Page 1

Quick Start Guide

00825-0100-4520, Rev BA

Rosemount™ 520 Level Transmitter

January 2021

Page 2

Quick Start Guide

January 2021

NOTICE

This guide provides basic guidelines for Rosemount 520 Level Transmitters. It does not provide instructions

for configuration, diagnostics, maintenance, service, troubleshooting, or Intrinsically safe installations. Refer

to the Rosemount 520 Reference Manual for more information.This manual is also available electronically on

Emerson.com/Rosemount

Explosions could result in death or serious injury.

Installation of this transmitter in hazardous areas must be in accordance with the appropriate local, national,

and international standards, codes, and practices. Review approvals section of the Rosemount 520 Reference

Manual for any restrictions associated with a safe installation.

Before connecting a HART®-based communicator in an explosive atmosphere, make sure the instruments in

the loop are installed in accordance with intrinsically safe or non-incentive field wiring practices.

Electrical shock can result in death or serious injury.

Avoid contract with the leads and the terminals. High voltage that may be present on leads can cause

electrical shock.

.

Contents

System readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mount the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connect wiring and power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Verify transmitter configuration (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Trim the transmitter (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Product certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

Page 3

January 2021

Quick Start Guide

1.0 System readiness

1.1 HART Communication

The Rosemount 520 utilizes the HART Communications Protocol. The most

notable advantage of employing HART Communications is that digital

information can be transmitted over legacy 4–20mA analog instrumentation

wiring. In addition to providing device diagnostics and process alerts, the ability

to communicate to the device remotely simplifies basic configuration,

calibration, and maintenance. A task-oriented, user optimized interface

eliminates errors and speeds routine maintenance tasks.

For the Rosemount 520, HART Protocol facilities two basic operation

configurations.

Point-to-point

In this configuration, digital signals are superimposed on the 4–20 mA loop

current. One process variable is sent on the 4–20 mA signal and other secondary

or calculated process variables can be transmitted digitally over the 4–20 mA

signal.

Multidrop

Multidrop refers to the connection of several transmitters to a single

communication transmission line. Communication between the host and the

transmitters occurs digitally with the analog output of the transmitters

deactivated. With HART Revision 7, up to 63 transmitters can be connected on a

single twisted pair of wires. Multidrop installation requires consideration of the

update rate necessary from each transmitter, the combination of transmitter

models, and the length of the transmission line.

For more information, reference “Connect wiring and power up” on page 13.

1.2 Configuration tools

There are several tools that can be used to configure the Rosemount 520.

The Field Communicator is a portable, handheld device used to configure field

devices or perform diagnostics for effective troubleshooting in the field without

having to use a laptop. The Field Communicator supports all HART devices and is

available in an intrinsically safe version.

™

HART modems allow AMS

devices using a PC serial port, PC USB port, or Bluetooth® connectivity. Serial and

USB HART modems attach directly to a PC or laptop computer and do not require

an external power supply. Bluetooth HART modems require a self-contained

power source (AAA batteries) as well as a Bluetooth-ready workstation PC.

HART modems also allow the AMS Instrument inspector to communicate with

HART devices using a PC USB or serial port. The AMS Instrument inspector is a

PC-based application that performs configuration and maintenance functions for

the Rosemount 520 Transmitter. AMS Instrument Inspector is only fully

compatible with MACTek VIATOR USB Modem.

Trex communicator to communicate with HART

3

Page 4

Quick Start Guide

The Rosemount 520 is not shipped with the AMS Instrument Inspector; the AMS

Instrument Inspector can be downloaded free of charge at

Emerson.com/ams-instrument-inspector

.

1.3 Confirm HART Revision capability

If using HART-based control or asset management systems, confirm the HART

capability of those systems prior to transmitter installation. Not all systems are

capable of communicating with HART Revision 7 Protocol.

1.4 Confirm correct device driver

Verify the latest device driver (DD/DTM™) is loaded on your system to ensure

proper communication.

Download the latest DD/DTM at Emerson.com

.

2.0 Handling

Proper handling of the Rosemount 520 is critical. To avoid damaging the

transmitter, avoid doing the following:

Lifting by the cable if the transmitter is mounted with fittings

Removing the protective diaphragm cap before installation

Applying pressure to the diaphragm using fingers, tools, or sharp objects

Using sharp objects to clean the diaphragm

Submerging or blocking the vent tube

Bending the cable within a radius of less than 90mm

January 2021

3.0 Mount the transmitter

Note

All installation methods described in the following sections are grounded. If a different installation

method is used, the transmitter must be grounded to meet EMC and hazardous location

requirements.

