Page 1

Reference Manual

00809-0100-4026, Rev HA

November 2014

Rosemount 5400 Series

Superior Performance Two-Wire Non-Contacting

Radar Level Transmitter

Page 2

Page 3

iii

Reference Manual

00809-0100-4026, Rev HA

November 2014

Rosemount 5400 Series

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Emerson Process Management has two toll-free assistance

numbers.

Customer Central:

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe / Middle East / Africa - 49 (8153) 9390

North American Response Center:

Equipment service needs.

1-800-654-7768 (24 hours a day — includes Canada)

For equipment service or support needs outside the United States, contact your local

Emerson Process Management representative.

There are no health hazards from the Rosemount 5400 Series transmitter. The microwave

power density in the tank is only a small fraction of the allowed power density according to

international standards.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

This product is designed to meet FCC and R&TTE requirements.

This device complies with part 15 of the FCC rules. Operation is subjec t to the following t wo

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Page 4

iv

Reference Manual

00809-0100-4026, Rev HA

November 2014

Page 5

v

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

1Section 1: Introduction

1.1 Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Product recycling/ disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2Section 2: Transmitter Overview

2.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.3 System architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.4 Process characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5 Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.6 Antenna selection guide/measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3Section 3: Mechanical Installation

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3 Mounting considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.1 Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.2 Special considerations in solids applications . . . . . . . . . . . . . . . . . . . . . . . . .24

3.3.3 Mounting in pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.3.4 Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.3.5 Nozzle considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.3.6 Nozzle recommendations and requirements . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.7 Service space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.3.8 Beamwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.3.9 Vessel characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.3.10Disturbing objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.3.11Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.4.1 Cone antenna flange connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.4.2 Process seal antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.4.3 Rod antenna threaded connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.4.4 Rod antenna flanged connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.4.5 Tri-Clamp™ tank connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Contents

Page 6

vi

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

3.4.6 Bracket mounting on wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

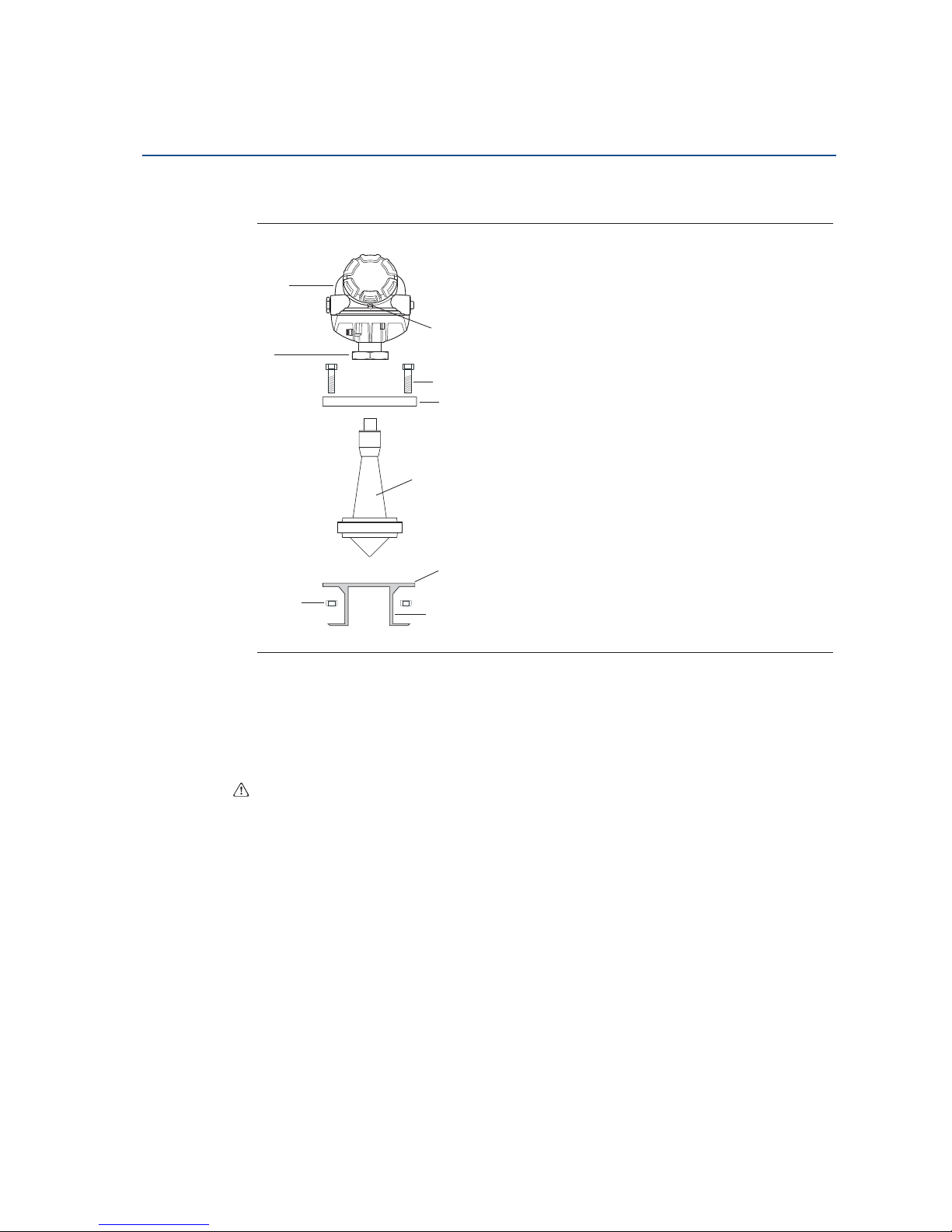

3.4.7 Bracket mounting on pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4Section 4: Electrical Installation

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.2 Wiring and power supply requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.3 Cable/conduit entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.3.1 Conduit electrical connector wiring (using minifast

®

). . . . . . . . . . . . . . . . .45

4.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.5 Cable selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.6 Hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.7 External circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.7.1 Connecting the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.8 HART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.8.1 Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.8.2 Load limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.8.3 Non-intrinsically safe power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.8.4 Intrinsically safe power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.8.5 Type N approvals: non-sparking / energy-limited power supply . . . . . . . .53

4.8.6 Transient protection terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.9 F

OUNDATION fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.9.1 Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.9.2 Non-intrinsically safe power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.9.3 Intrinsically safe power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.9.4 Type N approvals: non-sparking / energy-limited power supply . . . . . . . .59

4.10HART to Modbus Converter (HMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.10.1Connecting the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.10.2Connection terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.10.3RS-485 bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.10.4Installation cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.10.5External HART devices (slaves). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

4.11Establish HART communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

4.11.1Connect to the MA/MB terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

4.11.2Connect to the HART terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.12Optional devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.12.1Tri-Loop™ HART to analog converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.12.2751 Field Signal Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

4.12.3Smart Wireless THUM

™

Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Page 7

vii

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

5Section 5: Basic Configuration/Start-up

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

5.2.1 Basic configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

5.2.2 Configuration tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

5.3 Basic configuration parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.3.1 Measurement units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.3.2 Tank geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.3.3 Process conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

5.3.4 Volume configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

5.3.5 Analog output (HART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

5.3.6 Level and distance calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

5.3.7 Echo tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

5.3.8 ATC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

5.4 Basic configuration using RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

5.4.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

5.4.2 Help in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.4.3 Installing the RRM software for HART communication . . . . . . . . . . . . . . . .85

