Page 1

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Superior Performance Guided Wave Radar

www.rosemount.com

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Rosemount 5300 Series

Guided Wave Radar Level and

Interface Transmitters

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Emerson Process Management has two toll-free assistance

numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center:

Equipment service needs.

1-800-654-7768 (24 hours a day – Includes Canada)

For equipment service or support needs outside the United States, contact your local

Emerson Process Management representative.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

This product is designed to meet FCC and R&TTE requirements for a non-intentional

radiator. It does not require any licensing whatsoever and has no tank restrictions

associated with telecommunications issues.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Cover Photo: 5300_coverphoto.tif

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Table of Contents

SECTION 1

Introduction

SECTION 2

Transmitter Overview

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Product Recycling/Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Components of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Probe Selection Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transition Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Process Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Coating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Bridging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Foam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Vapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Boiling Hydrocarbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Measuring Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Vessel Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Heating Coils, Agitators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Tank Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

SECTION 3

Mechanical Installation

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Process Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installation of Single Lead Probes in Non-metallic Vessels . . . . . . 3-5

Installation in Concrete Silos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Considerations for Solid Applications. . . . . . . . . . . . . . . . . . . . . . . 3-6

Mounting in Chamber/ Still Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Replacing a Displacer in an Existing Displacer Chamber . . . . . . 3-10

Free Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Recommended Mounting Position for Liquids . . . . . . . . . . . . . . . 3-12

Recommended Mounting for Solids . . . . . . . . . . . . . . . . . . . . . . . 3-13

Insulated Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Flange Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Threaded Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Tri-Clamp Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Bracket Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Shortening the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Mounting a Centering Disc for Pipe Installations . . . . . . . . . . . . . 3-25

www.rosemount.com

Page 6

Rosemount 5300 Series

Reference Manual

00809-0100-4530, Rev BA

July 2009

SECTION 4

Electrical Installation

SECTION 5

Configuration

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cable/conduit entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Cable Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Hazardous Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

HART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Maximum Loop Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Connecting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Non-Intrinsically Safe Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Intrinsically Safe Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

OUNDATION Fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

F

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Connecting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Non-Intrinsically Safe Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Intrinsically Safe Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Optional Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Tri-Loop HART to analog converter . . . . . . . . . . . . . . . . . . . . . . . 4-13

751 Field Signal Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Echo Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

LCD Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Advanced Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Basic Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Tank and Probe Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Tank Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Volume Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Analog Output (HART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Basic Configuration Using a 375 Field Communicator . . . . . . . . . . . 5-11

Basic Configuration Using Rosemount Radar Master . . . . . . . . . . . . 5-13

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Help In RRM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Installing the RRM software for HART communication . . . . . . . . 5-14

Specifying the COM Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

To set the COM port buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Installing the RRM Software for FOUNDATION Fieldbus . . . . . . 5-16

Specifying Measurement Units. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Using the Setup Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Device Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Tank Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Analog Output (HART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Finish Configuration Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

TOC-2

Page 7

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Device Specific Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Restart the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

View Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Basic Configuration Using AMS Suite (HART) . . . . . . . . . . . . . . . . . 5-30

Basic Configuration Using DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

OUNDATION Fieldbus Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

F

Assigning Device Tag and Node Address . . . . . . . . . . . . . . . . . . 5-36

Foundation Fieldbus Block Operation . . . . . . . . . . . . . . . . . . . . . 5-37

Configure the AI Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

Application Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Application Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Application Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Tri-Loop HART to Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

HART Multi-drop Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

SECTION 6

Operation

SECTION 7

Service and

Troubleshooting

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Viewing Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Using the Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Specifying Display Panel Variables . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Viewing Measurement Data in RRM . . . . . . . . . . . . . . . . . . . . . . . 6-7

Viewing Measurement Data in AMS Suite . . . . . . . . . . . . . . . . . . . 6-8

Viewing Measurement Data in DeltaV . . . . . . . . . . . . . . . . . . . . . . 6-9

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Analyzing the Measurement Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Surface Pulse Not Found. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Probe End Projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Disturbance Echo Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Amplitude Threshold Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Disturbances at the Top of the Tank . . . . . . . . . . . . . . . . . . . . . . . 7-7

Interface Pulse not Found . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Signal Quality Metrics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Using the Echo Curve Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Using the Rosemount Radar Master . . . . . . . . . . . . . . . . . . . . . . 7-10

The Configuration Mode Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

The View/Record ModeTab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

The File ModeTab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Using the Echo Curve Analyzer with a 375 Field Communicator. 7-13

Interface Measurements with Fully Submerged Probes . . . . . . . . . . 7-15

Analog Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Level and Distance Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Logging Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Backing up the Transmitter Configuration . . . . . . . . . . . . . . . . . . . . . 7-20

Configuration Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Reset to Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Using the Simulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Write Protecting a Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Enter Service Mode in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Viewing Input and Holding Registers. . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Removing the Transmitter Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

TOC-3

Page 8

Rosemount 5300 Series

Changing a Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Probe and Firmware Compatibility . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Check Firmware and Probe Version. . . . . . . . . . . . . . . . . . . . . . . 7-30

Changing the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Diagnostic Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Measurement Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Interface Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Volume Calculation Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Analog Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

LCD Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

LED Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Foundation Fieldbus Error Messages . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Analog Input (AI) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Reference Manual

00809-0100-4530, Rev BA

July 2009

SECTION 8

Safety Instrumented

Systems (4-20 mA only)

APPENDIX A

Reference Data

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Applicable Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Skill Level of Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Alarm and Saturation Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Write Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Site Acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Failure Rate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Useful Lifetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Terms and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Process Temperature and Pressure Rating . . . . . . . . . . . . . . . . . .A-4

Flange Connection Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Flange Rating Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Ambient Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Remote Housing Measuring Range . . . . . . . . . . . . . . . . . . . . . . . .A-8

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-21

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-30

TOC-4

Page 9

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

APPENDIX B

Product Certifications

APPENDIX C

Advanced Configuration

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

EU Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

European ATEX Directive Information. . . . . . . . . . . . . . . . . . . . . . . . .B-3

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Flameproof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

National Supervision and Inspection Center for Explosion Protection

and Safety of Instrumentation (NEPSI) Approvals. . . . . . . . . . . . . . . .B-8

Factory Mutual (FM) Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-11

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-11

Explosion Proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-13

Canadian Standards Association (CSA) Approval. . . . . . . . . . . . . . .B-14

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-14

Explosion Proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-16

IECEx Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Flameproof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-20

Combination Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-22

Approval Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-22

Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

User Defined Upper Reference Point . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Handling of Disturbances from Nozzle . . . . . . . . . . . . . . . . . . . . . . . .C-4

Trim Near Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Changing the Upper Null Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Threshold Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Probe End Projection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

Echo Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12

Dielectric Constant Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

Static Vapor Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

Lower Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

Dynamic Vapor Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-15

Installation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18

Signal Quality Metrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-20

Viewing Signal Quality Metrics in RRM . . . . . . . . . . . . . . . . . . . .C-21

APPENDIX D

Remote Mounting

APPENDIX E

Performing Proof Test

APPENDIX F

Level Transducer Block

Remote Housing, New Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Remote Connection, Field Retrofit. . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Remote Housing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Performing Proof Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

375 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Rosemount Radar Master (RRM) . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-3

AMS Suite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Channel Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Supported Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

Unit Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-8

Diagnostics Device Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

TOC-5

Page 10

Rosemount 5300 Series

Reference Manual

00809-0100-4530, Rev BA

July 2009

APPENDIX G

Register Transducer

Block

APPENDIX H

Advanced Configuration

Transducer Block

APPENDIX I

Resource Transducer

Block

APPENDIX J

Analog-Input Block

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Register Access Transducer Block Parameters. . . . . . . . . . . . . . .G-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-1

Advanced Configuration Transducer Block Parameters. . . . . . . . .H-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

PlantWeb

Alarm Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

Recommended Actions for PlantWeb Alerts . . . . . . . . . . . . . . . . . I-7

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-3

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-4

Signal Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-5

Block Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-6

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-6

Alarm Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-7

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-8

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-8

Configure the AI Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-9

™

Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-5

TOC-6

Page 11

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . .page 1-4

SAFETY MESSAGES Procedures and instructions in this manual may require special preca utions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious

injury.

• Make sure only qualified personnel perform the installation.

• Use the equipment only as specified in this manual. Failure to do so may

impair the protection provided by the equipment.

Explosions could result in death or serious injury.

• Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

®

• Before connecting a HART

make sure the instruments in the loop are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

-based communicator in an explosive atmosphere,

www.rosemount.com

Any substitution of non-authorized parts or repair, other than exchanging the complete

transmitter head or probe assembly, may jeopardize safety and is prohibited.

Unauthorized changes to the product are strictly prohibited as they may unintentionally

and unpredictably alter performance and jeopardize safety. Unauthorized changes that

interfere with the integrity of the welds or flanges, such as making additional

perforations, compromise product integrity and safety. Equipment ratings and

certifications are no longer valid on any products that have been damaged or modified

without the prior written permission of Emerson Process Management. Any continued

use of product that has been damaged or modified without prior written authorization is

at the customer's sole risk and expense.

Page 12

Reference Manual

00809-0100-4530, Rev BA

Rosemount 5300 Series

July 2009

MANUAL OVERVIEW This manual provides installation, configuration and maintenance information

for the Rosemount 5300 Series Radar Transmitter.

Section 2: Transmitter Overview

• Theory of operation

• Description of the transmitter

• Process and vessel characteristics

Section 3: Mechanical Installation

• Mounting considerations

• Mounting

Section 4: Electrical Installation

• Grounding

• Cable selection

• Power requirements

• Wiring

• Optional devices

Section 5: Configuration

• Basic configuration

• Configuration using the 375 Field Communicator

• Configuration using the RRM software

• Configuration using AMS Suite

• Configuration using DeltaV

• Foundation™ Fieldbus

Section 6: Operation

• Viewing measurement data

• Display functionality

Section 7: Service and Troubleshooting

• Service functions

• Diagnostic messages

• Error messages

Section 8: Safety Instrumented Systems (4-20 mA only)

• Functional specifications

• Installation

• Configuration

• Operation and maintenance

•Spare parts

1-2

Appendix A: Reference Data

• Specifications

• Dimensional drawings

• Ordering information

Page 13

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Appendix B: Product Certifications

• Labels

• European ATEX Directive information

• NEPSI approvals

• FM approvals

• CSA approvals

• IECEx approvals

• Combination approvals

• Approval drawings

Appendix C: Advanced Configuration

• Advanced Tank Geometry

• Advanced Transmitter Co nfiguration

• Dynamic Vapor Compensation

• Signal Quality Metrics

Appendix D: Remote Housing

• Remote Housing, New Units

• Remote Housing, Field Retrofit

• Remote Housing Configuration

Appendix E: Performing Proof Test

• Describes the process of performing pr oo f te st.

Appendix F: Level Transducer Block

Describes the operation and parameters of the Level transducer block.

Appendix G: Register Transducer Block

Describes the operation and parameters of the Register tran sducer block.

Appendix H: Advanced Configuration Transducer Block

Describes the operation and parameters of the Advanced Configuration

transducer block.

Appendix I: Resource Transducer Block

Describes the operation and parameters of the Resource transducer

block.

Appendix J: Analog-Input Transducer Block

Describes the operation and parameters of the Analog Input transducer

block.

SERVICE SUPPORT To expedite the return process outside of the United States, contact the

nearest Emerson Process Management representative.

