temperature Rise vs. Extension

Length

6

Introduction

Page 17

Reference Manual

00809-0200-4702, Rev CA

Example

The transmitter specification limit is 185 °F (85 °C). If the ambient temperature is 131 °F (55 °C)

and the maximum process temperature to be measured is 1500 °F(815 °C), the maximum

permissible connection head temperature rise is the transmitter specification limit minus the

ambient temperature (moves 185 °F to 131 °F [85 to 55 °C]), or 86 °F (30 °C).

In this case, an extension of 5-in. (0.13 m) meets t his requirement, but 6-in. (0.15 m) provides

an additional margin of protection, thereby reducing risk of ambient thermal damage.

Temperature Limits

Section 1: Introduction

February 2013

Operating Limit Storage Limit

With LCD Display -4 to 175 °F

Without LCD Display -40 to 185 °F

1.5 Service Support

To expedite the return process outside of North America, contact your Emerson Process

Management representative,

Within the United States, call the Emerson Process Management Response Center toll-free

number 1 800 654 7768. The center, which is available 24 hours a day, will assist you with any

needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to

a hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

-20 to 80 °C

-40 to 85 °C

-40 to 185 °F

-40 to 85 °C

-40 to 185 °F

-40 to 85 °C

Introduction

7

Page 18

Section 1: Introduction

February 2013

Shipping Wireless Products (Lithium Batteries):

The unit was shipped with the Power Module not installed. Please remove the Power Module

from the unit before shipping.

Primary lithium batteries (charged or discharged) are regulated during transportation by the

U.S. Department of Transportation. They are also covered by IATA (International Air Transport

Association), ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure compliance

with these or any other local requirements. Consult current regulations and requirements

before shipping.

1.6 Product Recycling/Disposal

Recycling of equipment and packaging should be taken into consideration. The product and

packaging should be disposed of in accordance with local and national legislation.

Reference Manual

00809-0200-4702, Rev CA

8

Introduction

Page 19

Reference Manual

00809-0200-4702, Rev CA

Section 2: Configuration: Models 702DX22 and 702DX61

Section 2 Configuration: Models

702DX22 and 702DX61

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Configuring the Device Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Configuring the Device Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

HART menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 13

Remove Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

February 2013

2.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Process leaks could result in death or serious injury.

Do not remove the switch while in operation

Install and tighten switches before applying pressure

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

Configuration: Models 702DX22 and 702DX61

9

Page 20

Section 2: Configuration: Models 702DX22 and 702DX61

February 2013

2.1.2 Connecting the switches

The 702 transmitter is compatible with a number of simple switches. When ordered in the

optional configuration for Liquid Hydrocarbon Detection, option code 61, the 702 transmitter is

compatible with Tyco

page 11 shows the correct input connections to the switch terminals on the transmitter. To

ensure a proper switch connection, anchor the switch lead wires into the appropriate

compression terminals and tighten the screws.

Wiring the transmitter

If the switch is installed in a high-voltage environment and a fault condition or installation error

occurs, the sensor leads and transmitter terminals could carry lethal voltage. Use extreme

caution when making contact with the leads and terminals.

Use the following steps to wire the sensor and power supply to the transmitter:

1. Remove the transmitter enclosure cover (if applicable).

2. Attach the sensor leads according to the wiring diagram Figure 3-3 on page 4.

®

Tra ceTek® Fast Fuel Sensors and TraceTek sensing cable. Figure 2-1 on

Reference Manual

00809-0200-4702, Rev CA

3. Connect the Black Power Module.

4. Verify the connection by viewing the LCD.

5. Replace the cover and tighten (if applicable).

2.2 Configuring the Device Sensor

Remove the power module-side housing cover to expose the terminal block and HART

communication terminals, then connect the power module to power the unit for configuration.

The 702 transmitter will receive any HART communication from a handheld Field

Communicator, or AMS Wireless Configurator.

2.3 Configuring on the bench with a Field

Communicator

When using a Field Communicator, any configuration changes must be sent to the transmitter

using the Send key (F2). AMS Wireless Configurator configuration changes are implemented

when the Apply button is clicked.

Configuring on the Bench with AMS Wireless Configurator

10

AMS Wireless Configurator is capable of connecting to devices directly, using a HART modem,

or with the Gateway. When configuring on the bench with a HART modem, double click the

device icon, then choose the Configure/Setup tab (or right click and select Configure/Setup).

Configure the device settings using the Direct Connection menu. When configuring with the

Gateway, double click the device icon then choose the Configure/Setup tab (or right click and

select Configure/Setup). Configure the device settings using the Wireless Connection menu. To

check or change sensor configuration using a Field Communicator, enter the following Fast Key

Sequence: 2, 2, 2.

Configuration: Models 702DX22 and 702DX61

Page 21

Reference Manual

1

2

4

3

00809-0200-4702, Rev CA

Section 2: Configuration: Models 702DX22 and 702DX61

2.4 Configuring the Device Network

Configuring Device Network with Field Communicator

To communicate with the Gateway, and ultimately the Information System, the transmitter

must be configured to communicate with the wireless network.

Using a Field Communicator or AMS Wireless Configurator, enter the Network ID and Join Key so

they match the Network ID and Join Key of the Gateway and the other devices in the network. If

the Network ID and Join Key are not identical, the transmitter will not communicate with the

network. The Network ID and Join Key may be obtained from the Gateway on the Setup>Network>Settings page on the web server. Using a Field Communicator, the Network ID can be

configured by entering the Fast Key Sequence: 2, 2, 1, 1. The Join Key can also be configured

using a Field Communicator with the Fast Key Sequence: 2, 2, 1, 2.

Configuring Device Network with AMS Wireless Configurator

The final device network configuration piece is the Update Rate which, by default, is 1 minute. It

can be changed at commissioning, or at any time, by using AMS Wireless Configurator or the

Gateway’s web server. The Update Rate should be between 4 seconds and 60 minutes. To

change the Update Rate with a Field Communicator, use the Fast Key Sequence: 2, 2, 1, 3.

February 2013

If doing a bench top initial configuration, after completion remove the power module until

installation. When the device is installed, insert he power module and close the housing cover

securely. Always ensure a proper seal so that metal touches metal, but do not over tighten.

2.4.1 Configuring Transmitter with Dry Contact Inputs,

Measurement Option Code 22 (702DX22)

Figure 2-1. 702 Terminal Block

Connect the HART communication leads to the COMM terminals on the terminal block.