4

Page 5

January 2021

A

B

C

D

F

E

G

38

Ø 12

55

125

160

50

41

194.5

Quick Start Guide

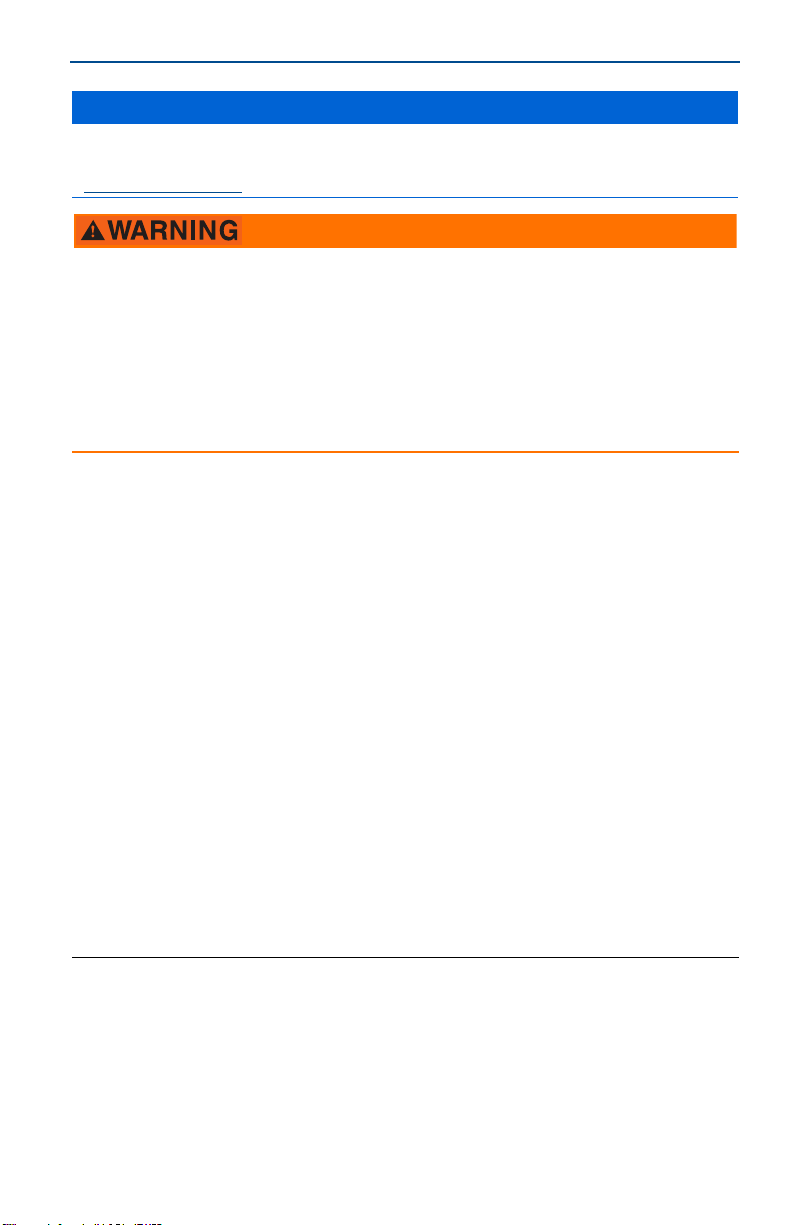

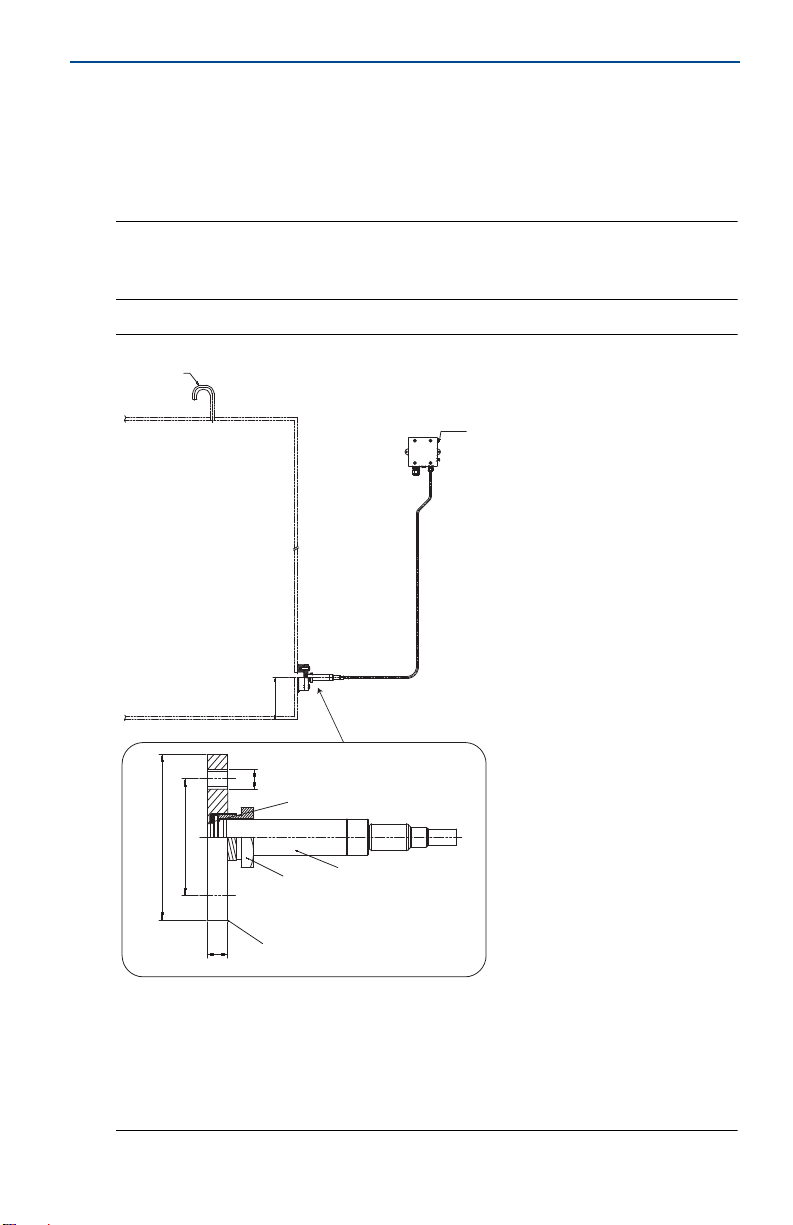

3.1 Internal mounting

1. Secure the bracket to the tank wall.

2. Secure the transmitter by use of the provided spring. The spring is fitted into

the two holes in the bracket. The transmitter can be mounted and

dismounted without the use of tools.

3. Secure the transmitter cable to the tank wall.

Note

Emerson recommends protecting the cable by appropriate means to avoid the cable being

damaged from, for example, sloshing waves.

Emerson recommends installing the transmitter in locations with limited or no turbulence.

