Page 1

Rosemount™ 520 Level Transmitter

Product Data Sheet

January 2021

00813-0100-4520, Rev BA

Suitable for installation in virtually any tank gauging application

5-year stability reduces maintenance costs

4-20 mA HART

Superior overpressure protection

Up to 25:1 rangeability and simplified range selection for increased flexibility

®

capabilities

Page 2

Rosemount 520

0.0%

0.1%

0.2%

0.3%

0.4%

0.5%

0 6 12 18 24 30 36 42 48 54 60

Percent (%) of URL

Months in service

Competitive unit with

o

ut calibration

Rosemo

u

n

t 520

Com

peti

ti

ve unit

January 2021

Legendary Rosemount performance customized for marine applications

The Rosemount 520 Level Transmitter is an all-titanium,

compact, reliable transmitter designed specifically to be

suitable for the harsh marine environment. The Rosemount 520

continues the Emerson tradition of delivering superior

performance, reliability and value.

Suitable for installation in virtually any tank gauging application with a comprehensive offering of installation kits

The flexibility in terms of a wide range of available installation

kits makes the transmitter suitable for all tank types, and the

all-welded titanium housing makes it compatible with all

commonly used liquids. Reducing the variety of different

transmitters used on-board the ship minimizes the cost

associated with design and installation.