Configuration: Models 702DX22 and 702DX61

11

Page 22

Section 2: Configuration: Models 702DX22 and 702DX61

February 2013

Reference Manual

00809-0200-4702, Rev CA

2.4.2 Configuring Transmitter with Liquid Hydrocarbon

Detection, Measurement Option Code 61(702DX61)

Making Terminal Block Connections

Figure 2-2. Fuel Sensor Terminal Diagram

Connect Tyco TraceTek and Fast Fuel sensor lead wires by matching the colors of wires to colors

on terminal block.

Figure 2-3. Field Communicator Connections

1

2

P/N 00753-9200-0020

3

COMM

4

For HART communication, a 702 DD is required.

12

Configuration: Models 702DX22 and 702DX61

Page 23

Reference Manual

00809-0200-4702, Rev CA

Section 2: Configuration: Models 702DX22 and 702DX61

February 2013

2.5 HART menu tree

For ease of operation, changing setup, such as switch type, can be completed in several locations.

2.5.1 Dry contact inputs, measurement option code 22 (702DX22)

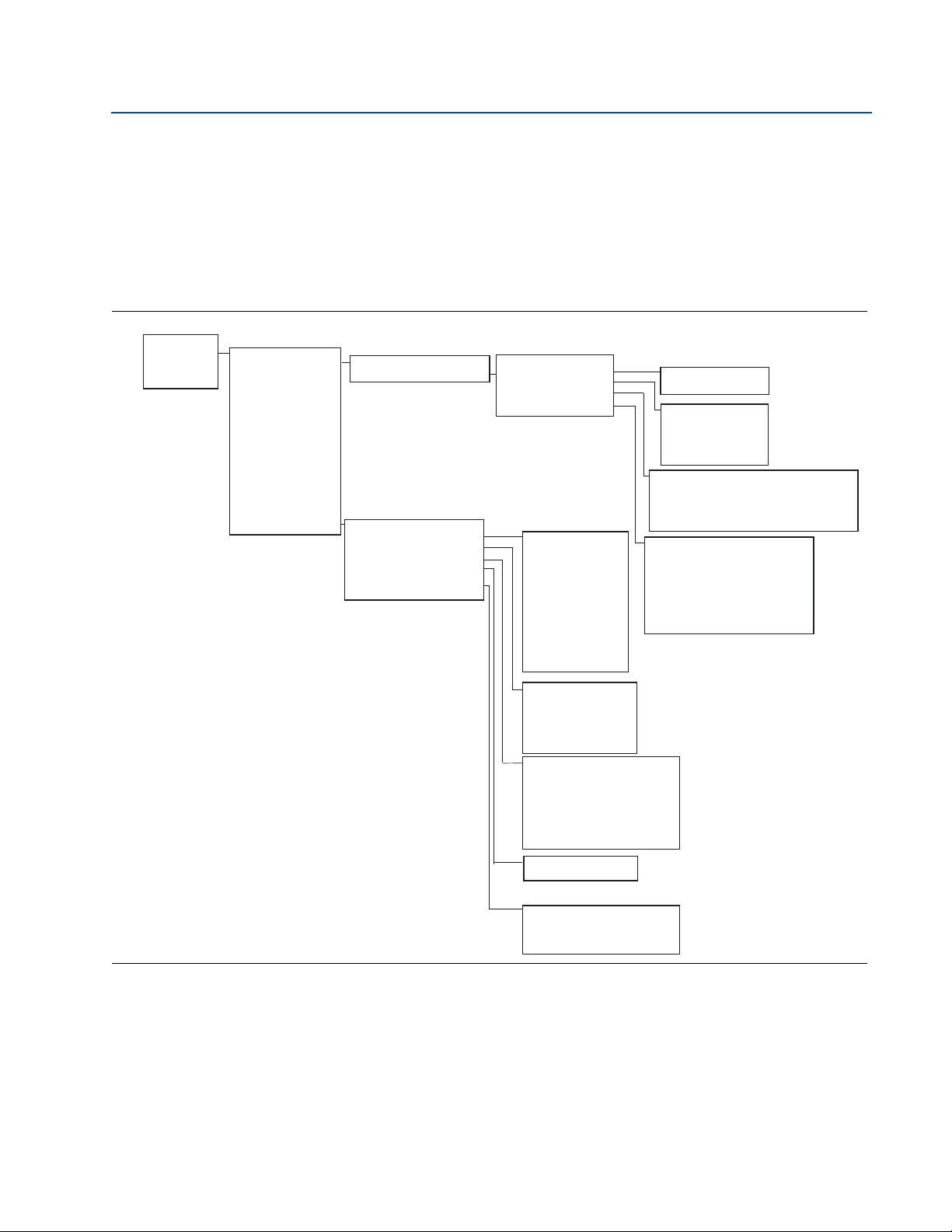

Figure 2-4. Field Communicator Menu Tree, DD Revision 2

1. Overview

2. Configure

3. Service Tools

1. Active Alerts

2. Communication Status

3. Discrete Input 1

4. Discrete 1 Status

5. Discrete Input 2

6. Discrete 2 Status

7. Last Update Time

8. DD Version

1. Guided Setup

2. Manual Setup

1. Join Device to Network

2. Configure Update Rate

3. Configure Discrete Application

4. Configure Device Display

1. Wireless

2. Discrete Sensors

3. Electronics Temperature

4. Device Information

5. Device Display

6. Other

1. Mode

1. Write Protect

2. AC Power Filter

3. Measurement and Status Log

1. Network ID

2. Join Device to Network

3. Broadcast Rates

4. Power Mode

5. Power Source

1. Configure Discrete Application

2. Discrete Input 1

3. Discrete Input 2

1. Electronics Temperature

2. Electronics Temperature Status

3. Unit

4. Maximum

5. Minimum

1. Tag

2. Long Tag

3. Device

4. Discrete Input 1

5. Discrete Input 2

6. Wireless

7. Write Protect

8. Poll Address

1. Configure Update Rate

2. Message 1

3. Message 2

4. Message 3

1. Discrete State

2. Invert Option

3. Sensor Serial Number

1. Discrete State

2. Invert Option

3. Sensor Serial Number

1. Manufacturer

2. Model

3. Final Assembly Number

4. Universal

5. Field Device

6. Software

7. Hardware

8. Descriptor

9. Message

10 Date

11 Model Number I

12 Model Number II

13 Model Number III

14 SI Unit Restriction

15 Country

16 Device ID

1. Sensor Serial Number

1. Sensor Serial Number

1. Manufacturer

2. Device Type

3. Device Revision

4. Software Revision

5. Hardware Revision

1. Active Alerts

2. History

1. Discrete Input 1

2. Discrete 1 Status

3. Discrete Input 2

4. Discrete 2 Status

5. Electronics Temperature

6. Electronics Temperature Status

