Page 1

00825-0300-4728, Rev EA

Rosemount™ 644H Temperature

Transmitter

with PROFIBUS® PA

Quick Start Guide

April 2020

Page 2

Quick Start Guide April 2020

Contents

About this guide...........................................................................................................................3

Mount the transmitter..................................................................................................................5

Wire and apply power...................................................................................................................8

Ground the transmitter.............................................................................................................. 11

Verify tagging............................................................................................................................ 15

Transmitter configuration.......................................................................................................... 16

Product certifications................................................................................................................. 20

Declaration of Conformity..........................................................................................................38

China RoHS................................................................................................................................ 42

2 Emerson.com/Rosemount

Page 3

April 2020 Quick Start Guide

1 About this guide

This guide provides basic guidelines for installing the Rosemount 644

Temperature Transmitter. It does not provide instructions for detailed

configuration, diagnostics, maintenance, service, troubleshooting, or

installation. Refer to the Rosemount 644 Reference Manual for more

instruction. The manual and this guide are also available electronically on

Emerson.com/Rosemount.

Safety messages

WARNING

The products described in this document are NOT designed for nuclearqualified applications.

Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your

local Emerson Sales Representative.

Follow instructions

Failure to follow these installation guidelines could result in death or serious

injury.

Ensure only qualified personnel perform the installation.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 3

Page 4

Quick Start Guide April 2020

WARNING

Explosions

Explosions could result in death or serious injury.

Installation of the transmitters in a hazardous environment must be in

accordance with the appropriate local, national, and international

standards, codes, and practices. Please review the Product Certifications

section for any restrictions associated with a safe installation.

Do not remove the connection head cover in explosive atmospheres

when the circuit is live.

Before connecting a handheld communicator in an explosive

atmosphere, ensure the instruments are installed in accordance with

intrinsically safe or non-incendive field wiring practices.Verify the

operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet explosionproof requirements.

Process leaks

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure.

Electrical shock

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

CAUTION

Conduit/cable entries

Unless otherwise marked, the conduit/cable entries in the housing

enclosure use a ½–14 NPT form. Only use plugs, adapters, glands, or

conduit with a compatible thread form when closing these entries.

Entries marked "M20" are M20 x 1.5 thread form.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

4 Emerson.com/Rosemount

Page 5

April 2020 Quick Start Guide

2 Mount the transmitter

Mount the transmitter at a high point in the conduit run to prevent moisture

from draining into the transmitter housing.

2.1 Install connection head

Head mount transmitter with DIN plate style sensor.

Prerequisites

WARNING

Enclosure

Enclosure covers must be fully engaged to meet explosion-proof

requirements.

Procedure

1. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying process pressure.

2. Assemble the transmitter to the sensor. Push the transmitter

mounting screws through the sensor mounting plate and insert the

snap rings (optional) into the transmitter mounting screw groove.

3. Wire the sensor to the transmitter.

4. Insert the transmitter-sensor assembly into the connection head.

Thread the transmitter mounting screws into the connection head

mounting holes. Assemble the extension to the connection head.

Insert the assembly into the thermowell.

5. Slip the shielded cable though the cable gland.

6. Attach the cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through the

cable entry. Connect and tighten the cable gland.

8. Connect the shielded power cable leads to the transmitter power

terminals.

Avoid contact with sensor leads and sensor connections.