Simplified ranges and up to 25:1 rangeability for increased flexibility

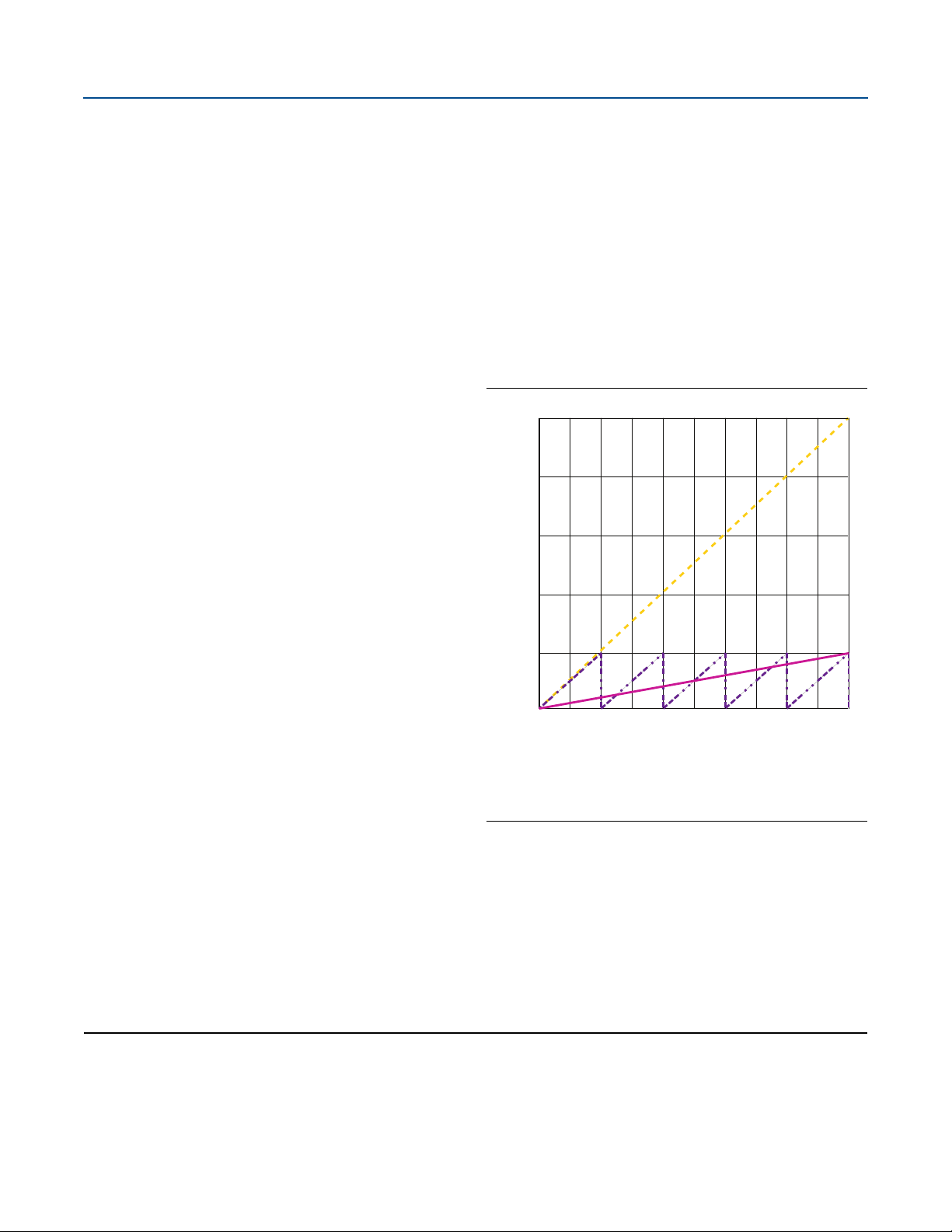

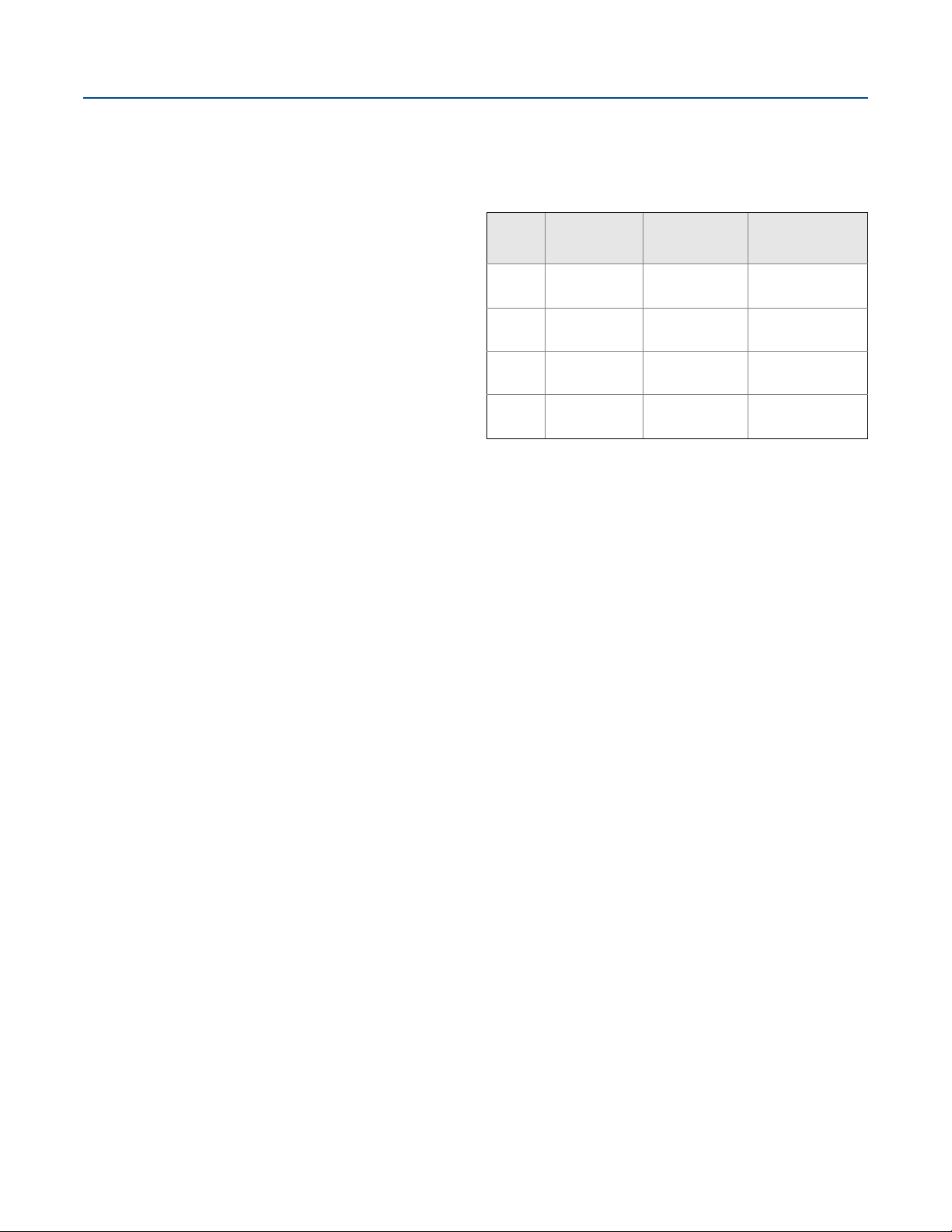

5-year stability guarantee reduces maintenance costs

Pressure transmitters can drift out of specification after just a

few months and require recalibration, which consumes both

time and money. The Rosemount 520 carries a 5-year stability to

reduce the frequency of calibration and reduce maintenance

costs.

Figure 1. Calibration Frequency Comparison

The rangeability allows you to cover a wide spectrum of

applications, level gauging from 0.8 mH

two transmitter ranges. This not only allows you to be flexible,

but also reduce inventories.

Superior overpressure protection

The superior overpressure capabilities ensure trouble-free

ownership. The transmitter is designed exclusively for harsh

marine applications, which reduces issues associated with, for

example, sloshing in the tanks.

Content

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

O to 100 mH2O with

2

Required performance: 0.1% URL

Rosemount 520 stability: 0.1% URL for 5 years

Competitive unit stability: 0.1% URL for 1 year

Product certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Emerson.com/Rosemount

Page 3

January 2021

Rosemount 520

Ordering information

Specifications and selection of product materials, options, or components must be made by the purchaser of the equipment.