7. Supply Voltage

8. Supply Voltage Status

1. Alerts

2. Variables

3. Communications

4. Maintenance

5. Simulate

9. Last Update Time

1. Join Status

2. Communication Status

3. Join Mode

4. Number of Available Neighbors

5. Number of Advertisements Heard

6. Number of Join Attempts

1. Sensor Calibration

2. Other

1. Discrete 1

2. Discrete 2

3. Ambient Temperature

4. Supply Voltage

Configuration: Models 702DX22 and 702DX61

1. Clear Alert History

1. Discrete Input 1 Sensor Wiring Offset

2. Discrete Input 2 Sensor Wiring Offset

1. Perform Master Reset

2. Measurement History

3. Advertise to New Devices

4. Install New Power Module

13

Page 24

Section 2: Configuration: Models 702DX22 and 702DX61

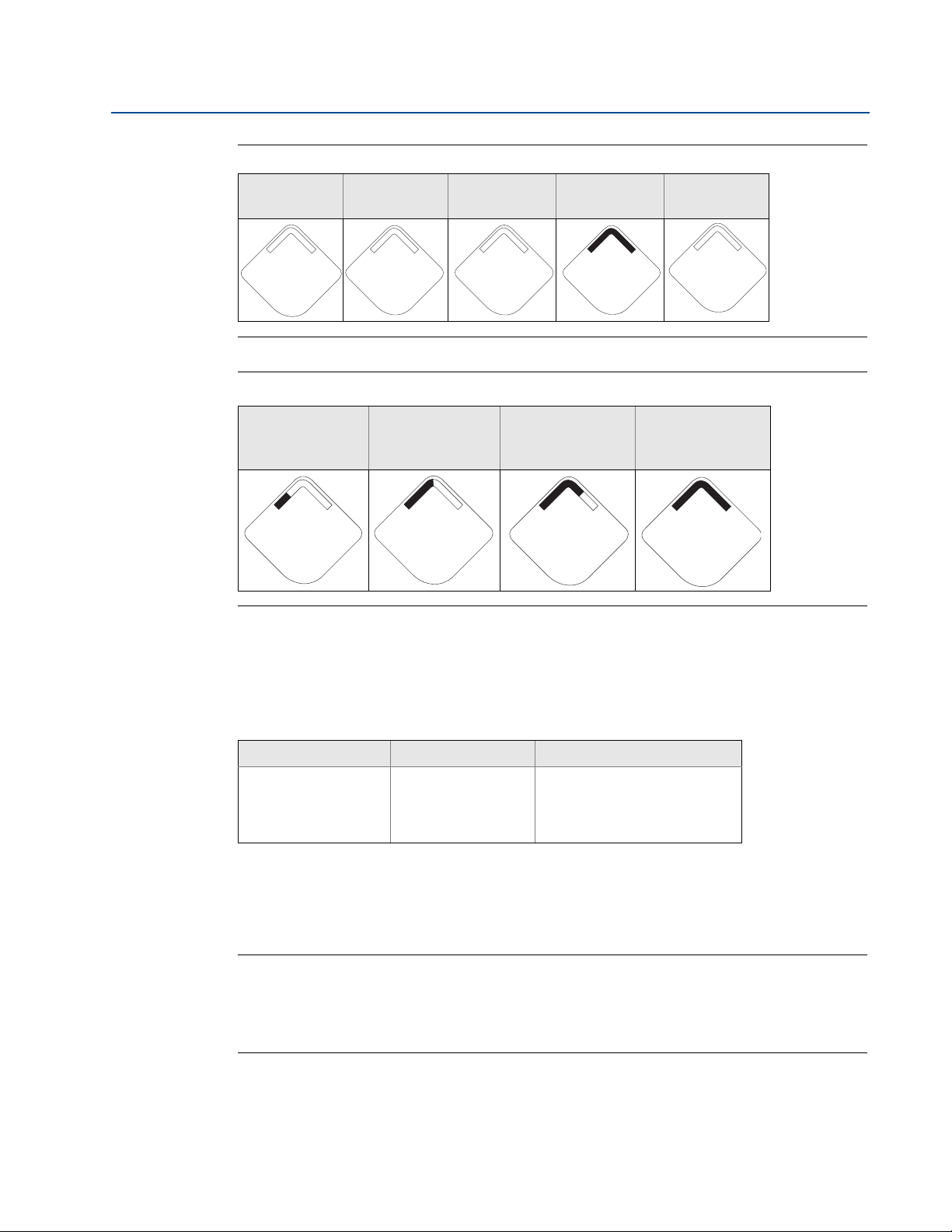

1. Overview

2. Configure

3. Service Tools

1. Device Status

2. Communication Status

3. Sensor State

4. Sensor Status

5. Update Rate

6. DD Revision

1. Guided Setup

2. Manual Setup

1. Alerts

2. Variables

3. Communications

4. Routine Maintenance

5. Simulate

1. Join Device to Network

2. Configure Update Rate

3. Configure Sensor

1. Wireless

2. Leak Sensor

3. Electronics Temperature

4. Device Information

5. Other

1. Refresh Alerts

2. History

1. Sensor State

2. Sensor Status

3. Electronics Temperature

4. Electronics temperature Status

5. Supply Voltage

6. Supply Voltage Status

7. Last Update Time

1. Join Status

2. Communication Status

3. Join Mode

4. Number of Available Neighbors

5. Number of Advertisements Heard

6. Number of Join Attempts

1. Other

1. Input

2. Electronics Temperature

3. Supply Voltage

1. Perform Master Reset

2. Measurement History

3. Advertise to New Devices

4. Install New Power Module

1. Network ID

2. Join Device to Network

3. Broadcast Rates

1. Configure Sensor

2. Sensor State

3. Sensor Status

4. Sensor Serial Number

1. Electronics Temperature

2. Electronics Temperature Status

3. Unit

4. Maximum

5. Minimum

1. Tag

2. Long Tag

3. Device

4. Leak Sensor

5. Wireless

6. Write Protect

7. Polling Address

1. Write Protect

2. AC Power Filter

3. Measurement and Status Log

4. Power Mode

5. Power Source

1. Configure Update Rate

2. Message 1

3. Message 2

4. Message 3

1. Manufacturer

2. Model

3. Final Assembly Number

4. Universal

5. Field Device

6. Software

7. Hardware

8. Descriptor

9. Message

10 Date

11 Model Number I

12 Model Number II

13 Model Number III

14 SI Unit Restriction

15 Country

16 Device ID

1. Sensor Serial Number

1. Manufacturer

2. Device Type

3. Device Revision

4. Software Revision

5. Hardware Revision

6. Transmit Power Level

February 2013

Reference Manual

00809-0200-4702, Rev CA

2.5.2 Liquid Hydrocarbon Detection, Measurement Option Code

61(702DX61)