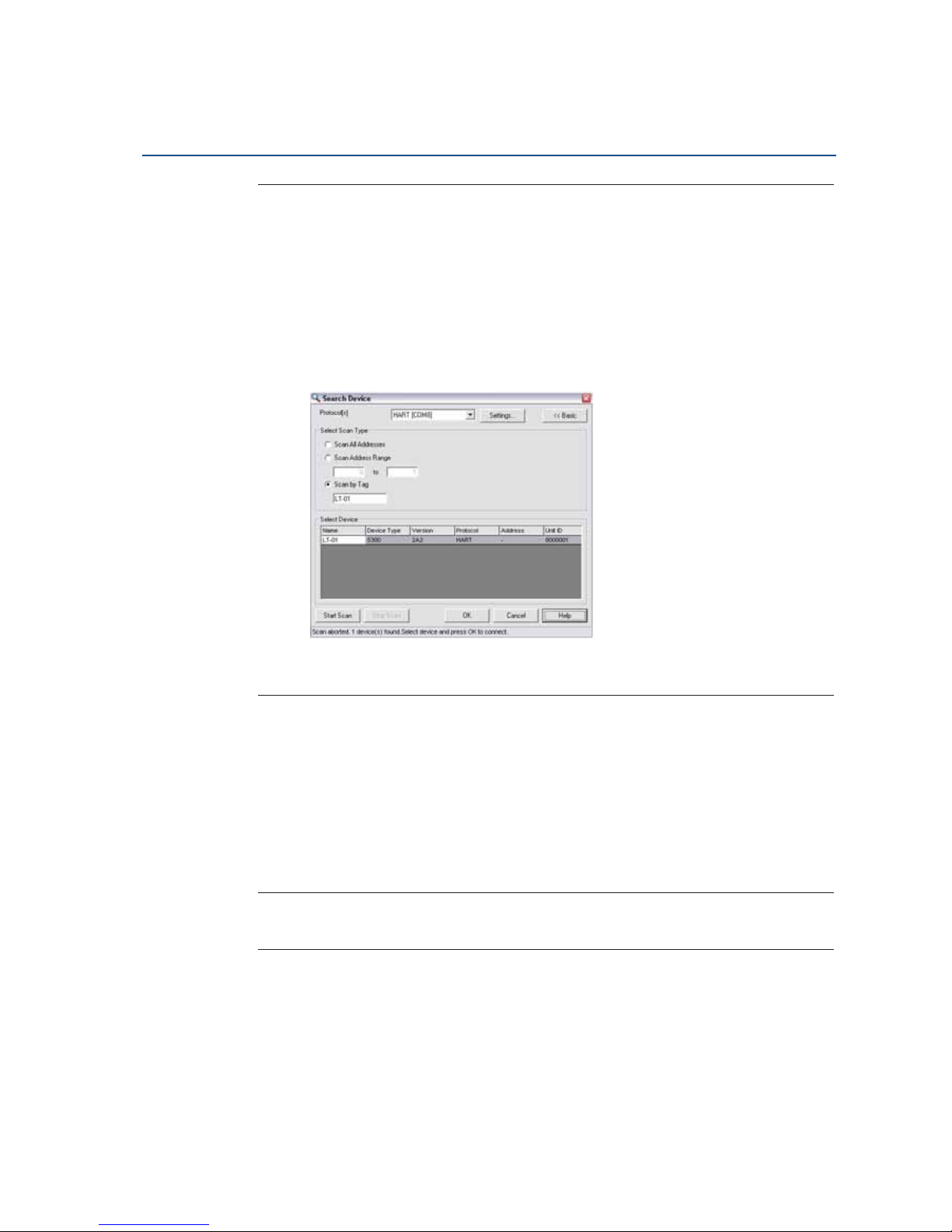

5.4.4 Specifying the COM port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

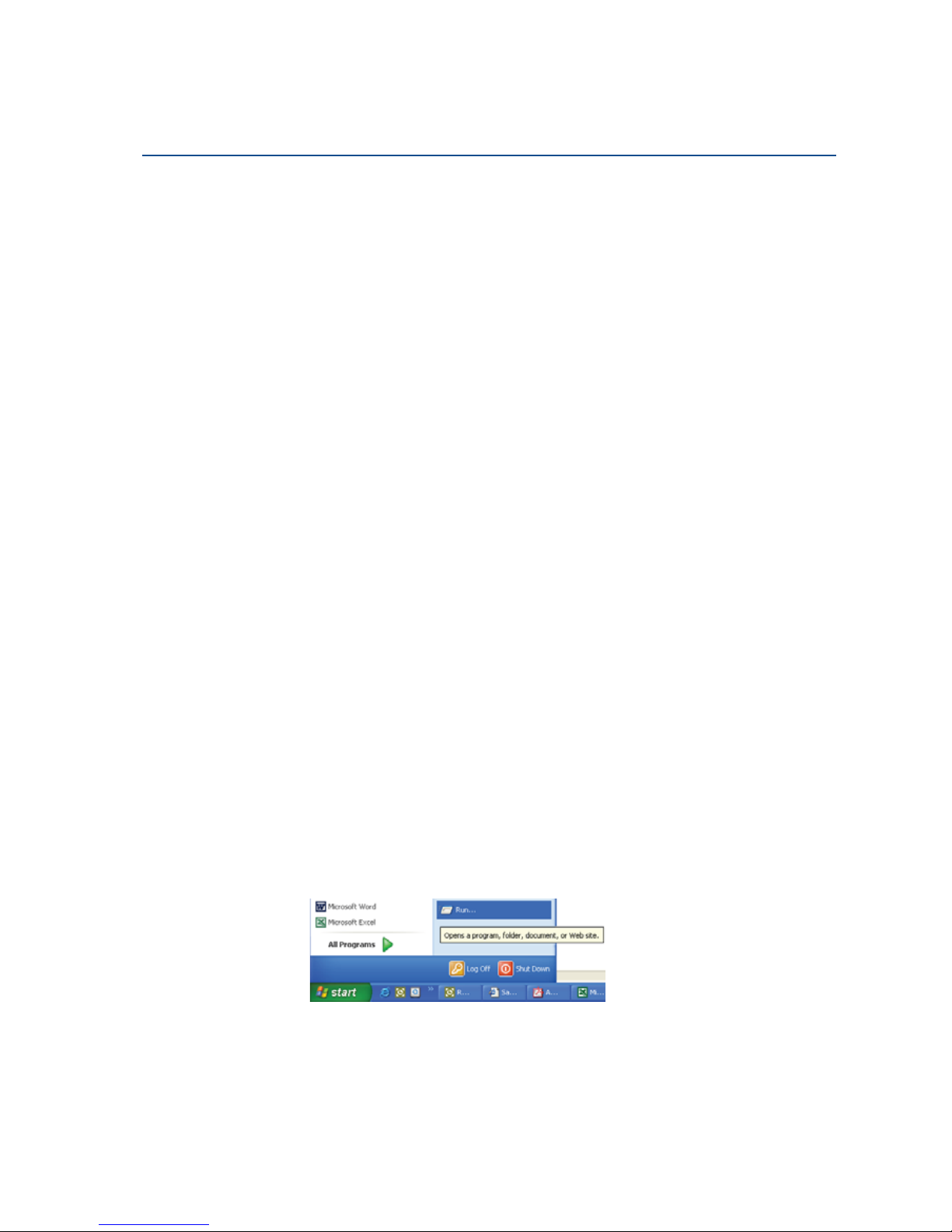

5.4.5 To set the COM port buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

5.4.6 Specifying measurement units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

5.4.7 Installing the RRM software for F

OUNDATION fieldbus . . . . . . . . . . . . . . . . . .88

5.4.8 Specifying measurement units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

5.4.9 Using the Setup functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5.4.10Guided setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

5.4.11Using the Setup functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.5 Configuration using a Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.7 Basic configuration using AMS Suite. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.8 Configuration using DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.8.1 Advanced configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.9 F

OUNDATION fieldbus overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5.9.1 Assigning device tag and node address . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.9.2 Foundation fieldbus block operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.10Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.10.1Radar level transmitter - level value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

5.10.2Radar level transmitter - level value in percent (%). . . . . . . . . . . . . . . . . . 116

5.11Tri-Loop™ HART to Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

5.12HART multidrop configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Page 8

viii

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

6Section 6: Operation

6.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.2 Viewing measurement data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.2.1 Using the display panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.2.2 Specifying display panel variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.2.3 Viewing measurement data in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

6.2.4 Viewing measurement data in AMS Suite and DeltaV . . . . . . . . . . . . . . . 125

6.3 LCD display error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6.4 LED error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

7Section 7: Service and Troubleshooting

7.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

7.2 Troubleshooting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

7.3 Service overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

7.3.1 Analyzing the measurement signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

7.3.2 Surface pulse not found. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.3.3 Registration of false echoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.3.4 Using the Echo Curve Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

7.3.5 Using the Echo Curve Analyzer with a Field Communicator . . . . . . . . . . 140

7.4 Analog Output calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

7.5 Logging measurement data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

7.6 Backing up the transmitter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7.7 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

7.8 Configuration report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.9 Viewing input and holding registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7.10Reset to factory settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.11Surface search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

7.12Using the Simulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

7.13Write protecting a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.14Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

7.14.1Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

7.14.2Device status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

7.14.3Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7.14.4Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

7.14.5Measurement status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

7.14.6Volume calculation status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7.14.7Analog Output status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

7.14.8Application errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Page 9

ix

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

7.15Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.15.1Resource block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

7.15.2Transducer block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7.15.3Analog Input (AI) function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8Section 8: Safety Instrumented Systems (4-20 mA Only)

8.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

8.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

8.2.1 Applicable models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

8.2.2 Skill level of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

8.3 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

8.4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

8.5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8.5.1 Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8.5.2 Alarm and saturation levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8.5.3 Amplitude threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.5.4 Write protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.5.5 Site acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.6 Operation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.6.2 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.7 References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.7.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.7.2 Failure rate data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.7.3 Useful lifetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.8 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.9 Terms and definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

AAppendix A: Reference Data

A.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

A.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

A.1.2 4-20 mA HART

®

(output option code H) . . . . . . . . . . . . . . . . . . . . . . . . . . 178

A.1.3 Foundation™ fieldbus (output option code F) . . . . . . . . . . . . . . . . . . . . . 181

A.1.4 RS-485 with Modbus communication

(output option code M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

A.1.5 Display and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

A.1.6 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

A.1.7 Temperature and pressure limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Page 10

x

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

A.2 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

A.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

A.2.2 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

A.2.3 Beam angle and beam width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

A.2.4 Transition zone and near zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

A.2.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

A.3 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

A.3.1 Material selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

A.3.2 Housing and closure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

A.3.3 Engineered solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

A.3.4 Tank connection and antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

A.4 Dimensional drawings and mechanical properties . . . . . . . . . . . . . . . . . . . . . . . 200

A.4.1 Rosemount 5402 and 5401 with SST Cone Antenna

(Model Code: 2S-8S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

A.4.2 Rosemount 5402 and 5401 with Protective Plate Cone Antenna

(Model Code: 2H-8H, 2M-8M, and 2N-8N) . . . . . . . . . . . . . . . . . . . . . . . . 201

A.4.3 Rosemount 5401 with Rod Antenna (Model Code: 1R-4R). . . . . . . . . . . 202

A.4.4 Rosemount 5402 with Process Seal Antenna

(Model Code: 2P-4P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

A.4.5 Bracket mounting (Model Code: BR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

A.4.6 Process connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

A.5 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

BAppendix B: Product Certifications

B.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

B.2 European Directive information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B.3 FCC and ICC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B.4 Safety Instrumented Systems (SIS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B.5 Hazardous locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

B.5.1 North-American certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

B.5.2 Canadian Standards Association (CSA) Approvals . . . . . . . . . . . . . . . . . . 221