Emerson recommends avoiding this specific mounting method for service tanks due to challenges

associated with performing service and maintenance. Other mounting methods, such as pole

mounting, flexible rubber tube mounting and flexible PTFE tube mounting are recommended for

installation inside service tanks.

Figure 1. Installation Drawing

A. Optional junction box

B. Optional bulkhead fitting

C. Dead zone

D. Lowest tank bottom

E. Transmitter

F. Mounting bracket

G. Mounting spring

5

Page 6

Quick Start Guide

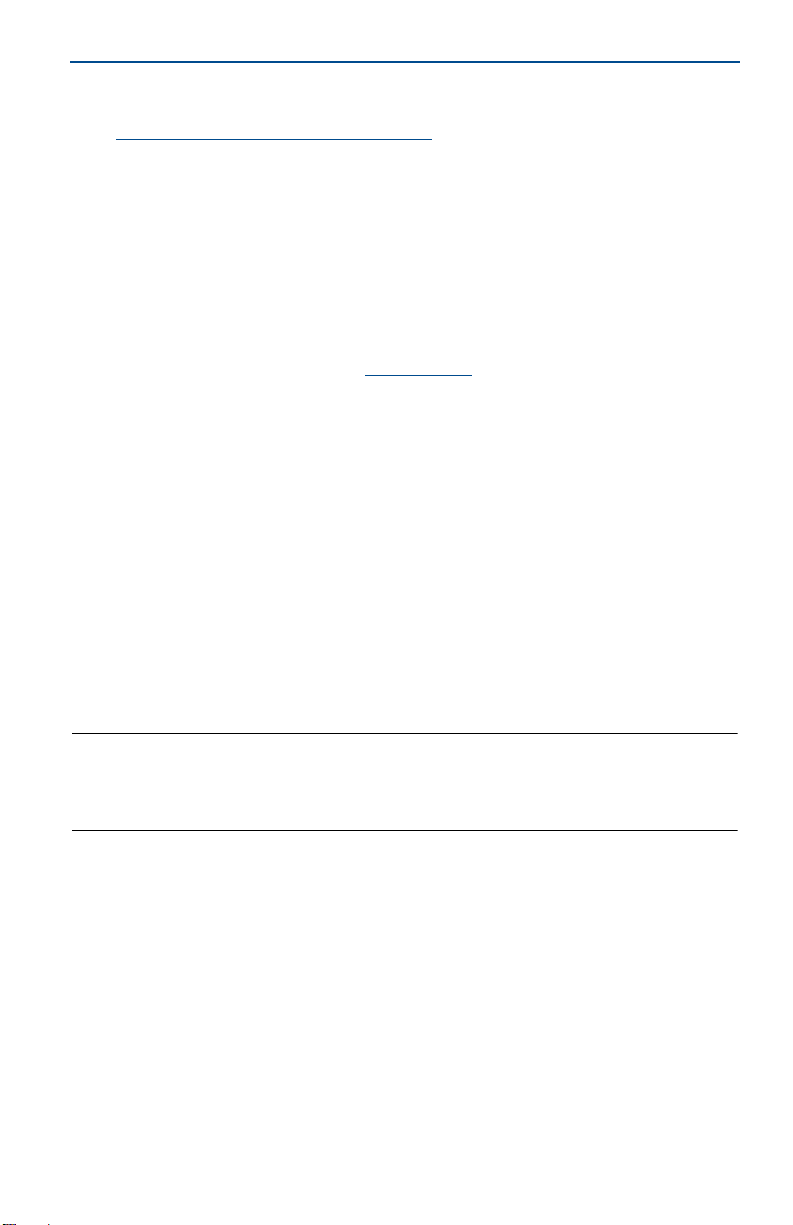

3.2 Pole mounting

1. Install a suitable deck socket on top of the tank.

2. Secure the transmitter inside the pipe by use of the provided nut and gasket.

The recommended torque is 20 N-m.