Figure 2-5. Field Communicator Menu Tree, DD Revision 1, for Leak Detection

14

Configuration: Models 702DX22 and 702DX61

Page 25

Reference Manual

00809-0200-4702, Rev CA

2.5.3 Fast Key Sequence

Ta bl e 2 - 1 lists the fast key sequence for common transmitter functions.

NOTE:

The fast key sequences assume that a current DD is being used: DD Rev 2 for dry contact inputs,

and DD Rev 1 for leak detection.

Table 2-1. 702 Fast Key Sequence

Function Key Sequence Menu Items

Section 2: Configuration: Models 702DX22 and 702DX61

February 2013

Device

Information

Guided Setup 2, 1 Join Device to Network, Configure Update

Manual Setup 2, 2 Wireless, Process Sensor, Percent of Range,

Wireless 2, 2, 1 Network ID, Join Device to Network,

Discrete Input

Configuration

2, 2, 4 Manufacturer, Model, Final Assembly

Number, Universal, Field Device, Software,

Hardware Descriptor, Message, Date,

Model Number, I, II, III, SI Unit Restriction,

Country

Rate, Configure Sensor, Calibrate Sensor,

Configure Display, Configure Process

Alarms

Device Temperature, Device Information,

Device Configure, Other

Configure Update Rate, Configure

Broadcast Power Level, Power Mode, Power

Source

2, 2, 2 Discrete Input Configuration

2.6 Remove Power Module

After the sensor and network have been configured, remove the power module and replace the

transmitter cover. The power module should be inserted only when the device is ready for

commissioning

Configuration: Models 702DX22 and 702DX61

15

Page 26

Section 2: Configuration: Models 702DX22 and 702DX61

February 2013

Reference Manual

00809-0200-4702, Rev CA

16

Configuration: Models 702DX22 and 702DX61

Page 27

Reference Manual

00809-0200-4702, Rev CA

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

Section 3 Mounting, Wiring Switches,

and Sensors: Models 702DX22

and 702DX61

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Installing the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Installing the Transmitter in a Direct Mount Configuration . . . . . . . . . . . . . . . . . . . . . . . page 19

Installing the Transmitter in a Remote Mount Configuration . . . . . . . . . . . . . . . . . . . . . . page 21

Wiring Switches and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Wiring Switches and Sensors with Dry Contact Inputs, Measurement Option Code 22

(702DX22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Liquid Hydrocarbon Detection,

Measurement Option Code 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

Grounding the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

3.1 Safety Messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

17

Page 28

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

3.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Only qualified personnel should perform the installation

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure that

the instruments are installed in accordance with intrinsically safe or non-incendive

field wiring practices

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications

Process leaks could result in death or serious injury.

