Page 1

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

Before installation these instructions must be fully read and understood

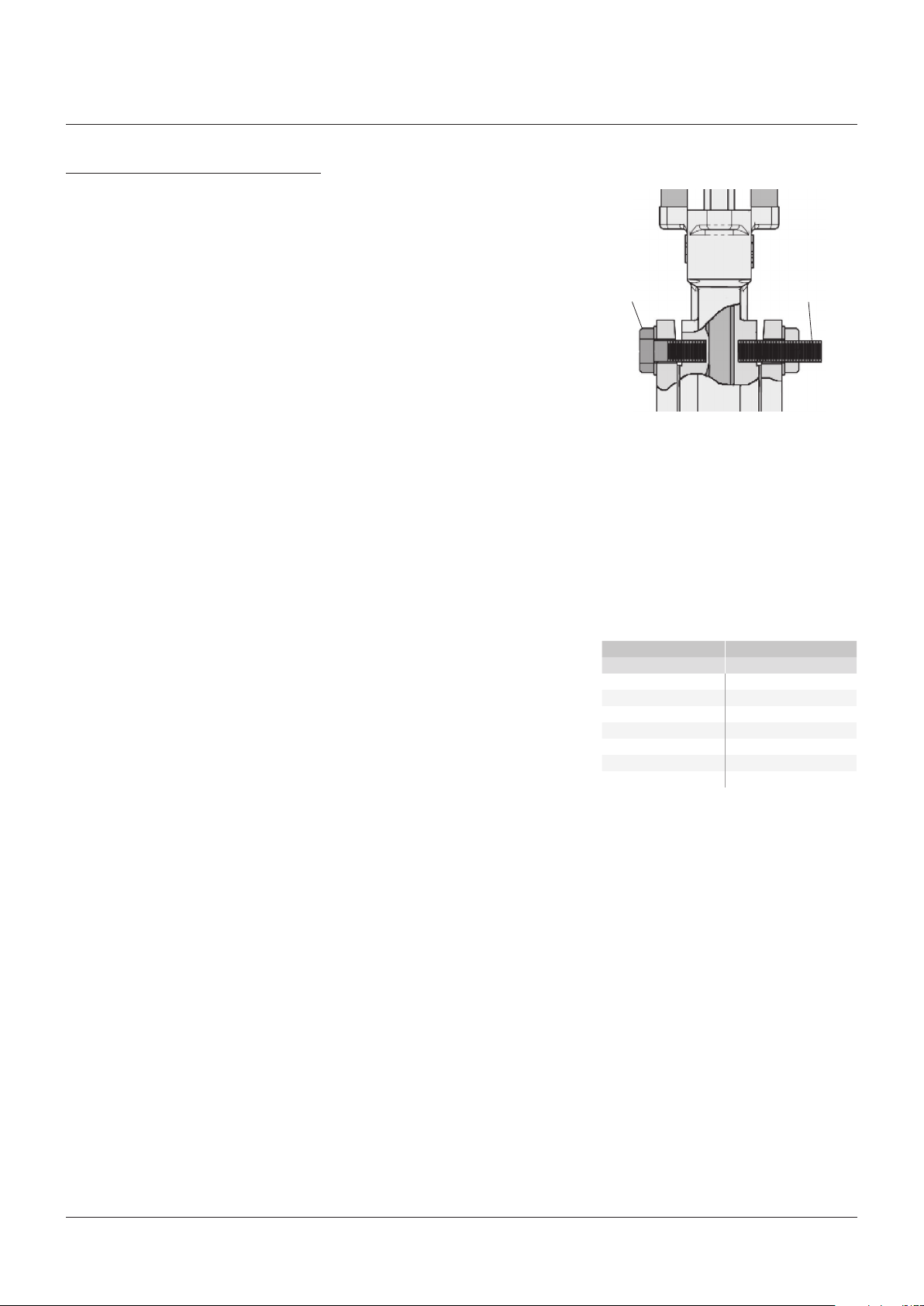

FIGURE 1

Inspect and tighten

packing gland nuts

to stop any leakage

FIGURE 2

Bolt holes in the chest

or upper flange area

are blind tapped

GENERAL INFORMATION

The Keystone PCS17 knife gate is a

bi-directional shut-off valve. It can be installed

without concern over direction of flow. Itwill

shut-off equally with in either direction.

Allvalves should be operated within the design

pressure and temperature ranges. Do not

exceed 100% of the maximum pressure rating

of the valve at any time during its operation.

Pressure spikes beyond the valve’s pressure

rating are solely the responsibility of the user.

Initial inspection

1. Examine entire valve and report any damage

or discrepancies immediately.

2. Accessories, if any, including solenoids,

limit switches, positioners, etc., are

tested for functionality prior to shipment.

Examinecarefully for damage which may

occur during shipment.

3. Operators: Standard manual handwheels

may be shipped loose for field installation.

It is necessary to use a pipe wrench or large

crescent wrench to properly tighten the

handwheel retaining nut. Be sure to fully

tighten.

4. Packing Assembly: The packing gland bolts

should be checked and adjusted to obtain

afirst time packing seal. Packing gland

nuts may become slightly loose when valve

is shipped. Field adjustment is expected

and desired. (Figure 1. Tighten just enough

to stop any leakage. Overtightening may

increase valve operating torque and shorten

packing life).

INSTALLATION INSTRUCTIONS

Please take note of the specific installation

tags provided with each valve.

