Page 1

Rosemount™ 385+

pH/ORP Sensors

Reference Manual

0809-0100-3386

0

Rev. AA

February 2019

Page 2

hasgkas

Page 3

Essential Instructions

Read this page before proceeding!

merson designs, manufactures and tests its products to meet many national and international stan-

E

dards. Because these sensors are sophisticated technical products, you MUST properly install, use,

and maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when installing,

using, and maintaining Rosemount products. Failure to follow the proper instructions may cause any

one of the following situations to occur: loss of life; personal injury; property damage; damage to this

sensor; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance

of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Reference Manual and per applicable local and national codes. Connect all products to

the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson. Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Third-party substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

The information contained in this document is subject to change without notice.

DANGER

Hazardous Area InstallationN

This sensor is not Intrinsically Safe. or Explosion Proof. Installations near flammable liquids or in hazardous

area locations must be carefully evaluated by qualified on site safety personnel.

To secure and maintain an intrinsically safe installation, an appropriate transmitter/safety barrier/sensor

combi nation must be used. The installation system must be in accordance with the governing approval

agency (FM, CSA or BASEEFA/CENELEC) hazardous area classification requirements. Consult your transmitter instruc tion manual for details.

Proper installation, operation and servicing of this sensor in a Hazardous Area Instal lation is entirely the

responsibility of the user.

CAUTION

Sensor/Process Application Compatibility

The wetted sensor materials may not be compatible with process composition and operating

conditions. Application compatibility is entirely the responsibility of the user.

WARNING

Retractable sensors must not be inserted nor retracted when process pressures are in excess of 64 psig

(542kPa)

Page 4

Page 5

Reference Manual Table of Contents

00809-0100-3386 February 2019

Contents

Section 1: Description and Specifications

1.1 Features and Applications....................................................................................1

1.2 Performance and Specifications ...........................................................................2

1.3 Ordering Information...........................................................................................3

1.4 Product Certifications..........................................................................................4

Section 2: Installation

2.1 Unpacking and Inspection ...................................................................................5

2.2 Mechanical Installation ........................................................................................5

2.3 Electrical Installation..........................................................................................10

Section 3: Startup and Calibration

3.1 Startup ..............................................................................................................17

3.2 pH Calibration Using Buffer Solutions or Grab Samples ......................................17

3.3 ORP Calibration .................................................................................................17

Section 4: Maintenance

4.1 Maintenance......................................................................................................19

4.2 Sensor Removal .................................................................................................19

4.3 pH Electrode Cleaning .......................................................................................20

4.4 Platinum Electrode Cleaning..............................................................................20

4.5 Sensor Tube Replacement (Code -02).................................................................21

Section 5: Diagnostics and Troubleshooting

5.1 Model 54/3081 pH Diagnostics..........................................................................25

5.2 Troubleshooting ................................................................................................25

5.3 Rosemount 1056/1057 SMART pH Diagnostics ..................................................26

Section 6: Accessories

6.1 Accessories........................................................................................................29

EC Declaration of Conformity ...............................................................................31

Intrisicallly Safe Sensor Installation Drawing - FM ......................................33

Table of Contents i

Page 6

Table of Contents Reference Manual

February 2019 00809-0100-3386

ii Table of Contents

Page 7

Reference Manual Description and Specifications

00809-0100-3386 February 2019

Section 1: Description and Specifications

• SMART enabled

• Retractable version allows removal and replacement under pressure without process shutdown.

• Long-life, triple junction reference electrode provides longer service life in applications where

poisoning ions are present.

• Disposable tefzel and titanium design provides maximum chemical resistance and economical advantage where minimum troubleshooting and maintenance downtime are of prime

importance.

1.1 Features and Applications

The Rosemount 385+ Sensor measures the pH or ORP (Oxidation Reduction Potential) of aqueous

solutions in pipelines, open tanks, or ponds. It is suitable for applications where a low cost,

industrial, disposable sensor is required. The combination electrode features a peripheral ceramic

junction. The triple junction reference cell provides longer life in processes containing sugar,

ammonia, chlorides, sulfides or other poisoning ions. The Rosemount 385+ body is constructed of

molded, chemically resistant Tefzel in two standard body versions.

The retraction version is housed in a titanium tube, with a plug-in style surface mount preamplifier

in a weatherproof junction box. It is designed for use with a standard 1-1/2 in. ball valve assembly

for process mounting where a separate sample stream is difficult or impossible to provide. The

entire installation process is accomplished without line depressurization and minimal process fluid

loss. Upon sensor removal, from the ball valve, maintenance and replacement is easy.

The insertion/submersion version has two body configurations: 25 ft (7.6 m) integral cable and

preamplifier; 15 ft (4.5) integral cable for use with remote preamplifier.

Description and Specifications 1

Page 8

Description and Specifications Reference Manual

February 2019 00809-0100-3386

1.2 Performance and Specifications

able 1-1: Percent linearity over pH

T

pH Range Option 10 Option 11

0-2 pH 94% 94%

-12 pH

2

12-13 pH 97% 98%

13-14 pH 92% 98%

Table 1-2: Rosemount 385+ sensor specifications

Measured Range

pH range 0 to 14 pH, GPHT ACCUGLASS

ORP range -1500 mV to 1500 mV

Maximum Pressure at Retraction or Insertion (ball valve version)

542 KPa abs (64 psig)

Maximum Process Pressure and Temperature

790 KPa abs (100 psig) at 100 °C (212 °F)

Temperature Compensation

(pH only) 0 to 100°C (32 to 212°F)

Wetted Materials

Tefzel, titanium, EPDM, 316 SS and Teflon (Code 02), Viton, glass, ceramic and (ORP only) platinum.

