Page 1

Rosemount™ 56

Dual Channel Transmitter

Quick Start Guide

00825-0100-3056, Rev AB

March 2020

Page 2

Quick Start Guide March 2020

Safety Information

Your instrument purchase from Emerson is one of the finest available for your particular application.

These instruments have been designed and tested to meet many national and international standards.

Experience indicates that its performance is directly related to the quailty of the installation and

knowledge of the user in operating and maintaining the instrument. To ensure its continued operation

to the design specifications, personnel should read this Quick Start Guide thoroughly before

proceeding with installation, commissioning, operation, and maintenance of this instrument. If this

equipment is used in a manner not specified by the manufacturer, the protection provided by it against

hazards may be impaired.

• Failure to follow the proper instructions may cause any one of the following situations to occur:

loss of life, personal injury, property damage, damage to this instrument, and warranty

invalidation.

• Ensure that you have received the correct model and options from your purchase order. Verify

that this Quick Start Guide covers your model and options. If it does not, call 800 854 8257 or 949

757 8500 to request the correct Quick Start Guide.

• For clarification of instructions, contact your Rosemount representative.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Use only qualified personnel to install, operate, program, and maintain the product.

• Install equipment as specified in the Installation section of this Quick Start Guide. Follow

appropriate local and national codes. Only connect the product to electrical and pressure sources

specified in this Quick Start Guide.

• Use only factory documented components for repair. Tampering or unauthorized substitution of

parts can affect product performance and cause unsafe operation of your process.

• All equipment doors must be closed, and protective covers must be in place unless qualified

personnel are performing maintenance.

WARNING

Risk of electrical shock

Installation and servicing of this product may expose personnel to dangerous voltages.

Equipment protected throughout by double insulation.

Disconnect main power wired to separate power source before servicing.

Do not operate or energize instrument with case open.

Signal wiring within this box must be rated at least 240 V for European mains operation.

Non-metallic cable strain reliefs do not provide grounding between conduit connections. Use

grounding type bushings and jumper wires.

Unused cable conduit entries must be securely sealed by non-flammable closures to provide

exposure integrity in compliance with personal safety and environmental protection

requirements. Unused conduit openings must be sealed with Type 4X or IP66 conduit plugs to

maintain the ingress protection rating (Type 4X).

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70)

and/or any other national or local codes.

Operate only with front panel fastened and in place.

Safety and performance require that this instrument be connected and properly grounded

through a three-wire power source.

Proper use and configuration is the operator's responsibility.

2 Emerson.com/Rosemount

Page 3

March 2020 Quick Start Guide

CAUTION

Radio interference

This product generates, uses, and can radiate radio frequency energy and thus can cause radio

communication interference. Improper installation or operation may increase such interference. As

temporarily permitted by regulation, this unit has not been tested for compliance within the limits of

Class A computing devices, pursuant to Subpart J of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference.

Operation of this equipment in a residential area may cause interference, in which case the

operator, at his own expense, will be required to take whatever measures may be required to

correct the interference.

CAUTION

This product is not intended for use in the light industrial, residential, or commercial environments per

the instrument's certification in ENG1226-1: 2006.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

Contents

First steps.....................................................................................................................................5

Install......................................................................................................................................... 13

Wire........................................................................................................................................... 16

Navigating the display................................................................................................................22

Start up transmitter....................................................................................................................26

Product certifications................................................................................................................. 28

Declaration of Conformity..........................................................................................................30

China RoHS table........................................................................................................................32

Quick Start Guide 3

Page 4

Quick Start Guide March 2020

4 Emerson.com/Rosemount

Page 5

March 2020 Quick Start Guide

1 First steps

1.1 Unpack and inspect

Procedure

1. Inspect the shipping container. If it is damaged, contact the shipper

immediately for instructions.

2. If there is no apparent damage, unpack the container. Be sure all

items shown on the packing list are present. If items are missing,

notify Emerson immediately.