B.5.3 European certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

B.5.4 IECEx Approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

B.5.5 EAC certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

B.5.6 Brazilian certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

B.5.7 Chinese certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

B.5.8 Japanese certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

B.5.9 Other certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

B.5.10Canadian Registration Number (CRN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Page 11

xi

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

B.6 Approval drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

CAppendix C: Advanced Configuration

C.1 Tank geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C.1.1 Distance offset (G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C.1.2 Minimum level offset (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

C.1.3 Hold off distance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

C.1.4 Calibration distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

C.2 Advanced analog output settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

C.3 Advanced transmitter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

C.3.1 Antenna type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

C.3.2 Empty tank handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

C.3.3 Full tank handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

C.3.4 Double bounce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

C.3.5 Surface echo tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

C.3.6 Filter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

C.4 Advanced functions in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

C.4.1 Empty tank handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

C.4.2 Full tank handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

C.4.3 Double bounce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

C.4.4 Surface echo tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

C.4.5 Hold off setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

DAppendix D: Performing Proof Test

D.1 Performing proof test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

D.2 Field communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

D.3 RRM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

D.4 AMS Suite. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

EAppendix E: Level Transducer Block

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

E.1.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

E.1.2 Channel definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

E.2 Parameters and descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

E.3 Supported units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

E.3.1 Unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

E.4 Diagnostics device errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Page 12

xii

Reference Manual

00809-0100-4026, Rev HA

Contents

November 2014

Contents

FAppendix F: Register Transducer Block

F. 1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

F. 1 .1 Register access transducer block parameters . . . . . . . . . . . . . . . . . . . . . . 265

GAppendix G: Advanced Configuration Transducer Block

G.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

G.1.1 Advanced configuration transducer block parameters . . . . . . . . . . . . . . 269

HAppendix H: Resource Block

H.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

H.2 Parameters and descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

H.2.1 PlantWeb® alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

H.2.2 Alarm priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

H.2.3 Recommended actions for PlantWeb alerts . . . . . . . . . . . . . . . . . . . . . . . 282

IAppendix I: Analog-Input Block

I.1 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

I.2 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

I.3 Signal conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

I.4 Block errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

I.5 Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

I.6 Alarm detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

I.6.1 Status handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

I.7 Configure the AI block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Page 13

1

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Section 1 Introduction

Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Product recycling/ disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

1.1 Manual overview

The sections in this manual provide installation, configuration, and maintenance information for

the Rosemount 5400 Series Radar Level Transmitter. The sections are organized as follows:

Section 2: Transmitter Overview

Theory of operation

Description of the transmitter

Process and vessel characteristics

Section 3: Mechanical Installation

Installation procedure

Mounting considerations

Mounting

Section 4: Electrical Installation

Cable/conduit entries

Grounding

Cable selection

Hazardous areas

External circuit breaker

Power requirements

Connecting the transmitter

Non-intrinsically safe power supply

Intrinsically safe power supply

Optional devices

Page 14

2

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Section 5: Basic Configuration/Start-up

Configuration instructions

Configuration using the Rosemount Radar Master (RRM) software

Configuration using a Field Communicator

Configuration using AMS

®

Suite

Configuration using DeltaV™

FOUNDATION

TM

fieldbus overview

Section 6: Operation

Viewing measurement data with a display panel

Viewing measurement data in RRM

Viewing measurement data in AMS Suite and DeltaV

Section 7: Service and Troubleshooting

Tro ub le sh oo ti ng

Error and warning codes

Communication errors

Section 8: Safety Instrumented Systems (4-20 mA Only)

Functional specifications

Installation

Configuration

Operation and maintenance

Spare parts

Appendix A: Reference Data

Specifications

Dimensional drawings and mechanical properties

Process connections

Ordering information

Appendix B: Product Certifications

Examples of labels

European ATEX Directive information

FM approvals

CSA approvals

IECEx approvals

TIIS approval

NEPSI approvals

INMETRO approvals

Approval drawings

Page 15

3

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Appendix C: Advanced Configuration

Advanced tank geometry

Advanced transmitter settings

Advanced functions in RRM

Appendix D: Performing Proof Test

Describes the process of performing proof test

Appendix E: Level Transducer Block

Describes the operation and parameters of the Level Transducer Block

Appendix F: Register Transducer Block

Describes the operation and parameters of the Register Transducer Block

Appendix G: Advanced Configuration Transducer Block

Describes the operation and parameters of the Advanced Configurations Transducer

Block

Appendix H: Resource Block

Describes the operation and parameters of the Resource Block

Appendix I: Analog-Input Block

Describes the operation and parameters of the Analog-Input function block

1.2 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Within the United States, call the Emerson Process Management Instrument and Valves

Response Center using the 1-800-654-RSMT (7768) toll-free number. This center, available 24

hours a day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. If the product being returned was exposed to a

hazardous substance as defined by Occupational Safety and Health Administration (OSHA),

a copy of the required Material Safety Data Sheet (MSDS) for each hazardous substance

identified must be included with the returned goods.

Page 16

4

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Emerson Process Management Instrument and Valves Response Center representatives will

explain the additional information and procedures necessary to return goods exposed to

hazardous substances.

1.3 Product recycling/ disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

1.4 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the safety messages listed at the beginning of each

section before performing an operation preceded by this symbol.

Page 17

5

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Failure to follow safe installation and service guidelines could result in death or

serious injury.

Make sure the transmitter is installed by qualified personnel and in accordance with

applicable code of practice.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any services other than those contained in this manual unless you are

qualified.

Any substitution of non-authorized parts or repair, other than exchanging the

complete transmitter head or antenna assembly, may jeopardize safety and is

prohibited.

Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize safety.

Unauthorized changes that interfere with the integrity of the welds or flanges, such as

making additional perforations, compromise product integrity and safety. Equipment

ratings and certifications are no longer valid on any products that have been damaged

or modified without the prior written permission of Emerson Process Management.

Any continued use of product that has been damaged or modified without prior

written authorization is at the customer's sole risk and expense.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations specifications. See “Product Certifications” on

page 217 in this manual.

To prevent ignition of flammable or combustible atmospheres, disconnect power

before servicing.

In an Explosion-proof/Flameproof installation, do not remove the transmitter cover

when power is applied to the unit.

Before connecting a HART

®

,

FOUNDATION™ fieldbus, or Modbus® based communicator

in an explosive atmosphere, make sure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

To avoid process leaks, only use O-rings designed to seal with the corresponding

flange adapter.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

Make sure the main power to the Rosemount 5400 Series transmitter is off and the

lines to any other external power source are disconnected or not powered while wiring

the transmitter.

Antennas with non-conducting surfaces.

Antennas with non-conducting surfaces (e.g. Rod antenna and Process Seal antenna)

may generate an ignition-capable level of electrostatic charge under extreme

conditions.

Therefore, when the antenna is used in a potentially explosive atmosphere,

appropriate measures must be taken to prevent electrostatic discharge.

Page 18

6

Reference Manual

00809-0100-4026, Rev HA

Section 1: Introduction

November 2014

Introduction

Page 19

7

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

Section 2 Transmitter Overview

Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

System architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Process characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Antenna selection guide/measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

2.1 Theory of operation

The Rosemount 5400 Series Radar Transmitter is a smar t, two-wire continuous level transmitter.

A 5400 transmitter is installed at the top of the tank and emits short microwave pulses towards

the product surface in the tank. When a pulse reaches the surface, part of the energy is reflected

back to the antenna for subsequent processing by the transmitter electronics. The time

difference between the transmitted and reflected pulse is detected by a micro-processor and is

converted into a distance, which calculates the level.

The product level is related to the tank height and the measured distance by the following

expression:

Level = Tank Height - Distance

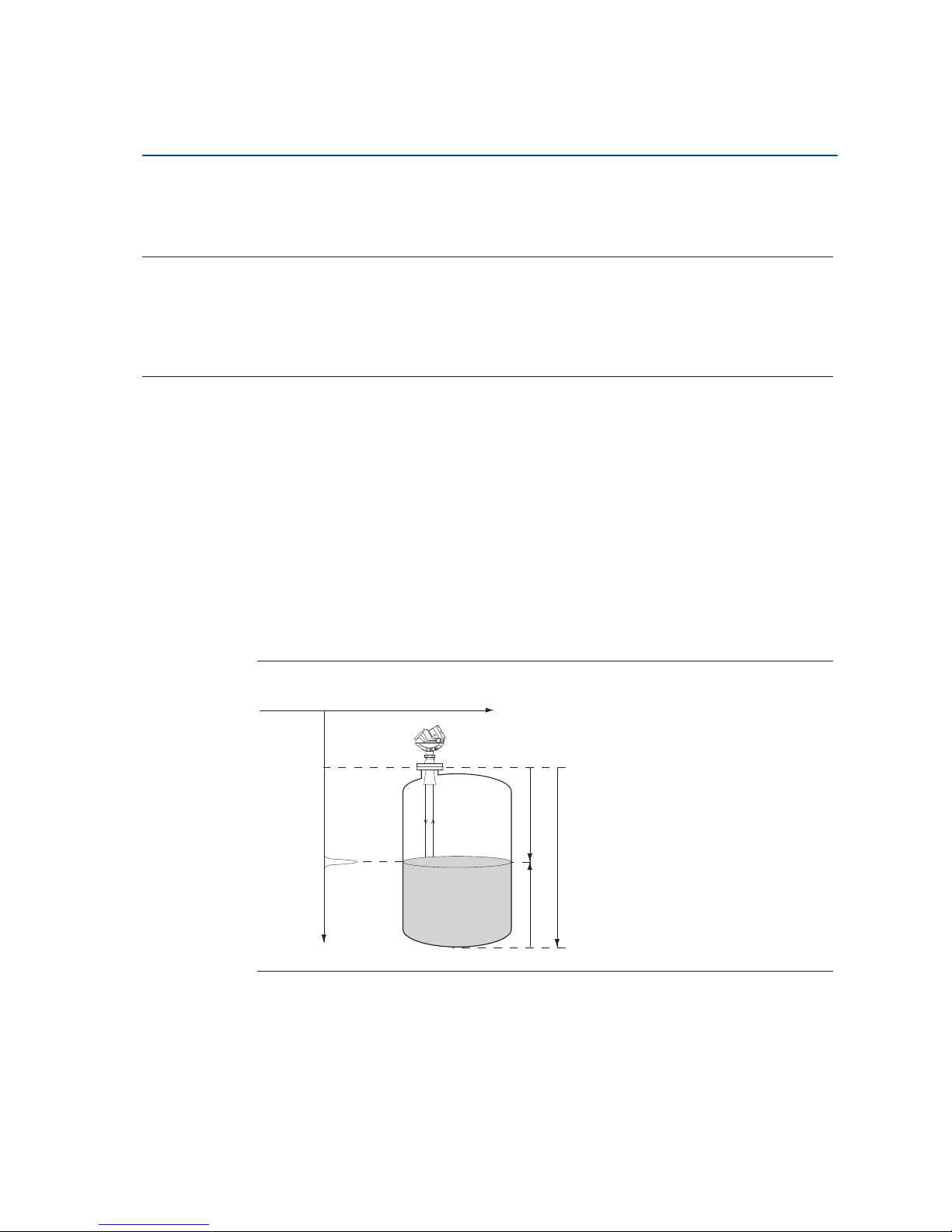

Figure 2-1. Measurement Principle for the Rosemount 5400 Series

Time

Level

Distance

Tan k H eig ht

Signal Amplitude

Radar Pulse

Page 20

8

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

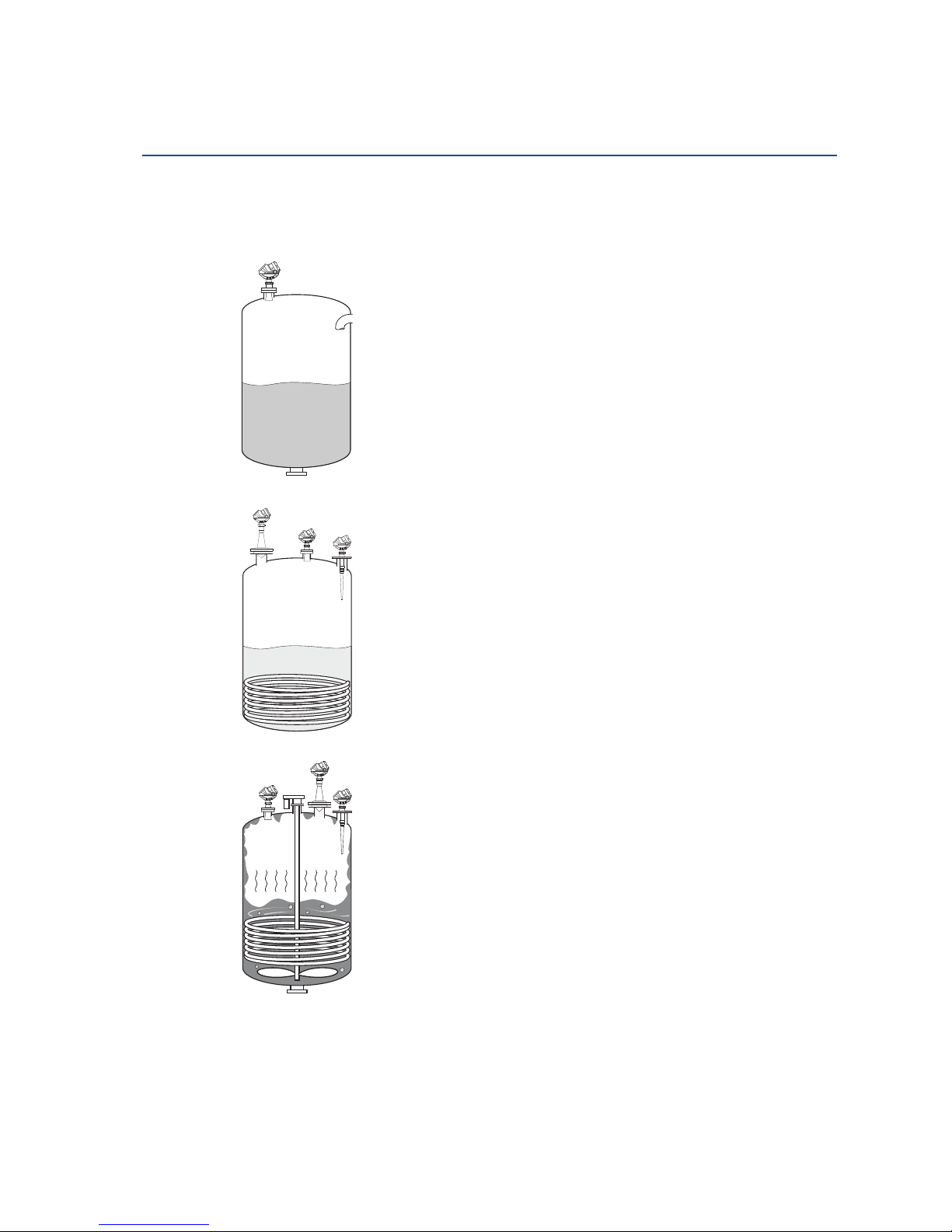

2.2 Application examples

Tanks, vessels, and containers with calm surfaces

Non-contacting radar can be used in less challenging applications,

such as storage and buffer tanks:

It is easy to mount, maintenance-free, and highly accurate

Gives precise monitoring and control of the process

Overfill and underfill detection

The Rosemount 5400 Series can be advantageous in risk reduction

systems:

Continuous measurement may reduce or simplify proof-tests

Multiple 5400s can be used in the same tank

Corrosives

Radar measurement is ideal for most corrosive products, such as

caustics, acids, solvents, and many other chemicals:

Does not contact the process product

Wide material offering such as PTFE, Alloy C-276 and Alloy 400

Works well in non-metallic tanks also

Sticky, viscous, and crystallizing products

The best-in-class Rosemount 5400 Series provides an accurate and

reliable level reading with difficult products, such as resins and

adhesives:

Non-contacting is best practice

Almost unaffected by coating and build-up because of the

uniquely designed condensation resistant antennas

Sludges and slurries

Applications like mud, pulp-stock, and lime slurries are ideal for

non-contacting measurement:

Immune to splashing and solids content

Unaffected by density changes

No re-calibration, no or little maintenance

Page 21

9

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

Reactor vessels

The innovative design of the Rosemount 5400 Series makes it an

excellent choice for the most difficult applications, such as reactor

vessels:

Unique circular polarization provides greater mounting

flexibility – no tank wall clearance distance is needed

Direct measurement – independent of most variations in

process conditions, such as density, dielectric, vapor,

temperature, and pressure

Can handle turbulent conditions created by agitation,

top-filling, or process reaction

Mounting flexibility

The versatile Rosemount 5400 Series can be used in mounting

configurations other than standard nozzles:

Fits most existing pipes: 2-8 in. (50-200 mm)

Easy to isolate from the process – use a ball-valve

Still-pipes reduce the influence of foam, turbulence, and tank

obstructions. Ball-valves can be used on both still-pipes and

nozzles.

Underground tanks

The mounting flexibility of the Rosemount 5400 Series makes it an

excellent choice for many underground tanks:

Easy top-mounting

Can handle long narrow nozzles up to 6 ft (2 m) as long as they

are clean and smooth, and pipes

Unaffected by dirty products with solids content

Page 22

10

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

2.3 System architecture

The Rosemount 5400 Series Radar Transmitter is loop-powered, and uses the same two wires

for power supply and output signal. The output is a 4-20 mA analog signal superimposed with a

digital HART

®

, FOUNDATION™ fieldbus or Modbus® signal.

By using the optional HART Tri-Loop™, the HART signal can be converted up to three additional

4-20 mA analog signals.

With the HART protocol, multidrop configuration is possible. In this case, communication is

restricted to digital, since current is fixed to the 4 mA minimum value.

The transmitter can be connected to a Rosemount 751 Field Signal Indicator, or it can be

equipped with an integral display.

The transmitter can easily be configured using a Field Communicator or a PC with the

Rosemount Radar Master (RRM) software. Rosemount 5400 Series transmitters can also be

configured with the AMS

®

Suite and DeltaV™ software, and other tools that support Electronic

Device Description Language (EDDL) functionality.

For HART communication, a minimum load resistance of 250 : within the loop is required.

Figure 2-2. HART System Architecture

Integral

Display

Rosemount 5400 Series

Radar Transmitter

Rosemount 751 Field

Signal Indicator

Field

Communicator

Tri -L oo p

3 x 4-20 mA

DCS

HART modem

RRM or

AMS Suite

Page 23

11

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

Figure 2-3. FOUNDATION fieldbus System Architecture

The RS-485 Modbus version communicates by Modbus RTU, Modbus ASCII, and Level Master

Protocols.

HART communication is used for configuration via HART terminals, or tunneling via the RS-485.

Figure 2-4. RS-485 with Modbus Communication

FOUNDATION

fieldbus

Note

Intrinsically safe

installations may

allow fewer devices

per I.S. barrier due to

current limitations.