Weight/Shipping Weight

Submersion/insertion 1.6 lb/2.8 lb (0.7 kg/1.25 kg)

Retraction 6 lb/11 lb (2.7 kg/5.0 kg)

Ball Valve 5 lb/10 lb (2.25 kg/4.5 kg)

Process Connections

With ball valve 1-1/2 in.

Without ball valve 1 in.

Cable Length

Code 02 Requires interconnecting cable P/N 9200273 (Unprepped) or P/N 23646-01 (Prepped)

Code 03 25 ft. Integral Cable

Code 04 15 ft. Integral Cable

9%

9

7%

9

2 Description and Specifications

Page 9

Reference Manual Description and Specifications

00809-0100-3386 February 2019

1.3 Ordering Information

able 1-3: Rosemount 385+ ordering information

T

odel

M

385+ pH/ORP Sensor

Body Configuration

02 Retractable with Sensor Head Junction Box, Preamplifier, and Process Connector

03 Insertion/Submersion with Integral Preamplifier and 25 ft. (7.6m) Cable

04 Insertion/Submersion for use with Remote Preamplifier and 15 ft.

Combination Electrode

10 pH - GPLR Glass

11 High pH Glass

12 Platinum ORP

Typical Model Number: 385+-03-10

1. Preamplifier is SMART for pH options only. A standard preamplifier is used with ORP sensors.

2. First time installations require a 1 x 1 inch NPT Process Connector (see accessories).

ensor type

S

(2)

1) (2)

(

(1)

Description and Specifications 3

Page 10

Description and Specifications Reference Manual

February 2019 00809-0100-3386

1.4 Product Certifications

lease see online certificates for further details.

P

IECEx

ensors without preamp (pH and ORP) – Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +60°C)

S

Sensors with preamp (pH only) – Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +60°C)

Sensors with standard preamp (ORP only) – Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +80°C) or Ex ia IIC T5 Ga

(-20°C ≤ Ta ≤ +40°C)

Per standards IEC60079-0 : 2011, IEC 60079-11 : 2011

ATEX

Sensors without preamp (pH and ORP) – II 1 G Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60 °C)

Sensors with SMART preamp (pH only ) – II 1 G Ex ia IIC T4 Ga (-20˚C ≤ Ta ≤ +60 °C)

Sensors with standard preamp (ORP only) – II 1 G Ex ia IIC T4 Ga (-20˚C ≤ Ta ≤ +80˚C) or

II 1 G Ex ia IIC T5 Ga (-20˚C ≤ Ta ≤ +40˚C)

Per standards EN 60079-0: 2012+A11:2013, EN 60079-11:2012

FM

See online FM Certificate of Compliance for applicable sensor options:

Intrinsically Safe for use in Class I, II, and III, Division 1, Groups A, B, C, D, E, F, and G; Temperature

Class T6 Ta = -20 °C to +60 °C

Intrinsically Safe for use in Class I, Zone 0, AEx ia IIC T6 Ta = -20 °C to +60 °C

Nonincendive for use in Class I, Division 2, Groups A, B, C, and D; Temperature Class T6 Ta = -20 °C

to +60 °C

Suitable for use in Class II and III, Division 2, Groups E, F, and G; Temperature Class T6 Ta = -20 °C

to +60 °C Hazardous (Classified) Locations

IS/I,II,III/1/ABCDEFG/T6 Ta = 60°C - 1400332; Entity; I/0/AEx ia IIC/T6 Ta = 60 °C - 1400332; Entity;

NI/I/2/ABCD/T6 Ta = 60 °C; S/II,III/2/EFG/T6 Ta = 60 °C

Per standards 3600:1998, 3610:2010, 3611:2004, 3810:2005

CSA

See online CSA Certificate of Compliance for applicable sensor options:

Intrinsically Safe:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2, Groups

ABCD; Ambient temperature rating -20 °C to +60 °C; Ex ia IIC; T6

Intrinsically Safe and Non-Incendive:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2, Groups

ABCD; Ex ia IIC; T6; Ambient temperature rating -20 °C to +60 °C: (Simple Apparatus)

Per standards C22.2 No. 0-10, C22.2 No. 0.4-M2004, C22.2 No. 94-M1991, C22.2 No. 142 –

M1987, C22.2 No 157 – M1992, CAN/CSA E60079-0:07, CAN/CSA E60079- 11:02, UL50 11th

Ed, UL508 17th Ed, UL913 7th Ed, UL 60079-0: 2005, UL 60079-11: 2002

4 Description and Specifications

Page 11

Reference Manual Installation

00809-0100-3386 February 2019

Section 2: Installation

2.1 Unpacking and Inspection

Inspect the outside of the carton for any damage. If damage is detected, contact the carrier

immediately. Inspect the instrument and hardware. Make sure all items in the packing list are

present and in good condition. Notify the factory if any part is missing.

NOTICE

Save the original packing cartons and materials as most carriers require proof of damage due to mishandling,

etc. Also, if it is necessary to return the instrument to the factory, you must pack the instrument in the same

manner as it was received. Refer to Section 6.0 for instructions.