1.2 Mount

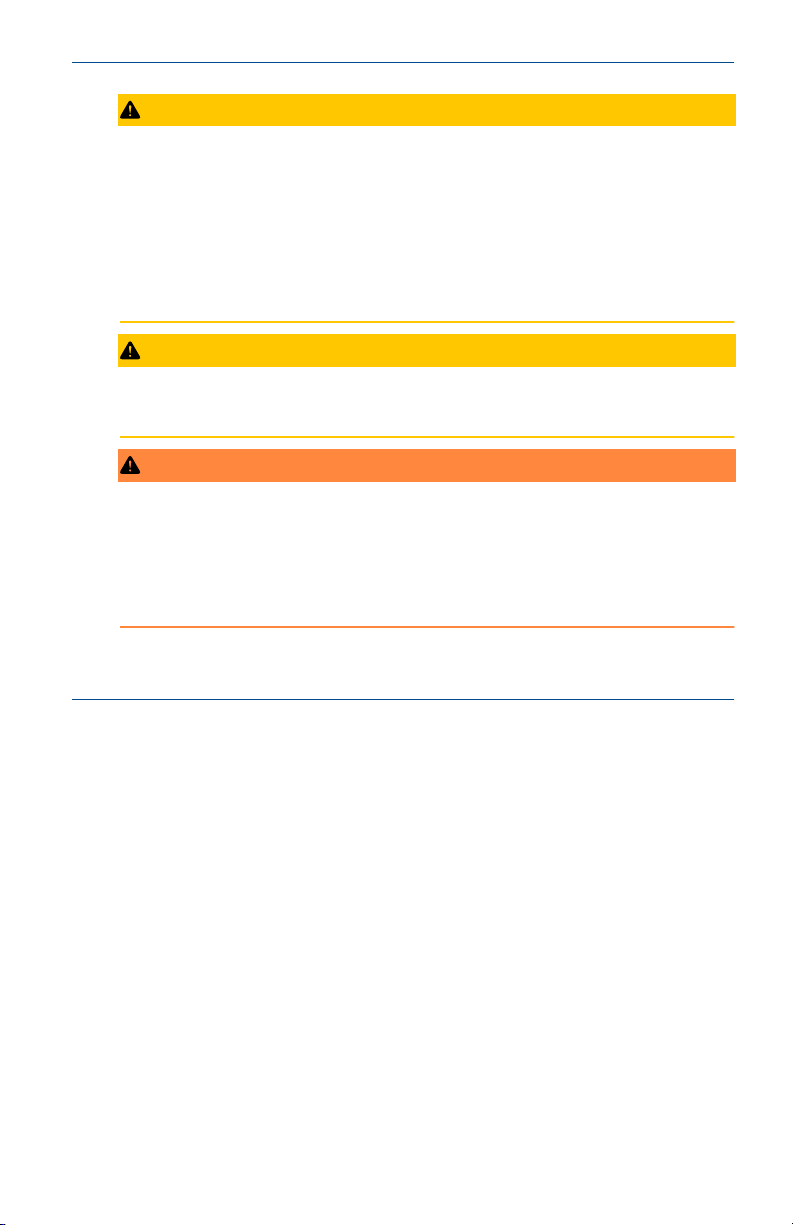

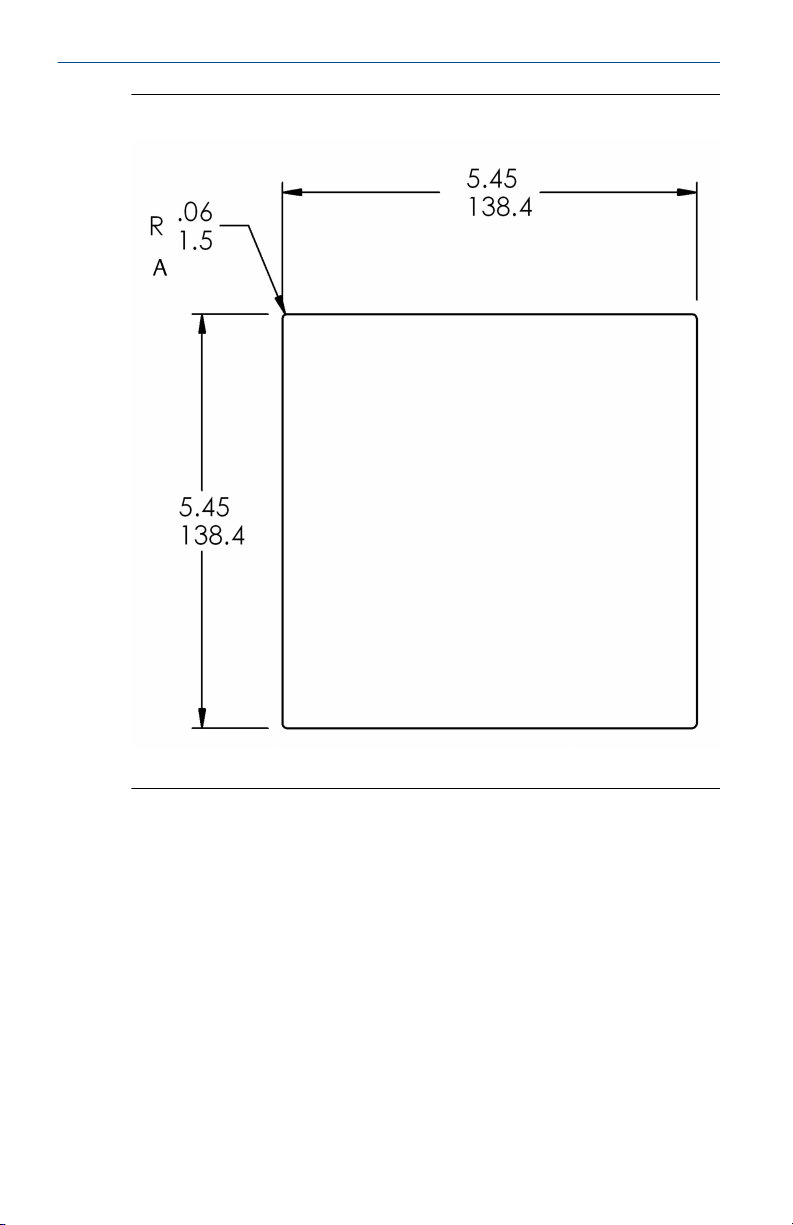

Figure 1-1: Panel Mount Front View

Quick Start Guide 5

Page 6

Quick Start Guide March 2020

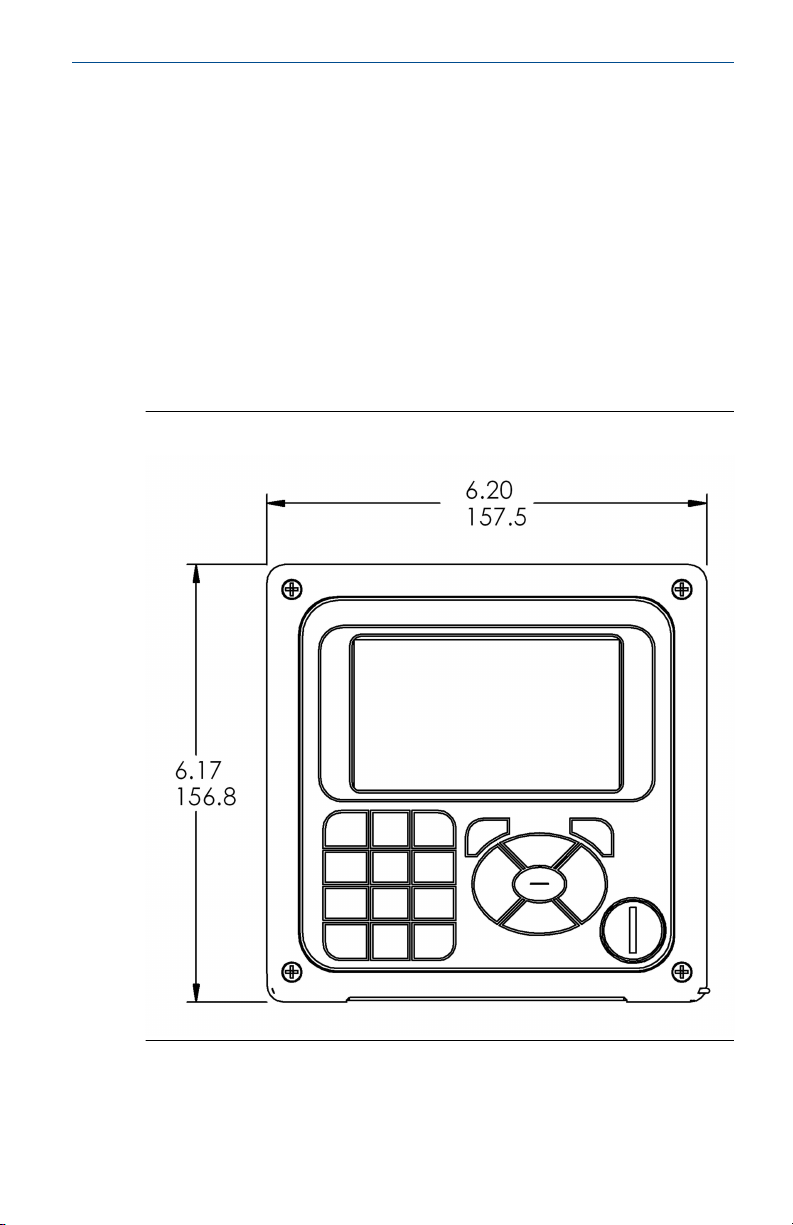

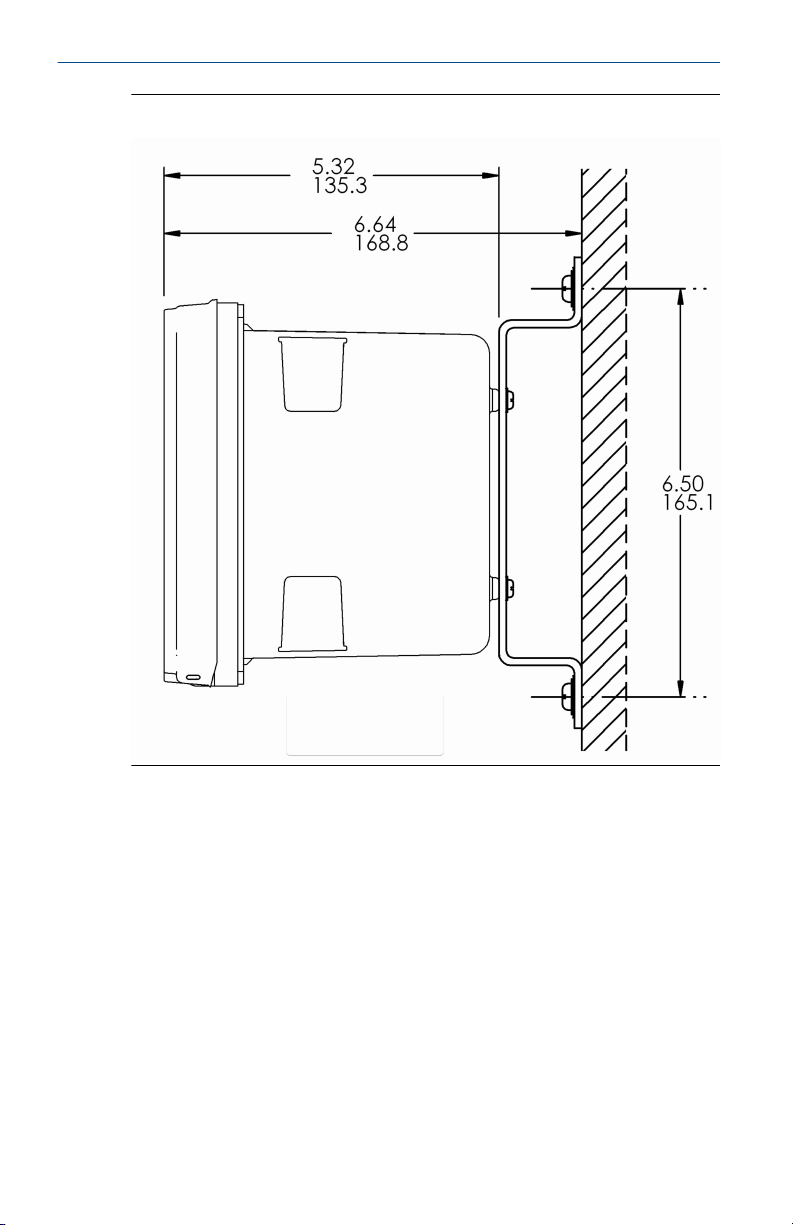

Figure 1-2: Panel Mount Side View

A. Panel mount gasket

B. Panel supplied by others. Maximum thickness: .375 in. (9.52 mm)

