Emerson Rosemount 3900VP, Rosemount 3900-02-12, Rosemount 3900, Rosemount 3900-01-12, Rosemount 3900VP-01-10 Instruction Manual

...

Rosemount

™

3900/3900VP

General Purpose pH/ORP Sensor

Instruction Manual

L

IQ-MAN-3900

Rev. G

April 2017

h

asgkas

E

merson designs, manufactures, and tests its products to meet many national and international

standards. Because these sensors are sophisticated technical products, you MUST properly install,

use, and maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when installing,

using, and maintaining Rosemount Analytical products. Failure to follow the proper instructions may

cause any one of the following situations to occur: loss of life; personal injury; property damage;

damage to this sensor; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the

product.

• Install your equipment as specified in the Installation Instructions of the appropriate Instruc-

tion Manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts spec-

ified by Emerson. Unauthorized parts and procedures can affect the product's performance,

place the safe operation of your process at risk, and VOID YOUR WARRANTY. Third-party substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when main-

tenance is being performed by qualified persons, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without notice.

Essential Instructions

Read this page before proceeding!

1. All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid

the danger due to a build up of an electrostatic charge.

2. All pH/ORP sensor models are intended to be in contact with the process fluid and may not meet the

500V r.m.s. a.c. test to earth.

This must be taken into consideration at installation.

CAUTION

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is entirely the responsibility of the user.

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

CAUTION

The solution used during calibration is an acid and should be handled with care. Follow the directions

of the acid manufacturer. Wear the proper protective equipment. Do not let the solution come in

contact with skin or clothing. If contact with skin is made, immediately rinse with clean water.

SENSOR/PROCESS APPLICATION COMPATIBILITY

SPECIAL CONDITIONS FOR SAFE USE

CAUTION

This manual contains instructions for installation and operation of the Rosemount 3900/3900VP

pH/ORP sensors. The following list provides the revision history for all changes of this document.

Rev. Level Date Notes

F 08/2016 Updated information with new Emerson Style Guidelines, Added

Ordering Information, Added Accessories Information. Added

Hazardous Location Certifications. Added EC Declaration of

Conformity.

G 04/2017 Updated Wiring Diagrams and Ordering Information.

About This Document

Contents

Section 1: Specifications

1.1 Specifications ......................................................................................................1

1.2 Product Certifications ..........................................................................................2

1.3 Ordering Information...........................................................................................3

Section 2: Installation

2.1 Storage................................................................................................................5

2.2 Electrode Preparation ..........................................................................................5

2.3 Sensor Installation ...............................................................................................5

Section 3: Calibration and Maintenance

3.1 pH Two Point Buffer Calibration .........................................................................13

3.2 Recommended pH Sensor Standardization ........................................................13

3.3 pH Electrode Maintenance.................................................................................13

3.4 ORP Calibration .................................................................................................14

3.5 ORP Electrode Maintenance...............................................................................14

Section 4: Accessories .............................................................................................15

EC Declaration of Conformity .............................................................................17

FM Installation.............................................................................................................19

Instruction Manual Table of Contents

LIQ-MAN-3900 April 2017

Table of Contents i

Table of Contents Instruction Manual

April 2017 LIQ-MAN-3900

ii Table of Contents

Section 1: Specifications

1.1 Specifications

Measurements and Ranges: pH : 0-14 / ORP: -1500 to +1500 mV

Percent Linearity Over pH Range:

Materials of construction:

Sensor Body: Ryton -- polyphenylene sulfide (PPS)

O-ring: EPDM

pH Electrode: Glass

ORP Electrode: Glass, platinum

Solution Ground: Stainless Steel

Reference Junction: PTFE (Teflon)

Maximum Pressure: 790 kPa [abs] (100 psig) at 212 °F (100 °C)

CRN rating: 60 psig up to 212 °F (100 °C).

Operating Temperature: 14 °F to 212 °F (-10 °C to 100 °C)

Automatic temperature compensation 14 °F to 212 °F (-10 °C to 100 °C)

Conductivity: Responds to changes in pH at a minimum conductivity of 0.1µS/cm when used

with the low flow cell panel. The sample flow rate must be controlled to 2 gph (7.6L/hr).

Process Connections:

Front facing: 3/4 inch and 1 inch MNPT

Rear facing: 1 inch MNPT

Weight/Shipping Weight: 1 lb./2 lb. (0.45 kg/0.9 kg)

Integral Cable: 32 ft (10m) cable with integral preamp; 15 ft (4.7m) cable without preamp

VP8 Cable: Use 24281-XX, 2.5 ft (0.8m) to 100 ft (31m) (see accessories)