9. Install and tighten the connection head cover.

Quick Start Guide 5

Page 6

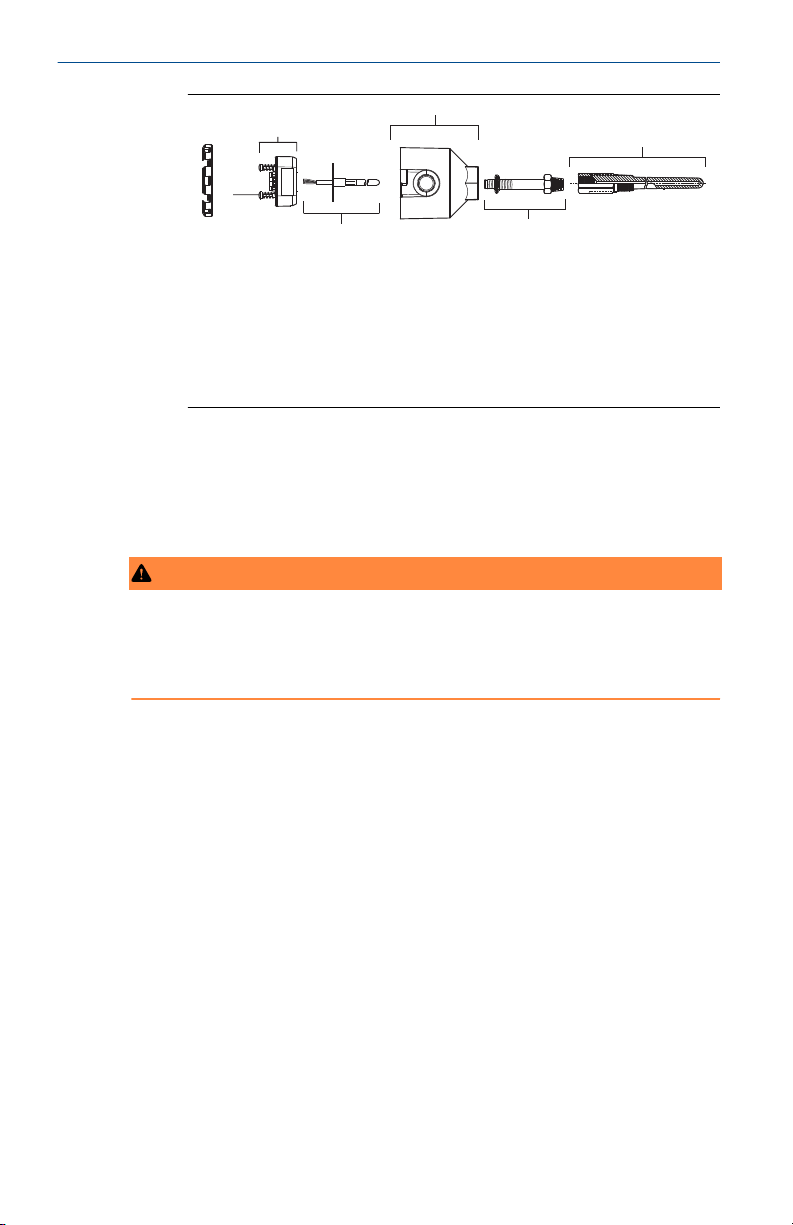

D

A

E

B

F

C

Quick Start Guide April 2020

A. Rosemount 644 Transmitter

B. Connection head

C. Thermowell

D. Transmitter mounting screws

E. Integral mount sensor with flying leads

F. Extension

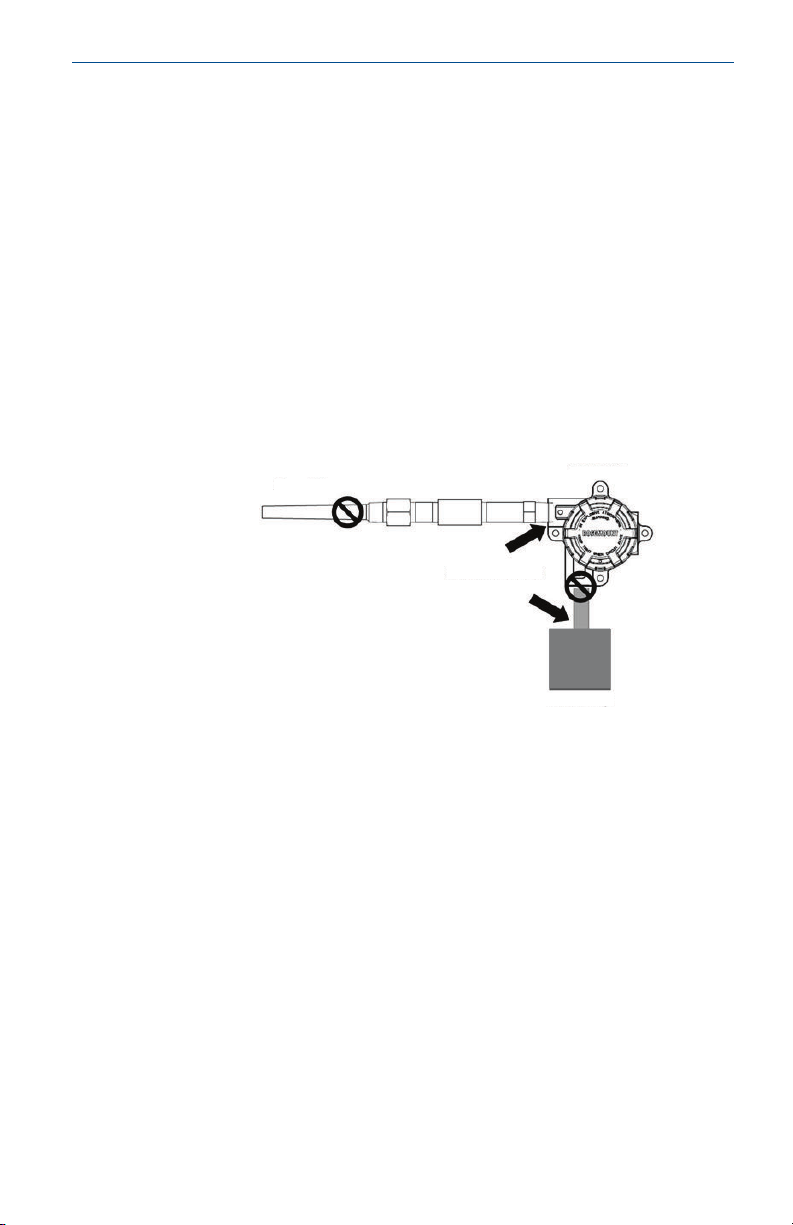

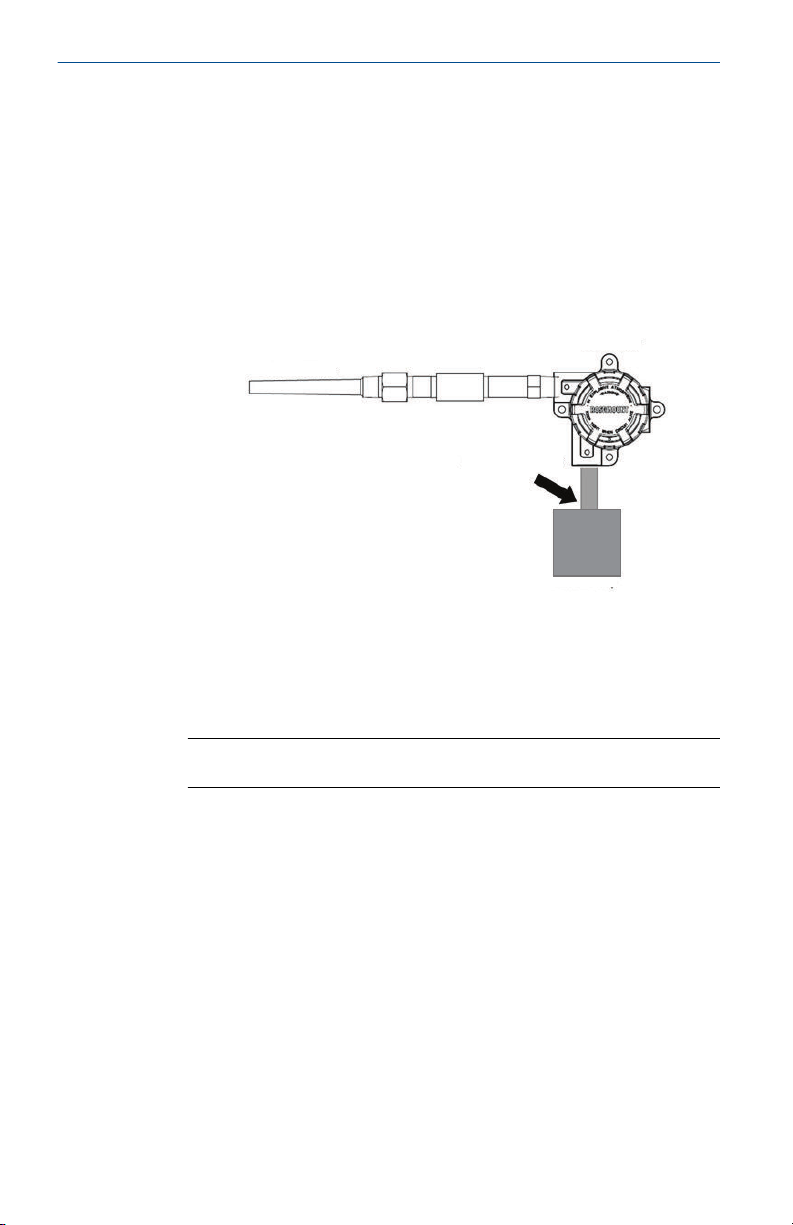

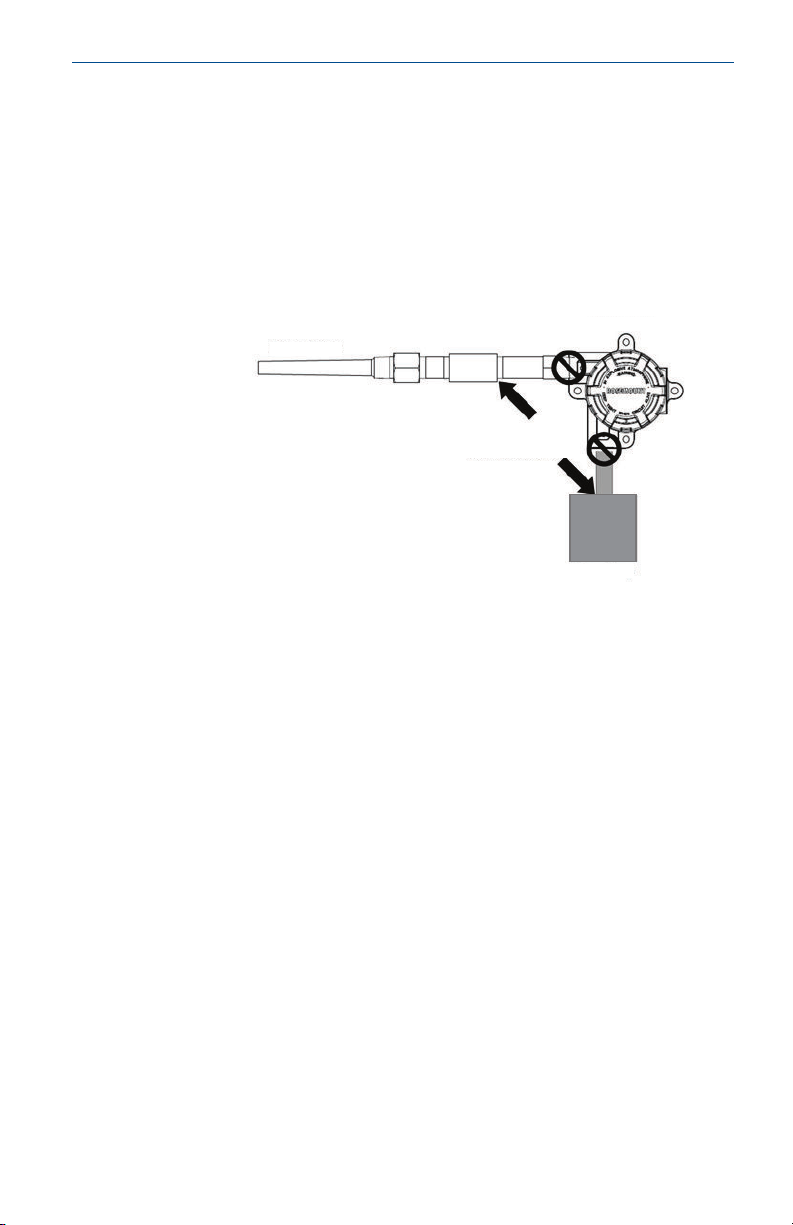

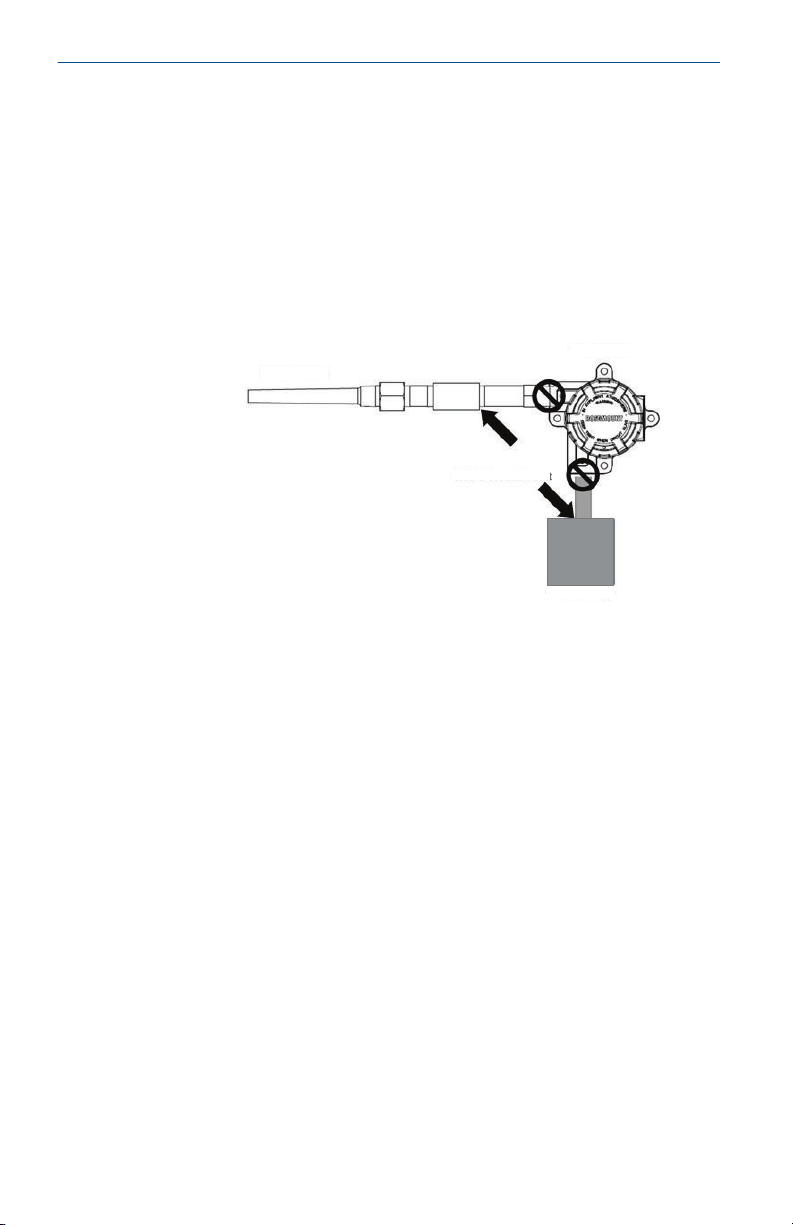

2.2 Install universal head

Head mount transmitter with threaded sensor.

Prerequisites

WARNING

Enclosure

Enclosure covers must be fully engaged to meet explosion-proof

requirements.

Procedure

1. Attach the thermowell to the pipe or process container wall. Install

and tighten thermowells before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell.

Seal the nipple and adapter threads with silicone tape.

3. Screw the sensor into the thermowell. Install drain seals if required

for severe environments or to satisfy code requirements.

4. Verify the correct installation of Integral Transient Protection (option

code T1).

a) Ensure the transient protector unit is firmly connected to the

transmitter puck assembly.

b) Ensure the transient protector power leads are adequately

secured under the transmitter power terminal screws.

c) Verify the transient protector’s ground wire is secured to the

6 Emerson.com/Rosemount

internal ground screw found within the universal head.

Page 7

A

B

C

D

E

April 2020 Quick Start Guide

Note

The transient protector requires the use of an enclosure of at least

3.5-in. (89 mm) in diameter.

5. Pull the sensor wiring leads through the universal head and

transmitter. Mount the transmitter in the universal head by

threading the transmitter mounting screws into the universal head

mounting holes.

6. Mount the transmitter-sensor assembly into the thermowell. Seal

adapter threads with silicone tape.

7. Install conduit for field wiring to the conduit entry of the universal

head. Seal conduit threads with PTFE tape.