C. 4X mounting bracket and screws provided with instrument

6 Emerson.com/Rosemount

Page 7

March 2020 Quick Start Guide

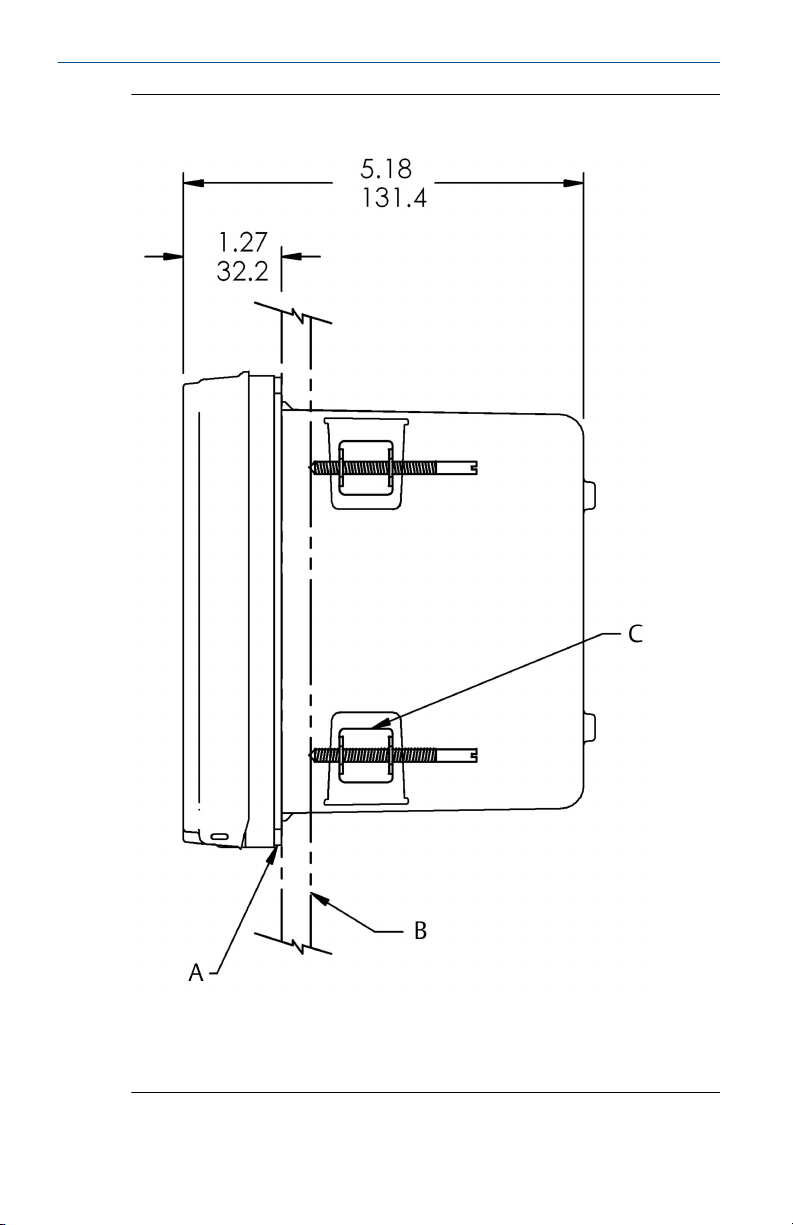

Figure 1-3: Panel Mount Bottom View

A. Conduit openings

Quick Start Guide 7

Page 8

Quick Start Guide March 2020

Figure 1-4: Panel Mount Panel Cut-Out

A. Maximum

8 Emerson.com/Rosemount

Page 9

March 2020 Quick Start Guide

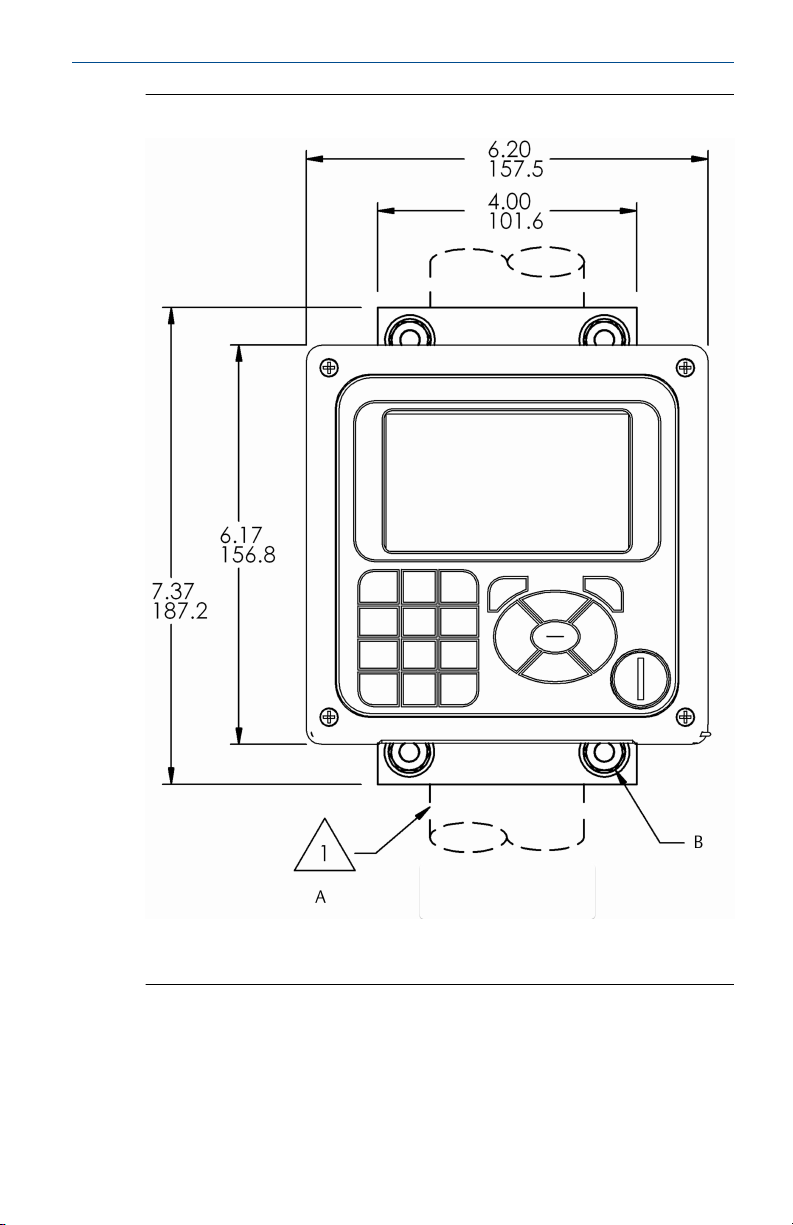

Figure 1-5: Wall Mount Front View

