Quick Start Guide

00825-0500-4408, Rev AA

October 2017

Rosemount™ 5408 and 5408:SIS Level

Transmitters

Process Seal Antenna

October 2017

2

Quick Start Guide

1.0 About this guide

This Quick Start Guide provides basic guidelines for the Rosemount 5408 and

5408:SIS Level Transmitters.

Refer to the Rosemount 5408 and 5408:SIS Reference Manual

for more

instructions. The manual and this guide are also available electronically on

Emerson.com/Rosemount

.

Failure to follow safe installation and service guidelines could result in death or serious injury.

Make sure the transmitter is installed by qualified personnel and in accordance with applicable code of

practice.

Use the equipment only as specified in this guide and the Rosemount 5408 and 5408:SIS Reference Manual

.

For installations in hazardous locations, the transmitter must be installed according to the Rosemount 5408

and 5408:SIS Product Certifications

document and System Control Drawing (D7000002-885).

Repair, e.g. substitution of components etc. may jeopardize safety and is under no circumstances allowed.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the appropriate hazardous

locations certifications.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

Do not remove the transmitter covers in explosive atmospheres when the circuit is alive.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals. High voltage that may be present on leads can cause

electrical shock.

Make sure the main power to the transmitter is off and the lines to any other external power source are

disconnected or not powered while wiring the transmitter.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully. If the process seal is damaged, gas might escape from

the tank.

Hot surfaces

The flange and process seal may be hot at high process temperatures.

Allow to cool before servicing.

Quick Start Guide

3

October 2017

2.0 Confirm approval type

For hazardous locations transmitters labeled with multiple approval types:

Permanently mark the checkbox of the selected approval type(s).

Contents

Confirm approval type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Mount the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Align transmitter head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Adjust display orientation (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Prepare the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Connect wiring and power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Configure transmitter using Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

October 2017

4

Quick Start Guide

3.0 Mount the transmitter

3.1 Installation procedure

Flanged version

Tri Clamp version

page 5

page 7

Quick Start Guide

5

October 2017

3.2 Flanged version

Step 1: Lower the transmitter into the nozzle

Note

Be careful not to scratch or otherwise damage the PTFE sealing.

PTFE sealing

October 2017

6

Quick Start Guide

Step 2: Tighten the bolts and nuts

Note

Re-tighten after 24 hours and again after the first temperature cycle.

Check at regular intervals and re-tighten if necessary.

Step 3: Align the transmitter head (see page 8)

Table 1. Torque Value, lb-ft (N-m)

(1)(2)

1. The conditions used for the calculation are: Standard mating metal flange, A193 B8M Cl.2 / A4-70

bolt material, and a friction coefficient of μ=0.16.

2. Low strength bolt and non-metallic mating flange may require lower tightening torque.

Process

connection size

Process connection rating

ASME B16.5 EN1092-1 JIS B2220

Class 150 Class 300 PN6 PN10/PN16 PN25/PN40 10K

2-in./DN50/50A 29 (40) 52 (70) 15 (20) 26 (35) 29 (40) 18 (25)

3-in./DN80/80A 33 (45) 48 (65) 37 (50) 37 (50) 41 (55) 22 (30)

4-in./DN100/100A 59 (80) 52 (70) 37 (50) 37 (50) 74 (100) 26 (35)

Quick Start Guide

7

October 2017

3.3 Tri Clamp version

Step 1: Lower the transmitter into the nozzle

Note

Be careful not to scratch or otherwise damage the PTFE sealing.

Step 2: Tighten the clamp

Tighten the clamp to the recommended torque (see the manufacturer’s

instruction manual).

Step 3: Align the transmitter head (see page 8)

PTFE sealing

October 2017

8

Quick Start Guide

4.0 Align transmitter head

Open tank

Align the marking on sensor module toward the tank wall.

Still pipe

Align the external ground screw toward the holes of the still pipe.

Chamber

Align the external ground screw toward the process connections.

Quick Start Guide

9

October 2017

Step 1: Loosen the nut slightly and turn the transmitter

Step 2: Verify transmitter is properly aligned

See page 8 for direction.

Step 3: Tighten the nut

Torque 355 in-lb (40 N-m)

60 mm

October 2017

10

Quick Start Guide

5.0 Adjust display orientation (optional)

To improve field access to wiring or to better view the optional LCD display:

1. Loosen the set screw until the transmitter housing can rotate smoothly.

2. First, rotate the housing clockwise to the desired location. If the desired

location cannot be achieved due to thread limit, rotate the housing

counterclockwise to the desired location (up to 360° from thread limit).

3. Re-tighten the set screw.

Figure 1. Rotate the Transmitter Housing

H3/32 in.