Within the United States, call the Emerson Process Management Instrument

and Valves Response Center using the 1-800-654-RSMT (7768) toll-free

number. This center, available 24 hours a day, will assist you with any needed

information or materials.

1-3

Page 14

Rosemount 5300 Series

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

process material to which the product was last exposed.

Emerson Process Management Instrument and Valves Response Center

representatives will explain the additional information and procedures

necessary to return goods exposed to hazardous substance can avoid injury if

they are informed of and understand the hazard. If the product being returned

was exposed to a hazardous substance as defined by OSHA, a co py of the

required Material Safety Data Sheet (MSDS) for each hazardous substance

identified must be included with the returned goods.

Reference Manual

00809-0100-4530, Rev BA

July 2009

PRODUCT

RECYCLING/DISPOSAL

Recycling of equipment and packaging should be taken into consideration

and disposed of in accordance with local and national legislation/regulations.

1-4

Page 15

Reference Manual

Time

Reference Pulse

Level

Interface Level

Signal Amplitude

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Section 2 Transmitter Overview

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-1

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Components of the Transmitter . . . . . . . . . . . . . . . . . . . .page 2-5

System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Probe Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-9

Process Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-11

Vessel Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-14

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-15

THEORY OF OPERATION The Rosemount 5300 Series Radar Transmitter is a smart, two-wire

continuous level transmitter based on Time Domain Reflectometry (TDR)

principles. Low power nano-second-pulses are guided alon g an immersed

probe. When a pulse reaches the surface, part of the energy is reflected back

to the transmitter, and the time difference between the generated and

reflected pulse is converted into a distance, which calculates the total level or

interface level (see below).

Figure 2-1. Measurement

Principle.

The reflectivity of the product is a key parameter for measurement

performance. Media with a high dielectric constant gives better reflection and

a longer measuring range.

www.rosemount.com

Page 16

Reference Manual

00809-0100-4530, Rev BA

Rosemount 5300 Series

July 2009

APPLICATIONS The Rosemount 5300 Series Radar Tr ansmitter series is suite d for aggregate

(total) level measurements on most liquids, semi-liquids, solids, and

liquid/liquid interfaces.

Guided microwave technology offers the highest reliability and precision to

ensure measurements are virtually unaffected by temperature, pressure,

vapor gas mixtures, density, turbulence, bubbling/boiling, low level, varying

dielectric media, pH, and viscosity.

Guided wave radar technology in combination with advanced signal

processing makes the Rosemount 5300 transmitters suitable for a wide r ange

of applications:

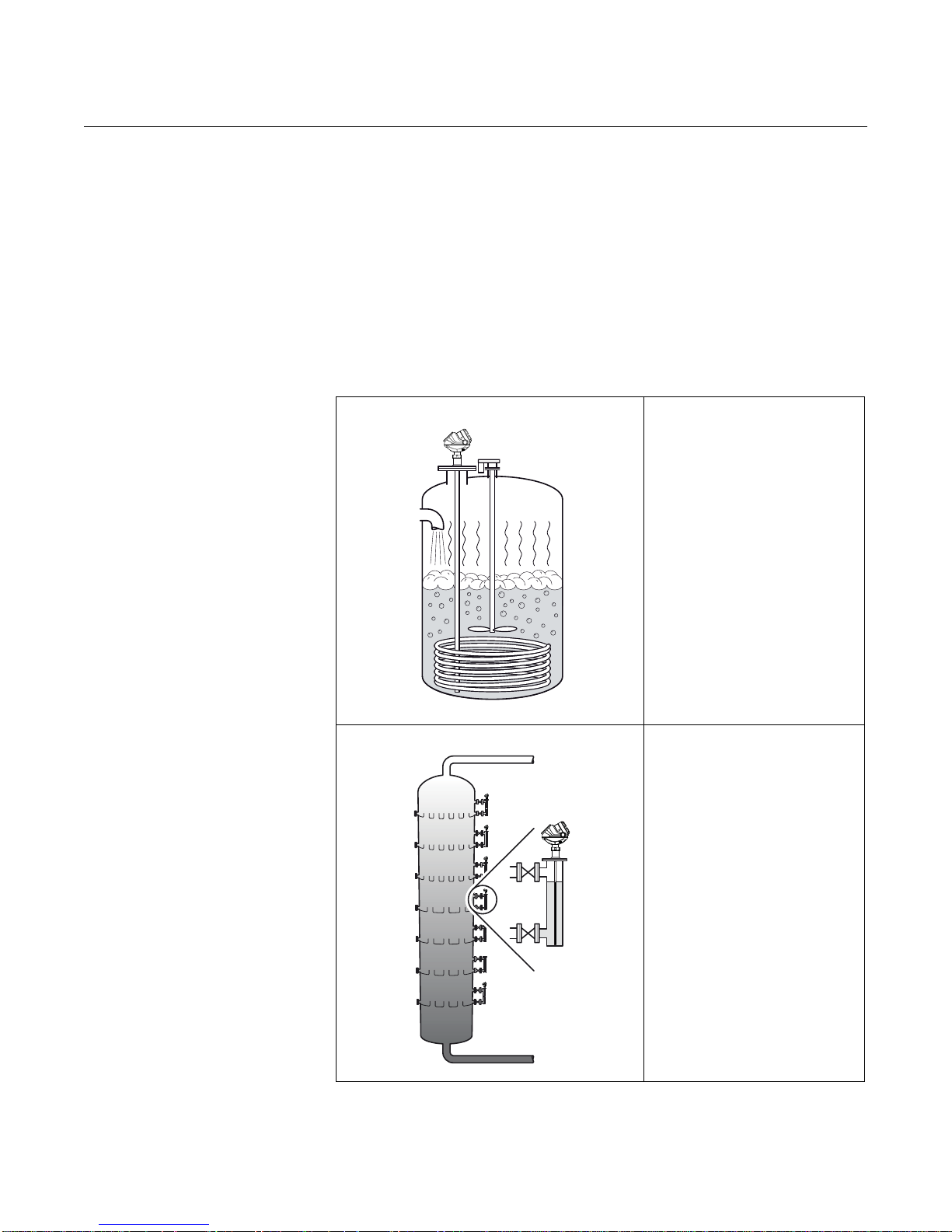

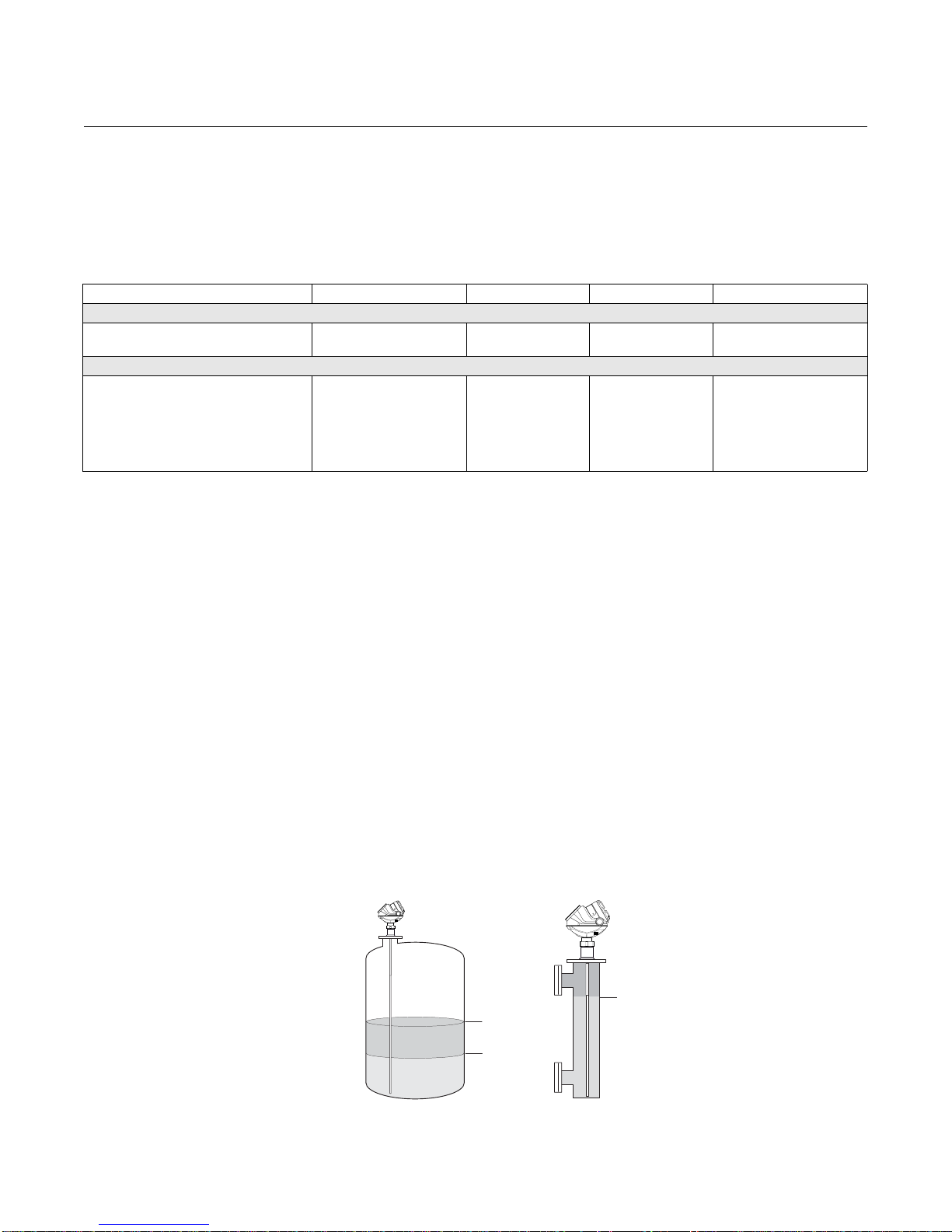

Figure 2-2. Application

examples

The Rosemount 5300 transmitter

works well in boiling conditions with

vapor and turbulence. If there are

disturbing objects in the vicinity of the

transmitter, the coaxial probe is

particularly suitable.

2-2

The Rosemount 5300 Series is well

suited for chamber applications, such

as distillation columns.