WARNING

Glass electrode must be wetted at all times (in storage and in line) to maximize sensor life.

2.2 Mechanical Installation

The Rosemount 385+ is available in two versions, the retraction version (Code 02) and the

insertion/submersion version (Code 03, & 04). Please refer to the appropriate section below.

2.2.1 Retraction Option (Code option 02)

The Rosemount 385+ sensor may be installed through a weldalet or in a pipe tee or “Y”, as shown

in Figure 2-1, when used with a ball valve. Insert the end of the sensor to a depth sufficient to ensure

that the glass bulb is continuously wetted by the process fluid.

The sensor can also be inserted directly into the process without the use of a ball valve for

applications not requiring continuous operation during sensor maintenance (Figure 2-2).

Allow sufficient room for safe retraction and insertion of the sensor. personnel should have room

for stable footing while performing removal or insertion of the sensor.

The sensor must be mounted within 10-90 degrees of the horizontal with the tip pointed

downward, thus keeping air bubbles out of the pH sensitive glass bulb. Bubbles settled in the glass

bulb disrupt the electrical continuity between the pH sensitive glass and the silver/silver chloride

measuring element.

If the retraction version is to be installed without a ball valve follow the installation procedure for

insertion service (Section 2.2.2). Perform the following steps for sensor installation through a ball

valve:

1. Carefully remove the liquid filled rubber boot which protects the glass electrode and keeps

the liquid junction wet during shipping and storage. Discard the liquid and boot. Make

sure the lubricated O-ring is in place in the groove inside the male connector on the sensor

body (Figure 4-1, item A).

CAUTION

Buffer solution, in the vinyl boot, may cause skin or eye irritation.

Installation 5

Page 12

Installation Reference Manual

February 2019 00809-0100-3386

. With the male connector on the sensor’s body, insert the sensor into the ball valve until it

2

gently touches the closed valve. The molded electrode guard will protect the glass bulb

from breakage.

3. Thread the male connector body tightly into the ball valve assembly. DO NOT tighten the

hex nut on the male connector body; doing so would not allow the sensor to be inserted

through the ball valve.

4. Pull back hard on the sensor assembly, as if trying to remove the sensor, to be certain that

the sensor cannot come free of the ball valve assembly. The built-in retraction stop will

butt against the shoulder of the male connector if properly installed.

CAUTION

The sensor must be captured by the valve assembly and the male connector so that it cannot be blown free

by process pressure if mishandled during insertion or retraction.

5. After confirming that the sensor assembly is properly secured by the valve assembly, the

valve may be opened and the sensor positioned into the process at the desired depth and

orientation.

6. While holding the sensor in position, tighten the hex nut of the male connector to firmly

secure the sensor in place. When the hex nut is tightened, the Teflon ferrule inside the

compression fitting clamps the sensor tube. (See Figure 4-2.)

CAUTION

Over tightening the hex nut may damage the ferrule.

NOTICE

A stainless steel ferrule is available if the TEFLON ferrule does not inadequately grip. When using the metallic

ferrule, care must be taken to avoid over tightening and damaging the sensor tube. If the male connector

leaks during insertion or retraction, replace the O-ring in the male connector.

2.2.2 Submersion/Insertion Option

Code Option -03 & -04). Figure 2-3 and Figure 2-4. The Rosemount 385+ may be installed through

a weldalet or a pipe tee or “Y” when used with a process connector (P/N 23166-00-01).

For submersion service, a process connector (P/N 23166-00-01 or 9510066) may be used with a

water tight 1 in. schedule 80 CPVC or PVDF standpipe conduit. Refer to Figure 2-5. Tapered threads

in plastic tend to loosen after installation. It is therefore recommended that TEFLON tape be used

on the threads and that the tightness of the connection be checked frequently to assure that no

loosening has occurred. The sensor should be installed within 80° of vertical, with the electrode

facing down.

6 Installation

Page 13

Reference Manual Installation

00809-0100-3386 February 2019

igure 2-1: Typical Mounting Details-Retraction Version

F

Figure 2-2: Dimensional Drawing Retraction Version (Code 02)

Installation 7

Page 14

Installation Reference Manual

February 2019 00809-0100-3386

Figure 2-3: Dimensional Drawing Submersion/Insertion Version (Code -03, -04)

Figure 2-4: Submersion Accessory (Code 03, 04)

8 Installation

Page 15

Reference Manual Installation

00809-0100-3386 February 2019

Figure 2-5: Submersion Installations, Handrail Mounting Assembly (P/N 11275-01)

Installations 9

Page 16

Installation Reference Manual

February 2019 00809-0100-3386

2.3 Electrical Installation

Make electrical connections as shown on Figures 2-6 through 2-14 using the following guidelines:

1. Pay particular attention to the analyzer or transmitter model number when following

details on the wiring diagrams to ensure that the connections are made to the proper

terminals.

2. Use Rosemount custom cable PN 9200273.

3. The maximum distance from the sensor to the analyzer is 15 ft without an integral

preamplifier.

4. Signal cable should be run in a dedicated conduit and should be kept away from AC power

lines.

For additional wiring information on this product, including sensor combinations not shown here,

please refer to the Liquid Transmitter Wiring Diagrams.