Figure 2. Installation Drawing

A

34

26

January 2021

40

B

C

A. Optional junction box

B. Tank top

C. Dead zone

D. Lowest tank bottom

E. Transmitter

D

F

E

30

193

H

I

G

24

26

41

F. Pipe max. length 2000 mm (yard supply)

G. Gasket

H. Welding nipple for pole, length 40 mm

I. 1-in. end cap

6

Page 7

January 2021

A

B

C

D

E

F

JHG

I

34

26

30

25

55

80

193

24

26

41

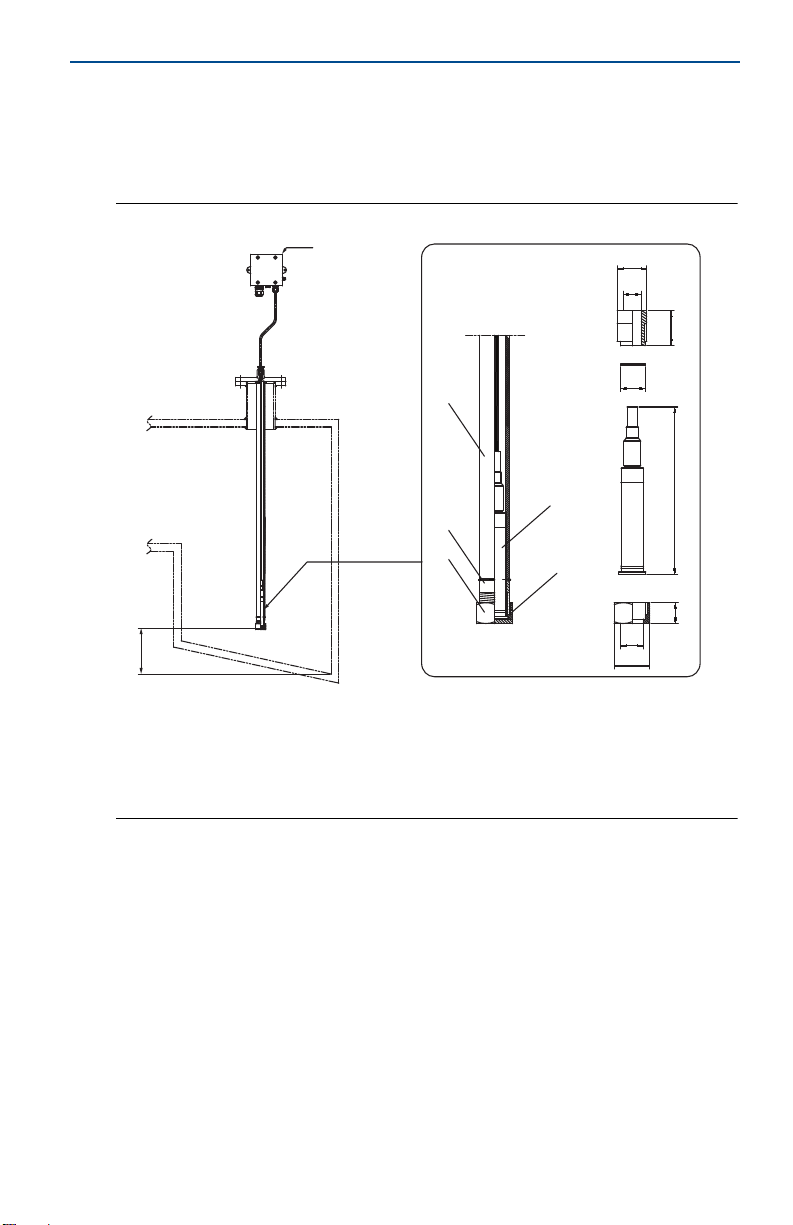

3.3 1-in. pipe end mounting

1. Secure the provided nipple pipe to the tank wall or to a ball valve.

2. Secure the transmitter to the nipple pipe by use of the provided nut and

gasket. The recommended torque is 20 N-m.