Torque 30 in-lb (3 N-m)

Quick Start Guide

11

October 2017

6.0 Prepare the electrical connections

Cable selection

Use 24-14 AWG wire. Twisted pairs and shielded wiring are recommended for

environments with high EMI (electromagnetic interference).

Two wires can be safely connected to each terminal screw.

Cable gland/conduit

For explosion-proof/flameproof installations, only use cable glands or conduit

entry devices certified explosion-proof or flameproof.

Power supply

The transmitter operates on 12-42.4 Vdc (12-30 Vdc in Intrinsically Safe

installations) at the transmitter terminals.

Power consumption

Max. 1 W, current max. 23 mA

Load limitations

For HART® communication, a minimum loop resistance of 250 is required.

Maximum loop resistance is determined by the voltage level of the external

power supply, as described by Figure 2.

Figure 2. Load Limitations

42.4

2417.8

12

0

400

200

1000

800

600

1200

1400

20 30 40 50

521

250

782

1322

External Power Supply Voltage (Vdc)

Loop Resistance (Ohms)

Maximum Loop Resistance = 43.5 * (External Power Supply Voltage - 12)

October 2017

12

Quick Start Guide

7.0 Connect wiring and power up

Step 1: Verify that the power supply is disconnected

Step 2: Remove the cover

Step 3: Remove the plastic plugs

Step 4: Pull the cable through the cable gland/conduit

½-14 NPT M20 x 1.5

Identification of thread size and type

(No marking =½-14 NPT)

Quick Start Guide

13

October 2017

Step 5: Connect the cable wires

Figure 3. Transmitter Wiring

A. Field Communicator

B. Approved IS barrier (for Intrinsically Safe installations only)

C. HART modem

D. Load resistance (≥250

E. Current meter

F. Power supply

Torq ue 7 in-lb (0.8 N - m )

A

C

B

E

F

-

+

-

+

D

123

456

7809

October 2017

14

Quick Start Guide

Step 6: Ensure proper grounding

Make sure grounding is done according to national and local electrical codes.

Failure to do so may impair the protection provided by the equipment.

Transmitter case grounding

The most effective grounding method is direct connection to earth ground with

minimal impedance. There are two grounding screw connections provided.

Figure 4. Ground Screws

A. Internal ground screw

B. External ground screw

Signal cable shield grounding

Make sure the instrument cable shield is:

Trimmed close and insulated from touching the transmitter housing.

Connected to the next shield if cable is routed through a junction box.

Connected to a good earth ground at the power supply end.