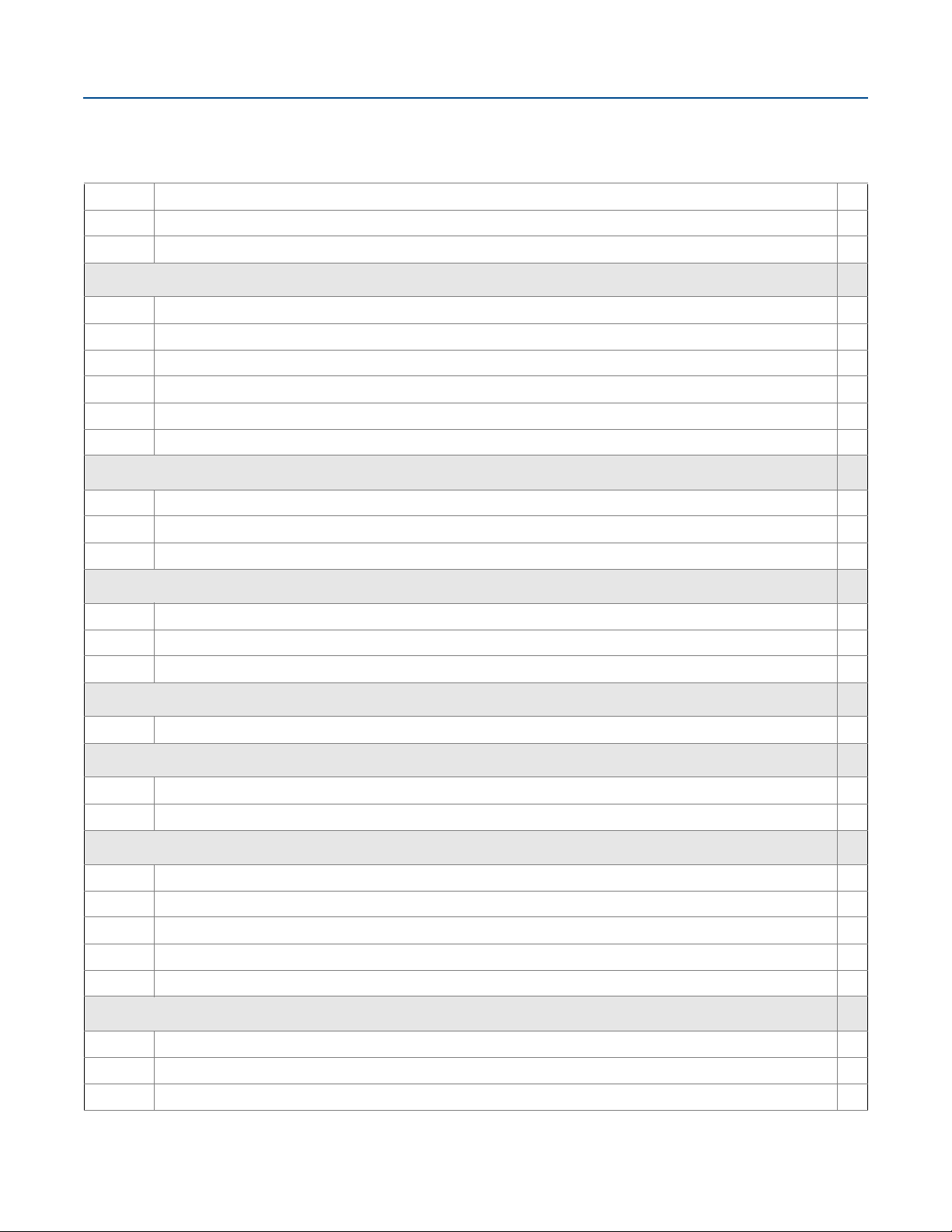

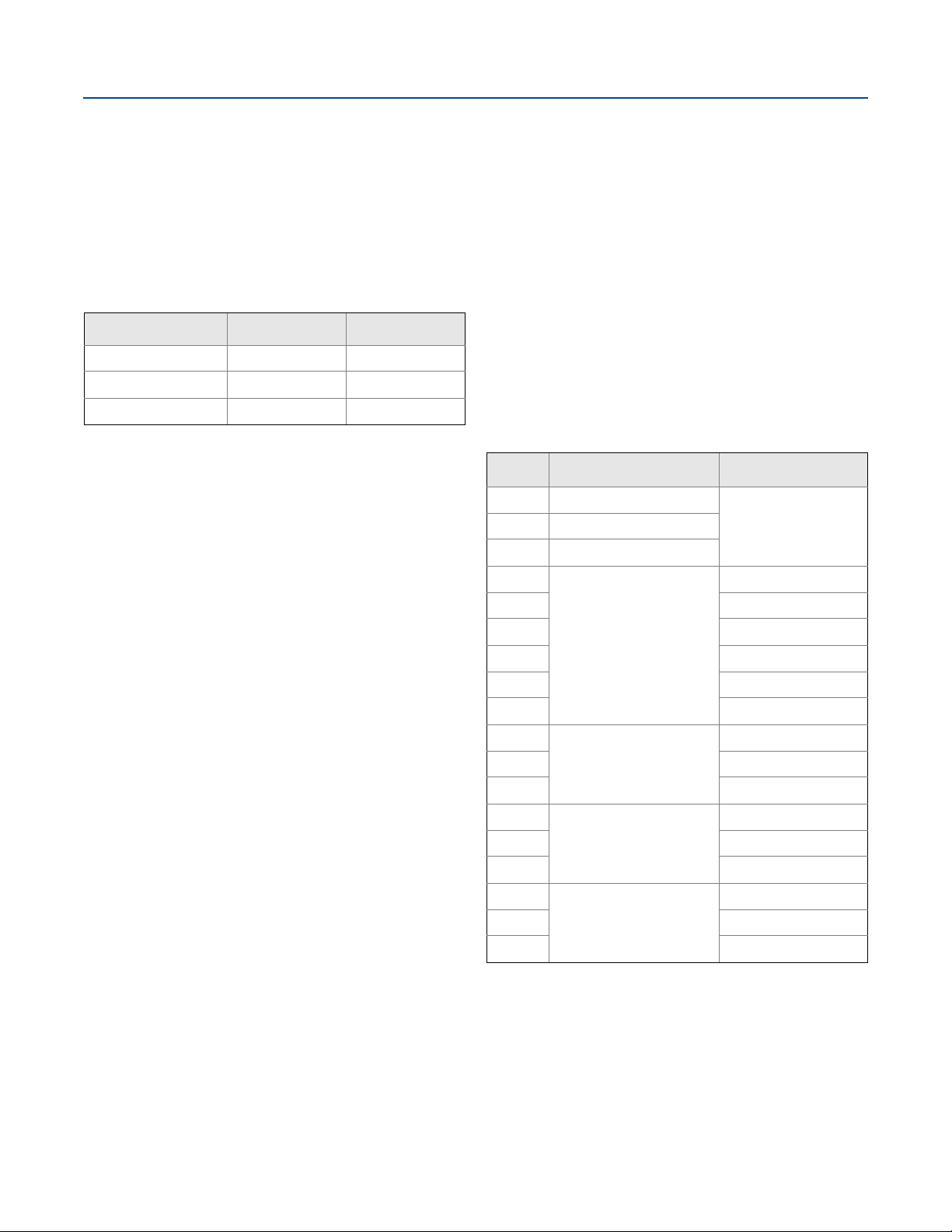

Table 1. Rosemount 520 Level Transmitter Ordering Information

★The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

The Expanded offering is subject to additional delivery lead time.

Model Transmitter type

520 Level Transmitter

Measurement type

GGauge

AAbsolute

Performance class

S1 0.25% reference accuracy with 5-year stability

Measurement range

1 -5.10 to 20.39 mH2O (-0,5 to 2 bar g), Minimum Span of 0.82 mH2O (0.08 bar g)

2 -5.10 to 101.97 mH2O (-0,5 to 10 bar g), Minimum Span of 4.08 mH2O (0.4 bar g)

30 to 20.39 mH

O (0 to 2 bar a), Minimum Span of 0.82 mH2O (0.08 bar a)

2

4 0 to 101.97 mH2O (0 to 10 bar a), Minimum Span of 4.08 mH2O (0.4 bar a)

Transmitter output

A 4–20 mA with digital signal based on HART protocol

Materials of construction

Sensor housing Isolating diaphragm Fill fluid

11 Titanium Grade 2 Titanium Grade 4 Silicone

★

★

★

★

★

★

★

★

★

★

Cable options

AXLPO standard cable

Cable length (m)

(1)

XXX 5 to 300 m (available in increments of 5 m for 5-50 m, available in increments of 25 m for 50-300 m)

Options

Junction box options

Material Conduit entry size

1A Polyester M25 cable gland (cable diameter 7–17 mm)

2A 316 SST M25 cable gland (cable diameter 7–17 mm)

Process connection

B1 Internal mounting bracket

B2 Pole mounting

B3 1-in. pipe end mounting

Emerson.com/Rosemount

★

★

★

★

★

★

★

3

Page 4

Rosemount 520

Table 1. Rosemount 520 Level Transmitter Ordering Information

★The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

The Expanded offering is subject to additional delivery lead time.