Specifications 1

Instruction Manual Section 1: Specifications

LIQ-MAN-3900 April 2017

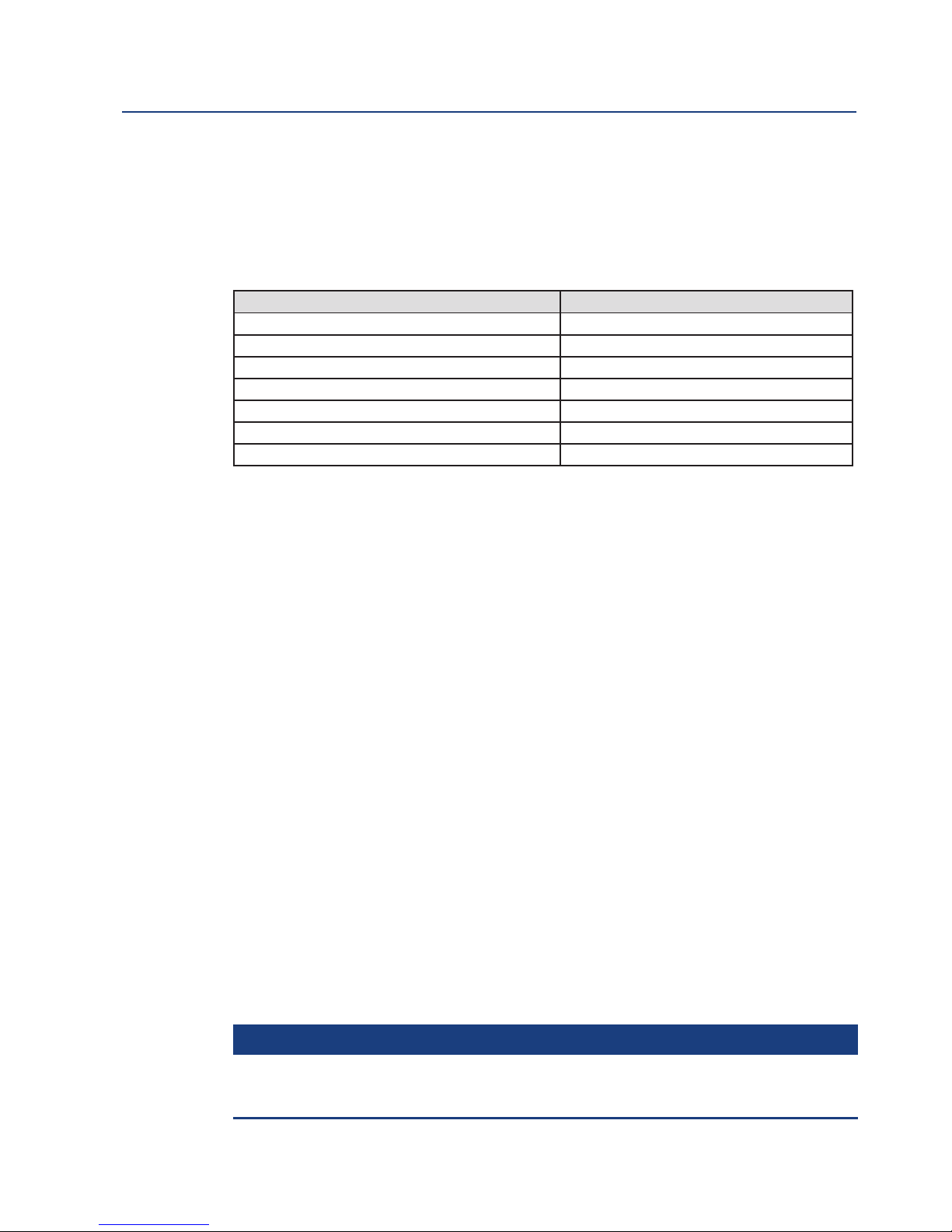

Range Linearity

0-7 97%

1

-7

9

8%

4-7 98%

7-10 99%

7-12 97%

7-13 96%

7-14 95%

The Rosemount 3900/3900VP Sensor responds to changes in pH at a minimum conductivity of

0.1

µ

S/cm in deionized water. Sample flow rate must be controlled to 2 gph (7.6L/hr). The offset is

approximately -0.2 pH after 3 months at ambient temperature.

NOTICE

2 Specifications

Section 1: Specifications Instruction Manual

April 2017 LIQ-MAN-3900

1.2 Product Certifications

IECEx

3900/3900VP without preamp (pH and ORP) – Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60 °C)

3900/3900VP with SMART preamp (pH only) – Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60 °C)

Per standards IEC60079-0 : 2011, IEC 60079-11 : 2011

ATEX

3900/3900VP without preamp (pH and ORP) – II 1 G Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60 °C)

3900/3900VP with SMART preamp (pH only) – II 1 G Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60 °C)

Per standards EN 60079-0: 2012+A11:2013, EN 60079-11:2012

FM

3900/3900VP with SMART preamp (pH only), with standard preamp (ORP only), and without

preamp (pH and ORP):

Intrinsically Safe for use in Class I, II, and III, Division 1, Groups A, B, C, D, E, F, and G; Temperature

Class T6 Ta = -20 °C to +60 °C

Intrinsically Safe for use in Class I, Zone 0, AEx ia IIC T6 Ta = -20 °C to +600 °C

Nonincendive for use in Class I, Division 2, Groups A, B, C, and D; Temperature Class T6 Ta = -20 °C

to +60 °C

Suitable for use in Class II and III, Division 2, Groups E, F, and G; Temperature Class T6 Ta = -20 °C

to +60 °C Hazardous (Classified) Locations

IS/I,II,III/1/ABCDEFG/T6 Ta = 60 °C - 1400332; Entity; I/0/AEx ia IIC/T6 Ta = 60 °C - 1400332;

Entity;

NI/I/2/ABCD/T6 Ta = 60 °C; S/II,III/2/EFG/T6 Ta = 60 °C

Per standards 3600:1998, 3610:2010, 3611:2004, 3810:2005

CSA

3900/3900VP with SMART preamp (pH only) – Intrinsically Safe:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2,

Groups ABCD; Ambient temperature rating -20 °C to +60 °C; Ex ia IIC; T6

3900/3900VP without preamp (pH and ORP) – Intrinsically Safe and Non-Incendive:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2,

Groups ABCD; Ex ia IIC; T6; Ambient temperature rating -20 °C to +60 °C: (Simple Apparatus)

Per standards C22.2 No. 0-10, C22.2 No. 0.4-M2004, C22.2 No. 94-M1991, C22.2 No. 142 –

M1987, C22.2 No 157 – M1992, CAN/CSA E60079-0:07, CAN/CSA E60079- 11:02, UL50 11th Ed,

UL508 17th Ed, UL913 7th Ed, UL 60079-0: 2005, UL 60079-11: 2002

Loading...

Loading...