Do not remove the switch while in operation

Install and tighten switches before applying pressure

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

Reference Manual

00809-0200-4702, Rev CA

18

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 29

Reference Manual

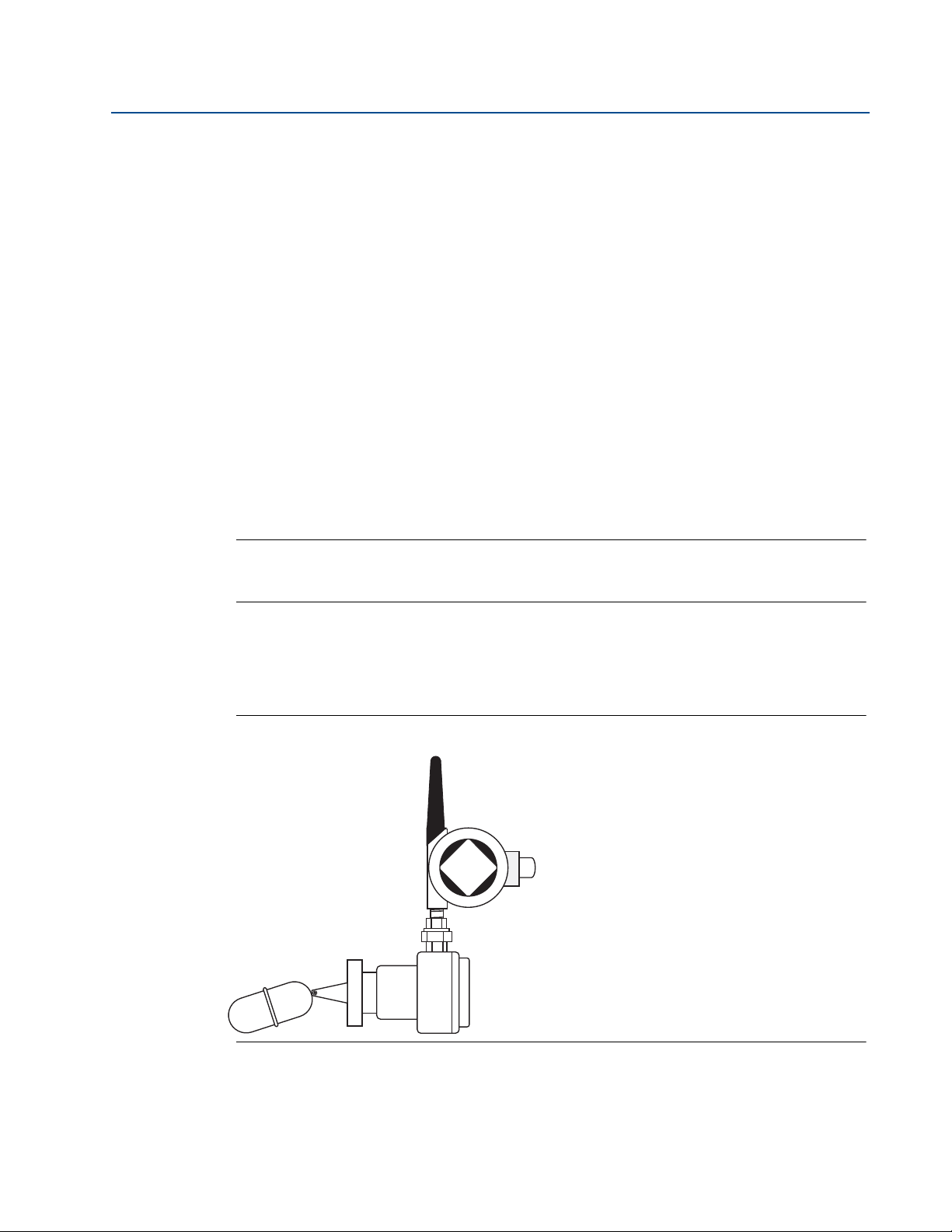

702 Transmitter

Float Switch

00809-0200-4702, Rev CA

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

3.2 Installing the transmitter

The 702 transmitter can be installed in one of two configurations:

Direct Mount: The switch is connected directly to the 702 transmitter housing’s conduit entry.

For installation instructions see “Installing the Transmitter in a Direct Mount Configuration” on

page 19.

Remote Mount: The switch is mounted separate from the 702 transmitter housing, then

connected to the 702 transmitter via conduit. For installation instructions see “Installing the

Transmitter in a Remote Mount Configuration” on page 21. Use Remote mount instructions for

the installation of liquid hydrocarbon sensors.

3.2.1 Installing the Transmitter in a Direct Mount Configuration

1. Install the switch according to standard installation practices making sure to use thread

sealant on all of the connections.

2. Attach the Rosemount 702 transmitter housing to the switch by using the pipe fittings

threaded into the conduit entries.

Note

Direct mount installation should not be employed when using tubing and connectors such as

Swagelok® fittings.

3. Attach the switch wiring to the terminals as shown in the wiring diagrams beginning on

page 22.

4. If commissioning the device, install the Black Power Module.

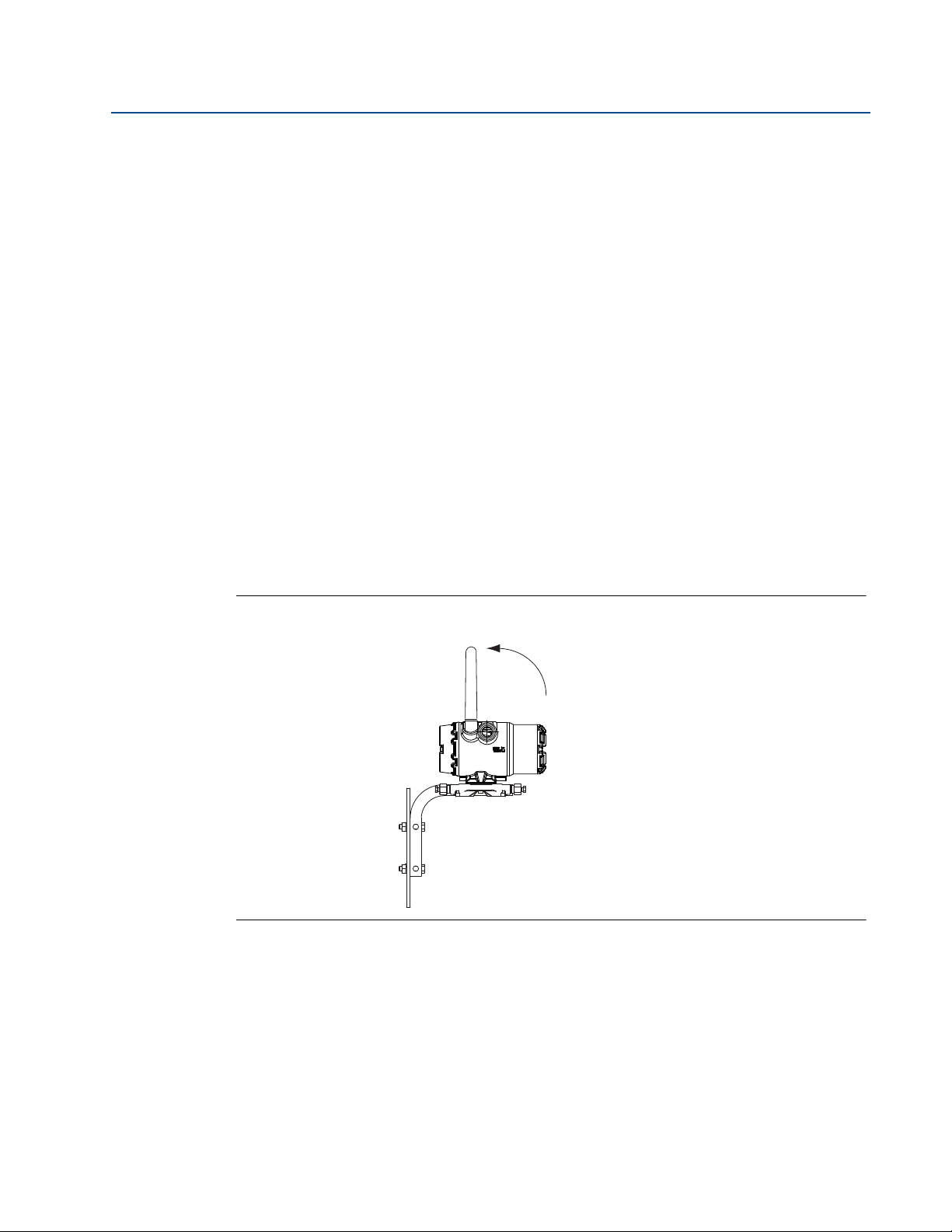

Figure 3-1. Direct Mount

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

19

Page 30

Section 3: Mounting, Wiring Switches, and Sensors:

Possible antenna rotation shown.

Antenna rotation allows for best

installation practices in any

configuration.

Models 702DX22 and 702DX61

February 2013

Note

Use caution when handling the power module, it may be damaged if dropped from heights in

excess of 20 feet.

Note

Wireless devices should only be powered up after the Smart Wireless Gateway, in order of

proximity from the Smart Wireless Gateway beginning with the closest device. This results in a

simpler and faster network installation.