Figure 5. Cable Shield

A.B.Insulate shield

Minimize distance

C.D.Trim shield and insulate

Connect shield back to the power supply ground

A

B

B

BA

CC

C

D

Quick Start Guide

15

October 2017

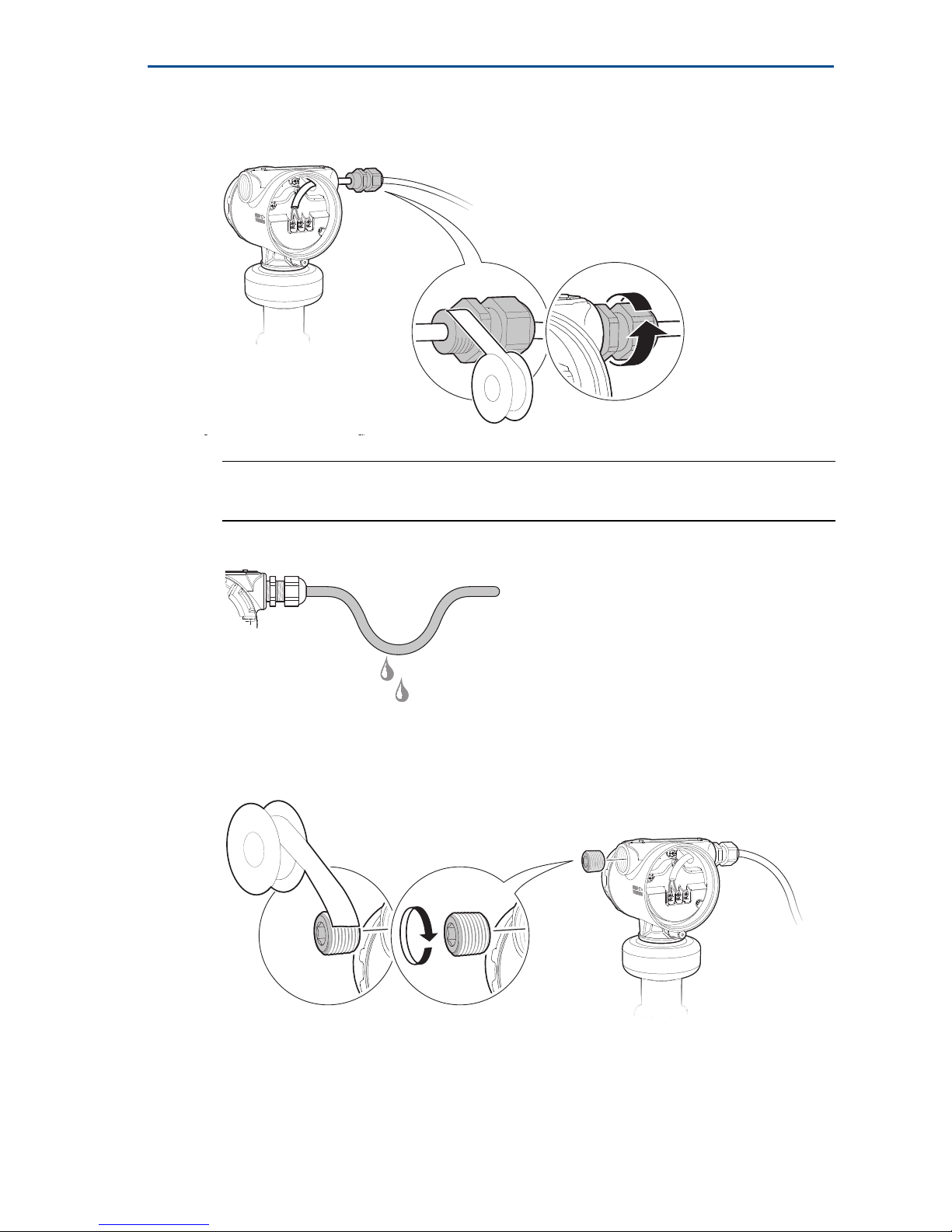

Step 7: Tighten the cable gland

Apply PTFE tape or other sealant to the threads.

Note

Arrange the wiring with a drip loop.

Step 8: Seal any unused port with the enclosed metal plug

Apply PTFE tape or other sealant to the threads.

October 2017

16

Quick Start Guide

Step 9: Attach and tighten the covers

1. Verify the cover jam screws are completely threaded into the housing.

2. Attach and tighten the covers. Make sure the covers are fully engaged.

3. Turn the jam screw counterclockwise until it contacts the cover.

Required for explosion-proof/flameproof installations only.

4. Turn the jam screw an additional ½ turn counterclockwise to secure the

cover.

Step 10: Connect the power supply

It may take up to 15 seconds before the LCD display lights up.

H2.5 mm

Cover jam screw

(one per side)

Quick Start Guide

17

October 2017

8.0 Configure transmitter using Guided Setup

The transmitter can easily be configured by using a PC with the Rosemount

Radar Master Plus software (launched through the Instrument Inspector™

Application), a Field Communicator, the AMS Device Manager, or any other

Device Descriptor (DD) or Field Device Integration (FDI) compatible host

system. Rosemount Radar Master is the recommended tool for configuration.

Rosemount Radar Master Plus

1. Start Instrument Inspector Application.

2. Under HART, double-click the device icon.

3. From the Overview screen, select Rosemount Radar Master Plus

4. Under Configure, select Guided Setup and follow the on-screen instructions.

AMS Device Manager

1. Start AMS Device Manager.

2. Select View > Device Connection View.

3. In the Device Connection View, double-click the HART modem icon.

4. Double-click the device icon.

5. From the Home screen, select Configure > Guided Setup.

6. Select Basic Setup and follow the on-screen instructions.

Field Communicator

1. Turn on the Field Communicator.

2. From the Main Menu, tap the HART symbol. The Field Communicator now

connects to the device.

3. From the Home screen, select Configure > Guided Setup.

4. Select Basic Setup and follow the on-screen instructions.

Get the latest FDI Device Package

The FDI Package or DD is typically installed together with the configuration tool.

Download the latest FDI Package at:

Emerson.com/RosemountRadarMasterPlus

Download the latest DD at:

EmersonProcess.com/devicefiles

Learn more

Visit Emerson.com/Rosemount to download the Rosemount 5408 and 5408:SIS

Reference Manual.

October 2017

18

Quick Start Guide

Quick Start Guide

19

October 2017

Manufactured by

Emerson Automation Solutions

Rosemount Tank Radar AB

Layoutvägen 1

S-435 33 Mölnlycke

Sweden

+46 31 337 00 00

+46 31 25 30 22

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/ user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/Terms-of-Use

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Instrument Inspector, Rosemount, and Rosemount logotype are

trademarks of Emerson.

HART is a registered trademark of the FieldComm Group.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0500-4408*

Quick Start Guide

00825-0500-4408, Rev AA

October 2017

Loading...

Loading...