8. Pull the field wiring leads through the conduit into the universal

head. Attach the sensor and power leads to the transmitter.

Avoid contact with other terminals.

9. Install and tighten the universal head cover.

A. Threaded thermowell

B. Standard extension

C. Threaded style sensor

D. Universal head (transmitter and LCD inside)

E. Conduit entry

Quick Start Guide 7

Page 8

Quick Start Guide April 2020

3 Wire and apply power

Wiring diagrams are located inside the terminal block cover.

An external power supply is required to power a Fieldbus segment.

The power required across the transmitter power terminals is 9 to 32 Vdc

(the power terminals are rated to 32 Vdc). To prevent damaging the

transmitter, do not allow terminal voltage to drop below 9 Vdc when

changing the configuration parameters.

3.1 Power filter

A Fieldbus segment requires a power conditioner to isolate the power supply

filter and decouple the segment from other segments attached to the same

power supply.

3.2 Power the transmitter

Procedure

1. Remove the terminal block cover (if applicable).

2. Connect the power lead to the power terminals.

The Rosemount with FOUNDATION Fieldbus is polarity insensitive.

If a transient protector is being used, the power leads will now be

connected to the top of the transient protector unit.

3. Tighten the terminal screws.

When tightening the sensor and power wires, the max torque is 6 in-

lb (0.7 N-m).

4. Reattach and tighten the cover (if applicable).

8 Emerson.com/Rosemount

Page 9

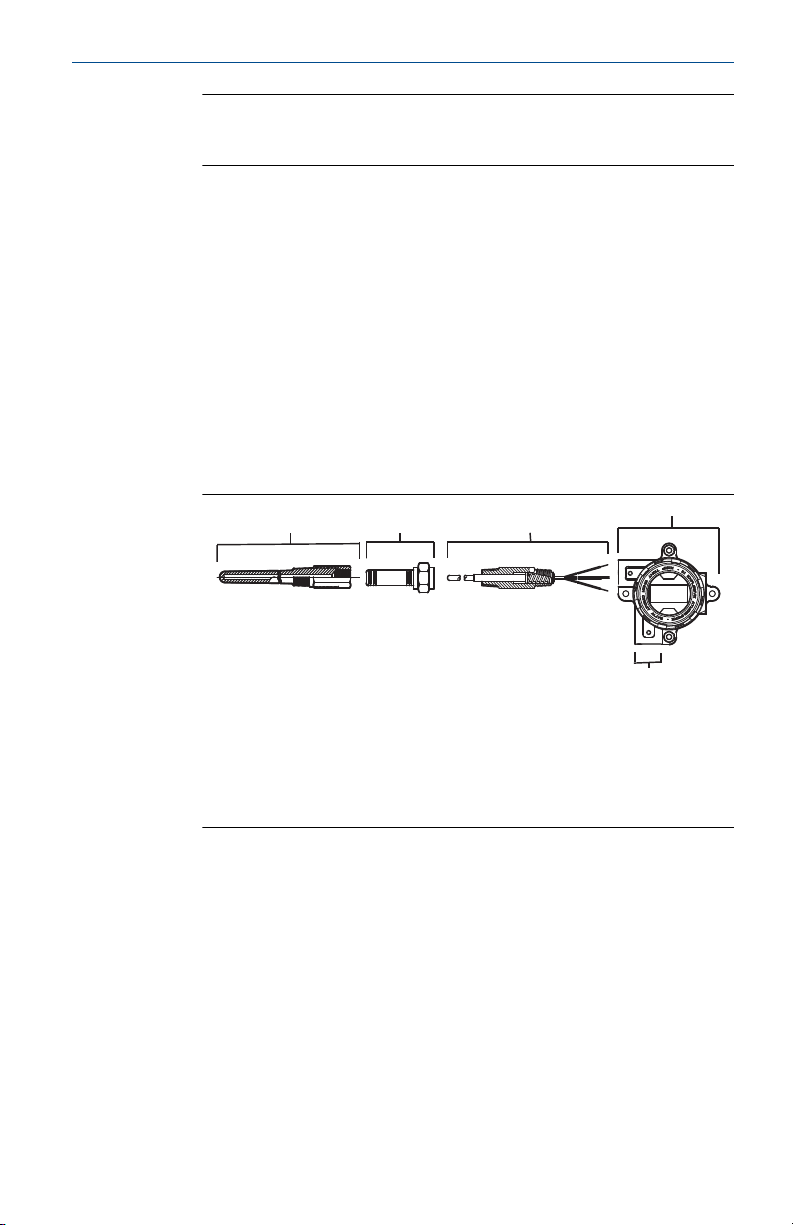

1 2 3 4

A

B

C

April 2020 Quick Start Guide

5. Apply power (9–32 Vdc).

A. Sensor terminals

B. Communication terminals

C. Power terminals

Figure 3-1: Sensor Connections

Two-wire RTD

and Ω

(1) Emerson provides four-wire sensors for all single element RTDs. Use

these RTDs in three-wire configurations by leaving the unneeded leads

disconnected and insulated with electrical tape.

(2) The transmitters must be configured for at least a three-wire RTD in

order to recognize an RTD with a compensation loop.