Figure 3-2. Power Module Installation

Reference Manual

00809-0200-4702, Rev CA

5. Close the housing cover and tighten to safety specifications. Always ensure a proper

seal by installing the electronic housing covers so that metal touches metal, but do not

over tighten.

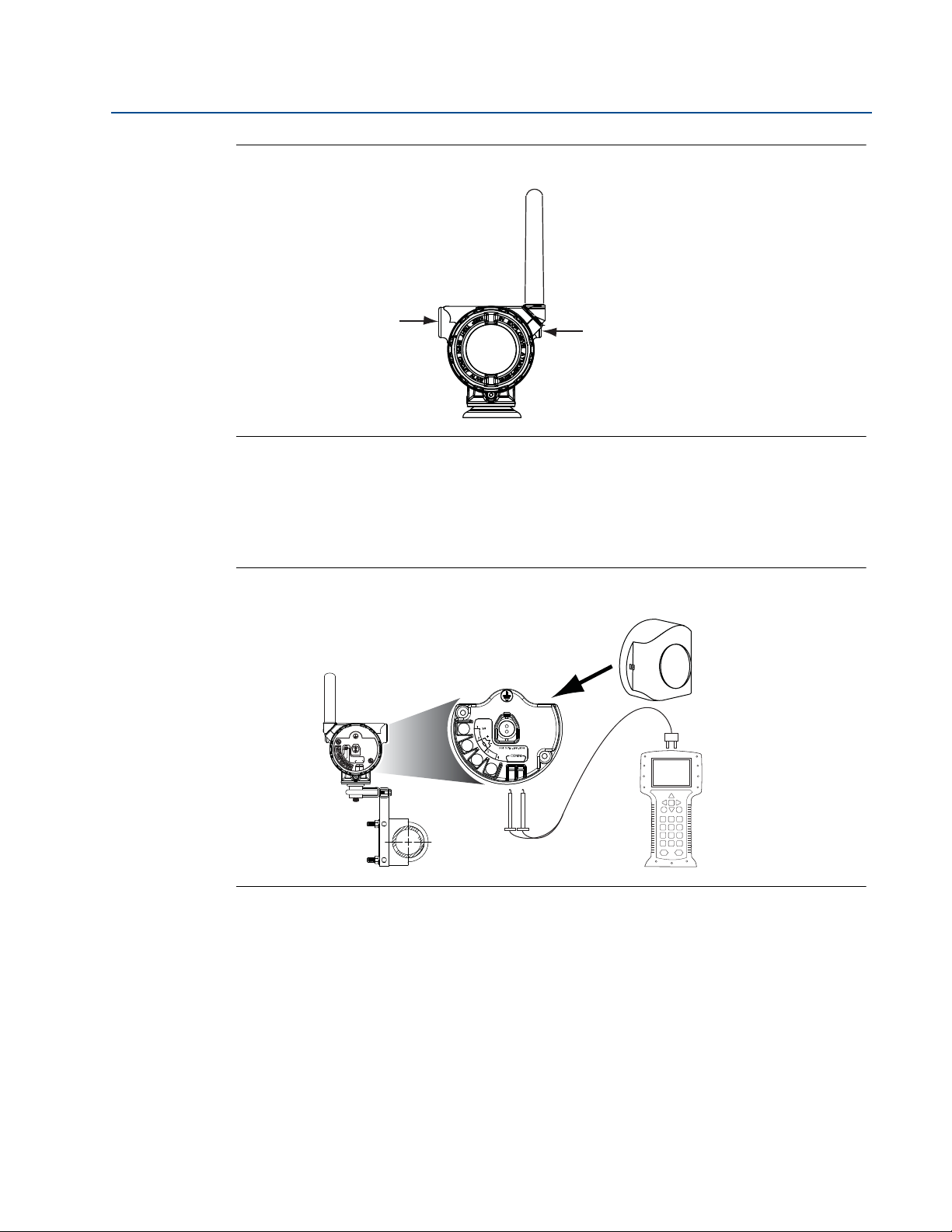

6. Position the antenna such that it is vertical, either straight up or straight down, as

shown in Figure 3-3. The antenna should be approximately 3-ft. (1 m) from any large

structures or buildings, to allow clear communication to other devices.

Figure 3-3. Antenna Positioning

20

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 31

Reference Manual

00809-0200-4702, Rev CA

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

3.2.2 Installing the Transmitter in a Remote Mount Configuration

1. Install the switch according to standard installation practices being sure to use thread

sealant on all of the connections.

2. Run wiring (and conduit, if necessary) from the switch to the 702 transmitter.

3. Pull the wiring through the threaded conduit entry.

4. Attach the switch wiring to the terminals as shown in the wiring diagrams beginning on

page 22.

5. If commissioning the 702 transmitter, connect the power module as shown in Figure

3-2 on page 20.

Figure 3-4. Remote Mount

NOTE

Use caution when handling the power module, it may be damaged if dropped from heights in

excess of 20 feet.

NOTE

Wireless devices should only be powered up after the Smart Wireless Gateway, in order of

proximity from the Gateway beginning with the closest device. This results in a simpler and

faster network installation.

6. Close the housing cover and tighten to safety specifications. Always ensure a proper

seal by installing the electronic housing covers so that metal touches metal, but do not

over tighten.

7. Position the antenna such that it is vertical, either straight up or straight down, as

shown in Figure 3-3 on page 20. The antenna should be approximately 3-ft. (1 m) from

any large structures or buildings, to allow clear communication to other devices.

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

21

Page 32

Section 3: Mounting, Wiring Switches, and Sensors:

1

2

4

3

Single Input Dual Input

S1

CMN

S2

CMN

S1

CMN

S2

CMN

Models 702DX22 and 702DX61

February 2013

3.3 Wiring Switches and Sensors

Wiring Switches and Sensors with Dry Contact Inputs,

Measurement Option Code 22 (702DX22)

Figure 3-5. Rosemount 702 Terminal Diagram

Reference Manual

00809-0200-4702, Rev CA

3.3.1 Wireless Output Specifications

Dual Input

The 702 transmitter will accept the input from one or two single pole single throw switches on

inputs S1 and S2. The wireless output of the transmitter will be both a primary variable (PV) and

a secondary variable (SV). The PV is determined by the S1 input. The SV is determined by the S2

input. A closed switch drives a TRUE output. An Open switch drives a FALSE output.

