Page 1

PSR

Pipe and Roof Deicing Heating Cable

Installation Instructions

General Information

• PSR heating cable may be used to help prevent water pipes

from freezing or to help prevent the formation of ice dams

on roofs.

• PSR heating cable is suitable for use on metal and plastic

pipes (such as PVC or polybutylene) but not on exible vinyl

tubing (such as garden hose).

• PSR heating cable is suitable for use in metallic and

nonmetallic gutters and downspouts.

• PSR heating cable is a self-regulating heating cable designed

to change its heat output as the surrounding temperature

changes. As the surrounding temperature increases, the

output of the PSR cable decreases.

• PSR heating cables feature a pilot light in the plug (120V

models only) to indicate when power is applied to the cable.

• PSR cable is suitable for shingle, slate, metal, wood and at

roofs with either plastic or metal gutters/downspouts.

Precautions

1. Heating cables must be installed in compliance with all

national, state, provincial and local electrical codes. Check

120 Volt Cable Selection Chart

Model No. Length in Ft. (m) Wattage @ 50°F (10°C)

PSR1006 6 (1.83) 30

PSR1012 12 (3.76) 60

PSR1018 18 (5.49) 90

PSR1024 24 (7.32) 120

PSR1050 50 (15.24) 250

PSR1075 75 (22.86) 375

PSR1100 100 (30.48) 500

with your local inspector for specic details.

2. These instructions must be retained and made available to the

user and transferred to future users.

3. Heating cables must not be energized in summer conditions; ensure

that all heating cables are de-energized during the summer.

4. It is recommended that the circuit supplying the heating cable

have ground fault protection; this is mandatory by electrical code

for some applications in many regions. Consult an electrical

inspector to determine the specic ground fault requirements for

your application prior to installation. If you are unsure that your

circuit has ground fault protection, consult an electrician.

5. Do not alter the length of the heating cable - cable is factory

sealed and alteration will result in risk of electrical re or shock.

6. Post warning labels (supplied with cable) to power supply disconnect

switch, circuit breaker panel, outdoor receptacle and any other

appropriate locations, as applicable. Also post labels along any pipe

(on outside of insulation) on which the cable is installed.

7. Do not bend cable to a diameter less than 5 times the cable

diameter.

8. Installing cable on a roof below 32°F (0°C) may damage the

shingle if it is brittle.

9. Minimum installation temperature for the heating cable set is

-30°C (-22°F).

240 Volt Cable Selection Chart

Model No. Length in Ft. (m) Wattage @ 50°F (10°C)

PSR2006 6 (1.83) 30

PSR2012 12 (3.76) 60

PSR2018 18 (5.49) 90

PSR2024 24 (7.32) 120

PSR2050 50 (15.24) 250

PSR2075 75 (22.86) 375

PSR2100 100 (30.48) 500

Breaker Size 120V Cable 240V Cable

15 Amp 125/115/100 250/225/205

20 Amp 170/150/135 335/300/270

Maximum total heater length (ft) / Circuit breaker size 20°F (-7°C)/0°F

(-20°C)/-20°F(-30°C) start-up

Pipe Freeze Protection

120V

240V

Planning

• Exposure to temperatures above 150°F (66°C) will shorten the

life of your cable. Before installing on hot water pipes, set the

water heater thermostat below 150°F (66°C).

• Remove any old heating tapes or insulation before installing

the new cable.

• Do not alter the length of the cable.

• Do not use thin 1/8" (3.18 mm) foil-backed foam insulation.

• If more than one heating cable is used on a single electrical

circuit please refer to the maximum heater length per circuit

breaker size chart. Check to make sure the total heating

cable length does not exceed the length specied in this

table.

Selection of heating cable. Select the appropriate cable length

from one of the two charts on next page. Cable may be up to

2 feet (60.96 cm) shorter than the pipe. Lengths assume lowest

ambient temperature is -20°F (-29°C), with a minimum of 1/2"

(12.7 mm) berglass insulation or equivalent. For protection to

-40°F (-40°C), use 1" (25.4 mm) berglass insulation. Note: Allow an

extra foot (30.48 cm) of heating cable for each valve.