Page 17

Reference Manual

Oil

Oil

Water

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

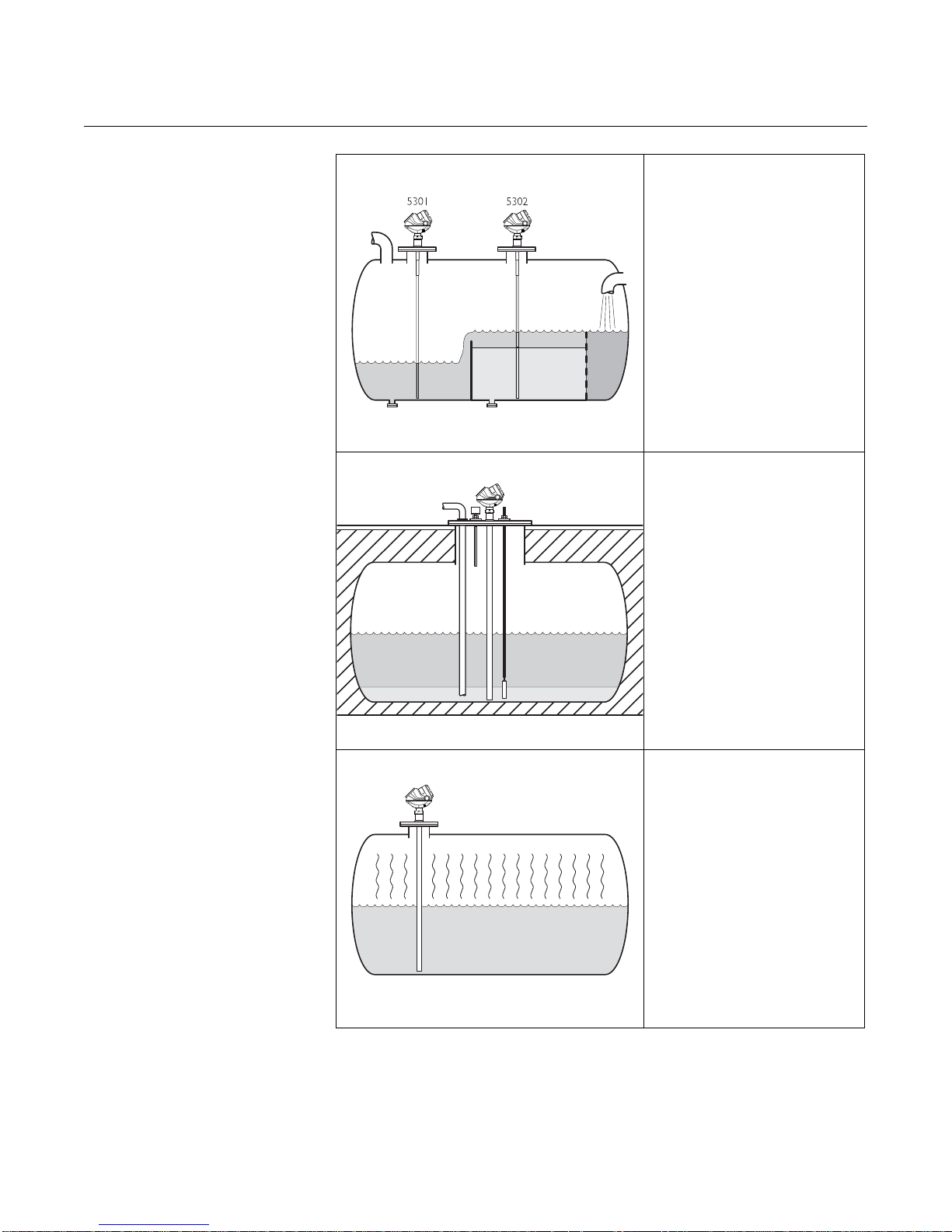

The Rosemount 5302 measures both

level and interface level in a separator

tank.

The Rosemount 5300 Series is a

good choice for underground tanks. It

is installed on the top of the tank with

the radar pulse concentrated near the

probe. It can be equipped with probes

that are unaffected by high and

narrow openings or nearby objects.

Guided wave radar technology

provides reliable measurements in

ammonia, LNG and LPG tanks.

2-3

Page 18

Rosemount 5300 Series

5303

Reference Manual

00809-0100-4530, Rev BA

July 2009

Model 5303, with a flexible single lead

probe, is the solution for solids,

powders and granules.

It measures independently of dust,

angled surfaces etc.

The Rosemount 5300 with Dynamic

Vapor Compensation will

automatically compensate for

dielectric changes in high pressure

steam applications and maintain the

level accuracy.

2-4

Page 19

Reference Manual

Radar Electronics

Probe

Dual Compartment Housing

Cable Entry:

½" NPT.

Optional adapters:

M20, eurofast,

minifast

Threaded

Process

Connections

Flanged

Process

Connections

BSP (G)

NPT

Co

a

x

ia

l

F

le

x

ib

l

e

T

w

in L

e

ad wi

t

h

we

ig

ht

Rigid

Tw in Lead

Ri

g

id

Si

n

g

le

Lea

d

F

l

ex

i

b

le

Sing

le

Lea

d

w

i

th weig

h

t

HTHP

Version

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

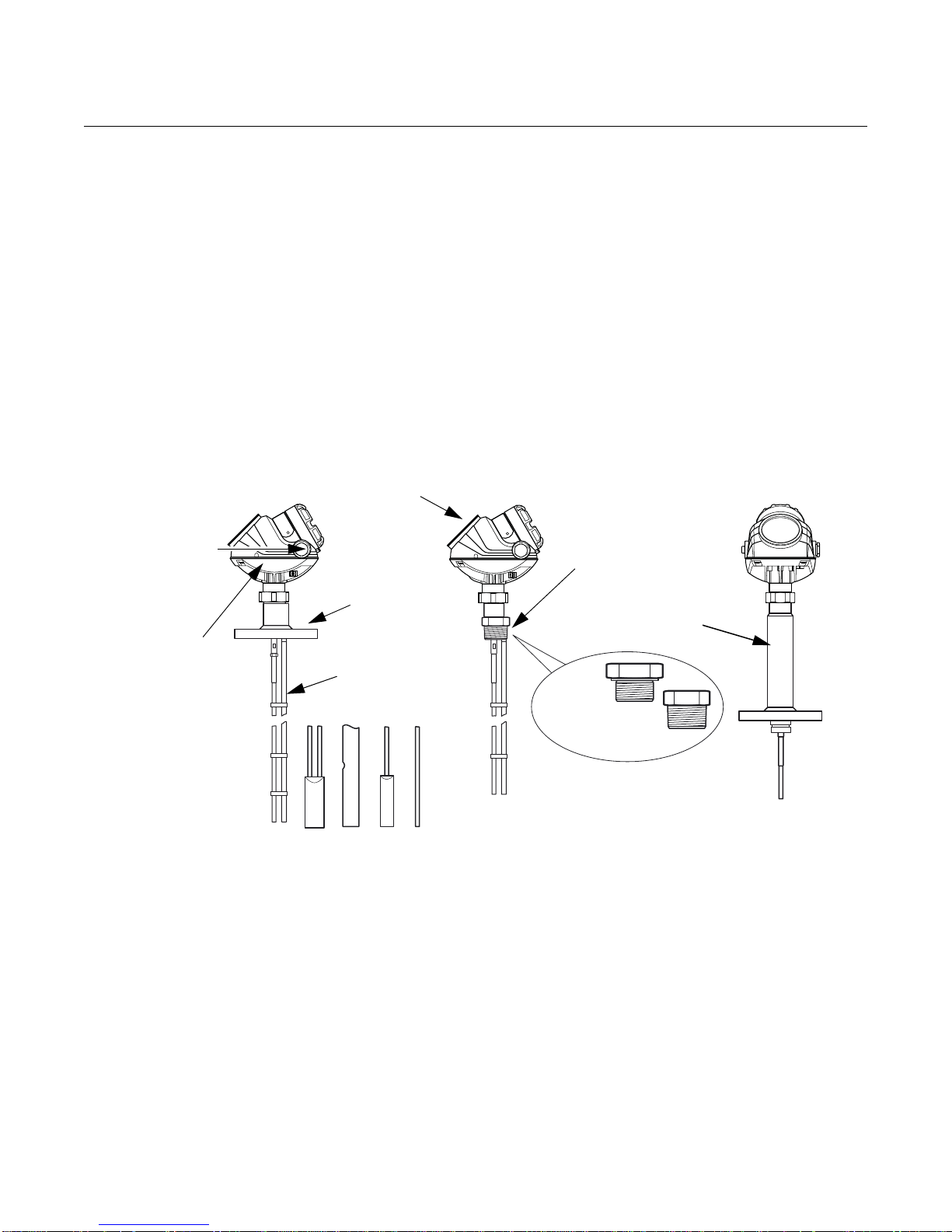

COMPONENTS OF THE

TRANSMITTER

Figure 2-3. Transmitter

components.

The Rosemount 5300 Series Radar T ransmitte r has an aluminum or st ainless

steel (SST) transmitter housing containing advan ced electronics and software

for signal processing. SST housing is preferred for harsh environment

applications, such as off-shore platforms or other location s where the housing

can be exposed to corrodents, such as salt solutions and caustics.

The radar electronics produces an electromag netic pulse that is guided by the

probe. It comes with flange, threaded or Tri-Clamp process connection.

There are different probe types available for various applications: Rigid Twin

Lead, Flexible Twin Lead, Rigid Single Lead, Flexible Single Lead, and

Coaxial.

2-5

Page 20

Rosemount 5300 Series

Dual Compartment

Housing

U-bolt Bracket

Clamping Brackets

M50 nut

Cable Remote Connection

Reference Manual

00809-0100-4530, Rev BA

July 2009

Figure 2-4. Remote Housing

components.

Remote Housing allows for the transmitter head to be mounted separately

from the probe.

2-6

Page 21

Reference Manual

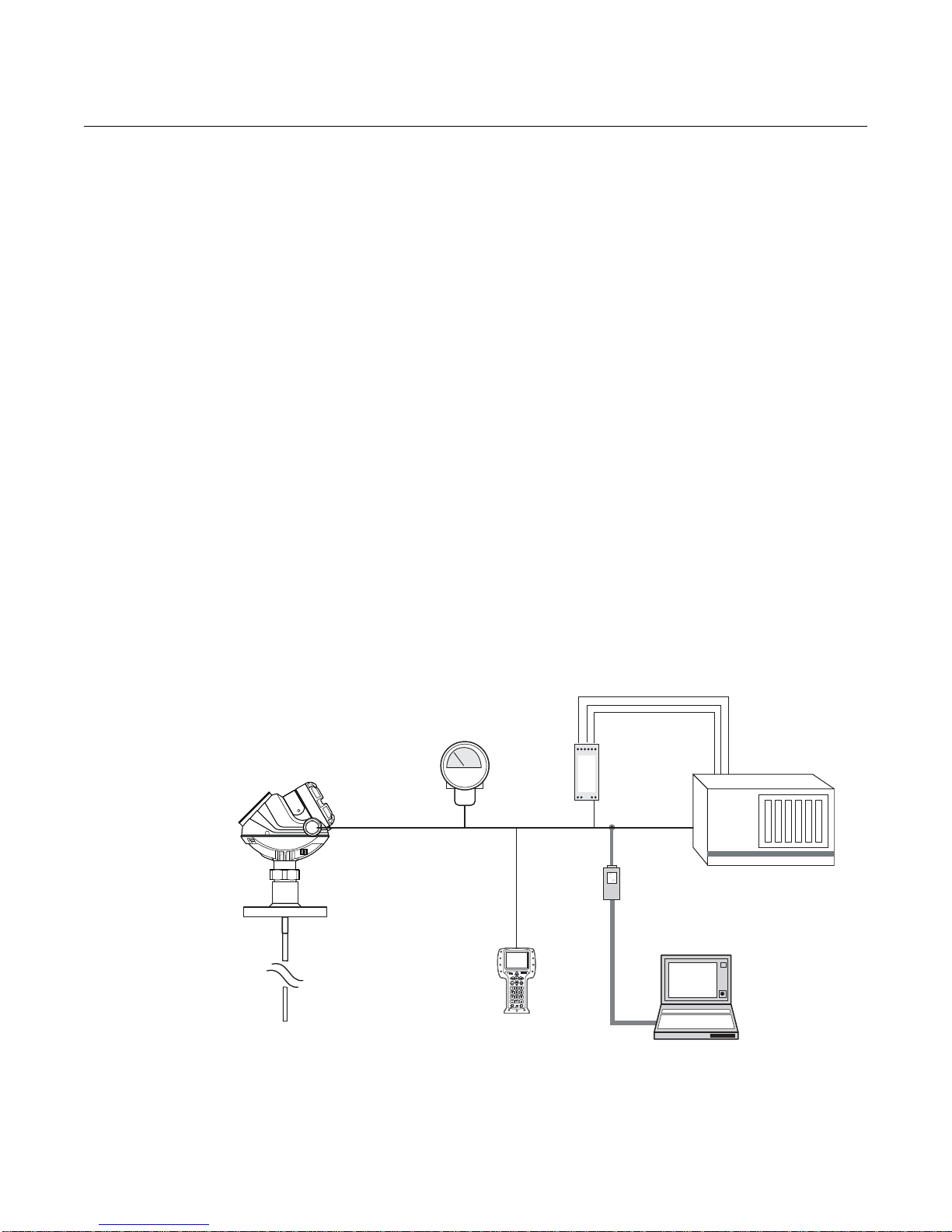

4-20 mA/HART

Rosemount 751

Field Signal Indicator

Rosemount 375

Field

Communicator

HART modem

5300 SERIES

RADAR

TRANSMITTER

DCS

Rosemount

333 HART

Tri-Loop

3 x 4-20 mA

Rosemount Radar Master

or

AMS Suite

Integral

Display

Note! For HART communication, a

minimum load resistance of

250 within the loop is required.