Figure 2-6: Rosemount 385+-02 Sensor Wiring to Rosemount 5081 Transmitter

10 Installation

Page 17

Reference Manual Installation

00809-0100-3386 February 2019

Figure 2-7: Rosemount 385+-03 Sensor Wiring to Rosemount 5081 Transmitter

Figure 2-8: Rosemount 385+-04 Sensor Wiring to Rosemount 5081 Transmitter

Installation 11

Page 18

Installation Reference Manual

February 2019 00809-0100-3386

Figure 2-9: Rosemount 385+-02 sensor Wiring to Rosemount 1056/56/1057 Transmitters

Figure 2-10: Rosemount 385+-03 Sensor Wiring to Rosemount 1056/56/1057 Transmitters

12 Installation

Page 19

Reference Manual Installation

00809-0100-3386 February 2019

Figure 2-11: Rosemount 385+-04 Sensor Wiring to Rosemount 1056/56/1057 Transmitters

Figure 2-12: Wiring Details - Submersion/Insertion (Code 03 & 04)

Installation 13

Page 20

Installation Reference Manual

February 2019 00809-0100-3386

Figure 2-13: Wiring Rosemount 385+-02 Sensor to Rosemount 1055-11-22-32 through Remote

Junction Box

Figure 2-14: Wiring Retraction Version (Code-02)

14 Installation

Page 21

Reference Manual Installation

00809-0100-3386 February 2019

Figure 2-15: Wiring Details - Remote J-Box for Extension Cable

Installation 15

Page 22

Installation Reference Manual

February 2019 00809-0100-3386

Figure 2-16: Wiring Details - Remote J-Box with Preamp

16 Installation

Page 23

Reference Manual Startup and Calibration

00809-0100-3386 February 2019

Section 3: Startup and Calibration

3.1 Startup

To obtain best accuracy, the sensor must be calibrated as a loop with the transmitter. Please refer

to the transmitter manual for proper calibration and setup procedures. Example of 1056 start-up

shown below.

3.2 pH Calibration Using Buffer Solutions or Grab

Samples

The loop may be calibrated with the sensor’s measuring tip submersed in standard pH buffer

solutions (two point calibration) or with a process grab sample of a known pH value (one point

standardization). Please refer to the corresponding transmitter manuals for proper procedures.

3.3 ORP Calibration

An ORP loop is best calibrated using an ORP standard solution.

3.3.1 Quinhydrone Solution

A commonly used ORP standard solution is a saturated quinhydrone solution. This can be made by

simply adding a few quinhydrone crystals to either a 4 pH or a 7 pH buffer. Quinhydrone is only

sightly soluble so only a few crystals will be required. The solution will have a yellow color. The

resulting potentials should be within ±20 millivolts of the value shown in Table 3-1. The ORP value

of saturated quinhydrone solution is not stable over long periods of time and therefore new

solutions should be made each time they are used.

Table 3-1: ORP of Saturated Quinhydrone Solution

pH 4 pH 7

Temperature °C 20 25 30 20 25 30

Millivolt Potential 268 264 260 94 87 80

Startup and Calibration 17

Page 24

Startup and Calibration Reference Manual

February 2019 00809-0100-3386

3.3.2 Ferric-Ferrous Ammonium Sulfate Solution

Although this solution is not as easy to prepare as the quinhydrone solution in Section 3.3.1, it

offers a much more stable solution which will maintain its millivolt value for approximately one

year when stored in a glass container.

CAUTION

The solution used during the following check is an acid and should be handled with care. Follow the directions

of the acid manu facturer. Wear the proper equip ment. Do not let the solution come in contact with skin or

clothing. If contact with skin is made, immediately rinse with clean

water.

To prepare solution, dissolve 39.2 grams of reagent grade ferrous ammonium sulfate [Fe(SO4) •

(NH)2SO4 • 6H2O] and 48.2 grams of reagent grade ferric ammonium sulfate [FeNH4(SO4)2 •

12H2O] in approximately 700 milliliters of water (distilled water is preferred, but tap water is

acceptable). Slowly and carefully add 56.2 milliliters of concentrated sulfuric acid. Add sufficient

water to bring the total solution volume up to 1,000 milliliters. This solution (ferric-ferrous

ammonium sulfate) will produce a nominal ORP of 476 ±20 mV at 25°C. Some tolerance in mV

values is to be expected due to the rather large liquid reference junction potentials which can arise

when measuring this strongly acidic and concentrated solution. However, if the measuring

electrodes are kept clean and in good operating condition, consistent repeatable calibrations can

be achieved.

NOTICE

Most industrial applications have a number of ORP reactions occurring in sequence or simultaneously. There

can be several components that are oxidized or reduced by the reagents that are used. Theoretically, the ORP

potential is absolute because it is the result of the oxidation-reduction equilibrium. However, the actual measured potential is dependent on many factors, including the condition of the surface of the ORP platinum electrode. Therefore, the sensor should be allowed 1-2 hours to become “conditioned” to the stream to be

measured when first setting up or after being cleaned.

18 Startup and Calibration

Page 25

Reference Manual Maintenance

00809-0100-3386 February 2019

Section 4: Maintenance

4.1 Maintenance

The Rosemount 385+ Sensor is a disposal type sensor and therefore requires only periodic cleaning

and calibration. If the sensor has failed, it should be discarded and replaced.

4.2 Sensor Removal

Please refer to the appropriate paragraph for instructions regarding removal of the sensor for

periodic maintenance.