©2012 EasyHeat www.easyheat.com 14022-001 Rev. 10

Page 2

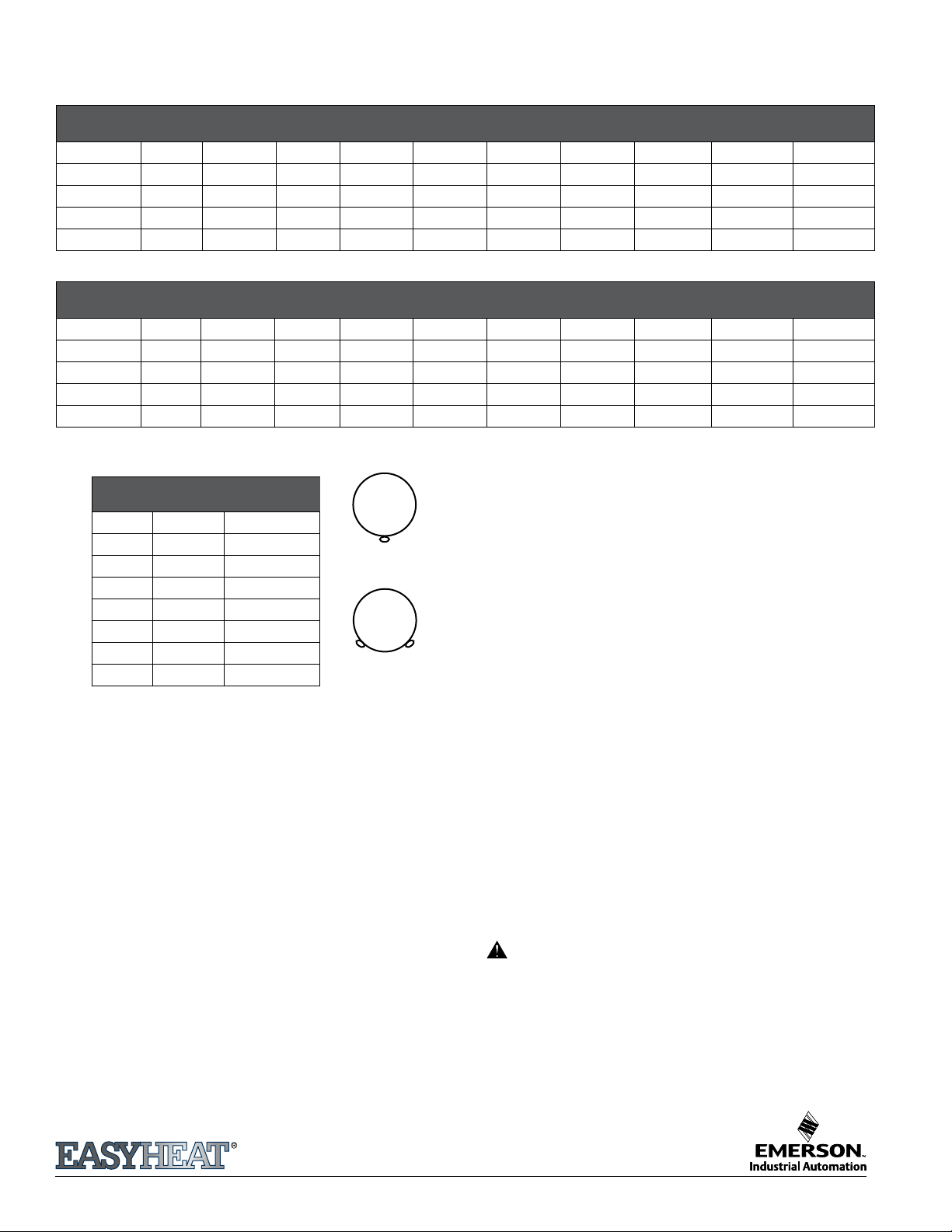

Cable Length Selection Chart

Ambient Temperature -20°F (-28.89°C), with 0.5" (12.7mm) Thick Fiberglass Insulation