Quick Start Guide 9

Three-wire RTD

and Ω

(1)

Four-wire RTD

and Ω

(2)

T/C and mV

Page 10

A

B

C

E

F

F

G

H

I

D

Quick Start Guide April 2020

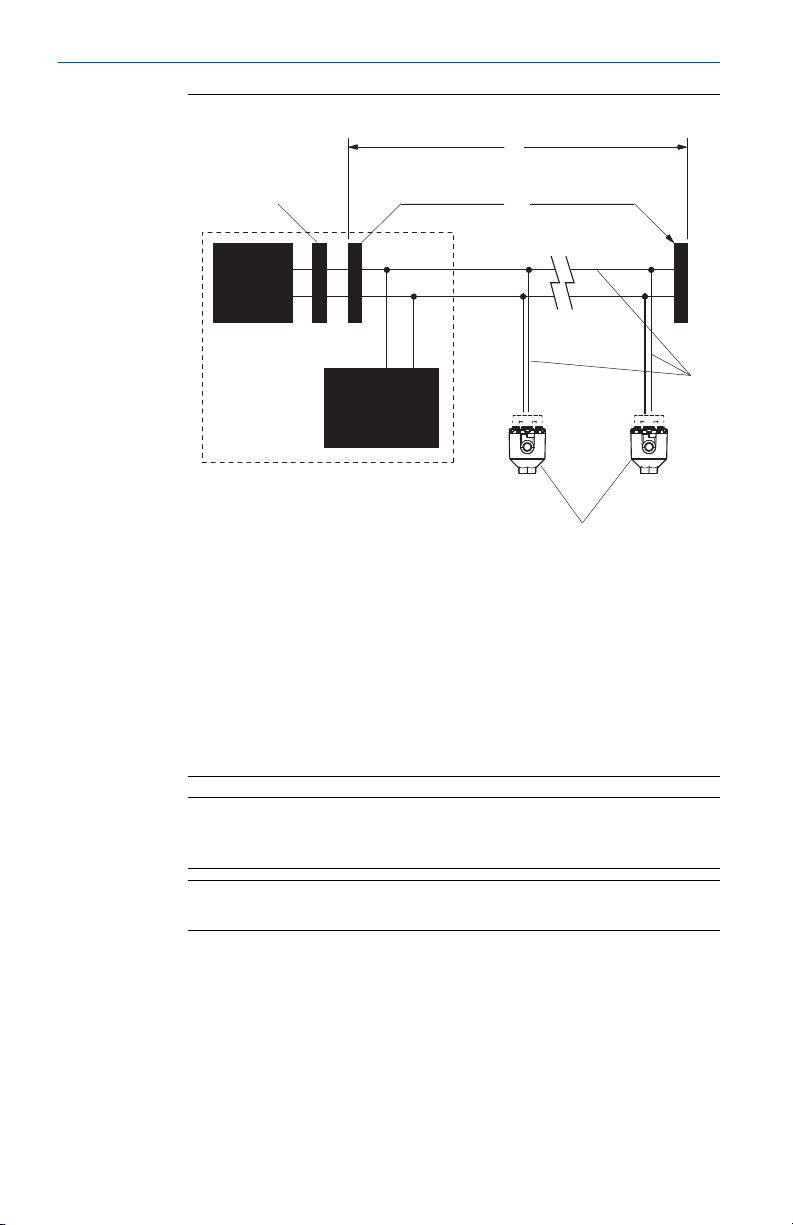

Figure 3-2: Typical Configuration for Fieldbus Networking

A. 6234 ft. (1900 m) max, depending upon cable characteristics

B. Integrated power conditioner and filter

C. Terminators

D. Power supply

E. Trunk

F. Spur

G. FOUNDATION Fieldbus configuration tool

H. Devices 1 through 16

I. Power/signal wiring

Note

The power supply, filter, first terminator, and configuration tool are

typically located in the control room.

Note

Each segment in a Fieldbus trunk must be terminated at both ends.

10 Emerson.com/Rosemount

Page 11

A

B

C

DCS

D

April 2020 Quick Start Guide

4 Ground the transmitter

4.1 Ungrounded thermocouple, mV, and RTD/Ohm inputs

Each process installation has different requirements for grounding. Use the

grounding options recommended by the facility for the specific sensor type,

or begin with grounding option 1 (the most common).

4.1.1 Ground the transmitter: option 1

Procedure

1. Connect sensor wiring shield to the transmitter housing.

2. Ensure the sensor shield is electrically isolated from surrounding

fixtures that may be grounded.

3. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. Shield ground point

D. 4-20 mA loop

Quick Start Guide 11

Page 12

A

B

C

D

DCS

Quick Start Guide April 2020

4.1.2 Ground the transmitter: option 2

Procedure

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from

the transmitter housing.

3. Ground shield at the power supply end only.

4. Ensure the sensor shield is electrically isolated from the surrounding

grounded fixtures.

A. Sensor wires

B. Transmitter

C. Shield ground point

D. 4-20 mA loop

Note

Connect shields together, electrically isolated from the transmitter.

12 Emerson.com/Rosemount

Page 13

DCS

A

B

C

D

April 2020 Quick Start Guide

4.1.3 Ground the transmitter: option 3

Procedure

1. Ground sensor wiring shield at the sensor if possible.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground the signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. Shield ground point

D. 4-20 mA loop

Quick Start Guide 13

Page 14

DCS

A

B

C

D

Quick Start Guide April 2020

4.2 Grounded thermocouple inputs

4.2.1 Ground the transmitter: option 4

Procedure

1. Ground sensor wiring shield at the sensor.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. Shield ground point

D. 4–20 mA loop

14 Emerson.com/Rosemount

Page 15

April 2020 Quick Start Guide

5 Verify tagging

5.1 Commissioning (paper) tag

To identify which device is at a particular location use the removable tag

provided with the transmitter. Ensure the physical device tag (PD Tag field)

is properly entered in both places on the removable commissioning tag and

tear off the bottom portion for each transmitter.

Note

The device description loaded in the host system must be at the same

revision as this device. You can download the device description from

Emerson.com/Rosemount.

Quick Start Guide 15

Page 16

Quick Start Guide April 2020

6 Transmitter configuration

Each PROFIBUS capable host or configuration tool has a different way of

displaying and performing configurations. Some use Device Descriptions

(DD) or DD methods for configuration and to display data consistently

across platforms. There is no requirement that a host or configuration tool

support these features.

The following is the minimum configuration requirement for a temperature

measurement. This guide is designed for systems not using DD methods. For

a complete list of parameters and configuration information refer to the

Rosemount 644 Head and Rail Mount Temperature Transmitter Reference

Manual.

The Rosemount 644 must be configured via a Class 2 master (DD or DTM

based). The basic configuration tasks for the PROFIBUS PA Temperature

Transmitter include:

• Assign address.

• Set sensor type and connection.

• Configure engineering units.

6.1 Assign address

Rosemount ships the transmitter with a temporary address of 126. To

establish communication with the host, change the address to a unique

value between 0 and 125. Usually, addresses 0-2 are reserved for masters or

couplers; therefore Emerson recommends using transmitter addresses

between 3 and 125.

Note

When shipped from the factory, Rosemount 644 PROFIBUS Profile 3.02

devices are defaulted in Identification Number ADAPTATION MODE. This

mode allows the transmitter to communicate with any PROFIBUS control

host with either the generic Profile GSD file (9700) or the Rosemount 644

specific GSD (4153) loaded in the host; therefore, you do not have to change

the transmitter identification number at startup.

6.1.1 Transducer function block

This block contains temperature measurement data for the sensors and the

terminal temperature. It also includes information about sensor types,

engineering units, damping, and diagnostics.

At a minimum, verify the parameters in Table 6-1.

16 Emerson.com/Rosemount

Page 17

April 2020 Quick Start Guide

Table 6-1: Transducer Block Parameters

Parameter Comments

Typical configuration

SENSOR_TYPE Example: “Pt 100_A_385 (IEC 751)”

SENSOR_CONNECTIONS Example: “2-wire”, “3-wire”, “4-wire”

Sensor matching configuration

SENSOR_TYPE “User Defined, Calvandu”

SENSOR_CONNECTIONS Example: “2-wire”, “3-wire”, “4-wire”

SENSOR_CAL_METHOD Set to “User Trim Standard”

SPECIAL_SENSOR_A Enter sensor specific coefficients

SPECIAL_SENSOR_B Enter sensor specific coefficients

SPECIAL_SENSOR_C Enter sensor specific coefficients

SPECIAL_SENSOR_R0 Enter sensor specific coefficients

6.1.2 Analog Input (AI) function block

The AI block processes field device measurements and makes the outputs

available to other function blocks. The output value of the AI block is in

engineering units and contains a status indicating the quality of the

measurements. Use the channel number to define the variable that the AI

block processes.

At a minimum, verify the parameters of each AI block in Table 6-2.

Table 6-2: AI Block Parameters

Configure one AI Block for each desired measurement.

Parameter Comments

CHANNEL Choices:

1. Sensor 1

2. Housing Temperature

LIN_TYPE This parameter defines the relationship between the block

Quick Start Guide 17

input and the block output. Since the transmitter does not

require linearization, this parameter will always be set to No

Linearization. This means that the AI block will only apply

scaling, filtering, and limit checking to the input value.

Page 18

Quick Start Guide April 2020

Table 6-2: AI Block Parameters (continued)

Parameter Comments

XD_SCALE Set desired measurement range and units. Units must be one

OUT_SCALE For “DIRECT” L_TYPE, set OUT_SCALE to match XD_SCALE

HI_HI_LIM

HI_LIM

LO_LIM

LO_LO_LIM

of the following:

• mV

• Ohms

• °C

• °F

• °R

• K

Process alarms.

Must be within the range defined by “OUT_SCALE”

Note

To make changes to the AI block, set the BLOCK_MODE (TARGET) to OOS

(out of service). After making the changes, return the BLOCK_MODE

TARGET to AUTO.

6.2

Physical block

The Physical Block encompasses all parameters and functions required to

identify the hardware and software (revision numbers, status values, device

address etc.) of the device. Use the IDENT_NUMBER_SELECTOR parameter

to change how the host sees the device.