Figure 3. Installation Drawing

Quick Start Guide

A. Optional junction box

B. Tank top

C. Dead zone

D. Tank bottom

E. Vent pipe

F. Gasket

G. Nut

H. Nipple pipe, length 80 mm

I. Transmitter

J. Ball valve (yard supply)

7

Page 8

Quick Start Guide

C

A

G

F

E

I

D

K

B

H

L

J

D

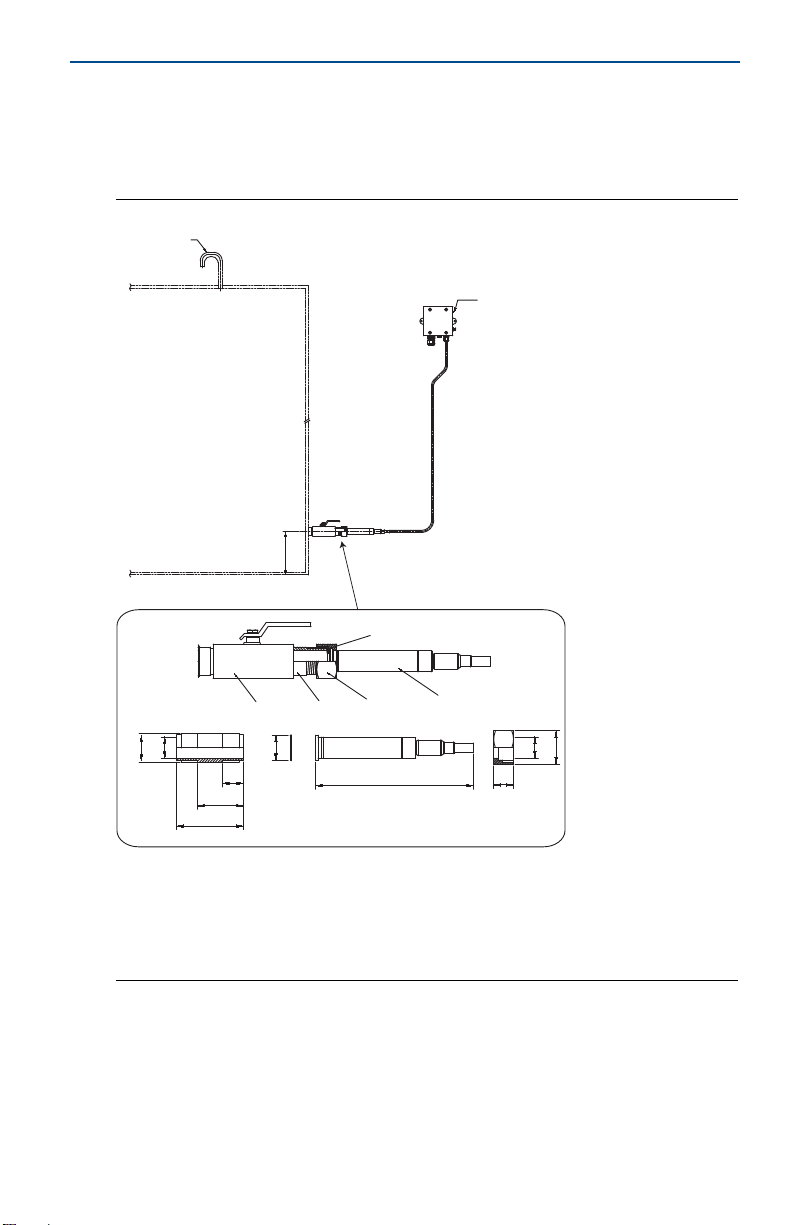

3.4 Flange mounting

1. Install a suitable flange connection to the tank wall.

2. Secure the provided flange to the tank flange connection.

3. Secure the transmitter in the flange by use of the provided nut and gasket. The

recommended torque is 20 N-m.

Note

Emerson recommends installing a ball valve between the tank wall and transmitter to

facilitate transmitter service and maintenance.

Figure 4. Installation Drawing

January 2021

8

A. Optional junction box

B. Refer to Table 1

C. Tank top

D. Refer to Table 1

E. Dead zone

F. Tank bottom

G. Vent pipe

H. Flange

I. Gasket

J. Transmitter

K. Refer to Table 1

L. Nipple pipe connector

Page 9

January 2021

Table 1. Flange Size for Flange Mounting

Standard D (mm) B (mm) K (mm) d x n (mm)

DN25 PN16 115 16 85 14 x 4

DN40 PN16 150 18 110 18 x 4

JIS25A—16K 125 14 90 19 x 4

JIS40A—16K 140 16 105 19 x 4

1-in. ANSI/150 108 16 79 16 x 4

11/2-in. ANSI/150 127 17.5 98.6 16 x 4

Quick Start Guide

9

Page 10

Quick Start Guide

3.5 Flange with 1-in. ball valve mounting

1. Install a suitable flange connection to the tank wall.

2. Secure the provided flange and ball valve to the tank flange connection.

3. Secure the transmitter in the ball valve by use of the provided nut and gasket.

The recommended torque is 20 N-m.