A. 2-in. (50.8 mm) pipe supplied by customer

B. Four cover screws

Quick Start Guide 9

Page 10

Quick Start Guide March 2020

Figure 1-6: Wall Mount Side View

10 Emerson.com/Rosemount

Page 11

March 2020 Quick Start Guide

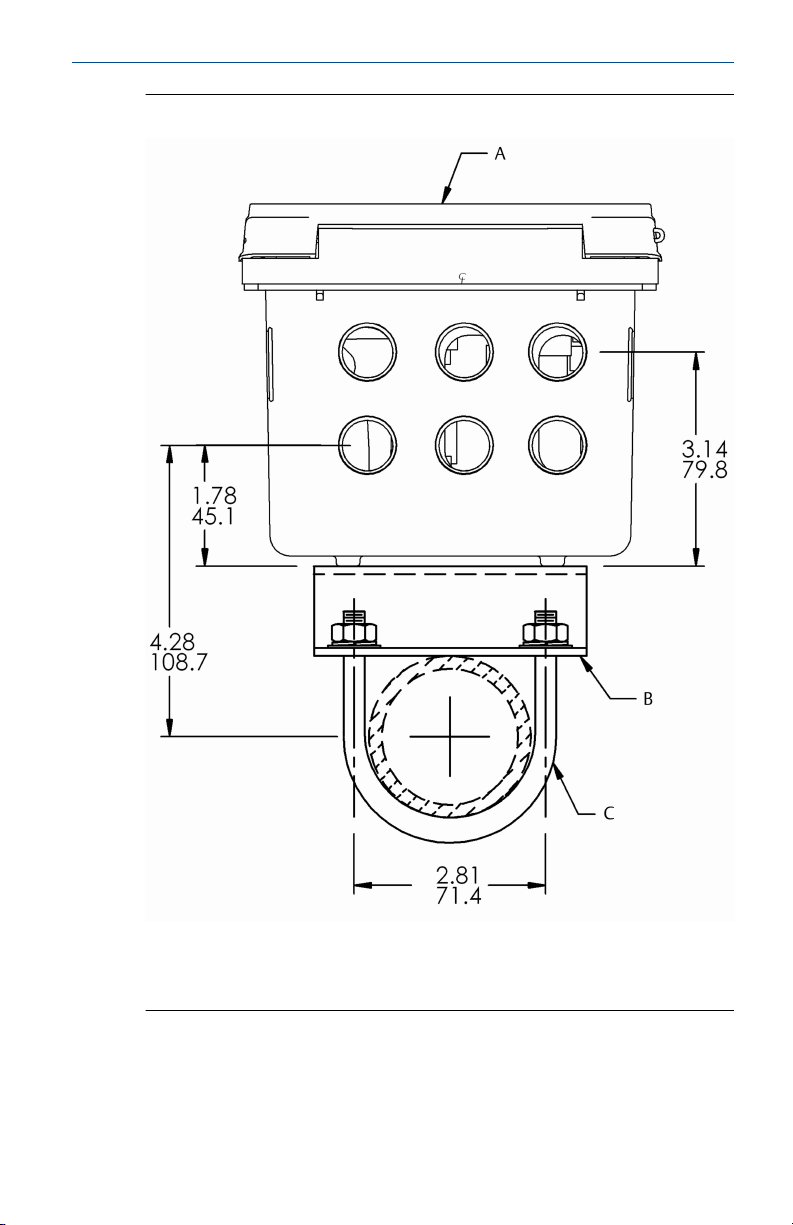

Figure 1-7: Pipe Mount Bottom View

A. Front panel

B. 2-in. (50.8 mm) pipe mount bracket

C. Two sets U-bolts for 2-in. (50.8 mm) pipe in kit PN 23820-00

Quick Start Guide 11

Page 12

Quick Start Guide March 2020

Figure 1-8: Pipe Mount Side View

12 Emerson.com/Rosemount

Page 13

March 2020 Quick Start Guide

2 Install

2.1 General installation information

1. Install the transmitter with a sunshield or out of direct sunlight and

areas with extreme temperatures. The transmitter cannot be

operated in ambient (shaded) conditions greater than 140 °F (60 °C).