Figure 3-6. Single, Dual Input

22

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 33

Reference Manual

Dual Input

Limit Contacts

S1

CMN

S2

CMN

Dual Input

Opposing Contact

S1

CMN

S2

CMN

00809-0200-4702, Rev CA

Dual Input, Limit Contact Logic

When configured for Limit Contact Logic, the 702 transmitter will accept the input from two

single pole single throw switches on inputs S1 and S2, and will use limit contact logic for the

determination of the wireless outputs. Please reference Figure 3-7 for details on the wireless

outputs available when using limit contact logic.

Figure 3-7. Dual Input, Limit Contacts

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

Dual Input, Opposing Contact Logic

When configured for Opposing Contact Logic, the 702 transmitter will accept the input from a

single pole double throw switch on inputs S1 and S2, and will use opposing contact logic for the

determination of the wireless outputs. Please reference Figure 3-8 for details on the wireless

outputs available when using opposing contact logic.

Figure 3-8. Dual Input, Opposing Contact

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

23

Page 34

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

Reference Manual

00809-0200-4702, Rev CA

3.3.2 Wiring Switches and Sensors with Liquid Hydrocarbon

Detection, Measurement Option Code 61(702DX61)

Figure 3-9. Fuel Sensor Terminal

The Liquid Hydrocarbon Detection configuration is intended for use with the Tyco® TraceTek®

Fast Fuel Sensor, or TraceTek sensing cable.

Figure 3-10. Fuel Sensor Connection

Connecting to the fast fuel sensor and TraceTek sensing cable

The connections to the Fast Fuel Sensor TraceTek sensing cable are made by matching the

appropriately colored wires to the matching colored termination lugs.

The Emerson Smart Wireless 702 transmitter can support up to 3 Fast Fuel sensors.

These Fast Fuel sensors are connected using TraceTek Modular Leader Cable

(TT-MLC-MC-BLK), optional modular jumper cables (TT-MJC-xx-MC-BLK) and branching

connectors (TT-ZBC-MC-BLK) as suggested in Figure 3-11.

If more than one Tyco Fast Fuel sensor is attached to a 702 transmitter, the detection of

liquid hydrocarbon by one sensor is sufficient to cause the 702 transmitter to send a

“Leak” message. However, it is not possible for the 702 transmitter to discern which

individual sensor has detected liquid hydrocarbon.

24

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 35

Reference Manual

TT-MLC-MC-BLK (Leader Cable)

TT-FFS-100 or TT-FFS-250

(Fast Fuel Sensor Probe)

TT-MLC-MC-BLK (Leader Cable)

TT-FFS-100 or TT-FFS-250

(Fast Fuel Sensor Probe)

TT-ZBC-xx-MC-BLK

(Branch Connector)

TT-MJC-xx-MC-BLK (Optional Jumper Cable)

TT-MLC-MC-BLK (Leader C able)

TT5000/TT5001 Sensor Cable

(up to 500 ft.)

TT-MET-MC (End Termination)

TT-MJC-xx-MC-BLK (Optional Jumper Cable)

TT-ZBC-xx-MC-BLK

(Branch Connector)

TT-MET-MC

(End Termination)

Up to 500 ft. TT5000 or TT5001

sensor cable

(Total per 702)

TT-MET-MC

(End Termination)

00809-0200-4702, Rev CA

Figure 3-11. Fuel Sensor wiring

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

Note

All part numbers on this page refer to products sold by Tyco Thermo Controls, LLC.

The Emerson Smart Wireless 702 transmitter can support up to 500 feet (150 m) of

TraceTek hydrocarbon or solvent sensor cable (TT5000 or TT5001 series). The total

amount of sensor cable connected to a single 702 transmitter is not to exceed 500 ft.

However leader cable, jumper cables (if used) and branch connectors are not included

in the 500 foot limit. See Figure 3-12 for typical configurations.

Figure 3-12. Fuel Sensor sensor cable wiring

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

25

Page 36

Section 3: Mounting, Wiring Switches, and Sensors:

LCD Display

LCD Cover

LCD

Pins

Models 702DX22 and 702DX61

February 2013

3.4 LCD Display

If an LCD display is ordered, it will be shipped attached to the transmitter.

Note

An LCD display is not available with measurement option code 61, for liquid hydrocarbon

detection.

The optional LCD display can be rotated in 90-degree increments by squeezing the two tabs,

pulling out, rotating and snapping back into place.

If the LCD pins are inadvertently removed from the interface board, carefully re-insert the pins

before snapping the LCD display back into place.

Installing the LCD Display

To install the LCD display, use Figure 3-13 on page 26 and the following instructions:

1. Remove the LCD cover. Do not remove the instrument cover in explosive environments

when the circuit is live.

Reference Manual

00809-0200-4702, Rev CA

2. Put the four-pin connector into the LCD display, rotate to the desired position and snap

into place.

Note the following LCD temperature limits:

Operating:-4 to 175 °F (-20 to 80 °C)

Storage:-40 to 185 °F (-40 to 85 °C)

3. Replace the transmitter cover.

NOTE

Only use Rosemount Wireless LCD Part Number: 00753-9004-0002.

Figure 3-13. Optional LCD Display

26

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 37

Reference Manual

00809-0200-4702, Rev CA

Section 3: Mounting, Wiring Switches, and Sensors:

3.5 Grounding the Transmitter

The 702 transmitter operates with the housing grounded or floating. Floating systems,

however, can cause extra noise that may affect many types of readout devices. If the signal

appears noisy or erratic, grounding at a single point may solve the problem. Grounding of the

electronics enclosure should be done in accordance with local and national installation codes.

Grounding is accomplished through the process connection using the internal or external case

grounding terminal.

Determining Grounding Requirements

Each process installation has different grounding requirements. Use the options recommended

by the facility for the specific switch type, or begin with Option 1, which is the most common.

Option 1:

1. Connect switch wiring shield to the grounded transmitter housing.

2. Ensure that the transmitter housing is electrically isolated from the switch wiring.

Models 702DX22 and 702DX61

February 2013

Option 2:

1. Ground switch wiring shield at the switch.

2. Ensure that the switch wiring and shield are electronically isolated from the transmitter

housing.

NOTE

Always use facility recommended wiring practices.