4.2.1 Retractable Version (Code-02)

WARNING

System pressure may cause the sensor to blow out with great force unless care is taken during removal.

Make sure the following steps are adhered to.

1. Be certain system pressure at the sensor is below 64 psig (442 kPa) before proceeding

with the retraction. It is also recommended that the personnel wear a face shield and have

a stable footing. Refer to Figure 4-1.

2. Push in on the sensor using the top of the J-box and slowly loosen the hex nut (B) of the

process end male connector (A).

CAUTION

Do not remove nut at this time.

3. When the hex nut is loose enough, slowly ease the sensor back completely until the

retraction stop collar is reached.

CAUTION

Failure to withdraw the sensor completely may result in damage to the sensor when the valve is closed.

4. Close the ball valve slowly. If there is resistance, the valve may be hitting the sensor. Double

check that the sensor has been retracted to the retraction.

WARNING

Before removing the sensor from the ball valve, be absolutely certain that the ball valve is fully closed.

Leakage from the male connector threads may indicate that the male connector is still under pressure.

Leakage through a partially open valve could be hazardous, however with the ball valve closed, some

residual process fluid may leak from the connector's pipe threads.

5. The Male Connector Body (A) may now be completely unthreaded from the reducing

coupling and the sensor removed for servicing stop collar.

CAUTION

If the male connector leaks during insertion or retraction, replace the O-ring (PN 9550099) in the male

connector A.

Maintenance 19

Page 26

Maintenance Reference Manual

February 2019 00809-0100-3386

4.2.2 Insertion/Submersion Version (Code -03 and -04 )

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

Remove the sensor from process for cleaning, calibration or replacement.

4.3 pH Electrode Cleaning

If the electrode is coated or dirty, it may be cleaned as follows:

1. Remove the sensor from process as instructed in Section 4.2.

2. Wipe the glass bulb with a soft, clean, lint free cloth or tissue. If this does not remove the

dirt or coating, proceed to step 3. If the sensor appears to be clean, go to step 5.

3. Wash the glass bulb in a strong detergent solution and thoroughly rinse with tap water. If

the bulb still appears to have a coating, proceed to step 4.

CAUTION

The solution used in the following step is an acid and should be handled with care. Follow the directions of the

acid manufacturer. Wear the proper protective equipment. Do not let the solution come in contact with skin

or clothing. If contact with the skin is made, immediately rinse with clean water.

4. Following the caution above, wash the glass bulb in dilute 5% hydrochloric acid solution

and then rinse it thoroughly in tap water. Replace the sensor if it cannot be cleaned. If the

glass bulb appears clean, proceed to step 5.

5. Buffer calibrate the sensor (Refer to Section 3.0). If the sensor appears to respond

sluggishly to pH change, soaking it overnight in a weak acid solution (5% hydrochloric acid)

may improve its response. Be sure to follow the CAUTION above and to rinse the sensor’s

tip thoroughly with tap water. If the sensor will not calibrate, it must be replaced.

4.4 Platinum Electrode Cleaning

Remove any film or dirt by wiping the electrodes platinum band with a clean, lint free, cloth. If

needed, a strong detergent should be used to remove any remaining dirt or film.

Platinum electrodes can become poisoned by cyanide or sulfide compounds. However, processes

involving these compounds (such as cyanide destruction) will destroy all the cyanides or sulfides

before they can react with the platinum.

Should poisoning occur, the electrode can be restored to normal operation by polishing the

platinum (metallic) surface with moistened baking soda (after a strong detergent wash to remove

any film on the platinum surface).

20 Maintenance

Page 27

Reference Manual Maintenance

00809-0100-3386 February 2019

4.5 Sensor Tube Replacement (Code -02)

Replacement of the retraction versions sensor tube assembly involves the removal and

installation of two sets of male connectors; one at the process end of the sensor, and the other at

the junction box end. Refer to Section 4.2 for proper removal of the sensor from process.

1. Remove sensor from process before proceeding. The junction box with attached male

connector must be recovered from the old sensor for reuse. Unscrew the junction box

cover and set aside. Disconnect electrical connections from printed circuit board inside

junction box. Disconnect BNC connector to preamp. Unscrew hex nut (D) from male

connector body (C). Separate junction box from used sensor. Set aside.

2. Pry off split ferrule from sensor and set aside for reuse. Remove hex nut (D) and set aside

for reuse. Check that the internal O-ring is in place in the male connector body (C) attached

to the junction box.

3. Remove hex nut (B) from male connector body (A) at process end of sensor and set aside.

Slide the Teflon ferrule and the male connector off sensor in the direction of junction box

and set aside. Discard sensor tube.

NOTICE

If stainless steel ferrule was used, male connector body (A) will have to be dis carded with the sensor tube.

4. Discard used O-ring from male connector body (A). Coat new O-ring with a thin film of the

O-ring lubricant provided. Position it in the machined O-ring groove in place of the

discarded O-ring.

CAUTION

Make sure lubricant does not contact any part of the sensor tip particularly the glass bulb.

5. Cover the 1in. MNPT pipe threads of the male connector body (A) with TEFLON tape (not

provided) to protect them from galling during reinstallation.

6. Pass the wires from the new sensor through the process end male connector (A). Make

sure that the beveled edge of the ferrule faces the process end of the sensor. Snug the hex

nut (B) to keep it in place. Do not tighten down fully on the hex nut at this time.