Figure 5. Installation Drawing

G

C

A

January 2021

F

DK

A. Optional junction box

B. Refer to Table 2

C. Tank top

D. Refer to Table 2

E. Dead zone

F. Tank bottom

G. Vent pipe

E

HIJ

D

B

LMN

64

315

H. Flange

I. 1-in. ball valve

J. 1-in. nipple pipe connector 1-to 1-in.

K. Refer to Table 2

L. Gasket

M. 1-in. nut

N. Transmitter

Table 2. Flange Size for Flange with 1-in Ball Valve

Standard D (mm) B (mm) K (mm) d x n (mm)

DN25 PN16 115 16 85 14 x 4

JIS25A—16K 125 14 90 19 x 4

1-in. ANSI/150 108 16 79 16 x 4

10

Page 11

January 2021

3.6 Flexible rubber tube mounting

The transmitter and flange are secured to the rubber tube by tightening clips.

This is done by the factory, prior to delivery.

1. Install a suitable pipe in the tank.

2. Insert the rubber tube into the pipe and secure the provided flange to the

deck socket.

Figure 6. Installation Drawing

A

D

K

M

B

C

D

L

I

Quick Start Guide

J

E

F

A. Optional junction box

B. Refer to Table 3

C. Tank top

D. Refer to Table 3

E. Dead zone

F. Lowest tank bottom

H. Washer

I. Tightening clip

J. Rubber tube

K. Refer to Table 3

L. Flange

M. Cable gland PG11, DIN 89280

G. Transmitter

Table 3. Flange Size for Flexible Rubber Tube and PTFE Tube

Standard D (mm) B (mm) K (mm) d x n (mm)

DN50 PN16 165 19 125 18 x 4

JIS50A—16K 155 20 120 19 x 4

2-in. ANSI/150 153 19 120 19 x 4

G

I

H

11

Page 12

Quick Start Guide

3.7 Flexible PTFE tube mounting

The transmitter is secured to the PTFE tube by a nut and a ferrule. The PTFE tube is

secured to the flange by fittings. This is done by the factory, prior to delivery.

1. Install a suitable pipe in the tank.

2. Insert the PTFE tube into the pipe and secure the provided flange to the deck

socket.

Note

The recommended minimum tube bending radius is 130 mm.

January 2021

Figure 7. Installation Drawing

A

B

D

C

E

F

A. Optional junction box

B. Refer to Table 3

C. Tank top

D. Refer to Table 3

E. Dead zone

F. Lowest tank bottom

G. Transmitter

H. Spacer

M

I. HY-Lok nut and ferrules

J. HY-Lok fitting with nut and ferrules

K. Refer to Table 3

L.Hydraline SV

M. Hydraline SB hose jacket

N. Hose fitting with BSP

O. Flange

P. Cable gland PG11, DIN 89280

D

K

P

O

N

L

H

1

/2-in. PTFE hose braided with stainless steel

1

/2-in. male thread

M

J

I

G

12

Page 13

January 2021

Quick Start Guide

4.0 Connect wiring and power up

4.1 Signal cable

Shielded twisted pair cable should be used for best result. Use wire with minimum

diameter of 0.51 mm (24 AWG). To ensure the functionality of the digital

communication the following table shall be used to determine the maximum

signal cable length:

Table 4. Signal Cable Length

Transmitter cable length Signal cable maximum length

0 m < x 25 m 825 m

25 m < x 50 m 770 m

50 m < x 100 m 660 m

100 m < x 200 m 440 m

200 m < x 300 m 220 m

Note

The calculated signal cable lengths are based on a conventionally constructed

cable with a capacitance equal to or less than 200 pF/m.

Maximum allowed transmitter cable length for installation in hazardous area is

75 m. Maximum allowed total cable length, transmitter cable plus signal

cable, must be determined by IS loop calculations.

4.2 Transmitter cable

The vent tube must be directed to an area with atmospheric pressure. If the

transmitter cable terminates in an area with overpressure or negative pressure

relative to the atmospheric pressure in the tank, the vent tube must be directed

to an area with atmospheric pressure equal to the pressure inside the tank.

4.3 Power supply

The power supply and load limitations are described in Figure 8 on page 14. The

total resistance load is the sum of the resistance of the signal cable and the load

resistance of the controller, indicator, and related equipment. Note that the

resistance of intrinsic safety barriers, if used, must be included.

13

Page 14

Quick Start Guide

~

A

B

Figure 8. Load Limitation

Maximum loop resistance = 43.5 x (Power supply voltage – 10)

HART communication requires a minimum loop resistance of 250 ohm.

Table 5. Load Resistance and Voltage Supply Limits

Parameter Limit

R

( ) 250

1

R

( ) 1130

2

V

(V) 10

min

V

(V) 15.75

1

V

(V) 36

2

January 2021

4.4 Wiring diagrams

Figure 9. Point-to-Point

A. Field Communicator or PC with HART modem

B. Rosemount 520

14

Page 15

January 2021

~

A

BBB

Figure 10. Multidrop

A. Field Communicator or PC with HART modem

B. Rosemount 520

Quick Start Guide

15

Page 16

Quick Start Guide

January 2021

5.0 Verify transmitter configuration (optional)

Transmitters are shipped from Emerson fully configured per request or by the

standard factory default configuration. The configuration can be verified using

any HART capable configuration tool. Configuration instructions for the Field

Communicator are included in this step.

