Emerson Rosemount 644H Profibus Quick Installation Manual

Quick Installation Guide

Start

End

Step 1: Mount the Transmitter

Step 2: Wire and Apply Power

Step 3: Verify Tagging

Step 4: Transmitter Configuration

Product Certifications

00825-0300-4728, Rev AA

July 2010

Rosemount 644

Rosemount 644H Profibus PA Temperature

Transmitters

www.rosemount.com

¢00825-0100-4728w¤

Quick Installation Guide

IMPORTANT NOTICE

WARNING

00825-0300-4728, Rev AA

Rosemount 644

© 2010 Rosemount Inc. All rights reserved. All marks property of owner. Rosemount and the Rosemount logotype are

registered trademarks of Rosemount Inc.

Emerson Process Management Rosemount Division

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 949-7001

Emerson Process Management GmbH & Co. OHG

Frankenstrasse 21

63791 Karlstein

Germany

T 49 (6188) 992 0

F 49 (6188) 992 112

Emerson Process Management Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

July 2010

This installation guide provides basic guidelines for the Rosemoun t 644. It does not

provide instructions for detailed configuration, diagnostics, maintenance, service,

troubleshooting, or installation. Refer to the 644 Reference Manual (document number

00809-0100-4728) for more instruction. The manual and this QIG are also available

electronically on www.rosemount.com.

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please

review the approvals section of this manual for any restrictions associated with a safe

installation.

In an Explosion-proof/Flameproof installation, do not remove the transmitter covers when

power is applied to the unit.

Process leaks may cause harm or result in death

• Install and tighten thermowells or sensors before applying pressure.

• Do not remove the thermowell while in operation.

Electrical shock can result in death or serious injury

• Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

2

Quick Installation Guide

STEP 1: MOUNT THE TRANSMITTER

A

D

B

C

EF

00825-0300-4728, Rev AA

July 2010

Rosemount 644

Mount the transmitter at a high point in the conduit run to prevent moisture from draining into

the transmitter housing.

Typical Connection Head Installation

Head Mount Transmitter with DIN Plate Style Sensor

1. Attach the thermowell to the pipe or process container wall. Install and tighten the

thermowell before applying process pressure.

2. Assemble the transmitter to the sensor. Push the transmitter mounting screws through

the sensor mounting plate and insert the snap rings (optional) into the transmitter

mounting screw groove.

3. Wire the sensor to the transmitter (see Step 4:Connect the Wiring).

4. Insert the transmitter-sensor assembly into the connection head. Thread the transmitter

mounting screw into the connection head mounting holes. Assemble the extension to the

connection head. Insert the assembly into the thermowell.

5. Slip the shielded cable though the cable gland.

6. Attach a cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through the cable entry.

Connect and tighten the cable gland.

8. Connect the shielded power cable leads to the transmitter power terminals. Avoid

contact with sensor leads and sensor connections.

9. Install and tighten the connection head cover. Enclosure covers must be fully engaged to

meet explosion-proof requirements.