1. The mating line flanges must be properly

aligned prior to attempting installation.

Slipon or weld flanges can be used.

Nevertry to make up for misaligned pipe

flanges by the line bolting. Pipe supports

and/or expansion joints should be used

tominimize pipe loads on valves.

2. Flange gaskets suitable for the application

are required, sized to fit the raised face of

the valve.

3. The port flanges of the PCS17, DN 50 to

600(NPS 2 to 24) are drilled and tapped

to ASME B16.5/150, DN 750 (NPS 30) is

per MSS-SP44 with the face to face per

MSS-SP81. The bolt holes in the chest

or upper flange area are blind tapped,

see Figure 2.

NOTE

Care must be taken when installing studs or bolts

in the tapped holes of the flange in the chest area

to prevent damage, see Figure 2 and Figure 3.

4. Cap screws or bolts that are too long can

pinch the valve body, thereby forcing the

body wall into the gate, springing the gate

out of line, see Figure 3. Additionaldamage

can occur on the gate face, such as scoring

or scratching of the gate. This type of

damage normally requires the valve be

returned to our shop for repair.

5. To avoid damage, it is recommended that

studs be used on all tapped bolt holes,

especially the upper chest holes. If cap

screws are used, be sure that they do not

enter beyond the depth of the tapped hole

when fully tightened.

NOTES

1. All knife gate valves are designed and

manufactured to be installed in applications where

no more than 1g (0.04 oz.) of force In excess of

gravity is applied to the valve in any direction. This

1g (0.04 oz.) force can be an effect of traffic, wind,

or earthquake. Allpiping systems should contain

independent support mechanisms and should not

utilize the valve as a sole means of support.

2. If the valve is supplied with an actuator other

than the standard handwheel operator, additional

support may be required. Especiallyif the valve is

not installed in the vertical position. See page 8 for

further details.

3. Accessories,ifany, including solenoids, limit

switches, positioners, etc., are tested for

functionality prior to shipment.

4. Examinecarefully for damage which may occur

during shipment.

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-02874-EN 19/05

Page 2

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

OPERATION

1. To close the valve and provide isolation,

the actuator (handwheel, bevel gear,

air/hydraulic cylinder or electric actuator)

moves the gate in a linear motion through

the packing box until the gate is seated

against the resilient seat. To open, reverse

the operation and the gate moves up and out

of the packing box, opening the valve port.

2. The valve packing assembly requires

occasional adjustment. Frequency of

adjustment is dependent application

conditions including but not limited to

pressure, temperature and number

ofcycles.

3. All valves should be operated within the

design pressure and temperature ranges.

Under no circumstances should the valves

be operated at conditions outside these

parameters.

4. The operator of any valve should have an

understanding of the effects of opening/

closing the valve with regards to its role

in the overall piping system. Operators of

valves under pressure should take Caution

to ensure that the valve is in good operating

condition prior to operating it under

pressure.

5. Certain processes utilize flammable,

caustic and/or otherwise unstable

media. Careshould be taken in these

circumstances to ensure the operator is

aware of the specific health and safety risks

associated with that medium. Additionally,

Caution should be taken around all valves

as injury or damage may occur from the

leakage of hot, high pressure and/or caustic

materials from a gasket and/or packing

joint. Packing and/or gasket leaks may

cause external corrosion damage to the

valve.

6. Take care in the manual actuation of

valves used in applications with elevated

temperatures. Ensure the individual

operating the valve does not come

in contact with any hot areas of the

valve. Inmany elevated temperature

applications, the handwheel may be too hot

to handle, take reasonable preCautions.

Severetemperature applications may

require optional insulation the valves

toprotect operators from the heat.

7. When operating the valve stand clear of any

moving parts such as the spindle and/or

gate assembly, use of gloves is suggested

when operating manual valves to minimize

the risk of injury.

8. All manually operated valves are designed

for hand input. Do not apply excessive input

torque via pipe wrenches, “cheater bars”,

or other devices. If a manual handwheel

actuated valve is difficult to operate due to

torque requirements, it is recommended

that the valve be supplied with or converted

to a bevel gear, air/hydraulic cylinder or

electric motor actuator.

9. Electric motor actuated valves should be

left in their factory set condition, unless

the system operating parameters dictate

a change. If changes are necessary, they

should be performed in small increments

using the lightest/lowest setting possible

to achieve the desired performance and

then the valve/actuator function inspected.

Excess torque and/or thrust in the motor

settings may damage or lockup the valve.

Never remove a motor operator, gear

operator or manual operating assembly

from a valve while it is pressurized unless

gate has been secured from movement and

lockout/tagout applied per company safety

procedures and policies. The valve must be

completely relieved of all pressure prior to

disassembly or removal from pipeline.

10. Motorized PCS17 valves are position

seated and should never be torque seated.

Donotuse the motor torque settings to seat

the valve.

11. Care should be taken to ensure that

electrical motors are wired correctly to the

power source. Incorrect phasing of 3-phase

wiring may cause valve/motor damage.