7. Pass the wires from the new sensor through the hex nut (D), the split ferrule (from the old

sensor), male connector body (C), O-ring, and through the junction box from the “neck”

opening and out to the printed circuit board in the junction box. Butt the ferrule’s beveled

edge and the sensor tube against the junction male connector (C). Screw the hex nut (D)

by hand until the tube is “locked” into the male connector body. Make sure that the male

connector body (C) is sufficiently tightened. The sensor will “click” into place by pulling

the sensor tube away from the junction box, but will not move from side to side or pull

clear of the male connector. If the sensor tube is correctly attached to the junction box,

wrench tighten hex nut (D) on male connector body (C) (see Figure 4-1). Do not put the

sensor tube in a vise or use a pipe wrench to tighten the hardware as these will damage

the sensor. If sensor tube is not correctly attached to the junction box, loosen hex nut (D)

and repeat.

Maintenance 21

Page 28

Maintenance Reference Manual

February 2019 00809-0100-3386

8. Connect the sensor wires to the terminals on the printed circuit board in the junction box

in the manner recommended on the junction box cover, or see Figure 2-4. Reattach the

NC connector to the preamp. Screw on the cover of the junction box.

B

. Insert the sensor in the process fitting. Stop it against the closed ball valve. Slide the

9

processend male connector down the sensor tube to mate with the process fitting. Tighten

the male connector into the process fitting.

10. Pull back hard on the sensor assembly, as if trying to remove the sensor, to be certain that

the sensor cannot come free from the valve assembly and male connector. The built-in

retraction stop collar at the end of the sensor will butt against the shoulder of the male

connector.

11. Open ball valve and position the sensor at the desired insertion depth and orientation.

Using a crescent or open end wrench, tighten the hex nut (B) to secure the sensor in place.

NOTICE

A stainless steel ferrule is available if the TEFLON ferrule does not adequately grip. When using the metallic

ferrule, be careful and avoid over tightening. This can damage the sensor tube.

CAUTION

If the male connector leaks during insertion or retraction, replace the O-ring (PN 9550099) in the male

connector body (A).

If the sensor is to be stored, the rubber boot should be filled with 7 pH buffer solution and replaced

on sensor tip until ready to use.

Figure 4-1: Sensor Tube Replacement

22 Maintenance

Page 29

Reference Manual Maintenance

00809-0100-3386 February 2019

Figure 4-2: Male Connector Tightening Diagram

Maintenance 23

Page 30

Maintenance Reference Manual

February 2019 00809-0100-3386

24 Maintenance

Page 31

Reference Manual Diagnostics and Troubleshooting

00809-0100-3386 February 2019

Section 5: Diagnostics and Troubleshooting

5.1 Model 54/3081 pH Diagnostics

The Models 54 and 54e Transmitters and Models 3081, 4081, and 5081 pH Transmitters

automaically search for fault conditions that would cause an error in the measured pH value. Refer

to the respective manual for a complete description of the transmitter’s fault conditions.

5.2 Troubleshooting

Table 5-1, below, lists the diagnostic messages that indicate a possible sensor problem. A more

complete description of the problem and a suggested remedy corresponding to each message is

also listed.

Table 7-1: Troubleshooting

Note: For any repair or warranty inquiries please contact our Customer Care group.

Diagnostics and Troubleshooting 25

Page 32

Diagnostics and Troubleshooting Reference Manual

February 2019 00809-0100-3386

5.3 Rosemount 1056/1057 SMART pH Diagnostics

Rosemount 1056 and 1057 transmitters automatically search for SMART sensors. Once the SMART

sensor is detected, 385+ (-03), and communication is established the start-up, screen will appear,

figure 5-1. Start-up and calibration of pH/ORP are described on page 16. Up to five (5) calibration

data sets can be found under DIAG/sensorX/calibration history, see figure 5-2.

Figure 5-1: SMART start-up screen

bleshoot.

Figure 5-2: Calibration History menu on Rosemount 1056

The calibration data contain slope, offset, temperature, method of calibration (page 16), glass

impedance, reference impedance and time stamp between the calibration, figure 5-3. Advanced

diagnostic data can be used for preventive maintenance, replacement and timely trou-

Figure 5-3: Calibration History screen

26 Diagnostics and Troubleshooting

Page 33

Reference Manual Diagnostics and Troubleshooting

00809-0100-3386 February 2019

Please refer to the corresponding installment manual for detailed description.

The factory calibration data can be found on the bottom of Calibration History menu

figure 5-2. Use key-pad to scroll down to the bottom, find Factory Cal. line and press

enter. The factory calibration screen will appear, figure 5-4. It contains the serial number

of the sensor, slope, offset, temperature offset, glass impedance and reference

inductance value. It's possible to retore the calibration settings to factory default.

Please, refer to corresponding instrument manual for correct procedure.