Host / DCS system (e.g. DeltaV)

Maintenance

Field

Communicator

Rosemo unt

5401

Rosemount

5402

Rosemo unt

5601

Fieldbus Modem

H1 - Low Speed Field Bus

6200 ft (1900 m) max

(depending upon cable

characteristics)

Configuration with RRM

(hooked up on Fieldbus

segment)

H2 - High Speed Field Bus

Rosemount 5400

Series Transmitter

HART

Modem

Power

Modbus, Levelmaster

Emulation / RS-485

Control

System

RS-232 / RS-485

Converter

PC

5400 Setup in RRM

PC

5400 Setup in RRM

through Tunneling

Field Communicator

Page 24

12

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

2.4 Process characteristics

Dielectric constant

A key parameter for measurement performance is reflectivity. A high dielectric constant of the

media provides better reflection and enables a longer measuring range.

Foam

Rosemount 5400 Series Radar Transmitter measurement in foamy applications depends on the

foam properties; light and airy or dense and heavy, high or low dielectrics, etc. If the foam is

conductive and creamy, the transmitter may measure the surface of the foam. If the foam is less

conductive, the microwaves may penetrate the foam and measure the liquid surface.

Turbulence

A calm surface gives better reflection than a turbulent surface. For turbulent applications, the

maximum range of the radar transmitters is reduced. The range depends on the frequency, the

antenna size, the dielectric of the material, and the degree of turbulence. Consult Tables 2-2 and

2-3 on page 16 for the expected maximum range with the variables listed.

Temperature/pressure/density and vapor

Temperature, pressure, product density, and vapor generally have no impact on measurements.

Condensation

For applications where heavy condensation and vapors may occur, the low frequency version

Rosemount 5401 is recommended.

Tank characteristics

The conditions inside the tank have a significant impact on measurement performance. For

more information see “Vessel characteristics” on page 35.

Solid surface

The surface of solid materials is rarely flat or horizontal. The angle of repose, or surface

inclination, will change as the vessel fills and empties. There is often a lot of dust during the fill

cycle. The dielectric value of many solids is fairly low. See Table 2-1 on page 2-13 for common

solids characteristics.

For solids applications, the high frequency version Rosemount 5402 with 4 inch cone antenna is

available.

Page 25

13

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

Table 2-1. Sample Solids Applications

(1)

Applications

Common characteristics

Particle size Vapor space

Dust or

Powder

Small

(<1 in.)

Larger

(>1 in.)

Dust

Steam or

Condensation

Wood chip bins Yes Yes Yes Yes Possible

Grain silo - small

kernel grains

Yes Yes No Yes No

Grain silo - large

kernel grains

No Yes No No No

Lime stone silo No Yes Yes Possible No

Cement - raw mill silo Yes Yes No Yes No

Cement - finished

product silo

Yes Yes No Yes No

Coal bin Yes Yes Yes Yes Yes

Saw dust Yes Yes No Yes No

High consistency pulp stock

No No No No Ye s

Alumina Yes Yes No Yes No

Salt No Yes Yes No No

(1) Air purging might be needed in dusty environments.

Page 26

14

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

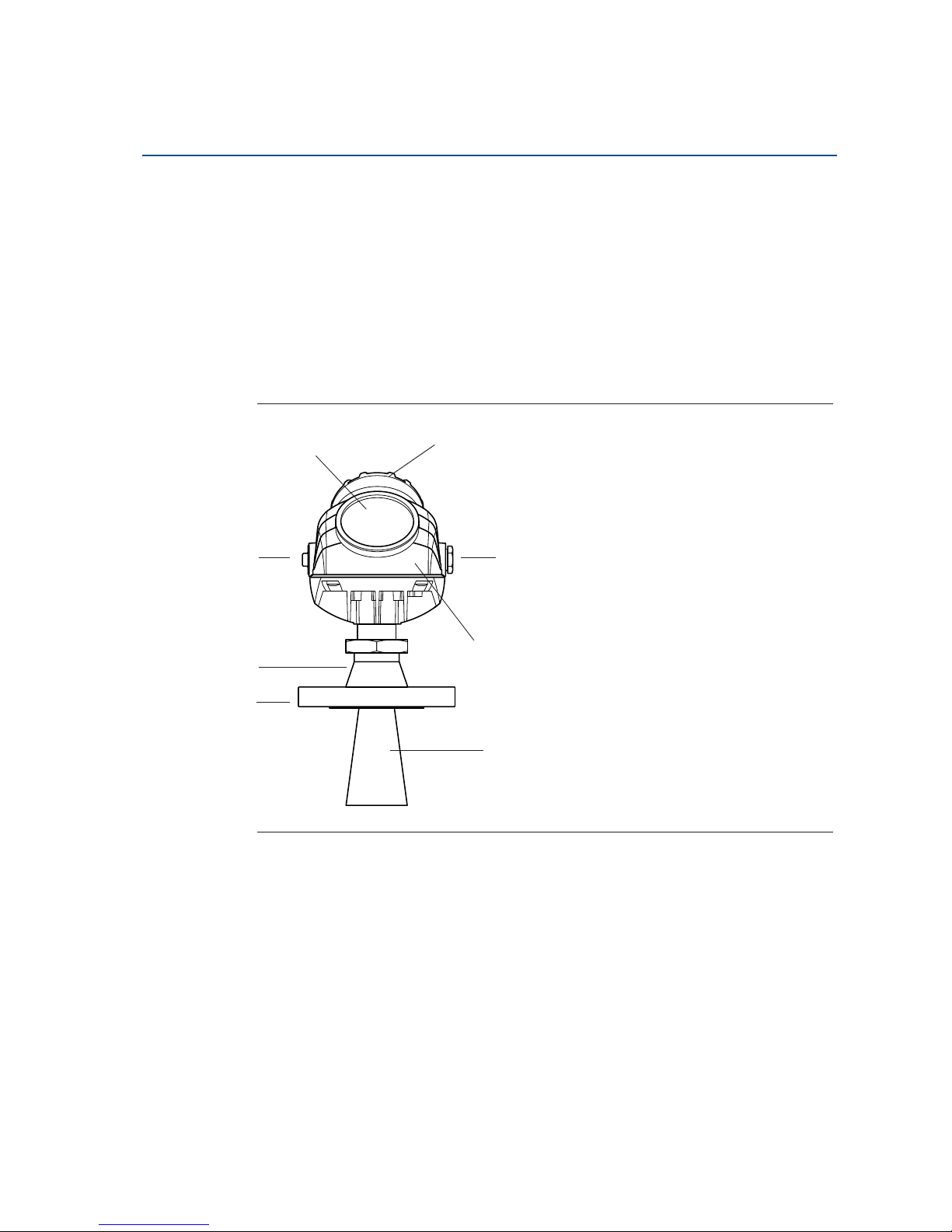

2.5 Components of the transmitter

The Rosemount 5400 Series Radar Transmitter is available with a die-cast aluminum or stainless

steel (SST) housing containing advanced electronics for signal processing.

The radar electronics produces an electromagnetic pulse that is emitted through the antenna.

There are different antenna types and sizes available for various applications.

The transmitter head has separate compartments for electronics and terminals, and can be

removed without opening the tank. The head has two entries for conduit/cable connections.

The tank connection consists of a Tank Seal and a flange (ANSI, EN (DIN) or JIS).

Figure 2-5. Transmitter Components

B

G

H

A

E

F

D

C

A. Display Panel

B. Cable Entry: ½" NPT.

Optional adapters: M20

C. Tank Seal

D. Flange

E. Terminal side

F. Cable Entry: ½" NPT.

Optional adapters: M20

G. Transmitter head with Radar electronics

H. Antenna

Page 27

15

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

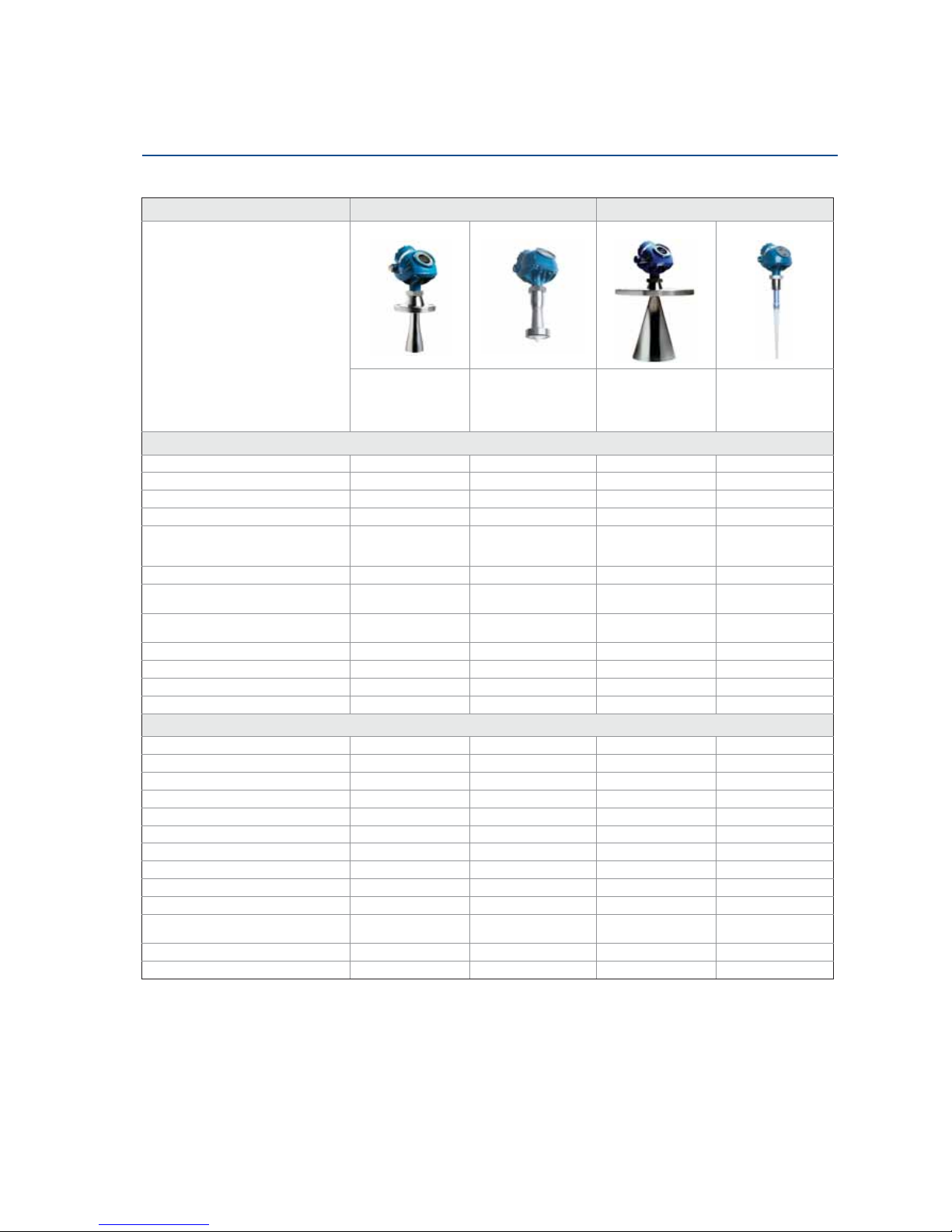

2.6 Antenna selection guide/measuring range

The measuring range depends on the microwave frequency, antenna size, the dielectric