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

27

Page 38

Section 3: Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

February 2013

Reference Manual

00809-0200-4702, Rev CA

28

Mounting, Wiring Switches, and Sensors:

Models 702DX22 and 702DX61

Page 39

Reference Manual

00809-0200-4702, Rev CA

Section 4: Commissioning: Models 702DX22 and 702DX61

Section 4 Commissioning: Models

702DX22 and 702DX61

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Configuring the transmitter to communicate with the wireless network . . . . . . page 30

Verifying operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

AMS Wireless Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

4.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

February 2013

4.1.1 Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Process leaks could result in death or serious injury.

Do not remove the switch while in operation.

Install and tighten sensors before applying pressure

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Note

The 702 transmitter and all other wireless devices should be installed only after the Gateway has

been installed and is functioning properly.

Wireless devices should be powered up in order of proximity from the Gateway, beginning with

the device closest to the Gateway. This will result in a simpler and faster network installation.

Commissioning: Models 702DX22 and 702DX61

29

Page 40

Section 4: Commissioning: Models 702DX22 and 702DX61

February 2013

Reference Manual

00809-0200-4702, Rev CA

4.2 Configuring the transmitter to communicate with

the wireless network

In order to communicate with the Smart Wireless Gateway, and ultimately the Information

System, the transmitter must be configured to communicate with the wireless network. This

step is the wireless equivalent of connecting wires from a transmitter to the information system.

Using a Field Communicator or AMS Wireless Configurator, enter the Network ID and Join Key so

that they match the Network ID and Join Key of the gateway and other devices in the network. If

the Network ID and Join Key are not identical, the 702 transmitter will not communicate with

the network. The Network ID and Join Key may be obtained from the Smart Wireless Gateway

on the Setup>Network>Settings page on the web server, shown in Figure 4-1.

Figure 4-1. Gateway Network Settings

4.3 Using AMS Wireless Configurator to configure the

transmitter

Right click on the 702 transmitter and select Configure. When the menu opens, select Join

Device to Network and follow the method to enter the Network ID and Join Key.

4.4 Using a field communicator to change the

network ID and join key

The Network ID and Join Key may be changed in the wireless device by using the following Fast

Key sequence. Set both Network ID and Join Key.

Func tion Key Sequence Menu Items

Wireless Setup

30

2, 1, 1

Network ID, Set Join Key

Commissioning: Models 702DX22 and 702DX61

Page 41

Reference Manual

i d - 1 2

3 4 5 6 7 8

n e t w k

13 0 5

I D

S u p l y

7. 2 1

v o l t s

00809-0200-4702, Rev CA

Section 4: Commissioning: Models 702DX22 and 702DX61

4.5 Verifying operation

There are four ways to verify operation: using the optional local display (LCD), using the Field

Communicator, using the Smart Wireless Gateway's integrated web interface, or by using AMS

Suite Wireless Configurator. If the 702 transmitter was configured with the Network ID and Join

Key, and sufficient time has passed, the transmitter will be connected to the network.

Troubleshooting

If the device is not joined to the network after power up, verify the correct configuration of the

Network ID and Join Key, and verify that Active Advertising has been enabled on the Gateway.

The Network ID and Join Key in the device must match the Network ID and Join Key of the

Gateway.

Operating the local display

The LCD displays the PV and SV values at the configured update rate, but no faster than once

every 60 seconds.

February 2013

®

Diagnostic button display sequence

More detailed diagnostic information can be obtained by removing the display cover of the 702

transmitter, and momentarily depressing the "DIAG" button. The LCD will display the diagnostic

screens as shown in Figure 4-3.

Press the Diagnostic button to display the TAG, Device ID, Network ID, Network Join Status and

Device Status screens.

Figure 4-2. Diagnostic Screen Sequence

Network Join

Tag Device ID Network ID

A b c d e

f g h

Status

n e t w k

O K

Device Status

Network join status

The chevron-shaped status bar at the top of the screen indicates the progress of the network

join process. When the status bar is filled, the device is successfully connected to the wireless

network. This is shown, in Figure 4-3 on page 32.

Commissioning: Models 702DX22 and 702DX61

31

Page 42

Section 4: Commissioning: Models 702DX22 and 702DX61

N E T w K

S R C H N G

n e t w k

N E G O T

n e t w k

O K

February 2013

Figure 4-3. Network Join Status Screens

Searching for

Network

Joining Network

Connecting with a Field Communicator

A 702 DD is required for HART communication. For connecting with a Field Communicator, refer

to Figure 2-3 on page 12.

Connected with

Limited

Bandwidth

n e t w k

L I M - O P

Reference Manual

00809-0200-4702, Rev CA

Connected

Func tion Key Sequence Menu Items

Communications 3,3 Join Status, Communication

Status, Join Mode, Number of

Available Neighbors, Number

of Advertisements Heard,

Number of Join Attempts

Checking for Communication Using the Smart Wireless Gateway

In the integrated web interface from the Gateway, navigate to the Explorer page. This page

shows whether the device has joined the network and if it is communicating properly.

NOTE:

The time to join the new device(s) to the network is dependent upon the number of devices

being joined and the number of devices in the current network. For one device joining an

existing network with multiple devices, it may take up to five minutes. It may take up to 60

minutes for multiple new devices to join the existing network.

What to do if there is Immediately an Alarm Present

If the device joins the network and immediately has an alarm present, it is likely due to sensor

configuration. Check the sensor wiring (see “702 Terminal Block” on page 11) and the sensor

configuration (see “Fast Key Sequence” on page 15).

32

Commissioning: Models 702DX22 and 702DX61

Page 43

Reference Manual

00809-0200-4702, Rev CA

Figure 4-4. Smart Wireless Gateway Explorer Page

Section 4: Commissioning: Models 702DX22 and 702DX61

February 2013

4.5.1 AMS Wireless Configurator

When the device has joined the network, it will appear in the Device Manager as illustrated

below

Troubleshooting

If the device is not joined to the network after power up, verify the correct configuration of the

Network ID and Join Key, and verify that Active Advertising has been enabled on the Gateway.

The Network ID and Join Key in the device must match the Network ID and Join Key of the

Gateway.

Commissioning: Models 702DX22 and 702DX61

33

Page 44

Section 4: Commissioning: Models 702DX22 and 702DX61

February 2013

The Network ID and Join Key may be obtained from the Gateway on the Setup>Network>Settings page on the web interface (see Figure 4-4 on page 33). The Network ID and Join Key may

be changed in the wireless device by using the following Fast Key sequence.