E1 Flange mounting DN25, PN16

E2 Flange mounting DN40, PN16

F1 Flange mounting 1-in. ANSI, 150 Ib

Process connection

January 2021

★

★

★

F2 Flange mounting 11/2- in. ANSI, 150 Ib

G1 Flange mounting JIS 25A, 16 K

G2 Flange mounting JIS 40A, 16 K

V1 Flange with 1-in. ball valve mounting DN25, PN16

V2 Flange with 1-in. ball valve mounting JIS 25A, 16 K

V3 Flange with 1-in. ball valve mounting 1-in. ANSI, 150 Ib

Flexible rubber tubing

TA Flexible rubber tube DN50, PN16

TB Flexible rubber tube 2-in. ANSI, 150 Ib

TC Flexible rubber tube JIS 50A, 16 K

Flexible PTFE tubing

UA Flexible PTFE tube DN50, PN16

UB Flexible PTFE tube 2-in. ANSI, 150 Ib

UC Flexible PTFE tube JIS 50A, 16 K

Flexible tubing length (mm)

(2)

XXXXX Rubber or PTFE tube length

Custom device configuration

★

★

★

★

★

★

★

★

★

★

★

★

★

C1 Custom software configuration (requires Configuration Data Sheet)

C2 Custom range point configuration

Alarm limit

C4 NAMUR alarm and saturation levels, high alarm

C5 NAMUR alarm and saturation levels, low alarm

C6 Custom alarm and saturation signal levels, high alarm (requires C1 and Configuration Data Sheet)

C7 Custom alarm and saturation signal levels, low alarm (requires C1 and Configuration Data Sheet)

C8 Low alarm (standard Rosemount alarm and saturation levels)

Product certifications

I1 ATEX Intrinsic Safety

I7 IECEx Intrinsic Safety

I2 INMETRO Intrinsically Safe

4

Emerson.com/Rosemount

★

★

★

★

★

★

★

★

★

★

Page 5

January 2021

Rosemount 520

Table 1. Rosemount 520 Level Transmitter Ordering Information

★The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

The Expanded offering is subject to additional delivery lead time.

Shipboard approvals

SBS American Bureau of Shipping (ABS) Type Approval

SBV Bureau Veritas (BV) Type Approval

SDN Det Norske Veritas (DNV) Type Approval

SLL Lloyd's Register (LR) Type Approval

SKR Korean Register (KR) Type Approval

SNK Nippon Kaiji Kyokai (NK) Type Approval

SCS China Classification Society (CCS) Type Approval

Calibration certification

Q4 Calibration certificate

Typical model number: 520 G S1 1 A 11 A 015 1A B1 SDN

1. Specify the total cable length in meters using 3 digits. Example model string: 015 equals 15 m cable length.

2. Specify the total tube length in millimeters using 5 digits. Example model string: 01200 equals 1200 mm tube length.

★

★

★

★

★

★

★

★

Emerson.com/Rosemount

5

Page 6

Rosemount 520

Specifications

January 2021

Performance specifications

Reference accuracy

Includes the combined effects from terminal based linearity,

hysteresis and repeatability.

(1)

± 0.25% of calibrated span for range down factors

1:1 to 25:1

1. Range down factor = Upper range limit/Calibrated span.

Long term stability

0.1% URL for five years under normal operating conditions

Vibration effect

Less than ±0.1% URL when tested per the requirements of

IACS E10 and IEC 60068-2-6

Ambient temperature effect

±0.054% URL + 0.054% span per 10 °C

Process temperature effect

Flanged mounted applications with proce ss temperatures above

85 °C to max temperature will produce an additional

temperature effect < ±2.0% of calibrated span.

from

Range and sensor limits

Range

1

2

3

4

Lower range

limit (LRL)

-5.10 mH

(-0.5 bar g)

-5.10 mH

(-0.5 bar g)

0 mH

2

(0 bar a)

0 mH

2

(0bar a)

O

O

O

2

O

2

Upper range

101.97 mH2O

101.97 mH2O

limit (URL)

20.39 mH2O

(2 bar g)

(10 bar g)

20.39 mH2O

(2 bar a)

(10 bar a)

Minimum span

0.82 mH2O

(0.08 bar g)

4.08 mH2O

(0.4 bar g)

0.82 mH2O

(0.08 bar a)

4.08 mH2O

(0.4 bar a)

Electromagnetic compatibility (EMC)

Meets all industrial environment requirements of EN61326 and

testing requirements of IACS E10. Maximum deviation < 1%

span during EMC disturbance.

1. During surge event, device may exceed maximum EMC deviation limit.

(1)

Sensor temperature

The integrated temperature sensor measures the temperature

of the transmitter. In submerged applications, this temperature

corresponds to the process temperature.

For submersed applications, the temperature sensor is accurate

within ±5 °C.

6

Emerson.com/Rosemount

Page 7

January 2021

Rosemount 520

Functional specifications

Dynamic performance

The response time is defined as the time before output reaches

63.2% from an input change.

The response time is

minimum.

Zero and span adjustment

Zero and span values can be set anywhere within the range.

Span must be greater than or equal to the minimum span.

Output

HART 4–20 mA; with digital process variable superimposed on

4–20 mA signal. Digital signal available to any host that

conforms to the HART protocol. Digital communication based

on HART Revision 7.

Power supply

Loop-supplied transmitter. External power supply required.

Standard transmitter operates on 10 to 36 VDC with no load.