constant (H

r

) of the liquid, and process conditions. A higher dielectric constant value produces a

stronger reflection. The figures in the tables below are guidelines for optimum performance.

Larger measuring ranges may be possible. For more information, contact your local Emerson

Process Management representative.

A. Oil, gasoline or other hydrocarbons, and petrochemicals (H

r

= 1.9-4.0). In pipes or with

ideal surface conditions, for some liquefied gases (H

r

= 1.4-4.0).

B. Alcohols, concentrated acids, organic solvents, oil/water mixtures, and acetone

(H

r

= 4.0-10.0).

C. Conductive liquids, e.g. water based solutions, dilute acids, and alkalis (H

r

> 10.0).

Table 2-2. Rosemount 5402, Maximum Recommended Measuring Range, ft (m)

High

frequency

antennas

Dielectric constant

(1)

(1) A. Oil, gasoline or other hydrocarbons, and petrochemicals (

H

r

= 1.9-4.0)

In pipes or with ideal surface conditions, for some liquefied gases (

H

r

= 1.4-4.0)

B. Alcohols, concentrated acids, organic solvents, oil/water mixtures, and acetone (

H

r

= 4.0-10.0)

C. Conductive liquids, e.g. water based solutions, dilute acids, and alkalis (

H

r

> 10.0)

A B C A B C A B C

2-in. Cone/

Process seal

33 (10) 49 (15) 66 (20) 82 (25) 115 (35) 115 (35) 9.8 (3) 20 (6) 33 (10)

3-in. Cone/

Process seal

49 (15) 66 (20) 98 (30) 82 (25) 115 (35) 115 (35) 13 (4) 30 (9) 39 (12)

4-in. Cone/

Process seal

66 (20) 82 (25) 115 (35) 82 (25) 115 (35) 115 (35) 23 (7) 39 (12) 49 (15)

Page 28

16

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

Table 2-3. Rosemount 5401, Maximum Recommended Measuring Range, ft (m)

Low

Frequency

Antennas

Dielectric Constant

(1)

(1) a. Oil, gasoline or other hydrocarbons, and petrochemicals (

H

r

= 1.9-4.0)

In pipes or with ideal surface conditions, for some liquefied gases (

H

r

= 1.4-4.0)

b. Alcohols, concentrated acids, org anic solvents, oil/water mixtures, and acetone (

H

r

= 4.0-10.0)

c. Conductive liquids, e.g. water based solutions, dilute acids, and alkalis (

H

r

> 10.0)

a b c a b c a b c

3-in. Cone

(2)

(2) Pipe installations only. NA = Not Applicable.

NA NA NA 82 (25) 115 (35) 115 (35) NA NA NA

4-in. Cone /

Rod

(3)

(3) Pipe installations are not allowed with rod antennas.

23 (7) 39 (12) 49 (15) 82 (25) 115 (35) 115 (35) 13 (4) 26 (8) 39 (12)

6-in. Cone

43 (13) 66 (20) 82 (25) 82 (25) 115 (35) 115 (35) 20 (6) 33 (10) 46 (14)

8-in. Cone

66 (20) 82 (25) 115 (35) 82 (25) 115 (35) 115 (35) 26 (8) 39 (12) 52 (16)

Page 29

17

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tra nsm itter Overview

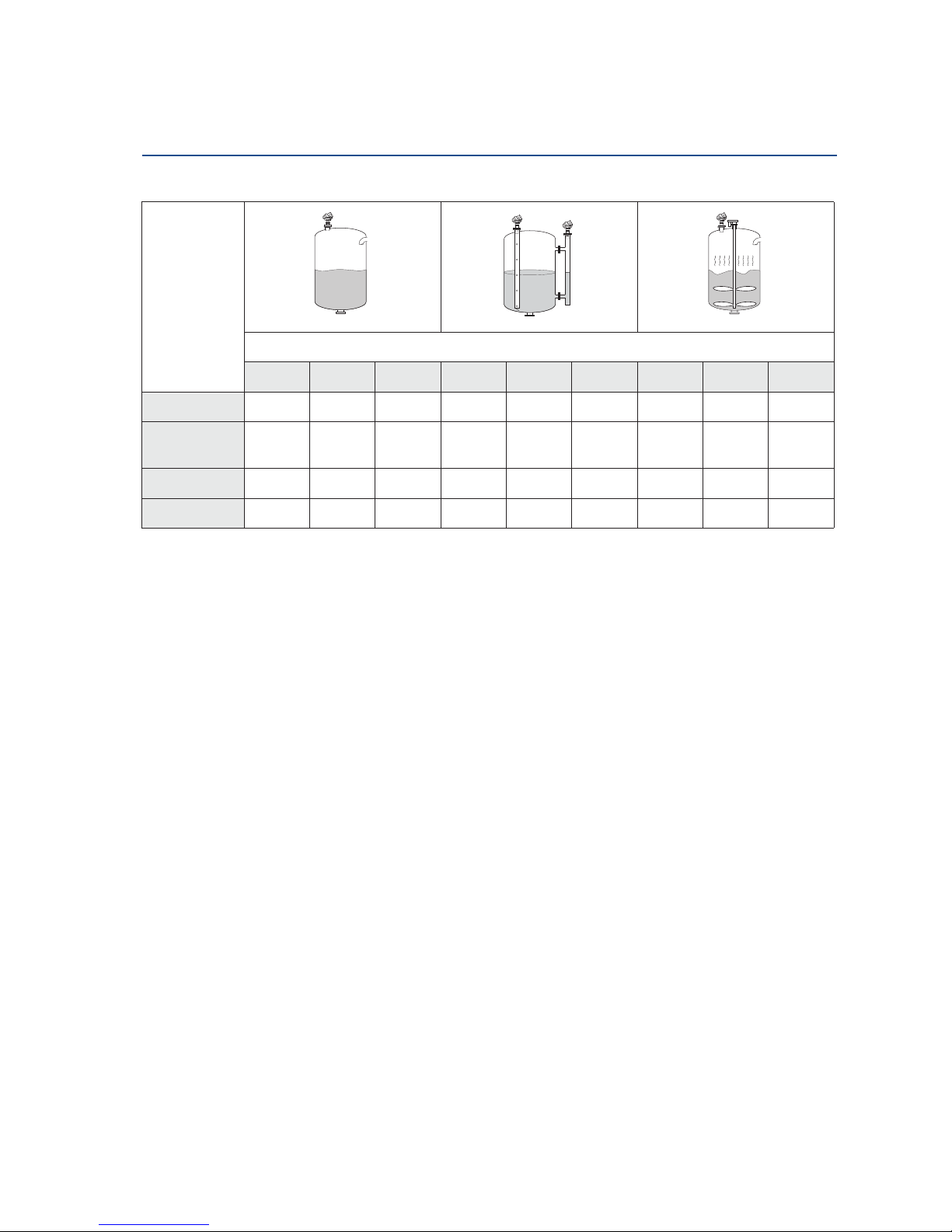

Table 2-4. Model and Antenna Guide

Model and antenna guide

5402 5401

This table gives guidelines on which

model and antenna to select, depending

on application.

G = Good

AD = Application Dependent (consult

your local Emerson Process

Management representative)

NR = Not Recommended

Cone (preferred) Process seal Cone (preferred) Rod

Best choice for a

broad range of

applications, free

propagation and pipe

installations.

Ideal for small tanks

and corrosive

applications. Also good

for heav y antenna

condensation/build-up.

Suitable for some

extreme process

conditions.

Suitable for small

process connections,

and corrosive

environmen t.

Tank considerations

Installation close to smooth tank wall G G G G

Multiple units on the same tank G G G G

Internal obstructions, directly in path

(1)

NR NR AD AD

Internal obstructions, avoidance

(1)

(1) The obstruction should not be within the radar beam. Preferred choices due to more narrow radar beam: Model 5402, and cone antenna.

G G NR NR

Beam angle 2” 19°

3” 14°

4” 9°

2” 19°

3” 14°

4” 9°

4” 37°

6” 23°

8” 17°

37°

Antenna extends below nozzle G G G G

Antenna recessed in smooth nozzle up to

6 ft (2 m)

GG NR

(2)

(2) If tall nozzle, use extended antenna.

NR

(3)

(3) The active part must protrude beneath the nozzle.

Antenna recessed in nozzle with

irregularities, such as bad welds

AD

(4)

(4) An e xtended cone antenna must be used.