5.1 Verify configuration using the Field Communicator

A Rosemount 520 Device Driver (DD) must be installed on the Field

Communicator to verify configuration. Emerson recommends installing the latest

DD to access the complete functionality. Visit Emerson.com

information.

Fast Key sequences for the latest DD are shown below in Table 6. A check (

indicates the basic configuration parameters. At minimum, these parameters

should be verified as part of configuration and startup.

Table 6. Fast Key Sequences (Device Revision 2, DD Revision 1)

Function Fast Key sequence

Alarm and Saturation Levels 2, 2, 2, 5, 7

Damping 2, 2, 1, 1, 5

Range Values 2, 2, 2

Tag 2, 2, 6, 1, 1

Units 2, 2, 1, 1, 4

Analog Output Alarm Direction 2, 2, 2, 5, 2

Transfer Function 2, 2, 1, 1, 6

Digital Zero Trim 3, 4, 1, 3

Upper Sensor Trim 3, 4, 1, 1

Lower Sensor Trim 3, 4, 1, 2

Scaled D/A Trim (4–20 mA Output) 3, 4, 2

Digital to Analog Trim (4–20 mA Output) 3, 4, 2

Date 2, 2, 6, 1, 5

Descriptor 2, 2, 6, 1, 6

Message 2, 2, 6, 1, 7

Long Tag 2, 2, 6, 1, 2

Scaled Variable 3, 2, 3

Burst Mode 2, 2, 4, 3

Rerange with Keypad 2, 2, 2, 1

Loop Test 3, 5, 1

Sensor Temperature/Trend 3, 3, 2

Simulate Digital Signal 3, 5, 2

Transmitter Security (Write Protect) 3, 4, 4, 1

for more

)

16

Page 17

January 2021

Quick Start Guide

6.0 Trim the transmitter (optional)

Devices are calibrated by the factory. Once installed, it is recommended to

perform a zero trim. A zero trim is a single-point adjustment to compensate for

mounting position. When performing a zero trim, ensure the vent tube is vented

to atmospheric pressure.

6.1 Zero trim using the Field Communicator

1. Connect the Field Communicator

(see “Connect wiring and power up” on page 13 for instructions).

2. At the main menu, input the 3, 4, 1, 3 Fast Key sequence.

3. Follow the commands to perform a zero trim.

17

Page 18

Quick Start Guide

7.0 Product certifications

Rev 1.1

7.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the Quick Start Guide.

The most recent revision of the EU Declaration of Conformity can be found at

Emerson.com/Rosemount

7.2 Europe

I1 ATEX Intrinsic Safety

Certificate: Baseefa15ATEX0075X

Standards: EN60079-0:2012+A11:2013, EN60079-11:2012

Markings: II 1 G Ex ia IIC T4 Ga (–40 °C T

Table 7. Input Parameters

Parameter HART

Voltage U

i

Current I

i

Power P

i

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is manufactured of titanium and may

present a frictional ignition risk and must be protected from impact or abrasion if

located in a zone 0.

2. When a junction box is not used, the free ends of the cable must be afforded a degree of

protection of at least IP20.

3. The optional polyester junction box present a potential electrostatic ignition risk and

must not be rubbed or cleaned with a dry cloth.

Installation in Hazardous Locations

When installing the Rosemount 520 in hazardous areas, to reduce the risk of electrostatic

charges the resistance of the titanium transducer to earth should be less than10

i

.

+85 °C)

a

30 V

200 mA

1.0 W

i

42 nF

77 H

January 2021

9

Ω.

7.3 International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 15.0050X

Standards: IEC60079-0:2011, IEC60079-11:2011

Markings: Ex ia IIC T4 Ga (–40 °C T

Table 8. Input Parameters

Parameter HART

Voltage U

i

Current I

i

Power P

i

Capacitance C

Inductance L

18

i

+85 °C)

a

30 V

200 mA

1.0 W

i

42 nF

77 H

Page 19

January 2021

Quick Start Guide

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is manufactured of titanium and may

present a frictional ignition risk and must be protected from impact or abrasion if

located in a zone 0.

2. When a junction box is not used, the free ends of the cable must be afforded a degree of

protection of at least IP20.

3. The optional polyester junction box present a potential electrostatic ignition risk and

must not be rubbed or cleaned with a dry cloth.

Installation in Hazardous Locations

When installing the Rosemount 520 in hazardous areas, to reduce the risk of electrostatic

charges the resistance of the titanium transducer to earth should be less than10

7.4 Brazil

I2 INMETRO Intrinsic Safety

Certificate: UL-BR 16.0260X

Standards: ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

Markings: Ex ia IIC T4 Ga (–40 °C T

Table 9. Input Parameters

Parameter HART

Voltage U

i

Current I

i

Power P

i

Capacitance C

Inductance L

i

i

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is manufactured of titanium and may

present a frictional ignition risk and must be protected from impact or abrasion if

located in a zone 0.

2. When a junction box is not used, the free ends of the cable must be afforded a degree of

protection of at least IP20.