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

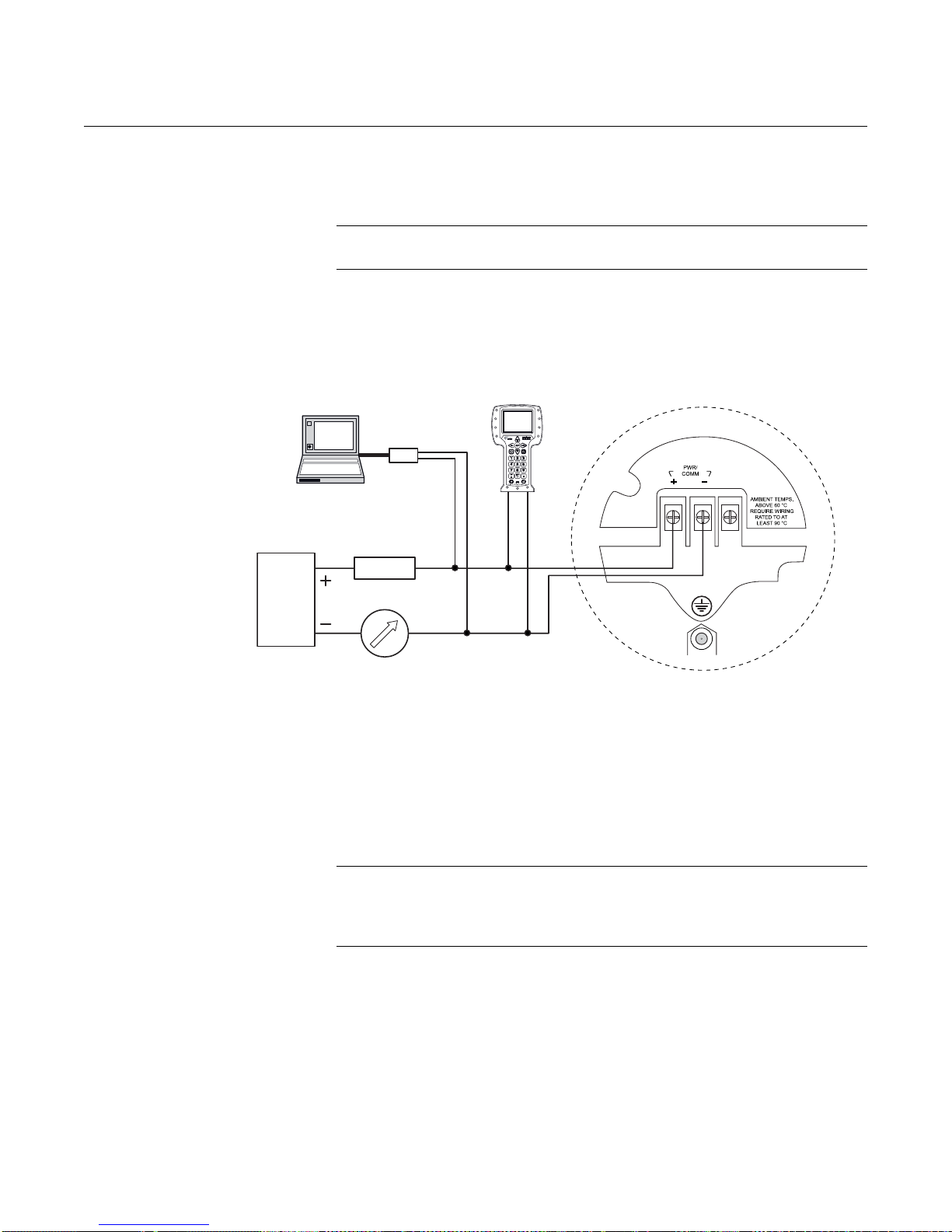

SYSTEM

ARCHITECTURE

Figure 2-5. HART system

architecture

The Rosemount 5300 Series Radar Transmitter is loop-powered, and it uses

the same two wires for both power supply and output signal. The output is a

4-20 mA analog signal superimposed with a digital HART

®

or FOUNDATION™

Fieldbus signal.

By using the optional Rosemount 333 HART Tri-loop, the HART signal can

convert up to three additional 4-20 mA analog signals.

With the HART protocol multidrop configuration is possible. In this case,

communication is restricted to digital, since current is fixed to the 4 mA

minimum value.

The transmitter can be connected to a Rosemount 751 Field Signal Indi ca tor,

or it can be equipped with an integral display.

The transmitter can easily be configured using a Rosemount 375 Field

Communicator or a PC with the Rosemount Radar Master software.

Rosemount 5300 Series transmitters can also be configured with the AMS

®

Suite and DeltaV™ software, and other tools supporting Electronic Device

Description Language (EDDL) functionality.

For HART communication a minimum load resistance o f 250 within the loop

is required.

2-7

Page 22

Rosemount 5300 Series

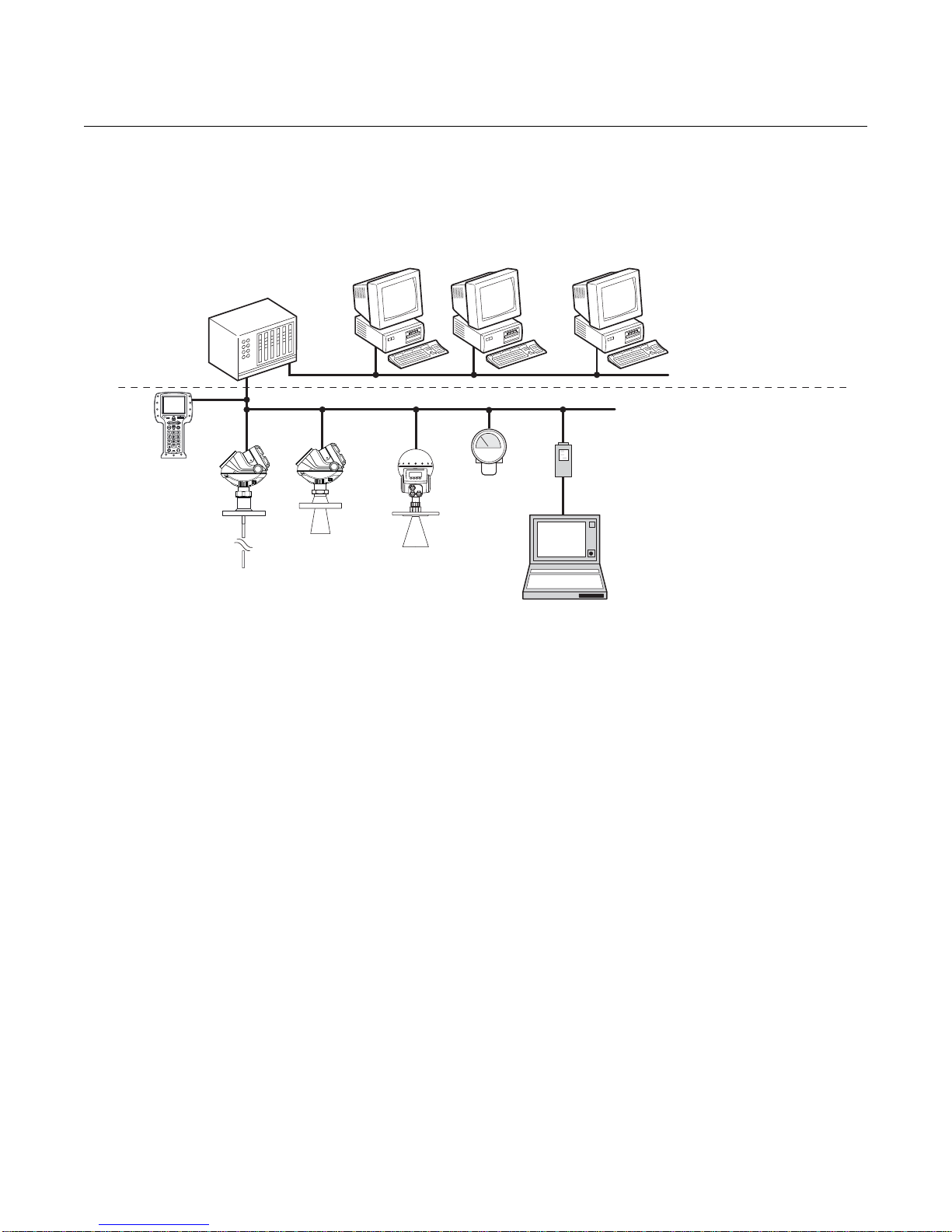

Host/DCS system (e.g. DeltaV®)

375 Field

Communicator

Maintenance

Rosemount 5300

Rosemount 5400

Rosemount 5600

PC with Rosemount

Radar Master

Fieldbus modem

H2 - High Speed Field Bus

H1 - Low Speed Field Bus

6234 ft (1900 m) maximum

(depending on cable

characteristics)

Display

Note:

Intrinsically safe

installations may

allow fewer devices

per I.S. barrier due to

current limitations.