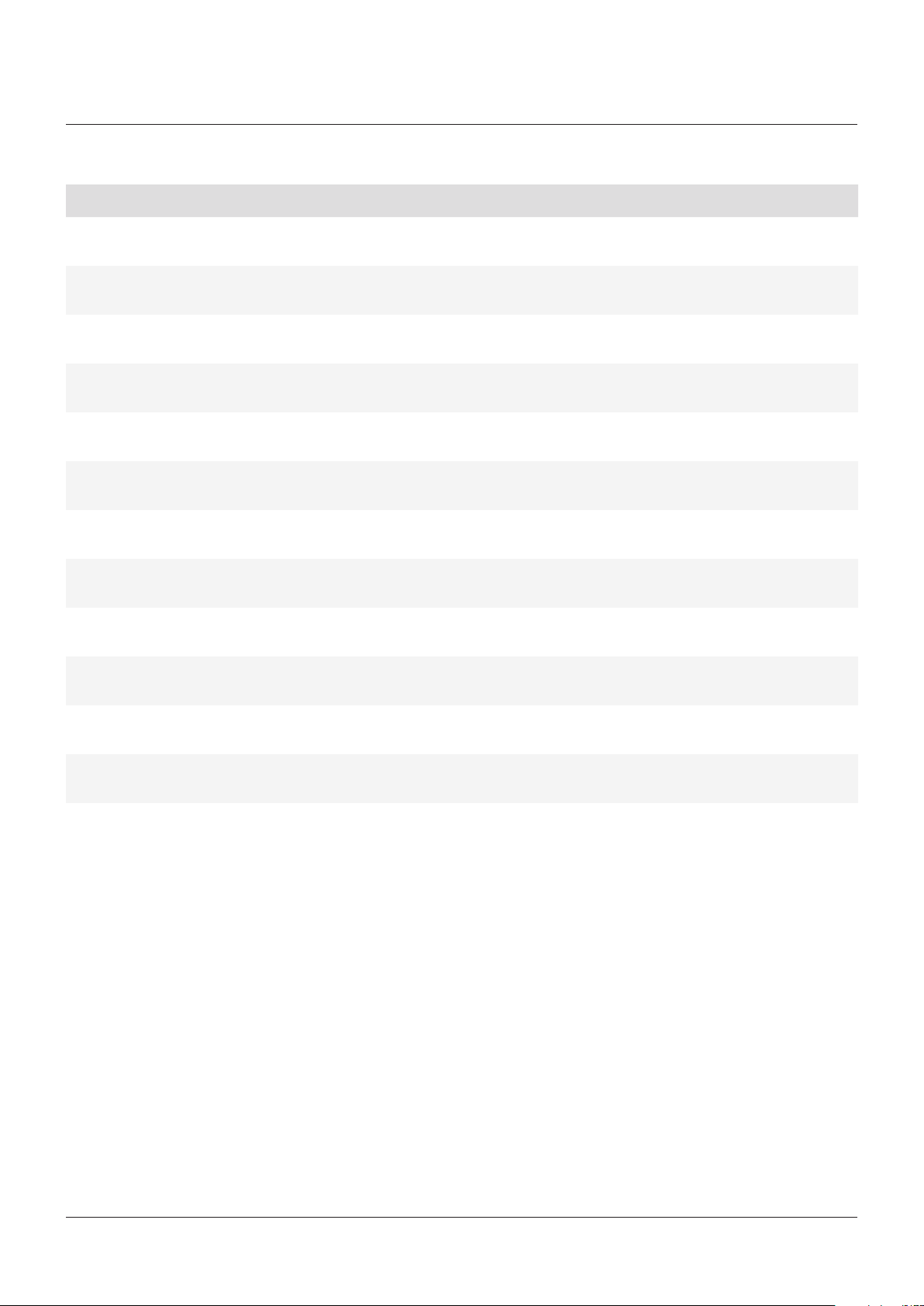

FIGURE 3

Cap screw

Wrong Right

NOTE

Body can be deformed or fractured if flange bolting

is too long or overtorqued.

Stud with nut

TABLE A - MAX. FLANGE BOLT TORQUE

Bolt size Torque

Imperial Metric lb/ft Nm

⅝" M16 55 75

¾" M20 65 88

⅞" M22 110 149

1" M25 135 183

1⅛" M30 150 203

1¼" M30 200 271

1½" M40 250 339

2

Page 3

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

FLANGE DIMENSIONS

Valve size

DN (NPS) Flange Bolt circle Dia. Quantity O.D. flange Dia. Bolt size Raised face Dia. Face-to-face Valve flange OD

50 (2) SP-81 120.65 (4.75") 4 152.4 (6") 15.875 (⅝" - 11) 91.948 (3.62") 47.752 (1.88") 165 (6.496")

TBL D 114 4 150 M16 90 47.752 165

TBL E 114 4 150 M16 90 47.752 165

80 (3) SP-81 152.4 (6") 4 190.5 (7.5") 15.875 (⅝" - 11) 127 (5") 50.8 (2") 190.5 (7.5")

TBL D 146 4 185 M16 122 50.8 190.5

TBL E 146 4 185 M16 122 50.8 190.5

100 (4) SP-81 190.5 (7.5") 8 228.6 (9") 15.875 (⅝" - 11) 157.226 (6.19") 50.8 (2") 228.6 (9")

TBL D 178 4 215 M16 154 50.8 228.6

TBL E 178 8 215 M16 154 50.8 228.6

150 (6) SP-81 241.3 (9.5") 8 279.4 (11") 19.05 (¾" - 10) 215.9 (8.5") 57.15 (2.25") 285.1 (11.224")

TBL D 235 8 280 M16 211 57.15 285.1

TBL E 235 8 280 M20 207 57.15 285.1

200 (8) SP-81 298.45 (11.75") 8 342.9 (13.5") 19.05 (¾" - 10) 269.748 (10.62") 69.85 (2.75") 342.9 (13.5")