3. The optional polyester junction box present a potential electrostatic ignition risk and

must not be rubbed or cleaned with a dry cloth.

30 V

200 mA

1.0 W

42 nF

77 H

+85 °C)

a

9

Ω.

19

Page 20

Quick Start Guide

7.5 Additional certifications

SBS American Bureau of Shipping (ABS) Type Approval

Certificate: 15-HS1462157-PDA

Intended Use: Marine & Offshore Applications – Pressure transmitter used for

determining tank levels

SBV Bureau Veritas (BV) Type Approval

Certificate: 43940

Requirements: Bureau Veritas Rules for the Classification of Steel Ships

Application: Class notations: AUT-UMS, AUT-CCS, AUT-PORT and AUT-IMS;

Pressure transmitter type 520 cannot be installed on diesel engines

SLL Lloyd’s Register (LR) Type Approval

Certificate: 16/60006

Requirements: Lloyd’s Register’s Type Approval System and Test Spec 1.

Application: ENV Categories 1-4

SDN Den Norske Veritas (DNVGL) Type Approval

Certificate: TAA000007Z

Requirements: Det Norske Veritas’ Rules for Classification of Ships, High Speed and

Light Craft, and Det Norske Veritas’ Offshore Standards

Application:

Location classes

Type 520

Temperature B

Humidity B

Vibration A

EMC A

Enclosure D/IP66/IP68

January 2021

SKR Korean Register (KR) Type Approval

Certificate: CPH21541-AE002

Certificate: SHI23018-AE001

Requirements: Pt. 6, Ch. 2, Art. 301 of the Rules for Classification, Steel Ships

SNK Nippon Kaiji Kyokai (NK) Type Approval

Certificate: TA17262M

Requirements: Chapter 1, Part 7 of "Guidance for the Approval and Type Approval of

Materials and Equipment for Marine Use" and the relevant Society's

Rules

SCS China Classification Society (CCS) Type Approval

Certificate: TAA000007Z

Requirements: Det Norske Veritas’ Rules for Classification of Ships, High Speed and

Light Craft, and Det Norske Veritas’ Offshore Standards

20

Page 21

January 2021

EU Declaration of Conformity

No: RMD 1107 Rev. C

Page 1 of 2

We,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Rosemount 520 Level Transmitter

manufactured by,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

(signature)

Vice President of Global Quality

(function name - printed)

Chris LaPoint

(name - printed)

1-Feb-19

(date of issue)

Figure 11. Rosemount 520 Declaration of Conformity

Quick Start Guide

21

Page 22

EU Declaration of Conformity

No: RMD 1107 Rev. C

Page 2 of 2

EMC Directive (2004/108/EC) This directive is valid until 19 April 2016

EMC Directive (2014/30/EU) This directive is valid from 20 April 2016

Harmonized Standards:

EN 61326-1:2013, EN 61326-2-3:2013

ATEX Directive (94/9/EC) This directive is valid until 19 April 2016

ATEX Directive (2014/34/EU) This directive is valid from 20 April 2016

Baseefa15ATEX0075X - Intrinsic Safety

Equipment Group II Category 1 G

Ex ia IIC T4 Ga

Harmonized Standards:

EN60079-0:2012+A11:2013, EN60079-11:2012

ATEX Notified Bodies

SGS FIMCO OY [Notified Body Number: 0598]

P.O. Box 30 (Särkiniementie 3)

00211 HELSINKI

Finland

ATEX Notified Body for Quality Assurance

SGS FIMCO OY [Notified Body Number: 0598]

P.O. Box 30 (Särkiniementie 3)

00211 HELSINKI

Finland

Page 23

January 2021

Quick Start Guide

23

Page 24

Emerson Automation Solutions

Damcos A/S

Aaderupvej 41

DK-4700 Naestved

Denmark

+45 55 78 72 00

+45 55 78 72

Emerson Automation Solutions Marine System

(Shanghai) Co. Ltd.

T3-7, 128 Long Gui Road JinQiao

Export Process Xone (South). Post

Code: 201201 Shanghai, China

+86 21 5858 9666 801

+86 21 3897 266

CN.NTM@Emerson.com

Emerson Automation Solutions

Rosemount Tank Radar AB

Box 13045

SE-40251 Gothenburg

Sweden

+46 31 337 00 00

+46 31 25 30 22

Quick Start Guide

00825-0100-4520, Rev BA

January 2021

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Emerson Terms and Conditions of Sale are available upon request.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Rosemount is a mark of one of the

Emerson family of companies.

All other marks are the property of their respective owners.

© 2021 Emerson. All rights reserved.

The contents of this publication are presented for information

purposes only, and while efforts has been made to ensure their

accuracy, they are not to be construed as warranties or guarantees,

expressed or implied, regarding the products or

services described herein or their use or applicability.

Standard Terms and Cond itions of Sale can be issued by contacting

Damcos A/S.

We reserve the right to modify or improve the designs and

specifications of our products at any time without notice.

Loading...

Loading...