Figure 2-6. FOUNDATION

Fieldbus system architecture

Reference Manual

00809-0100-4530, Rev BA

July 2009

2-8

Page 23

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

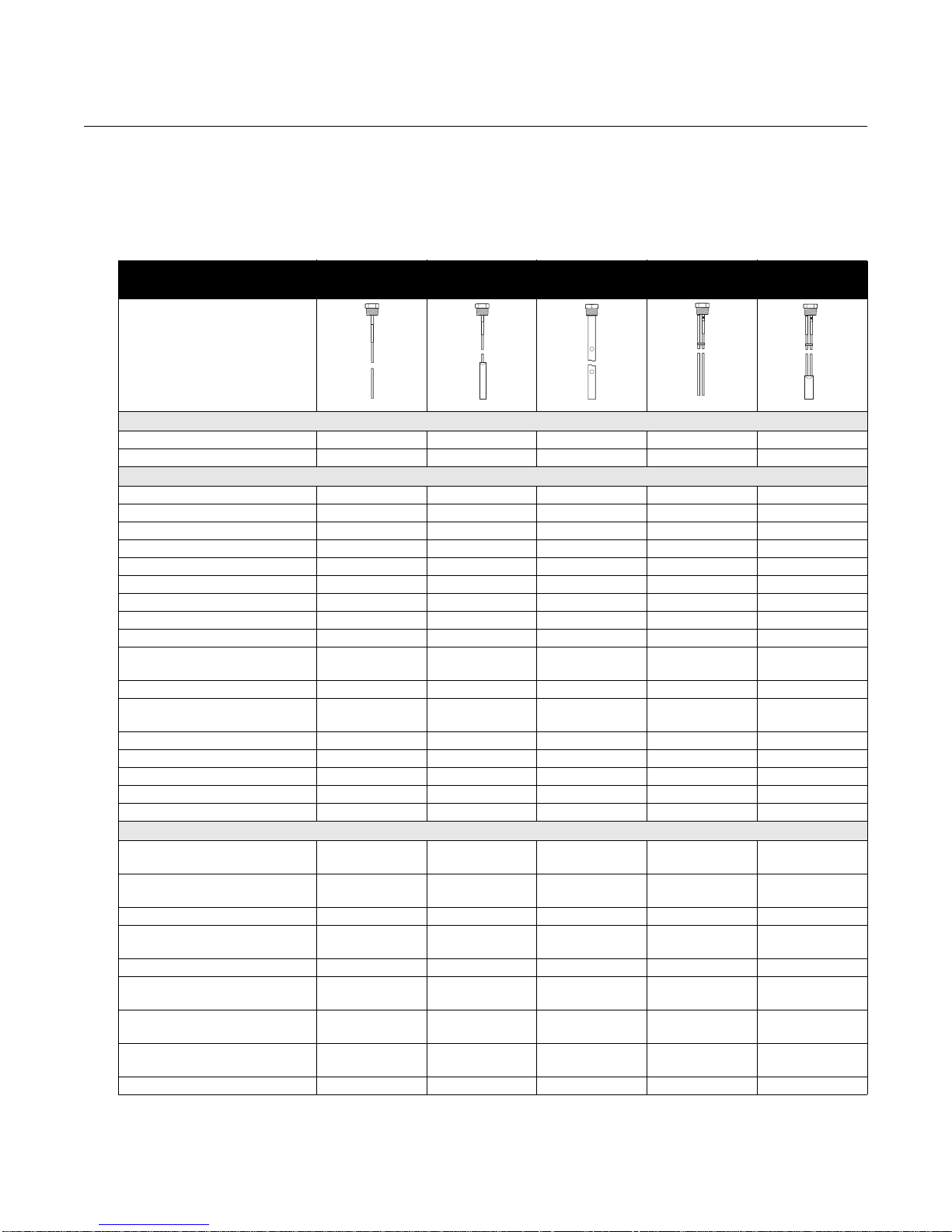

PROBE SELECTION

GUIDE

The following guidelines should be used to choose the appropriate probe for

the Rosemount 5300 transmitter:

Table 2-1. Probe selection guide.

Rigid Single

Lead

G=Good

NR=Not Recommended

AD=Application Dependent

(consult your local Emerson

Process Management

representative)

Level G G G G G

Interface (liquid/liquid) G G G G G

Changing density G G G G G

Changing dielectric

Wide pH variations G G G G G

Pressure changes G G G G G

Temperature changes G G G G G

Condensing vapors G G G G G

Bubbling/boiling surfaces G AD G G G

Foam (mechanical avoidance) NR NR AD NR NR

Foam (top of foam measurement) AD AD NR AD AD

Foam (foam and liquid

measurement)

Clean liquids G G G G G

Liquid with very low dielectric

constants, see also Table 2-4.

Coating/sticky liquids AD AD NR NR NR

Viscous liquids AD G NR AD AD

Crystallizing liquids AD AD NR NR NR

Solids, granules, powders AD G NR NR NR

Fibrous liquids G G NR NR NR

Probe is close (<12 in./30 cm) to

tank wall / disturbing objects

Probe might touch tank wall,

nozzle or disturbing objects

Turbulence G AD G G AD

Turbulent conditions causing

breaking forces

Tall, narrow nozzles AD AD G AD AD

Angled or slanted surface

(viscous or solids materials)

Liquid or vapor spray might touch

probe above surface

Disturbing Electromagnetic

interference in tank

Cleanability of probe G G NR AD AD

(1) For overall level applications, a changing dielectric has no effect on the measurement. For interface measurements, a changing dielectric for the

top fluid will degrade the accuracy of the interface measurement.

(2) Limited measuring range.

(1)

GGGGG

AD AD NR AD AD

GG

Tank Environment Considerations

AD AD G G G

NR NR G NR NR

NR AD NR NR AD

G G NR AD AD

NR NR G NR NR

AD AD G AD AD

Flexible Single

Lead

Measurements

Process Medium Characteristics

(2)

Coaxial Rigid Twin Lead Flexible Twin

GGG

Lead

(2)

2-9

Page 24

Reference Manual

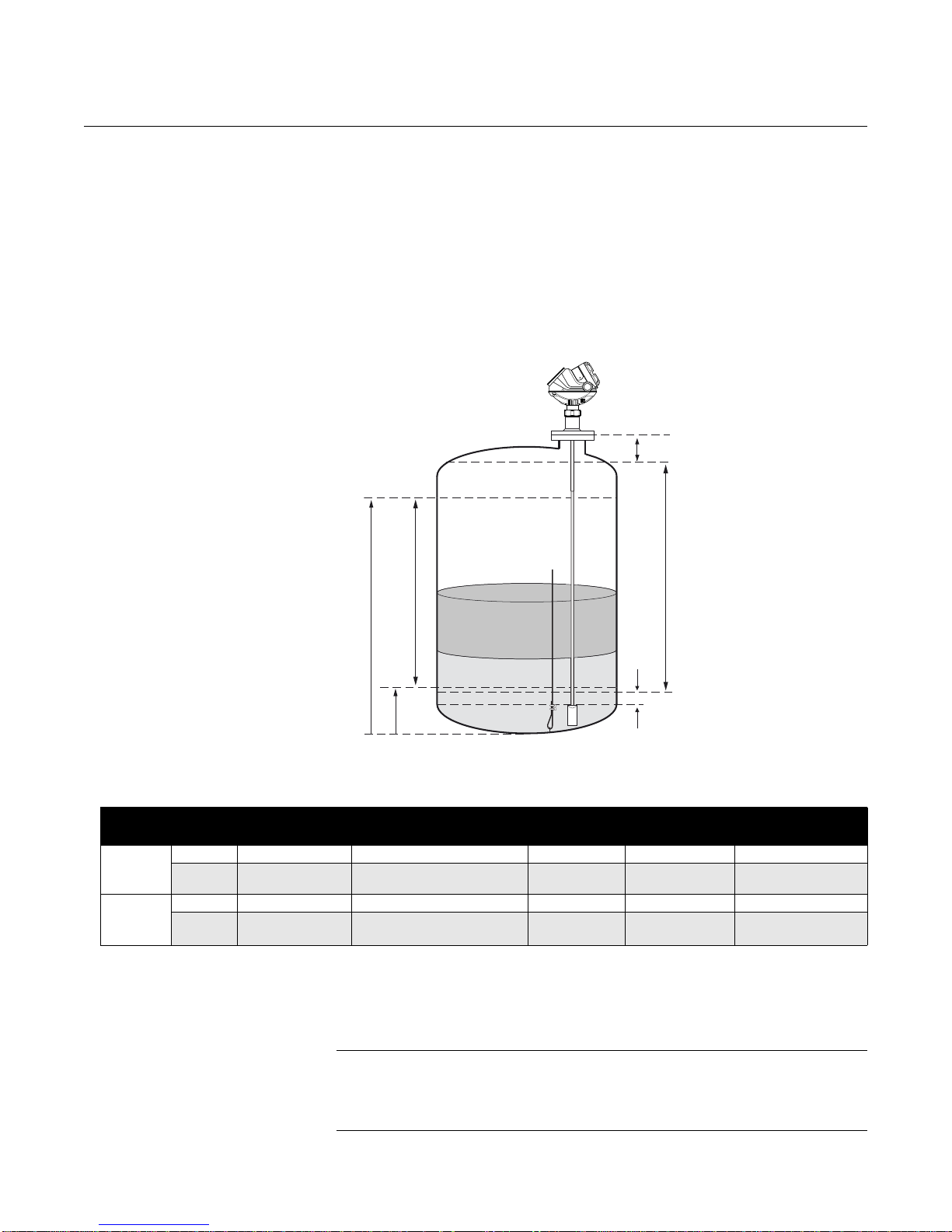

4mA

20mA

Upper Transition Zone

Lower Transition Zone

Range 0 -100 %

Maximum

Recommended

Measuring Range

Upper Reference Point

00809-0100-4530, Rev BA

Rosemount 5300 Series

July 2009

Transition Zones The measuring range depends on probe type and product properties, and is

limited by the Upper and Lower Transition Zones. In these zones,

measurement accuracy may be reduced. The Upper Transition Zone is the

minimum measurement distance between the upper reference point and the

product surface. At the end of the probe, the measuring accuracy is reduced

in the Lower Transition Zone. The Transition Zones vary depending on

probe type and product.

Figure 2-7 illustrates how the measuring range is related to the Transition

Zones:

Figure 2-7. Transition Zones

Table 2-2. Transition Zones for

different probe types and dielectric

constants

Dielectric

Constant

(1)

Upper

Transition

Zone

(2)

Lower

Transition

Zone

(1) The distance from the upper reference point where measurements have reduced accuracy, see picture above.

(2) The distance from the lower reference point where measurements have reduced accuracy, see picture above.

(3) The measuring range for the PTFE covered Flexible Single Lead probe includes the weight. For low dielectric media, special configuration may be

required.

(4) Note that the weight length adds to non-measurable area and is not included in the t able. See “Dimensional Drawings” on page A-9.

(5) If using a metal centering disc, the lower transition zone is up to 8 in. (20 cm). If using a PTFE centering disc, the lower transition zone is not affected.

80 4.3 in. (11 cm) 4.3 in. (11 cm) 4.3 in. (11 cm) 4.3 in. (11 cm) 4.7 in. (12 cm)

80 2 in. (5 cm) 0 in. (0 cm)

Rigid Single Lead Flexible Single Lead Coaxial Rigid Twin Lead Flexible Twin Lead

2 6.3 in. (16 cm) 7.1 in. (18 cm) 4.3 in. (11 cm) 5.5 in. (14 cm) 5.5 in. (14 cm)

2 2.8 in. (7 cm)

2 in. (5 cm) - long weight

(5)

3.2 in. (8 cm) - short weight

(4)(3)

0.4 in. (1 cm) 1.2 in. (3 cm) 2 in. (5 cm)

(4)

(4)

2 in. (5 cm) 4 in. (10 cm) 5.5 in. (14 cm)

NOTE!

Measurements in the Transition Zones may be non-linear, or have reduced

accuracy. It is recommended the 4-20 mA points be set between the

Transition Zones.

2-10

(4)

(4)

Page 25

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

PROCESS

CHARACTERISTICS

The Rosemount 5300 Series has high sensitivity because of its advanced

signal processing and high signal to noise ratio. This makes it able to handle

various disturbances, however, the following circumstances should be

considered before mounting the transmitter.

Coating Heavy coating of the probe should be avoided since it may decrease the

sensitivity of the transmitter and lead to measurement errors. In viscous or

sticky applications, periodic cleaning may be required.