METAL PIPE

Pipe Dia

0.5" (12.7mm) A A B B C C E F G

1.0" (25.4 mm) A A A B B C C E F G

1.5" (38.1 mm) A A A B B C D E F G

2.0" (50.8 mm) A B B C C D E F G H

2.5" (63.5 mm) A B B C C D E F G H

3'

.91m

4'-6'

1.2m-1.83m7'2.13m

8'-12'

2.44-3.66m

13'-14'

3.96-4.27m

15'-18'

4.57-5.49m

19'- 25'

5.79-7.62m

26'-50'

7.92-15.24m

51'-75'

15.54-22.86m

76'-100'

21.16-30.48m

PLASTIC PIPE

Pipe Dia

0.5" (12.7mm) A B B C D D E F G

1.0" (25.4 mm) A A B C C D E E F G

1.5" (38.1 mm) A B C D D E E F F H

2.0" (50.8 mm) A B C E E E E F G H

2.5" (63.5 mm) A B C E E E F F G H

3'

.91m

4'-6'

1.2m-1.83m7'2.13m

8'-12'

2.44-3.66m

13'-14'

3.96-4.27m

15'-18'

4.57-5.49m

19'- 25'

5.79-7.62m

26'-50'

7.92-15.24m

51'-75'

15.54-22.86m

76'-100'

21.16-30.48m

SELECTION CHART KEY

Model # # of Cables

A PSR (*)006 1 Cable

B PSR (*)012 1 Cable

C PSR (*)018 1 Cable

D PSR (*)024 1 Cable

E PSR (*)050 1 Cable

F PSR (*)075 1 Cable

G PSR (*)100 1 Cable

H PSR (*)100 2 Cable

Replace* with voltage code:

1 for 120V; 2 for 240V

Single Cable

Double Cable

Attaching heating cable to pipes

Wrap EasyHeat HCA (optional Application Tape) or nylon cable ties

at 6" (15.24 cm) intervals to secure the heating cable to the pipe.

• If the heating cable is the same length as the pipe, run it straight

along the bottom of the pipe. If two cables are required, position

them in the 4 and 8 o’clock positions.

• If the cable selected is exactly double the pipe length, apply a

single trace of cable straight along the pipe all the way to the

end, and loop back, applying cable straight along the pipe all

the way back to the starting point.

• If the cable selected is somewhat less than double the pipe

length, spiral the cable evenly along the entire length of pipe.

Protecting the system with thermal insulation

Before insulating, ensure that there is no damage, such as nicks or

cuts on the heating cables. Immediately cover the pipe, cables,

connections, valves and spigots with 1/2" (12.7 mm) to 1" (25.4 mm)

thick berglass insulation or equivalent. Do not leave the cables

exposed. Use re-resistant materials such as berglass wrap. Make

sure the insulation is waterproofed (with polyethylene or other

vapor barriers) in areas where water may come in contact with the

insulation.

Heating cable control options and power

connection

For 120 Volt cables, the heating cable can simply be plugged

into a ground fault protected electrical receptacle.

For 240 Volt cables, the cable is designed to be directly

connected into an appropriate electrical outlet box supplied

by ground fault protected circuit. Since it will be necessary

to remove power from the cable from time to time, such

as in summer, always connect the cable to an appropriate

double-pole electrical switch. If the heating cable is the only

load on the circuit, the branch circuit breaker may be used to

disconnect power from the cable (switch is not necessary).

In addition, a remote thermostat similar to EasyHeat model

C3RC can be used for 120 Volt or 240 Volt cables to reduce

energy consumption and extend the life of the cable. Consult

your local EasyHeat supplier or representative for other control

options.

Testing the system

Once the installation is complete, apply power to the heating

cable; wait about one hour, and then turn on a water tap

supplied by the protected pipe and test the temperature of

the water. It should feel warm almost immediately as the water

heated by the cable ows through the pipe.