Load limitations

Maximum loop resistance is determined by the voltage level of

the external power supply, as described by:

Max loop resistance = 43.5 (Power supply voltage – 10)

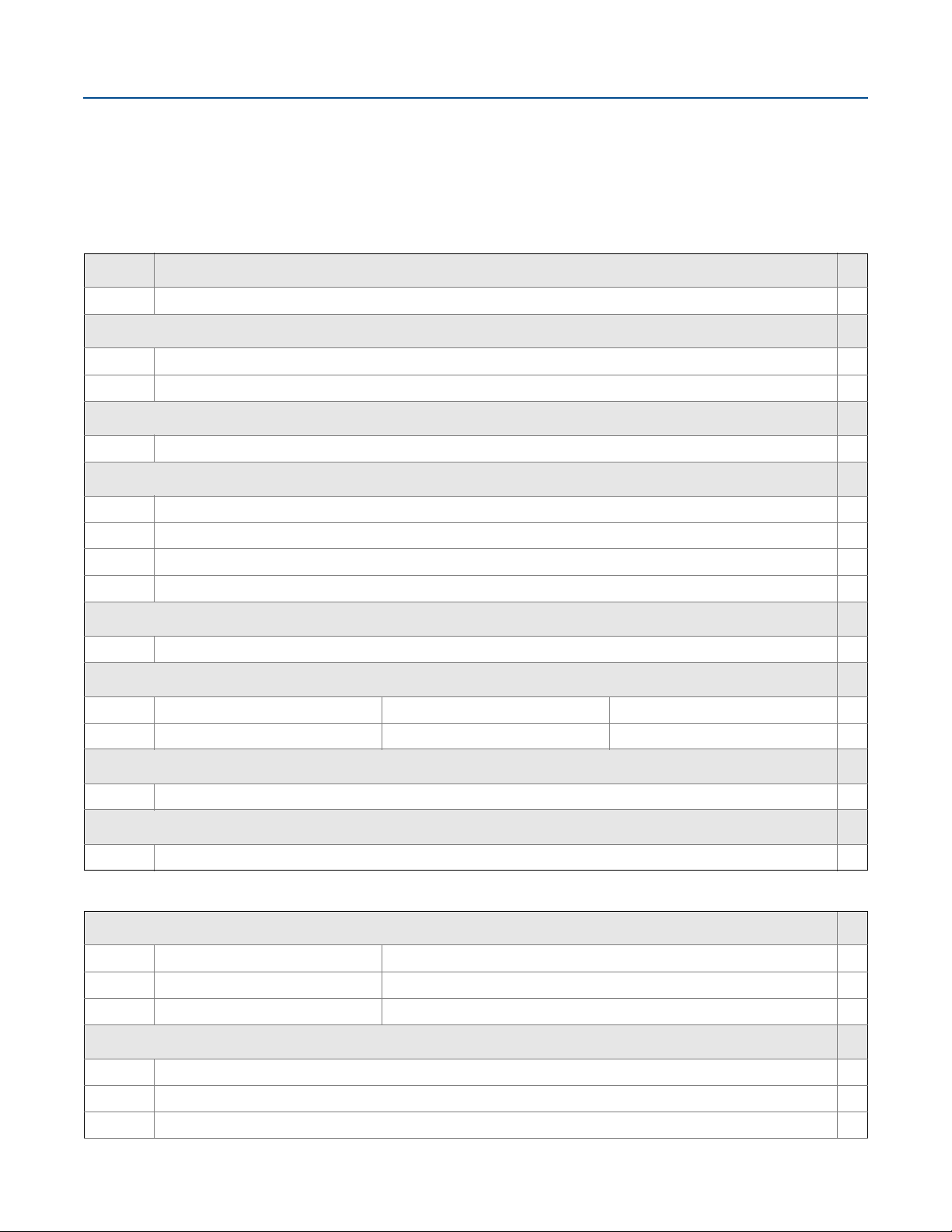

Figure 2. Load Resistance vs. Supply Voltage Limits

≤ 200 ms, at 24 °C and with damping set to

Table 2. Load Resistance and Voltage Supply Limits

Parameter

R1 (Ω)250

(Ω)1130

R

2

V

(V) 10

min

(V) 15.75

V

1

(V) 36

V

2

HART communication requires a minimum loop resistance of

250 ohms.

Limits

Overpressure limits

The transmitter withstands the following pressure without

damage:

Range 1, 3: 204 mH

Range 2, 4: 510 mH

O (20 bar)

2

O (50 bar)

2

Burst pressure limits

The transmitter withstands the following pressure without

dangerous rupture:

Range 1, 3: 1213 mH

Range 2, 4: 1978 mH

O (119 bar)

2

O (194 bar)

2

Temperature limits

Ambient

–40 to 85 °C

R

2

Load Resistance (Ω)

R

1

0

0

Minimum load for

Communications

V

min

Operating region

V

1

Supply Voltage (V)

Load limit line

Maximum

Voltage

V

2

Process temperature limits

–40 to 85 °C for submerged applications

–40 to 125 °C for side mounted flange connections

1. Process temperatures above 85 °C require derating ambient temperat ure

limits by 0.75:1 ratio.

(1)

Storage

–40 to 85 °C

Turn-on time

Performance within specifications less than two seconds after

power is applied to the transmitter

Damping

Analog output response to a step input change is user-selectable

from 0 to 60 seconds. This software damping is in addition to

sensor module response time.

Emerson.com/Rosemount

7

Page 8

Rosemount 520

January 2021

Failure mode alarm

If self-diagnostics detect a sensor or microprocessor failure, the

analog signal is driven either high or low to alert the user. The

values to which the transmitter drives its output in failure mode

depend on whether it is configured to standard,

NAMUR-compliant or customer levels. The values for each are as

follows:

Table 3. Alarm Configuration

High alarm Low alarm

Rosemount standard ≥ 21.75 mA

(2)

NAMUR

(3)

Custom

1. Default configuration.

2. Analog output levels are compliant with NAM UR Recommendation

NE 43.

3. Low alarm must be 0.1mA less than low saturation and high alarm must be

0.1mA greater than high saturation.

≥ 22.5 mA ≤ 3.6 mA

20.2 – 23 mA 3.4 – 3.8 mA

(1)

≤ 3.75 mA

Physical specifications

Material selection

Emerson provides a variety of Rosemount products with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, abrasives, contaminants, etc.), when specifying

product, materials, options and components for the particular

application. Emerson is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or

materials of construction selected.