AD AD

(4)

NR

(3)

Stilling well mounting G 2”- 4” pipe G 2”- 4” pipe G 3”- 8” pipe NR

Valves G G NR NR

Long ranges (>115’ / 35 m) NR NR NR NR

Cleanability of antenna AD G AD G

Process medium characteristics

Vapor (light, medium) G G G G

Vapor (heavy) NR AD G G

Condensing vapor/product build-up

(5)

(5) Build-up can often be avoided or reduced by using heat-tracing or cleaning arrangements.

AD G G AD

Boiling/Turbulent surface (low/medium) G G G G

Boiling/Turbulent surface (heav y) AD AD G

(6)

(6) Use a 6 or 8 in. (150-200 mm) cone antenna.

NR

Boiling/Turbulent surface (still-pipe) G G G NR

Foam

(7)

(7) Foam can either reflect, be invisible, or absorb the radar signal. Pipe mounting is advantageous since it reduces the foaming tendency.

NR NR AD AD

Foam (still-pipe)

(7)

GG GNR

Corrosive products (options available) G

(8)

(8) Other wetted material options include Alloy C-276 and Alloy 400. See the Rosemount 5400 Series Product Data Sheet (Document No. 00813-0100-4026) for details.

G

(8)

G

(8)

G

Materials with ver y low dielectric G G G AD

Changing density/dielectric/pH/

pressure/temperature

GG GG

Coating/viscous/crystallizing liquids G G G G

Solids, granules, powders G NR NR NR

Page 30

18

Reference Manual

00809-0100-4026, Rev HA

Section 2: Transmitter Overview

November 2014

Tran smitter Over view

Page 31

19

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

Section 3 Mechanical Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Mounting considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

3.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Page 32

20

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

Failure to follow safe installation and service guidelines could result in death or

serious injury.

Make sure only qualified personnel perform installation or service.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Any substitution of non-recognized spare parts may jeopardize safety. Repair, e.g.

substitution of components etc. may also jeopardize safety and is under no

circumstances allowed.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully. If the Process Seal is damaged, gas

might escape from the tank if the transmitter head is removed from the antenna.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations specifications.

In an Explosion-proof/Flameproof installation, do not remove the transmitter cover

when power is applied to the unit.

Before connecting a HART

®

-

based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

Make sure the main power to the Rosemount 5400 Series transmitter is off and the

lines to any other external power source are disconnected or not powered while wiring

the transmitter.

Antennas with non-conducting surfaces.

Antennas with non-conducting surfaces (e.g. Rod antenna and Process Seal antenna)

may generate an ignition-capable level of electrostatic charge under extreme

conditions.

Therefore, when the antenna is used in a potentially explosive atmosphere,

appropriate measures must be taken to prevent electrostatic discharge.

Page 33

21

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

3.2 Installation procedure

Follow these steps for proper installation:

Review installation

considerations

(see page 22)

Mount the transmitter

(see page 36)

Wire the transmitter

(see page 43)

Make sure covers and

cable/conduit

connections are tight

Power up the

transmitter

Configure the

transmitter

(see page 73)

Veri fy me asureme nts

Ground the housing

(see page 46)

Page 34

22

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

3.3 Mounting considerations

Before installing a Rosemount 5400 Series transmitter, consider specific mounting

requirements, vessel, and process characteristics.

3.3.1 Mounting location

For optimal performance, the transmitter should be installed in locations with a clear and

unobstructed view of the level surface (A):

Filling inlets creating turbulence (B), and stationary metallic objects with horizontal

surfaces (C) should be kept outside the signal beam – see page 33 for beamwidth

information

Agitators with large horizontal blades may reduce the performance of the transmitter,

so install the transmitter in a location where this effect is minimized. Vertical or slanted

blades are often invisible to radar, but create turbulence (D)

Do not install the transmitter in the center of the tank (E)

Because of circular polarization, there is no clearance distance requirement from the

tank wall if it is flat and free of obstructions such as heating coils and ladders (F).

Usually, the optimal location is

1

/4 of the diameter from the tank wall

Note

Proper mounting position is important to consider.

Figure 3-1. Proper Mounting Position

The antenna is normally aligned vertically

(D) (A) (E) (B) (F) (C)

Page 35

23

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

A metal still-pipe can be used to avoid disturbing objects, turbulence, and foam (G)

Figure 3-2. Mounting in Still-Pipe

The walls in non-metallic tanks are invisible to the radar signal, so nearby objects

outside of the tank may be detected

Choose the largest possible antenna diameter for installation. A larger antenna

concentrates the radar beam, will be less susceptible to obstruction interference, and

assures maximum antenna gain

Multiple Rosemount 5400 Series transmitters can be used in the same tank without

interfering with each other (H)

Figure 3-3. Multiple Rosemount 5400 Series Transmitters in the Same Tank

(G)

(H)

Page 36

24

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

3.3.2 Special considerations in solids applications

The transmitter should be mounted as close to the center of the tank as possible, but

not in the center of the tank. A general practice is to mount the transmitter at

2

/3 tank

radius from the tank wall, see Figure 3-4.

Figure 3-4. Transmitter Location in Solids Applications

The radar signal must never be shaded by the inlet nor the injected product, see

Figure 3-5.

Figure 3-5. Install the Transmitter with a Clear and Unobstructed View

Page 37

25

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

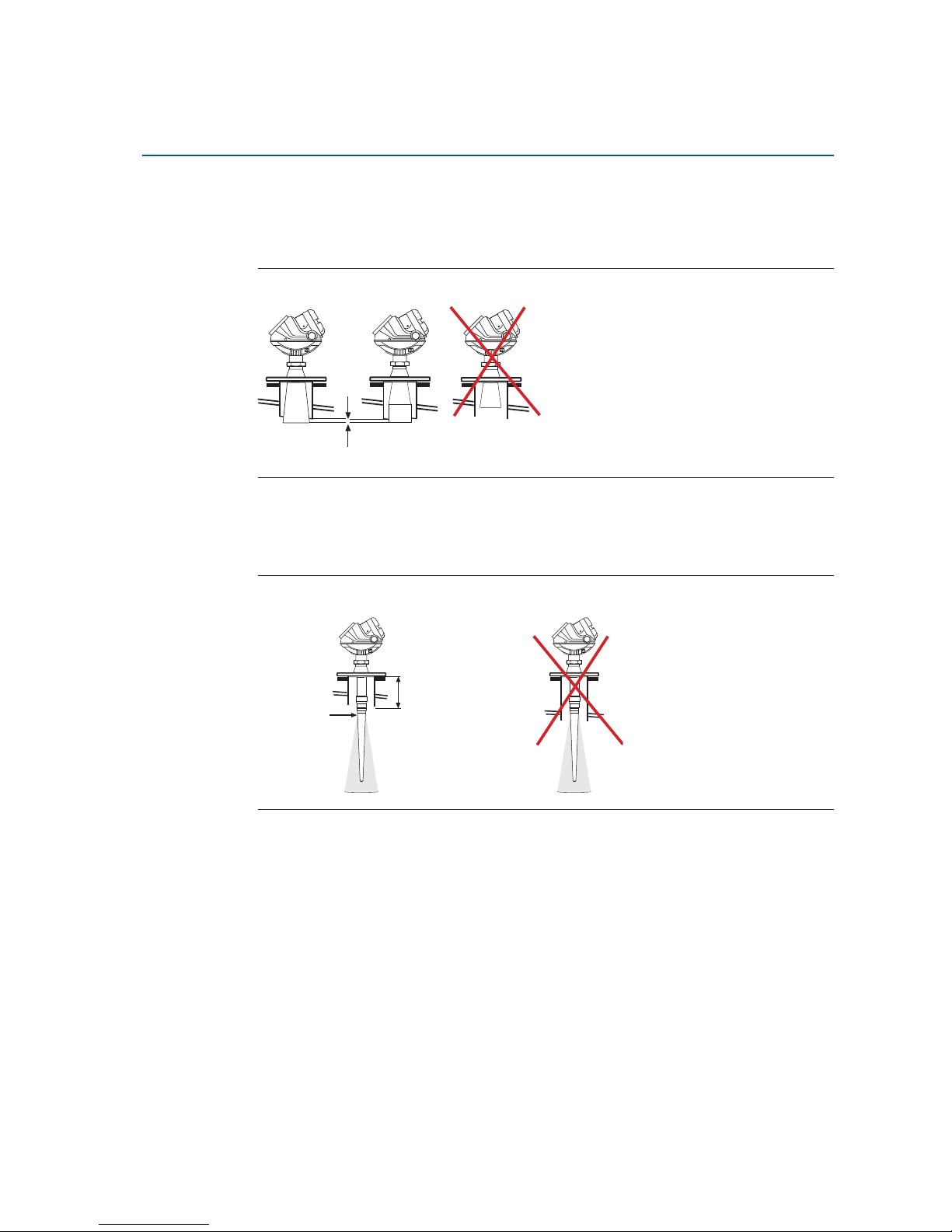

3.3.3 Mounting in pipes

Still-pipe mounting is recommended for tanks with extremely turbulent surface conditions. All

cone antenna sizes for the Rosemount 5400 Series of transmitters can be used for Still-pipe

installations. The 3 in. (75 mm) antenna for the 5401 is designed for use in Still-pipes only. Rod

antennas are not recommended for Still-pipes.

When the transmitter is mounted on a Still-pipe, the inclination should be

within 1°. The gap between the antenna and the Still-pipe may be up to 0.2 in. (5 mm).