Operation. Energize the cable/control upon the arrival of cold

weather in the fall and de-energize the cable in late spring.

Maintenance

Check cable each year for any damage before energizing the

heating cable. Check any ground fault protection device for

proper operation. Check pipe insulation and replace any that

may be loose or damaged. Do not operate the cable if any

damage is found.

www.easyheat.com

Page 3

Roof Deicing

Selection of heating cable. The total heating cable length for

deicing is determined by including all elements of the roof system

that need protection. Use Tables 1 and 2 to determine the total

length of cable. Usually one cable will be sufcient for both roof

and gutter areas. For larger installations, use separate cables for

roof area and gutter/downspout area.

Installation procedures

• Remove leaves, pine needles, or any combustible debris

from roof, gutters and downspouts before installing roof

deicing cable.

• Use ZH-C Roof Clips (sold separately) for attaching the heating

cable to the roof (shingle and metal roofs).

• For downspouts longer than 20 feet (6.10 m), use DSH

Downspout Hanger (sold separately) to support the heating

cable where it enters/exits a downspout.

One hanger is required for each downspout. Always loop the cable

down to the bottom of downspout and back up toward gutter,

clamping it into downspout hanger to prevent cable from being

damaged by drain/gutter edge. This also ensures that the cable tail is

secured on the roof. Cable to be linked to roof loop (see diagrams).

TYPICAL MEMBRANE ROOF

Valley

Roof Clips

Downward Slope

Drain

Heater Cable

Power Connection

Downward Slope

Table 1 Determination of total cable requirements

Model # # of Cables

Roof Edge From Table 2 based on eave overhang

Gutter 1' (30.48 cm) of cable/foot of gutter (if gutter is

wider than 6"(15.24cm), use 2 traces)

Downspout 2' (60.96 cm) of cable/foot of downspout–cable

is looped down and back

Roof Valley 6' (1.83m) of cable/valley - loop 3' (0.91m) up

valley and back

Dormer

1' (30.48 cm) of cable/foot of dormer perimeter

Perimeter

Table 2 Cable length factors vs. eave overhang

Eave

Overhang E

12"(30.48 cm) 18"(45.72 cm) 1.9 2.5

24"(60.96 cm) 30"(76.20 cm) 2.7 3.5

36"(0.91 m) 42"(1.07 m) 3.6 4.5

48"(1.22 m) 54"(1.37 m) 4.6 5.5

Cable length required = Length Factor × Roof Length (feet/m)

Notes:

* Typical shingle roof with sawtooth pattern. (See diagram)

** Typical metal roof with loop pattern spaced 24" (61 cm)

- for other spacing these factors will need to be adjusted

accordingly. (See diagram)

For other designs, contact EasyHeat.

Loop

Height H

Length Factor

Shingle Roof *

Length Factor

Metal Roof **

TYPICAL METAL ROOF (Separate cables shown for roof and gutter)

Roof Clip (ZH-C)

H

Heater Cable

Clip gutter cable to roof

cable to provide a path for

water to get to ground

End Seal

Must not be submerged

nor allowed to be at the

bottom end of a downspout.

DSH

Hanger Clamp

Weatherproof

outlet box

(by installer)

Drip Loop (Typ.)

Roof Clips

(@24" (60.96 cm)O.C.)

TYPICAL SHINGLE ROOF (Single cable shown for roof and gutter)

24"

Weatherproof Outlet

Box (by installer)

Drip Loop

Heater Cable

“H” loop height

“E” overhang distance from

roof edge to face of wall

overhang

END CIRCUIT

DOWNSPOUT

INSTALLATION

www.easyheat.com

MID CIRCUIT

DOWNSPOUT

INSTALLATION

Page 4

Heating cable control options and power

connection

For 120 Volt cables, the heating cable can be simply plugged

into a ground fault protected electrical receptacle, when icing

conditions are present on the roof. The (optional) EasyHeat RS-2

Roof Sentry (120 Volt) control can be used to automatically

ensure cables are energized only when icing conditions are

present on the roof, minimizing energy consumption and

extending cable life.