Electrical connections

Transmitter cable

Junction boxes

The optional junction boxes are equipped with a terminal block

and two cable glands:

M16 – transmitter cable entry

M25 – signal cable entry, suitable for cables with an outer

diameter of 7–17 mm

Cable length

Ex/hazardous area

Max 75 m

Non-Ex/safe area

Max 300 m

Table 4. Process Connection Options

Code Description Flange

B1 Internal mounting kit

(1)

B3 1-in. pipe end mounting

E1

E2 DN40, PN16

F1 1-in. ANSI, 150 Ib

Flange mounting

F2 11/2-in. ANSI, 150 Ib

G1 JIS 25A, 16 K

G2 JIS 40A, 16 K

V1

V2 JIS 25A, 16 K

Flange with 1-in. ball valve

mounting

V3 1-in. ANSI, 150 Ib

TA

TB 2-in. ANSI, 150 Ib

Flexible rubber tube

TC JIS 50A, 16 K

UA

UB 2-in. ANSI, 150 Ib

Flexible PTFE tube

UC JIS 50A, 16 K

N/AB2 Pole mounting

DN25, PN16

DN25, PN16

DN50, PN16

DN50, PN16

red wire +

black wire –

8

1. Max pipe length is 2000 mm.

Refer to the dimensional drawings for detailed description.

Emerson.com/Rosemount

Page 9

January 2021

Rosemount 520

Process-wetted parts

Transmitter

Electronics housing

Titanium, grade 2

Process isolating diaphragm

Titanium, grade 4

Cable

XLPO, cross-linked polyolefin

Process connection equipment

Metallic parts

AISI 316L/316

Gaskets

NBR, Nitrile rubber

Tubes

Stainless steel braided PTFE tube (option code UA, UB, UC)

Rubber tube (option code TA, TB, TC)

Non-wetted parts

Junction boxes

Cable

0.07 kg/m (0.15 lb/m)

Junction box

Polyester

0.4 kg (0.9 lb)

AISI 316L

1.2 kg (2.2 lb)

Housing

Polyester

AISI 316L

Cable glands

Polyester housing – Polyamide

AISI 316L housing – Nickel plated brass

Venting devices

Polyester housing – Polyamide

AISI 316L housing – AISI 316

Ingress protection rating

Transmitter

IP68

Junction box polyester

IP56

Junction box AISI 316L

IP66

Sensor fill fluid

Silicone

Weights

Transmitter

0.17 kg (0.37 lb)

Emerson.com/Rosemount

9

Page 10

Rosemount 520

January 2021

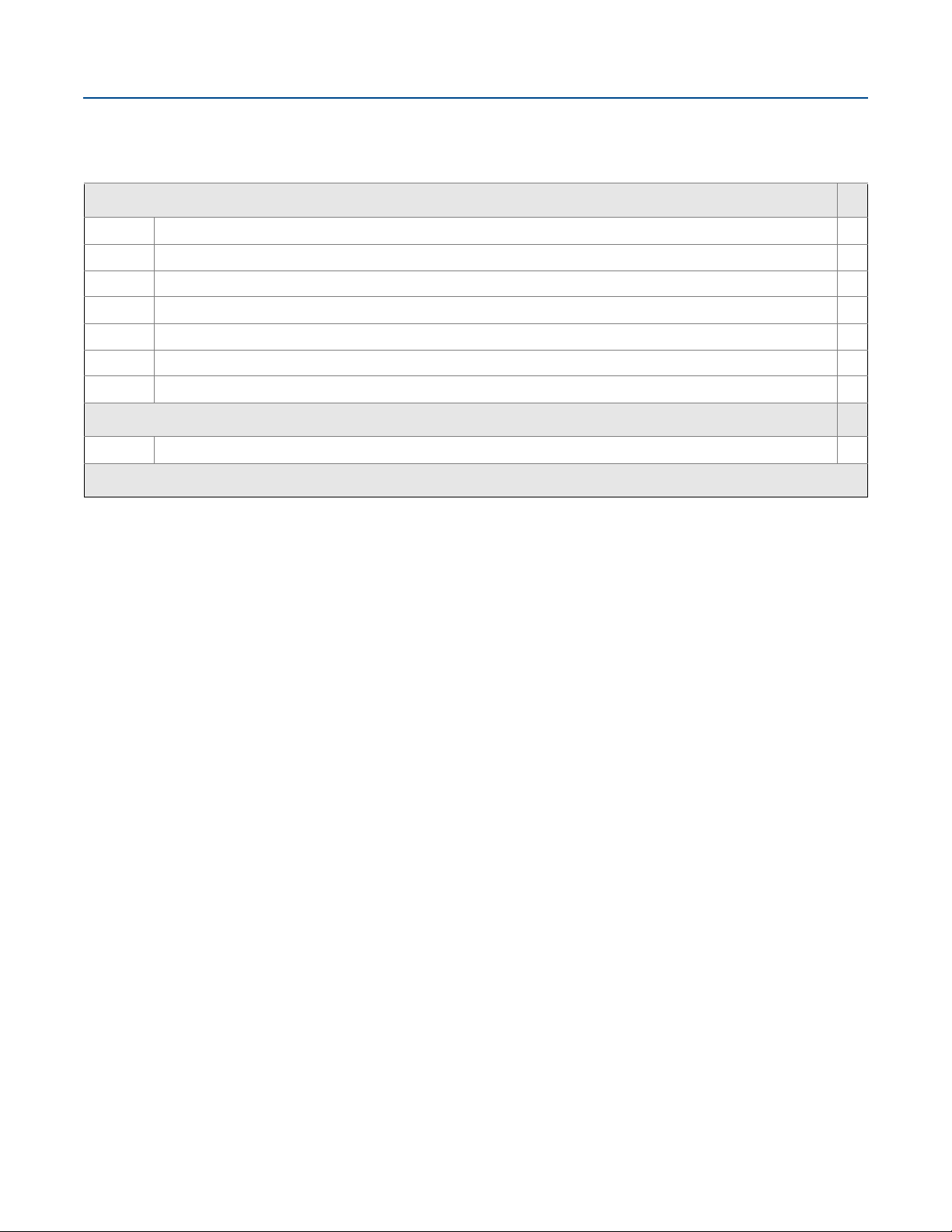

Table 5. Process Connection Equipment

Code Description Flange

B1 Internal mounting kit

B2 Pole mounting 0.2

B3

E1

E2 DN40, PN16 2.4

F1 1-in. ANSI, 150Ib 1.0

F2 1

G1 JIS 25A, 16K 1.5

G2 JIS 40A, 16K 1.9

V1

V2 JIS 25A, 16K 1.8

V3 1-in. ANSI, 150Ib 1.6

TA

TB 2-in. ANSI, 150Ib 2.4

TC JIS 50A, 16K 2.8

UA

UB 2-in. ANSI, 150Ib 2.6

UC JIS 50A, 16K 3.0

1. Rubber tube 0.55 kg/m.

2. PTFE tube 0.20 kg/m.

1-in. pipe end

mounting

Flange mounting

Flange with 1-in. ball

valve mounting

Flexible rubber

(1)

tube

Flexible PTFE tube

N/A

DN25, PN16 1.2

1

/2-in. ANSI, 150Ib 1.7

DN25, PN16 1.7

DN50, PN16 3.2

DN50, PN16 3.4

(2)