Figure 5-4: Factory Calibration

Diagnostics and Troubleshooting 27

Page 34

Diagnostics and Troubleshooting Reference Manual

February 2019 00809-0100-3386

28 Diagnostics and Troubleshooting

Page 35

Reference Manual Accessories

00809-0100-3386 February 2019

Section 6: Accessories

6.1 Accessories

Table 6-1: Accessories for Rosemount 385+ sensor

Part Number Description

11275-01 Handrail mounting assembly (Code 03, 04 only)

23550-00 Remote J-Box without preamplifier (Code 02, 03 only)

23555-00 Remote J-Box with preamplifier, (Code 04 only)

23166-00 Process connector, 316SS, insertion/submersion 1 in. MNPT (Code 02, 03, 04)

23166-01 Process connector, titanium, insertion/submersion 1 in. MNPT (Code 02, 03, 04)

9510066 Process connector, Nylon, submersion only, 1 in. MNPT (Code 03, 04)

9210012 Buffer solution, 4.01 pH, 16 oz

9210013 Buffer solution, 6.86 pH, 16 oz

9210014 Buffer solution, 9.18 pH, 16 oz

12707-00 Jet Spray Cleaner for submersion service

23566-00 Sensor Tube, pH, Pt 100, Titanium, Low Resistance Glass

23566-01 Sensor Tube, pH, Pt 100, Titanium, High pH

23566-02 Sensor Tube, ORP, Pt 100, Titanium, General Purpose

23240-00 Ball Valve Assembly 316 Stainless Steel

23646-01 Cable, 12 Conductor, Shielded, Prepped

23557-00 Preamplifier, J-box

33046-00 Ferrule, 1 in. 316 SS, Split

9310096 Nut, Swage, 1 in. 316 SS

9310100 Ferrule, 1 in. TEFLON

9550099 O-ring, 2-214, VITON

Accessories 29

Page 36

Accessories Reference Manual

February 2019 00809-0100-3386

30 Accessories

Page 37

Reference Manual EU Declaration of Conformity

00809-0100-3386 February 2019

EU Declaration of Conformity

ote: Please see websitefor most recent Declaration.