TBL D 292 8 335 M16 268 69.85 342.9

TBL E 292 8 335 M20 264 69.85 342.9

250 (10) SP-81 361.95 (14.25") 12 406.4 (16") 22.225 (⅞" - 9) 323.85 (12.75") 69.85 (2.75") 406.4 (16")

TBL D 356 8 405 M20 328 69.85 406.4

TBL E 356 12 405 M20 328 69.85 406.4

300 (12) SP-81 431.8 (17") 12 482.6 (19") 22.225 (⅞" - 9) 381 (15") 76.2 (3") 482.6 (19")

TBL D 406 12 455 M20 378 76.2 482.6

TBL E 406 12 455 M24 374 76.2 482.6

350 (14) SP-81 476.25 (18.75") 12 533.4 (21") 25.4 (1" - 8) 412.75 (16.25") 76.2 (3") 533.4 (21")

TBL D 470 12 525 M24 438 76.2 533.4

TBL E 470 12 525 M24 438 76.2 533.4

400 (16) SP-81 539.75 (21.25") 16 596.9 (23.5") 25.4 (1" - 8) 469.9 (18.5") 88.9 (3.5") 596.9 (23.5")

TBL D 521 12 580 M24 489 88.9 596.9

TBL E 521 12 580 M24 489 88.9 596.9

450 (18) SP-81 577.85 (22.75") 16 635 (25") 28.575 (1⅛" - 7) 533.4 (21") 88.9 (3.5") 641.4 (25.25")

TBL D 584 12 640 M24 532 88.9 641.4

TBL E 584 16 640 M24 552 88.9 641.4

500 (20) SP-81 635 (25") 20 698.5 (27.5") 28.575 (1⅛" - 7) 584.2 (23") 114.3 (4.5") 715 (28.149")

TBL D 641 16 705 M24 609 114.3 715

TBL E 641 16 705 M24 609 114.3 715

600 (24) SP-81 749.3 (29.5") 20 812.8 (32") 31.75 (1¼" -7) 692.15 (27.25") 114.3 (4.5") 840 (33.071")