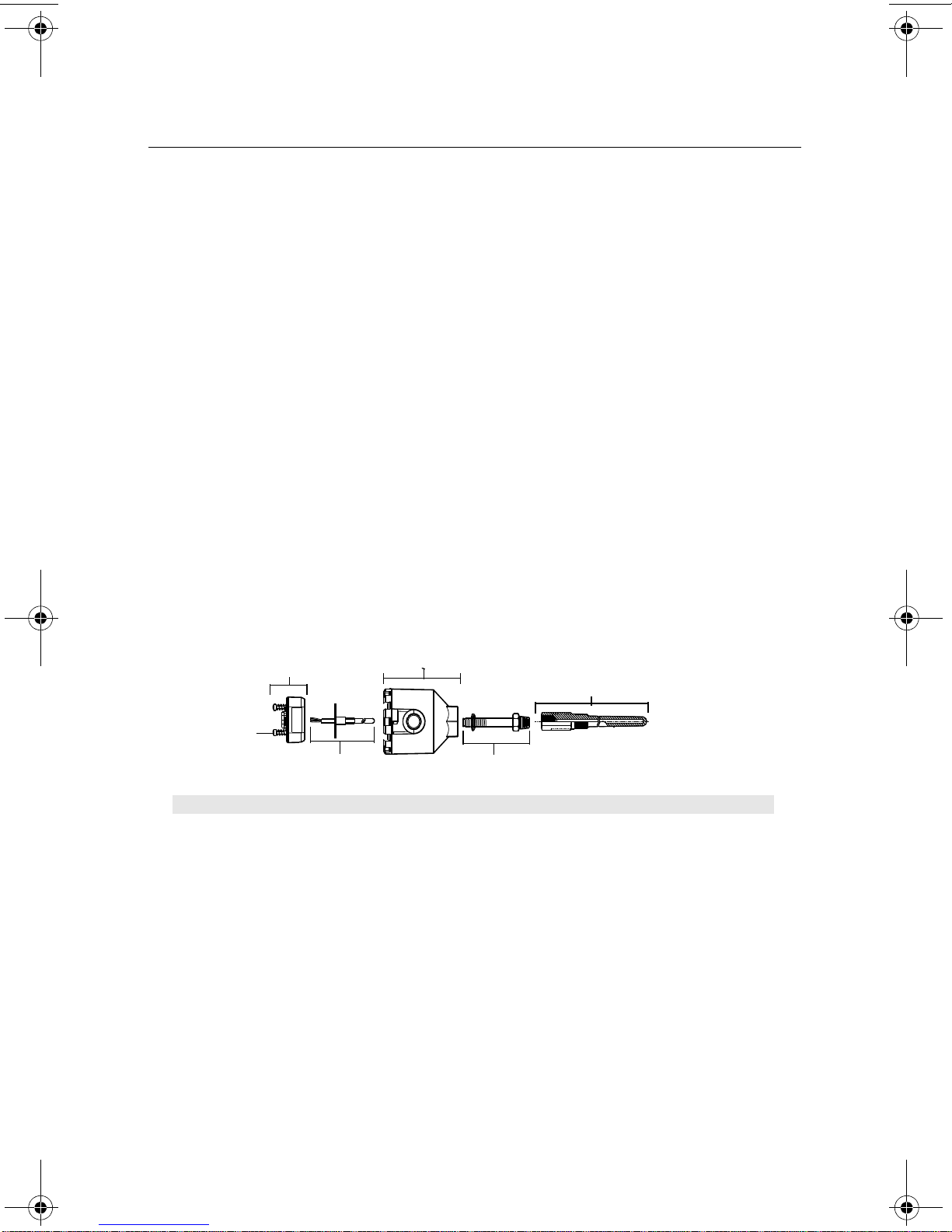

A = 644H Transmitter D = Transmitter Mounting Screws

B = Connection Head E = Integral Mount Sensor with Flying Leads

C = Thermowell F = Extension

3

Quick Installation Guide

STEP 1 CONTINUED...

A

B

C

D

E

00825-0300-4728, Rev AA

Rosemount 644

July 2010

Typical Universal Head Installation

Head Mount Transmitter with Threaded Sensor

1. Attach the thermowell to the pipe or process container wall. Install and tighten

thermowells before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell. Seal the nipple and

adapter threads with silicone tape.

3. Screw the sensor into the thermowell. Install drain seals if required for severe

environments or to satisfy code requirements.

4. Pull the sensor wiring leads through the universal head and transmitter. Mount the

transmitter in the universal head by threading the transmitter mounting screws into the

universal head mounting holes.

5. Mount the transmitter-sensor assembly into the thermowell. Seal adapter threads with

silicone tape.

6. Install conduit for field wiring to the conduit entry of the universal head. Seal conduit

threads with PTFE tape.

7. Pull the field wiring leads through the conduit into the universal head. Attach the sensor

and power leads to the transmitter. Avoid contact with other terminals.

8. Install and tighten the universal head cover. Enclosure covers must be fully engaged to

meet explosion-proof requirements.

A = Threaded Thermowell D = Universal Head (transmitter inside)

B = Threaded Style Sensor E = Conduit Entry

C = Standard Extension

4

Quick Installation Guide

STEP 2: WIRE AND APPLY POWER

1 2 3 4

Sensor Terminals

Communication Terminals

Power Terminals

2-wire

RTD and ⍀

3-wire RTD

and ⍀

4-wire RTD

and ⍀

T/C

and mV

**

*

1234

1234

1234

1234

00825-0300-4728, Rev AA

July 2010

Rosemount 644

• Wiring diagrams are located inside the terminal block cover and on the transmitter top

label.

• An external power supply is required to power a Profibus segment.

• The power required across the transmitter power terminals is 9 to 32 VDC (the power

terminals are rated to 32 VDC). To prevent damaging the transmitter, do not allow

terminal voltage to drop below 9 VDC when changing the configuration parameters.

Power Filter

A Profibus segment requires a power conditioner to isolate the power supply filter and

decouple the segment from other segments attached to the same power supply.

Power the Transmitter

1. Remove the terminal block cover (if applicable).

2. Connect the power lead to the power terminals (The 644 power terminals are polarity

insensitive for the Profibus protocol.)

3. Tighten the terminal screws. When tightening the sensor and power wires, the max

torque is 6 in.-lbs. (0.7 N-m).

4. Reattach and tighten the cover (if applicable).

5. Apply power (9 – 32 VDC).

* The transmitters must be configured for at least a 3-wire RTD in order to recognize an RTD with a

compensation loop.

** Emerson Process Management provides 4-wire sensors for all single element RTDs. Use these

RTDs in 3-wire configurations by leaving the unneeded leads disconnected and insulated with electrical

tape.

5

Sensor Connections Diagram

Rosemount 644

STEP 2 CONTINUED...

Profibus DP

RS-485 up to 12 MBd

PROFIBUS

Class 2

Master

(Configuration

Tool)

Terminators

6234 ft. (1900m) max

(Depending on cable characteristics)

Profibus PA

MBP-IS at 31.25KBd

Power/

Signal

Wiring

DP/PA

Coupler

Profibus Transmitter

Profibus Loop

Sensor Wires

Shield ground point

Transmitter

Typical Configuration for Profibus Networking

Quick Installation Guide

00825-0300-4728, Rev AA

July 2010

NOTE

1. Each segment in a Profibus trunk must be terminated at both ends.

2. Some DP/PA couplers contain the power supply, one terminator, and the power

3. The configuration tool is typically located in the control room.

Ground the Transmitter

Ungrounded Thermocouple, mV, and RTD/Ohm Inputs

Each process installation has different requirements for grounding. Use the grounding

options recommended by the facility for the specific sensor type, or begin with grounding

Option 1 (the most common).

Option 1:

1. Connect sensor wiring shield to the transmitter housing.

2. Ensure the sensor shield is electrically isolated from surrounding fixtures that may be

3. Ground signal wiring shield at the power supply end.

conditioner within the coupling device.

grounded.

6

Loading...

Loading...