For 240 Volt cables, the cable is designed to be directly

connected into an appropriate electrical connection box.

Since it will be necessary to remove power from the cable from

time to time, such as in summer, always connect the cable to

an appropriate double-pole electrical switch. If the heating

cable is the only load on the circuit, the branch circuit breaker

may be used to disconnect power from the cable (switch is

not necessary). Several automatic controls are available from

EasyHeat.

Always connect a pilot light into the circuit of 240V cables to

indicate when the cables are energized.

Testing the system. Once the installation is complete, apply

power to the heating cable; the surface of the cable will feel

warm after about 15 minutes.

Operation

If no automatic controls are installed, energize the cable only

when icing conditions are present on the roof, and de-energize

when icing conditions are no longer present. For 120 Volt models

only, the power cord plug contains a pilot light indicating that

power is being applied to the cable. Ensure power is removed

from the cable/control in summer.

Maintenance

Check cable annually for any damage, such as nicks or cuts

possibly caused by animals or other activity on the roof. Check

any ground fault protection devices for proper operation.

Remove all debris (leaves, twigs, pine needles, etc.) from roof,

gutters and downspouts prior to energizing the roof cable. Do

not attempt to energize the roof cable if any of these problems

are discovered.

LIMITED WARRANTY AND LIABILITY

EasyHeat warrants that if there are any defects in material

or workmanship in this product during the rst twelve (12)

months after the date of its purchase, we will replace the

product with an equivalent model, not including any labor

or other installation costs.

Our obligation to replace the product as described above

is conditioned upon (a) the installation of the product

conforms to the specications set forth in our installation

instructions and (b) the product not having been damaged

by unrelated mechanical or electrical activities.

Product replacement as described above shall be your sole

and exclusive remedy for a breach of this warranty. This limited

warranty does not cover any service costs relating to repair

or replacement.

We shall not be liable for any incidental, special or

consequential damages as a result of any breach of this

warranty or otherwise, whether or not caused by negligence.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

The warranty above is exclusive and makes no other warranties

with respect to description or quality of the product. No

afrmation of fact or promise made by us, by words or action,

shall constitute a warranty. If any model or sample was shown

to you, the model or sample was used merely to illustrate the

general type and quality of the goods and not to represent

that the goods would necessarily be of that type or nature. No

agent, employee or representative of ours has authority to bind

us to any afrmation, representation or warranty concerning

the goods sold unless such afrmation, representation or

warranty is specically incorporated by written agreement.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR PARTICULAR PURPOSE THAT MAY ARISE IN CONNECTION

WITH THE SALE OF THIS PRODUCT SHALL BE LIMITED IN DURATION

TO TWELVE (12) MONTHS FROM THE DATE OF PURCHASE. WE

DISCLAIM ALL OTHER IMPLIED WARRANTIES, UNLESS WE ARE

PROHIBITED BY LAW FROM DOING SO, IN WHICH CASE ALL

SUCH IMPLIED WARRANTIES SHALL EXPIRE AT THE EARLIEST TIME

PERMITTED BY APPLICABLE LAW. Some states do not allow

limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

This warranty gives you specic legal rights, and you may also

have other rights which vary from state to state or province

to province.

To obtain a replacement under this warranty any inoperative

product or component must be returned, with proof of

purchase, to EasyHeat at the addresses noted herein. Buyer is

responsible for all costs incurred in removal and re-installation

of product and must pre-pay shipment to factory or point of

purchase.

In CANADA

99 Union St.

Elmira, Ont. N3B 3L7

Tel. (800) 794-3766 • Fax (800) 361-4574

In USA

2 Connecticut South Drive

East Granby, CT 06026

Tel. (800) 537-4732 • Fax (800) 541-7451

www.easyheat.com

Loading...

Loading...