TBL D 756 16 825 M27 720 114.3 828.8

TBL E 756 16 825 M30 717 114.3 828.8

750 (30) SP-81 914.4 (36") 28 984.25 (38.75") 31.75 (1¼" -7) 857.25 (33.75") 117.348 (4.62") -

TBL D 845 20 910 M27 809 117.348 TBL E 845 20 910 M30 806 117.348 -

NOTES

1. These dimensions duplicate ASME B16.5 150 flange drilling

2. Flange thickness includes 1.5 mm (

3. Through bolt flange drilling is bolt size plus 3.1 mm (⅛")

1

/

16") raised face

3

Page 4

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

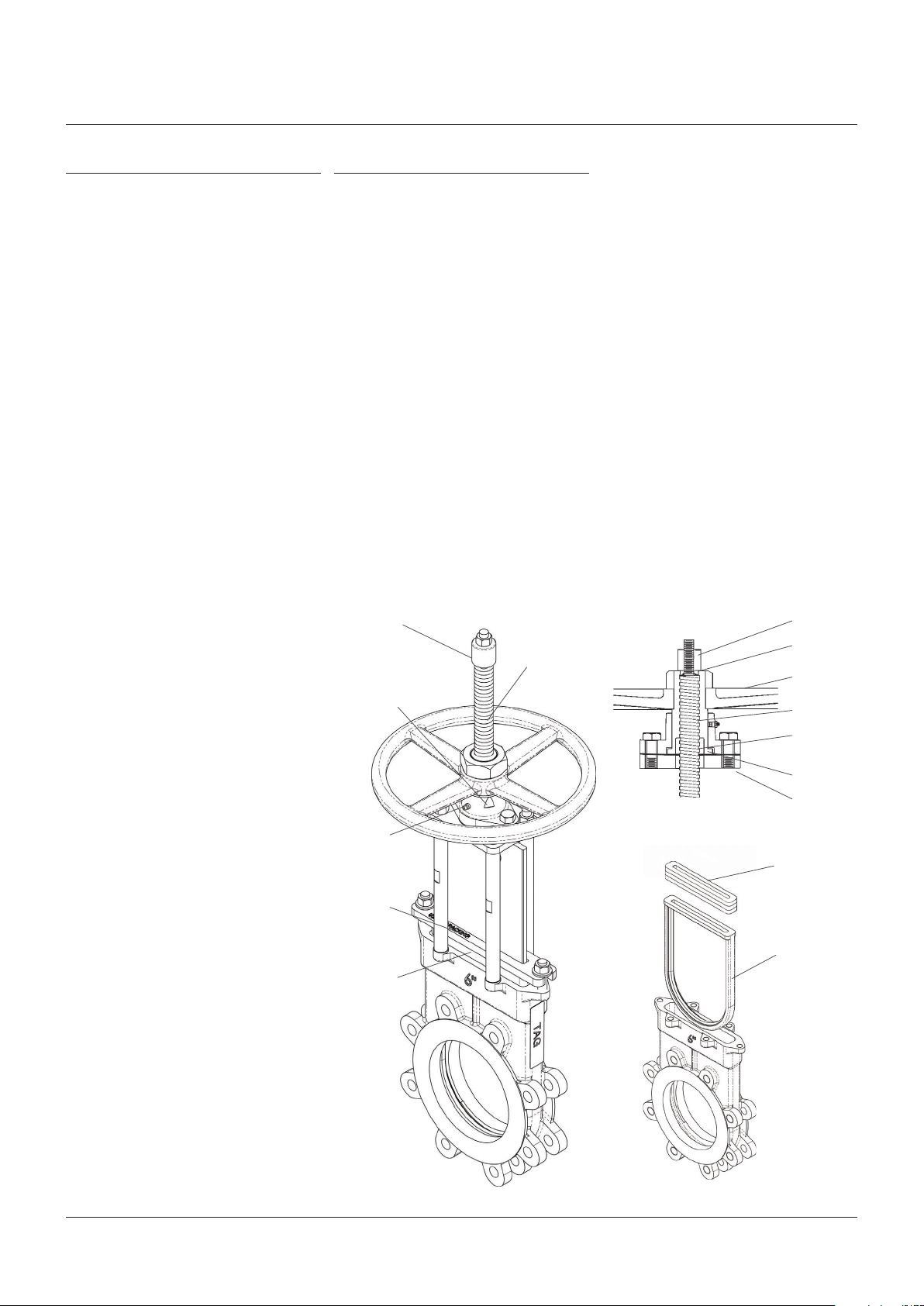

GENERAL MAINTENANCE

We recommend that all Keystone PCS17 knife

gates be inspected at least every 60 days.

The following points should be examined and

corrected as required (Figure 4):

1. Exterior overview: As piping system

components are subject to certain levels of

erosion and corrosion, periodic inspections

should be made as valves/components

may wear over time. Regular inspection

of the valve body and gate should be

performed, check for general signs of

corrosion, component wear and/or damage

caused by process media, i.e. wire draw,

steam cutting. If possible, check body wall

and gate thicknesses using calibrated

measuring devices such as micrometers

and/or ultrasonic thickness gauges.

Severe applications may require additional

inspection types and/or frequency.

2. Valve spindles, extension spindles, and

spindle nut: Look for excessive corrosion,

galling or lack of lubrication. If valve

spindle requires lubrication, utilize the

grease fitting provided and pump standard

bearing grease through the yoke hub

to lubricate the spindle and spindle nut

assembly. Additionallubrication may be

applied directly onto spindle or spindle

threads. (Use material which meets

ASTM4950GBLB.)

3. Stop nut adjustment (manual valves):

Checktightness of stop nut on valve spindle

4. Packing gland: Check for leaks or worn

packing. If leakage is occurring around the

packing gland, tighten the packing gland

bolts, being careful not to overstress the

bolting. If the valve requires repacking,

you may use any standard square braided

packing as suitable for your service.

Seeadditional instructions for repacking

on page 5.

5. If possible stroke the valve through the full

open and closed position to make sure it is

functioning properly.

SPARE PARTS

The following spare parts are recommended:

Cylinder operator (if applicable)

1 - Repair kit

Valves

1 - Replacement seat (Figure 6)

1 - Replacement packing set.

1. When ordering replacement parts for a

Keystone product or cylinder operator,

please include valve or cylinder size

andcomplete description including

serialnumber with your request.

2. Additional replacement parts such as

handwheels, spindle nut assemblies,

retainers, yoke posts, spindles, packing

glands, and gates are available from factory.

Again, please provide complete description

with serial number when ordering.

FIGURE 4

Stop nut

Spindle

Spindle nut

(under retainer)

Grease fitting

Packing gland

FIGURE 5

FIGURE 6

Stop nut

Retaining nut

Handwheel

Spindle nut

Spindle

assembly

Retainer

Retainer bolt

Packing

NOTES

1. Stop all small packing or seat leaks as soon as

possible as considerable damage can be done

tothe valve and the surrounding area if leakage

isallowed to continue to grow.

2. Replacement parts including handwheel and yoke

assemblies, gates, packing glands, seats and

packing canbe provided from our factory.

Seat

Packing

4

Page 5

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

REPACKING INSTRUCTIONS

Tools and materials required

1. Open end wrenches or sockets to fit packing

gland hex nuts and 4-Post yoke hex nuts.

2. Square braided packing suitable for

application - Keystone standard packing is

special PTFE impregnated synthetic (AFPL).

3. Knife, to cut packing.

1

4. 10 x 50 mm (

/

32 x 2") flat bar approximately

50 mm (2") long with rounded end.

5. Tool with radius end to fit inside of packing

box.

CAUTION

Follow required safety procedure and policies.

Assure line is not pressurized before loosening

packing and removing valve. Use proper lifting

and support techniques when moving valve and

orvalve subassemblies.

Prepare valve

1. Relieve pressure on valve or remove valve.

2. Close the valve.

3. Disconnect the spindle from the gate.

(Figure 7)

4. Raise spindle or rod to the fully raised

(open) position, providing clearance, or if

desired, the entire actuator assembly may

be pulled up and away from valve, see steps

a and b.

a. After step 3, remove top plate hex nuts

and washers from 4-Post yoke.

b. Pull valve spindle and entire actuator

assembly, excluding 4-Post yoke up and

away from valve, set aside.

5. Remove packing gland hex nuts, packing

gland, and old packing.

4. Reassemble packing gland to valve by

sliding it down gate, aligning bolt holes with

gland studs.

5. Tighten packing gland until the top row of

packing is slightly compressed.

6. Reassemble the actuator assembly, attach

lifter to gate.