18 Emerson.com/Rosemount

Page 19

April 2020 Quick Start Guide

Table 6-3: Physical Block Parameter

Parameter Comments

IDENT_NUMBER_SELECTOR Can be changed to Profile Specific,

Manufacturer Specific, or Adaptation

mode.

• Adaptation mode (default): The Host

chooses which file (GSD) it wants to

use and whether to view the device

GSD file in a generic or a

manufacturer specific way.

• Profile Specific mode: Shows the

generic GSD associated with the

PROFIBUS Profile version (9700) of

the device.

• Manufacturer Specific mode:

Displays the GSD file with

parameters specific to the

transmitter.

6.3 Host integration

Control host (Class 1)

The Rosemount 644 device utilizes Condensed Status as recommended by

the Profile 3.02 specification and NE 107. See manual for Condensed Status

bit assignment information.

The appropriate GSD file must be loaded on the control host - Rosemount

644 specific (rmt4053.gsd) or Profile 3.02 Generic (pa139700.gsd). These

files can be found on Emerson.com/Rosemount or www.profibus.com.

Configuration host (Class 2)

The appropriate DD or DTM file must be installed in the configuration host.

These files can be found at Emerson.com/Rosemount.

Quick Start Guide 19

Page 20

Quick Start Guide April 2020

7 Product certifications

Rev 4.4

7.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

7.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

7.3 North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

7.4 USA

7.4.1 E5 USA Explosionproof, Non-Incendive, Dust-Ignitionproof

Certificate:

Standards:

Markings:

7.4.2 I5 USA Intrinsic Safety and Non-Incendive

Certificate:

Standards:

Markings:

20 Emerson.com/Rosemount

1091070

FM Class 3600: 2011, FM Class 3615: 2006, FM Class 3616:

2011, ANSI/ISA 60079-0: Ed. 5, UL Std. No. 50E, CAN/CSA

C22.2 No. 60529-05

XP CL I, DIV 1, GP B, C, D; DIP CL II / III, DIV 1, GP E, F, G;

T5(-50 °C ≤ Ta ≤ +85 °C); Type 4X; IP66; See I5 description for

Non-Incendive markings.

1091070

FM Class 3600: 2011, FM Class 3610: 2010, FM Class 3611:

2004, ANSI/ISA 60079-0: Ed. 5, UL Std. No. 60079-11: Ed. 6,

UL Std. No. 50E, CAN/CSA C22.2 No. 60529-05

IS CL I/II/III, DIV I, GP A, B, C, D, E, F, G; CL I ZONE 0 AEx ia IIC;

NI CL I, DIV 2, GP A, B, C, D

Page 21

April 2020 Quick Start Guide

Special Conditions for Safe Use (X):

1. When no enclosure option is selected, the Rosemount 644

Temperature Transmitter shall be installed in a final enclosure

meeting type of protection IP20 and meeting the requirements of

ANSI/ISA 61010-1 and ANSI/ISA 60079-0.

2. Option code K5 is only applicable with a Rosemount enclosure.

However, K5 is not valid with enclosure options S1, S2, S3, or S4.

3. An enclosure option must be selected to maintain a Type 4X rating.

4. The Rosemount 644 Transmitter optional housings may contain

aluminum and is considered a potential risk of ignition by impact or

friction. Care must be taken during installation and use to prevent

impact and friction.

7.5 Canada

7.5.1 I6 Canada Intrinsic Safety and Division 2

Certificate:

Standards:

Markings:

1091070

CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966, CAN/

CSA-C22.2 No. 94-M91, CSA Std C22.2 No. 142-M1987, CAN/

CSA-C22.2 No. 157-92, CSA Std C22.2 No. 213-M1987, C22.2

No 60529-05, CAN/CSA C22.2 No. 60079-0:11, CAN/CSA

C22.2 No. 60079-11:14, CAN/CSA Std. No. 61010-1-12

[HART] IS CL I GP A, B, C, D T4/T6; CL I, DIV 2, GP A, B, C, D

[Fieldbus/PROFIBUS] IS CL I GP A, B, C, D T4; CL I, ZONE 0 IIC;

CL I, DIV 2, GP A, B, C, D

7.5.2 K6 Canada Explosionproof, Dust-Ignitionproof, Intrinsic Safety and Division 2

Certificate:

Standards:

Markings:

1091070

CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966, CSA

Std. C22.2 No. 30-M1986, CAN/CSA-C22.2 No. 94-M91, CSA

Std C22.2 No. 142-M1987, CAN/CSA-C22.2 No. 157-92, CSA

Std C22.2 No. 213-M1987, C22.2 No 60529-05, CAN/CSA

C22.2 No. 60079-0:11, CAN/CSA C22.2 No. 60079-11:14,

CAN/CSA Std. No. 61010-1-12

CL I/II/III, DIV 1, GP B, C, D, E, F, G

See I6 description for Intrinsic Safety and Division 2 markings

Quick Start Guide 21

Page 22

Quick Start Guide April 2020

7.6 Europe

7.6.1 E1 ATEX Flameproof

Certificate:

Standards:

Markings:

See Table 7-1 for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-Standard Paint options may cause risk from electrostatic

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-1: 2014, EN

60529:1991 +A1:2000+A2:2013

II 2 G Ex db IIC T6…T1 Gb, T6(–50 °C ≤ Ta ≤ +40 °C), T5…

T1(–50 °C ≤ Ta ≤ +60 °C)

a source of ignition in Group III environments.

joules.

to temperature probes with Enclosure option “N”.

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

7.6.2 I1 ATEX Intrinsic Safety

Certificate:

Standards:

Markings:

See Table 7-5 for entity parameters and temperature classifications.

22 Emerson.com/Rosemount

[Headmount HART]: Baseefa12ATEX0101X

[Headmount Fieldbus/PROFIBUS]: Baseefa03ATEX0499X

[Railmount HART]: BAS00ATEX1033X

EN IEC 60079-0: 2018, EN 60079-11: 2012

[HART]: II 1 G Ex ia IIC T6…T4 Ga

[Fieldbus/PROFIBUS]: II 1 G Ex ia IIC T4 Ga

Page 23

April 2020 Quick Start Guide

Special Conditions for Safe Use (X):

1. The equipment must be installed in an enclosure which affords it a

degree of protection of at least IP20 in accordance with the

requirements of IEC 60529. Non-metallic enclosures must have a

surface resistance of less than 1G Ω; light alloy or zirconium

enclosures must be protected from impact and friction when

installed in a Zone 0 environment.

2. When fitted with the Transient Protector Assembly, the equipment is

not capable of withstanding the 500 V test as defined in Clause

6.3.13 of EN 60079-11:2012. This must be taken into account during

installation.

7.6.3 N1 ATEX Type n – with enclosure

Certificate:

Standards:

Markings:

BAS00ATEX3145

EN 60079-0: 2012+A11: 2013, EN 60079-15: 2010

II 3 G Ex nA IIC T5 Gc (–40 °C ≤ Ta ≤ +70 °C)

7.6.4 NC ATEX Type n – without enclosure

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. The Rosemount 644 Temperature Transmitter must be installed in a

2. When fitted with the Transient Protector Assembly, the equipment is

[Headmount Fieldbus/PROFIBUS, Railmount HART]:

Baseefa13ATEX0093X

[Headmount HART]: Baseefa12ATEX0102U

EN IEC 60079-0: 2018, EN 60079-15: 2010

[Headmount Fieldbus/PROFIBUS, Railmount HART]: II 3 G

Ex nA IIC T5 Gc (–40 °C ≤ Ta ≤ +70 °C)

[Headmount HART]: II 3 G Ex nA IIC T6…T5 Gc; T6(–60 °C ≤

Ta ≤ +40 °C); T5(–60 °C ≤ Ta ≤ +85 °C)

suitably certified enclosure such that it is afforded a degree of

protection of at least IP54 in accordance with IEC 60529 and EN

60079-15.

not capable of withstanding the 500 V test as defined in Clause 6.5 of

EN 60079-15: 2010. This must be taken into account during

installation.

Quick Start Guide 23

Page 24

Quick Start Guide April 2020

7.6.5 ND ATEX Dust

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-Standard Paint options may cause risk from electrostatic

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-31: 2014, EN

60529:1991 +A1:2000

II 2 D Ex tb IIIC T130 °C Db, (–40 °C ≤ Ta ≤ +70 °C); IP66

See Table 7-1 for process temperatures.

a source of ignition in Group III environments.

joules.

to temperature probes with Enclosure option "N".

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information

7.7

International

7.7.1 E7 IECEx Flameproof

Certificate:

Standards:

Markings:

See Table 7-1 for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

24 Emerson.com/Rosemount

IECEx FMG 12.0022X

IEC 60079-0: 2011, IEC 60079-1: 2014

Ex db IIC T6…T1 Gb, T6(–50 °C ≤ Ta ≤ +40 °C), T5…T1(–50 °C ≤

Ta ≤ +60 °C)

a source of ignition in Group III environments.

Page 25

April 2020 Quick Start Guide

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option “N”.