Weight

(kg)

0.3

0.3

Options

Standard configuration

Unless otherwise specified, the transmitter is shipped as follows:

Engineering units

4mA

20 mA

Output

Alarm

Process connection option

Custom configuration

If option code C2 is ordered, the customer may specify the

following data in addition to the standard configuration

parameters:

Software tag

If option code C1 is ordered, the customer may specify the

following data in addition to the option code C2 and standard

configuration parameters:

Output information

Scaled variable

Transmitter information

Process variable output

Refer to the Rosemount 520 Configuration Data Sheet

details.

mH2O

0 mH2O

Upper range limit

Linear

High, 21.75 mA

Specified model code option

for

10

Emerson.com/Rosemount

Page 11

January 2021

Product certifications

Rev 1.1

Rosemount 520

European Directive Information

A copy of the EU Declaration of Conformity can be found at the

end of the Quick Start Guide. The most recent revision of the EU

Declaration of Conformity can be found at

Emerson.com/Rosemount

.

Europe

I1 ATEX Intrinsic Safety

Certificate: Baseefa15ATEX0075X

Standards: EN60079-0:2012+A11:2013,

EN60079-11:2012

Markings: II 1 G Ex ia IIC T4 Ga (-40 °C ≤ T

Table 6. Input Parameters

Parameter

Voltage U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is

manufactured of titanium and may present a frictional

ignition risk and must be protected from impact or

abrasion if located in a zone 0.

2. When a junction box is not used, the free ends of the cable

must be afforded a degree of protection of at least IP20.

3. The optional polyester junction box present a potential

electrostatic ignition risk and must not be rubbed or

cleaned with a dry cloth.

i

i

i

i

i

30 V

200 mA

1.0 W

42 nF

77 μH

≤ +85 °C)

a

International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 15.0050X

Standards: IEC60079-0:2011, IEC60079-11:2011

Markings: Ex ia IIC T4 Ga (-40 °C ≤ T

Table 7. Input Parameters

Parameter

Voltage U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is

manufactured of titanium and may present a frictional

ignition risk and must be protected from impact or

abrasion if located in a zone 0.

2. When a junction box is not used, the free ends of the cable

must be afforded a degree of protection of at least IP20.

3. The optional polyester junction box present a potential

electrostatic ignition risk and must not be rubbed or

cleaned with a dry cloth.

Installation in Hazardous Locations

When installing the Rosemount 520 in hazardous areas, to

reduce the risk of electrostatic charges the resistance of

the titanium transducer to earth should be less than 10

i

i

i

i

i

30 V

200 mA

1.0 W

42 nF

77 μH

≤ +85 °C)

a

9

Ω.

Installation in Hazardous Locations

When installing the Rosemount 520 in hazardous areas, to

reduce the risk of electrostatic charges the resistance of

the titanium transducer to earth should be less than 10

Emerson.com/Rosemount

9

Ω.

11

Page 12

Rosemount 520

January 2021

Brazil

I2 INMETRO Intrinsic Safety

Certificate: UL-BR 16.0260X

Standards: ABNT NBR IEC 60079-0:2013,

ABNT NBR IEC 60079-11:2013

Markings: Ex ia IIC T4 Ga (-40 °C ≤ T

Table 8. Input Parameters

Parameter

Voltage U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. The Rosemount 520 Transmitter enclosure is

manufactured of titanium and may present a frictional

ignition risk and must be protected from impact or

abrasion if located in a zone 0.

2. When a junction box is not used, the free ends of the cable

must be afforded a degree of protection of at least IP20.

3. The optional polyester junction box present a potential

electrostatic ignition risk and must not be rubbed or

cleaned with a dry cloth.

i

i

i

i

i

30 V

200 mA

1.0 W

42 nF

77 μH

≤ +85 °C)

a

Additional Certifications

SBS American Bureau of Shipping (ABS) Type Approval

Certificate: 15-HS1462157-PDA

Intended Use: Marine & Offshore Applications – Pressure

transmitter used for determining tank levels

SBV Bureau Veritas (BV) Type Approval

Certificate: 43940

Requirements: Bureau Veritas Rules for the Classification of

Steel Ships

Application: Class notations: AUT-UMS, AUT-CCS,

AUT-PORT and AUT-IMS;

Pressure transmitter type 520 cannot be

installed on diesel engines

SLL Lloyd’s Register (LR) Type Approval

Certificate: 16/60006

Requirements: Lloyd’s Register’s Type Approval System

and Test Spec 1

Application: ENV Categories 1-4

SDN Det Norske Veritas (DNVGL) Type Approval

Certificate: TAA000007Z

Requirements: Det Norske Veritas’ Rules for Classification

of Ships, High Speed and Light Craft, and

Det Norske Veritas’ Offshore Standards

Application:

Location classes

Type 520

Temperature B

Humidity B

Vibration A

EMC A

Enclosure D/IP66/IP68

SKR Korean Register (KR) Type Approval

Certificate: CPH21541-AE002

Certificate: SHI23018-AE001

Requirements: Pt. 6, Ch. 2, Art. 301 of the Rules for

Classification, Steel Ships

SCS China Classification Society (CCS) Type Approval

Certificate: CPH21541-AE002

Requirements: Chapter 2, Part Seven of China Classificat ion

Society Rules for Classification of Sea-going

Steel Ships 2015 and its Amendments

12

Emerson.com/Rosemount

Page 13

January 2021

Ø 7,8

A

193

Ø 25

Ø 303

Dimensional drawings

Figure 3. Rosemount 520 Level Transmitter

Rosemount 520

A. Transmitter cable

Emerson.com/Rosemount

13

Page 14

Rosemount 520

A

B

C

D

F

E

G

38

Ø 12

55

125

160

50

41

194.5

A

B

C

D

F

E

H

I

G

34

26

40

30

193

24

26

41

Figure 4. Installation Methods

Internal mounting

January 2021

A. Optional junction box

B. Optional bulkhead fitting

C. Dead zone

D. Lowest tank bottom

E. Transmitter

F. Mounting bracket

G. Mounting spring

Pole mounting

A. Optional junction box

B.Tank top

C. Dead zone

D. Lowest tank bottom

E. Transmitter

14

F. Pipe max. length 2000 mm (yard supply)

G. Gasket

H. Welding nipple for pole, length 40 mm

I. 1-in. end cap

Emerson.com/Rosemount

Page 15

January 2021

A

B

C

D

E

F

J

HG

I

34

26

30

25

55

80

193

24

26

41

C

A

G

F

E

I

D

K

B

H

L

J

D

Rosemount 520

1-in. pipe end mounting

A. Optional junction box

B. Tank top

C. Dead zone

D. Tank bottom

E. Vent pipe

F. Gasket

G. Nut

H. Nipple pipe, length 80 mm

I. Transmitter

J. Ball valve (yard supply)

Flange mounting

A. Optional junction box

B. Refer to Table 9

C. Tank top

D. Refer to Table 9

E. Dead zone

F. Tank bottom

G. Vent pipe

H. Flange

I. Gasket

J. Transmitter

K. Refer to Table 9

L. Nipple pipe connector

Emerson.com/Rosemount

15

Page 16

Rosemount 520

A

G

C

F

E

HIJ

LMN

64

315

DK

d

B

January 2021

Flange with 1-in. ball valve mounting

A. Optional junction box

B. Refer to Table 11

C. Tank top

D. Refer to Table 11

E. Dead zone

F. Tank bottom

G. Vent pipe

H. Flange

I. 1-in. ball valve

J. 1-in. nipple pipe connector 1-in. to 1-in.

K. Refer to Table 11

L. Gasket

M. 1-in. nut

N. Transmitter

Flexible rubber tube mounting

A

D

K

M

B

C

D

L

I

G

J

E

F

A. Optional junction box

B. Refer to Table 10

C. Tank top

D. Refer to Table 10

E. Dead zone

F. Lowest tank bottom

G. Transmitter

H. Washer

I. Tightening clip

J. Rubber tube

K. Refer to Table 10

L. Flange

M. Cable gland PG11, DIN 89280

I

H

16

Emerson.com/Rosemount

Page 17

January 2021

A

C

E

F

G

I

J

M

H

L

N

O

M

B

D

K

P

D

Rosemount 520

Flexible PTFE tube mounting

A. Optional junction box

B. Refer to Table 10

C. Tank top

D. Refer to Table 10

E. Dead zone

F. Lowest tank bottom

G. Transmitter

H. Spacer

I. HY-Lok nut and ferrules

J. HY-Lok fitting with nut and ferrules

K. Refer to Table 10

L. Hydraline SV

M. Hydraline SB hose jacket

N. Hose fitting with BSP

O. Flange

P. Cable gland PG11, DIN 89280

1

/2-in. PTFE hose braided with stainless steel

1

/2 male thread

Emerson.com/Rosemount

17

Page 18

Rosemount 520

165G20XX

Junction Box

110

75

44

AB

C

55

98

4 × Ø5

45

Table 9. Flange Size for Flange Mounting

January 2021

Standard

D (mm) B (mm) K (mm) d 3n (mm)

DN25 PN16 115 16 85 14 3 4

DN40 PN16 150 18 110 18 3 4

JIS25A—16K 125 14 90 19 3 4

JIS40A—16K 140 16 105 19 3 4

1-in. ANSI/150 108 16 79 16 3 4

11/2-in. ANSI/150 127 17,5 98,6 16 3 4

Table 10. Flange Size for Flexible Rubber Tube and PTFE Tube

Standard

DN50 PN16 165 19 125 18 3 4

JIS50A—16K 155 20 120 19 3 4

2-in. ANSI/150 153 19 120 19 3 4

D (mm) B (mm) K (mm) d 3n (mm)

Table 11. Flange Size for Flange with 1-in Ball Valve

Standard

DN25 PN16 115 16 85 14 3 4

JIS25A—16K 125 14 90 19 3 4

1-in. ANSI/150 108 16 79 16 3 4

D (mm) B (mm) K (mm) d 3n (mm)

Figure 5. Junction Boxes

Polyester AISI 316L

A. Conduit connection (M25) signal cable O.D. 7-17 mm

B. Venting device

1. Applicable only for gauge type of transmitter.

(1)

126

41

126

165G20XX

Junction Box

A

80

D

C

B

C. Conduit connection (M16) transmitter cable

D. Ground screw

Ø8

145

120

60

120

18

Emerson.com/Rosemount

Page 19

January 2021

Rosemount 520

Emerson.com/Rosemount

19

Page 20

Rosemount 520

00813-0100-4520, Rev BA

Product Data Sheet

January 2021

Emerson Automation Solutions

Damcos A/S

Aaderupvej 41 DK-4700 Naestved

Denmark

+45 55 78 72 00

+45 55 78 72 72

Emerson Automation Solutions Marine Systems

(Shanghai) Co. Ltd.

T3-7,128 Long Gui Road JinQiao

Export Process Zone (South)

Post Code: 201201 Shanghai, China

+86 21 5858 9666 801

+86 21 3897 2668

Emerson Automation Solutions

Rosemount Tank Radar AB

Box 150

SE-435 23 Mölnlycke

Sweden

+46 31 337 00 00

+46 31 25 30 22

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Emerson Terms and Conditions of Sale are available upon request.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount is a mark of one of the Emerson family of companies. All othe r marks

are the property of their respective owners.

© 2021 Emerson. All rights reserved.

The contents of this publication are presented for information purposes only, and

while efforts has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, expressed or implied, regarding the products or

services described herein or their use or applicability. Standard Terms and

Con diti ons of Sa le can b e issue d by con tacti ng Dam cos A/ S. We re serve t he rig ht to

modify or improve the designs and specifications of our products at any time

without notice.

Loading...

Loading...