7. Slowly charge line, stop when packing

leak is evident or until normal pressure

isreached.

8. Retighten packing gland bolts only enough

to stop the leakage, do not overstress the

bolting.

9. If normal pressure has not been achieved,

continue to add pressure and adjust packing

gland until normal pressure has been

reached.

10. Check gland bolts and snug all packing

gland nuts.

NOTES

1. Important, do not tighten packing gland bolts any

more than required to stop packing gland leaks

after line pressure is applied.

2. Self-mold packing is triangular in shape, 12.7 mm

(½”) (equilateral) on a side and about 63.5 mm

(21/2”) long. It can be broken into pieces to conform

to the shape of the packing box. Install one (or

two) row(s) of self-mold as appropriate for the size

valve. SeeFigure 8. Make sure that all voids are

filled.

3. High-temperature packing may not reach full

pliability until normal temperature is achieved.

Packing may require readjustment as temperature

changes.

FIGURE 7

Gate

Packing gland

Packing

Body

FIGURE 8

NOTE

Valve with self-mold packing illustrated

Installation of new packing

If valve is equipped with self-mold packing,

seenote 2 before starting.

1. Cut packing to exact length for each row

(Table 3). Starting on either side of the gate

install the packing all-around the gate one

row at a time.

2. Tamp packing into packing box, even and

flat using flat bar or other suitable tool.

3. Add next row, alternating sides of the gate

where the ends of the packing meet against

each other. (Ends of packing must not line

up. If they do premature leakage could

occur.) Complete by adding the number of

rows required. (Figure 8)

TABLE 3 PACKING SIZES

Valve size

DN (NPS)

50 (2) 3 10 85 (6⅜)

80 (3) 3 10 230 (9)

100 (4) 3 10 260 (10

150 (6) 4 10 380 (15)

200 (8) 5 10 485 (19⅛)

250 (10 4 10 595 (23½)

300 (12) 4 10 700 (28)

350 (14) 4 15 780 (30⅝)

400 (16) 4 15 890 (35)

450 (18) 4 15 990 (39)

500 (20) 4 15 1095 (43)

600 (24) 4 16 1320 (51⅞)

750 (30) 4 16 1655 (66⅛)

Number

ofrows

Cross

section

Cut length

mm (in.)

5

/

16)

5

Page 6

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

RESILIENT SEAT REPLACEMENT INSTRUCTIONS

CAUTION

Follow required safety procedure and policies.

Assure line is not pressurized before loosening

packing and removing valve. Use proper lifting

and support techniques when moving valve and

orvalve subassemblies.

Tools and materials required:

1. Open end wrenches or sockets to fit

packinggland and four-post yoke hex nuts.

2. Flat head screwdriver.

DISASSEMBLY

1. Flush line to remove solids and

contaminants from chest and seat channel

area, drain when flushing is complete.

2. Relieve pressure on valve/pipeline.

3. Remove packing gland hex nuts and loosen

packing gland. (Figure 9)

4. Fully open the valve.

5. Detach gate from valve lifter by removing

gate bolts.

6. Remove top plate hex nuts and washers

from four-post yoke.

7. Pull entire actuator assembly up and away

from valve, set aside.

8. Pull gate from valve body (examine gate for

flatness and damage, replace if necessary).

9. Thoroughly remove old packing.

10. Remove seat.

Note: to remove seat, it will be necessary

to slip a pry tool through the gate slot in the

packing support bar and pry up and out of the

valve body. Seat will most likely be damaged

beyond use when pulled from body.

Do not pull seat from body unless

replacement is planned for. A special tool is

available for this purpose, refer to Figure 10.

See chart for part number and description.

11. Closely examine packing box, valve chest

and seat channel. Remove any remaining

solids from seat channel.

FIGURE 9 FIGURE 10

Top plate hex nuts

(locatedon top of

yoke posts)

Gate bolts

Packing gland

Packing gland

hex nuts

Seat shown out of valve for clarity

6

Page 7

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

INSTALLATION OF NEW SEAT

1. Confirm seat is correct size and elastomer

for application.

2. Examine seat for cuts, tears and other

imperfections, do not use if seat is visibly

damaged. Apply a thin coating of Dow

Corning 111 or other similar, silicone-based

lubricant (do not use carbon-based grease)

to outside and inside edges of seat. This will

facilitate seat entry into valve body and gate

entry into seat. Soapy water may be used if

silicone-based lube is unavailable.

3. Insert seat through the valve packing box,

radiused end first, pushing it straight down

into valve throat (Figure 11).

4. Using a flat faced, round bar (no sharp

edges) and a hammer, tap packing support

bar all around the perimetre, driving the

seat until it bottoms-out in the packing box.

Take care to avoid cutting elastomer surface

of packing support bar. Seat should be

firmly seated inseat channel at this time.

5. Insert gate into packing box, radiused end

first, pushing it straight down through the

packing support bar and into valve throat as

far as possible by hand (Figure 12).

6. Repack valve, see Page 5 for instructions,

donot fully tighten.

7. Reassemble actuator assembly, aligning top

plate with four-post yoke and aligning gate

bolt holes with valve lifter, lower assembly

until top plate is in position, assemble with

hex nuts.

8. Reassemble gate to actuator assembly

using hex nuts.