For viscous or sticky applications, it is important to choose a suitable probe:

Table 2-3. Probe type guide for

different product viscosity

Coating not recommended Thin coating allowed, but no

(1) Consult your local Emerson Process Management representatvie for agitation/turbulence and high

(2) Be precautious in HTHP viscous or crystallizing media applications where temperature at instr ument

Maximum measurement error due to coating is 1-10% depending on probe

type, dielectric constant, coating thickness and coating height above product

surface.

Coaxial Twin Lead Single Lead

Maximum viscosity

500 cP 1500 cP 8000 cP

Coating/Build-up

Coating allowed

bridging

viscous products.

connection is significantly lower than process temperature with risk of coating in the upper part of

probe that may reduce the measurement signal. Consider using HP or STD probes in such

applications.

(1)(2)

Signal Quality Metrics (SQM) diagnostic option can give an indication of how

good the surface signal is compared to the noise, and when to clean the

probe.

Bridging Heavy product coating results in bridging between the two probes in a twin

lead version, or between the pipe and inner rod for coaxial probes, and may

cause erroneous level readings, so it must be prevented. A single lead probe

is recommended in these situations.

Foam The Rosemount 5300 Series Radar T ransmitter measurement in foamy

applications depends on the foam properties; light and airy or dense and

heavy, high or low dielectrics, etc. If the foam is conductive and creamy, the

transmitter may measure the surface of the foam. If the foam is less

conductive the microwaves may penetrate the foam and measure the liquid

surface.

Vapor In some applications, such as high pressure boiling water, there is a heavy

vapor above the product surface that could influence the level measurement.

The Rosemount 5300 Series Radar Transmitter can be configured to

compensate for the influence of vapor.

Boiling Hydrocarbons For products with very low dielectric constants, such as boiling hydrocarbons

and solids, the threshold may need to be lowered, and/or the Probe End

Projection (PEP) function activated.

2-11

Page 26

Reference Manual

Level

Interface Level

Level = Interface Level

5302

5301

00809-0100-4530, Rev BA

Rosemount 5300 Series

July 2009

Measuring Range The measuring range differs depending on probe type and characteristics of

the application. Table 2-4 can be used as a guideline for clean liquids.

See Appendix A: Reference Data for the measuring range when using

Remote Housing.

Table 2-4. Measuring Range

Rigid Single Lead Flexible Single Lead

Maximum Measuring Range

9 ft 10 in. (3 m) - for 8 mm probes

14 ft 9 in. (4.5 m) - for 13 mm probes

1.4 (1.25 if installed in a metallic

bypass or stilling well)

(1) The probe end projection software function will improve the minimum die lectric const ant. Consult you local Emer son Process Managemen t representa tive

for details.

(2) Measuring range may be lower depending on installation.

(1)(2)

164 ft (50 m) 19 ft 8 in. (6 m) 9 ft 10 in. (3 m) 164 ft (50 m)

Minimum Dielectric Constant at Maximum Measuring Range

1.4, up to 49 ft (15 m)

1.8, up to 82 ft (25 m)

2.0, up to 115 ft (35 m)

3, up to 138 ft (42 m)

4, up to 151 ft (46 m)

6, up to 164 ft (50 m)

(1)

(1)

(1)

(1)

Coaxial Rigid Twin Lead Flexible Twin Lead

1.2 (Standard)

1.4 (HP/C)

2.0 (HTHP)

1.4 1.4, up to 82 ft (25 m)

2.0, up to 115 ft (35 m)

2.5, up to 131 ft (40 m)

3.5, up to 148 ft (45 m)

6, up to 164 ft (50 m)

The maximum measuring range differs based on application according to:

• Disturbing objects close to the probe

• Media with higher dielectric constant (

) has better reflection and a

r

longer measuring range

• Surface foam and particles in the tank atmosphere might affect

measuring performance

• Heavy coating / contamination on the probe may redu ce the measuring

range and cause erroneous level readings

• Disturbing EMC environment in tank

• Tank material (e.g. concrete or plastic) for measurements with single

lead probes

(1)

(1)

(1)

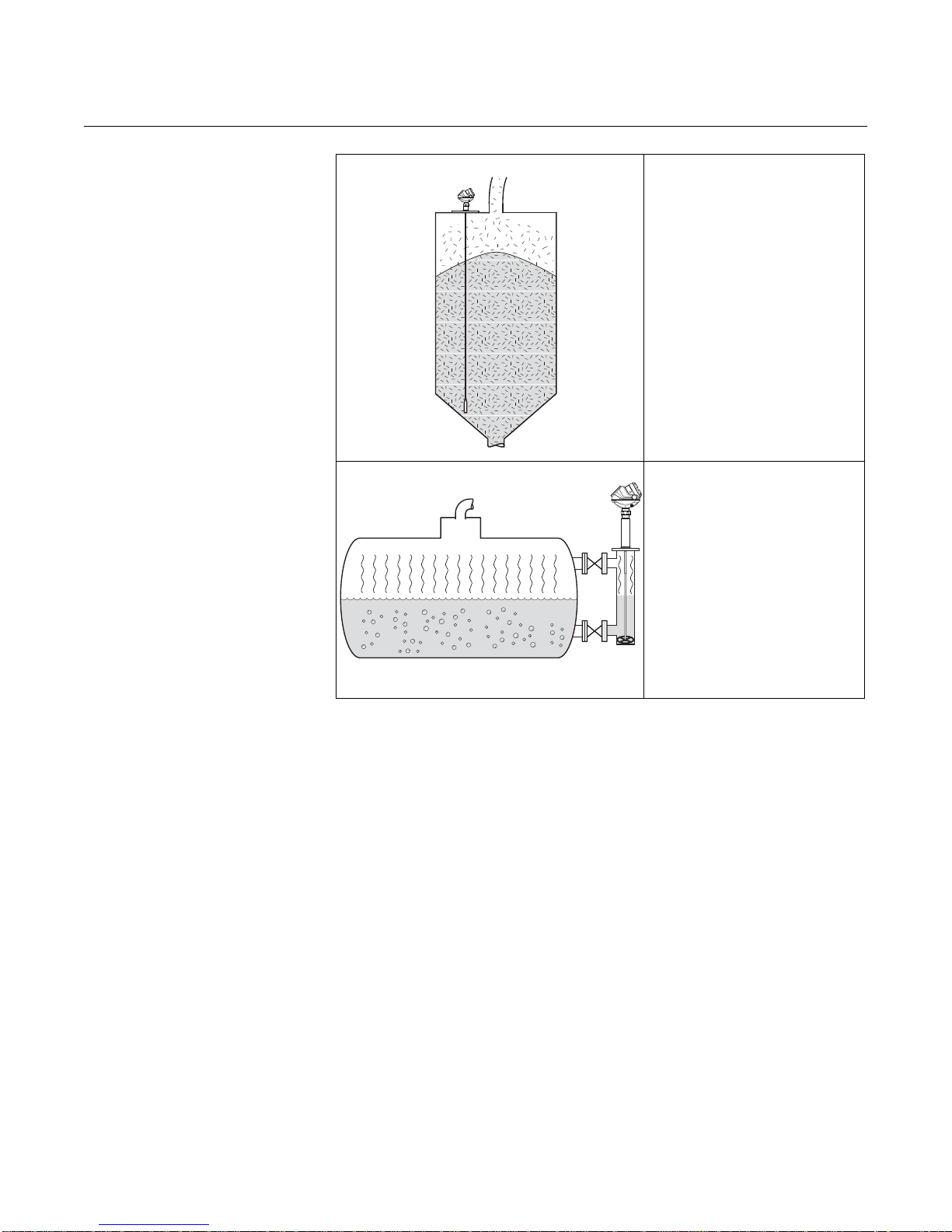

Interface Rosemount 5302 is the ideal choice for measuring the level of oil, and the

Figure 2-8. Interface

measurement with a Rosemount

5302 and a Rosemount 5301

(fully submerged probe).

2-12

interface of oil and water , or other liquids with significan t dielectric dif ferences.

Rosemount 5301 can also be used for interface measurement in applica tions

where the probe is fully submerged in the liquid.

Page 27

Reference Manual

1

35

7

9

11

0

16 (5)

33 (10)

49 (15)

66 (20)

82 (25)

98 (30)

115 (35)

80

40

20

10

Upper product dielectric constant

Maximum Upper Product

Thickness, ft (m)

Lower product

dielectric constant

Flexible Single Lead

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

For measuring interface level, the transmitter uses the residual wave of the

first reflection. Part of the wave, not reflected at the upper product surface,

continues until it is reflected at the lower product surface. The speed of this

wave depends fully on the dielectric constant of the upper product.

To measure interface, the following criteria have to be fulfilled:

• The dielectric constant of the upper prod uct must be known and sho uld

be constant. The Rosemount Radar Master software has a built- in

dielectric constant calculator to assist in determining the dielectric

constant of the upper product. (see “Dielectric Constant/Dielectr ic

Range” on page 5-23)

• The upper product must have a lower dielectr ic constant than the lower

product to have a distinct reflection

• The difference between the dielectric constants for the two products

must be greater than 6

• The maximum dielectric constant for the upper product: 10 for the

coaxial probe, 7 for the twin lead, and 8 for the single lead probes

• The upper product thickness must be greater than 5.1 in. (0.13 m) for

all probes, except the HTHP coaxial probe, which requires 8 in. (0.2 m),

to distinguish the echoes of the two liquids

The maximum allowable upper product thickness/measuring range is

primarily determined by the dielectric constants of the two liquids.

Target applications include interfaces between oil / oil-like and water /

water-like liquids with a low (<3) dielectric constant for the upper product and

a high (>20) dielectric constant for the lower product.

For such applications, the maximum measuring range is limited by the length

of the coaxial, rigid twin, and rigid single lead probes.

For flexible probes, the maximum measuring range is reduced by the

maximum upper product thickness, according to the diagram below . However,

characteristics may vary between the different applicat ion s .