2. Install the transmitter in an area where vibration and

electromagnetic and radio frequency interference are minimized or

absent.

3. Keep the transmitter and sensor wiring at least one foot from high

voltage conductors. Be sure there is easy access to the transmitter.

4. The transmitter is suitable for panel, pipe, or surface mounting. Refer

to Mount.

5. Install cable gland fittings and plugs as needed to properly seal the

transmitter on all six enclosure openings. The USB port cover must be

fully installed on the front cover to ensure proper transmitter sealing.

WARNING

Risk or electrical shock

Electrical installation must be in accordance with the National Electric Code

(ANSI/NFPA-70) and/or any other applicable national or local codes.

This symbol identifies a risk of electrical shock.

This symbol identifies a potential hazard. When this symbol

appears, consult the manual for appropriate action.

2.2 Prepare conduit openings

There are six conduit openings in all configurations of the transmitter.

Note

Emerson fits four of the openings with plugs upon shipment.

Quick Start Guide 13

Page 14

Quick Start Guide March 2020

Figure 2-1: Conduit Openings

A. Front panel/keypad

B. Power leads

C. Alarm relay leads

D. Sensor 1 cable

E. 4-20 mA/HART®/Profibus® leads

F. Sensor 2 cable

G. Spare opening

Note

Always use proper cable gland fittings and plugs for wire and cable

installations.

Conduit openings accept ½-in. (12.7 mm) conduit fittings or PG13.5 cable

glands. To keep the case watertight, block unused openings with Type 4X or

IP66 conduit plugs.

To maintain ingress protection for outdoor use, seal unused conduit holes

with suitable conduit plugs.

14 Emerson.com/Rosemount

Page 15

March 2020 Quick Start Guide

Note

Use watertight fittings and hubs that comply with your requirements.

Connect the conduit hub to the conduit before attaching the fitting to the

transmitter.

Quick Start Guide 15

Page 16

Quick Start Guide March 2020

3 Wire

3.1 General wiring information

The transmitter is easy to wire.

The front panel is hinged at the bottom. The panel swings down for easy

access to the wiring locations.

3.1.1 Removable connectors and signal input boards

The transmitter uses removable signal input boards and communication

boards for ease of wiring and installation.

You can remove each of the signal boards either partially or completely from

the enclosure for wiring. The transmitter has three slots for placement of up

to two signal input boards and one communication board.

Slot 1 - left Slot 2 - center Slot 3 - right

Profibus® board Signal board 1 Signal board 2

3.1.2 Signal input boards

Slots 2 and 3 are for signal input measurement boards.

Procedure

1. Wire the sensor leads to the measurement board following the lead

locations marked on the board.

2. Carefully slide the wired board fully into the enclosure slot and take

up the excess sensor cable through the cable gland.

3. Tighten the cable gland nut to secure the cable and ensure a sealed

enclosure.

Note

For the purpose of replacing factory-installed signal input boards,

Rosemount is the sole supplier.

3.1.3 Digital communication boards

HART® digital communication is standard on the transmitter. HART versions

5 and 7 are available on the transmitter and can be switched using the local

keypad. A Profibus® DP communication board is available as an option for

transmitter communication with a host.

HART communications support Bell 202 digital communications over an

analog 4-20 mA current output. Profibus DP is an open communications

protocol which operates over a dedicated digital line to the host.

16 Emerson.com/Rosemount

Page 17

March 2020 Quick Start Guide

3.1.4 Alarm relays

Emerson supplies four alarm relays with the switching power supply (85 to

264 Vac, 03 order code) and the 24 Vdc power supply (20 - 30 Vdc, 02 order

code). You can use all relays for process measurement(s) or temperature.

You can also configure any relay as a fault alarm instead of a process alarm.

In addition, you may configure any relay independently and program it to

activate pumps or control valves.

As process alarms, alarm logic (high or low activation or USP*) and

deadband are user-programmable. Customer-defined failsafe operation is

supported as a programmable menu function to allow all relays to be

energized or not energized as a default condition upon powering the

transmitter. You may program the USP* alarm to activate when the

conductivity is within a user-selectable percentage of the limit. USP*

alarming is available only when a contacting conductivity measurement

board is installed.

3.2 HART® current output wiring

Emerson ships all instruments with four 4-20 mA analog outputs.

Wire the relay leads on each of the independent relays to the correct

position on the main board using the lead markings (+/positive, -/negative)

on the board. Emerson provides male mating connectors with each unit.

3.3 Wire sensor to transmitter

Procedure

1. Wire the correct sensor leads to the main board using the lead

locations marked directly on the board.

2. Carefully slide the wired board fulling into the enclosure slot and take

up the excess sensor cable through the cable gland.

CAUTION

Keep sensor and output signal wiring separate from loop power

wiring. Do not run sensor and power wiring in the same conduit or

close together in a cable tray.

Quick Start Guide 17

Page 18

Quick Start Guide March 2020

Figure 3-1: Power Wiring for 24 Vdc Power Supply (02 Order Code) PN

24365-00

A. To main board (ribbon cable)

B. Rosemount 56 DC power supply board PN 24365-00

18 Emerson.com/Rosemount

Page 19

March 2020 Quick Start Guide

Figure 3-2: Power Wiring for 85-264 Vac Power Supply (03 Order Code)

PN 24538-00

A. Earth ground

B. Neutral

C. Line power

D. To main board (ribbon cable)

E. Rosemount 56 AC power supply board PN 24358-00

Quick Start Guide 19

Page 20

Quick Start Guide March 2020

Figure 3-3: Output Wiring for Main PCB PN 24308-00

A. To power supply PCB (ribbon cable)

B. To digital I/O comm. board

C. To sensor 1 signal board

D. To sensor 2 signal board

E. Hinge pin

F. Transmitter main board, CPU PCB PN 24308-00

G. Hinge pin

20 Emerson.com/Rosemount

Page 21

March 2020 Quick Start Guide

For recommended wire entry points, see Figure 2-1.