9. Open valve to full open position.

10. Close valve to fully closed position.

11. Apply pressure to pipeline,

Description Sizes DN (NPS) Material

Seat puller

assembly

Seat puller

assembly

Seat puller

assembly

Seat puller

assembly

50 - 200

(2 - 8)

50 - 200

(2 - 8)

250 - 750

(10 - 30)

250 - 750

(10 - 30)

Carbon steel

304 S/S

Carbon steel

304 S/S

FIGURE 11 FIGURE 12

CAUTION

Packing may leak, adjust as necessary to obtain

seal.

7

Page 8

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

SPINDLE NUT REPLACEMENT INSTRUCTIONS

It is not necessary, or desired, to remove the

yoke assembly to replace the nut.

Tools required

1. Pipe wrench or large crescent wrench

2. Appropriate size open end wrench for

retainer bolts

CAUTION

Follow required safety procedure and policies.

Use proper lifting and support techniques when

moving valve and or valve subassemblies.

Prepare the valve

1. Line should be depressurized or gate

secured prior to disassembly. If valve

is equipped with pin-style lockouts (see

Figure 16, page 10) gate can be locked in

the open or closed position using the lock

pin. If pin-style lockouts are not present,

the gate must be held in place to prevent

unwanted movement. These preCautions

arenecessary to keep the gate from moving

Disassembly

1. It is not necessary or desired to remove or

loosen the stop nut during disassembly.

Removing or loosening the stop nut will

compromise the seat/stroke adjustment.

2. Using pipe or crescent wrench, remove

handwheel retaining nut from spindle nut.

3. Remove handwheel.

4. Remove (2) or (4) retainer bolts.

5. Pull retainer off.

6. Rotate old spindle nut until free from

spindle.

CYLINDER SUPPORT METHODS FOR

HORIZONTALLY OR OFF-VERTICAL MOUNTING

Cylinders require additional support when

mounted in the other than vertical position.

Failure to do so could lead to premature

failure of cylinder and/or valve. The following

illustrations are suggestions, specific details

will have to be determined by customer so

support best suits surrounding area. It is

important that the cylinder/gate alignment be

maintained during valve operation. Supports

should be designed to maintain alignment and

support bulk of cylinder weight.

CAUTION

Tie-rod mounted supports are not recommended

on spring-style cylinder actuators.

FIGURE 13

Stop nut

Retaining nut

Handwheel

Spindle nut

Spindle

assembly

Retainer

Retainer bolt

Installation A

Appropriate tie-in capable of supporting load.

Turnbuckle for adjustment

Saddle style hanger

Installation B

Saddle style support

Reassembly

1. Apply standard bearing grease onto to

exposed spindle thread. (Use material which

meets ASTM 4950 GBLB).

2. Rotate new spindle nut onto spindle until it

bottoms against top plate.

3. Place retainer over spindle nut, lining up the

bolt holes.

4. Replace retainer bolts and nuts, tighten

completely.

5. Place handwheel over spindle nut, aligning

the hex.

6. Attach new handwheel retainer nut, using

pipe wrench or crescent wrench, tighten

completely.

7. Grease as required using grease fitting.

Appropriate tie-in capable of supporting load.

Installation C

Appropriate tie-in capable of supporting load.

Turnbuckle for adjustment

Alternate head-support,

saddle style preferred

8

Page 9

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

RETRO FITTING BEVEL GEAR OPERATORS

Conversion kits include bevel gear operator

with integral thrust style spindle nut,

conversion mounting plate, appropriate bolts,

and handwheel or drive nut as required.

Existing spindle and yoke posts will be reused.

If spindle or yoke posts require replacement,

contact the factory.

CAUTION

Follow required safety procedure and policies.

Assure line is not pressurized or gate has been

secured to prevent unwanted movement before

disassembly. Use proper lifting and support

techniques when moving valve and or valve

subassemblies.

Tools required

1. Pipe wrench or large crescent wrench

2. Appropriate size open end wrenches or

sockets

Prepare the valve

1. Line should be depressurized or gate

secured prior to disassembly. If valve

is equipped with pin-style lockouts

(Figure16,page 10) gate can be locked in

the open or closed position using the lock

pin. If pin-style lockouts are not present,

the gate must be held in place to prevent

unwanted movement.These preCautions are

necessary to keep the gate from moving.

Reassembly

1. The conversion kit will be shipped with the

thrust spindle nut installed in the bevel

gear.

2. Place the adapter plate over the 4-Post yoke

legs aligning the holes. (Figure 14)

3. Attach nuts onto 4-post yoke legs securing

the top plate into position.

4. Apply standard bearing grease onto to

exposed spindle thread. (Use material which

meets ASTM 4950 GBLB).

5. Slip the bevel gear over the spindle nut,

engaging the threads. Rotate the handwheel

which will in turn rotate the thrust spindle

nut down the spindle, bringing the bevel

gear into proper position, aligning the bolt

holes.

6. Bolt the bevel gear to the adapter plate.

Donot overstress bolting.

7. Stroke the valve from full open to full closed

making sure all parts are aligned and

working properly. Check bolts for tightness,

the gate and operator assembly should stay

snug with the valve body.

8. If binding or off-center movement of gate is

evident, loosen yoke bolts, stroke gate up

and down a few times, retighten yoke bolts.

FIGURE 14

Bevel gear actuator

Mount plate

Mount bolts

4-Post Yoke Leg

FIGURE 15

Thrust-style

spindle nut

included

Spindle

Disassembly

1. Using pipe or crescent wrench, remove

handwheel retaining nut from spindle nut.