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

7.7.2 I7 IECEx Intrinsic Safety

Certificate:

Standards:

Markings:

See Table 7-5 for Entity Parameters and Temperature Classifications.

Special Conditions for Safe Use (X):

1. The equipment must be installed in an enclosure which affords it a

2. When fitted with the Transient Protector Assembly, the equipment is

[Headmount HART]: IECEx BAS 12.0069X

[Headmount Fieldbus/PROFIBUS, Railmount HART]: IECEx

BAS 07.0053X

IEC 60079-0: 2017, IEC 60079-11: 2011

Ex ia IIC T6…T4 Ga

degree of protection of at least IP20 in accordance with the

requirements of IEC 60529. Non-metallic enclosures must have a

surface resistance of less than 1G Ω; light alloy or zirconium

enclosures must be protected from impact and friction when

installed in a Zone 0 environment.

not capable of withstanding the 500 V test as defined in Clause

6.3.13 of IEC 60079-11:2011. This must be taken into account during

installation.

7.7.3 N7 IECEx Type n – with enclosure

Certificate:

Standards:

Markings:

IECEx BAS 07.0055

IEC 60079-0: 2011, IEC 60079-15: 2010

Ex nA IIC T5 Gc (–40 °C ≤ Ta ≤ +70 °C)

Quick Start Guide 25

Page 26

Quick Start Guide April 2020

7.7.4 NG IECEx Type n – without enclosure

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. The Rosemount 644 Temperature Transmitter must be installed in a

suitably certified enclosure such that it is afforded a degree of

protection of at least IP54 in accordance with IEC 60529 and IEC

60079-15.

2. When fitted with the Transient Protector Assembly, the equipment is

not capable of withstanding the 500 V test. This must be taken into

account during installation.

7.7.5 NK IECEx Dust

Certificate:

Standards:

Markings:

[Headmount Fieldbus/PROFIBUS, Railmount HART]: IECEx

BAS 13.0053X

[Headmount HART]: IECEx BAS 12.0070U

IEC 60079-0: 2017, IEC 60079-15: 2010

[Headmount Fieldbus/PROFIBUS, Railmount HART]: Ex nA IIC

T5 Gc (–40 °C ≤ Ta ≤ +70 °C)

[Headmount HART]: Ex nA IIC T6…T5 Gc; T6(–60 °C ≤ Ta ≤ +40

°C); T5(–60 °C ≤ Ta ≤ +85 °C)

IECEx FMG 12.0022X

IEC 60079-0: 2011, IEC 60079-31: 2013

Ex tb IIIC T130 °C Db, (–40 °C ≤ Ta ≤ +70 °C); IP66

See Table 7-1 for process temperatures

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option “N”.

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

26 Emerson.com/Rosemount

Page 27

April 2020 Quick Start Guide

7. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

7.8 Brazil

7.8.1 E2 INMETRO Flameproof and Dust

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. See product description for ambient temperature limits and process

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Consult the manufacturer if dimensional information on the

UL-BR 13.0535X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-1:2016,

ABNT NBR IEC 60079-31:2014

Ex db IIC T6…T1 Gb; T6…T1: (–50 °C ≤ Ta ≤ +40 °C), T5…T1: (–

50 °C ≤ Ta ≤ +60 °C)

Ex tb IIIC T130 °C; IP66; (–40 °C ≤ Ta ≤ +70 °C)

temperature limits.

a source of ignition in Group III environments.

joules.

flameproof joints is necessary.

7.8.2 I2 INMETRO Intrinsic Safety

Certificate:

Standards:

Markings:

[Fieldbus]: UL-BR 15.0264X [HART]: UL-BR 14.0670X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

[Fieldbus]: Ex ia IIC T* Ga (–60 °C ≤ Ta ≤ +** °C) [HART]: Ex ia

IIC T* Ga (–60 °C ≤ Ta ≤ +** °C)

See Table 7-5 for Entity Parameters and Temperature Classifications.

Special Conditions for Safe Use (X):

1. The apparatus must be installed in an enclosure which affords it a

degree of protection of at least IP20.

2. Non-metallic enclosures must have a surface resistance of less than 1

G Ω; light alloy or zirconium enclosures must be protected from

impact and friction when installed in a zone 0 environment.

Quick Start Guide 27

Page 28

Quick Start Guide April 2020

3. When fitted with the Transient Protector Assembly, the equipment is

not capable of withstanding the 500 V test as defined on ABNT NBR

IEC 60079-11. This must be taken into account during installation.

4. The ingress protection degree IP66 is provided only for the

Rosemount 644 Field Mount Assembly which is formed by installing

an Enhanced Model 644 Temperature Transmitter within a dualcompartment enclosure Plantweb enclosure.

7.9 China

7.9.1 E3 China Flameproof

Certificate:

Standards:

GYJ16.1192X

GB3836.1-2010, GB3836.2-2010, GB12476.1-2013,

GB12476.5-2013

Markings:

Ex d IIC T6…T1; Ex tD A21 T130 °C; IP66

产品安全使用特定条件

产品防爆合格证后缀“X”代表产品安全使用有特定条件:

1. 涉及隔爆接合面的维修须联系产品制造商。

2. 产品铭牌材质为非金属,使用时须防止产生静电火花,只能用湿布

清理。

3. 产品使用环境温度与温度组别的关系为:

防爆标志

Ex d IIC T6~T1GbT6~T1 –50 °C ≤ Ta ≤ +40 °C

Ex Td A21 IP66

T130 ℃

温度组别 环境温度

T5~T1 –50 °C ≤ Ta ≤ +60 °C

N/A –40 °C ≤ Ta ≤ +70 °C

4. 产品外壳设有接地端子,用户在安装使用时应可靠接地。

5. 现场安装时,电缆引入口须选用国家指定的防爆检验机构按检验认

可、具有 Ex dⅡC, Ex tD A21 IP66 防爆等级的电缆引入装置或堵封

件,冗余电缆引入口须用堵封件有效密封。

6. 用于爆炸性气体环境中,现场安装、使用和维护必须严格遵守“断电

后开盖!”的警告语。用于爆炸性粉尘环境中,现场安装、使用、和

维护必须严格遵守“爆炸性粉尘场所严禁开盖!”的警告语。

7. 用于爆炸性粉尘环境中,产品外壳表面须保持清洁,以防粉尘堆

积,单严禁用压缩空气吹扫。

28 Emerson.com/Rosemount

Page 29

April 2020 Quick Start Guide

8. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB3836.15-2000“爆炸性气体环境用电气设备 第 15 部

分:危险场所电气安装(煤矿除外)”、GB3836.16-2006“爆炸性气

体环境用电气设备 第 16 部分:电气装置的检查和维护(煤矿除

外)”和 GB50257-2014“电气装置安装工程爆炸和火灾危险环境电

力装置施工及验收规范”和 GB15577-2007“粉尘防爆安全规程”、

GB12476.2-2010“可燃性粉尘环境用电气设备 第 2 部分 选型和安

装”的有关规定。

7.9.2 I3 China Intrinsic Safety

Certificate:

Standards:

Markings:

GYJ16.1191X

GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Ex ia IIC T4~T6 Ga

产品安全使用特殊条件

防爆合格证号后缀“X”代表产品安全使用有特定条件:

1. 温度变送器须安装于外壳防护等级不低于国家标准 GB/T4208-2017

规定的 IP20 的壳体中,方可用于爆炸性危险场所,金属壳体须符合

国家标准 GB3836.1-2010 第 8 条的规定,非金属壳体须符合

GB3836.1-2010 第 7.4 条的规定。

2. 非金属外壳表面电阻必须小于 1GΩ,轻金属或者锆外壳在安装时必

须防止冲击和摩擦。

3. 当 Transmitter Type 为 F、D 时,产品外壳含有轻金属,用于 0 区

时需注意防止由于冲击或摩擦产生的点燃危险。

4. 产品选用瞬态保护端子板(选项代码为 T1)时,此设备不能承受

GB3836.4-2010 标准中第 6.3.12 条规定的 500V 交流有效值试验电

压的介电强度试验。

产品使用注意事项

1. 产品环境温度为:

当 Options 不选择 Enhanced Performance 时

输出代码

最大输出功率(W) 温度组别环境温度

A 0.67 T6 –60 °C ≤ Ta ≤ +40 °C

0.67 T5 –60 °C ≤ Ta ≤ +50 °C

1 T5 –60 °C ≤ Ta ≤ +40 °C

1 T4 –60 °C ≤ Ta ≤ +80 °C

F 或 W 1.3 T4 –50 °C ≤ Ta ≤ +60 °C

Quick Start Guide 29

Page 30

Quick Start Guide April 2020

输出代码 最大输出功率(W) 温度组别环境温度

5.32 T4 –50 °C ≤ Ta ≤ +60 °C

当 Options 选择 Enhanced Performance 时

最大输出功率(W) 温度组别 环境温度

0.67 T6 –60 °C ≤ Ta ≤ +40 °C

0.67 T5 –60 °C ≤ Ta ≤ +50 °C

0.80 T5 –60 °C ≤ Ta ≤ +40 °C

0.80 T4 –60 °C ≤ Ta ≤ +80 °C

2. 参数:

当 Options 不选择 Enhanced Performance 时

输入端(+ , -)

输出代码 最高输

入电压

Ui(V)

A 30 200 0.67/1 10 0

F 或 W 30 300 1.3 2.1 0

F 或 W(FISCO) 17.5 380 5.32 2.1 0

最大输

入电流

I

i

(mA)

最大输

入功率

Pi(W)

最大内部等效参数

Ci (nF) Li (mH)

传感器端(1,2,3,4)

输出代码

A 13.6 80 0.08 75 0

F,W 13.9 23 0.079 7.7 0

最高输

出电压

Uo (V)

最大输

出电流

Io (mA)

最大输

出功率

Po (W)

最大内部等效参数

Co (nF) Lo (mH)

当 Options 选择 Enhanced Performance 时

输入端(+ , -)

最高输入电压

Ui (V)

30 150 (Ta ≤ +80 °C) 0.67/0.8 3.3 0

最大输入电流

Ii (mA)

170 (Ta ≤ +70 °C)

最大输入功

率

Pi (W)

最大内部等效参数

Ci (nF) Li (mH)

30 Emerson.com/Rosemount

Page 31

April 2020 Quick Start Guide

最高输入电压

Ui (V)

最大输入电流

Ii (mA)

190 (Ta ≤ +60 °C)

最大输入功

率

Pi (W)

最大内部等效参数

Ci (nF) Li (mH)

传感器端(1,2,3,4)

最高输 出

电压

Uo (V)

13.6 80 0.08 IIC 0.816 5.79

最大输 出

电流

Io (mA)

最大输 出

功率

Po (W)

组别 最大内部等效参数

Co (nF) Lo (mH)

IIB 5.196 23.4

IIA 18.596 48.06

注:本案电气参数符合 GB3836.19-2010 对 FISCO 现场仪表的参数

要求。

3. 该产品必须与已通过防爆认证的关联设备配套共同组成本安防爆系

统方可使用于爆炸性气体环境。其系统接线必须同时遵守本产品和

所配关联设备的使用说明书要求,接线端子不得接错。

4. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生。

5. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB/T3836.15-2017“爆炸性环境 第 15 部分:电气装置

的设计,选型和安装”、GB/T3836.16-2017“爆炸性环境 第 16 部

分:电气装置的检查和维护”、GB/T3836.18-2017“爆炸性环境 第

18 部分:本质安全电气系统”和 GB50257-2014“电气装置安装工程

爆炸和火灾危险环境电力装置施工及验收规范”的有关规定。

7.9.3 N3 China Type n

Certificate:

Standards:

Markings:

产品安全使用特殊条件

1. 产品温度组别和使用环境温度范围之间的关系为:

当 Options 不选择 Enhanced Performance 时:

温度组别

T5 –40 °C ≤ Ta ≤ +70 °C

Quick Start Guide 31

GYJ15.1502

GB3836.1-2010, GB3836.8-2014

Ex nA IIC T5/T6 Gc

环境温度

Page 32

Quick Start Guide April 2020

当 Options 选择 Enhanced Performance 时:

温度组别 环境温度

T6 –60 °C ≤ Ta ≤ +40 °C

T5 –60 °C ≤ Ta ≤ +85 °C

2. 最高工作电压:45Vdc

3. 现场安装时,电缆引入口须选用经国家指定的防爆检验机构检验认

可、具有 Ex e IIC Gb 防爆等级的电缆引入装置或堵封件,冗余电缆

引入口须用封堵件有效密封。电缆引入装置或封堵件的安装使用必

须遵守其使用说明书的要求并保证外壳防护等级达到 IP54(符合

GB/T4208-2017 标准要求)以上。

4. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生。

5. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB/T3836.15-2017“爆炸性环境 第 15 部分:电气装置

的设计、选型和安装”、GB/T3836.16-2017“爆炸性环境 第 16 部

分:电气装置的检查和维护”和 GB50257-2014“电气装置安装工程

爆炸和火灾危险环境电力装置施工及验收规范”的有关规定。

7.10 EAC - Belarus, Kazakhstan, Russia

7.10.1 EM Technical Regulation Customs Union TR CU 012/2011 (EAC) Flameproof

Standards:

Markings:

See Table 7-1 for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate TR CU 012/2011 for ambient temperature range.

2. Guard the LCD display cover against impact energies greater than 4

3. Flameproof joints are not intended for repair.

4. Non-standard paint options may cause risk from electrostatic

32 Emerson.com/Rosemount

GOST 31610.0-2014, GOST IEC 60079-1-2011

1Ex d IIC T6…T1 Gb X, T6 (-55 °C ≤ Ta ≤ +40 °C), T5…T1(-55 °C

≤ Ta≤ +60 °C);

joules.

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special code, contact the

manufacturer for more information.

Page 33

April 2020 Quick Start Guide

7.10.2 IM Technical Regulation Customs Union TR CU 012/2011 (EAC) Intrinsic Safety

Standards:

Markings:

See Table 7-5 for Entity Parameters and Temperature Classifications.

Special Conditions for Safe Use (X):

1. The equipment must be installed in an enclosure which affords it a

2. When fitted with the Transient Protector Assembly, the equipment is

3. See certificate TR CU 012/2011 for ambient temperature range.

GOST 31610.0-2014, GOST 31610.11-2014

[HART]: 0Ex ia IIC T6…T4 Ga X; [Fieldbus, FISCO, PROFIBUS

PA]: 0Ex ia IIC T4 Ga X

degree of protection of at least IP20 in accordance with the

requirements of GOST 14254-96. Non-metallic enclosures must have

a surface resistance of less than 1 Ω; light alloy or zirconium

enclosures must be protected from impact and friction when

installed in a Zone 0 environment.

not capable of withstanding the 500 V test as defined in GOST

31610.11-2014. This must be taken into account during installation.

7.10.3 KM Technical Regulation Customs Union TR CU 012/2011 (EAC) Flameproof, Intrinsic Safety, and Dust-Ignitionproof

Standards:

Markings:

GOST 31610.0-2014, GOST IEC 60079-1-2011, GOST

31610.11-2014, GOST R IEC 60079-31-2010

Ex tb IIIC T130 °C Db X (-55 °C ≤ Ta ≤ +70 °C); IP66

See Table 7-1 for process temperatures.

See EM for Flameproof Markings and see IM for Intrinsic Safety Markings.

Special Conditions for Safe Use (X):

1. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments. Label must be cleaned

by the damp cloth with antistatic to avoid store an electrostatic

discharge.

2. Guard the LCD display cover against impact energies greater than 4

joules.

See EM for Flameproof Specific Conditions of Use and see IM for Intrinsic

Safety Specific Conditions of Use.

Quick Start Guide 33

Page 34

Quick Start Guide April 2020

7.11 Japan

7.11.1 E4 Japan Flameproof

Certificate:

Markings:

Special Conditions for Safe Use:

1. Flameproof joints are not intended for repair.

2. Models with LCD display cover shall have the display cover protected

3. For Models 65 and 185, the user shall ensure the external surface

4. Non-standard paint options may cause risk from electrostatic

5. The wiring used shall be suitable for temperatures over 80 °C.

CML 17JPN1316X

Ex d IIC T6...T1 Gb; T6 (-50 °C < Ta < +40 °C); T5…T1(-50 °C ≤

Ta≤ 60 °C)

from impact energies greater than 4 Joules.

temperature of the equipment and the neck of the DIN Style probe

does not exceed 130 °C.

discharge.

7.11.2 I4 Japan Intrinsic Safety

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. The apparatus must be installed in an enclosure which affords it a

degree of protection of at least IP20.

CML 18JPN2118X

JNIOSH-TR-46-1, JNIOSH-TR-46-6

[Fieldbus] Ex ia IIC T4 Ga (–60 °C ≤ Ta ≤ +60 °C);

2. Non-metallic enclosures must have a surface resistance of less than 1

G Ω; light alloy or zirconium enclosures must be protected from

impact and friction when installed in a zone 0 environment.

7.12

Korea

7.12.1 EP Korea Flameproof and Dust-Ignitionproof

Certificate:

Markings:

34 Emerson.com/Rosemount

13-KB4BO-0559X

Ex d IIC T6... T1; Ex tb IIIC T130 °C

Page 35

April 2020 Quick Start Guide

Special Condition for Safe Use (X):

See certificate for special conditions for safe use.

7.12.2 IP Korea Intrnsic Safety

Certificate:

Markings:

Special Conditions for Safe Use (X):

See certificate for special conditions for safe use.