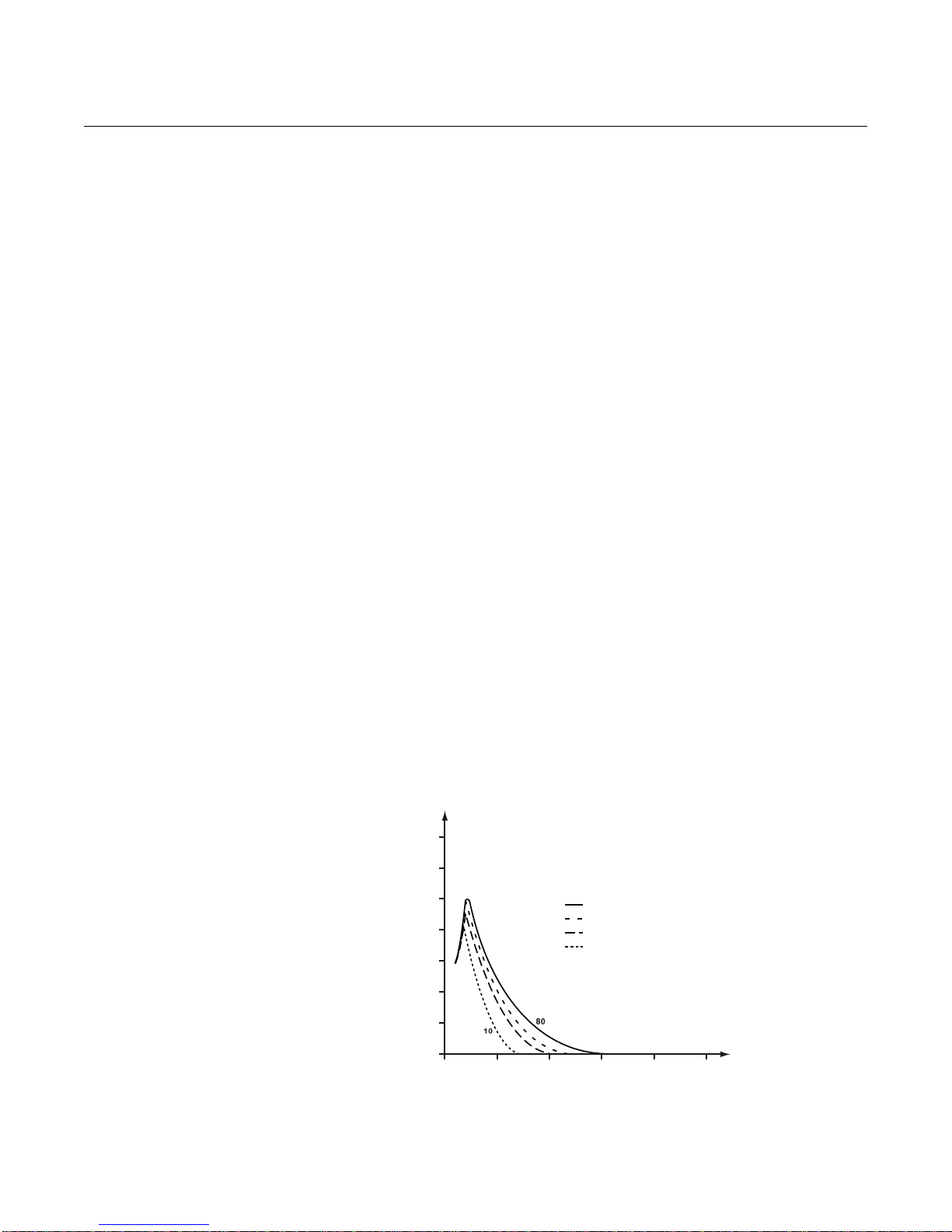

Figure 2-9. Maximum Upper

Product thickness for the

Flexible Single Lead probe.

2-13

Page 28

Rosemount 5300 Series

Lower product

dielectric constant

Upper product dielectric constant

Flexible Twin Lead

Maximum Upper Product

Thickness, ft (m)

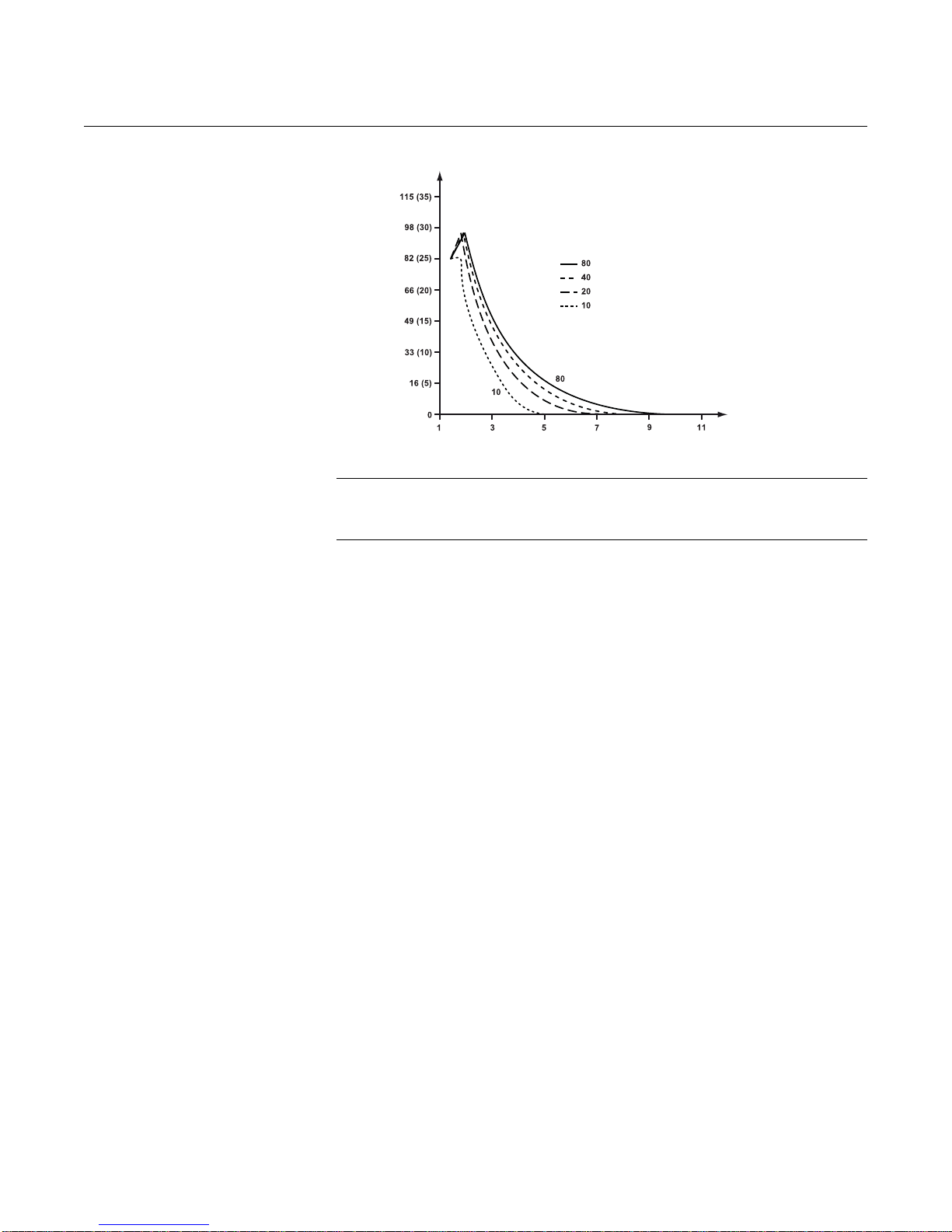

Figure 2-10. Maximum Upper

Product thickness for the

Flexible Twin Lead probe.

NOTE!

Maximum distance to the interface = 164 f t.(50 m) - Maximum Upper Product

Thickness.

Reference Manual

00809-0100-4530, Rev BA

July 2009

Emulsion Layers

Sometimes an emulsion layer (mix of the products) forms between the two

products and can affect interface measurements. For assistance with

emulsion applications, consult your local Emerson Process Management

representative.

V E SSEL

CHARACTERISTICS

Heating Coils, Agitators Because the radar signal is transmitted along a probe, the Rosemount 5300

Radar transmitter is generally not affected by objects in the tan k. Avoid

physical contact with metallic objects when Twin Lead or Single Lead probes

are used.

Avoid physical contact between probes and agitators, as well as applications

with strong fluid movement, unless the probe is anchored. If the probe is able

to move 1 ft. (30 cm) from any object, such as an agitator, during operation,

the probe tie-down is recommended.

To stabilize the probe for side forces, a weight may be hung at the probe end

(flexible probes only) or fix/guide the probe to the tank bottom.

Tank Shape The guided wave radar transmitter is insensitive to tank shape. Since the

radar signal travels along a probe, the shape of the tank bottom has virtually

no effect on the measurement performance. Th e transmitter can handle flat or

dish-bottom tanks.

2-14

Page 29

Reference Manual

Review Mounting

Considerations

(see page 3-3)

Mount the transmitter

(see page 3-15)

Wire the transmitter

(see Section 4:

Electrical Installation)

Make sure covers

and cable/conduit

connections are tight

Power up the

transmitter

Configure the

transmitter

(see Section 5:

Configuration)

Verify measurements

Set the Write

Protection

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

INSTALLATION

PROCEDURE

Follow these steps for proper installation:

2-15

Page 30

Rosemount 5300 Series

Reference Manual

00809-0100-4530, Rev BA

July 2009

2-16

Page 31

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Section 3 Mechanical Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . .page 3-3

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-15

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any services other than those contained in this manual unless you are

qualified.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully. If the Process Seal is damaged, gas

might escape from the tank if the transmitter head is removed from the probe.

www.rosemount.com

High voltage that may be present on leads could cause electrical shock:

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

Page 32

Rosemount 5300 Series

Any substitution of non-authorized parts or repair, other than exchanging the complete

transmitter head or probe assembly, may jeopardize safety and is prohibited.

Unauthorized changes to the product are strictly prohibited as they may unintentionally

and unpredictably alter performance and jeopardize safety. Unauthorized changes that

interfere with the integrity of the welds or flanges, such as making additional

perforations, compromise product integrity and safety. Equipment ratings and

certifications are no longer valid on any products that have been damaged or modified

without the prior written permission of Emerson Process Management. Any continued

use of product that has been damaged or modified without prior written authorization is

at the customer's sole risk and expense.

Reference Manual

00809-0100-4530, Rev BA

July 2009

3-2

Page 33

Reference Manual

Avoid nozzles with reducer

(unless using Coaxial probe)

UNZ

H

D

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

MOUNTING

CONSIDERATIONS

Before installing the Rosemount 5300 Series Radar Transmitter, consider

specific mounting requirements, vessel and process characteristics.

For Remote Housing installation see Appendix D: Remote Mounting.

Process Connection The Rosemount 5300 Series has a threaded con nection for easy mounting on

a tank roof. It can also be mounted on a nozzle by using differen t flanges.

Threaded Connection

Figure 3-1. Mounting on tank

roof using threaded connection.

Mounting on tank roof.

Figure 3-2. Mounting in nozzles

Flange Connection on Nozzles

3-3

Page 34

Rosemount 5300 Series

The transmitter can be mounted in nozzles by using an appropr iate flange.

The nozzle sizes given in Table 3-1 show the recommended dimensions. For

small nozzles, it may be necessary to increase the Upper Null Zone (UNZ) to

reduce the measuring range in the upper p art of the tank. Amplitude

Threshold adjustments may also be needed in th is case. A Trim Near Zone is

recommended in most nozzle installations, for example, when there are

disturbing obstacles in the near zone. See Appendix C: Handling of

Disturbances from Nozzle on page C-4.

NOTE!

The probe should not contact the nozzle, with the exception of the Coaxial

Probe. If the nozzle diameter is less than recommended, the mea suring range

may be reduced.

Table 3-1. Nozzle

considerations

Recommended

Nozzle Diameter (D)

Minimum Nozzle

Diameter (D)

Recommended

Nozzle Height (H)

(1) The Trim Near Zone function may be necessary or an Upper Null Zone setup may be required to mask

the nozzle.

(2) Longer nozzles may be used in certain applications. Consult your local Emerson Process

Management representative for details.

(3) When using single flexible probes in tall nozzles, it is recommended to use t he Long Stud (LS).

Reference Manual

00809-0100-4530, Rev BA

July 2009

Single (Rigid/Flexible) Coaxial Twin (Rigid/Flexible)

6 in. (150 mm)

(1)

(2)

2 in. (50 mm)

4 in. + Nozzle Diameter

> Probe Diameter 4 in. (100 mm)

> Probe Diameter 2 in. (50 mm)

(3)

N/A

4 in. + Nozzle

Diameter

3-4

Page 35

Reference Manual

Metal flange Ø>2

in./DN50

Metal sheet

Ø>8 in./200 mm

00809-0100-4530, Rev BA

July 2009

Figure 3-3. A single flexible

probe with a long stud.