2. Remove handwheel.

3. Remove (2) or (4) retainer bolts.

4. Pull retainer off

5. Rotate old spindle nut until free from

spindle.

6. Remove nuts from the 4-post yoke legs.

7. Pull existing top plate up and away from

valve.

9

Page 10

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

OPTIONAL LOCKOUTS

Valve is not suitable for man-safe conditions

due to potential for downstream leakage,

even in the closed and locked position.

Lockouts(ifprovided) are designed to prevent

unauthorized operation of the valve. Theyare

not designed to guarantee normal valve

performance if unauthorized operation is

attempted. The fit of the pin may allow the gate

9

to move up to 1.5mm (

/

16") from the closed

position. Unauthorized operation may result

in increased valve leakage, damage to the

operator assembly and the packing may be

compromised. Valve may require repair prior to

putting back in service.

Lockouts are designed to resist the normal

manual operating thrust. In order to assure

complete lockout compliance, any automatic

valve actuator must be placed in a ZERO

ENERGY STATE by isolating all potential energy

sources including electricity, operator supply

air or hydraulic fluids.

CAUTION

Valves supplied spring cylinders with the spring

compressed where the mechanical energy

cannot be placed in a ZERO ENERGY STATE.

Takeextreme care when inserting and removing

the lockout pin. If the valve is actuated or the

opposing pneumatic force is removed during the

insertion process injury may occur.

NOTE

See Figure 16, for available lockout assemblies,

not all lockout options are available on all valves.

The following are the factory’s

recommendations for storage procedures

to retain maximum product integrity during

longterm storage of 1 to 5 years.

The shelf life listed is a guideline and is not a

substitute for examination of cured material at

the time of intended use.

To maintain shelf life, spare seats should be

stored in accordance with the following.

1. Store at ambient temperature up to 30°C

(86°F), with 60 - 90% relative humidity away

from direct sunlight and at a minimum

distance of 4.6 meters (15 feet) away from

electric motors is mandatory.

2. Care must be taken to avoid storage in a

stressed condition such as piled too high or

on a plain pallet overhanging a sharp edge.

3. First in - first out inventory control should

be practiced.

4. The above elastomer shelf life guidelines

are for components that are not already

installed in a valve.

FIGURE 16

open

open

closed

closed

pin

L1: Pin style, both open and closed lock

positions, pin not included

L2: Pin style, open position only, pin not

included

L3: Pin style, closed position only, pin not

included

L4: Carbon steel bevel gear handwheel

lockout, does not require pin.

L5: Stainless steel bevel gear handwheel

lockout, does not require pin.

L6: Case hardened pin for use on L1, L2 or L3.

Order as L1L6, L2L6, or L3L6.

L7: Cable handwheel lockout for handwheel

valves only, not available on DN 750

(NPS 30).

10

Page 11

KEYSTONE FIGURE PCS17 KNIFE GATE VALVES

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

HANDWHEEL OR BEVEL GEAR OPERATED

VALVES

A. Equipment orientation: Valves may be

stored in the vertical or horizontal position.

B. Preparation for storage: Valves may be stored

as shipped, provided the above storage facility

and equipment orientation instructions above

are followed. If valve packaging is altered or

removed for receiving inspection, repackage

valve as originally received.

C. Storage inspection: Visual inspection shall

be performed on a semiannual basis and

results recorded. Inspection as a minimum

shall include reviewing the following:

Packaging

Flange covers

Dryness

Cleanliness

D. Maintenance: Maintenance shall consist

of correcting deficiencies noted during

inspection. All maintenance shall be

recorded. Contact factory prior to

performing any maintenance if valve is still

covered under warranty.

CYLINDER OPERATED VALVES

A.

Equipment orientation: The preferred

orientation for optimum protection is with

the valve fully opened and the cylinder in the

vertical position. This position gives the best

support to the cylinder rod and helps reduces

the chance of a “flat spot” developing on

the cylinder seals. Anacceptable alternate

position for valves with cylinder diameters of

less than 150 mm (6") is with the cylinder in

the horizontal position.

B.

Preparation for storage: Valves may be stored

as shipped, provided the above storage facility

and equipment orientation instructions above

are followed. If valve packaging is altered or

removed for receiving inspection, repackage

valve as originally received.

C.

Cylinder storage: These cylinder storage

instructions are not intended to replace

the instructions of the specific cylinder

manufacturer and are to be used as a guide

only. If specific instructions are required,

please contact our office. For storage of

up to 3 years; Squirt a high quality grade of

hydraulic oil or synthetic lubricant into the

cylinder ports and operate cylinder 6-12 times

on a yearly basis. For storage 3-5 years;

Lubricate as above. Additionally, extend

cylinder rod until the valve is fully closed. Coat

cylinder rod with high quality heavy grease or

synthetic lubricant. Retractcylinder rod until

valve is fully open, drawing lubricant into rod

end of cylinder. Securely plug cylinder ports

with pipe plugs, if cylinder is not prepiped to

control accessories. If cylinder is prepiped to

accessories, plug all input and output ports

accessories.

D. Storage inspection: Visual inspection shall

be performed on a semiannual basis and

results recorded. Inspection as a minimum

shall include reviewing the following:

- Packaging

- Flange covers

- Dryness

- Cleanliness

E. Maintenance: Maintenance shall consist

of correcting deficiencies noted during

inspection. All maintenance shall be

recorded. Contact factory prior to

performing any maintenance if valve is still

covered under warranty.

of

11

Page 12

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

Loading...

Loading...