13-KB4BO-0531X

Ex ia IIC T6…T4

7.13 Combinations

K1

K2

K5

K7

KA

KB

KC

KD

KP

Combination of E1, I1, N1, and ND

Combination of E2 and I2

Combination of E5 and I5

Combination of E7, I7, N7, and NK

Combination of K6, E1, and I1

Combination of K5 and K6

Combination of I5 and I6

Combination of E5, I5, K6, E1, and I1

Combination of EP and IP

7.14 Additional certifications

7.14.1 SBS American Bureau of Shipping (ABS) Type Approval

Certificate:

16-HS1553094-PDA

7.14.2 SBV Bureau Veritas (BV) Type Approval

Certificate:

Requirements:

Application:

26325 BV

Bureau Veritas Rules for the Classification of Steel Ships

Class notations: AUT-UMS, AUT-CCS, AUT-PORT and AUTIMS

7.14.3 SDN Det Norske Veritas (DNV) Type Approval

Certificate:

Quick Start Guide 35

TAA00000K8

Page 36

Quick Start Guide April 2020

Application:

Location Classes:Temperature: D; Humidity: B; Vibration: A;

EMC: B; Enclosure B/IP66: A, C/IP66: SST

7.14.4 SLL Lloyds Register (LR) Type Approval

Certificate:

Application:

11/60002

For use in environmental categories ENV1, ENV2, ENV3, and

ENV5.

7.15 Specification tables

Table 7-1: Process Temperature Limits

Sensor only

(no

transmitter

installed)

Any

extension

length

Table 7-2: Process Temperature Limits without LCD Display Cover

Transmitter Process temperature [°C]

No extension 131 °F

3-in.

extension

6-in.

extension

9-in.

extension

Process temperature [°C]

Gas Dust

T6 T5 T4 T3 T2 T1 T130 °C

85 °C

(185 °F )

Gas Dust

T6 T5 T4 T3 T2 T1 T130 °C

(55 °C)

131 °F

(55 °C)

140 °F

(60 °C)

149 °F

(65 °C)

100 °C

(212 °F)

158 °F

(70 °C)

158 °F

(70 °C)

158 °F

(70 °C)

167 °F

(75 °C)

135 °C

(275 °F)

212 °F

(100 °C)

230 °F

(110 °C)

248 °F

(120 °C)

266 °F

(130 °C)

200 °C

(392 °F)

338 °F

(170 °C)

374 °F

(190 °C)

392 °F

(200 °C)

392 °F

(200 °C)

300 °C

(572 °F)

536 °F

(280 °C)

572 °F

(300 °C)

572 °F

(300 °C)

572 °F

(300 °C)

450 °C

(842 °F)

824 °F

(440 °C)

842 °F

(450 °C)

842 °F

(450 °C)

842 °F

(450 °C)

130 °C

(266 °F)

212 °F

(100 °C)

230 °F

(110 °C)

230 °F

(110 °C)

248 °F

(120 °C)

Adhering to the process temperature limitation of Table 7-3 will ensure that

the service temperature limitations of the LCD cover are not exceeded.

Process temperatures may exceed the limits defined in Table 7-3 if the

Temperature of the LCD cover is verified to not exceed the service

temperatures in Table 7-4 and the process temperatures do not exceed the

values specified in Table 7-2.

36 Emerson.com/Rosemount

Page 37

April 2020 Quick Start Guide

Table 7-3: Process Temperature Limits with LCD Display Cover

Transmitter

with LCD

display cover

No extension 131 °F (55 °C) 158 °F (70 °C) 203 °F (95 °C) 203 °F (95 °C)

3-in. extension 131 °F (55 °C) 158 °F (70 °C) 212 °F (100 °C) 212 °F (100 °C)

6-in. extension 140 °F (60 °C) 158 °F (70 °C) 212 °F (100 °C) 212 °F (100 °C)

9-in. extension 149 °F (65 °C) 167 °F (75 °C ) 230 °F (110 °C) 110 °C (230 °F)

Process temperature [°C]

Gas Dust

T6 T5 T4...T1 T130 °C

Table 7-4: Service Temperature Limits

Transmitter

with LCD

display cover

No extension 149 °F (65 °C) 167 °F (75 °C) 203 °F (95 °C) 203 °F (95 °C)

Service temperature [°C]

Gas Dust

T6 T5 T4...T1 T130 °C

Table 7-5: Entity Parameters

Fieldbus/PROFIBUS

[FISCO]

Ui (V) 30 [17.5] 30 30

Ii (mA) 300 [380] 200 150 for Ta ≤ 80 °C

Pi (W) 1.3 at T4 (–50 °C ≤ Ta ≤

+60 °C)

[5.32 at T4 (–50 °C ≤

Ta ≤ +60 °C)]

Ci (nF) 2.1 10 3.3

Li (mH) 0 0 0

HART HART (Enhanced)

170 for Ta ≤70 °C

190 for Ta ≤60 °C

.67 at T6(–60 °C ≤ Ta ≤

+40 °C)

.67 at T5(–60 °C ≤ Ta ≤

+50 °C)

1.0 at T5(–60 °C ≤ Ta ≤

+40 °C)

1.0 at T4(–60 °C ≤ Ta ≤

+80 °C)

.67 at T6(–60 °C ≤ Ta ≤

+40 °C)

.67 at T5(–60 °C ≤ Ta ≤

+50 °C)

.80 at T5(–60 °C ≤ Ta ≤

+40 °C)

.80 at T4(–60 °C ≤ Ta ≤

+80 °C)

Quick Start Guide 37

Page 38

EU Declaration of Conformity

No: RMD 1016 Rev. Y

Page 1 of 4

We,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Rosemount™ 644 Temperature Transmitter

manufactured by,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

(signature)

Vice President of Global Quality

(function)

Chris LaPoint

(name)

1-April-2019

(date of issue)

Quick Start Guide April 2020

8 Declaration of Conformity

38 Emerson.com/Rosemount

Page 39

EU Declaration of Conformity

No: RMD 1016 Rev. Y

Page 2 of 4

EMC Directive (2014/30/EU)

Harmonized Standards: EN 61326-1:2013, EN 61326-2-3: 2013

ATEX Directive (2014/34/EU)

Rosemount 644 Enhanced Head/Field Mount Temperature Transmitters

(Analog/HART Output)

Baseefa12ATEX0101X – Intrinsic Safety Certificate

Equipment Group II, Category 1 G

Ex ia IIC T6…T4 Ga

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-11:2012

Baseefa12ATEX0102U – Type n Certificate; no enclosure option

Equipment Group II, Category 3 G

Ex nA IIC T6…T5 Gc

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-15:2010

Rosemount 644 Head Mount Temperature Transmitter

(Fieldbus Output)

Baseefa03ATEX0499X – Intrinsic Safety Certificate

Equipment Group II, Category 1 G

Ex ia IIC T4 Ga

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-11:2012

Baseefa13ATEX0093X – Type n Certificate; no enclosure option

Equipment Group II, Category 3 G

Ex nA IIC T5 Gc

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-15:2010

April 2020 Quick Start Guide

Quick Start Guide 39

Page 40

EU Declaration of Conformity

No: RMD 1016 Rev. Y

Page 3 of 4

Rosemount 644 Head/Field Mount Temperature Transmitter

(All output protocols)

FM12ATEX0065X – Flameproof Certificate

Equipment Group II, Category 2 G

Ex db IIC T6…T1 Gb

Harmonized Standards:

EN 60079-0:2012+A11:2013, EN 60079-1:2014

FM12ATEX0065X – Dust Certificate

Equipment Group II, Category 2 D

Ex tb IIIC T130°C Db

Harmonized Standards:

EN 60079-0:2012+A11:2013, EN 60079-31:2014

BAS00ATEX3145 – Type n Certificate

Equipment Group II, Category 3 G

Ex nA IIC T5 Gc

Harmonized Standards:

EN 60079-0:2012+A11:2013; EN 60079-15:2010

Rosemount 644R Rail Mount Temperature Transmitters

(HART Output)

BAS00ATEX1033X – Intrinsic Safety Certificate

Equipment Group II, Category 1 G

Ex ia IIC T6…T4 Ga

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-11:2012

Baseefa13ATEX0093X – Type n Certificate

Equipment Group II, Category 3 G

Ex nA IIC T5 Gc

Harmonized Standards:

EN IEC 60079-0:2018; EN 60079-15:2010

RoHS Directive (2011/65/EU)

644 HART Head Mount

Harmonized Standard: EN 50581:2012

Quick Start Guide April 2020

40 Emerson.com/Rosemount

Page 41

EU Declaration of Conformity

No: RMD 1016 Rev. Y

Page 4 of 4

ATEX Notified Bodies

FM Approvals Europe Limited [Notified Body Number: 2809]

One Georges Quay Plaza

Dublin, Ireland. D02 E440

SGS FIMCO OY [Notified Body Number: 0598]

P.O. Box 30 (Särkiniementie 3)

00211 HELSINKI

Finland

ATEX Notified Body for Quality Assurance

SGS FIMCO OY [Notified Body Number: 0598]

P.O. Box 30 (Särkiniementie 3)

00211 HELSINKI

Finland

April 2020 Quick Start Guide

Quick Start Guide 41

Page 42

Quick Start Guide April 2020

9 China RoHS

42 Emerson.com/Rosemount

Page 43

April 2020 Quick Start Guide

Quick Start Guide 43

Page 44

*00825-0300-4728*

00825-0300-4728, Rev. EA

Quick Start Guide

April 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...