Rosemount 5300 Series

A long stud - 10 in. (250 mm) - is recommen ded for sin gle flexible probes in a

tall nozzle.

Long Stud

10 in. (250 mm)

Installation of Single

Lead Probes in

Non-metallic Vessels

Figure 3-4. Mounting in

non-metallic vessels.

NOTE!

For single lead probes, avoid 10-in. (250 mm)/DN250 or larger diameter

nozzles, especially in applications with low dielectric constant. An alternative

is to install a smaller nozzle inside the nozzle.

For optimal single lead probe performance in non-metallic (plastic) vessels,

the probe must be mounted with a metal flange, or screwed in to a metal

sheet (d>8 in./200 mm), if the threaded version is used.

Electromagnetic disturbances should be kept to a minimum since they may

affect measurement performance.

3-5

Page 36

Rosemount 5300 Series

Metal

Installation in Concrete

Silos

Reference Manual

00809-0100-4530, Rev BA

July 2009

Considerations for Solid

Applications

The flexible single lead probe is recommended for solids and is available in

two versions to handle different loads and lengths:

• 0.16 in. (4 mm) diameter

Tensile strength is minimum 2698 lb (12 kN)

Collapse load is maximum 3597 lb (16 kN)

• 0.24 in. (6 mm) diameter

Tensile strength is minimum 6519 lb (29 kN)

Collapse load is maximum 7868 lb (35 kN)

Keep the following in mind when planning installation of the Rosemount 5300

in solid applications:

• There might be considerable down-pull forces on silo roofs caused by

the media, so the silo roof must withstand the maximum probe tensile

load

• The tensile load depends on silo size, material density, and the friction

coefficient. Forces increase with the buried length, the silo, and probe

diameter

• In critical cases, such as for products with a risk for build-up, use a 0.24

in. (6 mm) probe

• Depending on position, forces on probes are two to ten times greater

on probes with tie-down, than on probes with ballast weights

Guidelines for the tensile load from free-flowing solids acting on a suspended

probe without any tie-down or weight in a smooth metallic wall silo as shown

in Table 3-2. A safety factor of 2 is included for the figures. Consult your local

Emerson Process Management representative for more information.

(1)

3-6

(1) The weight should not be fixed for probe 100 ft (30 m) or longer.

Page 37

Reference Manual

Make sure that the probe

does not come into

contact with the chamber

wall, e.g. by using a

centering disk.

00809-0100-4530, Rev BA

July 2009

Table 3-2. Pulling force on probe installed in tanks with different products

Rosemount 5300 Series

Material Tensile load for 0.16 in. (4 mm)

Probe length 49 ft (15 m) Probe length 115 ft (35 m) Probe length 49 ft (15 m) Probe length 115 ft (35 m)

Tank Ø=

10 ft (3 m)

Wheat 670 (3) 1120 (5) 1800 (8) 4500 (20)

Polypropylene

Pellets

Cement 900 (4) 2020 (9) 2470 (11) 7310 (32.5)

340 (1.5) 670 (3) 810 (3.6) 2360 (10.5) 450 (2) 920(4.1) 1190 (5.3) 3510 (15.6)

flexible single lead probe, lb (kN)

Tank Ø=

39 ft (12 m)

Tank Ø=

10 ft (3 m)

Tank Ø=

39 ft (12 m)

Exceeds tensile

strength limit

Exceeds tensile

strength limit

NOTE!

For environments where electrost atic discharge s (p lastics) ar e li ke ly to occur,

it is recommended that the probe end is grounded.

Mounting in Chamber/

Still Pipe

The chamber is also known as bridle, side pipe, bypass pipe, and cage.

Dimensioning the chamber correctly and selecting the appropriate probe is

key to the success in these applications.

To prevent the probe from contacting the wall, centering discs are available

for the Rigid Single, Flexible Single, and Flexible Twin Lead Probes. The disc

is attached to the end of the probe, and thus keeps the probe centered in the

chamber. See also “Mou nting a Centering Disc for Pipe Installations“ on

page 3-25.

Tensile load for 0.24 in. (6 mm)

flexible single lead probe, lb (kN)

Tank Ø=

10 ft (3 m)

900 (4) 1690 (7.5) 2810 (12.5) 6740 (30)

1350 (6) 2920 (13) 3600 (16) 10790 (48)

Tank Ø=

39 ft (12 m)

Tank Ø=

10 ft (3 m)

Tank Ø=

39 ft (12 m)

Exceeds tensile

strength limit

Exceeds tensile

strength limit

NOTE!

To avoid disturbances from object near the pipe, metal-pipes are preferred,

especially in applications with low dielectric constant.

3-7

Page 38

Rosemount 5300 Series

Rigid Single

Flexible Single

N

L

Ø

Ø

Figure 3-5. Mounting Single

Probe in Chamber/Still Pipe

Inlet pipe diameter N<Ø. Effective measuring range L12 in. (300 mm).

Table 3-3. Recommended and

minimum chamber/still pipe

diameters for different probes.

Probe Type Recommended Diameter Minimum Diameter

Rigid Single 3 or 4 in. (75 or 100 mm) 2 in. (50 mm)

Flexible Single

Rigid Twin

Flexible Twin

Coaxial 3 or 4 in. (75 or 100 mm) 1.5 in. (37.5 mm)

(1) The center rod must be placed more than 0.6 in. (15 mm) away from the pipe wall.

The recommended chamber diameter is 3 in. (75 mm) or 4 in. (100 mm).

Chambers with a diameter less than 3 in. (75 mm) may cause problems with

build-up and it may also be difficult to avoid contact between chamber wall

and probe. Chambers larger than 6 in. (150 mm) can be used but provide no

advantages for radar measurement.

Reference Manual

00809-0100-4530, Rev BA

July 2009

4 in. (100 mm) Consult your local Emerson

Process Management

(1)

(1)

3 or 4 in. (75 or 100 mm) 2 in. (50 mm)

4 in. (100 mm) Consult your local Emerson

representative

Process Management

representative

3-8

It is recommended that single probes are used with the Rosemount 5300

Series. Other probe types are more susceptible to build-up and are not

recommended.

(1)

An exception is with liquefied gas > 40 bar when the coaxial

probe should be used.

The probe must not touch the chamber wall, should extend the full height of

the chamber, but not touch the bottom of the chamber. Probe type selection

depends on probe length:

Less than 14.7 ft (4.5 m): Rigid Single Probe is recommended. Use a

centering disc for a probe > 3.3 ft. (1 m). If installation requires less

head-space, use a Flexible Single Probe with a weight and centering disc.

(2)

More than 14.7 ft (4.5 m): Use Flexible Single Probe with a weight and

centering disc.

(1) The single probe creates a virtual coaxial probe with the chamber as the outer tube. The

extra gain provided by the twin and coaxial probes is not necessary; the electronics in the

Rosemount 5300 Series is very sensitive and is not a limiting factor.

(2) The transition zones and the height of the weight limit the use of single flexible probes

shorter than 3 ft. (1 m). If using the flexible probe, the short weight is recommended.

Page 39

Reference Manual

Side-and-Side

dimension

Side-and-Bottom

dimension

Centre-to-Centre

Centre-to-Centre

00809-0100-4530, Rev BA

July 2009

Figure 3-6. Insulated Chamber.

Rosemount 5300 Series

A short weight for the single flexible 0.16 in. (4 mm) SST probe can be used

for measuring close to the probe end. The height is 2 in. (50 mm) and the

diameter is 1.5 in.

(37.5 mm). Option code W2.

For hot applications, the chamber should always be insulated to prevent

personal injuries and to reduce the amount o f energy needed for heating . See

Figure 3-6. It is often an advantage, and sometimes even required, for the

radar measurement:

• In hot applications, insulation reduces the amount of condensation,

since it prevents the upper part of the chamber from becoming a cold

spot

• Insulation prevents product solidification inside the chamber, and

clogging of the inlet-pipes

See page 3-14 for more information.

When mounting in a Rosemount 9901 chamber, the probe length to use can

be calculated with these formulas:

Side-and-Side dimension: Probe length = Centre-to-Centre dimension +

19 in. (48 cm)

Side-and-Bottom dimension: Probe length = Centre-to-Centre dimension +

4 in. (10 cm)

3-9

Page 40

Rosemount 5300 Series

Replace

chamber flange

Displacer length

Probe

length

NOTE!

The formulas are not valid when using Dynamic Vapor Compensation probes.

Reference Manual

00809-0100-4530, Rev BA

July 2009

Replacing a Displacer in

an Existing Displacer

Chamber

A Rosemount 5300 Series transmitter is the perfect replacement for an

existing displacer chamber. To simplify installation, proprietary flanges are

offered to allow for using the same chambers.

Rosemount 5300 benefits

• No moving parts: Less maintenance - dramatically reduce d cos ts, and

as a result, improved measurement availability

• Reliable measurement, that is independent of density, turbulence, and

vibrations

Considerations when changing to Rosemount 5300

When changing from a displacer to a Rosemount 5300 Series transmitter,

make sure to correctly match the 5300 Series flange choice and probe length

to the chamber. Both standard ANSI and EN (DIN), as well as proprietary

chamber flanges are available.

Table 3-4. Required Probe

Length Depending on Chamber

Manufacturers

3-10

Table 3-4 shows probe length guidelines.

Chamber Manufacturer Probe Length

Major torque-tube manufacture (249B,

249C, 2449K, 249N, 259B)

Masoneilan (Torque tube operated),

proprietary flange

Others - torque tube

Magnetrol (spring operated)

Others - spring operated Displacer + 19.7 in. (500 mm)

(1)

Displacer + 9 in. (229 mm)

Displacer + 8 in. (203 mm)

(2)

(3)

(1) If flushing ring is used, add 1 in. (25 mm).

(2) For other manufacturers, there are small variations. This is an approximate value,

actual length should be verified.

(3) Lengths vary depending on model, SG and rating, and should be verified.

Displacer + 8 in. (203 mm)

Displacer + between 7.8 in. (195 mm)

to 15 in. (383 mm)

Page 41

Reference Manual

00809-0100-4530, Rev BA

July 2009

Rosemount 5300 Series

Free Space For easy access to the transmitter, make sure it is mounted with sufficient

service space. For maximum measurement performance, the transmitter

should not be mounted close to the tank wall or near other object s in the tank.

If the probe is mounted close to a wall, nozzle or other tank obstruction, noise

may appear in the level signal. The minimum clearance shown in Table 3-5

and Table 3-6 is recommended:

Figure 3-7. Free Space

Requirement

Table 3-5. Recommended

minimum free space L to tank

wall or other objects in the tank

Table 3-6. Recommended

minimum free space L to tank

wall or other objects in the tank

for Single Lead probes

Coaxial Rigid Twin Flexible Twin

0 in. (0 mm) 4 in. (100 mm) 4 in. (100 mm)

Rigid Single/Flexible Single

4 in. (100 mm) Smooth metal wall.

20 in. (500 mm)

(1) When measuring in low DC (around 1.4). For higher DC, the recommended

free space is lower.

(1)

Disturbing objects such as pipes and beams,