Figure 3-4: Contacting Conductivity Signal Board and Sensor Cable Leads

Quick Start Guide 21

Page 22

Quick Start Guide March 2020

4 Navigating the display

4.1 User interface

The transmitter has a large display which shows two live measurement

readouts in large digits and up to six additional process variables or

diagnostic parameters concurrently. The display is back-lit, and you can

customize the format to meet your requirements. You can use an alphanumeric keypad, similar to a cell phone keypad, to enter data during

programming and calibration or lengthy tags to describe process points,

sensors, or instrumentation.

22 Emerson.com/Rosemount

Page 23

March 2020 Quick Start Guide

4.2 Instrument keypad

There are three function keys, four navigation keys, and an alpha-numeric

keypad on the instrument keypad.

Function keys

Use the ENTER/MENU key to access menus for programming and calibrating

the instrument as well as retrieving sorted data. Eight top-level menu items

appear when you press ENTER/MENU.

• Calibrate: Calibrate the attached sensor(s) and analog output(s).

• Program: Program outputs, measurement, temperature, and security

codes.

• Hold: Suspend current outputs.

• Display Setup: Program graphic trend display, brightness, main display

format, tags, language, and warnings.

• Data storage and retrieval: Enable data and event storage, download data,

and view events.

• HART® or Profibus®: Program HART and Profibus communication

parameters.

• Time and Date: Set and view real-time clock settings.

• Reset: Reset all instrument settings, calibration settings, or current

outputs to factory defaults.

You can also use the ENTER/MENU key to enter selections or enable

programming and calibration steps.

Use the EXIT key to return to the previous menu level.

Use the INFO key to display detailed instructions and explanations during

programming and calibration procedures. You can also use it to see

troubleshooting tips for all faults and warnings that may occur during

calibration or continuous operation in process.

Navigation keys

The four navigation keys arranged around the ENTER/MENU key operate in

an intuitive manner similar to the navigation keys on a computer keyboard.

During menu operation, use these keys to move the highlighted screen

selection to another adjacent screen item. During tag entry, use the Left key

is used to delete entries during active alpha-numeric character entry.

Alpha-numeric keypad

The alpha-numeric keypad has 12 keys as outlined below.

• Nine keys are alpha-numeric.

Quick Start Guide 23

Page 24

Quick Start Guide March 2020

• One key is a dedicated 1 key.

• One key is a dedicated 0 key.

• One key is a dedicated "." (decimal point) key.

The alpha-numeric keypad operates the same as entries on a mobile phone.

The nine alpha-numeric keys have multiple characters that you can use for

tag entries or during programming and calibration steps. Make character

selections by pressing the key multiple times to toggle the characters that

are available on each key.

4.3 Main display

The transmitter displays one or two primary measurement values, up to six

secondary measurement values, a Fault and Warning banner, alarm relay

flags, and a digital communications icon.

Process measurements

Two process variables are displayed if two signal boards are installed. One

process variable and process temperature are displayed if one signal board is

installed with one sensor. The upper display area shows the Sensor 1 process

reading. The center display area shows the Sensor 2 process reading. For

dual conductivity, you can assign the upper and center display areas to

different process variables as follows:

Process variables for upper display example

Measure 1 Measure 1

% Reject Measure 2

% Pass % Reject

Ratio % Pass

Process variables for center display example

Ratio

Blank

For single input configurations, the upper display area shows the live process

variable, and you can assign the center display area to Temperature or Blank.

Secondary values

Up to six secondary values are shown in display quadrants at the bottom half

of the screen. You can program all six secondary value positions to any

displayable parameter available.

24 Emerson.com/Rosemount

Page 25

March 2020 Quick Start Guide

4.4 Menu system

The menu system is similar to a computer. Press the ENTER/MENU key at

any time to open the top-level menu including Calibration, Hold,

Programming, Display, Data, and HART® functions. To find a menu item, use

the directional navigation keys to highlight a menu item. Press ENTER/

MENU, direct the cursor to the desired operation, and follow the screen

prompts. Press the BACK screen control available on some menu screens to

revert to the immediate previous menu screen. Press the EXIT key to return

to the previous hierarchical menu level.

Fault and Warning banners

If the transmitter detects a problem with itself or the sensor, the Fault

banner (red) and/or Warning banner (yellow) appears at the bottom of the

main display. A fault requires immediate attention. A warning indicates a

problematic condition or an impending failure. For detailed troubleshooting

assistance, press INFO.

Quick Start Guide 25

Page 26

Quick Start Guide March 2020

5 Start up transmitter

Procedure

1. Wire sensor(s) to the signal boards.

See Wire for wiring instructions. Refer to the sensor Quick Start

Guide for additional details. Make current output, alarm relay, and

power connections.

2. Once connections are secured and verified, apply power to the

transmitter.

WARNING

Electrical shock

Electrical installation must be in accordance with the National

Electrical Code (ANSI/NFPA-70) and/or any other applicable national

or local codes.

This symbol identifies a risk of electical shock.

This symbol identifies a potential hazard. When this symbol

appears, consult the manual for appropriate action.