Figure 3-6. Mount the Transmitter Vertically

Recommendations for pipe installations

The pipe interior must be smooth

Not suitable for adhesive products

At least one hole is above the product surface

The hole diameter Ø should not exceed 10 % of the pipe diameter D

Holes should only be drilled on one side

Max. 0.2 in

(5 mm)

max. 1 °

Page 38

26

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

Figure 3-7. Recommended Hole Size for Pipe Installations

3.3.4 Installation considerations

Generally, the radar signal is unaffected by condensation and low pressure steam. If affected,

the lower microwave frequencies are less affected. The critical point is the tank penetration,

which acts as a cold spot, where the condensation will form. The radar antenna is located at this

cold spot.

If droplets of water build up on the antenna parts, the microwave signal may get partially or

even entirely blocked if the antenna is not designed for easy drip-off. Therefore, here it is

beneficial to use as large opening for the microwaves as possible, which is the main reason for

the oversized PTFE seal in the Rosemount 5400 Series Cone Antennas. An even better solution is

to use a Process Seal Antenna if the process pressure permits that.

To reduce the cold spot within the nozzle, it is always recommended to insulate the nozzle. By

doing so, the temperature in the nozzle will be the same as in the rest of the vessel and

condensation will thus be reduced. If the temperature in the tank is much higher than the

ambient temperature (i.e. tank is heated and located in a cold area), it might be necessary to

heat trace the nozzle in addition to the insulation.

Figure 3-8. Insulate Nozzle to Avoid Condensation

min. 6 in. (150 mm)

max. Ø: D/10.

D

Page 39

27

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

3.3.5 Nozzle considerations

Special considerations may have to be taken because of the nozzle, depending on the selection

of transmitter model and antenna.

5402 with cone antenna

The antenna can be recessed in smooth nozzles up to 6 ft (2 m). If the inside of the nozzle

contains disturbing objects, use the extended cone (I).

Figure 3-9. Nozzle Considerations for 5402 with Cone Antenna

5402 with process seal antenna

The antenna can be used on nozzles up to 6 ft (2 m), (J). Disturbing objects inside the nozzle (K)

may impact the measurement, and should therefore be avoided.

The flange on the tank should have a flat or raised face. Other tank flanges may be possible,

please consult your local Emerson Process Management representative for advice.

Figure 3-10. Nozzle Considerations for 5402 with Process Seal Antenna

Spray nozzle

(I)

Smooth nozzle

Bad weldings

(K) Bad welding

(J)

Page 40

28

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

5401 with cone antenna

The antenna should extend 0.4 in. (10 mm), or more, below the nozzle (L). If required, use the

extended cone solution.

Figure 3-11. Nozzle Considerations for 5401 with Cone Antenna

5401 with rod antenna

The active part of the rod antenna should protrude below the nozzle (M).

Figure 3-12. Nozzle Considerations for 5401 with Rod Antenna

Still-pipes in metallic materials

If used correctly, pipe measurement can be advantageous in many applications:

The 5402 is the preferred choice for smaller pipe diameters

Use the 5401 for larger pipe diameters (6-8 in./150-200 mm),

pipes with larger holes or slots, or for dirty/sticky media

Use cone or process seal antennas - not the rod antenna

The gap between the cone antenna and the still-pipe is limited to 0.2 in. (5 mm). If

required, order an oversized antenna and cut on location (N). Only applicable to 5401

cone antennas and cone antennas with wetted flange plate (i.e. straight antennas).

The inside of the chamber must be of a constant diameter

(L) 0.4 in. (10 mm) or more

Active part

starts here

(M)

Max. 4 or 10 in.

(100 or 250 mm)

for short and

long version

respectively

Page 41

29

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

Note

Match antenna size to the stilling well diameter.

Figure 3-13. Nozzle Considerations for Still-Pipes in Metallic Materials

Ball-valve installation

The Rosemount 5400 Series transmitter can be isolated from the process by using a valve:

The 5402 is the preferred choice for long nozzle measurement

Use the largest possible antenna

Use a full-port ball valve

Ensure there is no edge between the ball valve and the nozzle or stilling well, the inside

should be smooth

Valves can be combined with stilling wells

(N)

Max. 0.2 in.

(5 mm)

Page 42

30

Reference Manual

00809-0100-4026, Rev HA

Section 3: Mechanical Installation

November 2014

Mechanical Installation

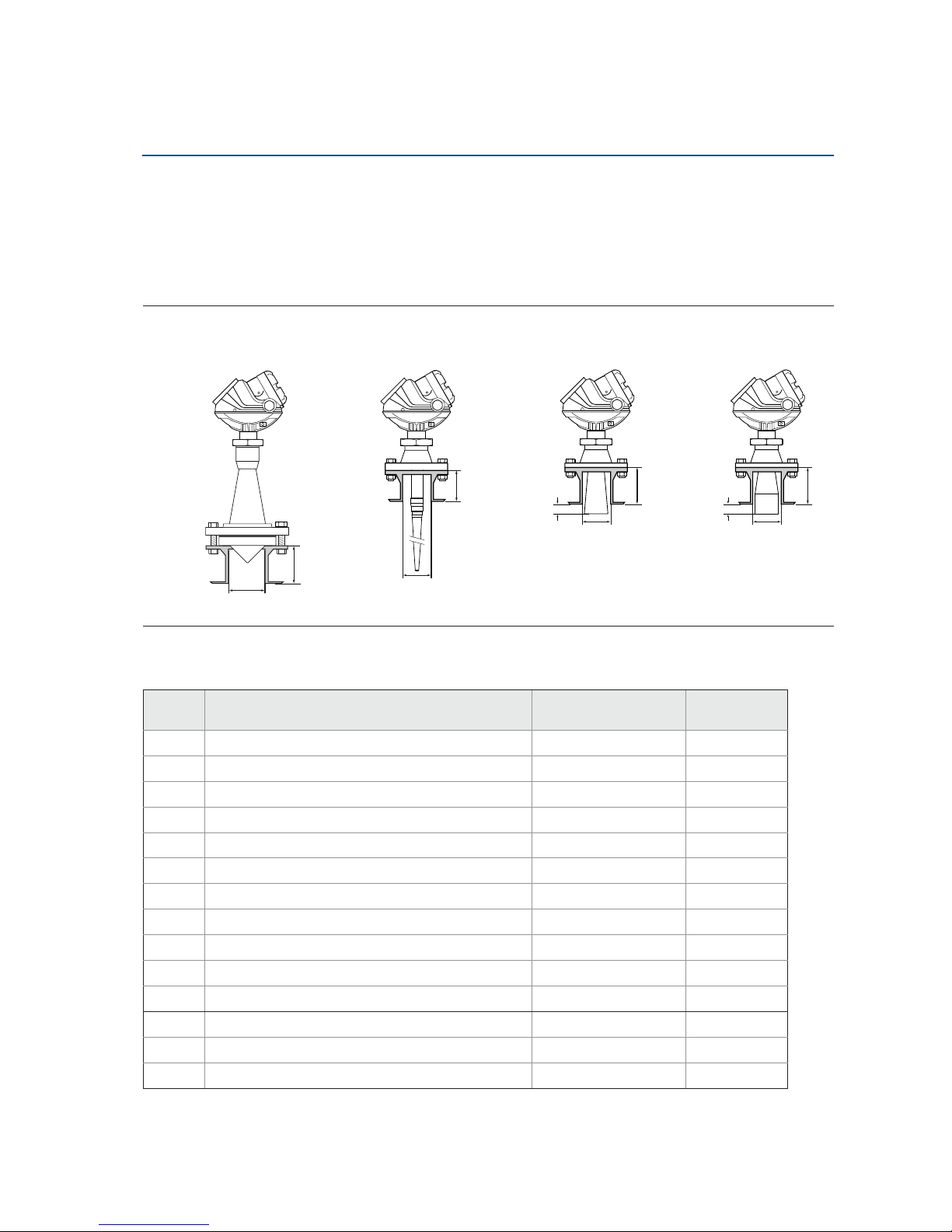

3.3.6 Nozzle recommendations and requirements

The Rosemount 5400 Series is mounted on a nozzle by using appropriate flanges. For best

performance, it is recommended that the nozzle meets the following recommendations for

height (L) and diameter:

Figure 3-14. Mounting of the Rosemount 5400 Series Transmitter

Table 3-1. Minimum Nozzle Diameter and Recommended Maximum Nozzle Height for Cone Antennas

Model Antenna / material

L

max

in. (mm)

Min. diameter

in. (mm)

5402

(1)

Cone 2 in. (50 mm) SST 6.1 (155) 2.2 (55)

Cone 3 in. (75 mm) SST 5.5 (140) 2.8 (72)

Cone 4 in. (100 mm) SST 8.5 (215) 3.8 (97)

Cone 2 in. (50 mm) Alloy C-276, Alloy 400 5.5 (140) 2.2 (55)

Cone 3 in. (75 mm) Alloy C-276, Alloy 400 6.5 (165) 2.8 (72)

Cone 4 in. (100 mm) Alloy C-276, Alloy 400 9.6 (240) 3.8 (97)

5401 Cone 3 in. (75 mm) SST Pipe installations only

Cone 4 in. (100 mm) SST 5.5 (140) 3.8 (97)

Cone 6 in. (150 mm) SST 6.9 (175) 5.7 (145)

Cone 8 in. (200 mm) SST 10.2 (260) 7.6 (193)

Cone 3 in. (75 mm) Alloy C-276, Alloy 400 Pipe installations only

Cone 4 in. (100 mm) Alloy C-276, Alloy 400 5.5 (140) 3.8 (97)

Cone 6 in. (150 mm) Alloy C-276, Alloy 400 6.9 (175) 5.7 (145)

Cone 8 in. (200 mm) Alloy C-276, Alloy 400 10.2 (260) 7.6 (193)

L

Minimum diameter

> 0.4 in.

(10 mm)

Minimum diameter

L

L

Minimum diameter

Minimum diameter

L