N

EU Declaration of Conformity 31

Page 38

EU Declaration of Conformity Reference Manual

February 2019 00809-0100-3386

32 EU Declaration of Conformity

Page 39

Reference Manual EU Declaration of Conformity

00809-0100-3386 February 2019

EU Declaration of Conformity 33

Page 40

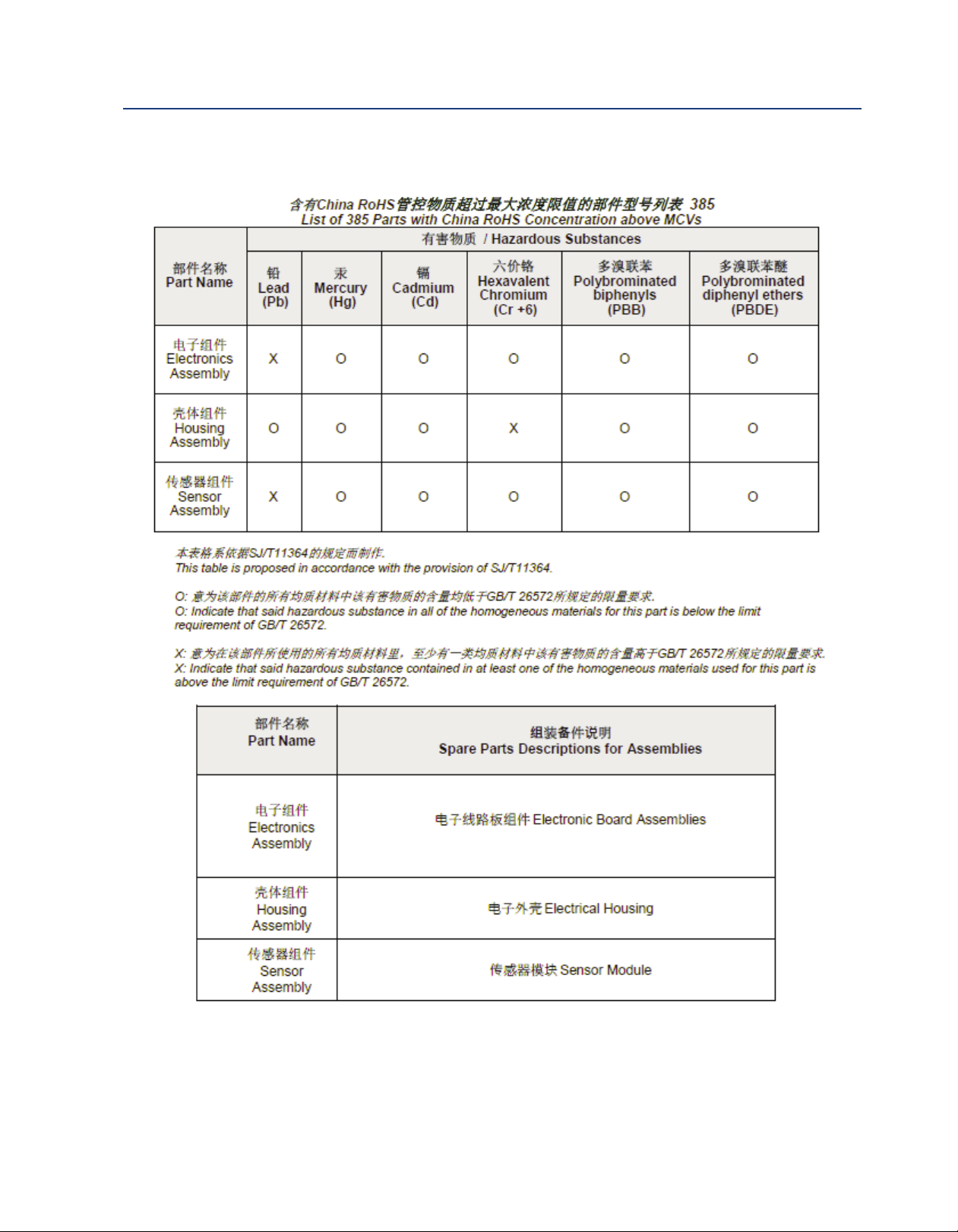

China RoHS Table Reference Manual

February 2019 00809-0100-3386

34 China RoHS Table

Page 41

ANY FM APPROVED

ASSOCIATED APPARATUS

HAVING ENTITY PARAMETERS

NO

N-

H

AZARDOUS

(UNCLASSIFIED)

AREA

CLASS I, II, III, DIVISION 1, GROUPS A-G

T6 Ta = 60C

SENSOR

ENTITY PARAMETERS

Ui = 13.1U, Ii = 358m A

Pi = 698 m W

Ci = 0.967 F, Li = 0.1m H

1. NO REVISION TO THIS DRAW ING IS PERM ITTED W ITHO UT

FM APPROVAL.

2. U

m ax

> U

t

; I

m ax

> I

t

; (C

i

OF ALL LOOPS + C CABLE) < C

a

;

(L

i

OF ALL LOO PS + L CABLE) < L

a

, P

m ax

OR P

i

> P

0.

3. SINGLE M ULTI-CHANNEL

IS BARRIER OR APPARATUS M UST BEFM APPROVED,

4. SINGLE M ULTI-CHANNEL

IS BARRIER OR APPARATUS M ANUFACTURE’S

CONTROL DRAW INGS M UST BE FOLLO W ED W HEN INSTALLING THE SYSTEM .

IS BARRIER OR EQUIPM ENT M AY BE INSTALLED W ITHIN THE HAZARDOUS

(CLASSIFIED) LOCATION FOR W HICH IT IS APPROVED

.

5. INSTALLATION M UST BE IN ACCORDANCE W ITH ARTICL

E 500 OF THE NEC

(ANSI/NFPA 70) AND ANSI/ISA RP 12.6.

W ARNING: SUBSTITUTION OF COM PONENTS MAY IM PA

IR INTRINSIC SAFETY.

6. pH & AM PEROM ETRIC SENSORS W ITHOUT PREAM PS ARE SIM PLE APPARATUS.

ZON E

ZONE 0

7. CONTROL EQUIPM ENT CONNECTED TO THE ASSOCIATED APPARATUS M UST

NO T USE OR GENERATE M ORE THAN 250V.

RESISTANCE BETW EEN INTRINSICALLY SAFE GROUND AND EARTH GROUND

M UST BE LESS THAN OR EQUAL TO 1 OHM .

ANY

FM APPROVED TRANSMITTER FOR

DIVISION 1 W ITH INTRINSICALLY SAFE

OUTPUT PARAMETERS. THIS

FM

APPROVED DEVICE M UST BE INSTALLED

PER ITS INSTALLATION DRAW ING.

FM

APPROVED EQUIPMENT (M AY BE

M ULTIPLE DEVICES, NUMBER IS LIM ITED

BY REQ UIREM ENTS TO M EET ALL OTHER

IS REQUIREMENTS FO R THE NETW ORK)

W ITH EQUIVALENT HAZARDOUS AREA

APPROVALS.

H

AZARDOUS

(CLASSI

F

IED)

AREA

INTRISICALLY SA FE

9. pH/O RP SENSOR M ODELS THAT M AY CONTAIN THE PREAM PLIFIER:

3900/VP

3500/VP

3300HT/VP

3400HT/VP

396/VP

396R/VP

396P/VP

398R/VP

399/VP

389/VP

385/385+

10. W ARNING: TO PREVENT IGNITION OF FLAM M ABLE OR COM BUSTIBLE

ATMOSPHERES, DISCONNECT POW ER BEFORE SERVIC

ING.

11. THE ENTITY CONCEPT ALLOW S INTECONNECTION OF INTRINSICALLY SAFE

APPARATUS W ITH ASSOCIATED APPARATUS W HEN THE FOLLOWING IS TRUE:

U

i

> U

o;

I

i

> I

o;

P

i

> P

o;

C

o

> C

i

+ C CABLE; L

o

> L

i

+ L CABLE.

12. COPY REVISIONS TO 1400332 TO pH/O RP SHIPPING M ANUALS.

13 Ci INCLUDES THE CAPACITANCE OF 500 FEET OF SEN SOR CABLE.

13

DW G NO.

1400332

8.

Reference Manual FM Installation

00809-0100-3386 February 2019

Intrinsically Safe Sensor Installation Drawing - FM

FM Installation 35

Page 42

00809-0100-3386

Rev. AA

February 2019

www.Emerson.com/RosemountLiquidAnalysis

Youtube.com/user/Rosemount

Twitter.com/Rosemount_News facebook.com/Rosemount

Emerson

8200 Market Blvd.

Chanhassen, MN 55317,

USA

Tel +1 800 999 9307

Fax +1 952 949 7001

Liquid.CSC@Emerson.com

©2019 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a mark of

one of the Emerson family of companies. All other marks are the property of their respective

owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available on request. We reserve the

right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...