When the transmitter is powered up for the first time, Quick Start

screens appear. Quick Start operating tips are as follows:

a. Window screens appear. The field with the focus appears with

dark blue back-lighting. To edit the field with focus, press

ENTER/MENU.

b. The Time and Date screen to set the real-time clock appears.

To accept the displayed time, press ENTER on Time and date

OK. To change the date and time, press Down to navigate to

Change the time and date.

3. To choose the language, press ENTER/MENU to edit the active field

and scroll to the language of choice. Press ENTER/MENU and then

press Down to highlight NEXT.

The navigation rules for operating the keypad are displayed.

4. Choose the measurement for Sensor 1 and Sensor 2.

Keypad operation guidlines appear to guide you on how to operate

the user interface.

26 Emerson.com/Rosemount

Page 27

March 2020 Quick Start Guide

Note

To edit a field with backlit focus, press ENTER/MENU. To scroll up or

down, use the keys above or below the ENTER key. To move the

cursor left or right, use the keys to the left or right of the ENTER key.

To edit a numeric value including decimal points, use the

alphanumeric keypad and then press ENTER.

Note

Press ENTER to store a setting or value. Press EXIT to leave without

storing changes. Press EXIT during Quick Start to return the display

to the initial startup screen (Select language). To proceed to the next

Quick Start step, use the Right or Down key to hightlight NEXT. Press

ENTER.

After the last step, the main display appears. The current outputs are

assigned to default values before probes are wired to the transmitter.

5. To change output and all settings, press ENTER/MENU from the live

screen. Using the Down and Right keys, select a menu and navigate

to the screen of choice.

6. To return the transmitter to the factory default settings, choose

Reset under the Menu selection screen.

Please call Rosemount Customer Support Center at 1-800-854-8527

if you need further support.

Quick Start Guide 27

Page 28

Quick Start Guide March 2020

6 Product certifications

Rev 1.0

6.1 European Directive information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

6.2 Ordinary location certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

6.3 Installing equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

6.4 USA

6.4.1 FM hazardous locations

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Sensors having exposed electrodes in the process will be used in a

non-flammable liquid only.

28 Emerson.com/Rosemount

FM17US0028X

FM Class 3600:2011

FM Class 3611:2004

FM Class 3810:2005

ANSI/IEC 60529:2004

Non-incendive Class I, Division 2, Groups ABCD

T4 Tamb -10 °C to +60 °C; dust tight

Class II, Division 2, Groups EFG; Class III

Per Drawing 1400667

IP66 enclosure

Page 29

March 2020 Quick Start Guide

6.4.2 CSA hazardous locations

Certificate

Standards

Markings

70173522

CSA Standard C22.2 No. 010, CSA Standard C22.2 No.

0.4-04, CSA Standard C22.2 No. 25-1966, CSA Standard

C22.2 No. 94-M1991, CSA Standard C22.2 No. 142M1987, CSA Standard C22.2 No. 213-M1987, CSA

Standard C22.2 No. 60529:05 (reaffirmed 2015),

ANSI/IEC 60529-2004 (reaffirmed 2011), ANSI/ISA

12.12.01: 2007, UL Standard No. 50, 11th edition, UL

Standard No. 508, 17th edition

Class I, Division 2, Groups A,B, C, and D;

Class II, Division 2, Groups E, F, and G; Class III

Maximum ambient 60 °C T4 Type 4X enclosure, IP66

6.4.3 UL ordinary locations

Certificate

Standards

Markings

20160921-E207618

UL 61010-1, CAN/CSA C22.2 No. 61010-1

6.5 Canada

6.5.1 CSA hazardous locations

Certificate

Standards

Markings

Quick Start Guide 29

70173522

CSA Standard C22.2 No. 010, CSA Standard C22.2 No.

0.4-04, CSA Standard C22.2 No. 25-1966, CSA Standard

C22.2 No. 94-M1991, CSA Standard C22.2 No. 142M1987, CSA Standard C22.2 No. 213-M1987, CSA

Standard C22.2 No. 60529:05 (reaffirmed 2015),

ANSI/IEC 60529-2004 (reaffirmed 2011), ANSI/ISA

12.12.01: 2007, UL Standard No. 50, 11th edition, UL

Standard No. 508, 17th edition

Class I, Division 2, Groups A,B, C, and D;

Class II, Division 2, Groups E, F, and G; Class III

Maximum ambient 60 °C T4 Type 4X enclosure, IP66

Page 30

Quick Start Guide March 2020

A Declaration of Conformity

Note

Please see website for most recent Declaration.

30 Emerson.com/Rosemount

Page 31

March 2020 Quick Start Guide

Quick Start Guide 31

Page 32

Quick Start Guide March 2020

B China RoHS table

32 Emerson.com/Rosemount

Page 33

March 2020 Quick Start Guide

Quick Start Guide 33

Page 34

Quick Start Guide March 2020

34 Emerson.com/Rosemount

Page 35

March 2020 Quick Start Guide

Quick Start Guide 35

Page 36

GLOBAL HEADQUARTERS

6021 Innovation Blvd.

Shakopee, MN 55379

+1 866 347 3427

+1 952 949 7001

RMTNA.RCCPO@Emerson.com

*00825-0100-3056*

Quick Start Guide

00825-0100-3056, Rev. AB

March 2020

NORTH AMERICA

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

RMTNA.RCCPO@Emerson.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box

17033

+971 4 811 8100

+971 4 886 5465

RMTNA.RCCPO@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RMTNA.RCCPO@Emerson.com

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

RMTNA.RCCPO@Emerson.com

©

2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service

mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies.

All other marks are the property of their

respective owners.

Loading...

Loading...